Page 1

Installation and Maintenance Manual IM-801

AHP Split System Heat Pumps

1-1/2 to 5 tons

Group: Unitary

Part Number: IM-801

Date: August 2005

Supersedes: January 2005

© 2004 McQuay International

IM-801 Page 1

Page 2

Table of Contents

MODEL NOMENCLATURE. . . . . . . . . . . . . . . . . . . . . . . . . . 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL WARNINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SCROLL COMPRESSORS . . . . . . . . . . . . . . . . . . . . . . . . . 4

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

COMPONENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PIPING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

EVAPORATOR COIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

INDOOR CFM AND HEATING CAPACITY

DETERMINATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

REFRIGERANT CHARGE DETERMINATION AND

ADJUSTMENT - HEAT PUMP - COOLING CYCLE . . . . . .10

HEAT PUMP - HEATING CYCLE . . . . . . . . . . . . . . . . . . . .11

STARTUP PROCEDURE AND CHECK LIST . . . . . . . . . . .11

OPERATION - DEFROST CONTROL . . . . . . . . . . . . . . . .12

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

THERMOSTAT DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . .15

"McQuay" is a registered trademark of McQuay International.

"Illustrations and information cover the McQuay International products at the time of publication and we reserve the right to make changes in

Page 2 IM-801

design and construction at any time without notice."

© 2004 McQuay International

Page 3

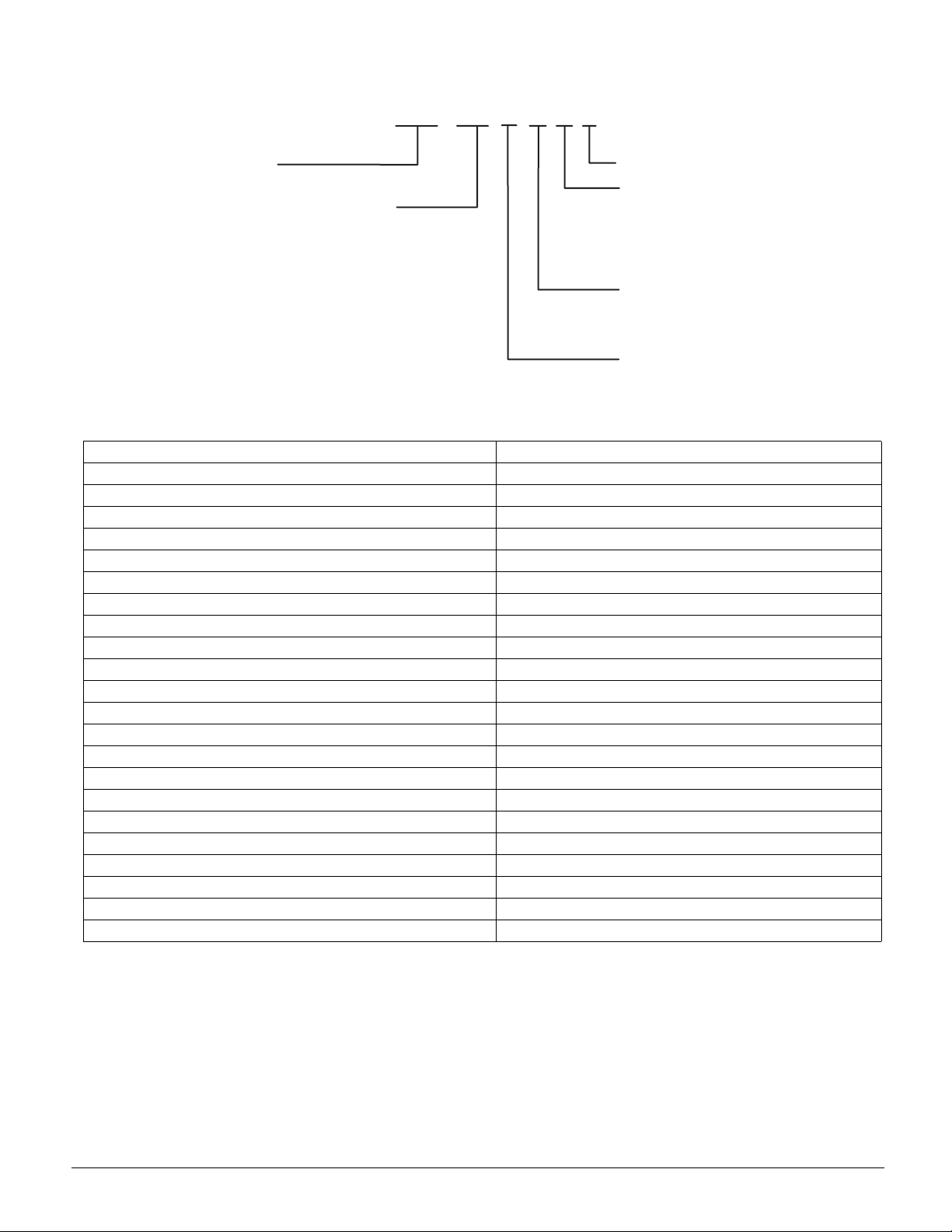

MODEL NOMENCLATURE

M

A

N

1

2

3

4

4

4

6

6

6

0*

A

*

odel

HP= Air Cooled Heat Pump

ominal Capacity (tons)

8 = 1-1/2

4 = 2

6 = 3

2 = 3-1/2

8 = 4

9 = 4

0 = 5

1 = 5

2 = 5

10 SEER Size 048 and 060 only.

Table 1: Unit Nameplate Model Number Identifier

Unit Nameplate McQuay Model Number

CPLE18-1C AHP018ARAY

CPLE24-1C AHP024ARAY

CPLE30-1C AHP030ARAY

CPLE36-1C AHP036ARAY

CPLE42-1C AHP042ARAY

CPLE48-1C AHP048ARAY

CPLE48-3C AHP048APAY

CPLE60-1C AHP060ARAY

CPLE60-3C AHP060APAY

CPLJ18-1B AHP018ARBY

CPLJ24-1B AHP024ARBY

CPLJ30-1B AHP030ARBY

CPLJ36-1B AHP036ARBY

CPLJ42-1B AHP042ARBY

CPLJ48-1B AHP048ARBY

CPLJ60-1B AHP060ARBY

CPLT24-1B AHP024ARCY

CPLT30-1B AHP030ARCY

CPLT36-1B AHP036ARCY

CPLT42-1B AHP042ARCY

CPLT48-1B AHP048ARCY

CPLT60-1B AHP060ARCY

AHP 018

RAY

Future Use

SEER

A = 10

B = 12

C = 13

Voltage/Phase

P = 208-230/3/6

R = 208-230/1/60

Vintage

IM-801 Page 3

Page 4

INTRODUCTION

General Description

These installation instructions cover the outdoor installation of

split system heat pumps from ½ to 5 tons. See the product catalog applicable to your model for information regarding specifications applicable to your model and accessories.

Receiving Inspection

McQuay products are carefully inspected prior to shipment

and the carrier has assumed responsibility for loss or damage

upon acceptance of the shipment.

Upon receiving your shipment, check all items carefully

against the Bill of Lading. Inspect the unit and/or accessories

for shipping damage as soon as they are received. Immediately file claims for loss or damage, either shipping or concealed, with the shipping company.

Check the unit nameplate to verify the model number and electrical characteristics are correct. In the event an incorrect unit

is shipped, it must be returned to the supplier and must NOT

be installed. The manufacturer disclaims all responsibility for

the installation of incorrectly shipped units.

