Page 1

Loudspeaker Systems

XLS360

yy

yXLS340

yy

yy

yXLS320

yy

yy

yXCS350

yy

Owner’s Manual

McIntosh Laboratory, Inc. 2 Chambers Street Binghamton, New York 13903-2699 Phone: 607-723-3512 FAX: 607-724-0549

Page 2

WARNING - TO REDUCE RISK OF

FIRE OR ELECTRICAL SHOCK, DO

NOT EXPOSE THIS EQUIPMENT TO

RAIN OR MOISTURE.

IMPORTANT SAFETY

INSTRUCTIONS!

PLEASE READ THEM BEFORE

OPERATING THIS EQUIPMENT.

NO USER-SERVICEABLE PARTS

INSIDE. REFER SERVICING TO

QUALIFIED PERSONNEL.

To prevent the risk of electric shock, do not remove cover or

back. No user serviceable parts inside.

1. Read these instructions.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with a dry cloth.

7. Install in accordance with the manufacturer’s

instructions.

8. This apparatus is capable of producing high

sound pressure levels. Continued exposure to

high sound pressure levels can cause permanent

hearing impairment or loss. User caution is

advised and ear protection is recommended when

playing at high volumes.

9. Do not install near any heat sources such as

radiators, heat registers, stoves, or other

apparatus (including amplifiers) that produce

heat.

10. Only use attachments/accessories specified by the

manufacturer.

11. Use only with the cart, stand, tripod, bracket, or

table specified by the manufacturer,

or sold with the apparatus. When a

cart is used, use caution when

moving the cart/apparatus

combination to avoid injury from

tip-over.

12. Refer all servicing to qualified service personnel.

Servicing is required when the apparatus has

been damaged in any way, liquid has been spilled

or objects have fallen into the apparatus, the

apparatus has been exposed to rain or moisture,

does not operate normally, or has been dropped.

13. Do not expose this equipment to dripping or

splashing and ensure that no objects filled with

liquids, such as vases, are placed on the

equipment.

2

Page 3

Thank Y ou

Table of Contents

Your decision to own a McIntosh Loudspeaker System

ranks you at the very top among discriminating music listeners. You now have “The Best.” The McIntosh dedication

to “Quality,” is assurance that you will receive many years

of musical enjoyment from this unit.

Please take a short time to read the information in this

manual. We want you to be as familiar as possible with all

the features and functions of your new McIntosh.

Please Take A Moment

The serial number, purchase date and McIntosh Dealer

name are important to you for possible insurance claim or

future service. The spaces below have been provided for

you to record that information:

Serial Number:

Purchase Date:

Dealer Name:

T echnical Assistance

If at any time you have questions about your McIntosh

product, contact your McIntosh Dealer who is familiar with

your McIntosh equipment and any other brands that may

be part of your system. If you or your Dealer wish additional help concerning a suspected problem, you can receive technical assistance for all McIntosh products at:

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723-1545

Fax: 607-772-3308

Customer Service

If it is determined that your McIntosh product is in need of

repair, you can return it to your Dealer. You can also return

it to the McIntosh Laboratory Service Department. For assistance on factory repair return procedure, contact the

McIntosh Service Department at:

Safety Instructions ............................................................ 2

Thank You and Please Take a Moment............................. 3

Technical Assistance and Customer Service .................... 3

Table of Contents.............................................................. 3

Important Information ...................................................... 4

Introduction ...................................................................... 4

Performance Features ....................................................... 5

Dimensions:

XLS320........................................................................... 6

XLS340........................................................................... 7

XLS360........................................................................... 8

XCS350 .......................................................................... 9

Installation:

Installation Overview ................................................... 10

Unpacking the XLS320 ................................................ 10

Unpacking the XLS340 ................................................ 10

Unpacking the XLS360 ................................................ 11

Unpacking the XCS350 ................................................ 12

Wall Mounting the XLS320.......................................... 13

Wall Mounting the XLS340.......................................... 14

Wall Mounting the XCS350 ......................................... 16

Locating the Loudspeaker ............................................ 18

Tweeter Array Optimization ......................................... 19

Connections:

Connecting the XLS320 (default setting)..................... 20

Connecting the XLS320 (optional setting)................... 21

Connecting the XLS340, XLS360 and XCS350

(with one amplifier) .................................................... 22

Connecting the XLS340, XLS360 and XCS350

(with two amplifiers) .................................................. 23

Specifications:

XLS320......................................................................... 24

XLS340......................................................................... 24

XLS360......................................................................... 25

XCS350 ........................................................................ 25

Packing Instructions:

XLS320......................................................................... 26

XLS340......................................................................... 26

XLS360......................................................................... 27

XCS350 ........................................................................ 27

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, New York 13903

Phone: 607-723-3515

Fax: 607-723-1917

Copyright 2005 © by McIntosh Laboratory, Inc.

3

Page 4

Caution: The XLS360 Loudspeaker weight is 107 pounds

(48.5kg) net. It requires two or more persons to handle

safely.

1. Loudspeaker Cables of adequate size are important to ensure

that there will be no significant power loss or heating. Cable

size is specified in Gauge numbers or AWG (American Wire

Gauge). The smaller the Gauge number, the larger the wire

size:

If the Loudspeaker Cables are 25 feet (7.62m) or less, use at

least 16 Gauge (AWG) wire size or larger.

If the Loudspeaker Cables are 50 feet (15.24m) or less, use at

least 14 Gauge (AWG) wire size or larger.

If the Loudspeaker Cables are 100 feet (30.48m) or less, use

at least 12 Gauge (AWG) wire size or larger.

The Loudspeaker Connection Terminals can accept up to 12

Gauge (AWG) wire.

2. For additional connection information, refer to the owner’s

manual(s) for any component(s) connected to the XLS320,

XLS340, XLS360 or XCS350 Loudspeaker.

3. The XLS and XCS Loudspeaker Systems have built-in

automatic resetting solid-state devices in the crossover

networks for protection. The protection allows a certain

amount of overdrive, however extended periods of overdrive

will trigger protection. If an obvious lack of high, mid or low

frequencies is noticed, the Protection Device may have

activated. These devices will automatically reset when the

volume level is reduced significantly and kept low until the

output of the affected Loudspeaker Element returns to normal.

4. When the XLS340, XLS360 or XCS350 Loudspeaker Systems

are driven by more than one amplifier, the output levels of the

different amplifiers connected to the Loudspeaker System

must be adjusted to achieve a proper balance between the

low, midrange/high frequencies reproduced. This adjustment

is best achieved through the use of audio test equipment

operated by a qualified installer.

IntroductionImportant Information

The McIntosh XLS320, XLS340, XLS360 and XCS350

Loudspeaker Systems are designed for Home Theater and

Music Reproduction. Many of today’s Loudspeakers are

designed only for Home Theater applications, not so with

these Loudspeaker Systems. They are also designed for the

accurate reproduction of music.

Motion picture sound effects, explosions, screams, and

vehicle crashes require a wide dynamic range and high

sound levels. These sounds are such that a speaker system

having moderate distortion would reproduce them with

little audible difference. This is not true with the reproduction of music. Music is by nature and definition harmonious. To reproduce it accurately, all forms of distortion, both

harmonic and intermodulation, must be kept to a minimum.

This has been the result of the design of the new McIntosh

XLS320, XLS340, XLS360 and XCS350 Loudspeaker

Systems. Each loudspeaker element and crossover component has been carefully designed for low distortion, durability and efficiency. The McIntosh XLS320, XLS340,

XLS360 and XCS350 Loudspeaker System will reproduce

music accurately and function as an excellent Home Theater Loudspeaker.

The XLS320 is a two-way system with a 6-1/2 inch LD/

1

woofer/midrange driver and five 1 inch dome tweeters

HP

in a Bessel Function Array. The XLS340 is a three-way

system consisting of two 8 inch LD/HP woofers, one 6-1/2

inch LD/HP midrange driver and five 1 inch dome tweeters

in a Bessel Function Array. The XLS360 is also a threeway system with two 10 inch LD/HP woofers, one 6-1/2

inch LD/HP midrange driver and five 1 inch dome tweeters

in a Bessel Function Array. The XCS350 Center Channel

Loudspeaker utilizes two 8 inch LD/HP woofers, one 6-1/2

inch LD/HP midrange driver and five 1 inch dome tweeters

in a Bessel Function Array.

