Page 1

In Wall

Mounting Kit

with Grille

CK320

yy

yCK340

yy

yy

yCK350

yy

Installation Guide

McIntosh Laboratory, Inc. 2 Chambers Street Binghamton, New York 13903-2699 Phone: 607-723-3512 FAX: 607-724-0549

Page 2

Installation

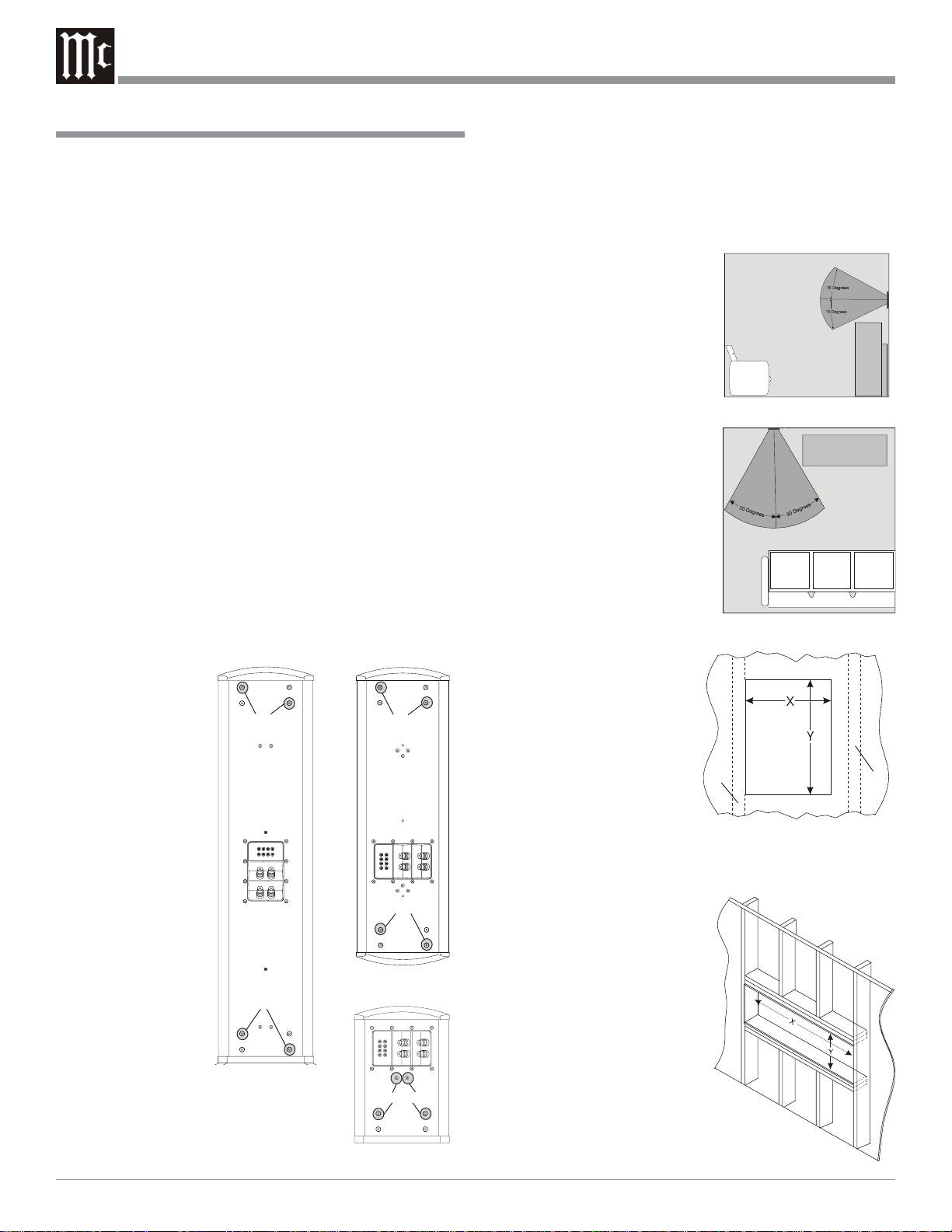

The following instructions are for installing the XLS320,

XLS340, and XCS350 Loudspeaker Systems into the wall using

the optional CK320, CK340 and CK350 In Wall Mounting Kits

with Grilles. The CK320, CK340 and CK350 Kits share a common mounting procedure with a varying number of mounting

brackets and fasteners used to install each Loudspeaker Model.