Codes and Regulations

This product is designed and manufactured to permit installation in accordance with National Codes. System design

should, where applicable, follow information presented in

accepted industry guides such as the ASHRAE Handbooks. It

is the installer' s responsibility to install the product in accordance with National Codes and/or prevailing local codes and

regulations. The manufacturer disclaims all responsibility for

equipment installed in violation of any code or regulations.

IMPORTANT

The United States Environmental Protection Agency

(EPA) regulations cover introduction and disposal of

refrigerants in this unit. Failure to follow those

regulations can harm the environment and lead to

substantial fines. Because regulations can change, a

certified technician should perform any work done on

this unit. If you have any questions, please contact the

local office of the EPA.

Important Message to the Installer

This equipment is to be installed by an experienced installation

company and fully trained personnel. Carefully read all

instructions and take into account any special considerations

prior to installing the unit. Give this manual to the owner and

explain its provisions.

Important Message to the Owner

Read these instructions carefully and keep them near the product for future reference. Although these instructions are

addressed primarily to the installer, useful maintenance information is included. Have the installer acquaint you with the

operation of the product and periodic maintenance requirements.

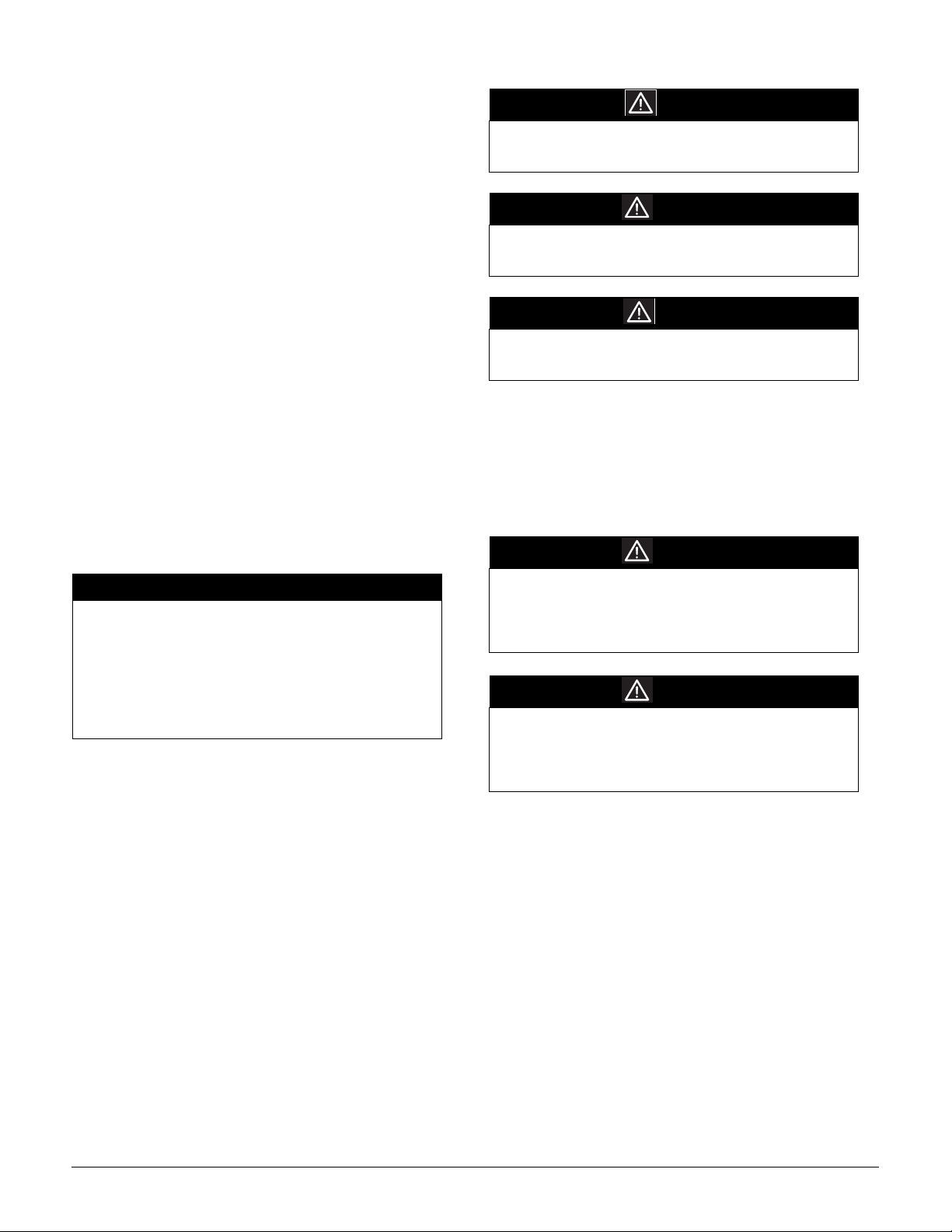

Recognize Safety Symbols, Words, and Labels

The following symbols and labels are used throughout this

manual to indicate immediate or potential hazards. It is the

owner's and installer's responsibility to read and comply with

all safety information and instructions accompanying these

symbols. Failure to heed safety information increases the risk

of property damage and/or product damage, serious personal

injury or death. Improper installation, operation and maintenance can void the warranty.

DANGER

Immediate hazards which WILL result in property

damage, product damage, severe personal injury and/

or death.

WARNING

Hazards or unsafe practice CAN result in property

damage, product damage, sever personal injury and/or

death.

CAUTION

Hazards or unsafe practices which CAN result in

property damage, product damage, and/or personal

injury.

Replacement Parts

Replacement parts can be obtained by contacting McQuay at

1

-800-37-PARTS. When contacting McQuay for service or

replacement parts, refer to the model number and serial number of the unit as stamped on the nameplate attached to the

unit.

GENERAL WARNINGS

WARNING

Do not allow combustible materials, gasoline or other

flammable liquids or vapors in the vicinity of this unit.

Property damage, severe personal injury or death can

result. Identify all cut-off devices, switches, etc. that

serve your comfort equipment.

WARNING

Do not connect duct work to any other heat-producing

device such as fireplace insert, stove, etc. Such

connection can cause property damage, fire, carbon

monoxide poisoning, explosion, personal injury or

death.

SCROLL COMPRESSORS

Read the following before installing units with scroll compressors.

Pump Down Procedure

Scroll-equipped units should never be used to evacuate the air

conditiong system. Vacuums this low can cause internal electrical arcing, resulting in a damaged or failed compressor.

Crankcase Heater

Scroll-equipped units do not have, and do not require, a crankcase heater.

Unbrazing System Components

If the refrigerant charge is removed from a scroll equipped unit

by bleeding the high side only, it is sometimes possible for the

scrolls to seal, preventing pressure equalization through the

compressor. This may leave the low side shell and suction line

tubing pressurized. If a brazing torch is then applied to the low

side while the low side shell and suction line contains pressure,

Page 4 IM-801

Page 5

the pressurized refrigerant and oil mixture could ignite when it

escapes and contacts the brazing flame. To prevent this occurrence, it is important to check both the high and low side with

a manifold gauge before unbrazing, or in the case of repairing

a unit on an assembly line, bleed refrigerant from both the high

and low side.

WARNING

Before unbrazing, check pressure on both high and low

side. Incorrect charge removal can leave pressurized

refrigerant and oil, which can ignite in contact with

brazing heat, causing property damage and severe

personal injury.

INSTALLATION

The manufacturer intends this unit to be used only with components indicated. An improper match voids the warranty.

See the unit catalog for Performance Values and Approved

System Matches.