The XLS320, XLS340, XLS360 and XCS350 Loudspeaker performance is designed to complement the capabilities of McIntosh’s legendary line of Preamplifiers/Control Centers, Signal Sources Devices and Power Amplifiers, without imparting distortion or coloration.

1

LD/HP Pat. No. 5,151,943

4

Page 5

Important Information, Connector Information, Introduction and Performance Features

Performance Features

Patented LD/HP Technology

•

The McIntosh Low Frequency and Midrange Loudspeaker

Elements feature the patented LD/HP motor structure. This

design, when compared to conventional Loudspeaker

Elements, reduces distortion significantly. It also increases

power handling and efficiency.

Five Tweeter Bessel Function Array

•

The XLS320, XLS340, XLS360 and XCS350 utilizes five

tweeters connected to produce a Bessel Function Array.

The individual tweeter amplitudes and phase relationships

are adjusted so the array acts as a high frequency point

source. One advantage of such an arrangement is a very

smooth and even acoustic polar response. This allows the

listener to move off axis without suffering a change in high

frequency output. The use of multiple tweeters, combined

with a mechanical heat sink, also provides greatly

increased power handling at high frequencies.

Mirror Image Phasing High Frequency Array

•

The five tweeter Bessel Function Array utilizes a unique

circuit design permitting the optimization of high

frequency dispersion for Mirror Imaging. This allows for

Loudspeaker placement in a room as the Left Channel,

Center Channel or Right Channel for use in a multichannel system.

Shielded Magnetic Field

•

The XLS320, XLS340, XLS360 and XCS350 may be used

in Home Theater Installations near a television receiver or

monitor without causing the television image to degrade.

McIntosh has designed special shielding around the

magnetic structure of the XLS320, XLS340, XLS360 and

XCS350 Loudspeaker Elements to prevent interference.

High Power Handling

•

The Loudspeaker Elements and crossover components of

the XLS320, XLS340, XLS360 and XCS350 are all chosen

for use with powerful amplifiers up to 600 watts.

High Efficiency

•

The Loudspeaker Elements used in the XLS320, XLS340,

XLS360 and XCS350 Loudspeaker Systems have also

been designed for high efficiency. As a result any McIntosh

Power Amplifier, even our smallest, will provide satisfying

room filling sound.

Automatic Overload Protection

•

The XLS320, XLS340, XLS360 and XCS350 have built-in

Loudspeaker Element Protection in the form of automatic

resetting solid-state devices as a part of the crossover network.

Gold Plated Input Connectors

•

The XLS320, XLS340, XLS360 and XCS350 input

connectors are gold plated for superior corrosion resistance

and high electrical conductivity.

Rigid Column Structure

•

The enclosures are an important part of the XLS320,

XLS340, XLS360 and XCS350 Loudspeaker Systems. The

Systems utilize a dampened rigid enclosure made from extruded aluminum and houses the Loudspeaker Drivers and

Crossover. The XLS340 and XLS360 Columns, due to

their height, have additional front to back internal bracing

to form a dampened rigid Column Structure. The Column’s

small footprint allows for a variety of different placements

in a room.

Special Crossover Network

•

The Crossover Networks used in the XLS320, XLS340,

XLS360 and XCS350 Loudspeaker Systems are designed

to ensure an even frequency response over the entire audible range. The Network utilizes First, Second and Third

Order design for optimal response.

5

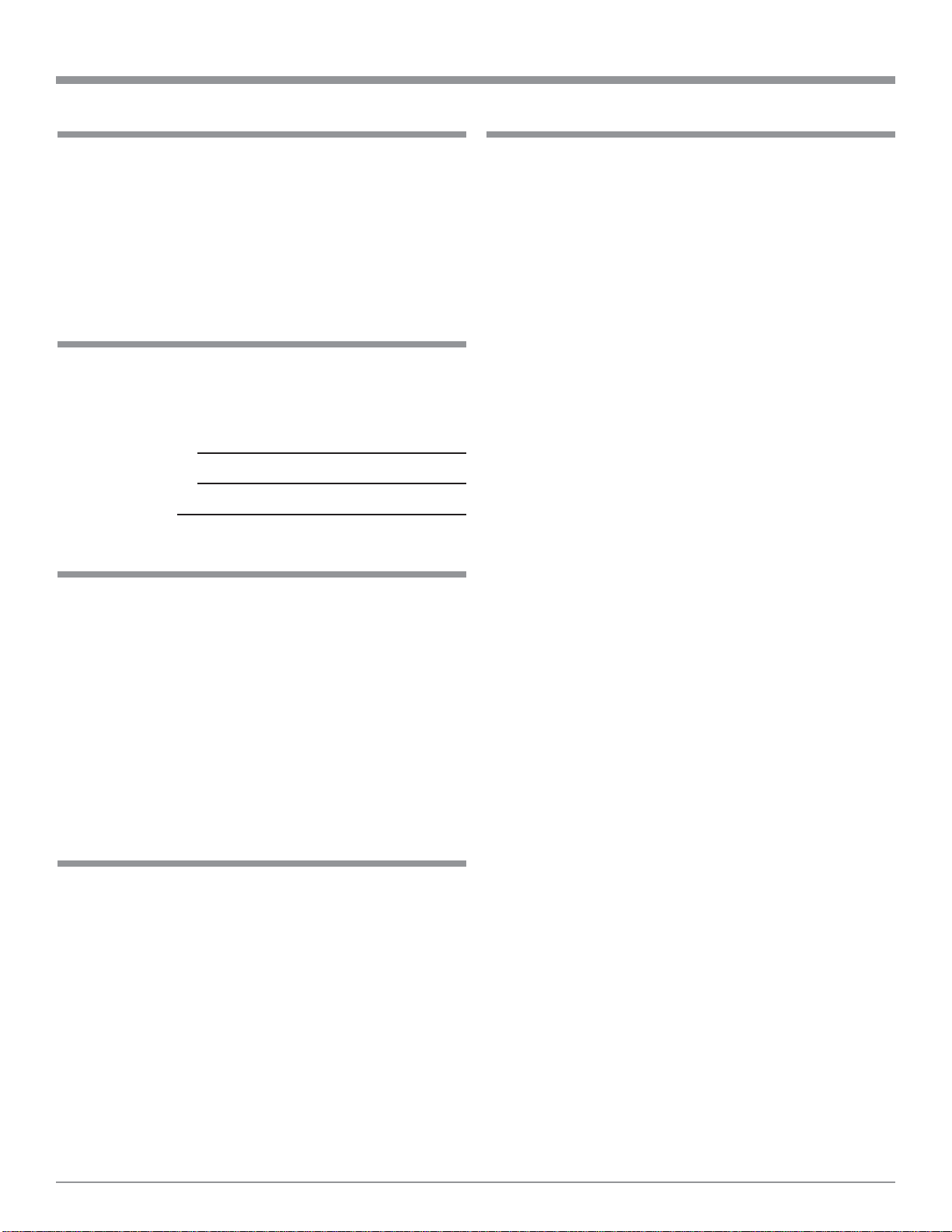

Page 6

Dimensions

The following dimensions can assist in determining the

best location for the XLS320 or XLS340 Loudspeaker System. There is additional information on page 18 pertaining

to installing the Loudspeaker.

Front View of XLS320

with Grille Removed

Rear View of XLS320

10

27.0cm

6

-11/16"

17.0cm

-5/8"

5

14.8cm

10

-5/8"

27.0cm

-13/16"

5

-5/16"

13.5cm

15

-5/16"

38.9cm

8

-9/16"

21.7cm

12

-5/8"

32.0cm

Side View of XLS320

6

7

-5/16"

18.6cm

5

-1/4"

13.3cm

4

-1/2

11.4cm

"

Page 7

Dimensions

Front View of

XLS340 with

Grille Removed

39

-3/8

100.0cm

"

34

-9/16

87.8cm

"

15

-3/16

38.6cm

"

5

-13/16

5.8cm

Rear View of

XLS340

10

-5/8

"

27.0cm

44

-1/16

"

"

2

-1/16

5.2cm

4

-1/16

"

10.3cm

24

-11/16

62.7cm

"

"

18"

45.7cm

4

-1/16

10.3cm

35

-9/32

89.6cm

"

111.9cm

"

7

-3/8

"

18.7cm

Note: The XLS340 is supplied

with optional adjustable

feet, four Tiptoes and

four Glides. If they are

used with the XLS340

please allow for the

added height.

