Page 1

INSTALLATION INSTRUCTIONS

Before the dryer is removed from service or discarded,

(ORIgINAL INSTRUCTIONS)

CommerCial Washer

Models maT20CsBGW, maT20mNBGW, maT20PDBGW, and maT20PrBGW0

INSTRUCTIONS D’INSTALLATION

(INSTRUCTIONS D’ORIgINe)

lave-liNGe CommerCial

Modèles maT20CsBGW, maT20mNBGW, maT20PDBGW et maT20PrBGW0

INSTRUCCIONeS De INSTALACIÓN

(INSTRUCCIONeS ORIgINALeS)

lavaDora ComerCial

Modelos maT20CsBGW, maT20mNBGW, maT20PDBGW y maT20PrBGW0

ISTRUZIONI D’INSTALLAZIONe

(ISTRUZIONI ORIgINALI)

lavaTriCe CommerCiale

Modellos maT20CsBGW, maT20mNBGW, maT20PDBGW e maT20PrBGW0

W11344547A

www.maytagcommerciallaundry.com

Page 2

TABLE OF CONTENTS

Page

Washer Safety .......................................................................... 3

FOR OWNER

General Use Instructions ........................................................ 4

Typical Full Load Sizes ............................................................ 4

Transporting Your Washer ......................................................5

If You Need Assistance or Service ......................................... 5

FOR MAYTAG AUTHORIZED SERVICE PERSON ONLY

Tools & Parts ............................................................................ 6

Alternate Parts & Accessories ............................................... 6

Dimensions .............................................................................. 7

Location Requirements ...........................................................8

Installation Instructions .......................................................... 9

Level Washer ..........................................................................10

Connect Drain Hose .............................................................. 11

Drain System .......................................................................... 12

Connect Inlet Hoses .............................................................. 13

Electrical Requirements........................................................14

Complete Installation ............................................................ 15

Installing Coin Slide and Coin Box ....................................... 15

Electronic Controls Set-Up Instructions

(PD & PN Models) .................................................................. 16

Washer Disposal .................................................................... 20

Warranty ................................................................................. 21

MODEL NOMENCLATURE:

MAT – Maytag

20 – Model Type Number

CS – Coin Slide

MN – Timer Non-Pay

PD – Coin Drop

PN – Electronic Non-Pay

PR – Electronic Control -

Card Ready

ÍNDICE

Página

Seguridad de la lavadora ....................................................... 42

PARA EL PROPIETARIO

Instrucciones del uso general ............................................... 43

Tamaños de cargas típicas de volumen completo ..............44

Transporte de la lavadora ...................................................... 44

Si necesita asistencia o servicio ........................................... 44

PARA EL PERSONAL DE SERVICIO AUTORIZADO

DE MAYTAG

Herramientas y piezas ...........................................................45

Piezas y accesorios alternativos ..........................................45

Dimensiones ...........................................................................46

Requisitos de ubicación ........................................................47

Instrucciones de instalación .................................................48

Nivelación de la lavadora ....................................................... 49

Conexión de la manguera de desagüe ................................. 50

Sistema de desagüe ............................................................... 51

Conexión de las mangueras de entrada ..............................52

Requisitos eléctricos .............................................................53

Complete la instalación ........................................................54

Instalación del tragamonedas y la caja de monedas ..........54

Instrucciones para programar los controles

electrónicos (Modelos PD y PN) ...........................................55

Eliminación de la lavadora ..................................................... 60

Garantía ................................................................................... 61

NOMENCLATURA DEL MODELO:

MAT – Maytag

20 – Número de tipo de

modelo

CS – Tragamonedas

MN – Temporizador operado

sin monedas

2

PD – Depósito de monedas

PN – Operado sin monedas

electrónico

PR - Control electrónico

- Habilitado para

tarjetas

TABLE DES MATIÈRES

Page

Sécurité du lave-linge ........................................................... 22

POUR LE PROPRIÉTAIRE

Instructions de l’utilisation général ..................................... 23

Taille typique des charges complètes ................................. 23

Transport du lave-linge ......................................................... 24

Si vous avez besoin d’assistance ou service ...................... 24

POUR LE PERSONNEL D’ENTRETIEN AUTORISÉ

PAR MAYTAG

Outillage et pièces ................................................................. 25

Pièces supplémentaires et accessoires .............................. 25

Dimensions ............................................................................ 26

Exigences d’emplacement ................................................... 27

Instructions d’installation ..................................................... 28

Établissement de l’aplomb du lave-linge ............................ 29

Raccordement du tuyau de vidange .................................... 30

Système de vidange .............................................................. 31

Raccordement des tuyaux d’arrivée d’eau ......................... 32

Spécications électriques .................................................... 33

Achever l’installation ............................................................. 34

Installation de la glissière et de la boîte à monnaie ........... 34

Instructions de paramétrage des commandes

électroniques (Modèles PD et PN) ....................................... 35

Élimination du lave-linge ...................................................... 40

Garantie .................................................................................. 41

NOMENCLATURE DES MODÈLES :

MAT – Maytag

20 – ## (p. ex. 25) Numéro

de type du modèle

CS – Glissière à pièces

MN – Minuterie non payant

PD – Chute de pièce

PN – Non payant électronique

PR – Commande électronique

– Compatible carte

SOMMARIO

Pagina

Sicurezza della lavatrice ....................................................... 62

PER IL PROPRIETARIO

Istruzioni del uso generale ................................................... 63

Dimensioni tipiche a carico completo ................................. 64

Transporto della lavatrice ..................................................... 64

Se avete bisogno dell’assistenza o servizio ....................... 64

PER IL PERSONALE DI ASSISTENZA

AUTORIZZATO MAYTAG

Attrezzi e componenti ........................................................... 65

Parti e accessori alternativi .................................................. 65

Dimensioni ............................................................................. 66

Requisiti di posizionamento ................................................. 67

Istruzioni d’installazione ....................................................... 68

Livellamento della lavatrice .................................................. 69

Connessione del tubo di scarico ......................................... 70

Sistema di scarico ................................................................. 71

Collegare i tubi d’ingresso .................................................... 72

Requisiti elettrici .................................................................... 73

Completamento dell’installazione ....................................... 74

Installazione dello scivolo monete e della gettoniera ........ 74

Istruzioni di congurazione dei comandi elettronici

(Modelli PD e PN) ................................................................... 75

L’eliminazione della lavatrice ............................................... 79

Garanzia ................................................................................. 80

NOMENCLATURA DI MODELLO:

MAT – Maytag

20 – Numero di Tipo

di modello

CS – Scivolo gettoni

MN – Temporizzatore

non a gettoni

PD – Imbuto monete

PN – Non a gettoni

elettroniche

PR - Controllo elettronico

- Carta pronta

Page 3

WASHER SAFETY

Before the dryer is removed from service or discarded,

Washer installation and service must be performed by a Whirlpool authorized service person.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the washer,

follow basic precautions, including the following:

n Read all instructions before using the

washer.

n Do not wash articles that have been

previously cleaned in, washed in, soaked

in, or spotted with petrol, dry-cleaning

solvents, or other ammable or explosive

substances as they give off vapours that

could ignite or explode.

n Do not add petrol, dry-cleaning solvents, or

other ammable or explosive substances to

the wash water. These substances give off

vapours that could ignite or explode.

n Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for 2 weeks or

more. HYDROGEN GAS IS EXPLOSIVE.

If the hot water system has not been used

for such a period, before using the washer,

turn on all hot water taps and let the water

ow from each for several minutes. This will

release any accumulated hydrogen gas. As

the gas is ammable, do not smoke or use

an open ame during this time.

n The appliance must be disconnected from

its power source during service and when

replacing parts. The power cord plug should

be visible at all times once disconnected to

verify that power remains removed.

n This appliance is not intended for use

by children or by persons with reduced

physical, sensory, or mental capabilities,

or lack of experience and knowledge,

unless they have been given supervision

or instructions concerning safe use of the

appliance by persons responsible for their

safety. Such persons must also understand

the possible hazards involved during use.

n The appliance can be used by children

age 8 years and above and persons with

reduced physical, sensory, or mental

capabilities, or lack of experience and

knowledge if they have been given

supervision or instructions concerning

safe use of the washer, and if they

understand the hazards involved.

n Children of less than 3 years should be kept

away unless continuously supervised.

SAVE THESE INSTRUCTIONS

3

Page 4

n This appliance is intended to be used in

household and similar applications such

as staff kitchen areas, shops, ofces, other

working environments, farm houses. It can

also be used by clients in hotels, motels,

other residential type environments, bed

and breakfast type environments, areas

for communal use in blocks of ats, or

in launderettes.

n No washer can completey remove oil. Do not

dry anything that has ever had any type of oil

on it (including cooking oils). Doing so can

result in death, explosion, or re.

n It is recommended that berglass items not

be washed in coin-operated washers. If

these items are washed in the washer, run

the washer through a complete cycle to rinse

away any residue that might be left in the

washer.

n Cleaning and user maintenance by children

must be supervised.

n Do not allow children to play on, in, or with

the washer. Close supervision of children

is necessary when the washer is used near

children.

n Before the washer is removed from service

or discarded, remove the door or lid.

n Do not reach into the washer if the basket,

tub, or agitator is moving.

n Do not install or store the washer where it will

be exposed to the weather.

n Do not tamper with controls.

n After installation, access to mains plug or

mains supply via a double-pole switch must

be maintained at all times in order to ensure

immediate deactivation of the washer in case

of emergency.

n Do not repair or replace any part of the washer

or attempt any servicing unless specically

recommended in this manual. You must also

understand these instructions and have the

skills to carry them out.

n See “Electrical Requirements” for grounding

instructions.

n Water pressure of 138–690 kPa (20–100 psi)

is needed for operation of the washer.

n Use new hoses supplied with the washer.

Do not reuse old hoses.

n If the supply cord is damaged, it must be

replaced by the manufacturer, its service

agent, or similarly qualied persons in order

to avoid a hazard.

n This appliance incorporates an earth

connection for functional purposes only.

n IEC capacity: 7.7 kg.

SAVE THESE INSTRUCTIONS

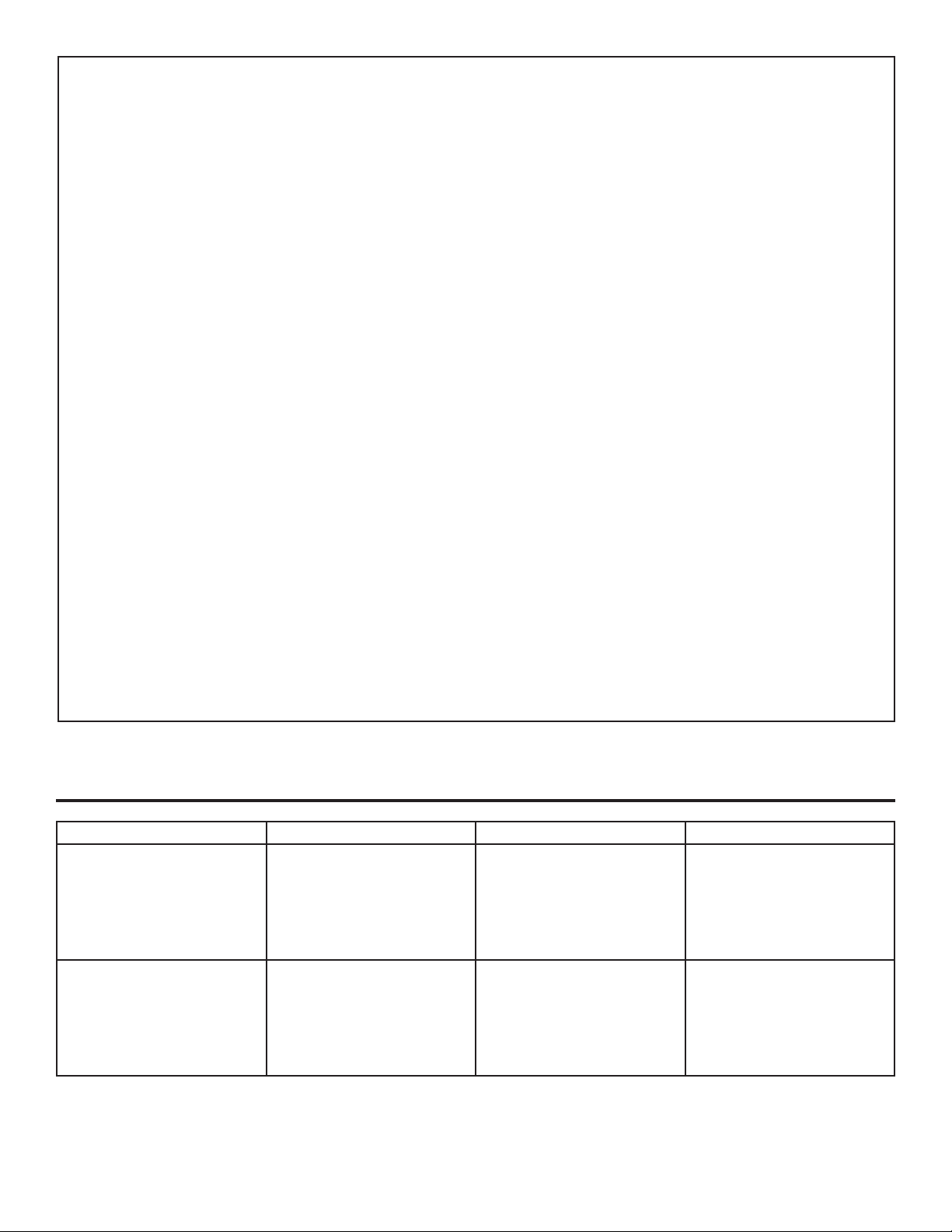

TYPICAL FULL LOAD SIZES (7.7 kg maximum load size)

Load Type Loading Suggestion Load Type Loading Suggestion

Mixed Load 3 double sheets

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

2 blouses

8 handkerchiefs

Permanent Press 2 double or 1 king size sheet

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

Heavy Work Clothes 3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

Knits 3 blouses

4 slacks

6 shirts

4 tops

4 dresses

4

Page 5

MAYTAG COMMERCIAL LAUNDRY

LIMITED WARRANTY

TRANSPORTING YOUR WASHER

n Shut off both water faucets. Disconnect and drain water

inlet hoses.

n Disconnect drain from drain system and drain any remaining

water into a pan or bucket. Disconnect drain hose from back

of washer.

n Unplug power cord.

n Place inlet hoses and drain hose inside washer basket.

n Drape power cord over edge and into washer basket.

n Place packing tray from original shipping materials back inside

washer and reuse shipping base to support the motor and tub.

If you do not have original packaging, place heavy blankets

or towels above basket, between the washer top and the tub

ring. Close lid and place tape over lip and down the front of the

washer. Keep lid taped until washer is moved to new location.

IF YOU NEED ASSISTANCE OR SERVICE

Your installation may require additional parts. To order, please contact your authorised commercial laundry distributor from

whom you purchased your washer or an authorised service company.

You will need the washer model number and serial number. Both numbers can be found on the serial-rating plate located

on the washer.

