Page 1

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 1 Dienstag, 18. Januar 2011 11:03 11

BHE 2243

KHE 2443

Operating Instructions........... page

Mode d’emploi ...................... page

Instrucciones de manejo .... página

Instruções de serviço ......... página

5

10

15

20

170 27 0730 - 0111

Page 2

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 2 Dienstag, 18. Januar 2011 11:03 11

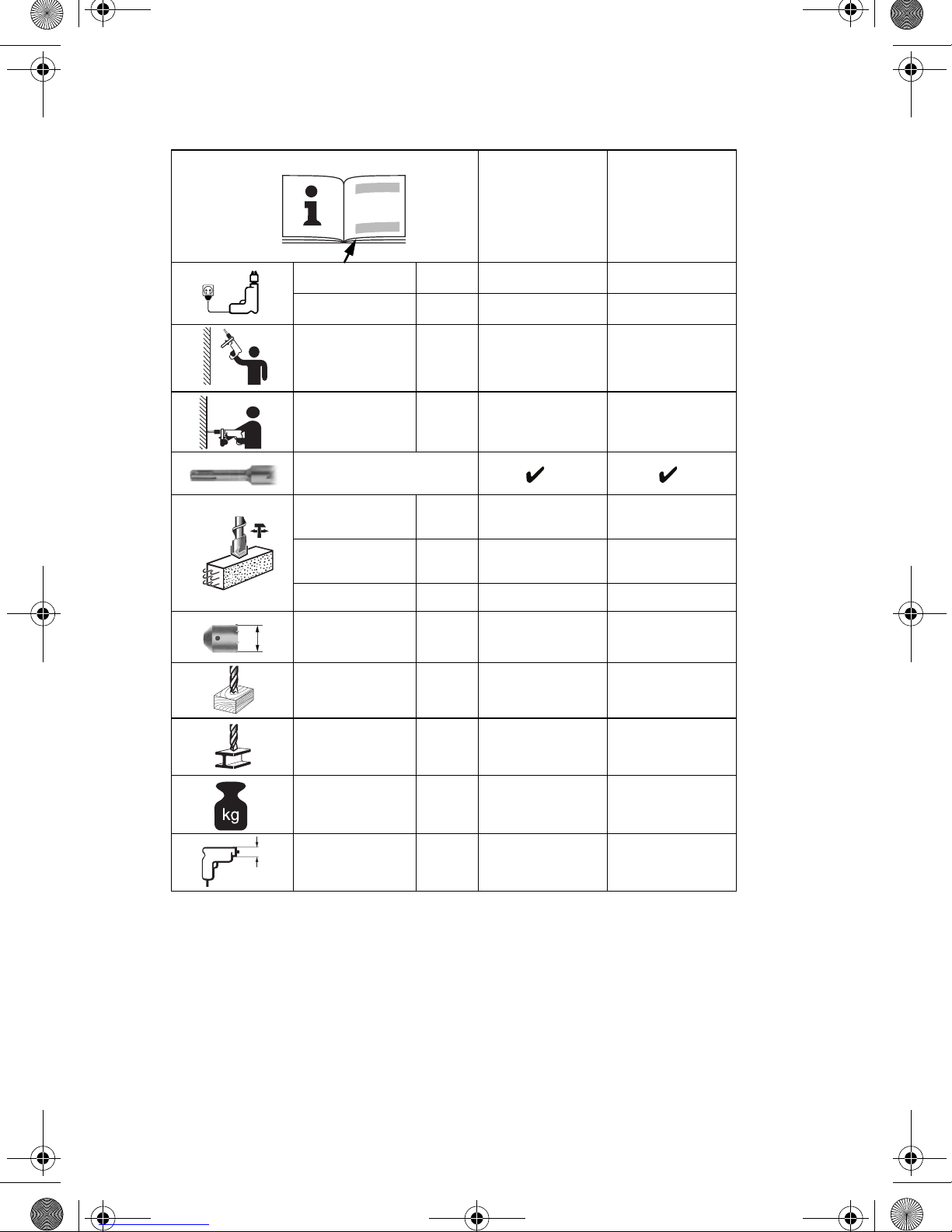

BHE 2243 KHE 2443

14

P

1

P

2

n

1

n

2

W 800 800

W 410 410

/min

rpm

/min

rpm

0 - 1150 0 - 1150

960 960

SDS-plus

ø max.

s max.

mm

in

/min

bpm

7

/8) 24 (15/16)

22 (

5400 5400

WJ2,4 2,4

ø max.

ø max.

mm

in

mm

in

68

(2

30 (1

5

/8)

3

/16)30 (1 3/16)

68

(2 5/8)

ø max.

m

D

mm

in

kg

lbs

mm

in

1

13 (

/2) 13 (1/2)

2,5 (5.5) 2,5 (5.5)

11

43 (1

/16) 43 (1 11/16)

© 2011

Metabowerke GmbH,

Postfach 1229

Metabo-Allee 1

D-72622 Nürtingen

Germany

2

Page 3

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 3 Dienstag, 18. Januar 2011 11:03 11

3

L

0

2

R

4

5

1

0

1

678

3

Page 4

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 4 Dienstag, 18. Januar 2011 11:03 11

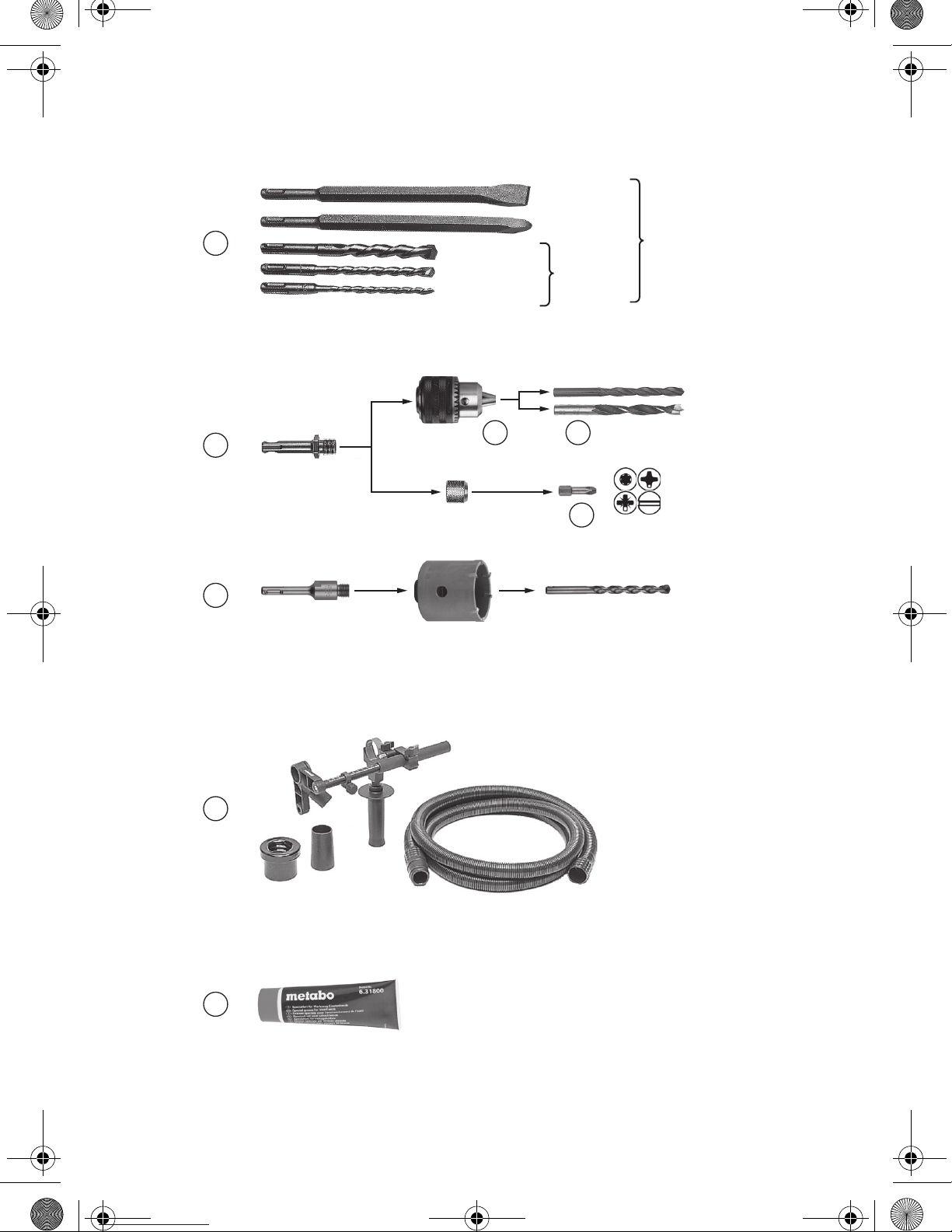

A

B

F

BHE 2243

6.35035

6.31285

6.31285

6.27043 6.27040

Ø 25 mm = 6.23390

Ø 30 mm = 6.23391

Ø 35 mm = 6.23392

Ø 40 mm = 6.23393

Ø 50 mm = 6.23394

Ø 68 mm = 6.23395

C

D

E

KHE 2443

...

...

G

H

4

6.31600

6.31800

Page 5

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 5 Dienstag, 18. Januar 2011 11:03 11

ENGLISH

ENG

Operating Instructions

Dear Customer,

Thank you for the trust you have placed in us by buying a Metabo power tool. Each Metabo power tool

is carefully tested and subject to strict quality controls by Metabo's quality assurance. Nevertheless, the

service life of a power tool depends to a great extent on you. Please observe the information contained

in these instructions and the enclosed documentation. The more carefully you treat your Metabo power

tool, the longer it will provide dependable service.