Side View of

XLS340

12"

30.5cm

5

-1/4

13.3cm

4

-1/2

11.4cm

14

-3/4

"

"

37.5cm

"

7

Page 8

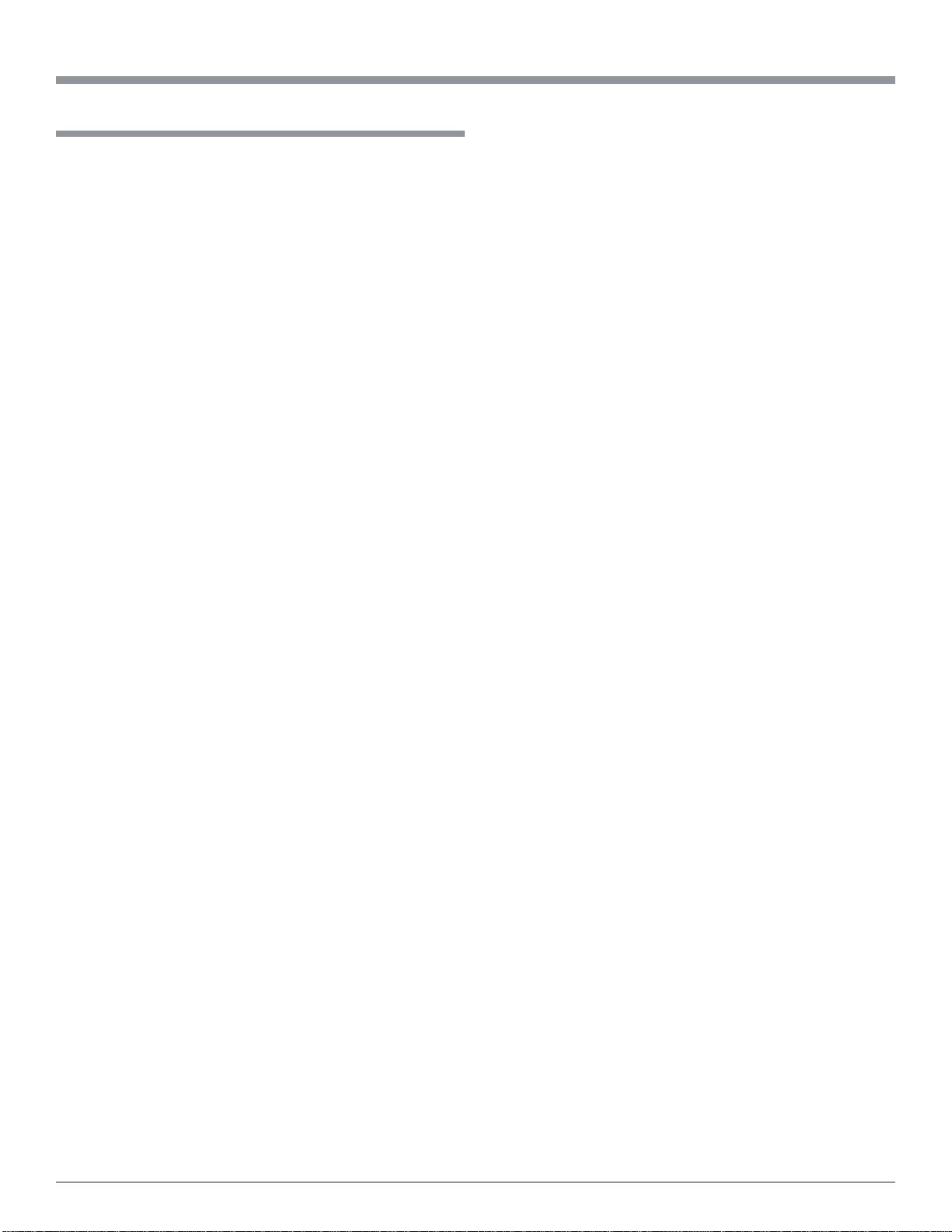

Dimensions, con’t

The following dimensions can assist in determining the

best location for the XLS360 or XCS350 Loudspeaker System. There is additional information on page 18 pertaining

to installing the Loudspeaker.

13

-1/8

33.3cm

"

Front View of

XLS360 with

Grille Removed

46

-9/16

118.3cm

41

106.0cm

"

-3/4

8

22.5cm

"

19

-3/16

48.7cm

-7/8

"

"

7

-3/16

18.3cm

Rear View of

XLS360

4

-1/16

"

10.3cm

51

-3/8

"

130.5cm

37

-3/4

"

95.9cm

33

-15/16

"

27

69.2cm

-1/4

"

2

-1/16

5.2cm

86.2cm

"

"

17

-3/4

"

9

-1/4

23.5cm

"

8

-5/16

"

21.1cm

45.1cm

3

-13/16

"

Note: The XLS360 is supplied

with optional adjustable

9.7cm

Side View of

XLS360

feet, four Tiptoes and four

Glides. If they are used

with the XLS360 please

allow for the added

height.

13"

33.0cm

8

Page 9

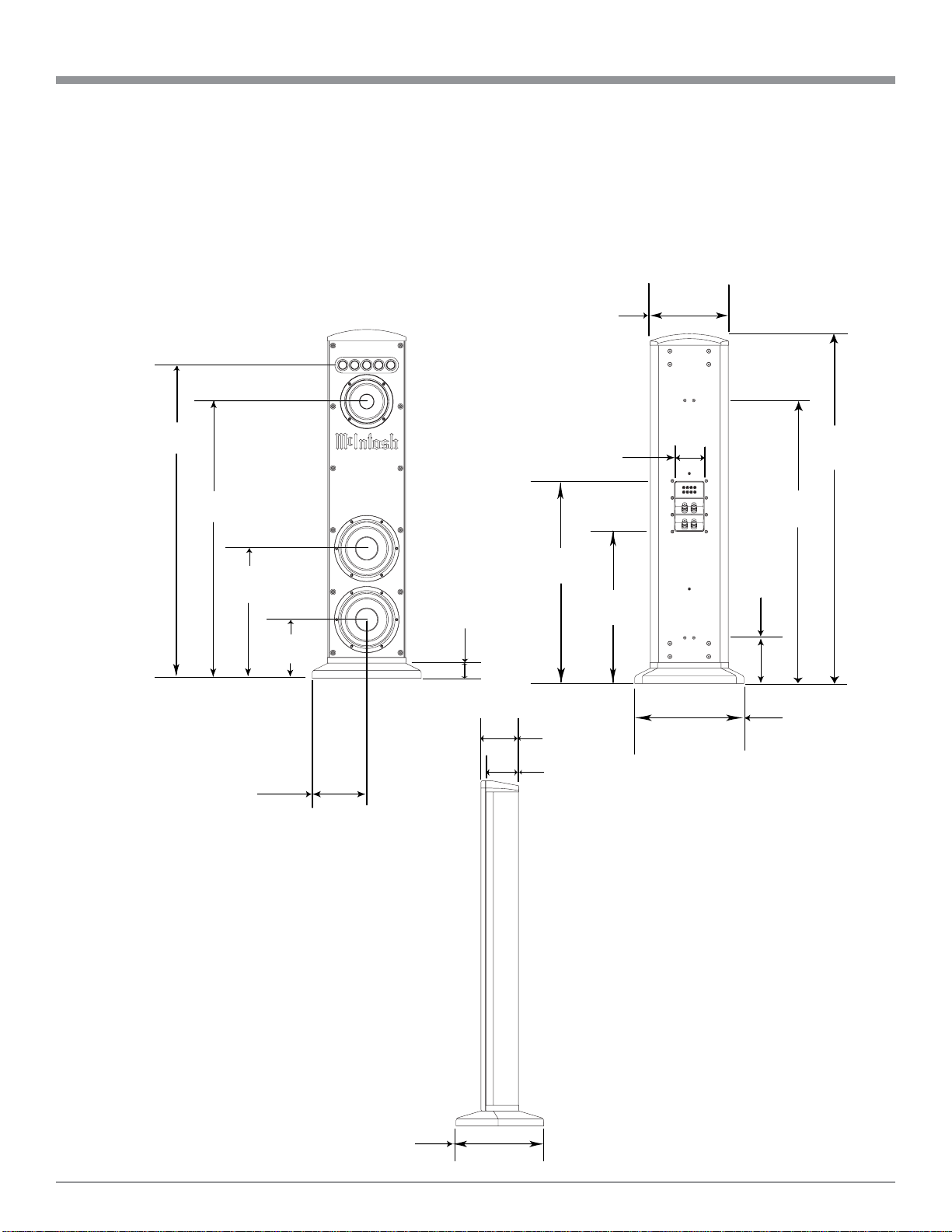

Note: The XCS350 is supplied with an adjustable Stabilizer

Bar. Please allow for various height/angle.