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag Commercial Laundry

distributor, visit .

www.maytagcommerciallaundry.com

For written correspondence:

Maytag Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632 USA

5

Page 6

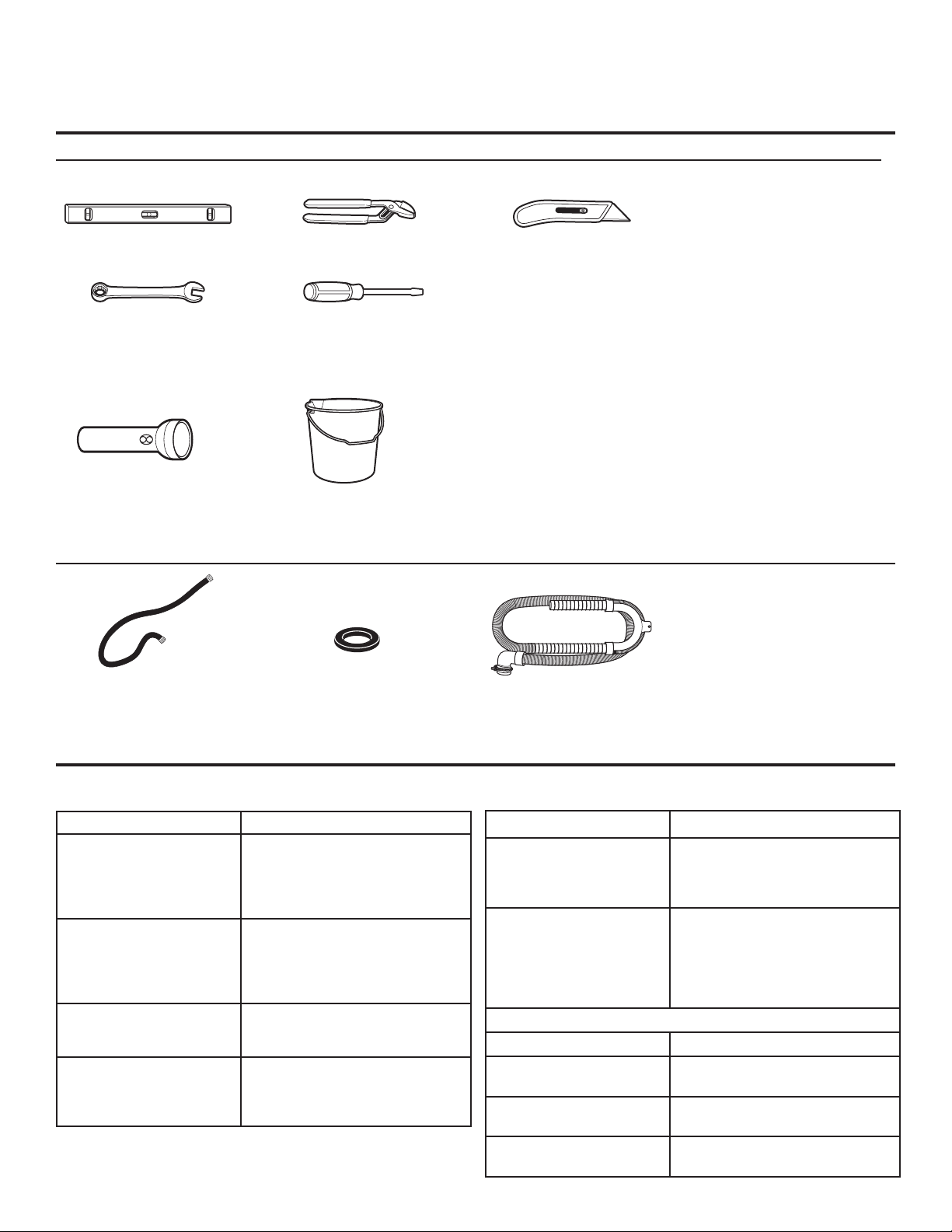

FOR MAYTAG AUTHORIZED SERVICE PERSON ONLY

TOOLS & PARTS

Tools Needed:

Level Pliers Utility Knife

9/16" Open-End Wrench

or Adjustable Wrench

Flat-Blade Screwdriver

Optional tools:

Flashlight Bucket

Parts Supplied:

Water Inlet Hoses (2) Inlet Hose Washers (4)

ALTERNATE PARTS & ACCESSORIES

Drain Hose with Clamp,

U-Form, and Cable Tie

Your installation may require additional parts. To order, please contact the dealer from whom you purchased your washer or

an authorised service company.

If You Have: You Will Need:

Overhead sewer Standard 76 L (20 gal.)

990 mm (39") tall drain tub or

utility sink, sump pump, and

connectors (available from local

plumbing suppliers)

25 mm (1") standpipe 51 mm (2") diameter to

25 mm (1") diameter Standpipe

Adapter Part Number 3363920,

Connector Kit Part Number

285835

Lint clogged drain Drain Protector Part Number

367031, Connector Kit Part

Number 285835

Floor drain system Siphon Break Part Number

285320, Connector Kit (x2) Part

Number 285835, Extension Drain

Hose Part Number 285863

If You Have: You Will Need:

Water faucets beyond

reach of ll hoses

2 longer water ll hoses:

1.8 m (6 ft.) 90° bend hose

Part Number 76314, 3.0 m (10 ft.)

Part Number 350008

Inlet hoses are sold as a pair

in kit W10575888

Argentina Power Cord W11318405

British Power Cord W11318406

Euro Power Cord W11318407

Austrailia Power Cord W11318408

Accessories

If You Have: You Will Need:

Washer Drip Trays

Part Number 8212526

Fabric Softener Dispenser Kit

Part Number 63594

Drain beyond the reach

of drain hose

1.2 m (4 ft.) Drain Hose Extension

Part Number DRNEXT4

6

Page 7

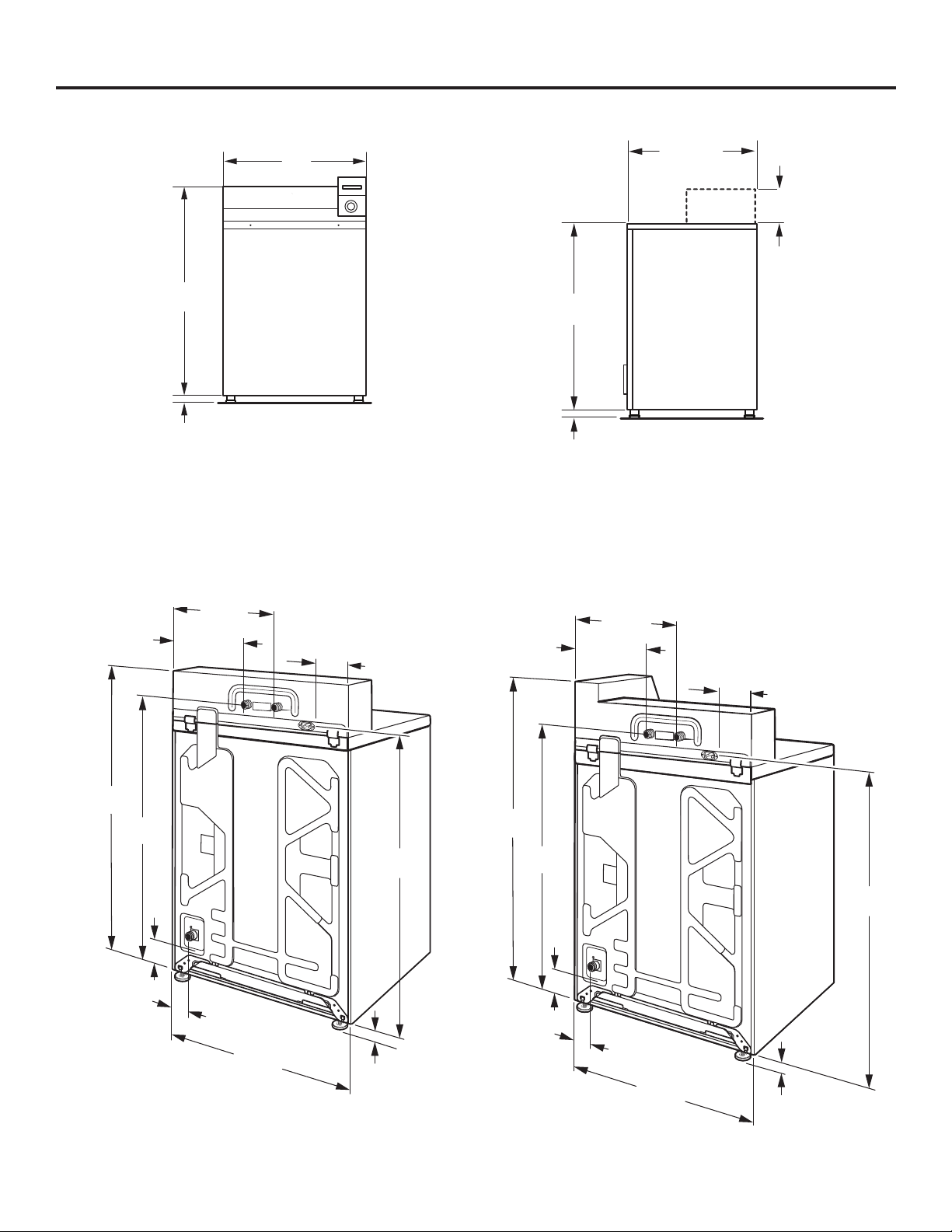

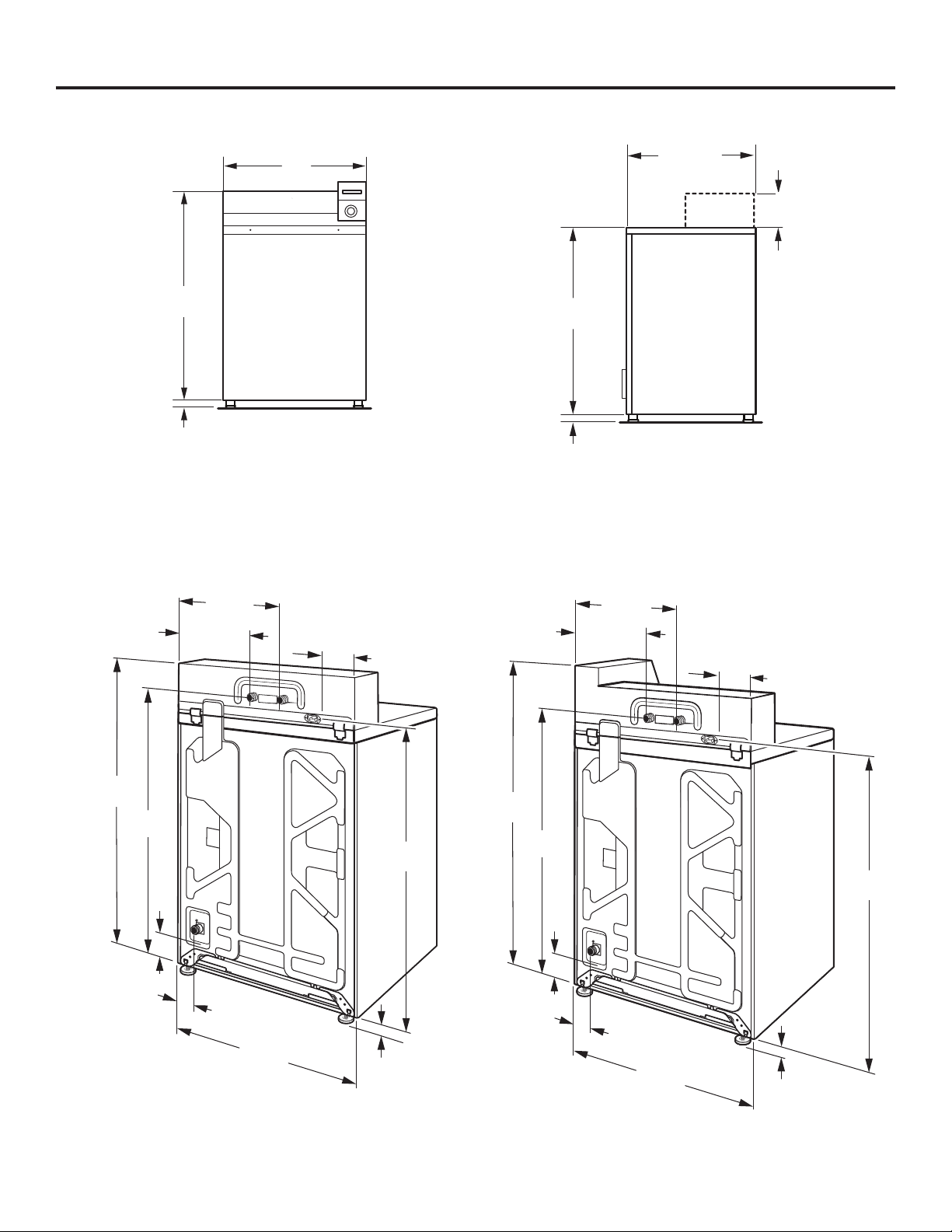

DIMENSIONS

406 mm

Front View Side View

1.080 m

1

/2")

(42

25mm

25 mm

(1")

(1")

686 mm

(27")

921 m

1

(36

/4")

25 mm

686 mm

(27")

(1")

Back View

Non-coin-operated models Coin-operated models

Non-coin-operated

models:

159 mm (61⁄4")

210 mm

1

Coin-operated

(8

/4")

models:

210 mm (91⁄4")

267 mm

(101/2")

1.080 m

(421/2")

946 mm

(371/4")

171 mm

(6

3

/4")

(16")

108 mm

(41/4")

686 mm

(27")

140 mm

(51/2")

933 mm

(36

25 mm

(1")

3

/4")

267 mm

(10

1.130 m

(441/2")

946 mm

(37

171 mm

3

(6

1

/4")

/2")

1

/4")

406 mm

(16")

108 mm

(41/4")

686 mm

(27")

140 mm

(51/2")

933 mm

(363/4")

25 mm

(1")

7

Page 8

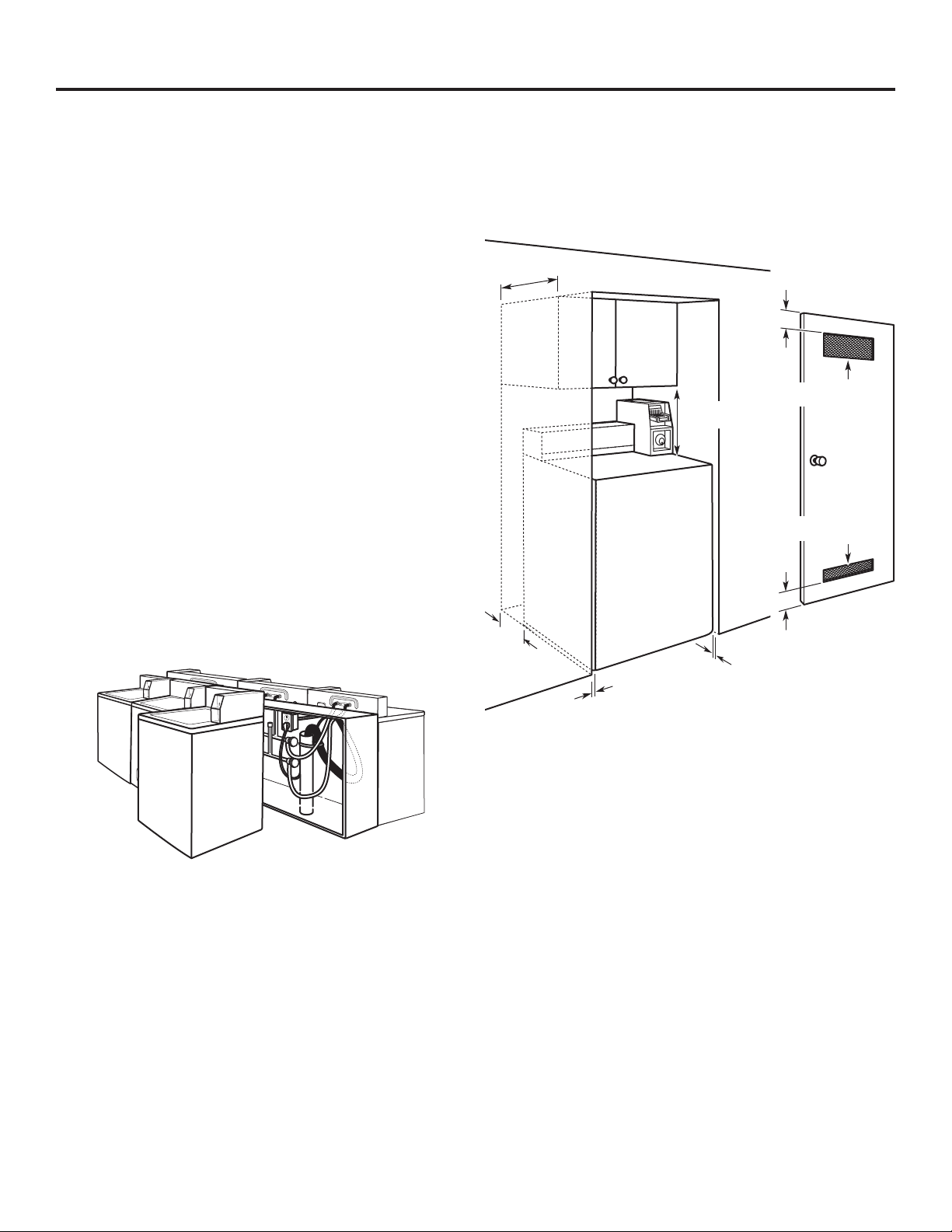

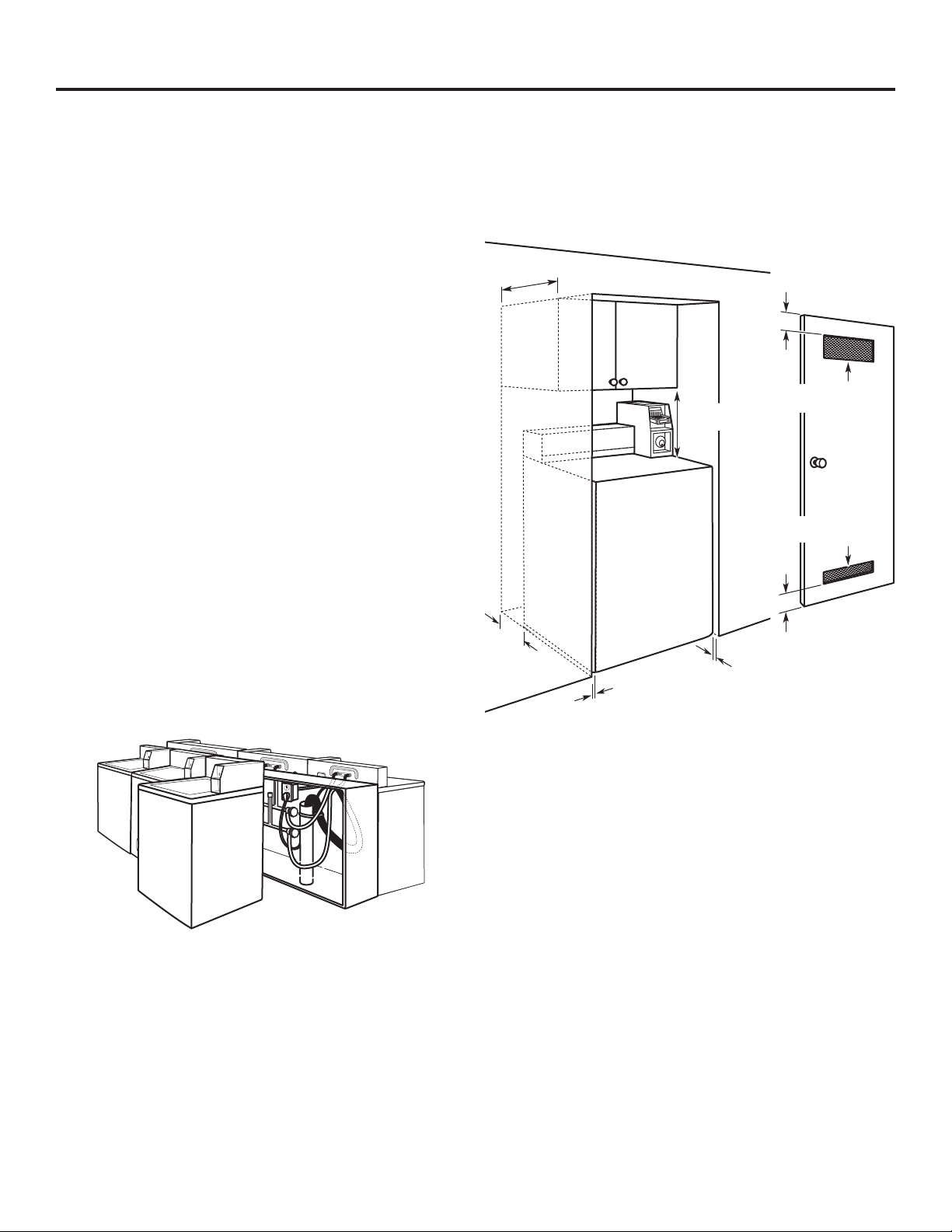

LOCATION REQUIREMENTS

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room,

or recessed area. See “Drain System.”