Pre-Installation Checkpoints

Perform pre-installation checkpoints before attempting any

installation. Consider the following check points:

• Structural strength of supporting members

• Clearances and provision for servicing

• Power supply and wiring

• Air duct connections

• Drain facilities and connections

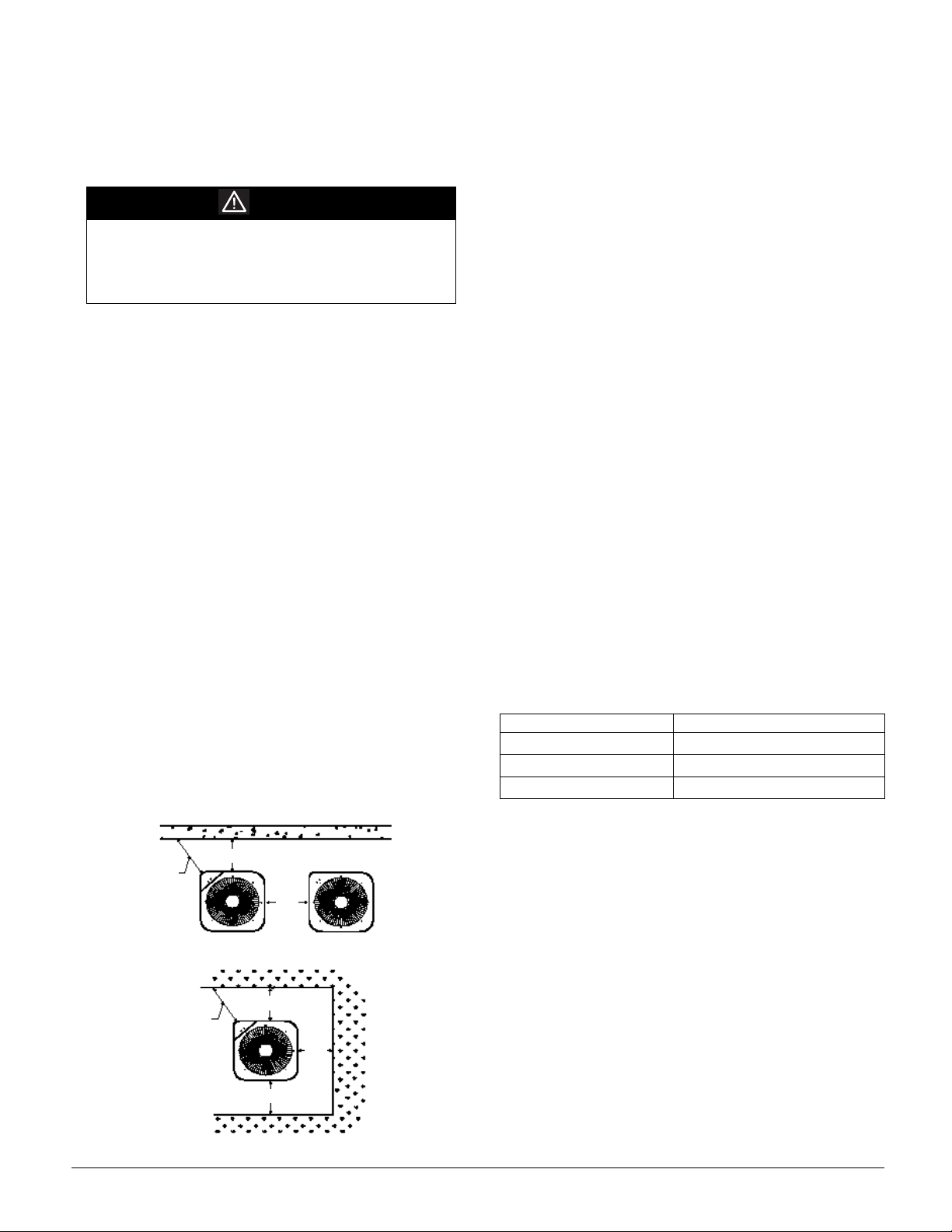

Clearance

The outdoor heat pump unit is designed to be located outside

the building with unobstructed condenser air inlet and discharge. Additionally, the unit must be situated to permit access

for service and installation. Condenser air enters from three

sides. Air discharges upward from the top of the unit. Refrigerant tube electrical connections are made on the right side of

the unit as you face the compressor compartment. The best

and most common application is for the unit to be located 10”

from a back wall with the connection side facing the wall.

This “close to the wall” application minimizes exposed tubing

and wiring and reduces the space for children to run around the

unit, which can damage the tubes or wiring.

Figure 1. Clearances and Accessibility

10"

Service

Access

18" Min.

20"

Close to the wall application provides free, unobstructed air to

the other two sides. In more confined application spaces, such

as corners, provide a minimum 10” clearance on all air inlet

sides. Allow 18” minimum for service access to the compressor compartment and controls.

The top of the unit should be completely unobstructed. If units

are to be located under an overhang, there should be a minimum of 36” clearance and provisions made to deflect the

warm discharge air out from the overhang.

Location

Consider the effect of outdoor fan noise on the conditioned

space and any adjacent occupied space. Place the unit so the

discharge does not blow toward windows less than 25 feet

away.

Set the outdoor unit on a solid, level foundation - preferably a

concrete slab at least 4 inches thick. The slab should be above

ground level and surrounded by a graveled area for good drainage. Any slab used as a unit foundation should not adjoin the

building, as it is possible that sound and vibration may be

transmitted to the structure. For rooftop installation, use steel

or treated wood beams as a unit support for load distribution.

Heat pumps require special location consideration in areas of

heavy snow accumulation and/or areas with prolonged continuous subfreezing temperatures. Heat pump unit bases are cutout under the outdoor coil to permit drainage of frost

accumulation. The unit must be situated to permit free, unobstructed drainage of the defrost water and ice. A minimum 3"

clearance under the outdoor coil is required in the milder climates.

In more severe weather locations, elevate the unit to allow

unobstructed drainage and air flow. Table 2 lists recommended

elevation minimums:

Table 2: Elevation Minimums

Design Temperature Suggested Minimum Elevation

+15

-5

o

below -5

and above

o

to + 14

o

o

2 1/2"

8"

12"

Elevation Limitations

If the outdoor unit is mounted above the air handler, the maximum lift should not exceed 70 feet (suction line). If the air

handler is mounted above the outdoor unit, the lift should not

exceed 50 feet (liquid line).

Note: When installing systems where the indoor - outdoor

sections are separated by more than 15 feet, observe

the maximum elevation separations limitations.

Service

Access

18" Min.

IM-801 Page 5

10"

10"

10"

Page 6

Figure 2. Maximum Refrigerant Line Lengths

CONDENSING UNIT

PITCH SUCTION LINE TOWARD OUTDOOR

UNIT 1/2" FOR EVERY 10' OF LINE

LIQUID LINE

EVAPORATOR BLOWER

CCAUTION

Before starting equipment after prolonged shutdowns or at the time of initial start up, verify that the

circuits to the units are closed for at least 24 hours.

CONDENSING UNIT

ADDITIONAL SUCTION LINE OIL

70' MAX

CONDENSING UNIT

LIQUID LINE

SUCTION LINE OIL TRAPS WHEN INDOOR UNIT

IS 4 FEET OR MORE BELOW OUTDOOR UNIT

INVERTED LOOP

LIQUID LINE

SUCTION LINE

TRAP FOR EACH 20' RISE OF PIPE

EVAPORATOR BLOWER

EVAPORATOR BLOWER

8'

50' MAX

ELECTRICAL

WARNING

Before attempting any service or adjustments, lock

and tag out all gas and electrical supplies. Failure

to follow this warning can cause property damage,

personal injury and or death.