Front View of

XCS350 with

Grille Removed

6

-9/16

"

16.7cm

17

-1/32

"

43.3cm

27

-1/2

"

69.9cm

4

-3/16

10.6cm

Dimensions, con’t

"

5

-5/16

"

13.5cm

9"

22.9cm

Rear View of

XCS350 with the

stabilizer bar

removed

9

-9/16

24.3cm

10

27.0cm

"

-5/8

5

13.3cm

34

-1/16

"

86.5cm

25

-9/16

"

64.9cm

20

-1/8

"

6

-11/16

4

-1/2

11.4cm

"

"

51.1cm

"

24

-3/16

"

61.4cm

-1/4

"

17.0cm

Top View of

XCS350

3/4

"

1.9cm

9

Page 10

Installation

Installation Overview

The instructions that follow are for the unpacking, assembly and setup of the XLS320, XLS340, XLS360 and

XCS350 Loudspeaker Systems as supplied. For several

models, an optional In Wall Mounting Kit is available. If

the Loudspeaker is to be Mounted On or In Wall, refer to

“Locating the Loudspeaker System” on page 18, “Tweeter

Array Optimization” on page 19 and “How to Connect”

starting on page 20, before beginning the Mounting Process. For additional information on the different types of

installation, refer to figure 1.

Caution: The XLS360 Loudspeaker weight is 107 pounds

(48.5kg) net and requires two or more persons to

safely handle during unpacking, assembly and

placement.

It is recommended that the Professionals at your McIntosh Dealer, who are skilled in all aspects of installation

and operation, install the Loudspeaker System and any associated audio/video equipment.

carton.

Fasteners

Grille

Refer to

figure 2.

Grom-

Loudspeaker

7. Orient the

Loudspeaker

and the

Grille

Foam

end

Foam

end

with the

rounded

ends

pointing

Figure 2

in the same direction.

8. Align the Grille fasteners to the Loudspeaker Grommets (two on each side). Carefully push down to secure

the Grille to the Loudspeaker.

9. Proceed to “Locating the Loudspeaker System” on

page 18.

Unpacking the XLS320 Loudspeaker

1. Remove the entire assembly (Loudspeaker System,

Loudspeaker Grille and foam end caps) by lifting up on

the bottom of the assembly (Loudspeaker rear) and

place it along side the shipping carton on a flat surface.

2. Release the Loudspeaker Grille from the foam end

caps and remove it from the protective plastic shipping

film and set it aside.

3. In a similar manner, lift out the Loudspeaker System.

4. Close the top flaps of the shipping carton and place the

two foam end caps on top of the carton.

5. Carefully remove the protective plastic shipping film

from the Loudspeaker System so as not to mar the finish or damage the Loudspeaker System Drivers.

Notes: 1. The XLS320 Loudspeaker is supplied with an On

Wall Mounting Bracket and Hardware. If the

XLS320 is to be mounted on the wall at this time,

proceed to “How to Mount the XLS320

Loudspeaker On the Wall” on page 13.

2. When the optional In Wall Mounting Kit is

chosen, refer to the supplied installation guide.

6. Place the Loudspeaker System, with the front facing

up, on foam end caps located on top of the shipping

1. Remove the entire assembly (Loudspeaker System,

Loudspeaker Grille and foam end caps) by lifting up on

the bottom of the assembly (Loudspeaker rear) and

place it along side the shipping carton on a flat surface.

2. Release the Loudspeaker Grille from the foam end

caps and remove it from the protective plastic shipping

film and set it aside.

3. In a similar manner, lift out the Loudspeaker System.

4. Close the top flaps of the shipping carton and place the

two foam end caps on top of the carton.

5. Carefully remove the protective plastic shipping film

from the Loudspeaker System so as not to mar the finish or damage the Loudspeaker System Drivers.

Notes: 1. When the XLS340 is to be used with the supplied

Floor Standing Base and Hardware, proceed to

step 6.

2. The XLS340 Loudspeaker is also supplied with

On Wall Mounting Brackets and Hardware. If the

XLS340 is to be mounted on the wall at this time,

proceed to “How to Mount the XLS340

Loudspeakers On the Wall” on page 14.

3. When the optional In Wall Mounting Kit is

chosen, refer to the supplied installation guide.

Installation Methods

Loudspeaker Model Floor Base Stabilize r Bar On Wa ll Mounting Kit In W all Mounting Kit

XLS320 ---- ---- Supplied Optional

XLS340 Supplied ---- Supplied Optional

XLS360 Supplied ---- ---- ----

XCS350 ---- Supplied Supplied Optional

Figure 1

10

Unpacking the XLS340 Loudspeaker

Page 11

Installation

6. Place the Loudspeaker System, with the front facing

up, on foam end caps located on top of the shipping

carton, with the bottom of the XLS340 overhanging the

end of the shipping carton. Refer to figure 3.

Bottom of XLS340

with the flat surface

Foam end caps

Figure 3

7. Using the supplied Allen Wrench, remove four screws

from the XLS340

Bottom. Refer to

Remove

Two Screws

Remove

Two Screws

figure 4.

8. Unpack the Floor

Standing Base

from the other

shipping carton.

9. Orient the Floor

Standing Base

with the widest

end of the base

Figure 4

facing up and the

totally flat side of the base pointing away from the

XLS340. Refer to figure 5.

10. Attach the Floor Standing Base to the XLS340 using

the four supplied machine bolts and washers.

FastenersGrommets

Floor

standing

base

Bolts and

washers

Figure 5

11. Orient the Loudspeaker and the Grille with the rounded

ends pointing in the same direction.

12. Align the Grille fasteners to the Loudspeaker Grommets (three on each side). Carefully push down to secure the Grille to the Loudspeaker.

Note: There are four Tiptoes and Glides supplied with the

XLS340. To prevent crushing

carpet use the Tiptoe spikes; to

protect non-carpeted flooring use

the chrome Glides. Both the

Glides and Tiptoes have a

threaded shaft and locking nut

that screw into the tapped holes

in the bottom of the Floor

Standing Base. The feet can be independently

adjusted to compensate for uneven flooring.

Tiptoes

Glides

13. Proceed to “Locating the Loudspeaker System” on

page 18.

Unpacking the XLS360 Loudspeaker

1. Remove the entire assembly (Loudspeaker System,

Loudspeaker Grille and foam center/end caps) by lifting up on the bottom of the assembly (Loudspeaker

rear) and place it along side the shipping carton on a

flat surface.

2. Release the Loudspeaker Grille from the foam center/

end caps and remove it from the protective plastic shipping film and set it aside.

3. In a similar manner, lift out the Loudspeaker System.

4. Replace the shipping carton top onto the shipping carton bottom. Place one foam end cap and one foam center cap on top of the carton. Refer to figure 6 on the

next page.

5. Carefully remove the protective plastic shipping film

from the Loudspeaker System so as not to mar the finish or damage the Loudspeaker System Drivers.

Note: The XLS360 is a sealed Acoustic System.

Grille

If it is to be used without the supplied

Floor Standing Base attached to the

bottom, the four unused holes on the

bottom of the loudspeaker need to be

plugged up with suitable material to

prevent air leaks. Proceed to step 10 if

the Floor Standing Base is not used.

6. Place the Loudspeaker System, with the

front facing up, on foam end caps located

on top of the shipping carton, with the bottom of the XLS360 overhanging the end

of the shipping carton. Refer to figure 6 on

the next page.

7. Unpack the Floor Standing Base from the

other shipping carton.