Companion appliance location requirements should also be

considered.

IMPORTANT: Do not install or store the washer where it will

be exposed to the weather. Do not store or operate the washer

in temperatures at or below 0°C (32°F). Some water can remain

in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

You will need:

n A water heater set to 49°C (120°F).

n An earthed electrical outlet located within 1.2 m (4 ft.) of

power cord on back of washer. See “Electrical Requirements.”

n Hot and cold water faucets located within 1.2 m (4 ft.) of hot

and cold water ll valves on washer, and water pressure

of 138–690 kPa (20–100 psi). A pressure reduction valve

should be used in the supply line where inlet pressure

entering the building exceeds 690 kPa (100 psi) to avoid

damage to the washer mixing valve.

n Single washer installations require 300 mm (12") minimum

risers to provide an air cushion and avoid noise and damage

to valves.

n A level oor with maximum slope of 25 mm (1") under entire

washer. Installing on carpet is not recommended.

n Floor must support washer’s total weight (with water and load)

of 143 kgs (315 lbs).

n A oor drain under the bulkhead. Prefabricated bulkheads

with electrical outlets, water inlet lines, and drain facilities

should be used only where local codes permit.

Recessed Area or Closet Installation

This washer may be installed in a recessed area or closet.

The installation dimensions shown are the minimum spaces

allowable. Additional spacing should be considered for ease of

installation and servicing. Companion appliance spacing should

be considered.

Minimum installation spacing

356 mm

(14" max.)

127 mm

(5")

25 mm

(1")

457 mm

406 mm

(18")

(16")

25 mm

76 mm

(3"/3")

310 cm2

(48 inch2/48 inch2)

155 cm2

(24 inch2/24 inch2)

76 mm

(3"/3")

(1")

8

Page 9

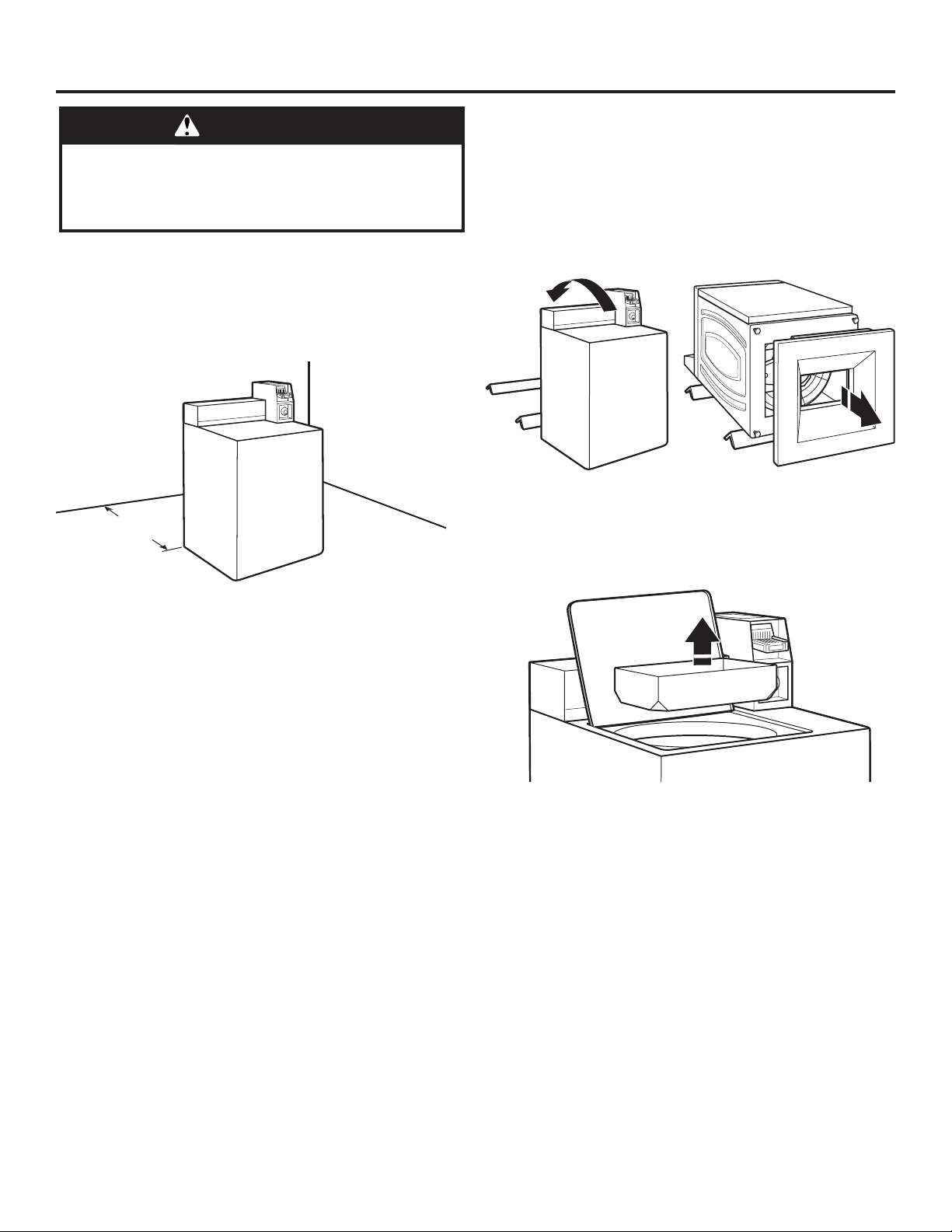

INSTALLATION INSTRUCTIONS

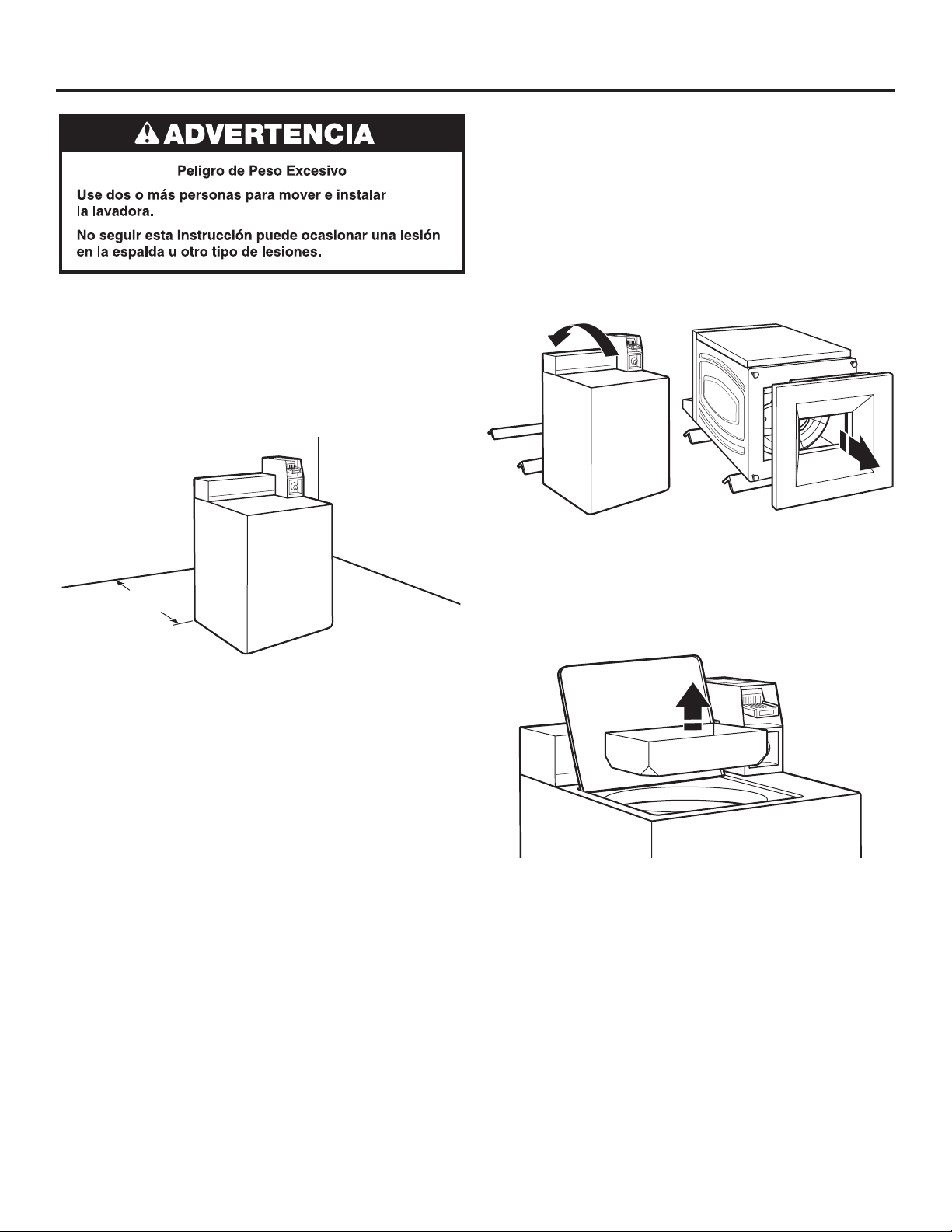

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

It is necessary to remove all shipping materials for proper

operation and to avoid excessive noise from washer.

1. Move washer to within 1.2 m (4 ft.) of its nal location; it must

be in a fully upright position.

NOTE: To avoid oor damage, set washer onto cardboard

before moving it and make sure lid is taped shut.

1.2 m

1,2 m

(48")

(48")

2. To avoid damaging oor, place cardboard supports from

shipping carton on oor behind washer. Tip washer back

and place on cardboard supports. Remove shipping base.

Set washer upright.

IMPORTANT: Removing shipping base is necessary for proper

operation. If your washer includes a sound shield, please refer

to the instructions included with the sound shield to install it

at this time.

NOTE: Keep shipping base in case you need to move washer

later.

3. Remove tape from washer lid, open lid, and remove cardboard

packing tray from tub. Be sure to remove all parts from tray.

NOTE: Tray must be removed prior to plugging the washer

into an outlet. Keep tray in case you need to move washer

later.

9

Page 10

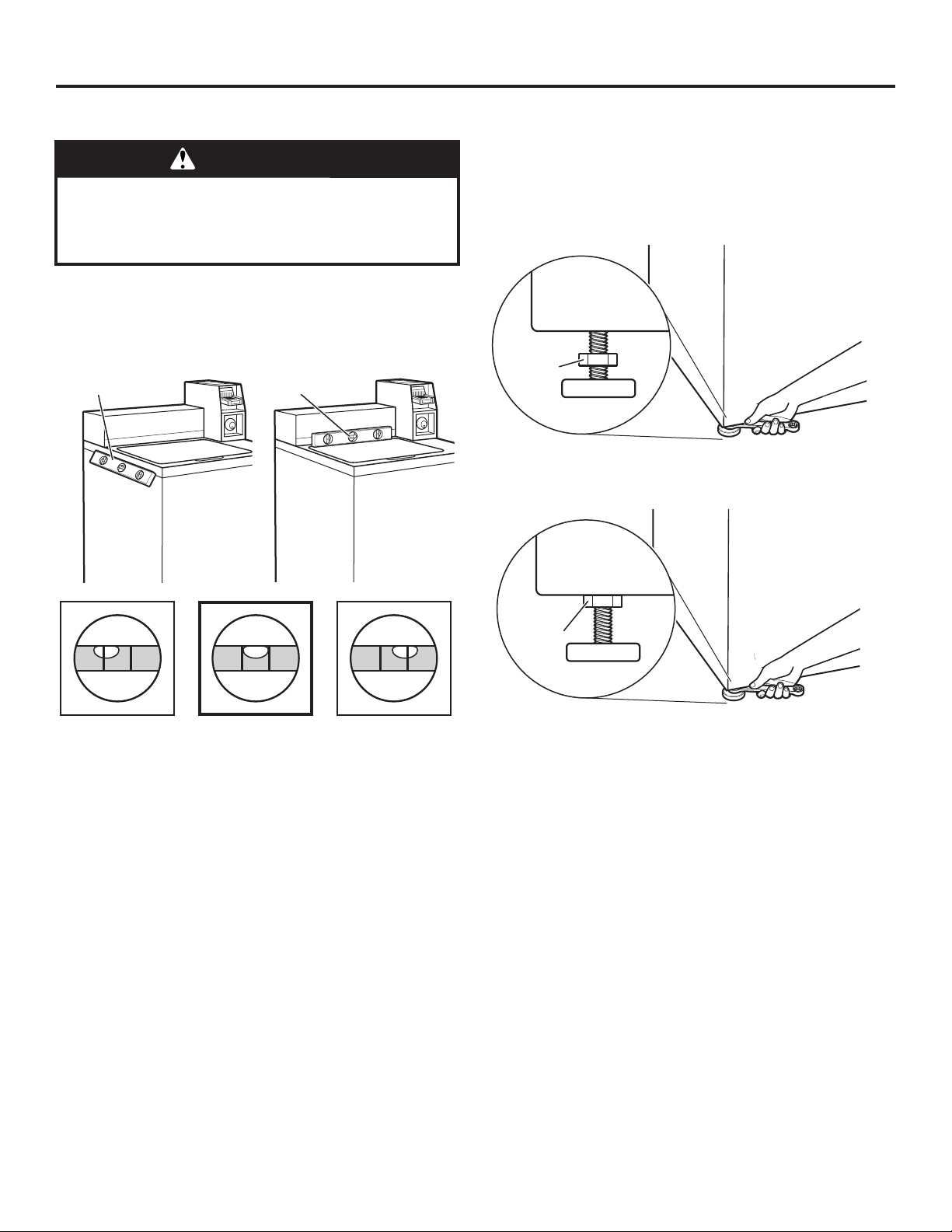

LEVEL WASHER

IMPORTANT: Level washer properly to reduce excess noise

and vibration.

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

1. Move the washer to its nal location. Place a level on top

edges of washer. Use side seam as a guide to check levelness

of sides. Check levelness of front using lid, as shown. Rock

washer back and forth to make sure all four feet make solid

contact with oor.

Place level here

Place level here

Place level here

Place level here

2. Use a 14 mm or 9/16" open-end or adjustable wrench to turn

jam nuts clockwise on feet until they are about 13 mm (1/2")

from the washer cabinet. Then turn the leveling foot clockwise

to lower the washer or counterclockwise to raise the washer.

Recheck levelness of washer and repeat as needed.

HELPFUL TIP: You may want to prop up front of washer about

102 mm (4") with a wood block or similar object that will support

weight of washer.

Jam nut

Jam nut

3. When washer is level, use a 14 mm or 9/16" open-end

or adjustable wrench to turn jam nuts counterclockwise

on leveling feet tightly against washer cabinet.