Contents

1 Specified Use

2 General Safety Instructions

3 Special Safety Instructions

4Overview

5 Special Product Features

6 Commissioning

7Use

8 Tips and Tricks

9 Servicing

10 Troubleshooting

11 Accessories

12 Repairs

13 Environmental Protection

14 Technical Specifications

1 Specified Conditions of Use

In conjunction with the appropriate accessories,

this rotary hammer drill is suitable for impact

drilling and chiselling (KHE 2443 only) into

concrete, stone and other such materials, into

brickwork with drill bits, and non-impact drilling

into metal, wood etc. and for driving screws.

The user bears sole responsibility for any damage

caused by inappropriate use.

Generally accepted accident prevention

regulations and the enclosed safety information

must be observed.

2 General Safety Information

WARNING – Reading the operating

instructions will reduce the risk of injury.

For your own protection and for the

protection of your power tool pay attention to all parts of the text that are

marked with this symbol!

General Power Tool Safety Warnings

WARNING

all instructions. Failure to follow the warn-

ings and instructions may result in electric shock,

fire and/or serious injury.

Read all safety warnings and

Save all warnings and

instructions for future reference!

"power tool" in the warnings refers to your mainsoperated (corded) power tool or battery-operated

(cordless) power tool.

1) Work area safety

a)

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

b)

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust.

tools create sparks which may ignite the dust

or fumes.

c)

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools.

and matching outlets will reduce risk of electric shock.

b)

Avoid body contact with earthed or

grounded surfaces, such as pipes, radiators, ranges and refrigerators.

increased risk of electric shock if your body is

earthed or grounded.

c)

Do not expose power tools to rain or wet

conditions.

increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts.

entangled cords increase the risk of electric

shock.

e)

When operating a power tool outdoors, use

an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces

the risk of electric shock.

f)

If operating a power tool in a damp location

is unavoidable, use a residual current

device (RCD) protected supply.

RCD reduces the risk of electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and

use common sense when operating a

Water entering a power tool will

The term

Power

Unmodified plugs

There is an

Damaged or

Use of an

5

Page 6

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 6 Dienstag, 18. Januar 2011 11:03 11

ENG

b)

c)

d)

e)

f)

g)

4) Power tool use and care

a)

b)

c)

d)

ENGLISH

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

Use personal protective equipment.

Always wear eye protection. Protective

equipment such as dust mask, non-skid safety

shoes, hard hat, or hearing protection used for

appropriate conditions will reduce personal

injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or battery

pack, picking up or carrying the tool.

Carrying power tools with your finger on the

switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on. A wrench

or a key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

control of the power tool in unexpected

situations.

Dress properly. Do not wear loose clothing

or jewellery. Keep your hair, clothing and

gloves away from moving parts.

clothes, jewellery or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used.

Use of dust collection can reduce

dust-related hazards.

Do not force the power tool. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch

does not turn it on and off. Any power tool

that cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source and/or the battery pack from the

power tool before making any adjustments,

changing accessories, or storing power

tools.

Such preventive safety mea ures reduce

the risk of starting the power tool accidentally.

Store idle power tools out of the reach

of children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Loose

Maintain power tools. Check for misalign-

e)

ment or binding of moving parts, breakage

of parts and any other condition that may

affect the power tool's operation. If

damaged, have the power tool repaired

before use.

poorly maintained power tools.

Keep cutting tools sharp and clean.

f)

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

g)

Use the power tool, accessories and tool

bits etc. in accordance with these instructions, taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from those intended could result in a

hazardous situation.

5) Service

a)

Have your power tool serviced by a

qualified repair person using only identical

replacement parts.

safety of the power tool is maintained.

Many accidents are caused by

This will ensure that the

3 Special Safety Information

Wear ear protectors.

cause loss of hearing.

Use auxiliary handles supplied with the tool.

Loss of control can cause personal injury.

Hold power tool by insulated gripping surfaces,

when performing an operation where the

cutting accessory may contact hidden or it’s

own cord.

wire may make exposed metal parts of the power

tool “live” and could give the operator an electric

shock.

Work only with the additional handle correctly

installed.

Always hold the machine with both hands using

the handles provided, stand securely and concentrate.

Always wear protective goggles, gloves, and

sturdy shoes when working with this tool.

Ensure that the spot where you wish to work is

free of

(e.g. using a metal detector).

Smaller workpieces must be secured such that

they are not carried along with the drill bit when

drilling (e.g. by clamping in a vice or on a work

bench with screw clamps).

Metabo S-automatic safety clutch.

When the safety clutch responds, switch off the

machine immediately!

Cutting accessory contacting a “live”

power cables, gas lines or water pipes

Exposure to noise can

6

Page 7

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 7 Dienstag, 18. Januar 2011 11:03 11

Avoid inadvertent starts by always unlocking the

switch when the plug is removed from the mains

socket or in case of a power cut.

Do not touch the rotating tool!

Remove chips and similar material only with the

machine at standstill.

Caution must be exercised when driving screws

into hard materials (driving screws with metric or

imperial threads into steel)! The screw head may

break or a high reverse torque may build up on the

handle.

Pull the plug out of the plug socket before any

adjustments or servicing are performed.

Dust from material such as paint containing lead,

some wood species, minerals and metal may be

harmful. Contact with or inhalation of the dust may

cause allergic reactions and/or respiratory

diseases to the operator or bystanders.

Certain kinds of dust are classified as carcinogenic

such as oak and beech dust especially in conjunction with additives for wood conditioning (chromate, wood preservative). Material containing

asbestos must only be treated by specialists.

- Where the use of a dust extraction device is

possible it shall be used.

- The work place must be well ventilated.

- The use of a dust mask of filter class P2 is

recommended.

Follow national requirements for the materials you

want to work with.

SYMBOLS ON THE TOOL:

.......Class II Construction

V...........volts

A...........amperes

Hz.........hertz

W..........watts

BPM.....beat per minute

~

..........alternating current

n0.........rated speed

rpm ......revolutions per minute

.../min...revolutions per minute

ENGLISH

• Single-button control

A single switch button allows you to switch

between drilling, hammer drilling and chiselling

modes, depending on the features.

• Metabo S-automatic safety clutch:

If the tool jams or catches, the power supply to

the motor is restricted. Due to the strong force

which can arise, always hold the machine with

both hands using the handles provided, stand

securely and concentrate.

• Electronic smooth start-up for precision drilling

• Rotary stop (KHE2443):

Chiselling can be carried out if the rotary motion

is switched off.

• Lockable switch for convenient operation

during continuous chiselling

ENG

6Start of Operation

Before plugging in check to see that the

rated mains voltage and mains frequency,

as stated on the rating label, match with your

power supply.

6.1 Side handle installation

For safety reasons, always use the side

handle supplied.

Open the clamping ring by turning the side handle

(1) counter-clockwise. Place the side handle onto

the machine's collar. Insert the depth stop (3).

Tighten the side handle in the required angle

depending on the task at hand.

7Use

7.1 Depth Stop Setting

Loosen the side handle (1). Set depth stop (3) to

the desired drilling depth and retighten the side

handle.

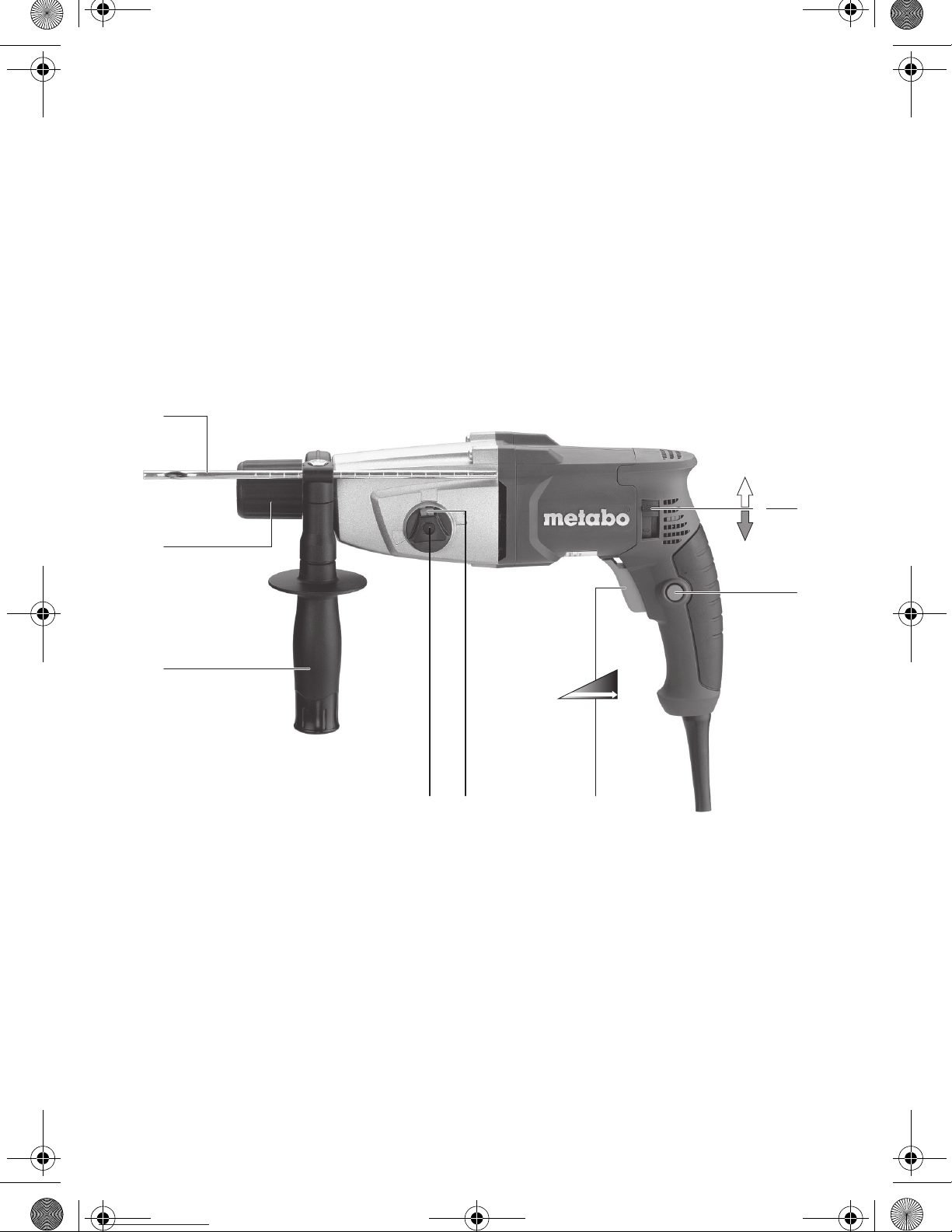

4Overview

See page 3 (please unfold).