11

Page 12

Installation, con’t

Bottom of XLS360

with the flat surface

Foam center cap

Figure 6

Foam end cap

8. Orient the Floor Standing Base with the widest end of

the base facing up and the totally flat side of the base

pointing away from the XLS360. Refer to figure 7.

FastenersGrommets

Floor

standing

base

Bolts and

washers

Figure 7

9. Attach the Floor Standing Base to the XLS360 using

the four supplied machine bolts and washers.

10. Orient the Loudspeaker and the Grille with the

rounded ends pointing in the same direction.

11. Align the Grille fasteners to the Loudspeaker Grom-

mets (four on each side). Carefully push down to secure the Grille to the Loudspeaker.

Note: There are four Tiptoes and Glides supplied with the

XLS360. To prevent crushing

carpet use the Tiptoe spikes; to

protect non-carpeted flooring use

the chrome Glides. Both the

Glides and Tiptoes have a

threaded shaft and locking nut

that screw into the tapped holes

in the bottom of the Floor

Standing Base. The feet can be

Tiptoes

Glides

independently adjusted to compensate for uneven

flooring.

12. Proceed to “Locating the Loudspeaker System” on

page 18.

Unpacking the XCS350 Loudspeaker

1. Remove the entire assembly (Loudspeaker System,

Loudspeaker Grille and foam end caps) by lifting up on

the bottom of the assembly (Loudspeaker rear) and

place it along side the shipping carton on a flat surface.

2. Release the Loudspeaker Grille from the foam end

caps and remove it from the protective plastic shipping

film and set it aside.

3. In a similar manner, lift out the Loudspeaker System.

4. Close the top flaps of the shipping carton and place the

two foam end caps on top of the carton.

5. Carefully remove the protective plastic shipping film

from the Loudspeaker System so as not to mar the

Grille

finish or damage the Loudspeaker System

Drivers.

Notes: 1. When the XCS350 is to be used with

the supplied Stabilizer Bar and

Hardware, proceed to step 6.

2. The XCS350 Loudspeaker is also

supplied with On Wall Mounting

Brackets and Hardware. If the XCS350

is to be mounted on the wall at this

time, proceed to “How to Mount the

XCS350 Loudspeakers On the Wall”

on page 16.

3. When the optional In Wall Mounting

Kit is chosen, refer to the supplied

installation guide.

6. Place the Loudspeaker System, with the

front facing down, on foam end caps located on top of the shipping carton. Refer to

figure 8.

Stabilizer Bar

Rubber Bumpers

Foam end caps

Figure 8

Rubber Bumpers

12

Page 13

Installation, con’t

7. Attach the four rubber bumpers to the bottom long

edge of the XCS350 Loudspeaker System. Refer to figure 8.

8. Loosen, but do not remove, the three screws securing

the Stabilizer Bar to the back of the XCS350. Refer to

figure 9.

Stabilizer Bar Screws

Stabilizer Bar

Figure 9

9. Reposition the Stabilizer Bar even with the previously

applied rubber bumpers on the side edge of the

XCS350 enclosure. Refer to figure 10.

FastenersGrommets Grille

Figure 12

13. Locate the Loudspeaker Grille and align the Grille fasteners to the Loudspeaker Grommets (four on each

side). Carefully push down to secure the Grille to the

Loudspeaker.

14. Proceed to “Locating the Loudspeaker System” on

page 18.

Figure 10

10. Tighten the three screws securing the Stabilizer Bar to

keep it in place, but not enough to prevent changing the

angle of the XCS350 in the following steps.

11. The vertical angle of the XCS350 may be changed ±5.5

degrees from perpendicular, allowing the sound to be

directed upwards or downwards to accommodate the

seating arrangement in the room. Refer to figure 11.

This can be accomplished by temporarily loosening the

three screws and

moving the Stabilizer

Bar up or down.

When the desired

angle is achieved,

tighten the three

Figure 11

screws.

12. Rotate the XCS350 Loudspeaker over with the front

facing up, being careful not to damage the Loudspeaker Drivers. Refer to figure 12.

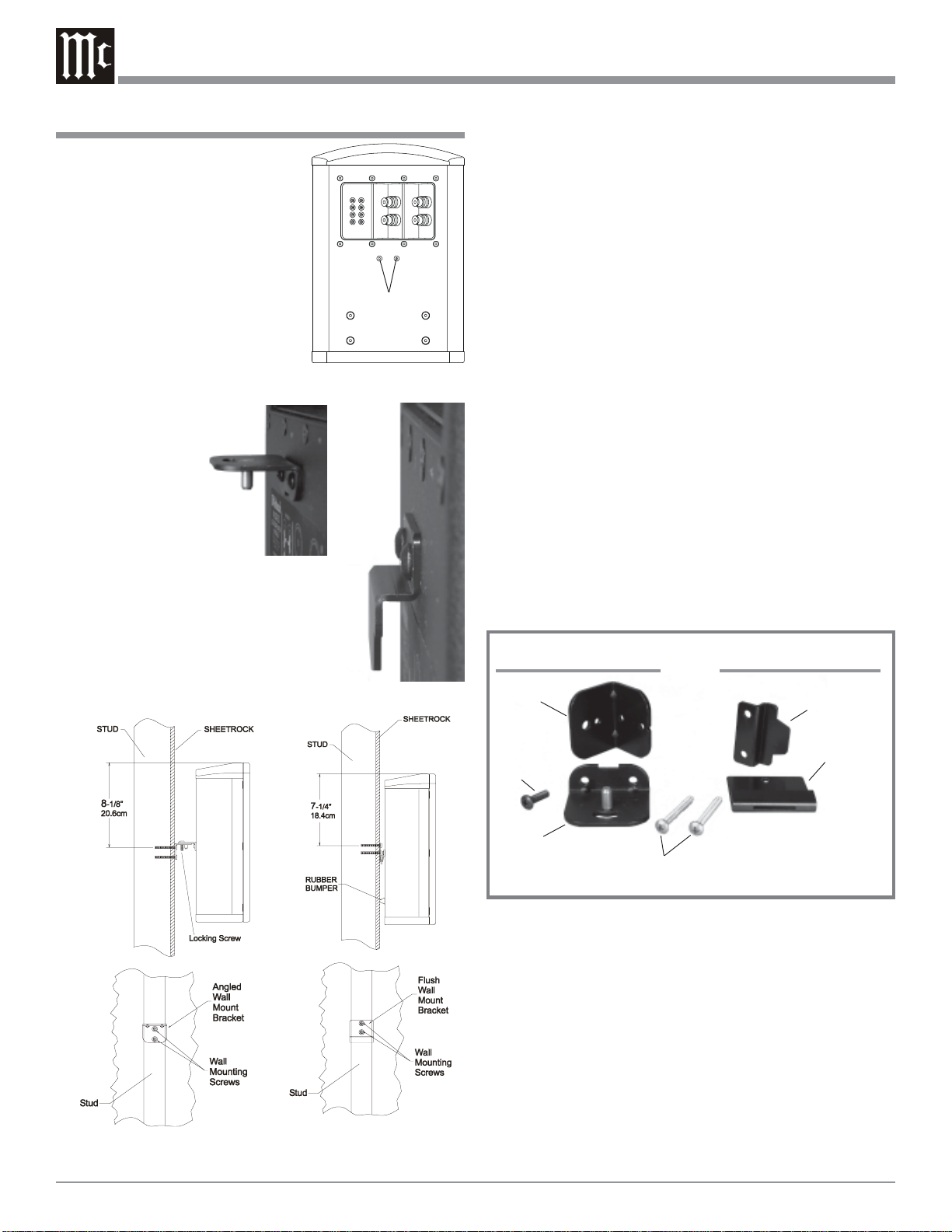

How to Mount the XLS320 Loudspeaker On the Wall

The supplied On Wall Mounting Brackets allow for two

different mounting positions of the XLS320 Loudspeaker

relative to the wall. The first position is flush mount, with

the Loudspeaker close to and parallel with the wall. The

second position is angle mount, which places the Loudspeaker further away from the wall and allows for horizontal rotation of ± 30 Degrees. Refer to figure 13.

Angled Wall Mounting

Hardware

Wall

Bracket

Locking

Screw

Loudspeaker

Bracket

Wall Mounting

Screws

Figure 13

Flush Wall Mounting

Hardware

Loudspeaker

Bracket

Wall

Bracket

1. Using the supplied Allen Wrench, remove two screws

from the rear of the XLS320 Loudspeaker System located below the recessed connection plate. Refer to figure 14 on the next page.