Before proceeding with these instructions refer to the

XLS320, XLS340 and XCS350 Owner’s Manual sections including “Unpacking the Loudspeaker” starting on page 10, to

“Locating the Loudspeaker System” on page 18, “Tweeter Array

Optimization” on page 19 and “How to Connect” starting on

page 20, before beginning the Mounting Process. It is recommended that the Professionals at your McIntosh Dealer, who are

skilled in all aspects of installation and operation, install the

Loudspeaker System and any associated audio/video equipment.

Caution: Due to the size and weight of the XLS340 and

XCS350 Loudspeakers, two or more persons may

be required to install them safely.

Unpacking the Loudspeaker

Unpacking the XLS320, XLS340 and XCS350 Loudspeaker by

referring to the instructions contained in the Owner’s Manual

starting on page 10. Then perform the following steps:

1. Place the Loudspeaker System, with the front facing

down, on top of the packing material located on top of the

shipping carton

as illustrated in

the Owner’s

Manual.

2. Using the supplied

Allen Wrench, remove the screws

at locations illustrated in figure

1.

Note: The

XCS350

Loudspeaker

requires

removal of

the

Stabilizer

Bar and

replacement

of the three

screws

used to

attach the

Stabilizer

Bar, with

screws of the same

type but shorter in

length (supplied

with the XCS350) to prevent

air leaks.

Screw Removal Location

XLS340

Remove Screws

Remove Screws

Figure 1

XCS350

Remove Screws

Remove Screws

XLS320

Remove Screws

Installing the Loudspeaker System

The XLS320, XLS340 and XCS350 Loudspeakers’ Smooth Frequency Response may be altered by a large object(s) located in

the sound waves path or by locating the Loudspeaker too close

to a side wall. There should be an unobstructed area in front of

the Loudspeaker of at least 15 degrees either top or bottom from

the center axis and 30 degrees side

to side for the best performance. Refer to figures 2 and 3.

3. Use a suitable wall stud finder

or metal detector to verify a

proper mounting location for

the Loudspeaker System before cutting into the wall. The

XLS320 and XLS340 are de-

Figure 2

signed for mounting between

vertical wall studs with 16

inch (40.64cm) centers. Refer

to figure 4. The XCS350 is

designed for mounting horizontally in a special prepared

opening. Refer to figure 5.

Note: Make sure there are

no Plumbing Pipes, AC

Electrical Wiring or

Heating/Cooling

Ductwork in the wall

Figure 3

between the studs

where the

Loudspeaker is to be

mounted.

4. For the XLS320 and

XLS340, cut an opening in

the existing finished wall

using the dimensions in the

Stud

Stud

figure 6 Chart. The In Wall

Mounting Bracket(s) can be

oriented for anchoring the

Figure 4

Bracket to the wall stud either on the left or right hand

side of the Loudspeaker. Refer to the Top Inside Views in

figures 7 and 8.

Note: The In Wall

Bracket(s) must be

secured to a wall stud

on one side, with the

other side clamped to

the dry wall. In new

construction the

Loudspeaker

Mounting Bracket(s)

should be secured to

wall studs on both

sides.

5. To mount the XCS350 Hori-

Figure 5

zontally requires wall con-

2

Page 3

Installation

Cut Out Dim e ns ions

In-Wa ll kit X Y

7/8

inches*

CK320

CK340

CK350

11-

11-

34

-5/8

30.16cm

7/8

inches*

30.16cm

inches

87.96cm

* F or new construction, place studs on a 12- 15/16 inch ce nt er

w ith a drywall cutout ope n ing of 11-3/16 inche s 28 .42cm

Figure 6

struction of a specially prepared opening with the dimensions in the figure 6 Chart.