Side handle

1

2

Tool lock

3

Depth stop

4

Rotation selector switch

5

Lock button

6

Trigger

7

Stop

8

Control knob

5 Special Product Features

• Aluminium die casting-gearbox

7.2 Switching on/off

To start the machine, press the trigger (6).

The speed can be changed at the trigger.

For continuous operation the trigger can be locked

with the lock button (5). To stop the machine,

press the trigger again.

If switched on continuously, the machine

continues running if it is jerked out of your

hands. Therefore, always hold the

machine with both hands on the handles, stand

safely, and concentrate on your work.

7.3 Operating mode selection

Select the desired operating mode by turning the

control knob (8). To turn, push the stop (7).

7

Page 8

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 8 Dienstag, 18. Januar 2011 11:03 11

ENG

In chiselling mode, the chisel is locked so that it

cannot turn.

To position the chisel for a particular application,

set the switch button (8) between and .

7.4 Setting the direction of rotation, engag-

See page 3 (please unfold).

R = Clockwise setting

L = Counter-clockwise setting

7.5 Tool Change with SDS Chuck

order no. 6.31800)! Use only SDS-plus tools.

Inserting the tool:

Turn the tool while inserting, until it engages.

The tool is automatically locked.

Removing the tool:

ENGLISH

Drilling

Hammer drilling

Chiselling

(KHE 2443 only)

When a chisel is fitted, only operate the

machine in the chiselling operating mode

.

Avoid levering with the machine when a

chisel is fitted.

ing the transporting safety device

(switch-on lock)

Do not activate the rotation selector switch

(4) unless the motor has completely stopped.

Before fitting, clean tool shank and

apply special grease (accessories

8Tips and Tricks

Only moderate pressure is required for hammer

drilling and chiselling. Exerting a high force does

not increase performance.

When drilling deep holes, remove the drill bit

periodically from the hole to release the stone

dust.

Drill tiles and other brittle materials without impact.

9 Maintenance

The vent slots of the machine should be cleaned

from time to time.

10 Trouble Shooting

If the trigger (6) can not be depressed, check to

see that the direction of rotation selector switch (4)

is fully set to the R or L position.

f

11 Accessories

Use only genuine Metabo accessories.

If you need accessories, check with your dealer.

For the dealer to select the correct accessory, he

needs to know the exact model designation of

your power tool.

See page 4.

A Tools with SDS-plus shank

B Connecting piece

CGeared chuck

D Twist drills for metal and wood

E Screwdriver bit

F Carbide core cutter

G Dust extraction kit

H Special grease (for lubricating the tool shanks)

For complete range of accessories, see

www.metabo.com or the main catalogue.

Turn tool lock (2) in direction indicated by arrow

(a) and remove the tool (b).

8

12 Repairs

Repairs to electrical tools must be carried out by

qualified electricians ONLY!

Contact your local Metabo representative if you

have Metabo power tools requiring repairs. For

addresses see www.metabo.com.

You can download a list of spare parts from

www.metabo.com.

Page 9

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 9 Dienstag, 18. Januar 2011 11:03 11

13 Environmetal Protection

Metabo's packaging can be 100% recycled.

Worn out power tools and accessories contain

considerable amounts of valuable raw and plastic

materials, which can be recycled.

These instructions are printed on chlorine-free

bleached paper.

14 Technical Specifications

Explanatory notes on the information on page 2.

Changes due to technological progress reserved.

P

1

P

2

n

1

n

2

ø max = max. solid drill diameter

s max = max. impact rate

W = single impact strength

m=weight

D = spindle collar diameter

Wear hearing protection!

= rated input

= rated output

= no-load speed

= load speed

ENGLISH

ENG

The stated technical specifications are subject to

tolerances (as specified in the respective current

standards).

9

Page 10

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 10 Dienstag, 18. Januar 2011 11:03 11

F

FRANÇAIS

Mode d'emploi

Cher client,

merci de la confiance que vous nous avez témoignée en achetant un outil électrique Metabo. Tous les

outils électriques Metabo sont testés avec soin et font l'objet de contrôles qualité très stricts effectués

par le Service Qualité Metabo. Mais c'est vous qui avez la plus grande influence sur la durée de vie de

votre outil électrique. Veuillez respecter les informations contenues dans ces instructions d'utilisation et

dans les documents ci-joints. En prenant grand soin de votre outil électrique Metabo, vous en

augmenterez la durée de vie et en garantirez le bon fonctionnement.

respectez les passages de texte marqués de ce

Sommaire

1 Utilisation conforme aux prescriptions

2 Consignes de sécurité générales

3 Consignes de sécurité particulières

4Vue d'ensemble

5 Particularités du produit

6Mise en service

7 Utilisation

8 Conseils et astuces

9 Maintenance

10 Dépannage

11 Accessoires

12 Réparations

13 Protection de l'environnement

14 Caractéristiques techniques

1 Utilisation conforme aux

prescriptions

Equipé des accessoires correspondants, le

marteau perforateur est prévu pour travailler avec

des forets marteau et des burins (uniquement

modèle KHE 2443) dans le béton, la pierre ou des

matériaux similaires, et avec des trépans dans les

tuiles, etc., ainsi que pour percer sans percussion

dans le métal, le bois, etc. ou pour serrer des vis.

L'utilisateur sera entièrement responsable de tous

dommages résultant d'une utilisation non

conforme à la destination de la machine.

Il est impératif de respecter les consignes

générales de protection contre les accidents ainsi

que les consignes de sécurité ci-jointes.

2 Consignes générales de

sécurité

AVERTISSEMENT – Lire la notice d'utilisation afin d'éviter tout risque de blessure.

Dans l'intérêt de votre propre sécurité

et afin de protéger votre outil électrique,

symbole !

Avertissements de sécurité généraux

pour l'outil

AVERTISSEMENT

sements de sécurité et toutes les instruc-

tions.

Ne pas suivre les avertissements et instructions peut donner lieu à un choc électrique, un

incendie et/ou une blessure sérieuse.

tous les avertissements et toutes les instructions pour pouvoir s'y reporter ultérieurement!

Le terme "outil" dans les avertissements fait

référence à votre outil électrique alimenté par

le secteur (avec cordon d'alimentation) ou votre

outil fonctionnant sur batterie (sans cordon

d'alimentation).

1) Sécurité de la zone de travail

a)

Conserver la zone de travail propre et bien

éclairée. Les zones en désordre ou sombres

sont propices aux accidents.

b)

Ne pas faire fonctionner les outils électriques en atmosphère explosive, par

exemple en présence de liquides

inflammables, de gaz ou de poussières.

Les outils électriques produisent des étincelles

qui peuvent enflammer les poussières ou les

fumées.

c)

Maintenir les enfants et les personnes

présentes à l'écart pendant l'utilisation de

l'outil.

Les distractions peuvent vous faire

perdre le contrôle de l'outil.

2) Sécurité électrique

a)

Il faut que les fiches de l'outil électrique

soient adaptées au socle. Ne jamais

modifier la fiche de quelque façon que ce

soit. Ne pas utiliser d'adaptateurs avec des

outils à branchement de terre.

non modifiées et des socles adaptés réduiront

le risque de choc électrique.

b)

Eviter tout contact du corps avec des

surfaces reliées à la terre telles que les

tuyaux, les radiateurs, les cuisinières et les

réfrigérateurs.

choc électrique si votre corps est relié à la

terre.

c)

Ne pas exposer les outils à la pluie ou à des

conditions humides.

Il existe un risque accru de

Lire tous les avertis-

Conserver

Des fiches

La pénétration d'eau à

10

Page 11

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 11 Dienstag, 18. Januar 2011 11:03 11

l'intérieur d'un outil augmentera le risque de

choc électrique.

d)

Ne pas maltraiter le cordon. Ne jamais

utiliser le cordon pour porter, tirer ou

débrancher l'outil. Maintenir le cordon à

l'écart de la chaleur, du lubrifiant, des

arêtes ou des parties en mouvement.

Des cordons endommagés ou emmêlés

augmentent le risque de choc électrique.

e)

Lorsqu'on utilise un outil à l'extérieur,

utiliser un prolongateur adapté à l'utilisation extérieure

adapté à l'utilisation extérieure réduit le risque

de choc électrique.

f)

Si l'usage d'un outil dans un emplacement

humide est inévitable, utiliser une alimentation protégée par un dispositif à courant

différentiel résiduel (RCD)

RCD réduit le risque de choc électrique.