13

Page 14

Installation, con’t

2. Attach either the flush mount or

angle mount bracket to the rear

of the Loudspeaker using the

two screws (just removed in the

previous step), being sure to

orient the bracket as illustrated

in figures 15 and 16.

3. Determine the Loudspeaker

Mounting Location on the wall,

making sure the Mounting

Bracket will be anchored to a

stud located inside the wall.

Note: Use

extreme

caution to

avoid any

existing

electrical

wiring,

plumbing, etc.,

located inside

the wall.

Figure 15

4. Refer to figures 17

and 18 to install the appropriate Wall

Bracket on the wall (orient the

bracket as illustrated) using the supplied Mounting Screws. If the Flush

Mount Bracket is used, attach the

Remove

Screws

Figure 14

Figure 16

two cone shaped rubber bumpers to the rear of the

Loudspeaker, near the bottom.

Note: If the wall covering material and/or thickness is

different from the illustration, the two supplied

Mounting Screws need to be replaced with screws

of the appropriate type and length.

5.Orient the Loudspeaker with the rounded end at the

Top, carefully line up the Loudspeaker Bracket with

the Wall Bracket and lower the Loudspeaker. If the

angle mount is used, install the Locking Screw to secure the Loudspeaker at the desired angle.

6. Align the Grille fasteners to the Loudspeaker Grommets (two on each side). Carefully push down to secure

the Grille to the Loudspeaker.

How to Mount the XLS340 Loudspeaker On the Wall

The supplied On Wall Mounting Brackets allow for two

different mounting positions of the XLS340 Loudspeaker

relative to the wall. The first position is flush mount, with

the Loudspeaker close to and parallel with the wall. The

second position is angle mount, which places the Loudspeaker further away from the wall and allows for horizontal rotation of ± 30 Degrees. Refer to figure 19.

1. Using the supplied Allen Wrench, remove four screws

Angled Wall Mounting

Hardware

Wall

Bracket

Flush Wall Mounting

Hardware

Loudspeaker

Bracket

14

Figure 17

Figure 18

Locking

Screw

Loudspeaker

Bracket

Wall Mounting

Screws

Figure 19

Wall

Bracket

from the rear of the XLS340 Loudspeaker System. Refer to figure 20.

2. Attach either the flush mount or angle mount brackets

to the rear of the Loudspeaker using the four screws

(just removed in the previous step), being sure to orient

the bracket as illustrated in figures 21 and 22.

3. Determine the Loudspeaker Mounting Location on the

wall, making sure the Mounting Brackets will be anchored to a stud located inside the wall.

Page 15

Note: Use extreme caution to

avoid any existing electrical

wiring, plumbing, etc.,

located inside the wall.

4. Refer to figures 23 and 24 to install the appropriate Wall Brackets on the wall (orient the bracket

as illustrated) using the supplied

Mounting Screws. If the Flush

Remove

Screws

Mount Brackets are used, optionally attach the two cone shaped

rubber bumpers to the rear of the

Loudspeaker, near the bottom.

Note: If the wall covering

material and/or thickness is

different from the

illustration, the two

supplied Mounting Screws

need to be replaced with

screws of the appropriate

type and length.

5. Orient the Loudspeaker with the

Remove

Screws

rounded end at the Top, carefully

line up the Loudspeaker Brackets

with the Wall Brackets and lower

the Loudspeaker. If the angle

mount is used, install the Locking

Figure 20

Screw for the top Bracket to secure the Loudspeaker at

the desired

angle.

6. Align the

Grille fasteners to

the Loudspeaker

Grommets

(three on

Figure 21

each side).

Carefully push down to secure the

Grille to the Loudspeaker.

Installation, con’t

Figure 23 Figure 24

Figure 22

15

Page 16

Installation, con’t

How to Mount the XCS350 Loudspeaker On the Wall

The supplied On Wall Mounting Brackets allow for four

different mounting positions of the XCS350 Loudspeaker

relative to the wall, both vertical and horizontial. Two positions are flush mount, with the Loudspeaker close to and

parallel with the wall. The other positions are angle mount,

which places the Loudspeaker further away from the wall

and allows for rotation of ± 30 Degrees. Refer to figure 25.

Angled Wall Mounting

Hardware

Wall

Bracket

Locking

Screw

Loudspeaker

Bracket

Figure 25

1. Using the supplied Allen Wrench, remove the three

screws securing the Stabilizer Bar to the back of the

XCS350. Refer to figure 26. Replace the just removed

center screw with a supplied one of the same type, but

shorter length. Refer to figure 28.

Note: Retain the three removed screws and Stabilizer Bar

for possible future use.

Stabilizer Bar

Figure 26

2. Attach either the flush mount or angle mount brackets

to the rear of the Loudspeaker using the supplied

screws. Refer to figures 27, 28 and 29 for the screw

location. Also, be sure to orient the bracket as illustrated in figure 30.

Flush Wall Mounting

Hardware

Loudspeaker

Bracket

Wall

Bracket

Wall Mounting Screws

Stabilizer Bar Screws

Location of

Mounting

Screws

Screws - A

Screws - B

Figure 29

3. Determine the Loudspeaker

Mounting Location on the wall,

making sure the Mounting Bracket

Replace with

supplied

shorter screw

Location of

Mounting

Screws

will be anchored to a stud located

inside the wall.

Note: Use extreme caution to avoid

any existing electrical

wiring, plumbing, etc.,

located inside the wall.

4. Refer to figures 31 thru 34 to install the appropriate Wall Bracket

on the wall (orient the bracket as

illustrated) using the supplied

Figure 28

Mounting Screws. If the Flush

Mount Bracket is used, attach the

two cone shaped rubber

bumpers to the rear of the Loudspeaker, near the bottom.

Note: If the wall covering material and/or thickness is

different from the illustration, the two supplied

Mounting Screws need to be replaced with screws

of the appropriate type and length.

5. Orient the Loudspeaker to line up with the Wall Brackets and attach them together. If the angle mount is

used, install the Locking Screw to secure

the Loudspeaker at

the desired angle.

Figure 30

XCS350 Screw Removal for Mounting

Mounting Type Screw s - A Screws - B

Ve rtica l Flush Mount ---- Remove

Ve rtica l Angle Mount ---- Remove

Horizontal Flush Mount Re move ---Horizontal Angle M ount ---- Remove

Figure 27

16

Page 17

6. Align the Grille fasteners to the Loudspeaker Grommets (four on each side). Carefully push down to secure the Grille to the Loudspeaker.

Installation, con’t

Figure 33

Figure 31

Figure 34

Figure 32

17

Page 18

Installation, con’t

Locating the Loudspeaker System

Loudspeaker placement in a room can greatly affect

performance. The XLS320, XLS340, XLS360 and XCS350

are designed for use as a Left and Right Loudspeaker in a

Music System, or as a Front and Surround Loudspeakers in

a Home Theater System.

The optimal method for selecting speaker locations includes the use of a real time spectrum analyzer operated by

the Professionals at your McIntosh Dealer. An uncompromising installation would take into consideration the floor,

wall and ceiling coverings, the type and placement of furniture and can even include the architectural design of the

room and its construction materials.

Locating Loudspeakers for use in Home Theater

In a Home Theater application, the placement of Front

Loudspeakers can be limited by such considerations as the

size and location of the video monitor. The locating

suggestions in the “for use in a Music System” section

below can still be helpful. Side Surround Loudspeakers

work best located to either side of and above the listening

position, the same distance from the monitor. Back

Surround Loudspeakers work best on the back wall. Refer

to figure 35.

Figure 35

Locating Loudspeakers for use in a Music System

When used in a Music System, the distance between the

loudspeakers should not exceed the distance between the

listener and either loudspeaker for the best sound imaging.

Refer to figure 36. The Loudspeaker System’s Tweeter

Array should be inline with the listeners’ ears. Placement

near a wall, corner, floor, ceiling or any intersecting

surfaces will reinforce some bass frequencies. Which bass

frequencies are boosted by placement in a particular

location is dependent on the dimensions of the room. Test

the various loudspeaker locations by playing music with

continuous bass, setting up the speakers and listening to

them from the main listening spot. Move the loudspeakers

to an alternate location and repeat the listening, paying

attention to how articulate the bass notes are. Experiment

with various loudspeaker positions until the locations that

sound best are found.

