Merrychef Evolution Service Manual

Page 1

CAUTION MICROWAVE EMISSIONS

DO NOT BECOME EXPOSED TO EMISSIONS FROM THE MICROWAVE

GENERATOR OR PARTS CONDUCTING MICROWAVE ENERGY

SERVICE MANUAL

Evolution

SERVICE MANUAL

For all Evolution models manufactured f r om January 2001

Part No. 32Z3382e Issue No. 3

Page 2

Table of Contents

Safety Code ................................................................3

Product Specifications ................................................4

Dimensions. Location and Installation ........................5

Manual RHS controls .................................................. 7

Error Codes and Diagnostics ...................................... 8

Main Features ............................................................ 9

A -Power Output Testing to EN 60335-2-90:1996 ..... 10

B - Power Output Testing ..........................................11

C - Power Transformer Test .....................................11

D - High Voltage Capacitor Test ............................... 12

E - High Voltage Rectifier Test .................................. 12

Principal Components: Right side view ..................... 13

Principal Components: Right side view ..................... 14

Principal Components: Rear view, top view ..............15

Oven Door Assembly ................................................ 16

Door Interlock Operation ........................................... 17

Error Light Operation ............................................... 17

Input Wiring Details ................................................... 18

Control Panel Assembly ............................................19

Membrane Panel Circuit ............................................ 20

Circuit Diagram .................................................21 & 22

Parts Matrix ............................................................... 23

Reply Form ............................................................... 24

Merrychef Limited,

Station Road West,

Ash Vale,

Aldershot, Hampshire GU12 5XA,UK.

Tel: +44 (0)1252 371000 Fax: +44 (0)1252 371007

Internet address: http://www.merrychef.co.uk

E-mail: sales@merrychef.co.uk

or

service@merrychef.co.uk

Page 3

This manual is designed to assist engineers who have been on a recognised product familiarisation

and training course run by Merrychef Limited. It has been prepared to off er tec hnical guidance f or the

Merrychef Evolution range of Combination Microwave Ovens.

Please remember that it is wiser

not

to attempt a service task if you are unsure of being able to

complete it competently, quickly, and above all

safely

.

To avoid injury to yourself, and to protect the appliance from possible damage, please follow this

Safety Code when servicing these ovens.

Before attempting to repair the oven, check it for microwave leakage.

Check that the oven is not emitting microwaves, even when supposedly not in operation.

Check that the oven is not operating continuously, whether the display indicates cooking

or not.

Always discharge the HT capacitors before working on the oven using a suitably insulated

10 MΩ Resistor

Before removing the rear cover from the oven, do all

of the following:

•

Switch off the mains supply and remove the plug from the wall socket.

or

•

If the oven is hard wired, ensure that the power is turned off at the isolator switch.

Note:

The On/Off switch on the oven is

not

adequate protection against electric shock , as it does

not isolate all of the internal wiring from the mains.

Upon completion of a service on a Evolution oven, or before r econnecting the appliance to the m ains

supply for testing, check all

of the following points:

•

All internal electrical connections are correct.

•

All wiring insulation is correct and is not touching a sharp edge.

•

All Earth connections are electrically and mechanically secure.

•

All four door safety interlocks are secure and mechanically sound.

•

The door operation is smooth, and the arms run freely in the slots.

•

The door activates all four of the door interlock switches

in the correct order

.

•

All fuse-holder safety covers are correctly fitted.

•

The temperature sensor is correctly connected to the Power PCB.

Before finishing the service call, recheck the following points:

•

All of the electronics are functioning correctly, and all of the touch pads are working

•

The turntable is rotating freely

•

The power output of the oven is correct

•

Microwave emission is below permissible limit - 5 mW/cm² (see BS EN 60335-2-90:1998)

•

Oven has correct 120 mm air gap all round and 100 mm above. Air flow should not be