3) Sécurité des personnes

Rester vigilant, regarder ce que vous êtes

a)

en train de faire et faire preuve de bon sens

dans votre utilisation de l'outil. Ne pas

utiliser un outil lorsque vous êtes fatigué ou

sous l'emprise de drogues, d'alcool ou de

médicaments.

cours d'utilisation d'un outil peut entraîner des

blessures graves des personnes.

b)

Utiliser un équipement de sécurité.

Toujours porter une protection pour les

yeux.

Les équipements de sécurité tels que

les masques contre les poussières, les

chaussures de sécurité antidérapantes, les

casques ou les protections acoustiques

utilisés pour les conditions appropriées

réduiront les blessures de personnes.

c)

Eviter tout démarrage intempestif.

S'assurer que l'interrupteur est en position

arrêt avant de brancher l'outil au secteur

et/ou au bloc de batteries, de le ramasser

ou de le porter.

doigt sur l'interrupteur ou brancher des outils

dont l'interrupteur est en position marche est

source d'accidents.

Retirer toute clé de réglage avant de mettre

d)

l'outil en marche.

une partie tournante de l'outil peut donner lieu

à des blessures de personnes.

e)

Ne pas se précipiter. Garder une position et

un équilibre adaptés à tout moment. Cela

permet un meilleur contrôle de l'outil dans des

situations inattendues.

f)

S'habiller de manière adaptée. Ne pas

porter de vêtements amples ou de bijoux.

Garder les cheveux, les vêtements et les

gants à distance des parties en mouvement.

Des vêtements amples, des bijoux ou

.

L'utilisation d'un cordon

.

L'usage d'un

Un moment d'inattention en

Porter les outils en ayant le

Une clé laissée fixée sur

FRANÇAIS

les cheveux longs peuvent être pris dans des

parties en mouvement.

g)

Si des dispositifs sont fournis pour le

raccordement d'équipements pour

l'extraction et la récupération des poussières, s'assurer qu'ils sont connectés

et correctement utilisés.

collecteurs de poussière peut réduire les

risques dus aux poussières.

4) Utilisation et entretien de l'outil

a)

Ne pas forcer l'outil. Utiliser l'outil adapté

à votre application.

mieux le travail et de manière plus sûre au

régime pour lequel il a été construit.

b)

Ne pas utiliser l'outil si l'interrupteur ne

permet pas de passer de l'état de marche

à arrêt et vice versa.

pas être commandé par l'interrupteur est

dangereux et il faut le réparer.

c)

Débrancher la fiche de la source d'alimentation en courant et/ou le bloc de batteries

de l'outil avant tout réglage, changement

d'accessoires ou avant de ranger l'outil.

De telles mesures de sécurité préventives

réduisent le risque de démarrage accidentel

de l'outil.

d)

Conserver les outils à l'arrêt hors de la

portée des enfants et ne pas permettre

à des personnes ne connaissant pas l'outil

ou les présentes instructions de le faire

fonctionner.

les mains d'utilisateurs novices.

Observer la maintenance de l'outil. Vérifier

e)

qu'il n'y a pas de mauvais alignement ou de

blocage des parties mobiles, des pièces

cassées ou toute autre condition pouvant

affecter le fonctionnement de l'outil. En cas

de dommages, faire réparer l'outil avant de

l'utiliser.

à des outils mal entretenus.

Garder affûtés et propres les outils

f)

permettant de couper. Des outils destinés

à couper correctement entretenus avec des

pièces coupantes tranchantes sont moins

susceptibles de bloquer et sont plus faciles

à contrôler.

g)

Utiliser l'outil, les accessoires et les lames

etc., conformément à ces instructions, en

tenant compte des conditions de travail et

du travail à réaliser.

pour des opérations différentes de celles

prévues pourrait donner lieu à des situations

dangereuses.

5) Maintenance et entretien

a)

Faire entretenir l'outil par un réparateur

qualifié utilisant uniquement des pièces de

rechange identiques.

sécurité de l'outil est maintenue.

Les outils sont dangereux entre

De nombreux accidents sont dus

Utiliser des

L'outil adapté réalisera

Tout outil qui ne peut

L'utilisation de l'outil

Cela assurera que

F

la

11

Page 12

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 12 Dienstag, 18. Januar 2011 11:03 11

F

FRANÇAIS

respiratoires chez l'utilisateur ou les personnes

3 Consignes de sécurité

particulières

Porter une protection auditive.

susceptible de provoquer une perte de capacité

auditive.

Utiliser la poignée complémentaire fournie

avec l'outil.

risque de blessures.

Lors d'opérations où l'accessoire risque de

rencontrer des conducteurs électriques non

apparents, voire son câble d'alimentation, tenir

l'outil exclusivement par les côtés isolés des

poignées.

électrique sous tension peut également mettre

les parties métalliques de l'outil sous tension et

provoquer un choc électrique.

Toujours travailler avec la poignée supplémentaire

correctement installée.

Tenir toujours l'outil avec les deux mains au niveau

des poignées, veiller à un bon équilibre et travailler

de manière concentrée.

Portez toujours des lunettes de protection, des

gants de travail et des chaussures de sécurité

lorsque vous travaillez avec votre outil électrique !

Vérifiez que l'endroit où vous allez intervenir ne

comporte

de gaz

Les pièces à usiner plus petites doivent être assurées de sorte à ne pas pouvoir être emportées par

le foret lors du perçage (par exemple lors du

serrage dans un étau ou sur l'établi avec des serrejoints).

Débrayage de sécurité Metabo S-automatic.

En cas de déclenchement du débrayage de sécurité, immédiatement arrêter la machine !

Eviter les démarrages intempestifs : la gâchette

doit toujours être déverrouillée lorsque l'on retire le

connecteur de la prise ou après une coupure de

courant.

Ne pas toucher l'outil de travail pendant

qu'il tourne !

Eliminer sciures de bois et autres uniquement

lorsque la machine est à l'arrêt.

Attention pour les vissages en force (avec des vis

à pas métrique ou en pouces sur de l'acier) !

Risque d'arrachement de la tête de vis ou d'apparition de couples de réaction élevés sur la poignée.

Débrancher le cordon d'alimentation de la prise

de courant avant toute opération de réglage ou de

maintenance.

Les poussières de matériaux tels que les peintures

au plomb, certains types de bois, de minéraux et

de métaux peuvent s'avérer nocives pour la santé.

Toucher ou inhaler ces poussières peut entraîner

des réactions allergiques et/ou des maladies

En cas de perte de contrôle, il y a un

Le contact avec un conducteur

aucune conduite électrique, d'eau ou

(par ex. à l'aide d'un détecteur de métaux).

Le bruit est

se trouvant à proximité.

Certaines poussières provenant par exemple du

chêne ou du hêtre sont considérées comme

cancérigènes, particulièrement lorsqu'elle sont

associées à des adjuvants de traitement du bois

(chromate, produit de protection du bois). Seuls

des spécialistes sont habilités à traiter les

matériaux contenant de l'amiante.

- Utiliser le plus possible un système d'aspiration

des poussières.

- Veiller à une bonne aération du site de travail.

- Il est recommandé de porter un masque antipoussières avec filtre à particules de classe 2.

Respecter les directives nationales en vigueur

relatives aux matériaux à traiter.

SYMBOLES SUR L’OUTIL:

....... Construction de classe II

V ........... volts

A........... ampères

Hz......... hertz

W.......... watts

BPM ..... frappe par minute

~ ........... courant alternatif

n

.......... vitesse à vide

0

rpm....... révolutions par minute

.../min ... révolutions par minute

4Vue d'ensemble

Voir page 3 (à déplier).

Poignée collier

1

2

Douille de l'outil

3

Butée de profondeur

4

Commutateur du sens de rotation

5

Bouton de blocage

6

Gâchette

7

Dispositif de blocage

8

Sélecteur

5 Particularités du produit

• Carter en aluminium coulé sous pression

• Commande à un seul bouton

Avec un seul bouton de commande, en fonction

de l'équipement, il est possible de commuter

entre perçage, perçage à percussion et burinage.

• Débrayage de sécurité Metabo S-automatic :

Si un outil de travail est coincé ou accroché,

la transmission d'effort au moteur est limitée.

Comme cette situation génère des efforts

importants, veiller à toujours bien maintenir la

machine avec les deux mains au niveau des

poignées, à prendre un bon équilibre et à

travailler de manière concentrée.

• Démarrage progressif électronique pour un

perçage précis.

12

Page 13

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 13 Dienstag, 18. Januar 2011 11:03 11

• Désactivation de la rotation (KHE 2443) :

En désactivant le mouvement de rotation, il est

possible d'effectuer des travaux de burinage.

• Interrupteur blocable pour un burinage confortable en utilisation continue.

6 Mise en service

Avant la mise en service, comparez si la

tension secteur et la fréquence secteur

indiquées sur la plaque signalétique

correspondent aux caractéristiques de votre

réseau de courant.

6.1 Installation de la poignée collier

Pour des raisons de sécurité, utilisez

toujours la poignée collier qui est

comprise dans la livraison.

Ouvrir l'anneau de serrage en tournant la poignée

(1) vers la gauche. Faire coulisser la poignée sur le

collier du marteau. Introduire la butée de profondeur (3). Selon l'utilisation souhaitée, serrer

vigoureusement la poignée dans l'angle désiré.

7 Utilisation

7.1 Réglage de la butée de profondeur

Desserrer la poignée collier (1). Régler la butée de

profondeur (3) sur la profondeur de forage désirée

et resserrer la poignée collier.

7.2 Marche/arrêt

Pour mettre la machine en marche, appuyer sur la

gâchette (6).