Figure 36

18

Page 19

T weeter Array Optimization

The XLS320, XLS340, XLS360 and XCS350 Loudspeaker

Systems incorporate a special feature in the Crossover

Network for optimization of the sound coming from the

five tweeter array, refer to figure 37. The three different

settings in the

crossover network

have to do with the

physical location of

the Loudspeaker in

the Home Theater

and/or Music System.

On the rear panel of the Loudspeaker System there is a

recessed connection

plate with binding

posts for connection of

hookup cables. Adjacent to the binding

posts on the same recessed connection

plate, are two rows of

jacks with two McIntosh Jumpers already

inserted, refer to figure

38. The default postion

of the jumpers for the

XLS320, XLS340, and

XLS360 Loudspeaker

Systems, is RIGHT,

refer to figure 39. The

XCS350’s default

postion of the jumpers

is CENTER, refer to figure 40.

For the best sound performance, it is important to make

sure the jumpers are set according to the Loudspeaker System location in the room. Refer to the chart below for the

correct Jumper positions; if necessary, remove the two

jumpers and reinsert them for the Loudspeaker location.

Jacks and Jumpers

Connection plate

Figure 37

Binding posts

Figure 38

Installation, con’t

Jumper Position for

RIGHT

Figure 39

Jumper Position for

Center

Figure 40

XLS320/340/360 and XCS350 Crossover Jumper Settings

Loudspeaker Loca tion Left Center Right

Left Front Jumpers ---- ---Center Front ---- Jumpers ---Right Front ---- ---- Jumpers

Le ft Surround Jumpe rs ---- ---Right Surr ound --- - -- -- Jumpers

Left Bac k Surround ---- ---- Jumpers

Right Bac k Surr ound Jumpe rs ---- ----

Jumper Position for

LEFT

Figure 41

19

Page 20

Connection for use with a Low Power

Amplifier (default setting)

Preparing Hookup Cables

The McIntosh Loudspeaker Systems utilize binding posts

for speaker wire connections. Prepare the Loudspeaker

Hookup Cables that attach to the Power Amplifier Output

Terminals:

Bare wire cable ends:

Carefully remove sufficient insulation from the cable

ends, refer to figures 43, 44 and 45. If the cable is

stranded, carefully twist the

strands together as

tightly as possible.

Note: If desired, the twisted ends can be tinned with

solder to keep the strands together and/or attach a

spade lug.

Spade lug or prepared wire connection:

Insert the spade lug connector or prepared section of

the cable end into the terminal side access hole, and

tighten the

terminal

cap until

the cable

is firmly

clamped

into the terminal so the wires cannot slip out. Refer to

figures 46, 47 and 48.

3. Tighten all of the Loudspeaker and Amplifier Binding

Posts.

Note: The Low Frequency Response of a XLS320

Loudspeaker may be extended when it is connected

to a lower power amplifier. The Low Frequency

Response of a XLS320 Loudspeaker may be

extended even further with the addition of a

Powered Subwoofer, like the McIntosh XLS112, to

the Music/Home Theater System and connected as

illustrated on page 18.

4. Connect the remaining Loudspeaker(s) and Amplifier

Channel(s) in the same manner.

Connection plate

Jumper

Connections using a single Amplifier

1. Connect a Loudspeaker cable from the COMmon

(Negative) Binding Post of the appropriate

Amplifier Channel to the Loudspeaker

LOW POWER NEGATIVE (-) Binding

Post.

2. Connect a Loudspeaker cable from the 8S

(OHM) or Positive (+) Binding Post of the

same Amplifier Channel to the Loudspeaker LOW POWER POSITIVE (+)

Binding Post.

Note: The HIGH POWER and LOW

POWER POSITIVE (+) Binding Posts

must have a jumper installed between

them.

20

McIntosh Multi-Channel Power Amplifier

Page 21

Connection for use with a High Power

Amplifier (optional setting)

How to Connect the XLS320 Loudspeakers

Preparing Hookup Cables

The McIntosh Loudspeaker Systems utilize binding posts

for speaker wire connections. Prepare the Loudspeaker

Hookup Cables that attach to the Power Amplifier Output

Terminals:

Bare wire cable ends:

Carefully remove sufficient insulation from the cable

ends, refer to figures 43, 44 and 45. If the cable is

stranded, carefully twist the

strands together as

tightly as possible.

Note: If desired, the twisted ends can be tinned with

solder to keep the strands together and/or attach a

spade lug.

Spade lug or prepared wire connection:

Insert the spade lug connector or prepared section of

the cable end into the terminal side access hole, and

tighten the

terminal

cap until

the cable

is firmly

clamped

into the terminal so the wires cannot slip out. Refer to

figures 46, 47 and 48.

3. Tighten all of the Loudspeaker and Amplifier Binding

Posts.

Note: The Low Frequency Response of a XLS320

Loudspeaker may be extended with the addition of

a Powered Subwoofer like the McIntosh XLS112 to

the Music/Home Theater System.

4. Connect the remaining Loudspeaker(s) and Amplifier

Channel(s) in the same manner.

Connection plate

Jumper

Connections using a single Amplifier

1. Connect a Loudspeaker cable from the COMmon

(Negative) Binding Post of the appropriate Amplifier

Channel to the Loudspeaker HIGH POWER

NEGATIVE (-) Binding Post.

2. Connect a Loudspeaker cable from the 8S

(OHM) or Positive (+) Binding Post of the same

Amplifier Channel to the Loudspeaker HIGH

POWER POSITIVE (+) Binding Post.

Note: The HIGH POWER and LOW POWER

NEGATIVE (-) Binding Posts must have a

jumper installed between them.

McIntosh Two Channel Power Amplifier

21

Page 22

Connection with one Amplifier

Preparing Hookup Cables

The McIntosh Loudspeaker Systems utilize binding posts

for speaker wire connections. Prepare the Loudspeaker

Hookup Cables that attach to the Power Amplifier Output

Terminals:

Bare wire cable ends:

Carefully remove sufficient insulation from the cable

ends, refer to

figures 43, 44

and 45. If the

cable is

stranded, carefully twist the

strands together as tightly as possible.

Note: If desired, the twisted ends can be tinned with

solder to keep the strands together and/or attach a

spade lug.

Spade lug or prepared wire connection:

Insert the spade lug connector or prepared section of

the cable end into the terminal side access hole, and

tighten the

terminal

cap until

the cable

is firmly

clamped

into the terminal so the wires cannot slip out. Refer to

figures 46, 47 and 48.

3. Tighten all of the Loudspeaker and Amplifier Binding

Posts.

4. Connect the remaining Loudspeaker(s) and Amplifier

Channel(s) in the same manner.

Connection plate

Jumpers

Connections using a single Amplifier

1. Connect a Loudspeaker cable from the COMmon

(Negative) Binding Post of the appropriate Amplifier

Channel to the Loudspeaker NEGATIVE (-) Binding

Post.

2. Connect a Loudspeaker cable from the 8S (OHM) or

Positive (+) Binding Post of the same Amplifier Channel to the Loudspeaker POSITIVE (+) Binding Post.

Note: The WOOFER and MID/TWT NEGATIVE (-) Binding

Posts must have a jumper installed between them.

Likewise, the WOOFER and MID/TWT POSITIVE (+)

Binding Posts must also have a jumper installed

between them.

22

To other McIntosh

Loudspeaker

McIntosh T wo Channel

Power Amplifier

Page 23

Connection with two Amplifiers

How to Connect the XLS340, XLS360 and XCS350 Loudspeakers

Preparing Hookup Cables

The McIntosh Loudspeaker Systems utilize binding posts

for speaker wire connections. Prepare the Loudspeaker

Hookup Cables that attach to the Power Amplifier Output

Terminals:

Bare wire cable ends:

Carefully remove sufficient insulation from the cable

ends, refer to

figures 43, 44

and 45. If the

cable is

stranded, carefully twist the

strands together as tightly as possible.

Note: If desired, the twisted ends can be tinned with

solder to keep the strands together and/or attach a

spade lug.