restricted

SAFETY CODE

Page 4

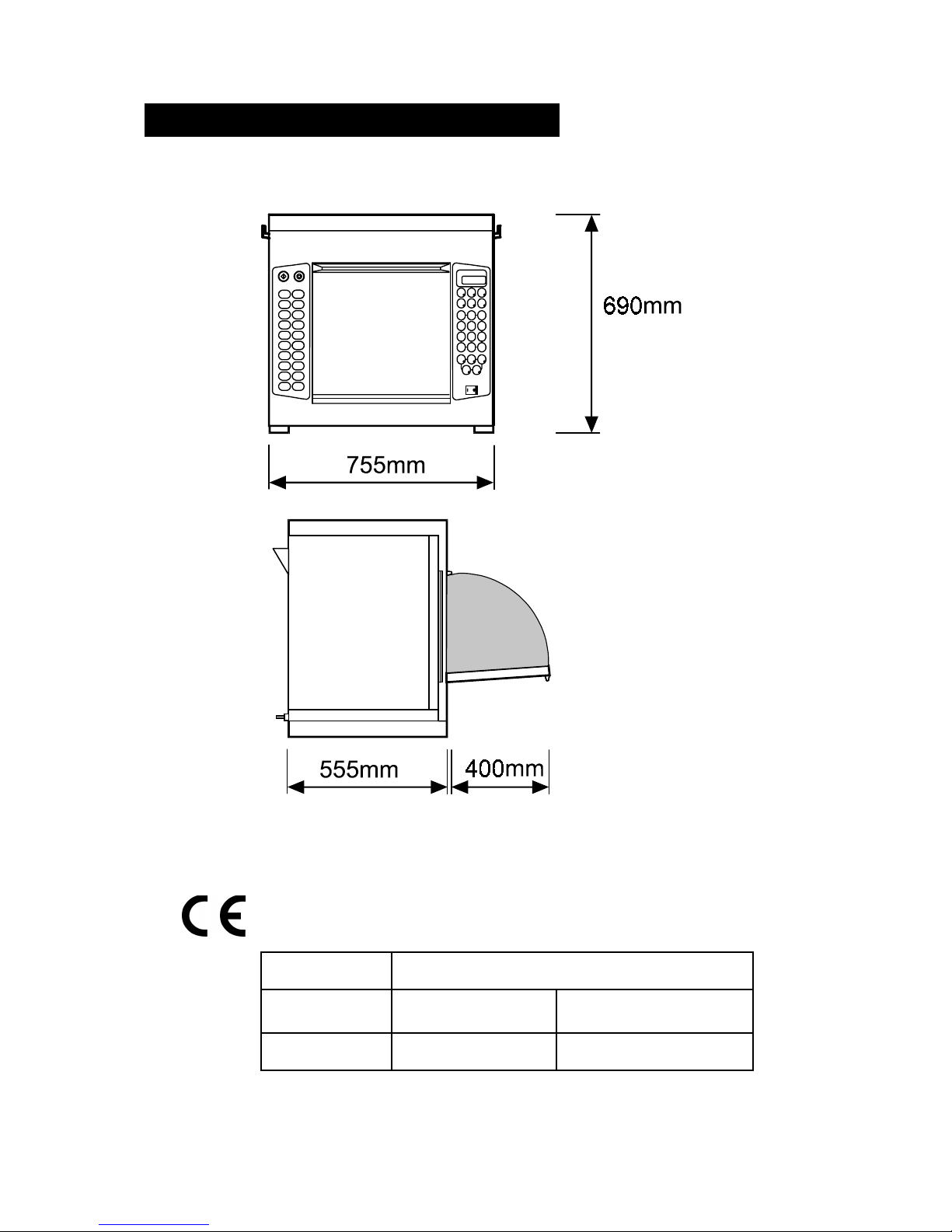

Model Number: EV + Voltage + Frequency + Phase + Version

Power Output

Microwave 100%

Convection Heat

Combination

2000 Watts (IEC 705 Rating) Single & Twin supply

1800 Watts (IEC 705 Rating) Three Phase supply

5000 Watts

2000 Watts Microwave + 5000 Watts Convection Heat

External

Dimensions

Height

Width

Depth

700 mm (Plus 100 mm minimum clearance above = 800 )

755 mm (Plus 100 mm minimum clearance each side = 955 )

555 mm (Plus 100 mm clearance behind = 655 )

Internal

Dimensions

Height

Width

Depth

Turntable

Capacity

315 mm

330 mm

330 mm

300 mm Diameter

34.3 litres (1.21 ft³)

Weight

Net

Gross packed

82 kg

90 kg

Construction

Cavity

Casework

304 Stainless Steel

304 Stainless Steel

Settings

Microwave

Temperature

Timer

100%,75%,50%,25%, Convection only

Off, 150°, 200°, 250°, 275°,300°C

Up to 30 minutes (Manual)

3 cooking stages of up to 30 minutes each (Programed)