La vitesse peut être modifiée au niveau de la

gâchette.

Pour un fonctionnement en continu, il est possible

de bloquer la gâchette à l'aide du bouton de

blocage (5). Pour arrêter la machine, appuyer

à nouveau sur la gâchette.

Si elle est réglée sur marche continue,

la machine continue à tourner si elle

s'arrache de la main. Pour cette raison,

il faut systématiquement saisir la machine des

deux mains aux poignées prévues à cet effet,

veiller à bien se camper sur ses jambes et à se

concentrer sur son travail.

FRANÇAIS

Perforation

Burinage

(uniquement modèle KHE 2443)

En position "burinage", le burin est bloqué et ne

peut tourner.

Pour positionner le burin dans la position

souhaitée, placer le bouton de commande (8) entre

et .

Lorsque le burin est monté, la machine

doit être utilisée exclusivement en mode

"burinage" .

Eviter tout mouvement de levier sur la

machine lorsque le burin est fixé.

7.4 Réglage du sens de rotation / sécurité

de transport (protection contre tout

enclenchement intempestif)

S'assurer que le moteur est à l'arrêt avant

d'actionner le commutateur du sens de

rotation (4).

Voir page 3 (à déplier).

R =Réglé sur sens de rotation à droite

L =Réglé sur sens de rotation à gauche

7.5 Changement d'outil avec le mandrin

marteau

Nettoyer et graisser la tige de l'outil avec

une graisse spéciale avant le montage

(voir accessoires : réf. de cde 6.31800) !

Ne monter que des outils à emmanchement

SDS-plus !

Introduire l'outil :

Tourner l'outil et l'introduire jusqu'à

enclenchement. L'outil sera automatiquement

bloqué.

Retirer l'outil :

F

7.3 Sélectionner le mode de

fonctionnement

Choisir le mode de fonctionnement désiré en

tournant le sélecteur (8). Pour tourner le sélecteur,

enfoncer le dispositif de blocage (7).

Perçage

Tourner la douille de l'outil (2) dans le sens de la

flèche (a) et déposer l'outil (b).

13

Page 14

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 14 Dienstag, 18. Januar 2011 11:03 11

F

FRANÇAIS

8 Conseils et astuces

Pour le perçage au marteau et le travail au burin,

une pression moyenne est suffisante. Même si la

pression est plus forte, le rendement effectif n'en

sera pas plus important.

En cas de perçages profonds, il faut retirer de

temps en temps le foret du trou pour éliminer les

poussières de pierre.

Les carrelages, ainsi que les matériaux cassants,

sont à percer sans percussion.

9 Maintenance

Nettoyer les grilles d'aération de la machine de

temps à autre.

10 Dépannage

Lorsque la gâchette (6) ne se laisse pas enfoncer,

vérifier si le commutateur de sens de rotation (4)

est complètement en position R ou L.

f

11 Accessoires

Utilisez uniquement du matériel Metabo.

S'il vous faut des accessoires, veuillez vous

adresser à votre revendeur.

Pour pouvoir sélectionner les accessoires

appropriés, veuillez indiquer le type exact de votre

outil électrique au distributeur.

Voir page 4.

A Outils à emmanchement SDS-plus

B Raccord

C Mandrin à couronne dentée

D Forets pour métal et bois

E Embout de vissage

F Trépan de perforation en carbure

G Kit d'aspiration de poussière

H Graisse spéciale (pour lubrifier les extrémités

des outils)

Voir programme complet des accessoires sur

www.metabo.com ou dans le catalogue principal.

13 Protection de

l'environnement

Les emballages Metabo sont recyclables à 100 %.

Les outils et accessoires électriques qui ne sont

plus utilisés contiennent de grandes quantités de

matières premières et de matières plastiques de

grande qualité pouvant être également recyclées.

Ce mode d'emploi est imprimé sur du papier

blanchi sans chlore.

14 Caractéristiques

techniques

Commentaires sur les indications de la page 2.

Sous réserves de modifications allant dans le sens

du progrès technique.

P

1

P

2

n

1

n

2

ø max = Capacité de perçage maximale

s max = Cadence de frappe maxi

W = Energie de frappe par coup

m = Poids de la machine

D = Diamètre du collet

Porter un casque anti-bruit !

Les caractéristiques indiquées sont soumises

à tolérance (selon les normes en vigueur

correspondantes).

= Puissance nominale absorbée

= Puissance utile

= Vitesse à vide

= Vitesse en charge

12 Réparations

Les travaux de réparation sur les outils électriques

ne peuvent être effectués que par un spécialiste !

Pour toute réparation sur un outil Metabo,

contacter le représentant Metabo. Voir les

adresses sur www.metabo.com.

Les listes des pièces détachées peuvent être

téléchargées sur www.metabo.com.

14

Page 15

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 15 Dienstag, 18. Januar 2011 11:03 11

ESPAÑOL

ES

Instrucciones de manejo

Estimado cliente,

Le agradecemos la confianza mostrada al comprar una máquina Metabo. Cada máquina Metabo ha sido

probada cuidadosamente y ha pasado los estrictos controles de calidad de la garantía de calidad de

Metabo. Sin embargo, la vida útil de una máquina depende en gran medida de usted. Le rogamos tenga

en cuenta la información contenida en estas instrucciones y en los documentos adjuntos. Cuanto mejor

cuide su máquina Metabo, mayor será el tiempo durante el que le proporcionará un servicio fiable..

Lea íntegramente estas

La no observa-

Guarde estas instrucciones

Las herramientas

Los enchufes

El riesgo a quedar

Contenido

1 Aplicación de acuerdo a la finalidad

2 Instrucciones generales de seguridad

3 Instrucciones especiales de seguridad

4 Descripción general

5 Características especiales del producto

6 Puesta en marcha

7 Manejo

8 Consejos y trucos

9 Mantenimiento

10 Localización de averías

11 Accesorios

12 Reparación

13 Protección ecológica

14 Especificaciones técnicas

1 Aplicación de acuerdo a la

finalidad

Junto con el accesorio correcto, el martillo

perforador es adecuado para trabajar con

martillos perforadores y cincelar en hormigón

(sólo KHE 2443 ), en piedra o en materiales

similares, así como para taladrar sin percusión

en metal, madera, etc. y para atornillar.

Cualquier daño causado por un uso inadecuado

es de la sola responsabilidad del usuario.

Deben observarse las normas para prevención

de accidentes aceptadas generalmente y la

información sobre seguridad incluida.

2 Instrucciones generales de

seguridad

AVISO: Para reducir el riesgo de lesiones,

lea el manual de instrucciones.

Para su propia protección y la de su

herramienta eléctrica, observe las

partes marcadas con este símbolo

Instrucciones generales de seguridad para

herramientas eléctricas

¡ATENCIÓN

instrucciones de seguridad.

ción de las instrucciones de seguridad siguientes

puede dar lugar a descargas eléctricas, incendios

y/o lesiones graves.

en un lugar seguro! El término "herramienta eléc-

trica" empleado en las siguientes instrucciones se

refiere a su aparato eléctrico portátil, ya sea con

cable de red, o sin cable,

en caso de ser accionado por acumulador.

1) Puesto de trabajo

a)

Mantenga limipo y bien iluminado su

puesto de trabajo. El desorden y una

iluminación deficiente en las áreas de trabajo

pueden provocar accidentes.

b)

No utilice la herramienta eléctrica en un

entorno con peligro de explosión, en el que

se encuentren combustibles líquidos,

gases o material en polvo.

eléctricas producen chispas que pueden

llegar a inflamar los materiales en polvo

o vapores.

c)

Mantenga alejados a los niños y otras

personas de su puesto de trabajo al

emplear la herramienta eléctrica. Una

distracción le puede hacer perder el control

sobre el aparato.

2) Seguridad eléctrica

a)

El enchufe de la herramienta eléctrica

debe corresponder a la toma de corriente

utilizada. No es admisible modificar el

enchufe en forma alguna. No emplee

adaptadores con herramientas eléctricas

dotadas de una toma de tierra.

sin modificar adecuados a las respectivas

tomas de corriente reducen el riesgo de una

descarga eléctrica.

b)

Evite que su cuerpo toque partes conectadas a tierra como tuberías, radiadores,

cocinas y refrigeradores.

expuesto a una sacudida eléctrica es mayor

si su cuerpo tiene contacto con tierra.

c)

No exponga las herramientas eléctricas a

la lluvia y evite que penetren líquidos en su

interior.

descarga eléctrica si penetran ciertos líquidos

en la herramienta eléctrica.

d)

No utilice el cable de red para transportar

o colgar la herramienta eléctrica, ni tire

Existe el peligro de recibir una

15

Page 16

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 16 Dienstag, 18. Januar 2011 11:03 11

ES

e)

f)

3) Seguridad de personas

a)

b)

c)

d)

e)

ESPAÑOL

de él para sacar el enchufe de la toma

de corriente. Mantenga el cable de red

alejado del calor, aceite, esquinas

cortantes o piezas móviles.

red dañados o enredados pueden provocar

una descarga eléctrica.

Al trabajar con la herramienta eléctrica a la

intemperie utilice solamente cables de

prolongación homologados para su uso en

exteriores.

prolongación adecuado para su uso en

exteriores reduce el riesgo de una descarga

eléctrica.

Si fuera necesario utilizar la herramienta

eléctrica en un entorno húmedo, utilice un

interruptor de protección diferencial.

utilización de un cable de prolongación

adecuado para su uso en exteriores reduce

el riesgo de una descarga eléctrica.