The supply power, voltage, frequency and phase must coincide

with those listed on the nameplate. Carefully check all wiring

against the manufacturer’s diagrams or with the diagram on

the unit’s access panel. Field wiring must be connected in

accordance with the National Code or other local codes that

may apply. Verify that the equipment is adequately grounded

per local code requirements. Use only copper wire between the

disconnect and unit.

Over-current protection less than what is recommended in the

unit catalog could result in unneccessary fuse failures and service calls. The manufacturer is not responsible for equipment

damage resulting from not using the recommended size protective devices as listed on the unit rating plate.

This unit has undergone a run test prior to packaging for shipment. This equipment has been started at minimum rated voltage and checked for satisfactory operation. Do not attempt to

operate this unit if the available voltage is not within the minimum and maximum shown on nameplate.

The condensing unit control wiring requires a 24-Volt minimum and a 40 VA service from the indoor transformer as

shown on the wiring diagram.

COMPONENTS

Contactor

This control is activated (closed) by the room thermostat for

both heating and cooling. It is de-energized (open) during

emergency heat. The contactor has a 24-Volt coil and supplies

power to the compressor and outdoor fan motor.

Crank Case Heater

The heater is factory wired so it is in operation whenever the

main power supply to the unit is “ON”. It warms the compressor crankcase, preventing liquid migration and subsequent

compressor damage. It is connected electrically to the contactor L1 and L2 terminals.

Condenser Motor

This is activated by the contactor during heating and cooling

except during defrost and emergency heat operation.

Compressor

This is activated by the contactor for heating and cooling

except during emergency heat. It is protected by an internal

overload device.

Defrost Control

This provides time/temperature initiation and termination of

the defrost cycle.

Loss of Charge Protector

If the system loses refrigerant charge, the control will open to

allow the compressor contactor to open.

Outdoor Thermostats

These optional controls are used to prevent full electric heater

operation at varying outdoor ambient (0°F to 45°F). They are

normally open above their set points and closed below to permit staging of indoor supplemental heater operation.

Reversing Valve Coil

This is activated by the thermostat (system’s switch) during

cooling only and during defrost. It positions the reversing

valve pilot valve for cooling operation.

PIPING

Once located, the outdoor unit is ready to be interconnected

with the indoor section, using the refrigeraion tubing sizes

noted in the “Long Line Recommendations” Table. Use only

refrigeration grade (dehydrated and capped) copper tubing.

CCAUTION

Keep refrigeration tubing clean and dry prior to and

during installation to avoid equipment damage.

Use insulation of at least 1/2” wall thickness on the vapor gas

line to prevent condensation when cooling and heat loss when

heating. Install the insulation on the tubing prior to unit instal-

Page 6 IM-801

Page 7

lation. Run the insulation the entire length of the installed line.

Cover the end of the tubing over which the insulation is

slipped so no foreign material is introduced to the interior of

the tubing. The outdoor units are equipped with two refrigerant line service valves. As shipped, the valves are in the frontseated or “down” position.

Line Set Installation Instructions

Use the following instructions to install line sets:

1. Cut tubing square. Verify it is round and free of burrs at the

connecting ends. Clean the tubing to prevent contaminants

from entering the system.

2. Wrap a wet rag around the copper valve stub before braz-

ing.

3. Braze or silver solder the joint.

4. After brazing, quench with a wet rag to cool the joint.

Evacuate and charge the connecting lines as outlined in

these instructions.

5. Remove the valve top cap. It is important to keep the cap

in a clean area to provide proper sealing once replaced.

6. Using a standard L-shaped Allen wrench, break open the

valve body. To expedite opening the valve body after it is

broken, use a ratchet wrench with a short Allen stub.

Please note that it is normal to see oil on the valve stem

body once the cap is removed.

7. Replace the valve cap and tighten with a wrench. Verify

that the the cap is sealed.

Table 3: Long Line Recommendations

REFRIGERANT LINE LENGTH (Ft)

Cond

Unit

Ton s

1 1/2 5/8 1/4 3/4 3/8 3/4 3/8

2 5/8 1/4 3/4* 3/8 3/4 3/8

2 1/2 3/4 3/8 3/4** 3/8 7/8 3/8

3 3/4 3/8 3/4** 3/8 7/8 3/8

3 1/2 3/4 3/8 7/8** 3/8 1 1/8 3/8

4 7/8 3/8 1 1/8 3/8 1 1/8 3/8

5 7/8 3/8 1 1/8 3/8 1 1/8 3/8

0-24 25-49 50-74***

Line Diameter (In. OD)

Suct Liq Suct Liq Suct Liq

* 7/8" required for full ratings

** 1 1/8" required for full ratings

EVAPORATOR COIL

CCAUTION

Evaporator coils are shipped under high pressure.

Use extreme care and follow the installation instructions provided with the evaporator coil to avoid personal injury.

The indoor coil is pressurized. The copper caps must be punctured to permit a gradual escape of the pressure prior to unsweating caps. Immediately couple the tubing to the indoor

unit to avoid exposing the coils to moisture. A properly sized

filter drier is furnished in the condenser. When heating the

copper to make solder connections, use a dry nitrogen flow

through the line to prevent oxidization inside of the copper.

Hard solder (Sil-Fos) is recommened, to provide a longer lasting joint.

INDOOR CFM AND HEATING

CAPACITY DETERMINATION

Prior to using the methods described below to check the system’s charge, it is important to verify the operating capacity of

the system and that the system is delivering sufficient air

across the indoor coil (CFM). The following procedures are

suggested methods for determining the system’s operating

capacity and CFM.

Airflow Determination - Indoor Coil

The heat pump system has been designed for optimum performance with an airflow across the indoor coil equaling approximately 400 CFM/TON (e.g. A 2 TON system should have 2 x

400 CFM/TON = 800 CFM). The system’s airflow can be

determined by several methods.

Airflow Test Instruments

There are a number of readily available instruments that can be

used in the field for airflow determination such as Barometers,

Volume-Aire Air Balancers, Anemometers, and Velometers.

When using these devices, it is important to follow the instructions provided by their manufacturer.

Temperature Rise Resistive Heat Method

Although it is not as accurate as the use of test equipment, the

Temperature Rise Method can be used to determine the indoor

airflow in a system employing electric resistance heat as the

backup heat source.The following formula is used:

WHERE

KW = The indoor section’s measured input = Volts x Amps

Volts = The measured Volts at the Indoor Section

Amps = The measured Amps at the Indoor Section

Temperature

Rise =

3413 = BTU per KW

1.08 = Specific Heat Air Constant

e.g. :

The input power to the indoor section = 10 KW

The Temperature Rise = 20°F

Refer to the Airflow Measurement Table.

Note: The compressor circuit (outdoor unit) must be

The temperature of the supply air - the temperature of

the return air

“OFF” so that the Temperature Rise measured

across the indoor unit is due only to the electric heat.

IM-801 Page 7

Page 8

Use the following instructions to determine the temperature

rise across the indoor section:

1. Use the same thermometer for the measuring the return and

supply air temperatures to avoid thermometer error.

2. Measure the temperatures within 6 feet of the indoor sec-

tion and downstream from any mixed air source. Verify

that the thermometer is not exposed to any radiant heat

areas.

3. Verify that the air temperature is stable before making mea-

surement.

Figure 3. Temperature Rise Measurement

Temperature Rise Heat Pump Only Method

The Temperature Rise Resistive Heat Method can be used to

determine the heating capacity of the heat pump system in the

heat pump “only” mode. The results obtained using this

method should agree within 10% of the data published in the

unit catalog for the combination of indoor and outdoor section.