Control System

Wipe-clean touch pad operating microprocessor based control system

Single touch control of temperature

Direct readout of time, power and temperature set

Digital readout of cavity temperature available

100 Pre-programmed cooking sequences

Built-in diagnostic messages

Safety

Features

Four door interlock switches

Cavity Overheat Sensor

Magnetron Overheat Sensor

Blocked Air Filter Sensor

Automatic Lock-out on invalid time setting

Convection Fan and Heater disabled when door open

Additional

Features

•

Easy-to-use multistage programming

•

Manual and Pre-programmed mode always available

•

Rapid cavity pre-heat

•

Low-loss insulated cavity and door

•

One-touch selection of temperature

•

Magnetron soft-start circuit for increased life and faster activation

PRODUCT SPECIFICATIONS

Power Requirement Voltage Current Microwave Convection Combination

Single EV2451B

240V 45A 20A 21A 41A

P1 240V 25A 20A 1A 20A

P2 240V 25A 0 20A 20A

Twin EV2452B

Model prefix Voltage Frequency Phase Control Type

24=240V 5 = 50 Hz

6 = 60 Hz

1 = Single

2 = Twin

3= Three Phase

B

EV

Page 5

DIMENSIONS AND LOCATION

A sample of this product has been tes ted and found to be in conformity

with the following directives:

Directive

EMC 89/336 EEC EN 55011

EN 50082-1

1991 (Emissions)

1992 (Immunity)

LVD 73/23 EEC EN 60 335-2-90

Harmonised standards applied.

Page 6

Power Supply Requirements

The Evolution should be connected to a suitable electricity supply, which can cope with the

switching-on surge that occurs with certain types of catering equipment, such as microwaves.

Because of this requirement, we strongly recommend that a separate, suitably rated supply is

installed for the oven.

The supply for the oven should be fitted with a

Type "C"

circuit breaker. Please ref er to rating

plate for details.

If the oven is hard wired to the supply a double-pole isolator switch with a contact gap of at least

3mm should be fitted.

Positioning the Oven

In order to maintain adequate ventilation for air intake and exhaust, and to allow access for

cleaning filters, you must allow a minimum of 100 mm clearance at the sides and 100 at the rear

of the oven, and at least 100 mm above. Air intake temperature should not exceed 35°C excessive temperature can lead to reduced operating duty cycle or premature ageing of internal

components.

NEVER

Install an oven above fryers, grills, griddles or any other major heat source.

NEVER

Stack machines on top of each other - always use a double stand.