Esté atento a lo que hace y emplee la herramienta eléctrica con prudencia. No utilice

la herramienta eléctrica si estuviese

cansado, ni tampoco después de haber

consumido alcohol, drogas o medicamentos.

herramienta eléctrica puede provocarle serias

lesiones.

Utilice un equipo de protección y en todo

caso unas gafas de protección. El riesgo

de lesionarse se reduce considerablemente si,

dependiendo del tipo y la aplicación de la

herramienta eléctrica empleada, se utiliza un

equipo de protección adecuado como una

mascarilla antipolvo, zapatos de seguridad

con suela antideslizante, casco, o protectores

auditivos.

Evite una puesta en marcha fortuita del

aparato. Asegúrese de que la herramienta

eléctrica está apagada antes de conectarla

a la toma de corriente y/o la batería, de

desconectarla o de transportarla.

porta la herramienta eléctrica sujetándola por

el interruptor de conexión/desconexión, o si

introduce el enchufe en la toma de corriente

con el aparato conectado, puede dar lugar

a un accidente.

Retire las herramientas de ajuste o llaves

fijas antes de conectar la herramienta

eléctrica.

en una pieza rotante puede producir lesiones

al ponerse a funcionar.

Evite trabajar con posturas forzadas.

Trabaje sobre una base firme y mantenga

el equilibrio en todo momento.

permitirá controlar mejor la herramienta

eléctrica en caso de presentarse una situación

inesperada.

La utilización de un cable de

El no estar atento durante el uso de una

Una herramienta o llave colocada

Los cables de

Ello le

La

Si trans-

f)

Lleve puesta una vestimenta de trabajo

adecuada. No utilice vestimenta amplia ni

joyas. Mantenga su pelo, vestimenta y

guantes alejados de las piezas móviles.

La vestimenta suelta, las joyas y el pelo largo

se pueden enganchar con las piezas en

movimiento.

g)

Siempre que sea posible utilizar equipos

de aspiración o captación de polvo,

asegúrese que éstos estén montados

y que sean utilizados correctamente.

utilización de un equipo de aspiración de

polvo puede reducir los riesgos de aspirar

polvo nocivo para la salud.

4) Trato y uso cuidadoso de herramientas

eléctricas

a)

No sobrecargue el aparato. Use la herramienta prevista para el trabajo a realizar.

Con la herramienta adecuada podrá trabajar

mejor y más seguro dentro del margen de

potencia indicado.

b)

No utilice herramientas con un interruptor

defectuoso. Las herramientas que no se

puedan conectar o desconectar son

peligrosas y deben hacerse reparar.

c)

Saque el enchufe de la red y/o retire la

batería antes de realizar un ajuste en la

herramienta, cambiar de accesorio o

guardar el aparato.

reduce el riesgo de conectar accidentalmente

el aparato.

d)

Guarde las herramientas eléctricas fuera

del alcance de los niños. No permita que

las utilcen personas que no estén familiarizadas con ellas o que no hayan leído estas

instrucciones.

por personas inexpertas son peligrosas.

Cuide sus herramientas eléctricas con

e)

esmero. Controle si funcionan correctamente, sin atascarse, las partes móviles de

la herramienta y si existen partes rotas

o deterioradas que pudieran afectar a su

funcionamiento. Si la herramienta eléctrica

estuviese defectuosa, hágala reparar antes

de volver a utilizarla.

accidentes se deben a aparatos con un

mantenimiento deficiente.

Mantenga los útiles limpios y afilados. Los

f)

útiles mantenidos correctamente se dejan

guiar y controlar mejor.

g)

Utilice las herramientas eléctricas, los

accesorios, las herramientas de inserción,

etc. de acuerdo con estas instrucciones.

Considere en ello las condiciones de

trabajo y la tarea a realizar.

herramientas eléctricas para trabajos

diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

Esta medida preventiva

Las herramientas utilizadas

Muchos de los

El uso de

La

16

Page 17

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 17 Dienstag, 18. Januar 2011 11:03 11

5) Servicio

a)

Únicamente haga reparar su herramienta

eléctrica por un profesional, empleando

exclusivamente piezas de repuesto

originales.

seguridad de la herramienta eléctrica.

Solamente así se mantiene la

3 Instrucciones de seguridad

especiales

¡Utilice cascos protectores!

puede provocar pérdida auditiva.

Utilice la empuñadura complementaria suministrada con la herramienta.

resultar herido por la pérdida del control de la

herramienta.

Sujete la herramienta por las superficies de la

empuñadura aisladas cuando realice trabajos

en los que la herramienta de inserción pudiera

entrar en contacto con cables eléctricos

ocultos o con el propio cable de alimentación

El contacto con un cable conductor de corriente

puede electrizar también las partes metálicas de la

herramienta y causar una descarga eléctrica.

Trabaje sólo con una empuñadura complementaria correctamente montada.

Sujete siempre la herramienta con ambas manos

por las empuñaduras existentes, adopte una

postura segura y trabaje sin distraerse.

Lleve siempre puestas gafas protectoras, guantes

de trabajo y calzado firme cuando trabaje con su

herramienta eléctrica.

Asegúrese de que en el lugar de trabajo no existan

cables, tuberías de agua o gas

ayuda de un detector de metales).

Las piezas de trabajo pequeñas deben asegurarse

de manera que la broca no las arrastre consigo al

taladrar (p. ej. sujetándolas en el tornillo de banco

o fijándolas en la mesa de trabajo con mordazas

de rosca).

Acoplamiento de seguridad S-automático de

Metabo.

Si se activa el acoplamiento de seguridad,

desconecte inmediatamente la máquina.

Evite que la máquina se ponga en funcionamiento

por error: desconecte la máquina siempre al

extraer el enchufe de la toma de corriente o

cuando se haya producido un corte de corriente.

¡No toque la herramienta de inserción en rotación!

La máquina debe estar siempre detenida para

eliminar virutas y otros residuos similares.

Atención en caso de un roscado duro (atornillado

de tornillos con roscado métrico o rosca inglesa en

acero) La cabeza del tornillo puede desprenderse

o pueden producirse momentos de retroceso en la

empuñadura.

El efecto del ruido

El usuario puede

.

(por ejemplo, con

ESPAÑOL

Desenchufe el equipo antes de llevar a cabo

cualquier ajuste o mantenimiento.

El polvo procedente de algunos materiales, como

la pintura con plomo o algunos tipos de madera,

minerales y metales, puede ser perjudicial para la

salud. Tocar o respirar el polvo puede causar reacciones alérgicas y/o enfermedades respiratorias al

usuario o a las personas próximas a él.

Algunas maderas, como la madera de roble o de

haya, producen un polvo que podría ser cancerígeno, especialmente en combinación con otros

aditivos para el tratamiento de madera (cromato,

conservante para madera). Sólo personal especializado debe trabajar el material con contenido de

asbesto.

- Si fuera posible, utilice un aspirador de polvo.

- Ventile su lugar de trabajo.

- Se recomienda utilizar una máscara de protección contra el polvo con clase de filtro P2.

Preste atención a la normativa vigente en su país

respecto al material que se va a trabajar.

SÍMBOLOS SOBRE LA HERRAMIENTA:

.......Classe II de construcción

V...........voltios

A...........amperios

Hz.........hertzios

W..........vatios

BPM .....puñetazo por minuto

~

..........corriente alterna

n0..........velocidad sin carga

rpm.......revoluciones por minuto

.../min ...revoluciones por minuto

ES

4 Descripción general

Véase la página 3 (desplegarla).

Empuñadura de sujeción

1

2

Enclavamiento de la herramienta

3

Tope de profundidad de taladro

4

Inversor del sentido de rotación

5

Botón de retención

6

Interruptor

7

Enclavamiento

8

Interruptor

5 Características especiales

del producto

• Bastidor de engranaje de aluminio fundido

a presión

• Mando de botón único:

un solo interruptor para alternar entre taladro,

martillo perforador y cincel.

• Acoplamiento de seguridad S-automatic de

Metabo:

Si se atasca o se engancha la herramienta de

inserción, se reduce el flujo de potencia al

motor. A causa de las grandes fuerzas que se

17

Page 18

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 18 Dienstag, 18. Januar 2011 11:03 11

ES

liberan, se deberá sujetar siempre la máquina

con ambas manos por sus empuñaduras.

Igualmente se debe adoptar una posición

adecuada de seguridad y trabajar sin distraerse.

• Arranque suave electrónico para empezar a

taladrar de forma precisa.

• Eliminación de giro (KHE 2443):

Mediante la desconexión del movimiento de

giro es posible realizar trabajos de cincelado.

• Interruptor bloqueable para un cincelado

cómodo en trabajos prolongados.

ESPAÑOL

6 Puesta en marcha

Antes de enchufar compruebe que la

tensión y la frecuencia de la red, indicadas

en la placa de identificación, corresponden a

las de la fuente de energía.

6.1 Montaje de la empuñadura de sujeción

Por razones de seguridad, utilice siempre

la empuñadura de sujeción suministrada.

Abrir el anillo de fijación girando la empuñadura de

sujeción (1) hacia la izquierda. Deslizar la empuñadura de sujeción sobre el collarín del eje de la

máquina. Colocar el tope de profundidad de

taladro (3). Apretar con fuerza la empuñadura de

sujeción en el ángulo requerido para la aplicación.

7 Manejo

7.3 Seleccionar el modo de operación

Seleccione el modo de operación deseado

girando el botón (8). Para girar, presione el

dispositivo de bloqueo (7).

Taladrado

Taladrar con martillo perforador

Cincelado

(Sólo KHE 2443)

En la posición de cincelado el cincel se bloquea

mediante un seguro de torsión.

Coloque el interruptor (8) entre y para

situar el cincel en el modo de uso correspondiente.