Not Level LEVEL Not Level

Jam nut

Jam nut

10

Page 11

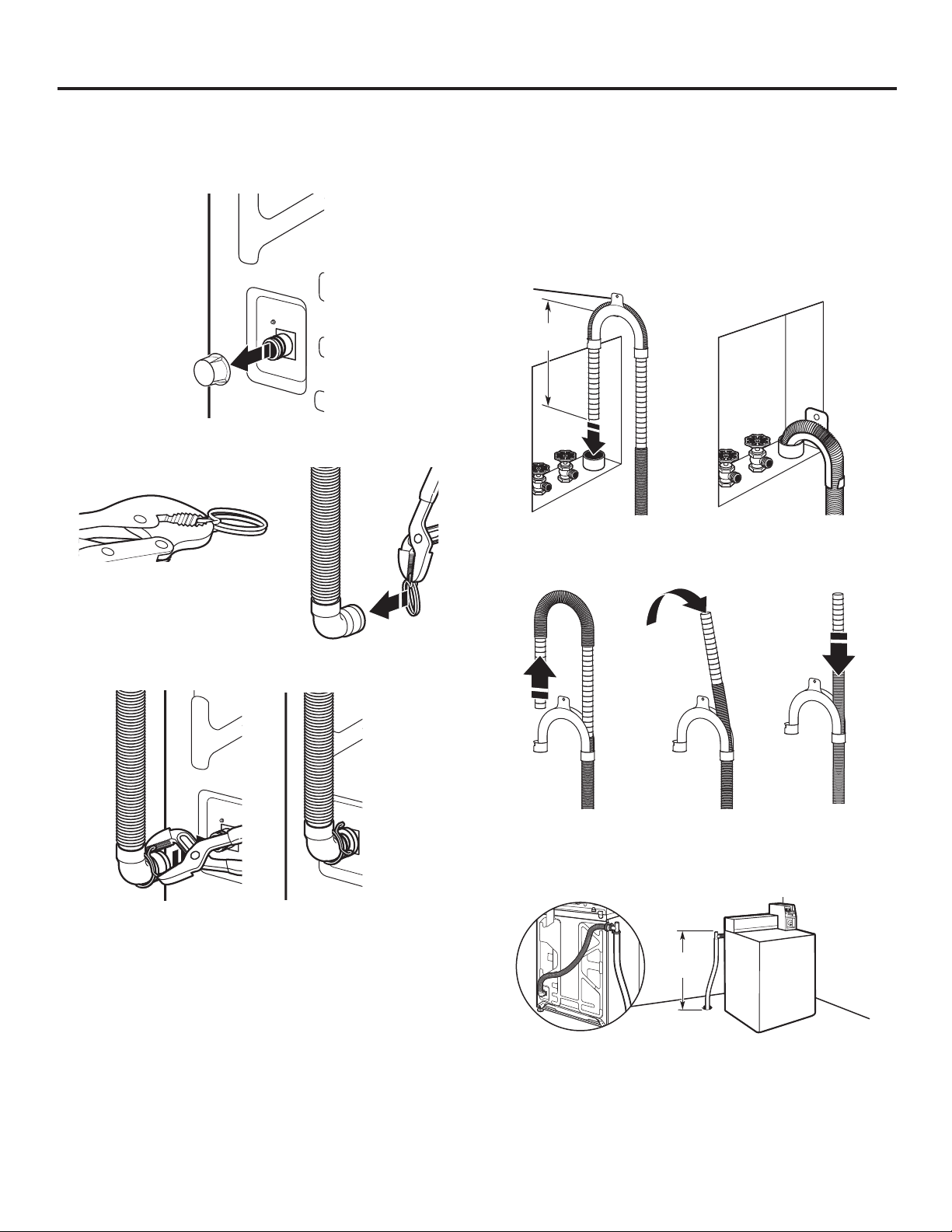

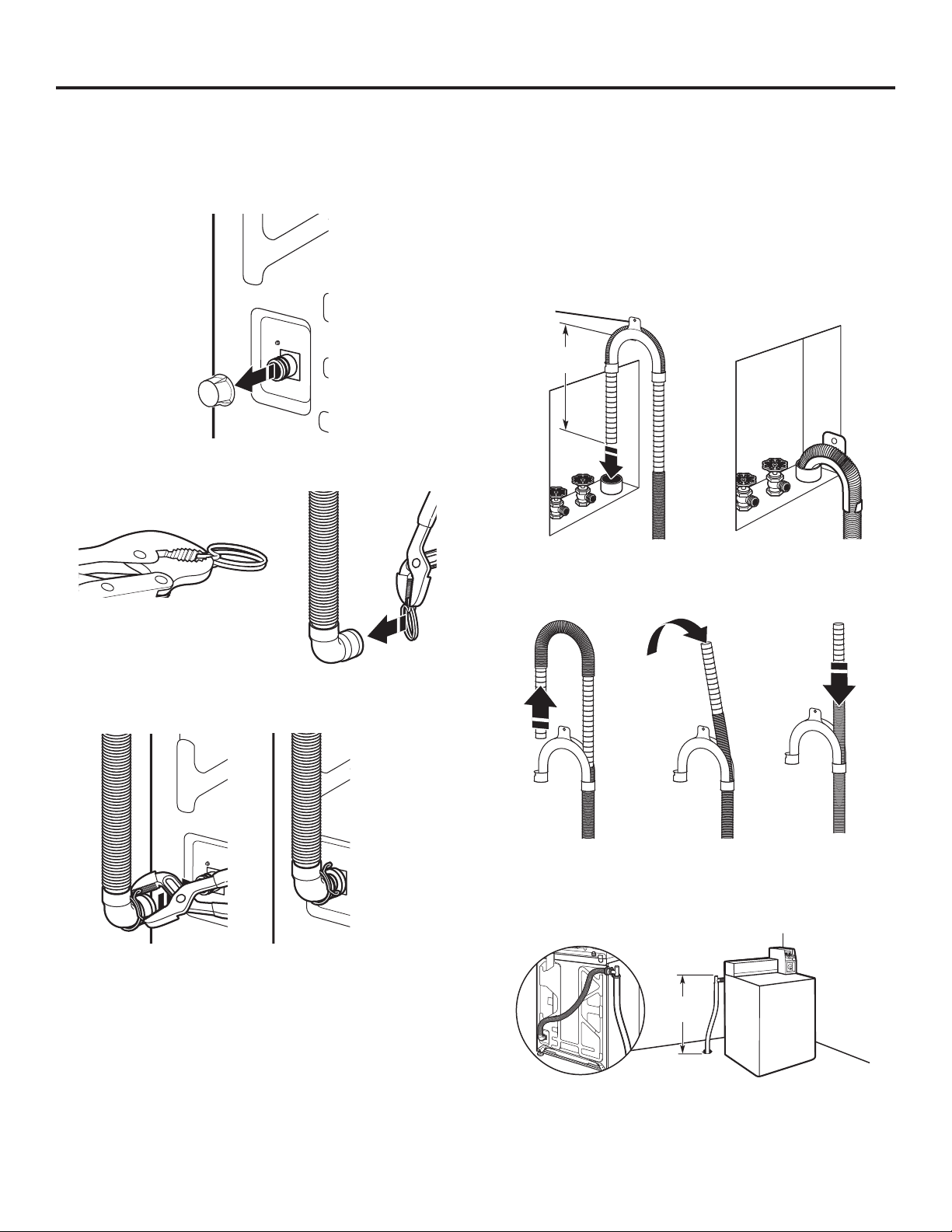

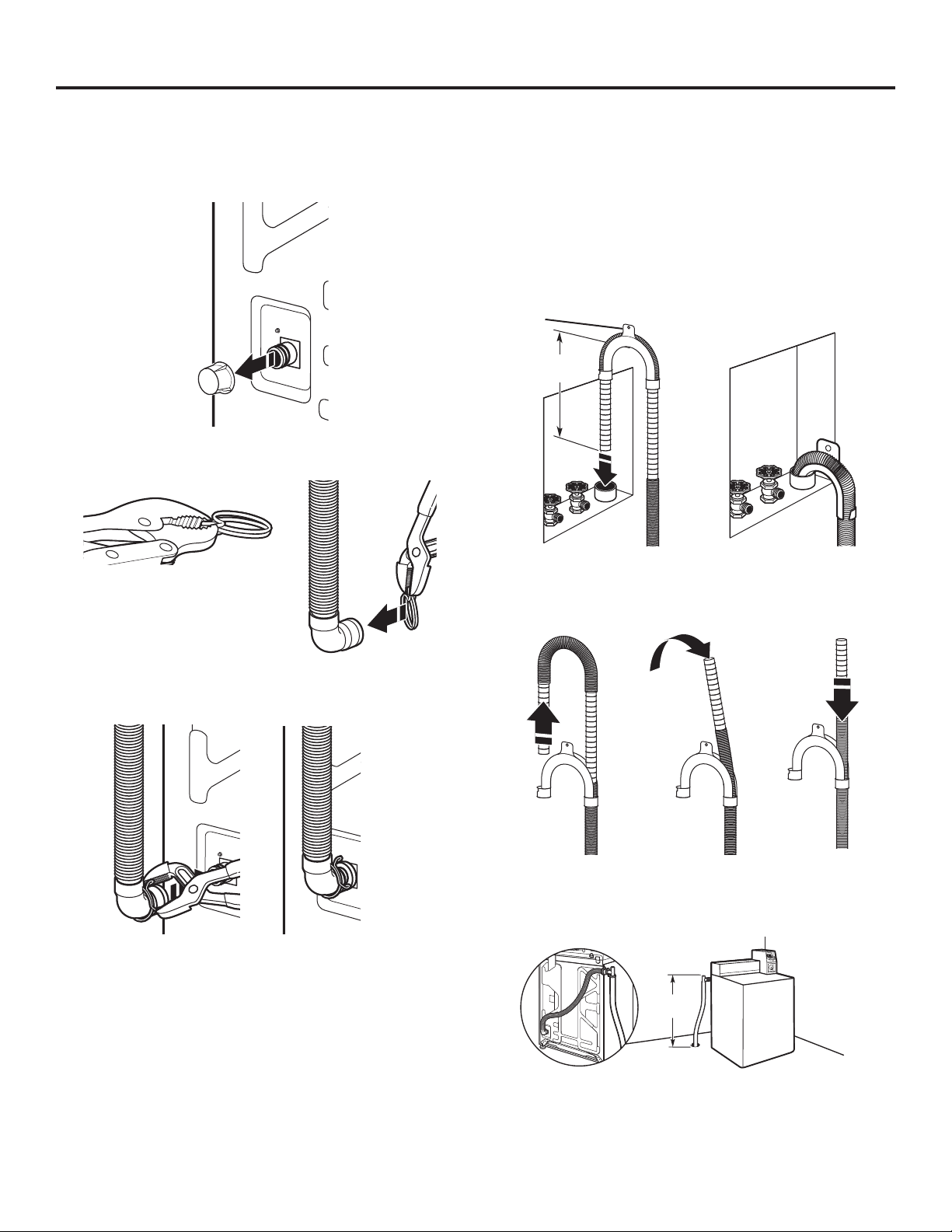

CONNECT DRAIN HOSE

Proper routing of the drain hose avoids damage to your oor

due to water leakage.

Remove drain hose from the washer basket

1. Remove cap from the washer drain port on the back

of the washer.

2. If clamp is not already in place on elbow end of drain hose,

slide it over end as shown.

5. Place hose into standpipe (shown in picture) or over side

of laundry tub.

IMPORTANT:

n Drain hose is not to exceed 203 mm (8") into drain pipe;

do not force excess hose into standpipe or lay on bottom

of laundry tub. Drain hose form must be used.

n It is the responsibility of the installer to install and secure

the drain hose into the provided plumbing/drain in a

manner that will avoid the drain hose coming out of,

or leaking from, the plumbing/drain.

Drain

hose

form

203 mm

8"

(8")

(203 mm)

6. For oor drain installations, you will need to remove the drain

hose form from the end of the drain hose. You may need

additional parts with separate directions. See “Tools and Parts.”

3. Squeeze clamp with pliers and slide elbow end of drain

hose onto washer drain port and secure with clamp.

4. The washer drain system can be installed using a oor drain,

wall standpipe, oor standpipe, or laundry tub.

7. The oor drain system requires a siphon break that may be

purchased separately. The siphon break (Part Number 285320)

must be a minimum of 710 mm (28") from the bottom of the

washer. Additional hoses might be needed.

710 mm

(28")