INSTALLATION INSTRUCTIONS

Page 7

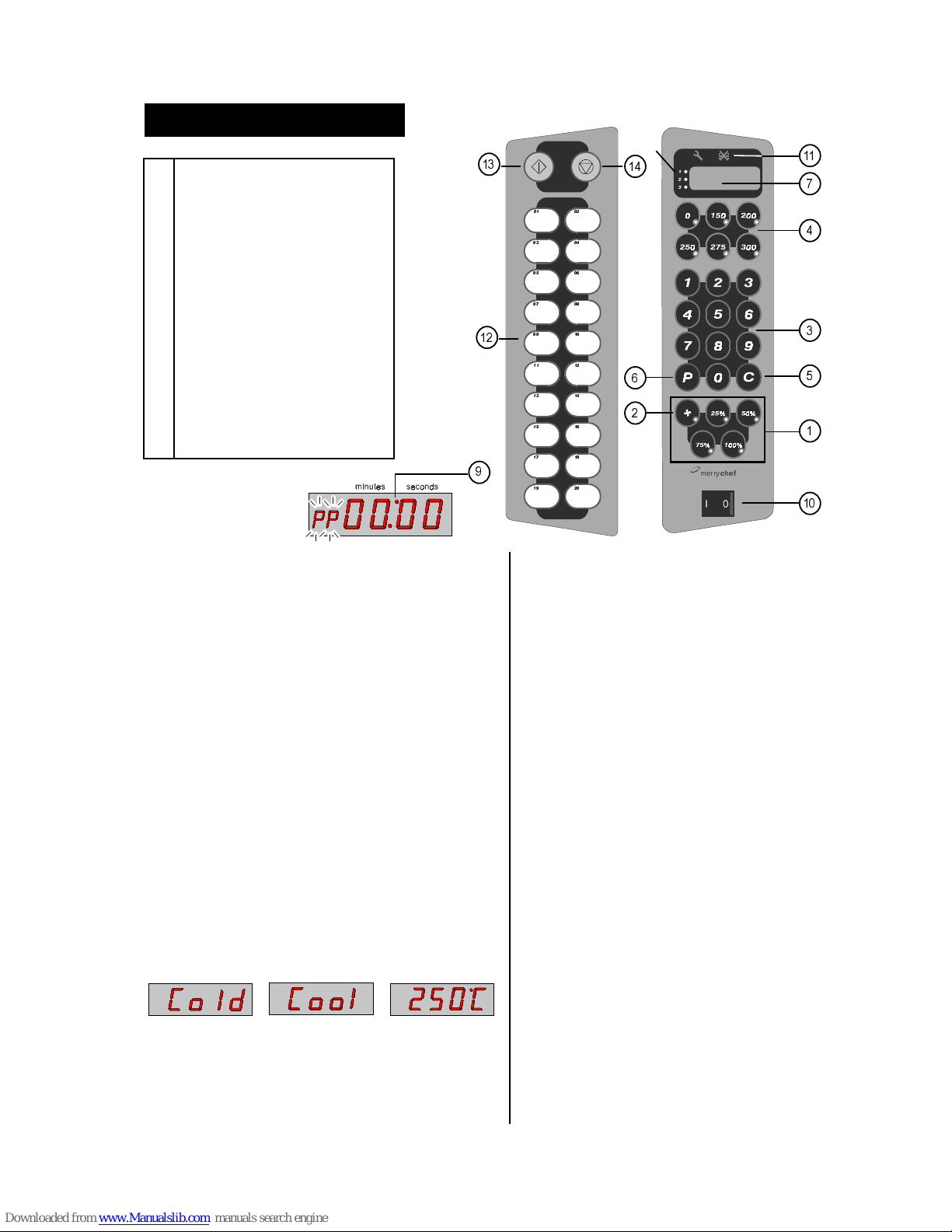

MANUAL CONTROLS

below 100ºC

100C-125ºC

above 125ºC

1 POWER PADS

2 CONVECTION PAD

3 TIME/PROGRAM SELECT PADS

4 TEMPERATURE SETTING PADS

5 CANCEL PAD

6 PROGRAM PAD

7 TIME AND PROGRAM DISPLAY

8 MULTI-STAGE INDICATOR

9 COLON

10 ON/OFF SWITCH

11 ERROR DISPLAY

7 TIME AND

PROGRAM

DISPLAY

1. POWER PADS

There are 4 Microwave Power Pads to select from:

25%, 50%, 75%, and 100%. A light will indicate the

one in use.

2. CONVECTION PAD

This is used when foods only require browning( no

microwave)

Note: when cooking the MICROWAVE and

CONVECTION pads start the cycle and timer. You

may alter power levels during a manual cooking cycle.

When cooking is interrupted, a light will flash as a

reminder that the time is being held (see PAUSE).

3. TIME/PROGRAM SELECT PADS

These pads are used for setting the cooking time in 1

second steps to a maximum of 30 minutes.

They are also used for programs from 21-99.

4. TEMPERATURE SETTING PADS

These pads are used to set the convection

temperature. A light will indicate the temperature set.

Selecting the ‘0’ key will switch convection off. If a

temperature key is pressed and held the current oven

temperature will be displayed in the time display

window.

5. CANCEL/ CALLBACK ‘C’ PAD

Cancels all timed cooking cycles, pre-programmed

operations and stop the microwave energy. It does not

alter the oven temperature . If the oven is hot food will

continue to cook and should be removed from the oven

immediately. This pad will also cancel any incorrect

operations. It will not erase programs. It can also be

used to view the details of stored programs.

(see CALL BACK)

6. PROGRAM ‘P’ PAD

Activate or set program

7. TIME AND PROGRAM DISPLAY

Shows the time set in minutes and seconds and counts down

in 1 second steps during a cooking cycle.

Also displays error messages and oven temperature.

(PROBLEM SOLVING section 8)

The program display indicates the program number

selected. ‘PP’ indicates programming

8. MULTI-STAGE INDICATOR

Indicates stage in multi-stage cooking

9. COLON

W hen programming the colon will flash to indicate the

time may now be entered.