6. Attach the single bracket for the XLS320 to the rear of the

Loudspeaker using the supplied machine screws. Refer to

figures 1 and 10.

7. Attach two brackets to the rear XLS340 and XCS350

Loudspeaker using the supplied machine screws. Refer to

figures 1 and 11.

8. For the XLS320, attach the wall clamp to the rear of the

bracket (left or right side) with the two machine screws,

lock washers and flat washers, rotate the screws several

turns into the clamp. Refer to figures 10 and 12.

Stud and

Screw

Top of the Loudspeaker

-15/16

15

40.48cm

-5/8

44

113.36cm

-3/16

11

28.42cm

Drywall

Clamp

and Screw

inches

inches

inches

Openings for the

screws securing the

bracket to the wall

stud

Bracket

Openings for the

screws securing the

bracket to the wall

stud

Openings for the

screws securing the

grille frame to the

bracket

Openings for the

screws securing dry

wall clamp to the

bracket

Openings for the

screws securing the

bracket to the

XLS320

Figure 10

Openings for the

screws securing dry

wall clamp to the

bracket

Openings for the

screws securing the

bracket to the

XLS340 and XCS350

Openings for the

screws securing the

bracket to the wall

stud

Openings for the

screws securing

the bracket to the

wall stud

Bracket

Bracket

Drywall

Clamp

and Screw

Figure 7

Top of the Loudspeaker

Figure 8

Bracket

Note: If new construction is applicable (with studs on 12-

15/16 inch centers) skip this step and proceed to

step 14 on the next page.

9. Position the clamp towards the center of the

bracket with the screw heads in the “Install”

position. Refer to figure 9.

Note: If you have not already done so, set

the Jumpers for Tweeter Array

Optimization and connect the hookup

cable to the Loudspeaker terminals at

this time.

10. For the XLS340 and XCS350, attach the

wall clamp to the rear of the brackets (left

or right side) with the two machine screws,

lock washers and flat washers, rotate the

Stud and

Screw

Bracket

Install

Figure 9

Clamp

Bracket

Openings for the screws securing

the grille frame to the bracket

Figure 11

screws several turns into the clamp. Refer to figures 11,

13 and 14.

Note: If new construction is applicable (with studs on 12-

15/16 inch centers) skip this step and proceed to

step 14.

11. Position the clamp towards the center of the bracket with

the screw heads in the “Install” position. Refer to figure

9.

Note: If you have not already done so, set the Jumpers for

Tweeter Array Optimization and connect the

hookup cable to the Loudspeaker terminals at this

time.

12. Place the Loudspeaker, with the attached bracket(s), into

the prepared wall opening with the side containing the

dry wall clamp first.

13. Secure the bracket(s) through the wall finish material and

into the studs, using the supplied wood screws. Refer to

figures 10, 11 and 12.

14. On the other side of the bracket, position the clamp to engage the inside of the dry wall with the screws moved to

the “Clamp” position and tighten the machine screws

3

Page 4

without compressing the dry wall. Refer to figures 9 and

12.

Note: If new construction is applicable secure the other

side of the bracket(s) into the stud using the supplied

wood screws instead of the above step.

15. Attach the grille frame to the just installed Loudspeaker/

Bracket(s) using the supplied sheet metal screws. Refer to

figures 10 and 12 for the XLS320; or 11 and 13 for the

XLS340; or 11 and 14 for the XCS350.

Note: Before tightening the sheet metal screws, check the

grille frame position with a leveling device.

16. Orient the Loudspeaker Grille even with the recessed cutout of the Loudspeaker Grille Frame. Carefully push in to

secure the Grille to the Column.

Note: The Loudspeaker Grille is held in place with

magnets embedded into the Grille Frame.

17. Attach the supplied McIntosh Logo to the Loudspeaker

Grille.

Figure 12

Figure 13

McIntosh Laboratory, Inc.

2 Chambers Street

Binghamton, NY 13903

Figure 14

The continuous improvement of its products is the policy of

McIntosh Laboratory Incorporated who reserve the right to

improve design without notice.

Printed in the U.S.A.

McIntosh Part No. 04093800

Loading...

Loading...