Spade lug or prepared wire connection:

Insert the spade lug connector or prepared section of

the cable end into the terminal side access hole, and

tighten the

terminal

cap until

the cable

is firmly

clamped

into the terminal so the wires cannot slip out. Refer to

figures 46, 47 and 48.

NEGATIVE (-) Binding Post.

3. Connect a Loudspeaker cable from the 8S (OHM) or

Positive (+) Binding Post of the same Channel of Amplifier Number One to the Loudspeaker WOOFER

POSITIVE (+) Binding Post.

4. Connect a Loudspeaker cable from the COMmon

(Negative) Binding Post of the appropriate Channel of

Amplifier Number Two to the Loudspeaker MID/TWT

NEGATIVE (-) Binding Post.

5. Connect a Loudspeaker cable from the 8S (OHM) or

Positive (+) Binding Post of the same Channel of Amplifier Number Two to the Loudspeaker MID/TWT

POSITIVE (+) Binding Post.

6. Tighten all of the Loudspeaker and Amplifier Binding

Posts.

7. Connect the remaining Loudspeaker(s) and Amplifier

Channel(s) in the same manner.

Connection plate

Connections using two Amplifiers

1. Remove both Jumpers between WOOFER and MID/

TWT Binding Posts.

2. Connect a Loudspeaker cable from the COMmon

(Negative) Binding Post of the appropriate Channel of

Amplifier Number One to the Loudspeaker WOOFER

McIntosh Two Channel Power

Amplifier Number One

To other McIntosh

Loudspeaker

To other McIntosh

Loudspeaker

McIntosh Two Channel Power

Amplifier Number Two

23

Page 24

XLS320 Specifications

XLS340 Specifications

Driver Complement

One 6-1/2 inch LD/HP Woofers/Midrange

Five 1 inch Dome Tweeters (in a Bessel Function Array)

Impedance

8 ohms Nominal

Frequency Response

50Hz - 34kHz -6dB (Typical Room)

80Hz - 34kHz + 2dB (Anechoic Response)

High Pass Filter (High Power Connection)

12dB per octave roll off below 80Hz

Sensitivity

85dB (2.8V/1m)

Crossover Frequency

1.5kHz

Power Handling

250 Watts Maximum

Power Handling (High Power Connection)

400 Watts Maximum

Overall Dimensions

15-5/16 inches (38.9cm) Height

10-5/8 inches (27.0cm) Width

5-1/4 inches (13.3cm) Depth

Enclosure Finish

The outside of the enclosure is finished with a textured

black powder coated finish; the front, top and bottom of the

enclosure is covered with a thermal vacuum formed durable surface in a textured black finish.

Grille Finish

Black knit fabric with wood trim strips finished in

Champagne Gold

Optional Wood Trim Finishes

Natural Cherry, Red Cherry or Black Ash

(Check with your McIntosh Dealer for Additional Details)

Weight (each)

24 pounds (10.9kg) net, 27 pounds (12.2kg) in shipping

carton

Driver Complement

Two 8 inch LD/HP Woofers

One 6-1/2 inch LD/HP Midrange

Five 1 inch Dome Tweeters (in a Bessel Function Array)

Impedance

8 ohms Nominal

Frequency Response

38Hz - 34kHz -6dB (Typical Room)

65Hz - 34kHz + 2dB (Anechoic Response)

Sensitivity

85dB (2.8V/1m)

Crossover Frequencies

1.5kHz

250Hz

Power Handling

400 Watts Maximum

Overall Dimensions (including Floor Standing Base)

44-1/16 inches (111.9cm) Height

14-3/4 inches (37.5cm) Width

12 inches (30.5cm) Depth

Enclosure Finish

The outside of the enclosure is finished with a textured

black powder coated finish; the front, top and bottom of the

enclosure is covered with a thermal vacuum formed durable surface in a textured black finish. The base is also

covered with a thermal vacuum formed durable surface in a

textured black finish

Grille Finish

Black knit fabric with wood trim strips finished in

Champagne Gold

Optional Wood Trim Finishes

Natural Cherry, Red Cherry or Black Ash

(Check with your McIntosh Dealer for Additional Details)

Weight (each)

69 pounds (31.3kg) net, 76 pounds (34.5kg) in shipping

carton

24

Page 25

Specifications

XLS360 Specifications

Driver Complement

Two 10 inch LD/HP Woofers

One 6-1/2 inch LD/HP Midrange

Five 1 inch Dome Tweeters (in a Bessel Function Array)

Impedance

8 ohms Nominal

Frequency Response

34Hz - 34kHz -6dB (Typical Room)

55Hz - 34kHz + 2dB (Anechoic Response)

Sensitivity

85dB (2.8V/1m)

Crossover Frequencies

1.5kHz

250Hz

Power Handling

600 Watts Maximum

XCS350 Specifications

Driver Complement

Two 8 inch LD/HP Woofers

One 6-1/2 inch LD/HP Midrange

Five 1 inch Dome Tweeters (in a Bessel Function Array)

Impedance

8 ohms Nominal

Frequency Response

45Hz - 34kHz -6dB (Typical Room)

80Hz - 34kHz + 2dB (Anechoic Response)

Sensitivity

85dB (2.8V/1m)

Crossover Frequencies

1.5kHz

250Hz

Power Handling

400 Watts Maximum

Overall Dimensions (including Floor Standing Base)

51-3/8 inches (130.5cm) Height

17-3/4 inches (45.1cm) Width

13 inches (33.0cm) Depth

Enclosure Finish

The outside of the enclosure is finished with a textured

black powder coated finish; the front, top and bottom of the

enclosure is covered with a thermal vacuum formed durable surface in a textured black finish. The base is also

covered with a thermal vacuum formed durable surface in a

textured black finish

Grille Finish

Black knit fabric with wood trim strips finished in

Champagne Gold

Optional Wood Trim Finishes

Natural Cherry, Red Cherry or Black Ash

(Check with your McIntosh Dealer for Additional Details)

Weight (each)

107 pounds (48.5kg) net, 120 pounds (54.4kg) in shipping

carton

Overall Dimensions (including Stablizer Bar)

10-5/8 inches (27cm) Height

34-1/16 inches (86.5cm) Width

6 inches (15.3cm) Depth

Enclosure Finish

The outside of the enclosure is finished with a textured

black powder coated finish; the front and side ends of the

enclosure are covered with a thermal vacuum formed durable surface in a textured black finish.

Grille Finish

Black knit fabric with wood trim strips finished in

Champagne Gold

Optional Wood Trim Finishes

Natural Cherry, Red Cherry or Black Ash

(Check with your McIntosh Dealer for Additional Details)

Weight (each)

49 pounds (22.2kg) net, 55 pounds (24.9kg) in shipping

carton

25

Page 26

Packing Instructions

In the event it is necessary to repack the equipment for

shipment, the equipment must be packed exactly as shown

below. The XLS360 shipping carton uses banding straps to

make sure the box is held together securely.

Note: The Floor Stand must be removed from the XLS340/

XLS360 Loudspeaker and packed in its own

shipping carton.

XLS320 Shipping Carton and Parts List

Use the original shipping carton and parts only if they

are in good serviceable condition. If a shipping carton or

any of the interior part(s) are needed, please call or write

Customer Service Department of McIntosh Laboratory.

Please see the Parts List for the correct part numbers.

Quantity Part Number Description

1 034293 Shipping carton

2 034291 Foam end caps

XLS340 Shipping Cartons and Parts List

Quantity Part Number Description

1 034292 Shipping carton

2 034291 Foam end caps

1 034207 Floor stand shipping carton

1 033300 Microfoam to wrap up the

floor stand

1 033085 Air Cap bottom pad

26

Page 27

XLS360 Shipping Cartons and Parts List

Packing Instructions

Quantity Part Number Description

1 034290 Shipping carton top

1 034289 Shipping carton bottom

2 034244 Foam end caps

1 034245 Foam center cap

1 034309 Floor stand shipping carton

1 033300 Microfoam to wrap up the

floor stand

1 033085 Air Cap bottom pad

XCS350 Shipping Carton and Parts List

27

Page 28

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, NY 13903

The continuous improvement of its products is

the policy of McIntosh Laboratory Incorporated

who reserve the right to improve design without

notice.

Printed in the U.S.A.

McIntosh Part No. 04094100

Loading...

Loading...