10. ON/OFF SWITCH

11. ERROR DISPLAY See PROBLEM SOLVING Section 8.

12. QUICK ACCESS PADS

For programs 01-20

13. START

Starts a quick access program

14. STOP

Stops a quick access program

PHUU\

FKHI

Page 8

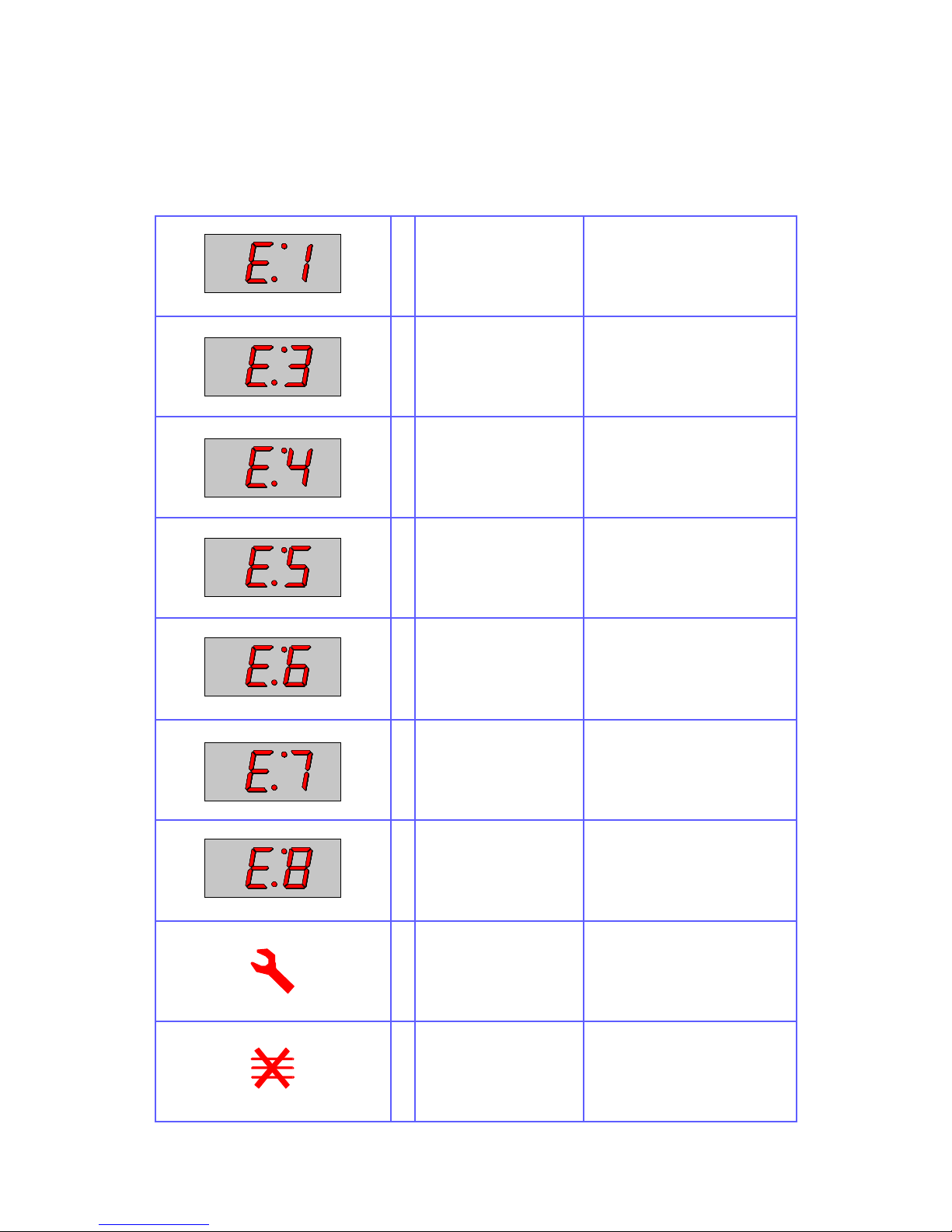

Error Codes and Diagnostics

The Evolution will identify some of the most common problem s by flashing an error m es sage code in

the time display window. (See also Error Light Operation page 17).

These are the error messages and suggestions for repairing them.

1

2

Door not fully shut.

Possible electrical fault

Close door fully.

Door switch inoperative.

1

2

3

No time has been set.

Invalid time has been set.

Invalid program has been

set.

Set a time.

Set a valid time.

Use call-back to check program.

1

2

3

Oven not heating up.

Possible Heater fault.

Possible Sensor fault.

Check heater fuse.

Confirm operation of heater circuit.

(RS units) Check slave heater relay and second supply.

1

Oven Cavity overheating.

Confirm heater relay is operating.

(RS units) Check slave heater re-

lay .

1

Oven is not at correct temperature to start program.

Remove food.

Allow oven to reach correct temperature.

Operator Error !!

1 Left Hand

Magnetron overheating.

Check air filters.

Check location, air inlet temperature and air filters.

Note : this will lead to condition

shown below. See Page 18

1 Right Hand

Magnetron overheating

Check air filters.

Check location, air inlet temperature and air filters.

Note : this will lead to condition

shown below. See Page 18

1

2

Magnetron has overheated but has now recovered.

Internal diagnostic fault

Check that magnetron cooling fan

and turntable are working correctly.

Check installation, air inlet temperature and air filters.

See Page 18

1

Oven control area is overheating.

Check air filters.

Check axial fan.

Check installation for hot air intake.

Loading...

Loading...