Page 1

INSTALLATION INSTRUCTIONS

COMMERCIAL WASHER

120-volt, 60-Hz Models

INSTRUCTIONS D'INSTALLATION DE LA

LAVEUSE COMMERCIALE

ModUles 120 V, 60 Hz

"m

Write down the model and serial numbers before installingwasher.

Both numbers are listed on the model/serial rating plate located

under the lid.

Model #

Serial #

Date of Purchase

Prendre note des numeros de modele et de serie avant d'installer

la laveuse.

Les deux numeros sont indiqu6s sur la plaque signaletique sous

le couvercle.

Numero de modele

Numero de serie

Date d'achat

W10135312B

www.maytagcommerciallaundry.com

Page 2

Tableof Contents

WASHER SAFETY ........................................................................ 2

INSTALLATION REQUIREMENTS .............................................. 3

Tools and Parts ........................................................................... 3

Location Requirements .............................................................. 3

Drain System .............................................................................. 4

Electrical Requirements ............................................................ 5

INSTALLATION INSTRUCTIONS ............................................ 6

Remove Shipping Strap ............................................................ 6

Connect the Hoses .................................................................... 6

Level the Washer ...................................................................... 7

Complete Installation ................................................................ 8

ELECTRONIC CONTROLS SETUP .......................................... 10

WARRANTY ................................................................................ 14

Tabledes matii res

SECURITE DE LA LAVEUSE .................................................... 15

EXIGENCES D'INSTALLATION ................................................ 16

Outillage et pieces .................................................................. 16

E×igences d'emplacement ...................................................... 16

Systeme de vidange ................................................................ 17

Specifications electriques ........................................................ 18

INSTRUCTIONS D'INSTALLATION ........................................ 19

Enlever la sangle d'expedition ................................................ 19

Raccordement des tuyaux ...................................................... 19

Reglage de I'aplomb de la laveuse ........................................ 20

Achever I'installation ................................................................ 21

REGLAGE DE LA COMMANDE ELECTRONIQUE .................. 23

GARANTIE .................................................................................... 27

WASHERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kilt or hurt you and others.

All safety messages wilt follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic precautions,

including the following:

Read all instructions before using the washer.

Do not wash articles that have been previously cleaned

in, washed in, soaked in, or spotted with gasoline,

dry-cleaning solvents, other flammable, or explosive

substances as they give off vapors that could ignite or

explode.

Do not add gasoline, dry-cleaning solvents, or other

flammable, or explosive substances to the wash water.

These substances give off vapors that could ignite or

explode.

Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been used

for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the water

flow from each for several minutes. This will release

any accumulated hydrogen gas. As the gas is

flammable, do not smoke or use an open flame during

this time.

SAVE THESE INSTRUCTIONS

INSTALLATIONREQUIREMENTS

Gatherthe requiredtools and partsbefore starting installation.

Tools needed

• Level

• Utility knife

• Scissors

• 8" or 10" adjustable wrench

• Flat-blade screwdriver

• Pliers

• Bucket

Parts supplied

Remove parts bag from washer. Check that all parts were

included.

• 1 hose clamp

• 2 inlet hoses

• 4 flat water hose washers

• 2 front-leveling legs with nuts

• 1 drain hose

Do not allow children to play on or in the washer. Close

supervision of children is necessary when the washer is used

near children.

Before the washer is removed from service or discarded,

remove the door or lid.

• Do not reach into the washer if the drum, tub or agitator is

moving.

• Do not install or store the washer where it wilt be exposed to

the weather.

Do not tamper with controls.

Do not repair or replace any part of the washer or attempt any

servicing unless specifically recommended in this manual or in

published user-repair instructions that you understand and

have the skills to carry out.

• See "Electrical Requirements" for grounding instructions.

You will need:

• A water heater set to deliver 120°F (49°C) water to the washer.

• A grounded electrical outlet located within 4 ft (1.2 m) of where

the power cord is attached to the back of the washer.

See "Electrical Requirements."

• Hot and cold water faucets located within 4 ft (1.2 m) of the

back of the washer, and provide water pressure of 10-100 psi

(69-690 kPa). A pressure reduction valve should be used in

the supply line where inlet pressure entering the building

exceeds 100 psi (690 kPa) to prevent damage to the washer

mixing valve.

• A level floor with a maximum slope of 1" (25 mm) under entire

washer.

• A sturdy floor to support the washer weight (washer, water,

and load) of 315 Ibs (143 kgs).

• A 12" (300 mm) minimum riser to provide an air cushion and

prevent noise and damage to valves for a single washer

installation.

• A floor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water supply

lines and drain facilities should be used only where local

codes permit.

NOTE: Front access to the pump area is available by removing

2 No. T20 TORX ®t security screws and then removing the front

panel.