Note: When using the following procedure to determine

the system’s capacity, verify that the indoor section

backup heat source is de-energized.

1. Use the same procedure described in the Temperature Rise

Resistive Heat Method to determine the system’s CFM and

temperature rise across the indoor section.

2. Determine the BTU output of the system for the measured

Temperature Rise and system CFM by using the following

formula:

BTU = CFM x TEMPERATURE x 1.08

Page 8 IM-801

Page 9

Table 4: Airflow Measurements

IM-801 Page 9

Page 10

REFRIGERANT CHARGE DETERMINATION AND ADJUSTMENT - HEAT

PUMP - COOLING CYCLE

Weigh In Charge Method

To verify that the heat pump system is properly charged,

weigh in the amount of refrigerant specified on the outdoor

section nameplate, with additional adjustments for line size,

line length and other system components. Heat Pump units are

supplied with an R-22 charge sufficient for a typical matching

evaporator and approximately 15 ft. of inner-connecting tubing. Systems having more than 15 ft of interconnecting refrigerant lines require an additional charge allowance of R-22.

Table 5: Line Charge Allowance (R-22-oz./lb.)

LINE O.D. (IN) LIQUID LINE SUCTION LINE

1/4 0.22

3/8 0.58

1/2 1.14

5/8 1.86 0.04

3/4 0.06

7/8 0.08

1 1/8 0.15

1 3/8 0.22

Superheat Method

The following information has been developed to determine

the proper charge for McQuay heat pump systems that are

already in operation.

Note: Many field variations exist that may affect the oper-

ating temperature and pressure readings of a heat

pump system. All McQuay heat pump systems use

fixed orifice refrigerant control devices. The following procedure has been developed for this type of

refrigerant control device.

1. With both base valves fully open, connect a set of service

gages to the base valves’ service ports, being careful to

purge the lines.

2. Allow the system to operate at least 10 minutes or until the

pressures stabilizes.

3. Temporarily install a thermometer on the suction (large)

line near the condensing unit base valve. Make sure that

there is good contact between the thermometer and the

refrigerant line and wrap the thermometer and line with

insulating tape to provide accurate readings.

4. Determine the systems superheat as follows:

a. Read the system’s suction pressure.

b. Using Table 6, determine the system’s saturated suction

temperature.

c. Read the suction line temperature.

d. The system’s superheat = the suction line temperature -

the saturated liquid temperature.

Table 6: Saturated Suction Pressure (R-22)

SUCTION PRESSURE PSIG

50 26

53 28

55 30

58 32

61 34

63 36

66 38

69 40

72 42

75 44

78 46

81 48

SATURATED SUCTION

TEMPERATURE

o

F

5. Adjust the charge as necessary by adding charge to lower

the superheat or bleeding the charge to raise the superheat.

Table 7: System Superheater.

AMBIENT CONDENSER INLET

TEMPERATURE

o

F DB

100

95

90

85

80

75 5 10172529

70 5 14202832

65 13 19 26 32 35

60 17 25 30 33 37

RETURN AIR TEMPERATURE

65 70 75 80 85

579

71218

5 101720

5 122126

o

F DB

55

CCAUTION

Remove the service gauge set from the lines carefully. Escaping liquid refrigerant can cause burns.

Expansion Valve System-Subcooling Charge

Method

1. Fully open both base valves.

2. Connect service gauge manifold to base-valve service parts

verify that lines are purged. Run system at least 10 minutes to allow pressure to stabalize.

3. Temporarily install the thermometer to liquid (small) line

near the condensing unit. Be sure that the contact between

thermometer and line is good. Wrap the thermometer with

insulating material to provide an accurate reading.

4. Referring to Table 8, adjust charge to obtain a temperature

12-15°F below the saturated liquid temperature.

Example:

If liquid pressure is 260 psig, refer to Table 8. 260 psig = 120°

saturated temperature. Subtract the liquid line temperature

obtained from thermostat connected to the liquid line. The liquid line temperature must be 12° - 15° cooler than the refrigeration saturation temperature. If the liquid line temperature is

warmer than 12° - 15°, add charge to decrease. If the temperature of the liquid line is cooler than 12° - 15°, recover charge

from the system.

Page 10 IM-801

Page 11

Table 8: Saturated Liquid Temperature

LIQUID PRESSURE PSIG

200 102

210 105

220 108

230 111

240 114

250 117

260 120

270 123

280 126

290 128

300 131

SATURATED TEMPERATURE

o

F

HEAT PUMP - HEATING CYCLE

As in the cooling mode, the proper method of verifying that

the system is properly charged is by weight, with the additional

charge adustments for line size, line length, and other system

components.

Hot Gas Method

The following procedure can be employed as a method to

check for system charge in the heating mode by measuring the

hot discharge gas at the compressor.

1. Allow the system to operate at least 20 minutes.

2. Attach and insulate an electronic thermometer probe to the

vapor service valve (large line) at the base valve.

NOTE - Make sure that the probe is well insulated from

the outdoor air.

3. Allow the system to operate at least 10 minutes. Then, use

an accurate electronic thermometer to measure the temperature of the discharge gas at the probe.

4. Using the electronic thermostat, measure the outdoor ambient temperature.

5. For verification, the temperature measured on the hot gas

line should be equal to the outdoor ambient temperature

plus 110°F +/- 4°F. (e.g: if the Outdoor Ambient is 45°F,

then the temperature measured by the thermometer probe

should be 155°F for a system that is properly charged). If

the temperature measured by the thermometer’s probe is

higher than the outdoor ambient plus 110°F, the system

charge should be adjusted by adding refrigerant to lower

the temperature. If the temperature measured is lower than

the outdoor ambient plus 110°F, the system charge should

be adjusted by recovering charge to raise the temperature

Note: When adjusting the charge in this manner, allow the

system to operate for at least 10 minutes before taking the next temperature reading.

STARTUP PROCEDURE AND CHECK

LIST

CCAUTION

Turn off power at all disconnects.

1. Set first-stage thermostat heat anticipator to .12 and turn

thermostat system switch to “COOL” and fan switch to

“AUTO”.

2. Turn cooling temperature setting as high as it will go.

3. Inspect all registers and set them to the normal open position.

4. Turn on the unit electrical supply at the fused disconnect

switch, both for the indoor unit and the outdoor unit.

5. Turn the fan switch to the “ON” position. The blower

should operate 10 to 15 seconds later.

6. Turn the fan switch to the “AUTO” position. The blower

should stop 90 seconds later.

Note: If outdoor temperature is below 55°F, proceed to

step 9. Do not check the cooling mode.

7. Slowly lower the cooling temperature until the first mercury bulb makes contact. The compressor, indoor blower,

and outdoor fan should now be running. Verify cool air is

being supplied by the unit.

8. Turn the system switch to “HEAT” and the fan switch to

“AUTO”.

9. Slowly raise the heating temperature setting. After the heating first-stage mercury bulb (upper) makes contact, stop

moving the lever. The compressor, indoor blower and outdoor fan should now be running. After giving the unit time

to settle out, verify heated air is being supplied by the

indoor unit.

10.If the outdoor ambient is above 70°F, the compressor may

trip on internal overload.

11.In the event that the outdoor ambient temperature is too

high to allow a thorough heating cycle check, postpone the

test until conditions are more suitable. However, do not fail

to perform a through heating cycle check.

12.If the unit operates properly on the heating cycle, raise the

heating temperature until the heating second-stage mercury

bulb (lower) makes contact.