11

Page 12

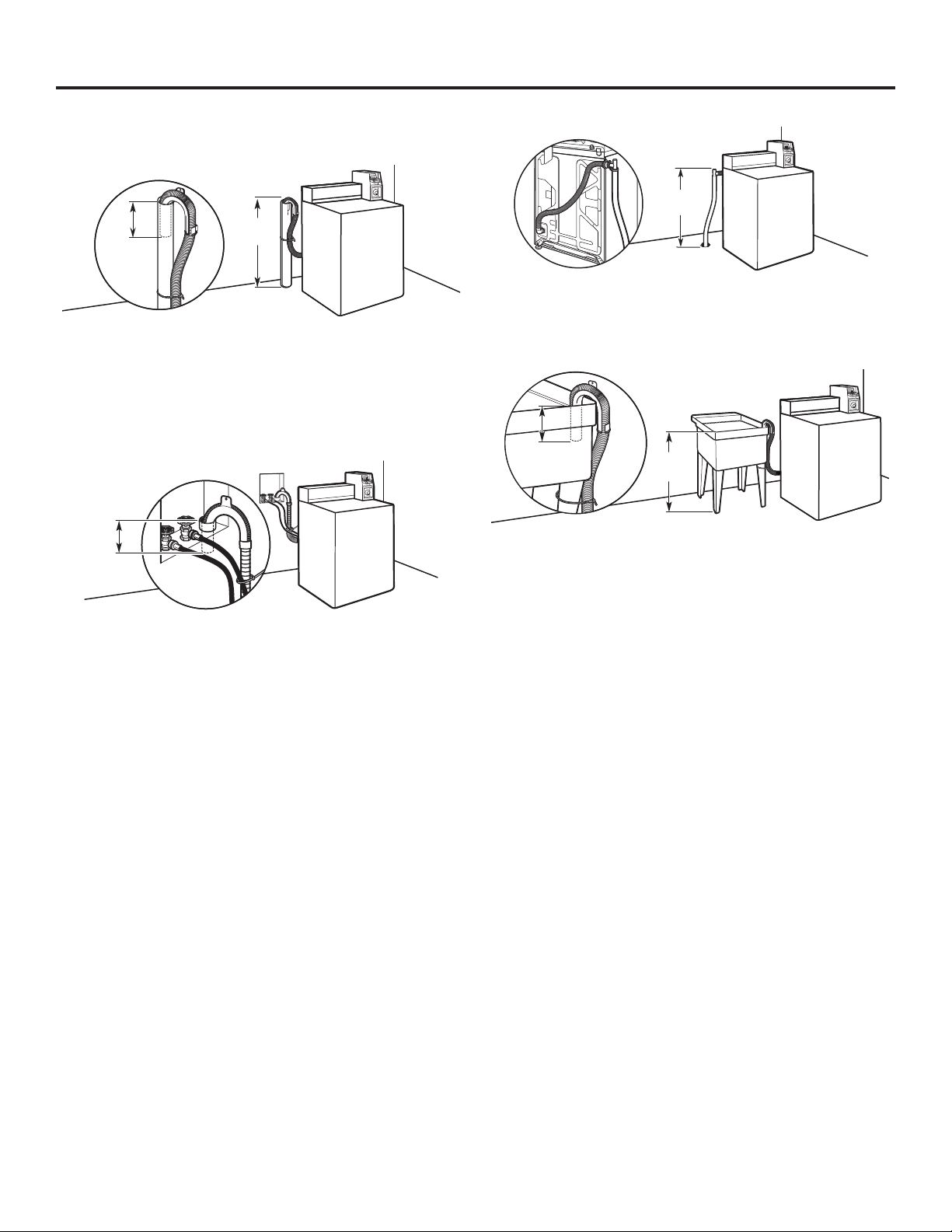

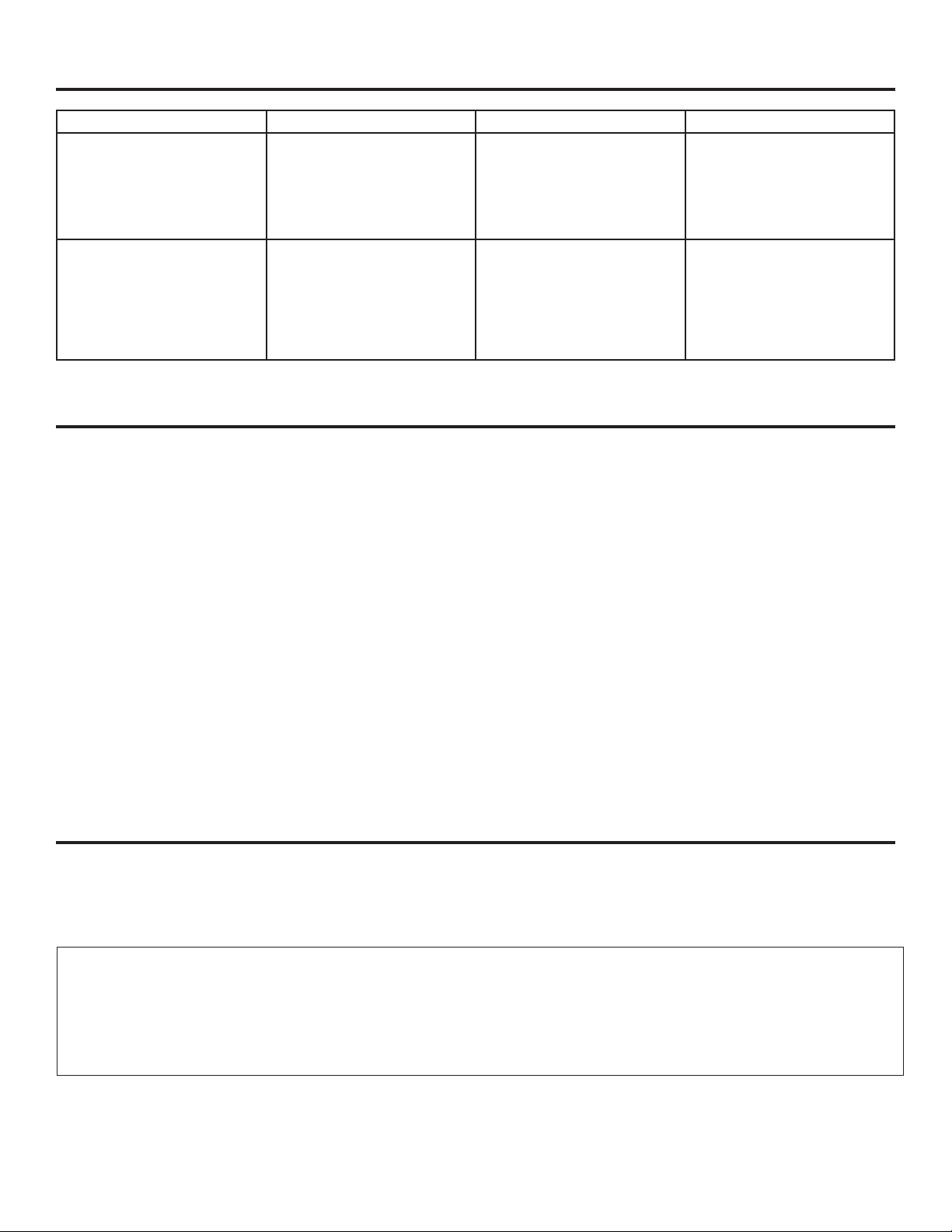

DRAIN SYSTEM

Drain system can be installed using a oor drain, wall standpipe,

oor standpipe, or laundry tub. Select method you need.

Floor standpipe drain system

990 mm

203 mm

(8")

Minimum diameter for a standpipe drain: 51 mm (2"). Minimum

carry-away capacity: 38 L (10 gal.) per minute. Top of standpipe

must be at least 990 mm (39") high; install no higher than

2.44 m (96") from bottom of washer.

(39")

Wall standpipe drain system

203 mm

(8")

Floor drain system

710 mm

(28")

Floor drain system requires a Siphon Break Kit

(Part Number 285320). Minimum siphon break: 710 mm (28")

from bottom of washer. Additional hoses may be needed.

Laundry tub drain system

203 mm

(8")

Minimum capacity: 76 L (20 gal.). The top of the laundry tub

must be at least 990 mm (39") above oor.

990 mm

(39")

See requirements for oor standpipe drain system.

12

Page 13

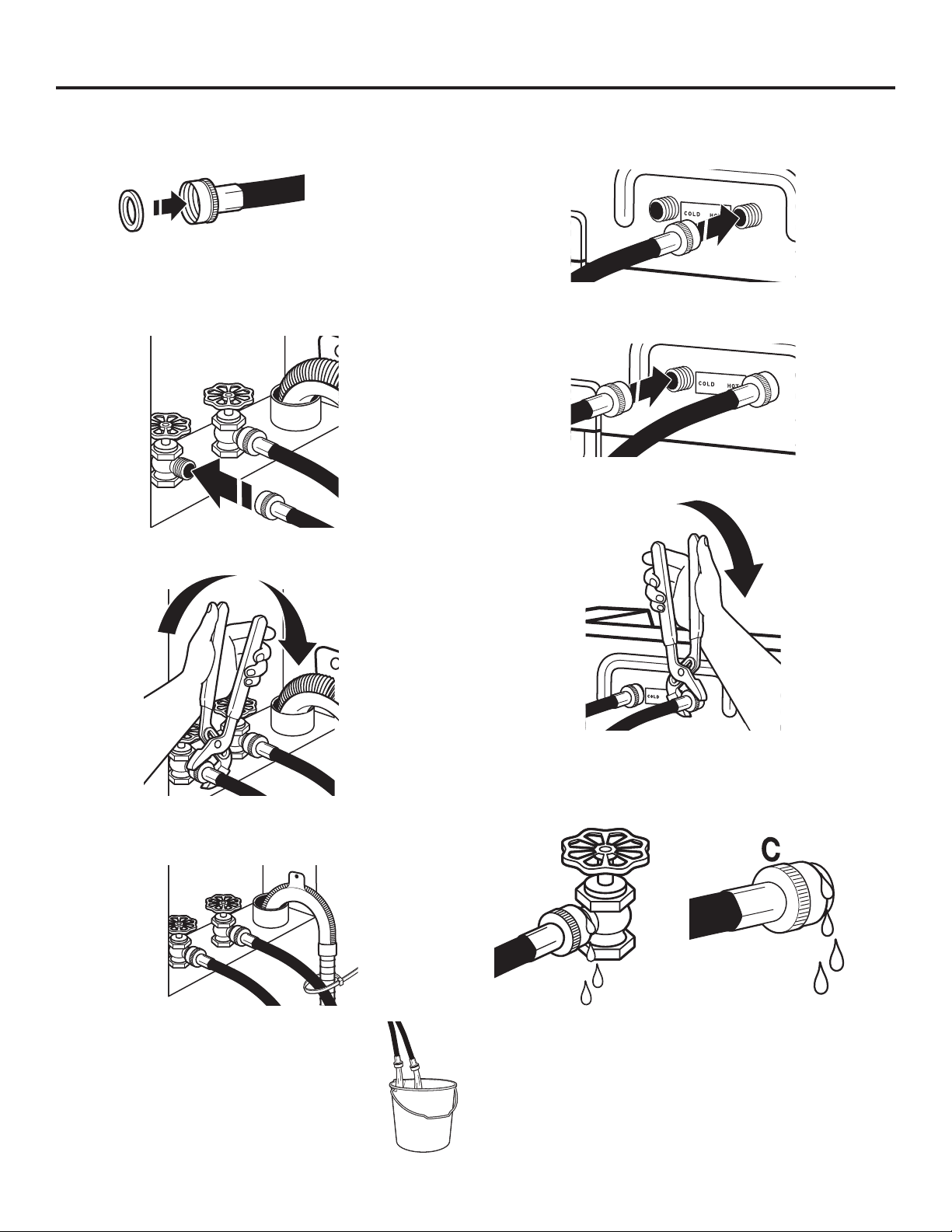

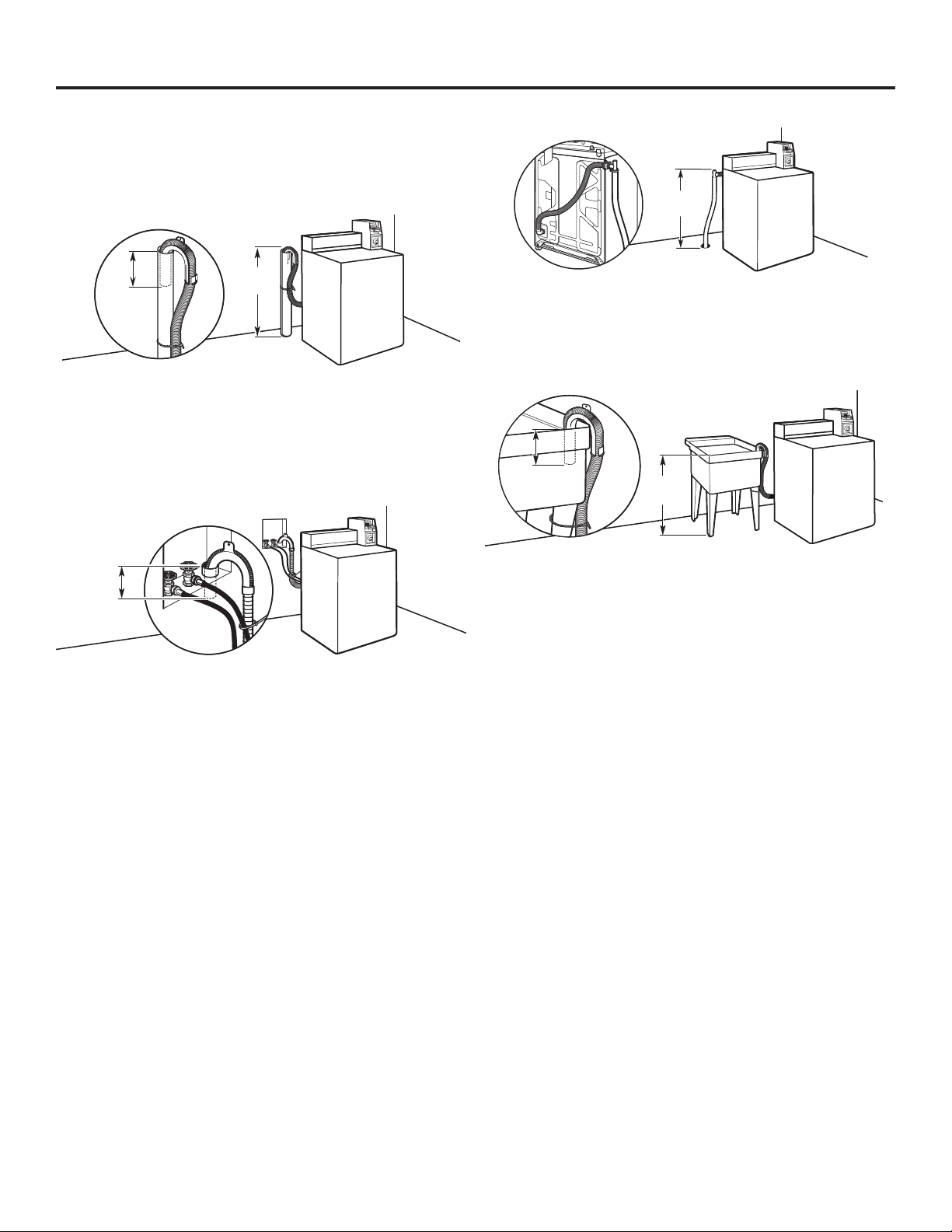

CONNECT INLET HOSES

Insert new hose washers (supplied) into each end of the inlet

hoses. Firmly seat the washers in the couplings.

NOTE: Use new hoses supplied with the washer. Do not reuse

old hoses.

CouplingWasher

Connect Inlet Hoses to Water Faucets

1. Attach hose to hot water faucet. Screw on coupling until

it is seated on washer. Repeat process for cold water.

2. Use pliers to tighten the couplings an additional

two-thirds turn.

Connect Inlet Hoses to Washer

1. Attach cold water hose to cold water inlet valve marked with

a blue ring. Screw coupling by hand until it is snug.

2. Attach hot water hose to hot water inlet valve marked with

a red ring. Screw coupling by hand until it is snug.

3. Use pliers to tighten couplings an additional two-thirds turn.

IMPORTANT: Do not overtighten or use tape or sealants on valve

when attaching to faucets or washer. Damage can result.

3. Secure drain hose to inlet hose with zip strap.

Clear Water Lines

n Run water through both faucets and inlet hoses,

into a laundry tub, drainpipe, or bucket to get

rid of particles in the water lines that might clog

the inlet valve screens.

n Check the temperature of the water to make

sure that the hot water hose is connected to

the hot water faucet and that the cold water

hose is connected to the cold water faucet.

NOTE: Do not overtighten. Damage to the valve can result.

4. Turn on water faucets to check for leaks. A small amount

of water may enter washer. It will drain later.

NOTE: Replace inlet hoses after ve years of use to reduce

the risk of hose failure. Record hose installation or replacement

dates on the hoses for future reference.

Periodically inspect and replace hoses if bulges, kinks, cuts,

wear, or leaks are found.

13

Page 14

ELECTRICAL REQUIREMENTS

n A 220–240 V, 50 Hz, AC-only, 10 A, fused electric supply is

required. A time-delay fuse or circuit breaker is recommended.

It is recommended that a separate circuit serving only this

appliance be provided.

n After installation, access to mains plug or disconnection from

mains supply via a double-pole switch must be ensured at all

times in order to ensure immediate deactivation of the washer

in case of emergency.

n This washer has provided with an appliance inlet intended

to be attached to a power supply cord. The plug should

be accessible for disconnection from the supply. Internal

connection part number W11323676. Available power cord

part numbers listed in Alternate Parts & Accessories Section.

n If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or similarly qualied persons

in order to avoid a hazard.

EARTHING INSTRUCTIONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance – if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

14

Page 15

COMPLETE INSTALLATION

Check that all parts are now installed. If there is an extra part,

q

go back through steps to see what was skipped.

Check that you have all of your tools.

q

Check that shipping materials were completely removed

q

from washer.

Dispose of/recycle all packaging materials.

q

Check that the water faucets are on.

q

Check for leaks around faucets and inlet hoses.

q

Remove lm from console and any tape remaining on

q

washer.

Plug into an earthed outlet or connect power.

q

Check that circuit breaker is not tripped or fuse is not blown.

q

Start washer using the payment system (if available) to

q

check that the wash cycle completes without an error code

or water leak.

Check electrical requirements. Be sure that you have the

q

correct electrical supply and the recommended earthing

method.