Con el cincel insertado, accione la herramienta únicamente en el modo de funcio-

namiento Cincelar.

Evite los movimientos de la palanca en la

máquina con el cincel insertado.

7.4 Dirección de giro, ajustar seguro de

transporte (bloqueo de conexión)

Pulsar el conmutador de giro (4) sólo durante

el estado de parada del motor.

Véase la página 3 (desplegar).

R = Giro a la derecha activado

L = Giro a la izquierda activad

7.1 Ajuste del tope de profundidad

Aflojar la empuñadura de sujeción (1). Ajustar el

tope de profundidad de taladro (3) a la

profundidad de taladro deseada y apretar

nuevamente la empuñadura de sujeción.

7.2 Conexión/Desconexión (On/Off)

Para poner en marcha la máquina, pulse el

interruptor pulsador (6).

La velocidad puede ser variada mediante el

interruptor.

Para un funcionamiento continuado se puede fijar

el interruptor pulsador con el botón de retención

(5). Para parar la máquina, pulse el interruptor

pulsador de nuevo.

En marcha continua, la máquina sigue

funcionando cuando es arrancada de las

manos. Por este motivo, sujetarla siempre

con ambas manos en las empuñaduras previstas para ello, adoptar una postura segura y

trabajar con concentración.

7.5 Cambio de herramienta portabrocas

de martillo

Limpie el vástago de la herramienta antes

de insertarlo y engráselo con grasa especial (como accesorio: nº de pedido 6.31800).

Inserte sólo herramientas SDS-plus

Inserción de la herramienta:

Girar la herramienta e introducirla hasta que encaje

en su sitio. La herramienta se bloquea

automáticamente.

Sacar la herramienta:

18

Page 19

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 19 Dienstag, 18. Januar 2011 11:03 11

Girar el enclavamiento de la herramienta (2) en el

sentido indicado por la flecha (a) y sacar la

herramienta (b).

8 Consejos y trucos

Para el taladrado con percutor y para el uso de

cincel solamente se requiere una presión

moderada. Las prestaciones no mejoran por

ejercer una fuerza elevada.

Para hacer taladros profundos se debe retirar la

broca de vez en cuando a fin de sacar el polvo del

orificio.

Taladre baldosas y otros materiales quebradizos

sin usar percusión.

9 Mantenimiento

De cuando en cuando deben limpiarse las ranuras

de ventilación de la máquina.

10 Localización de averías

ESPAÑOL

ES

12 Reparación

¡Las reparaciones de herramientas eléctricas

SOLAMENTE deben ser efectuadas por

electricistas especializados!

En caso de tener herramientas eléctricas que

necesiten ser reparadas, diríjase, por favor, a su

representante de Metabo. En la página

www.metabo.com encontrará las direcciones

necesarias.

En la página web www.metabo.com puede

descargar listas de repuestos.

13 Protección ecológica

Los envases Metabo son 100% reciclables.

Las herramientas eléctricas y sus accesorios fuera

de uso contienen grandes cantidades de materia

prima y plásticos que también pueden ser

reciclados.

Estas instrucciones están impresas en papel

blanqueado sin cloro.

Si no se puede accionar el interruptor pulsador (6),

comprobar que el selector de sentido de giro (4)

esté colocado correctamente en la posición

R o en la L.

f

11 Accessorios

Use solamente accesorios originales Metabo.

Si necesita accesorios, consulte a su

concesionario.

Para que el concesionario pueda seleccionar el

accesorio correcto, necesita saber la designación

exacta del modelo de su máquina.

Vea la página 4.

A Herramientas de inserción SDS-plus

BPieza de conexión

C Portabrocas de corona dentada

D Brocas para metal y madera

E Lámina de destornillador

F Corona de taladrado de percusión de metal

duro

G Set de aspiración para polvo

H Grasa especial (para el engrasado del gorrón

empotrable de la herramienta)

Programa completo de accesorios disponible en

www.metabo.com o en el catálogo principal.

14 Especificaciones técnicas

Notas explicativas sobre la información de la

página 2.

Nos reservamos el derecho a efectuar

modificaciones conforme al avance técnico.

P

1

P

2

n

1

n

2

ø max = diámetro máximo de taladro

s max = número de percusiones máximo

W = energía de percusión por cada

m=peso

D = diámetro de cuello de sujeción

¡Lleve auriculares protectores!

Las especificaciones técnicas aquí indicadas se

entien-den dentro de determinadas tolerancias

(conformes a las normas que rigen actualmente).

= potencia nominal absorbida

= potencia entregada

= N° de revoluciones de marcha

en vacío

= N° de revoluciones de marcha

bajo carga

golpe

19

Page 20

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 20 Dienstag, 18. Januar 2011 11:03 11

PT

PORTUGUÊS

Instruções de Serviço

Caro Cliente,

Agradecemos-lhe a confiança que deposita em nós ao comprar-nos esta ferramenta eléctrica Metabo.

Cada ferramenta Metabo é cuidadosamente testada e sujeita a controlos de qualidade exaustivos antes

de ser entregue. No entanto a vida útil de um equipamento deste tipo depende em grande parte do uso

e dos cuidados que lhe dão. Cumpra pois todas as indicações incluídas neste manual . Quanto mais

cuidadosamente tratar a sua ferramenta Metabo, maior será a longevidade que poderá esperar dela.

Regras gerais de segurança para ferramentas

Índice

1 Utilização autorizada

2 Recomendações gerais de segurança

3 Indicações de segurança especiais

4Vista geral

5 Características especiais do produto

6 Colocação em operação

7 Utilização

8Conselhos úteis

9 Manutenção

10 Detecção de avarias

11 Acessórios

12 Reparações

13 Protecção do meio ambiente

14 Dados técnicos

1 Utilização autorizada

O martelo perfurador com os acessórios correspondentes, é adequado para trabalhar com

brocas de martelo e trabalhos de demolições

(apenas KHE 2443) em betão, pedra e matérias

similares, e com brocas de coroa oca em tijolos

e semelhantes, bem como para perfurar sem

impacto em metal, madeira, etc., e para aparafusar.

O utilizador é inteiramente responsável por

qualquer dano que seja fruto de um uso indevido.

Deve sempre cumprir-se toda a regulamentação

aplicável à prevenção de acidentes, assim como a

informação sobre segurança que aqui se incluí.

2 Recomendações gerais de

segurança

AVISO – Leia as Instruções de Serviço

para evitar riscos de ferimentos e lesões.

Para sua própria protecção e para

proteger a sua ferramenta, cumpra

muito em especial todas as referências

marcadas com o símbolo!

eléctricas

AVISO Leia todas as regras de segurança e instruções.

cumprimento das regras de segurança e das

instruções podem haver choque eléctrico,

incêndio e/ou graves lesões.

regras de segurança e instruções para futuras

consultas!

zado nas regras de segurança, refere-se a ferra

mentas eléctricas com conexão a rede (com cabo)

e a ferramentas eléctricas operada a pilhas

(sem cabo).

1) Segurança na área de trabalho

a)

b)

c)

2) Segurança eléctrica

a)

b)

c)

d)

O termo "ferramenta eléctrica" utili-

Mantenha a sua área de trabalho limpa e

bem iluminada.

trabalho com fraca iluminação podem levar

a acidentes.

Não trabalhe com a ferramenta eléctrica

em áreas com risco de explosão, nas quais

se encontrem líquidos, gases ou pós

inflamáveis.

produzem faíscas que podem provocar

a ignição de pó e vapores.

Mantenha crianças e outras pessoas

afastadas da ferramenta eléctrica durante

o trabalho com a ferramenta.

podem causar a falta de controle sobre

o aparelho.

A ficha da ferramenta eléctrica deve caber

na tomada. A ficha não deve ser modificada de modo algum. Não use fichas

adaptadoras junto com ferramentas

eléctricas com protecção-terra.

sem modificações e tomadas adequadas

reduzem o risco de choques eléctricos.

Evite que o corpo entre em contacto com

superfícies ligadas à terra, como por

exemplo tubos, radiadores, fogões e

geladeiras.

eléctricos, caso o corpo for ligado à terra.

A ferramenta eléctrica não deve ser

exposta à chuva nem humidade.

tração de água na ferramenta eléctrica

aumenta o risco de choques eléctricos.

Não utilize o cabo da ferramenta eléctrica

para outros fins como transporte, para

Ferramentas eléctricas

Há um risco elevado de choques

A um descuido no

Guarde todas as

Desordem ou áreas de

Distrações

Fichas

A pene-

20

Page 21

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 21 Dienstag, 18. Januar 2011 11:03 11

pendurar a ferramenta eléctrica, nem para

puxar a ficha da tomada. Mantenha o cabo

afastado de calor, óleo, cantos afiados ou

partes em movimento do aparelho.

danificados ou torcidos aumentam o risco

de choques eléctricos.

e)

Ao trabalhar com a ferramenta eléctrica ao

ar livre, use um cabo de extensão

adequado para áreas externas.

um cabo apropriado para áreas externas reduz

o risco de choques eléctricos.

f)

Aquando for extremamente necessário

operar a ferramenta eléctrica num ambiente húmido, use um interruptor de

protecção diferencial.

interruptor de protecção diferencial diminui

o risco de um choque eléctrico.