13.Supplementary resistance heat, if installed, should now

come on. Verify it is operating correctly. If outdoor thermostats are installed, the outdoor ambient temperature must be

below the set point of these thermostats for heaters to operate. It may be necessary to jumper these thermostats to

check heater operation if outdoor ambient temperature is

mild.

14.For thermostats with an emergency heat switch, return to

Step #9. The emergency heat switch is located at the bottom of the thermostat. Move this switch to emergency heat.

The heat pump will stop, the indoor blower will continue to

run, all heaters will come on and the thermostat emergency

heat light will come on.

15.If checking the unit on the heating cycle in the winter

(when the outdoor coil is cold enough to actuate the defrost

control), observe at least one defrost cycle to verify that the

unit defrosts properly.

16.Check to see if all supply and return air grilles are adjusted

and the air distribution system is balanced for the best compromise between heating and cooling.

17.Check for air leaks in the ductwork.

IM-801 Page 11

Page 12

18.Verify that the heat pump is free of “rattles” and the tubing

in the unit is free from excessive vibration. Also verify that

tubes or lines are not rubbing against each other, sheet

metal surfaces or edges. If so, correct the issue.

19.Set the thermostat at the appropriate setting for cooling and

heating or automatic changeover for normal use.

20.Instruct the owner on the unit operation, filter servicing,

correct thermostat operation, etc. The foregoing “Start-up

Procedure and Check List” is recommended to serve as an

indication that the heat pump system will operate normally.

OPERATION - DEFROST CONTROL

Timing

When operating, the power to the circuit board is controlled by

a temperature sensor that is clamped to a return bend on the

outdoor coil. Timing periods of 30, 60, or 90 minutes may be

selected by connecting the circuit board jumper wire to 30, 60

or 90 respectively. Accumulation of time for the selected timing period begins when the sensor closes (approximately 28°F)

and when the wall thermostat is calling for heat. At the end of

the timing period, a defrost cycle will be initiated, provided the

sensor remains closed. When the sensor opens (approximately

65°F), the defrost cycle is terminated. If the defrost cycle is not

terminated due to the sensor temperature, a 10 minute override

interrupts the defrost period.

apply to the heat pump when it is on the cooling cycle. Most

apply to the heating cycle, except that “condenser” becomes

“evaporator”, “evaporator” becomes “condenser” and “cooling” becomes “heating”. When the heat pump is on the heating cycle, it is necessary to redirect the refrigerant flow

through the refrigerant circuit external to the compressor. This

is accomplished with a reversing valve. Thus, the hot discharge vapor from the compressor is directed to the inside coil

(evaporator on the cooling cycle) where the heat is removed,

and the vapor condenses into liquid. It then goes through a

capillary tube, or expansion valve, to the outside coil (condenser on the cooling cycle) where the liquid is evaporated,

and vapor goes to the compressor.

When the solenoid valve is operated either from heating to

cooling or vice versa, it moves the pilot valve, thus putting

suction pressure (low pressure) on one side of the piston of the

reversing valve. Because discharge pressure (high pressure) is

on the other side of the piston, the piston slides to the low pressure side and reverses the flow of the refrigerant in the circuit.

The following figures show a schematic of a heat pump on the

cooling cycle and the heating cycle.

Figure 4. Heat Pump Refrigeration Circuit

Field Testing / Trouble Shooting

A. Run unit in heat mode.

B. Check unit for proper charge. Note: Bands of frost indicate

low refrigerant charge

C. Shut off power to unit.

D. Disconnect outdoor fan by removing the purple lead from

“DF2” on defrost control.

E. Restart unit and allow frost to accumulate.

F. After a few minutes of operation, the defrost thermostat

should close. To verify this, check for 24 volts between

“DFT” and “C” on the board. If the temperature at the thermostat is less than 28°F and the thermostat is open, replace

the thermostat as it is defective.

G. When the defrost thermostat has closed, short the “test”

pins on the board until the reversing valve shifts, indicating

defrost. This could take up to 21 seconds depending on

what timing period the board is set on. After defrost initiation, the short must instantly be removed or the defrost

period will only last 2.3 seconds.

H. After the defrost has terminated, check the defrost thermo-

stat for 24 volts between “DFT” and “C”. The reading

should indicate 0 volts (open sensor).

I. Shut off power to unit.

J. Replace the outdoor fan motor lead and turn on the power.

General Explanation and Guidance

The heat pump operates similar to a summer air conditioning

unit when it is on the cooling cycle. Therefore, all of the charts

and data for service that apply to summer air conditioning also

Page 12 IM-801

In addition to a reversing valve, a heat pump is equipped with

an expansion device and check valve for the inside coil, and

similar equipment for the outside coil. It is also provided with

a defrost control system.

Page 13

The expansion device performs the same function on the heating cycle as on the cooling cycle. The check valves are

required due to the reverse flow of refrigerant when changing

from cooling to heating or vice versa.

When the heat pump is on the heating cycle, at which time the

outdoor coil is functioning as an evaporator, the temperature of

the refrigerant in the outdoor coil must be below the temperature of the outdoor air in order for the refrigerant in the outdoor

coil to extract heat from the air. Thus, the greater the difference

in outdoor temperature and outdoor coil temperature, the

greater the heating capacity of the heat pump. Since this is

characteristic of heat pumps, it is good practice to provide supplementary heat for all heat pump installations in areas where

the temperature drops below 45°F. It is also good practice to

provide sufficient supplementary heat to handle the entire heating requirements in case of a of heat pump failure (e.g. a compressor failure, refrigerant leak, etc).

Because the temperature of the liquid refrigerant in the outdoor

coil during the heating cycle is generally below the freezing

point, frost forms on the surfaces of the outdoor coil under certain weather conditions of temperature and relative humidity.

Therefore, it is necessary to reverse the flow of refrigerant to

provide hot gas in the outdoor coil and melt the frost accumulation. This is accomplished by reversing the heat pump to the

cooling cycle. At the same time, the outdoor fan stops to hasten the temperature rise of the outdoor coil and lessen the time

required for defrosting. The indoor blower continues to run

and the supplementary heaters are energized.

MAINTENANCE

General

Outdoor units do not require a planned maintenance program

under normal operating conditions. However, not less than

once each cooling season, the unit should be inspected and, if

necessary, cleaned. Particular attention should be given to the

air inlet side of the outdoor coil to verify that leaves, grass,

etc., are not being drawn into the unit. Restricting air flow

across the coil will result in loss of system capacity, high operating pressures and excessive operating costs. If the outdoor

unit is installed adjacent to a grassy area, lawn mowers should

be routed so the discharge of the mower will be directed away

from the unit. Air filters must be installed in the system at

some point upstream to the indoor coil. Inspect and, if necessary, replace and/or clean air filters at least once a month.

If disposable filters are used, an adequate supply of clean,

unused filters of the correct size should be available.

CCAUTION

Equipment should never be operated without filters.

Permanent type filters may be vacuumed and/or washed; but

they should not be reinstalled until thoroughly dry. Most air filters are marked to indicate the direction of airflow and this

should be carefully noted when they are being installed.

CCAUTION

Never turn a dirty filter to allow airflow in the opposite direction.

The blower and motor bearings are permanently lubricated and

do not require additional lubrication.

The owner should have at least one set of replacement fuses of

the size supplied with the original equipment.

CWARNING

Do not replace fuses with sizes other than those

supplied. Improper current protection can cause

equipment damage, severe personal injury or death.

Common Causes of Unsatisfactory Operation of

Heat Pumps on the Heating Cycle

A. Dirty filters or inadequate air volume through the

indoor coil. When the heat pump is on the heating cycle,

the indoor coil is functioning as a condenser. Therefore, the

filters must always be clean and sufficient air volume must

pass through the indoor coil to prevent excessive discharge

pressure and high-pressure cutout.