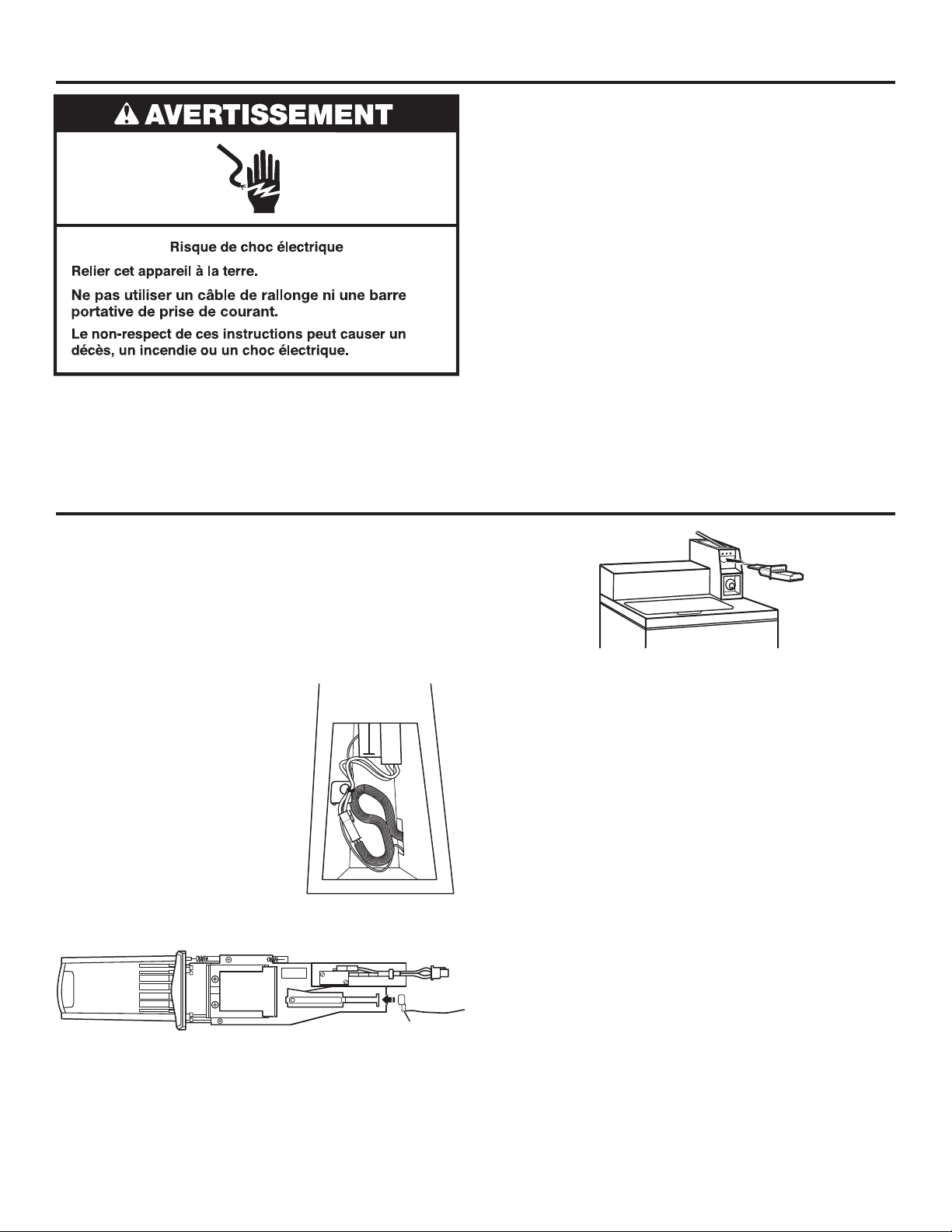

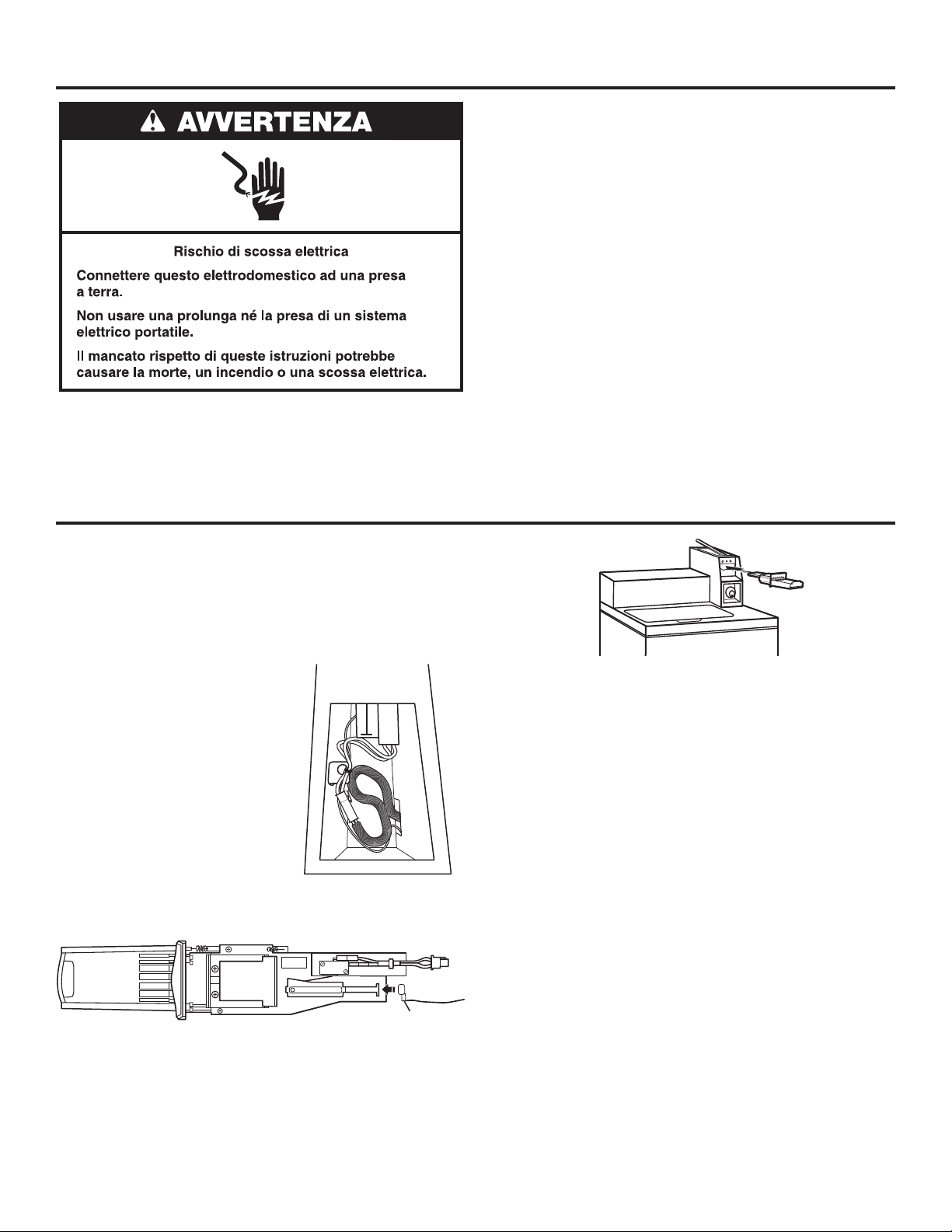

INSTALLING COIN SLIDE AND COIN BOX

The coin slide mechanism, service door lock and key, and coin

box lock and key are not included with some models but can

be obtained from the usual industry sources. The coin slide

(W10813856) supplied by Greenwald was used for testing and

evaluation purposes. If a different supplier is used, ensure that

the switch is D41 or a similarly qualied switch construction.

Alternative constructions require review by

a Whirlpool codes engineer.

Remove the service door of the

meter case by lifting it up at the

back. Install the money-accepting

device. (Refer to manufacturer’s

instructions for proper installation.)

Extra wire should be coiled and

tie-wrapped to the mounting hole

inside the meter case.

An earthing connection is needed

for the coin slide, which can be

made by connecting the available

harness (W10846503) to the coin

slide. The provided earthing clip is

designed for 0.89–1.27 mm material

thickness.

Install a lock and cam on the meter case service door. Install

the coin vault with lock and key in the meter case opening.

For Free Vend, an OPL kit can be purchased from Whirlpool.

Whirlpool part number W10222023.

Earthing

Earthing

connection

connection

15

Page 16

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS (PD & PN MODELS)

Basic Operation of Commercial Washer

n For additional information, see

www.maytagcommerciallaundry.com.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is nished, but

failure may occur at a later date due to ESD stress.

n Use an anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the washer.

-OR-

Touch your nger repeatedly to a green earth connection point

or unpainted metal in the washer.

n Before removing the part from its package, touch the

anti-static bag to a green earth connection point or

unpainted metal in the washer.

n Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

n When repackaging failed electronic control assembly in

anti-static bag, observe above instructions.

Cold Start (initial use)

Washer is programmed at the factory as follows:

n POWERWASH = 12 min agitation

NORMAL = 9 min agitation

DELICATES = 6 min agitation

NORMAL ECO = 8 min agitation

n NORMAL = 1 rinse and 2 minutes of rinse agitation

POWERWASH = 1 deep rinse with spin-out

DELICATES = 1 deep rinse with spin-out

NORMAL ECO = 1 spray rinse

n NORMAL = $2.00

DELICATES = $1.75

POWERWASH = $2.50

NORMAL ECO = $1.75

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to

the portion of the cycle that existed at time of the power failure.

To continue the cycle, press START/PAUSE.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, “SELECT CYCLE” will appear and cycle price will show

“0.00.”

Display

After the washer has been installed and plugged in, the display

will show “SYnC” for a few seconds, then “0 MINUTES.” Once

the washer has been plugged in and the washer lid opened and

closed, the display will show the price. In washers set for free

cycles, the display will ash “SELECT CYCLE,” and will display

“PRICE 0.00.”

OPTIONSCYCLES

POWERWASH

NORMAL

DEEP WATER

DELICATES

NORMAL

ECO

TEMPERATURE

SOIL LEVEL

EXTRA RINSE

GENERAL INFORMATION

Blank Display

This condition indicates the washer is inoperative.

“0 Minutes” showing in display

This condition indicates the washer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in

escrow but cannot be used until normal operation is restored by

opening and closing the door. If a door switch fails, it must be

replaced before normal operation can be restored.

16

Page 17

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

Control Set-Up Procedures

IMPORTANT: Read all instructions before operating.

The top three key pads on the left side, the top key pad on the

right side, and the digital display are used to set up the controls.

The display can contain four numbers and/or letters and a

decimal point. These are used to indicate the set-up codes and

related code values available for use in programming the washer.

How to use the key pads to program the controls

1. The POWERWASH key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value.

Rapid adjustment is possible by holding the key pad down.

2. The NORMAL key pad will advance you through the

set-up codes. Pressing the key pad will advance you to

the next available set-up code. Holding the key pad down

will automatically advance through the set-up codes at a rate

of one (1) per second.

3. The DELICATES key pad is used to select or deselect options.

4. The TEMPERATURE key pad is used to decrease set-up code

value.

Start Operating Setup

n PD Models: Insert access door key, turn, and lift to remove

access door.

n PR models set for free vend: Refer to bottom of page for

operating setup.

IMPORTANT: The console must not be opened unless power

is rst removed from the washer. To access connector AA1:

g Unplug washer or disconnect power.

g Open console, disconnect plug on AA1, close console.

g Plug in washer or reconnect power.

The washer is now in the set-up mode.

Before proceeding, it is worth noting that, despite all of the

options available, an owner can simply choose to uncrate a new

commercial washer, hook it up, plug it in, and have a unit that

operates.

Set-Up Codes

n The NORMAL key pad will advance from code to code.

n The POWERWASH key pad will increase the code value.

n The DELICATES key pad will select or deselect options.

n The TEMPERATURE key pad will decrease the code value.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

CODE EXPLANATION

6.07

DELICATES

6.07

NORMAL

ECO

6.07

POWERWASH

6.08

NORMAL

g Press the NORMAL key pad once to advance to next code.

7.00 ADDITIONAL WASH TIME

7.00 This is the number of minutes that can be added to a Wash Cycle.

g Press the NORMAL key pad once to advance to next code.

8.00 ADDITIONAL RINSE TIME

8.00 This is the number of minutes that can be added to a

g Press the NORMAL key pad once to advance to next code.

9.00 CYCLE COUNTER OPTION

9.00 Not Selected “OFF.”

9.0C Selected “ON” and not able to be deselected.

g Press the NORMAL key pad once to advance to next code.

1.00 MONEY COUNTER OPTION

1.00 Not Selected “OFF.”

1.0C Selected “ON.”

1.C0 Selected “ON” and not able to be deselected.

g Press the NORMAL key pad once to advance to next code.

2.00 SPECIAL PRICING OPTION

2.00 Not Selected “OFF.”

2.SP Selected “ON.” Press the DELICATES key pad once for this

If SPECIAL PRICING OPTION is selected, there is access to codes “3.”

through “9.”.

NOTE: An external battery needs to be added to keep the clock running during

periods of power outages.

g Press the NORMAL key pad once to advance to next code.

DELICATES Regular Cycle Vend Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

NORMAL ECO Regular Cycle Vend Price – Increase or

decrease between 0 and 200 by pressing the POWERWASH

or TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

POWERWASH Regular Cycle Vend Price – Increase or

decrease between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

NORMAL Regular Cycle Vend Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 8 coins = $2.00.

Choose from 00–05 minutes by pressing the POWERWASH

key pad.

RINSE Cycle. Choose from 00–05 minutes by pressing the

POWERWASH key pad.

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

Press the DELICATES key pad three consecutive times to select

“ON.” Once selected “ON” it cannot be deselected.

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

Press the DELICATES key pad three consecutive times to select

“ON” and three consecutive times to remove (Not Selected

“OFF.”) Counter resets by going from “OFF” to “ON.”

To select “ON” and not able to be deselected, rst select “ON,”

then within two seconds press the DELICATES key pad twice,

the POWERWASH key pad once, and exit the set-up mode.

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

selection.

17

Page 18

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

CODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3.07

DELICATES

3.07

NORMAL ECO

3.07

POWERWASH

3.08

NORMAL

g Press the NORMAL key pad once to advance to next code.

5.00 TIME-OF-DAY CLOCK, MINUTES

5.00 This is the TIME-OF-DAY CLOCK, minute setting; select

g Press the NORMAL key pad once to advance to next code.

6.00 TIME-OF-DAY CLOCK, HOURS

6.00 This is the TIME-OF-DAY CLOCK, hour setting; select between

g Press the NORMAL key pad once to advance to next code.

7.00 SPECIAL PRICE START HOUR

7.00 This is the start hour; select between 0 and 23 hours by pressing

g Press the NORMAL key pad once to advance to next code.

8.00 SPECIAL PRICE STOP HOUR

8.00 This is the stop hour; select between 0 and 23 hours by pressing

g Press the NORMAL key pad once to advance to next code.

9.00 SPECIAL PRICE DAY

9.10 This represents the day of the week and whether special pricing

g Press the NORMAL key pad once to advance to next code.

DELICATES Special Cycle Vend Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

NORMAL ECO Special Cycle Vend Price – Increase between 0

and 200 by pressing the POWERWASH or decrease by pressing

the TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

POWERWASH Special Cycle Vend Price – Increase or

decrease between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 7 coins = $1.75.

NORMAL Special Cycle Vend Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 8 coins = $2.00.

between 0 and 59 minutes by pressing the POWERWASH or

TEMPERATURE key pad.

NOTE: Uses military time or 24 hr. clock.

0 and 23 hours by pressing the POWERWASH or TEMPERATURE

key pad.

NOTE: Uses military time or 24 hr. clock.

the POWERWASH or TEMPERATURE key pad.

NOTE: Uses military time or 24 hr. clock.

the POWERWASH or TEMPERATURE key pad.

is selected for that day. A number followed by “0” indicates no

selection that particular day (9.10). A number followed by an “S”

indicates selected for that day (9.1S).

Days of the week (1–7) can be chosen by pressing the

POWERWASH key pad. Press the POWERWASH key pad once

to select special pricing for each day chosen.

When exiting set-up code “9,” the display must show current day

of week:

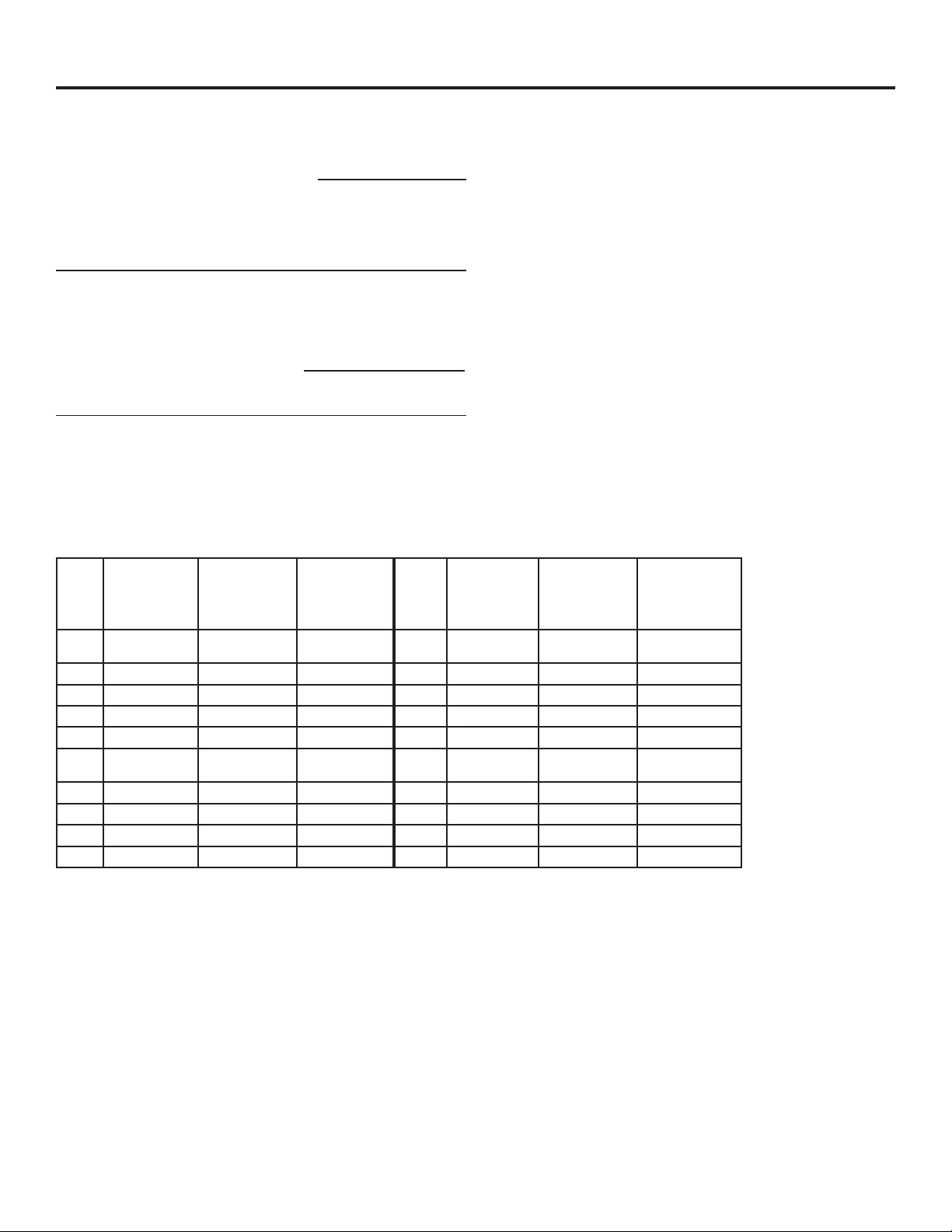

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

CODE EXPLANATION

A.00 VAULT VIEWING OPTION

A.00 Not Selected “OFF.”