3) Segurança de pessoas

a)

Esteja alerta, observe o que está a fazer,

e tenha prudência ao trabalhar com a ferramenta eléctrica. Não use a ferramenta

eléctrica se estiver fatigado ou sob a

influência de drogas, álcool ou medicamentos.

durante a operação da ferramenta eléctrica

pode resultar em graves lesões.

b)

Usar um equipamento pessoal de

protecção. Sempre utilizar um óculos de

protecção.

de segurança como por exemplo, máscara

de protecção contra pó, sapatos de segurança

anti-derrapantes, capacete de segurança ou

protecção auricular, de acordo com o tipo

e aplicação da ferramenta eléctrica, reduzem

o risco de lesões.

c)

Evite um accionamento involuntário. Assegure-se de que a ferramenta eléctrica

esteja desligada antes de conectá-la

à corrente eléctrica e/ou ao acumulador,

antes de apanhá-la ou carregá-la.

o dedo sobre o interruptor ao transportar a

ferramenta eléctrica ou conectar a ferramenta

já ligada à rede, pode levar a graves acidentes.

d)

Remover chaves de ajustes ou chaves de

fenda, antes de ligar a ferramenta eléctrica.

Uma chave de fenda ou chave de ajuste que

se encontre numa parte móvel do aparelho,

pode levar a lesões.

e)

Evite uma postura anormal. Mantenha

uma posição firme e mantenha sempre

o equilíbrio.

fácil controlar a ferramenta eléctrica em

situações inesperadas.

f)

Use roupa apropriada. Não use roupa larga

ou jóias. Mantenha o cabelo, roupa e luvas

afastadas de partes em movimento.

Roupas largas, jóias ou cabelos longos podem

ser agarradas por partes em movimento.

Um momento de falta de atenção

A utilização de equipamentos

Desta forma poderá ser mais

A utilização de um

O uso de

Cabos

Manter

PORTUGUÊS

g)

Se for prevista a montagem de dispositivos

de aspiração de pó e de recolha, assegurese de que estão conectados e que sejam

utilizados de forma correcta.

de um dispositivo de aspiração de pó pode

reduzir os riscos provocados pelo pó.

4) Tratamento cuidadoso e utilização de

ferramentas eléctricas

a)

Não sobrecarregue a ferramenta eléctrica.

Use para o seu trabalho a ferramenta

A ferramenta correcta

Muitos acidentes tem como

Ferramentas de cortes

b)

c)

d)

e)

f)

g)

5) Serviço

a)

eléctrica correcta.

realizará o trabalho de forma melhor e mais

segura dentro da faixa de potência indicada.

Não utilize a ferramenta eléctrica se o

interruptor não puder ser ligado nem

desligado.

que não possa ser controlada através do

interruptor de ligar-desligar, é perigosa e

deve ser reparada.

Puxe a ficha da tomada e/ou remova o

acumulador antes de efectuar ajustes

na ferramenta, substituir acessórios ou

armazenar a ferramenta eléctrica.

medida de segurança evita que a ferramenta

eléctrica seja ligada acidentalmente.

Guarde ferramentas eléctricas que não

estiverem sendo utilizadas, for a do

alcance de crianças. Não permita que

a ferramenta seja utilizada por pessoas

não familiarizadas com a mesma ou que

não tenham lido estas instruções.

mentas eléctricas são perigosas nas mãos

de pessoas sem treinamento.

Trate a sua ferramenta eléctrica com

cuidado. Verifique se as partes móveis

funcionam perfeitamente e não emperram,

se há peças quebradas ou danificadas que

possam influenciar o funcionamento da

ferramenta eléctrica. Peças danificadas

devem ser reparadas antes da utilização

da ferramenta.

causa uma manutenção insuficiente das

ferramentas eléctricas.

Mantenha as ferramentas de corte sempre

afiadas e limpas.

devidamente tratadas, com cantos afiados

travam com menos frequência e podem ser

controladas com maior facilidade.

Use a ferramenta eléctrica, os acessórios,

os bits da ferramenta etc. de acordo com

estas instruções. Considere também as

condições de trabalho e o trabalho a ser

efectuado.

eléctrica para outros fins que os previstos,

pode resultar em situações perigosas.

A sua ferramenta eléctrica só deve ser

reparada por pessoal qualificado e só

Qualquer ferramenta eléctrica

A utilização da ferramenta

A utilização

Esta

Ferra-

PT

21

Page 22

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 22 Dienstag, 18. Januar 2011 11:03 11

PT

PORTUGUÊS

devem ser colocadas peças sobressalentes originais. Desta forma é assegurada

a segurança da ferramenta eléctrica.

3 Notas de segurança

especiais

Utilize protecção auditiva.

barulho podem afectar a audição.

Utilize o punho adicional fornecido junto com a

ferramenta.

mentos.

Segure a ferramenta nas superfícies isoladas

do punho quando executar trabalhos nos quais

o acessório acoplável poderá atingir condutores de corrente ocultados ou o próprio cabo

de rede.

corrente eléctrica também pode colocar as peças

de metal da ferramenta sob tensão, e ocasionar a

um choque eléctrico.

Trabalhar somente com o punho adicional devidamente montado.

Segure a máquina sempre com ambas as mãos

nos punhos previstos, posicione-se de forma

segura e concentre-se no trabalho.

Use óculos de protecção, luvas de trabalho e

sapatos firmes aquando usar a sua ferramenta

eléctrica!

Certifique-se de que no local em que trabalha,

há tubagens de corrente eléctrica, água ou gás

(p.ex. com ajuda de um aparelho detector de

metais).

Peças menores a serem trabalhadas devem ser

fixas de forma a que não possam ser levadas pela

broca durante a perfuração (p.ex. por meio de um

torno de bancada ou com pinças sobre a bancada

de trabalho).

Embraiagem automática de segurança Metabo

S-automatic.

Desligar imediatamente a ferramenta a uma

reacção da embraiagem automática de segurança!

Evitar o arranque involuntário: sempre destravar o

interruptor quando a ficha for retirada da tomada

ou no caso de falta de energia eléctrica.

Não pegar na ferramenta em utilização a rodar!

Remover aparas e semelhantes apenas quando

a máquina estiver parada.

Tomar cuidado em caso de situação de aparafu-

samento "dura" (aparafusamento de parafusos em

aço, com rosca métrica ou de polegadas)! A

cabeça do parafuso pode romper ou poderão

surgir torques elevados de reversão no punho.

Antes de iniciar qualquer manutenção ou ajuste,

puxe a ficha da tomada da rede.

Os pós de materiais como revestimentos que

A perda de controlo pode levar a feri-

O contacto com um condutor de

As influências do

não

contenham chumbo, alguns tipos de madeira,

minerais e metais podem ser nocivos à saúde.

O contacto ou a inalação de pós pode causar

reacções alérgicas e/ou doenças das vias

respiratórias ao operador ou a pessoas a se

encontrar nas proximidades.

Determinados pós como de carvalho ou faia são

cancerígenos, principalmente quando em

contacto com substâncias adicionais para tratamento da madeira (cromato, substâncias para

tratamento da madeira). Material de asbesto só

pode ser tratado por pessoas que comprovam ter

conhecimentos técnicos.

- Assim que possível, utilize um dispositivo

aspirador de pó.

- Providencie uma boa ventilação do local de

operação.

- Recomenda-se o uso de uma máscara

respiratória com classe de filtração P2.

Siga as regulamentações válidas no seu País,

para os materiais a serem tratados.

SÍMBOLOS NA FERRMENTA:

...... Constru

V .......... volts

A.......... amperes

Hz........ hertz

W......... watts

BPM .... pun

~

.......... corrente alternada

n0......... velocidade sem carga

rpm...... rotações por minuto

.../min .. rotações por minuto

ção da Classe II

ção por minuto

4Vista Geral

Ver página 3 (desdobrar a página).

Punho de suporte

1

2

Bloqueio da ferramenta

3

Limitador de profundidade

4

Comutador de direcção de giro

5

Botão de bloqueio

6

Gatilho

7

Trava

8

Botão de ligação

5 Características Especiais

do Produto

• Carcaça da engrenagem em alumínio fundido

• Operação de um único botão

A comutação entre furar, perfurar com martelo

e demolir pode ser activada conforme equipamento, através de um único interruptor.

• Embraiagem automática de segurança Metabo

S-automatic:

Assim que o acessório acoplável empenar ou

encravar, será limitada a força de corrente ao

motor. Devido às forças que surgem através

destas altas forças, sempre deverá segurar a

22

Page 23

17027073_0111 BHE 2243 KHE 2443 NAFTA.book Seite 23 Dienstag, 18. Januar 2011 11:03 11

ferramenta com ambas as mãos e nos punhos

previstos, manter uma posição segura e

trabalhar com toda concentração.

• Arranque suave electrónico para furar com

exactidão.

• Paragem de rotação (KHE 2443):

Graças ao desligamento do movimento rotativo, podem ser executados trabalhos de demolição.

• Interruptor bloqueável para demolição confortável no regime contínuo.

6 Colocação em operação

Antes de ligar o cabo de alimentação

verifique se a voltagem e a frequência da

rede de alimentação se adequam aos valores

inscritos na placa técnica da ferramenta.

6.1 Montagem do punho de suporte

Por uma questão de segurança utilize

sempre o punho lateral que é fornecido.

Abra o anel de aperto ao girar o punho lateral (1).

Faça deslizar o punho lateral ao longo da gola

tensora da máquina. Insira o limitador de profundidade (3). Aperte o punho lateral com o ângulo que

mais lhe convier para o seu trabalho.

7 Utilização

7.1 Regulação do limitador de

profundidade

Desaperte o punho lateral (1). Ajustar o limitador

de profundidade (3) à profundidade do furo que se

pretende e voltar a apertar o punho de suporte.

7.2 Ligar/desligar

Para ligar a máquina, prima o gatilho (6).

A rotação pode ser modificada no gatilho.

Em operação contínua o gatilho pode-se prender

com o botão de bloqueio (5). Para desligar,

prime-se novamente o gatilho .

No ligamento contínuo a máquina