B. Outside air into return duct. Cold outside air should not

be introduced in the return duct close enough to the indoor

coil to reduce temperature of the air entering the coil below

65°F during the heating cycle. Air below this temperature

will cause low discharge pressure, low suction pressure and

excessive defrost cycling that will result in low heating output. It may also cause false defrosting.

C. Undercharge. Undercharge on the heating cycle will cause

low discharge pressure, resulting in low suction pressure

and frost accumulation on the lower part of the outdoor

coil.

D. Poor “terminating” defrost thermostat contact. The

defrost thermostat must make good thermal contact on the

return bend. Otherwise, it may not terminate the defrost

cycle quickly enough to prevent the unit from cutting out

on high discharge pressure during the defrost cycle.

E. Causes of Malfunctioning Reversing Valve:

1. Solenoid not energized. In order to determine if the

solenoid is energized, touch the nut that holds the solenoid cover in place with a screwdriver. If the nut magnetically holds the screwdriver in the Cooling mode,

the solenoid is energized.

2. No voltage to solenoid. Check the voltage and if there

is no voltage, check the wiring circuit.

3. Valve will not shift:

a. Undercharged: check for leaks.

b Valve Body Damaged: Replace valve.

c. Unit Properly Charged: If it is on the heating

cycle, raise discharge pressure by restricting airflow through the indoor coil. If the valve does

not shift, tap it lightly on both ends with a screwdriver handle.

IM-801 Page 13

Page 14

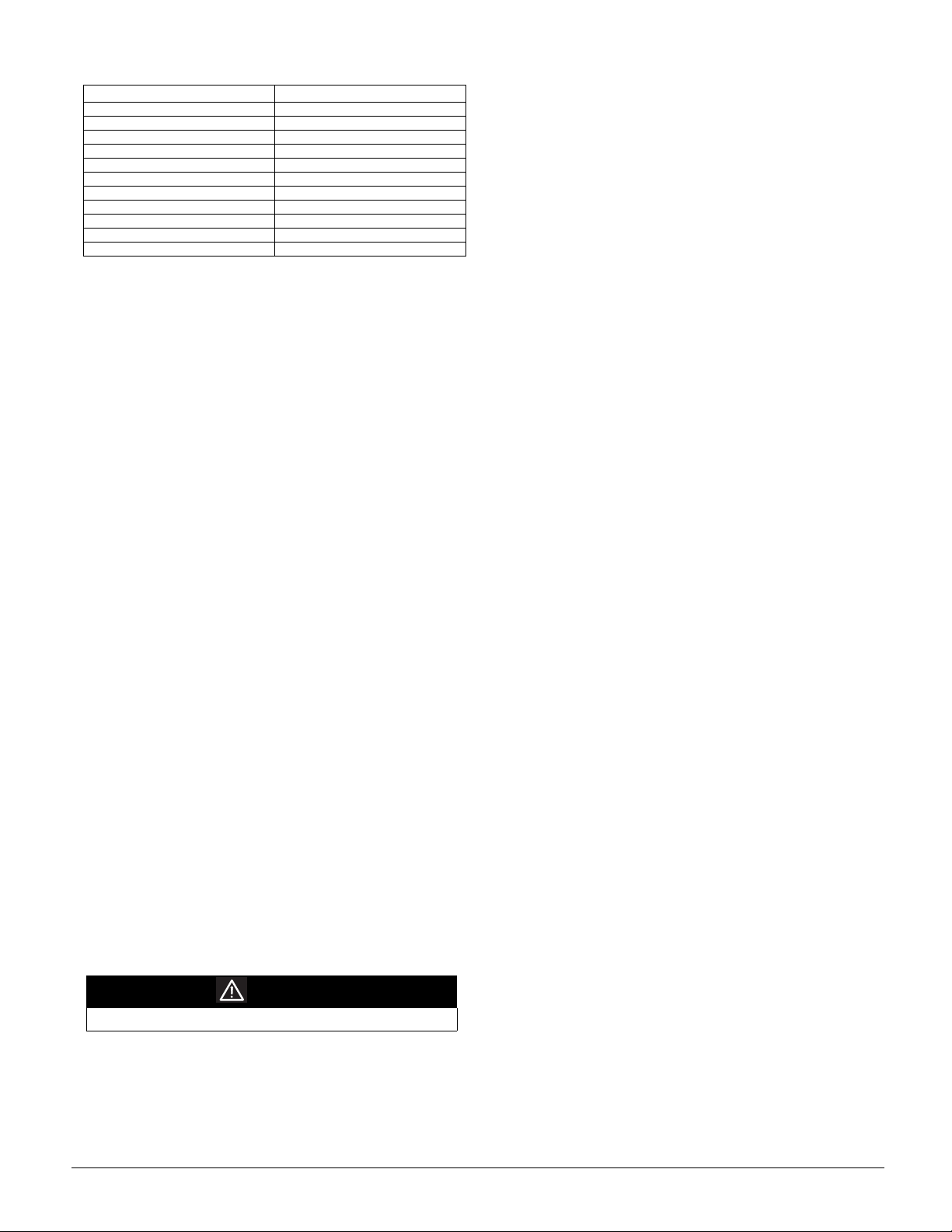

WIRING DIAGRAM

C M O U T D O O R F A N M O T O R

C O M P C O M P R E S S O R

C C O N T A C T O R

D C D E F R O S T C O N T R O L

L V D R L O W V O L T A G E D E F R O S T D E L A Y

C H C R A N

K C A S E H E A T E R

I O I N T E R N A L O V E R L O A D

L P L O W P R E S S U R E S W I T C H

O T O U T D O O R T H E R M O S T A T ( O P T I O N A L )

R C C F R U N C A P A C I

T O R F O R C O M P R E S S O R A N D F A N

D F T D E F R O S T T H E R M O S T A T

R V C R E V E R S I N G V A L V E C O I L

S C S T A R T C A P A C I T O R F O R C O M P R E

S S O R ( O P T I O N A L )

S R S T A R T R E L A Y F O R C O M P R E S S O R ( O P T I O N A L )

H V D R H I G H V O L T A G E D E F R O S T R E L A Y

L 2

C

T 2

S C

R C C F

1

S R

S

C O M P .

M A I N

S E E R A T I N G P L A T E

O U T D O O R P O W E R S U P P L Y

5 2

T 1

C

L 1

C

D F 1

H V D R

F

( I F U S E D )

S T A R T A S S I S T

A U X

I O

C

C O N T A C T O R

D O U B L E P O L E

A L T E R N A T E

D F 2

C M

C H

A U X

M A I N

I O

O

B L

Y

C

D C

Y

( I F U S E D )

D F T

L V D R

D F T

R

C

Y

R V C

L P

Y

O

W 2

R

W 2

O

O

R

N O T E S :

I N D O O R P O W E R S U P P L Y

N I T

T F A C T O R Y E Q U I P P E D

2 . S E E I N D O O R A N D O U T D O O R U

T H E R M O S T A T .

T E R M I N A L B L O C K A N D I N D O O R

1 . T O I N D O O R U N I T L O W V O L T A G E

3 . S T A R T A S S I S

O U T D O O R T H E R M O S T A T .

C O N N E C T I O N O F O P T I O N A L

I N S T A L L A T I O N I N S T R U C T I O N S F O R

W H E N R E Q U I R E D .