A.SC Selected “ON.” Press the DELICATES key pad once for this

g Press the NORMAL key pad once to advance to next code.

b.05 VALUE OF COIN 1

b.05 This represents the value of coin 1 in number of 5% increments

g Press the NORMAL key pad once to advance to next code.

C.20 VALUE OF COIN 2

C.20 This represents the value of coin 2 in number of 5% increments

g Press the NORMAL key pad once to advance to next code.

d.00 COIN SLIDE OPTION

d.00 Not Selected “OFF.”

d.CS Selected “ON.” Press the DELICATES key pad three consecutive

g Press the NORMAL key pad once to advance to next code.

E.00 ADD COINS OPTION

E.00 Not Selected “OFF.”

E.AC Selected “ON.” Press the DELICATES key pad three consecutive

g Press the NORMAL key pad once to advance to next code.

H.00

COLD

H.00

COOL

H.00

WARM

H.00

HOT

H.00

HEAVY

18

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

selection. When selected, the money and/or cycle counts will be

viewable (depending on what is selected) when the coin box is

removed.

of the larger coin value. 5 x 5% = 25%.

By pressing the POWERWASH or TEMPERATURE key pad,

there is the option of between 1 and 199 for the quantity of 5%

increments.

of the larger coin value. 2 x 5% = 100%.

By pressing the POWERWASH or TEMPERATURE key pad,

there is the option of between 1 and 199 for the quantity of 5%

increments.

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

times for this selection.

When coin slide mode is selected, set “b.” equal to value of slide

in 5% increments. Set Step 6 (regular cycle price) and Step 3

(special cycle price) to number of slide operations. If the installer

sets up “CS” on a coin drop model, it will not register coins.

This option is either SELECTED “ON” or NOT SELECTED “OFF.”

This option causes the customer display to show the number

of coins (coin 1) to enter, rather than the monetary amount.

times for this selection.

COLD Temperature Upgrade Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 0 coins = $0.00.

COOL Temperature Upgrade Price – Increase or decrease

between 0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 1 coins = $0.25.

WARM Temperature Upgrade Price –

between

0 and 200 by pressing the POWERWASH or

TEMPERATURE key pad. Factory preset for 2 coins = $0.50.

HOT Temperature Upgrade Price – Increase or decrease between

0 and 200 by pressing the POWERWASH or TEMPERATURE key

pad. Factory preset for 3 coins = $0.75.

HEAVY SOIL LEVEL Upgrade Price

between 0 and 200 by pressing the

TEMPERATURE

key pad. Factory preset for 1 coins = $0.25.

Increase or decrease

–

Increase or decrease

POWERWASH

or

Page 19

ELECTRONIC CONTROLS SET-UP INSTRUCTIONS

CODE EXPLANATION

H.00

EXTRA

RINSE

EXTRA RINSE Upgrade Price - Increase or decrease between 0

and 200 by pressing the POWERWASH or TEMPERATURE key

pad. Factory preset for 1 coins = $0.25.

If cycle counter (9.0C) is selected, the following is true:

1 xx Number of cycles in THOUSANDS. 1 02 = 2,000

2xxx Number of cycles in ONES. 2225 = 225

TOTAL CYCLES = 2,225

g Press the NORMAL key pad once to advance to next code.

J.Cd COIN/DEBIT OPTION

J.Cd Both coin and debit selected.

J.C_ Coins selected, debit disabled. Press the DELICATES key pad

three times for this selection.

J._d Debit Card selected, coins disabled. Press the DELICATES key

pad three times for this selection.

J.Ed Enhanced Debit is self-selected when a Generation 2 card reader

is installed in the washer. The Ed option cannot be manually

selected or deselected.

g Press the NORMAL key pad once to advance to next code.

L.00 PRICE SUPPRESSION OPTION

This option causes the customer display to show “ADD”

or “AVAILABLE” rather than the amount of money to add.

(Used mainly in debit installations.)

L.00 Not Selected “OFF.”

If money counter (1.0C or 1.C0) is selected, the following is

true:

3 xx Number in THOUSANDS. 3 01 = $1,000.00

4xxx Number in ONES. 4600 = $ 600.00

5 xx Number of HUNDRETHS. 5 75 = $ 00.75

TOTAL = $1,600.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

n PD Models: Reinstall access door.

If preferred, just wait through two minutes of inactivity. All settings

will be saved and the display will revert to Select Cycle screen.

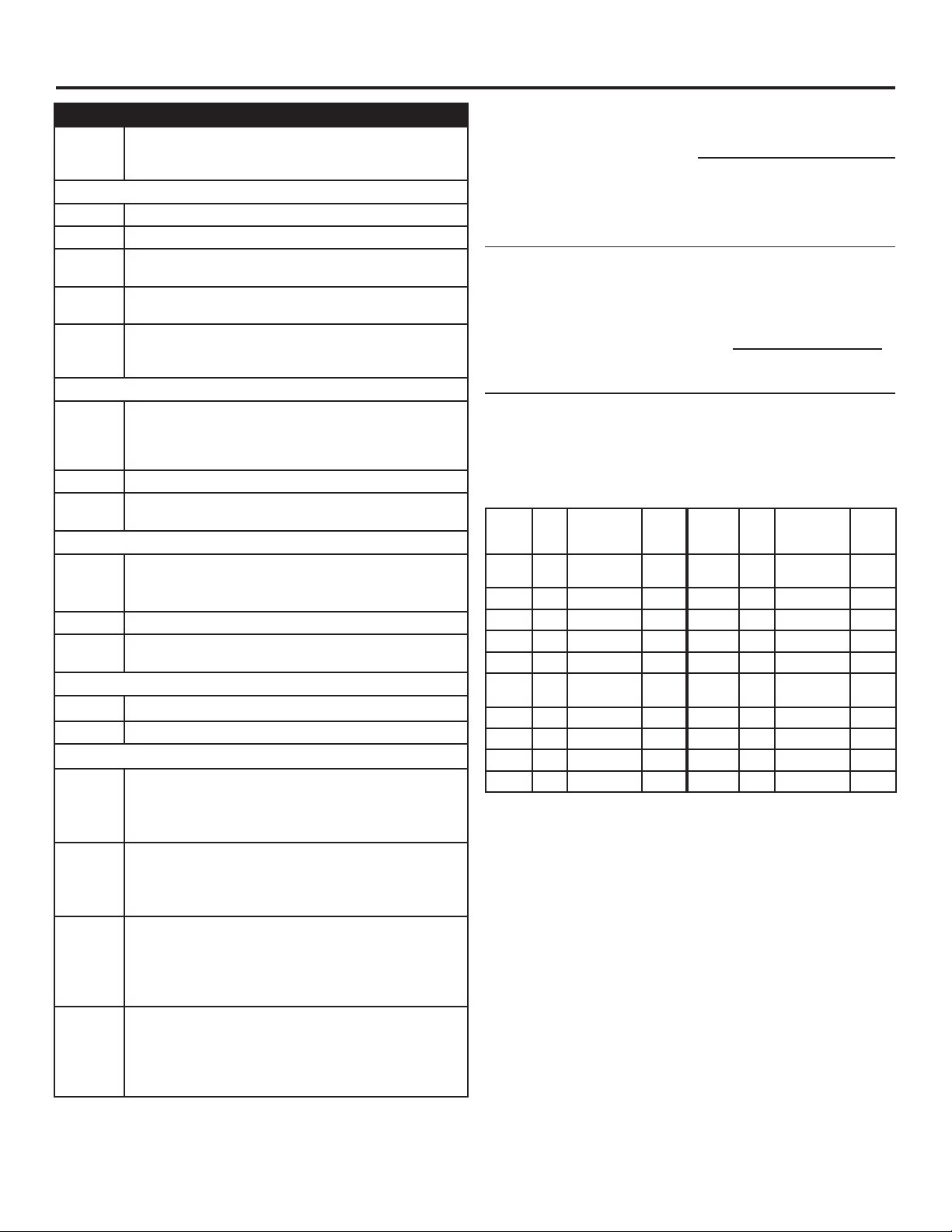

Table 1

L.PS Selected “ON.” Press the DELICATES key pad once for this

selection.

g Press the NORMAL key pad once to advance to next code.

n. CE CLEAR ESCROW OPTION

A3, A4,

A5, A6

00 Off Off Tap

When selected, money held in escrow for 30 minutes without

further escrow or cycle activity will be cleared.

n. CE Selected “ON.”

n. 00 Not selected “OFF.” Press the DELICATES key pad once to

deselect this selection.

g Press the NORMAL key pad once to advance to next code.

U.00 COIN (HUNDREDTH) INCREMENT OFFSET

U.00 For use with card reader applications only.

g Press the NORMAL key pad once to advance to next code.

A3.03 NORMAL Cycle Settings. Allows the owner to select the cycle

01 Off Off Cold 11 On Off Cold

02 Off Off Cool 12 On Off Cool

03 Off Off Warm 13 On Off Warm

04 Off Off Hot 14 On Off Hot

08 Off On Tap

09 Off On Cold 19 On On Cold

a Off On Cool 1A On On Cool

B Off On Warm 1B On On Warm

C Off On Hot 1C On On Hot

default options of Water Temperature, Soil Level, and Extra Rinse.

See Table 1 for specic settings. Normal is set to 03 from the

factory.

A4.01 DELICATES Cycle Settings. Allows the owner to select the cycle

default options of Water Temperature, Soil Level, and Extra Rinse.

See Table 1 for specic settings. Delicates is set to 01 from the

factory.

A5.1C POWERWASH Cycle Settings. Allows the owner to select the

cycle default options of Water Temperature, Soil Level, and Extra

Rinse.

See Table 1 for specic settings. Powerwash is set to 1C from the

factory.

A6.03 NORMAL ECO Cycle Settings. Allows the owner to select the

cycle default options of Water Temperature, Soil Level, and Extra

Rinse.

See Table 1 for specic settings. Normal Eco is set to 03 from the

factory.

Technician Service Access Code

This method is only available on PR washers set to free vend

(6 00).

To enter service mode:

Press the POWERWASH, EXTRA RINSE, TEMPERATURE, and

DELICATES key pads within 10 seconds.

To exit service mode:

Wait two minutes without touching any key pads (without

diagnostic modes running)

or

Power down the washer; then reapply power.

NOTE: If a service cycle is in progress upon exiting service mode,

the cycle will complete normally with cycle status information

displayed. The display will resume normal customer operation

mode when the cycle ends.

This is “VIEW ONLY” and cannot be cleared.

Press the NORMAL key pad once to advance

to next code.

Extra

Rinse

Soil Level

(Heavy-On,

Normal-Off)

Water

Temp

Cold

Cold

A3, A4,

A5, A6

Extra

Soil Level

Rinse

(Heavy-On,

Normal-Off)

10 On Off Tap

18 On On Tap

Water

Temp

Cold

Cold

19

Page 20

WASHER DISPOSAL

This appliance is marked according to the European directive 2012/19/EU on Waste Electrical and Electronic Equipment

(WEEE).

By ensuring this product is disposed of correctly, you will help avoid potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate waste handling of this product.

The symbol on the product, or on the documents accompanying the product, indicates that this appliance may not be

treated as household waste. Instead it shall be handed over to the applicable collection point for the recycling of electrical

and electronic equipment.

Disposal must be carried out in accordance with local environmental regulations for waste disposal.

For more detailed information about treatment, recovery and recycling of this product, please contact your local city ofce,

your household waste disposal service or the shop where you purchased the product.

20

Page 21

MAYTAG COMMERCIAL LAUNDRY

LIMITED WARRANTY

IF YOU NEED SERVICE:

Contact your authorized Maytag Commercial Laundry distributor. To locate your authorized Maytag Commercial Laundry

distributor, visit .

www.maytagcommerciallaundry.com

Maytag Commercial Laundry Service Department

Benton Harbor, Michigan 49022-2632 USA

WHAT IS COVERED

For written correspondence:

2000 N M 63

FIVE YEAR LIMITED WARRANTY

WHAT IS NOT

COVERED

FIVE YEAR LIMITED WARRANTY

(PARTS ONLY — LABOR NOT INCLUDED)

For the first five years from the original date of

purchase, when this commercial appliance is

installed, maintained, and operated according to the

instructions attached to or furnished with the product,

Maytag brand of Whirlpool Corporation (hereafter

“Maytag”) will pay for factory specified replacement

parts to correct defects in materials or workmanship

that existed when this commercial appliance was

purchased. This limited warranty does not include

labor.

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS

LIMITED WARRANTY SHALL BE PRODUCT REPAIR

AS PROVIDED HEREIN. Maytag recommends that

you use an “authorized” service provider to diagnose

and repair your Commercial Laundry product.

Maytag will not be responsible under this warranty

to provide additional replacement parts as a result

of incorrect diagnosis or repair by an “unauthorized”

service company. Except in the European Union, this

limited warranty is valid only when the commercial

appliance is used in the country in which it was

purchased. This limited warranty is effective from

the date of the original consumer purchase. Proof

of original purchase date is required to obtain service

under this limited warranty.

1.

All other costs including labor, transportation, shipping, or custom duties for

covered parts.

2.

Factory specified replacement parts if this commercial appliance is used for other

than normal, commercial use or when it is used in a manner that is inconsistent

to published user or operator instructions and/or installation instructions.

3.

Service calls to correct the installation of your commercial appliance, to instruct

you on how to use your commercial appliance, to replace or repair house fuses,

or to correct external wiring or plumbing.

4.

Service calls to repair or replace appliance light bulbs, air filters, or water filters.

Consumable parts are excluded from warranty coverage.

5.

Damage resulting from improper handling of product during delivery, theft,

accident, alteration, misuse, abuse, fire, flood, acts of God, improper installation,

installation not in accordance with local electrical or plumbing codes, or use of

products not approved by Maytag.

6.

Pick up and delivery. This commercial appliance is designed to be repaired

on location.

7.

Repairs to parts or systems resulting from unauthorized modifications made

to the commercial appliance.

8.

The removal and reinstallation of your commercial appliance if it is installed

in an inaccessible location or is not installed in accordance with published

installation instructions.

9.

Damage resulting from exposure to chemicals.

10.

Changes to the building, room, or location needed in order to make the

commercial appliance operate correctly.

11.

Factory specified replacement parts on commercial appliances with original

model/serial numbers that have been removed, altered, or cannot be easily

determined.

12.

Discoloration, rust, or oxidation of stainless steel surfaces.

13.

Factory specified replacement parts as a result of incorrect diagnosis or repair

by an “unauthorized” service company.

The cost of repair or replacement under these excluded circumstances shall

be borne by the customer.

DISCLAIMER OF IMPLIED WARRANTIES

IMPLIED WARRANTIES, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR IMPLIED WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE, ARE LIMITED TO FIVE YEARS OR THE SHORTEST PERIOD ALLOWED BY LAW. Some locations may not allow

limitations on the duration of implied warranties of merchantability or fitness, so this limitation may not apply to you. This warranty gives

you specific legal rights, and you also may have other rights that vary.

DISCLAIMER OF REPRESENTATIONS OUTSIDE OF WARRANTY

Maytag makes no representations about the quality, durability, or need for service or repair of this major appliance other than the

representations contained in this Warranty. If you want a longer or more comprehensive warranty than the limited warranty that comes

with this major appliance, you should ask your retailer about buying an extended warranty. The benefits to you given by this warranty

are in addition to other rights and remedies available to you under a law in relation to the goods or service to which this warranty relates.

Please contact Maytag for further information on warranty terms.

LIMITATION OF REMEDIES; EXCLUSION OF INCIDENTAL AND CONSEQUENTIAL DAMAGES

YOUR SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED HEREIN.

MAYTAG SHALL NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. Some locations do not allow the

exclusion or limitation of incidental or consequential damages, so these limitations and exclusions may not apply to you. This warranty

gives you specific legal rights, and you also may have other rights that vary by location.

04/17

21

Page 22

SÉCURITÉ DU LAVE-LINGE

Before the dryer is removed from service or discarded,

L'installation et la maintenance doivent être réalisées par un technicien agréé par Whirlpool.

IMPORTANTES INSTRUCTIONS DE SECURITE

AVERTISSEMENT : An de réduire le risque d’incendie, de choc électeiue ou de blessures

corporellles lors de l’utilisation du lave-linge, il convient d’observer certaines précautions

fondamentales, notamment :

n Lire toutes les instructions avant d’utiliser

le lave-linge.

n Ne pas laver des articles qui ont été

précédemment nettoyés, lavés, trempés ou

tachés avec de l’essence, un solvant pour

nettoyage à sec ou d’autres substances

inammables ou explosives; ces substances

dégagent des vapeurs qui pourraient

s’enammer ou provoquer une explosion.

n Ne pas ajouter d’essence, de solvant pour

nettoyage à sec ou d’autre substance

inammable ou explosive à l’eau de lavage;

ces substances dégagent des vapeurs qui

pourraient s’enammer ou provoquer une

explosion.

n Dans certains conditions, un circuit d’eau

chaude qui n’a pas été utilisé depuis

2 semaines ou plus peut contenir de

l’hydrogène. L’HYDROGENE EST UN GAZ

EXPLOSIF. Si le circuit d’eau chaude est

resté inutilisé pendant une telle période,

ouvrir tous les robinets d’eau chaude et

laisser l’eau s’écouler pendant plusieurs

minutes avant d’utiliser le lave-linge.