O T - 1

P U

D F 2

H V D R

L V D R

D C

O T - 2

R

D F 1

W

D F T

O O W 2 R R

C Y

B K

O

B L

R

O T - 3

Y

W 2

W

S E E N O T E 2

R

B L

Y

R

D F T

R

Y

Y

L P

Y

B R

B K

B K

R

B K

Y

Y

C

O

R

C O M P O N E N T C O D E

W I R I N G C O D E

N O T E 1

T 1 T 2

R

T 2

T 1

Y

Y

B R

R

R

C O N T R O L B O X

F A C T O R Y W I R I N G F I E L D W I R I N G

E R N A T E

L 1 L 2

A L T

C

B K

B K

B K

C O N T A C T O R

D O U B L E P O L E

L 2

L 1

B L

P O W E R S U P P L Y

( S E E R A T I N G P L A T E )

U S E L 1 F O R N E U T R A L O R

B L

G R O U N D S U P P L Y I F U S E D

U S E C O P P E R C O N N E C T O R S O N L Y

Y

R

H I G H V O L T A G E H I G H V O L T A G E

L O W V O L A G E L O W V O L T A G E

O P I O N A L H I G H V O L T A G E

O P T I O N A L S T A R T A S S I S T

Y

S T A R T A S S I S T

R V C

B K B K

M A I N

E Q U I P M E N T G R O U N D U S E

C O M P .

A U X

R

C S

Y

C O P P E R C O N D U C T O R S O N L Y

R

B R

P U

A U X

M A I N

A N D T H E R M O S T A T I N " O F F " P O S I T I O N

C O N T R O L S S H O W N W I T H U T I L I T I E S I N " O N " P O S I T I O N

C H

( C R A N K C A S E H E A T I F U S E D )

B K

B K

B K

I O

C M

B K

1

S R

5

2

R

B L

S C

B L A C K

C O L O R C O D E

B K

P U R P L E

R E D

R

B R O W N

O R A N G E

B L U E

Y E L L O W

Y

B L

W H I T E

B R

P U

U S E N . E . C . C L A S S 2 W I R E

O

W

Page 14 IM-801

Page 15

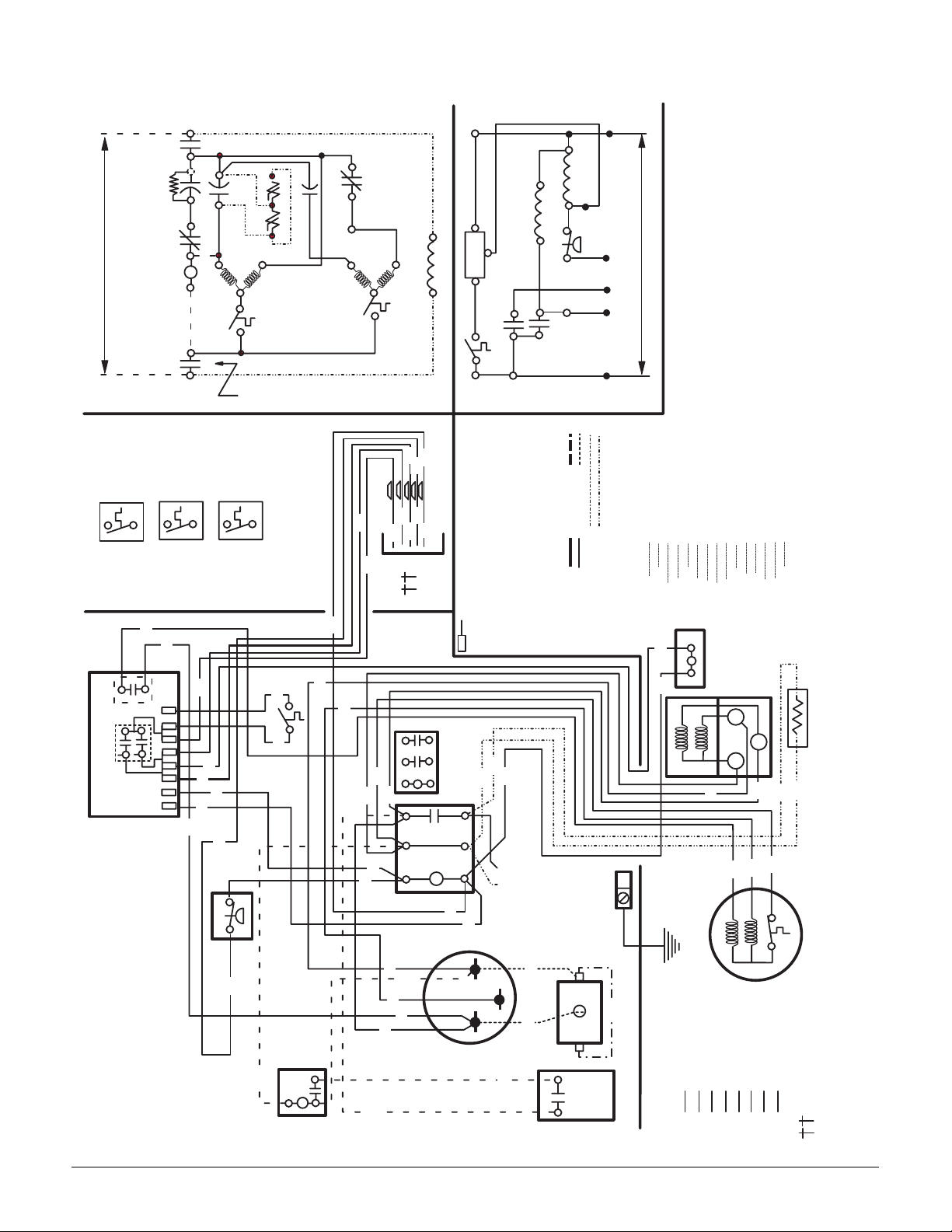

THERMOSTAT DIAGRAM

e

SYSTEM COMPOSITE DIAGRAM

SAH018 to 060

18-60

10 KW & BELOW

Heat Pump

W2

C

OYR

BL

OR

W

R

Y

R

Y

OR

W

BL

Outdoor Thermostat

(optional) Make On Fall

SAH018 to 060

SYSTEM COMPOSITE DIAGRAM

18-60

10 KW & BELOW

Heat Pump

W2

C

OYR

BL

OR

W

R

Y

R

Y

OR

W

BL

OT1

Note

OT2

#18GA. 7 Wire Needed When 2

Outdoor Thermostat Are Used

Conventional

Room Thermostat

O

#18 GA. 5 Wire

Room Thermostat

O

#18 GA. 5 Wire

W2

CY

GE

R

R

GR

See

BL

Note 3

BR

W

BL

#18GA. 6 Wire Needed When

Outdoor Thermostat Is Used

Conventional

CY

W2 G E

See

Note 3

R

GR

See

Note 2

W

1

EHR

2

4

3

BL

BR

#18 GA. 7 Wire

Pink

#18 GA. 7 Wire

AR Indoor Unit

Pink

R

NOTES:

1. Outdoor Thermostat (OT1) should be the first

to close and the first to open.

2. Install jumper if Outdoor Thermostat (OT2) is

not used.

NOMENCLATURE :

OT - Outdoor Thermostat (Optional)

MOF - Make On Fall

EHR - Emergency Heat Relay (Optional)

COLOR CODES

R - Red OR - Orang

Y - Yellow W - White

BL - Blue G- Green

BR - Brown

3. Remove wire when using Outdoor Thermostat.

#18 Ga. 7 wire needed when (2) OTs are used.

IM-801 Page 15

Page 16

This document contains the most current product information as of this printing. For the most up-to-date

product information, please go to www.mcquay.com.

www.mcquay.com • 800-432-1342

Loading...

Loading...