Ceci permettra l’évacuation de toute

accumulation d’hydrogène. Le gaz est

inammable : ne pas fumer ou utiliser

une amme nue durant cette période.

CONSERVER CES INSTRUCTIONS

n L’appareil doit être débranché de sa source

de courant électrique durant les interventions

de service et le remplacement des pièces.

Après son débranchement, la che du

cordon d’alimentation doit rester bien visible

pendant toute la durée de l’intervention an de

s’assurer que l’appareil n’est pas sous tension.

n Cet appareil ne convient pas à une utilisation

par des enfants ou par des personnes à

capacités physiques, sensorielles ou mentales

réduites, ou dépourvues d’expérience et de

connaissances, à moins qu’elles ne soient

placées sous supervision ou qu’elles aient

reçu des instructions concernant l’utilisation

sécuritaire de l’appareil par une personne

responsable de leur sécurité. De telles

personnes doivent aussi comprendre les

risques possibles qu’implique l’utilisation.

n Cet appareil peut être utilisé par des enfants

à partir de 8 ans et des personnes dont les

capacités physiques, sensorielles ou mentales

sont réduites ou des personnes manquant

d’expérience et de connaissances, mais

uniquement si ces enfants et personnes sont

placés sous la surveillance d’une personne

responsable ou ont reçu des instructions sur

l’utilisation en toute sécurité de l’appareil.

22

Page 23

n Les enfants de moins de 3 ans doivent

être tenus à distance de l’appareil ou être

surveillés en permanence.

n Cet appareil est conçu pour un usage

domestique et des utilisations similaires

telles que les suivantes : espace cuisine du

personnel dans les magasins, bureaux et

autres environnements de travail ; fermes ;

par les clients dans les hôtels, les motels

et les autres environnements de type

résidentiel ; dans les environnements de

type chambres d’hôtes, zones communes

dans les immeubles d’appartements ou

dans des laveries.

n Aucun lave-linge ne peut complètement

enlever l’huile. Ne pas faire sécher des

articles qui ont été salis par tout genre

d’huile (y compris les huiles de cuisson).

Le non-respect de ces instructions peut

causer un décès, une explosion ou un

incendie.

n Il est recommandé de ne pas laver

d’articles en bre de verre dans un lavelinge payante. Si on lave ces articles

dans le lave-linge, faire fonctionner un

programme complet pour rincer les

éventuels résidus restés dans le lave-linge.

n Les enfants qui effectuent le nettoyage

et l’entretien doivent être supervisés.

n Ne pas laisser des enfants jouer sur,

à l’intérieur de ou avec le lave-linge. Bien

surveiller les enfants lorsque le lave-linge

est utilisé à proximité d’enfants.

n Avant que le lave-linge ne soit mis hors

service ou mis au rebut, enlever la porte

ou le couvercle.

n Ne pas mettre la main dans le lave-linge

si le panier, la cuve ou l’agitateur sont en

mouvement.

CONSERVER CES INSTRUCTIONS

n Ne pas installer au entreposer le lave-linge

dans un endroit où il serait exposé aux

intempéries.

n Ne pas effectuer d’intervention non autorisée

sur les commandes.

n Après l’installation, l’accès à la prise secteur

ou l’alimentation secteur via un interrupteur

bipolaire doit être maintenu à tout moment

pour assurer une désactivation immédiate

du lave-linge en cas d’urgence.

n Ne pas réparer ou au remplacer un

composant quelconque du lave-linge, ni

entreprendre une opération de service, si ce

n’est spéciquement recommandé dans ce

manuel. Il est alors essential que la personne

concernée comprenne ces instructions et soit

compétente pour les exécuter.

n Pour les instructions de liaison à la terre,

voir “Spécications électriques”.

n La pression de l’eau doit être de 138 à 690 kPa

(20 à 100 lb/po2) pour le fonctionnement du

lave-linge.

n Utiliser les tuyaux fournis avec le nouvel

appareil ; ne pas réutiliser celui de l’appareil

précédent.

n Si le cordon d’alimentation est endommagé,

il doit être remplacé par le fabricant, son

technicien d’entretien ou des personnes

présentant une qualication similaire pour

éviter tout risque.

n Cet appareil est muni d’une connexion de

mise à la terre à des ns fonctionnelles

seulement.

n Capacité IEC : 7,7 kg.

23

Page 24

GARANTIE LIMITÉE SUR LES PRODUITS MAYTAG

COMMERCIAL LAUNDRY

TAILLE TYPIQUE DES CHARGES COMPLÈTES

Type de charge Suggestion de chargement Type de charge Suggestion de chargement

Charge mixte 3 draps (lit à 2 places)

4 taies d’oreiller

6 shorts

8 T-shirts

2 chemises

2 chemisiers

8 mouchoirs

Pressage permanent 2 draps (lit à 2 places) ou

1 drap (lit très grand)

1 nappe

1 robe

1 chemisier

2 pantalons

3 chemises

2 taies d’oreiller

Vêtements de travail très sales 3 pantalons

Tricots 3 chemisiers

(taille de charge maximale 7,7 kg)

3 chemises

1 combinaison

4 jeans

1 salopette

4 pantalons

6 chemises

4 tricots

4 robes

TRANSPORT DU LAVE-LINGE

n Fermer les deux robinets d’eau. Débrancher et vidanger

les tuyaux d’arrivée d’eau.

n Déconnecter le tuyau d’évacuation du système de vidange

et vider l’eau qui reste dans un bac ou un seau. Déconnecter

le tuyau d’évacuation de l’arrière du lave-linge.

n Débrancher le cordon d’alimentation.

n Placer les tuyaux d’arrivée d’eau et le tuyau d’évacuation

dans le panier du lave-linge.

n Faire passer le cordon d’alimentation par dessus le bord

et le mettre dans le panier du lave-linge.

n Replacer le support d’emballage issu du matériel d’expédition

d’origine à l’intérieur du lave-linge et réutiliser la base

d’expédition pour soutenir le moteur et la cuve. Si vous n’avez

plus l’emballage d’origine, placer des couvertures lourdes

ou des serviettes au-dessus du panier, entre le sommet du

lave-linge et le pourtour de la cuve. Fermer le couvercle et

placer du ruban adhésif sur le couvercle et jusqu’à la partie

inférieure avant du lave-linge. Laisser le couvercle fermé par

l’adhésif jusqu’à ce que le lave-linge soit installé à son nouvel

emplacement.

SI VOUS AVEZ BESOIN D’ASSISTANCE OU SERVICE

Il se peut que l’installation nécessite des pièces supplémentaires. Contacter le revendeur autorisé d’appareils de buanderie à usage

commercial où le lave-linge a été acheté ou un service d’entretien agréé.

Lors de votre appel, vous aurez besoin du numéro de modèle et de série du lave-linge. Ces deux numéros gurent sur la plaque

signalétique située sur le lave-linge.

POUR CONTACTER LE SERVICE APRÈS-VENTE :

Adressez-vous à votre distributeur Maytag Commercial Laundry agréé. Pour identifier le distributeur Maytag Commercial Laundry

agréé le plus proche, consultez le site Internet www.maytagcommerciallaundry.com.

Pour écrire au service après-vente, utilisez cette adresse :

24

Maytag Commercial Laundry Service Department

2000 N M 63

Benton Harbor, Michigan 49022-2632, États-Unis

Page 25

POUR LE PERSONNEL D’ENTRETIEN AUTORISÉ PAR MAYTAG

OUTILLAGE ET PIÈCES

Outillage nécessaire :

Niveau Pince Couteau utilitaire

Clé plat ou clé à molette

de 9/16"

Tournevis à lame plate

Outillage facultatif :

Lampe de poche Seau

Pièces fournies :

Tuyaux d’alimentation (2) Rondelles pour tuyau

d’alimentation (4)

Tuyau de vidange avec

bride, bride de retenue en

forme de u et attache-câble

PIÈCES SUPPLÉMENTAIRES ET ACCESSOIRES

Il se peut que l’installation nécessite des pièces supplémentaires. Pour passer une commande, contacter le revendeur auprès duquel

le lave-linge a été acheté ou un service d’entretien agréé.

Si vous avez : Il vous faudra :

Un égout surélevé Tuyau de vidange standard de

Tuyau de rejet à

l’égout rigide de diamètre

25 mm (1")

Le système d’évacuation

obstrué par de la charpie

Système d’avaloir de sol Brise-siphon, référence 285320,

Robinets d’eau hors

d’atteinte des tuyaux

d’alimentation

76 L (20 gal.) de 990 mm (39")

de haut ou évier de décharge,

pompe de puisard et connecteurs

(disponibles chez les vendeurs

de matériel de plomberie locaux)

Adaptateur pour tuyau rigide de

rejet à l’égout rigide de diamètre

51 mm (2") à 25 mm (1"),

Pièce numéro 3363920

Ensemble de connection,

Pièce numéro 285835

Protecteur de canalisation,

pièce numéro 367031

Ensemble de connection,

Pièce numéro 285835

Ensemble de raccordement (x2),

référence 285835

Prolongateur de tuyau exible

de vidange, référence 285863

2 tuyaux de remplissage plus

longs : tuyau coudé à 90° de

1,8 m (6 pi), Pièce numéro 76314

3 m (10 pi), Pièce numéro 350008

Si vous avez : Il vous faudra :

Les tuyaux d’arrivée d’eau sont

vendus en paire dans l’ensemble

W10575888

Cordon d’alimentation pour

l’Argentine W11318405

Cordon d’alimentation pour le

Royaume-Uni W11318406

Cordon d’alimentation pour

l’Europe W11318407

Cordon d’alimentation pour

l’Australie W11318408

Accessoires

Si vous avez : Il vous faudra :

Plateau d’égouttement du

lave-linge, Pièce numéro 8212526

Ensemble distributeur

d’assouplissant pour tissu,

Pièce numéro 63594

La vidange est hors

d’atteinte du tuyau

de vidange

Rallonge du tuyau de vidange

de 1,2 m (4 pi),

Pièce numéro DRNEXT4

25

Page 26

DIMENSIONS

Vue de face Vue latérale

1.080 m

1,080 m

1

/2")

(42

(421⁄2")

686 mm

(27")

921 m

686 mm

(361/4")

25 mm

25mm

(1")

(1")

25 mm

(1")

Vue arrière

Modèles non payants Modèles payants

(27")

Modèles

non payants

159 mm (61⁄4")

210 mm

1

Modèles

(8

/4")

payants

210 mm (91⁄4")

267 mm

(101/2")

1,080 m

1.080 m

(421⁄2")

(421/2")

946 mm

(371/4")

171 mm

3

(6

/4")

406 mm

(16")

108 mm

(41/4")

686 mm

(27")

140 mm

(51/2")

933 mm

(363/4")

25 mm

(1")

267 mm

(101/2")

1.130 m

1,130 m

1

(441⁄2")

(44

/2")

946 mm

(371/4")

171 mm

(63/4")

406 mm

(16")

108 mm

(41/4")

686 mm

(27")

140 mm

(51/2")

933 mm

(363/4")

25 mm

(1")

26

Page 27

EXIGENCES D’EMPLACEMENT

Le choix d’un emplacement approprié pour le lave-linge

en améliore le rendement et réduit au minimum le bruit

et le “déplacement” possible du lave-linge.

Le lave-linge peut être installée dans un sous-sol, une buanderie

ou un encastrement. Voir “Système de vidange”.

Il faut aussi prendre en compte les exigences d’emplacement

des appareils voisins.

IMPORTANT : Ne pas installer ou remiser le lave-linge dans un

endroit où il sera exposé aux intempéries. Ne pas remiser ou faire

fonctionner le lave-linge à des températures égales ou inférieures

à 0 °C (32 °F). Une quantité d’eau peut demeurer dans le lavelinge et causer des dommages à des températures basses.

C’est à l’utilisateur qu’incombe la responsabilité de réaliser

une installation correcte.

Il vous faudra :

n Un chauffe-eau réglé à 49 °C (120 °F).

n Une prise électrique reliée à la terre et située à moins de

1,2 m (4 pi) du cordon d’alimentation situé à l’arrière du

lave-linge. Voir “Spécications électriques”.

n Des robinets d’eau chaude et d’eau froide situés à moins

de 1,2 m (4 pi) des électrovannes de remplissage d’eau

chaude et d’eau froide situées sur le lave-linge et une

pression d’eau de 138 à 690 kPa (20 à 100 lb/po²). Lorsque

la pression d’alimentation à l’entrée du bâtiment est

supérieure à 690 kPa (100 lb/po2), on devrait installer une

vanne de réduction de la pression pour éviter une éventuelle

détérioration de la vanne de mixage du lave-linge.

n L’installation d’un seule lave-linge nécessite une colonne

montante d’au moins 300 mm (12") pour assurer un coussin

d’air et éviter le bruit et l’endommagement des vannes.

n Un plancher de niveau avec une pente maximale de

25 mm (1") sous l’ensemble du lave-linge. L’installation

sur de la moquette n’est pas recommandée.

n

Un plancher capable de supporter le poids total de

143 kg (315 lb) du lave-linge (eau et charge comprises).

n Un avaloir de sol sous le coffrage. Les coffrages préfabriqués

équipés de prises électriques, lignes d’arrivée d’eau et

conduites d’évacuation doivent être utilisés seulement

là où les codes locaux l’autorisent.

Installation dans un encastrement ou un placard

Ce lave-linge peut être installé dans un encastrement ou un

placard. Les dimensions d’installation indiquées correspondent

à l’espacement minimal permis. Prévoir davantage d’espace

pour faciliter l’installation et l’entretien. Il faut aussi prendre

en compte l’espace requis entre les appareils voisins.

Dégagement d’installation minimum

356 mm

(14" max.)

127 mm

(5")

25 mm

(1")

457 mm

406 mm

(18")

(16")

25 mm

76 mm

(3"/3")

310 cm2

(48 po2/48 po2)

155 cm2

(24 po2/24 po2)

76 mm

(3"/3")

(1")

27

Page 28

INSTRUCTIONS D’INSTALLATION

Il est nécessaire de retirer tout le matériel d’expédition pour un

fonctionnement correct et pour éviter que le lave-linge ne fasse

trop de bruit.

1. Déplacer le lave-linge à moins de 1,2 m (4 pi) de son

emplacement nal; il doit être en position complètement

verticale.

REMARQUE : Pour éviter d’endommager le plancher, installer

le lave-linge sur un carton avant de la déplacer. Assurer que

le couvercle est retenu en place avec le ruban adhésif.

2. An d’éviter d’endommager le plancher, placer les supports

en carton du carton d’expédition sur le plancher, derrière

le lave-linge. Incliner le lave-linge vers l’arrière et la placer sur

les supports en carton. Retirer la base d’expédition. Redresser

le lave-linge en position verticale.

IMPORTANT : Le retrait de la base d’expédition en polystyrène

est nécessaire au bon fonctionnement du lave-linge. Si le

lave-linge comprend une plaque d’insonorisation, consulter

les instructions fournies avec la plaque d’insonorisation pour

l’installer maintenant.

REMARQUE : Conserver la base d’expédition au cas

où il faudrait déplacer le lave-linge ultérieurement.

1,2 m

(48")

3. Retirer le ruban adhésif du couvercle du lave-linge, ouvrir

le couvercle et retirer le carton plat d’emballage de la cuve.

Veiller à retirer toutes les pièces du carton plat.

REMARQUE : Le plateau doit être retiré avant de brancher

le lave-linge sur une prise. Conserver le carton plat au cas

où il faudrait déplacer le lave-linge ultérieurement.

28

Page 29

ÉTABLISSEMENT DE L’APLOMB DU LAVE-LINGE

IMPORTANT : L’établissement correct de l’aplomb

du lave-linge permet de réduire les nuisances sonores

et de limiter les vibrations.

1. Mettre le lave-linge est à son emplacement nal. Placer un

niveau sur les bords supérieurs du lave-linge. Utiliser une rive

latérale comme guide pour déterminer l’aplomb des côtés.

Vérier l’aplomb de l’avant à l’aide du couvercle, tel qu’indiqué.

Faire bouger le lave-linge d’avant en arrière pour s’assurer que

les quatre pieds sont bien en contact avec le plancher.

Placer le niveau

à cet endroit

Place level here

Placer le niveau

à cet endroit

Place level here

2. Utiliser une clé plate ou une clé à molette de 14 mm ou 9/16"

pour tourner les contre-écrous sur les pieds dans le sens horaire

jusqu’à ce qu’ils se trouvent à environ 13 mm (1/2") de la caisse