IMPORTANT : Do not install or store the washer where it will be

exposed to the weather. Do not store or operate the washer in

temperatures at or below 32°F (0°C). Some water can remain in

the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

1 ®TORX is a registered trademark of Acument Intellectual Properties, LLC.

3

Page 4

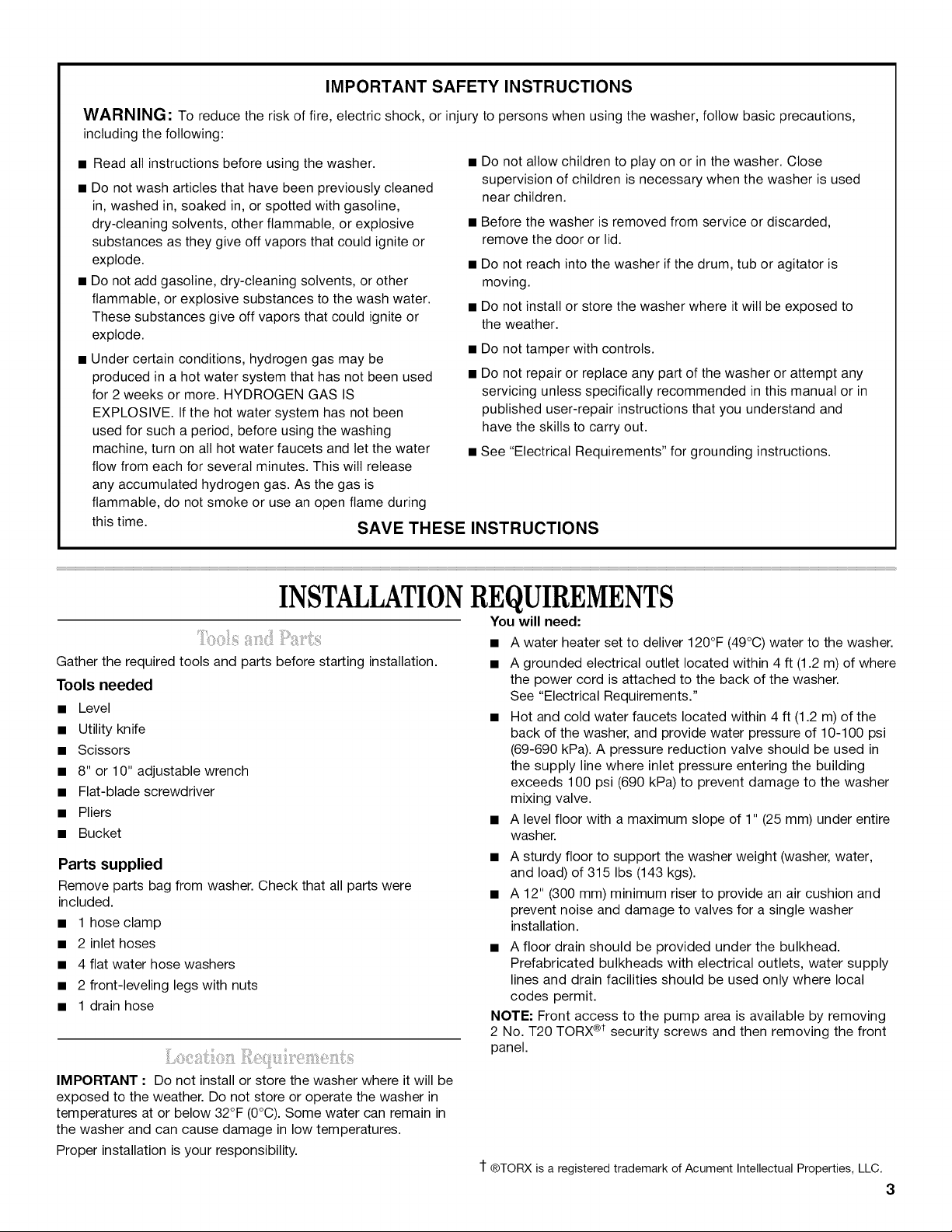

Recessed Area and Closet Installation Instructions

This washer may be installed in a recessed area or closet.

The installation spacing shown is in inches and is the minimum

allowable. Additional spacing should be considered for ease of

installation, servicing, and compliance with local codes and

ordinances.

If closet door is installed, the minimum unobstructed air openings

in the top and bottom are required. Louvered doors with

equivalent air openings are acceptable.

Minimum Installation Clearances

jCIoset door

olo

17"

(432 mm)

+

4"

(102 mm)

min.

Product Dimensions

N

/

Recessed front view

48,,2

Closet side view

3" (76 mm)

(3,10m_)*

+

Frontview

*Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

• Additional spacing should be considered for the ease of

installation and servicing.

• Additional clearances may be required for wall, door, and floor

moldings.

• Additional spacing of 1" (25 mm) on all sides of the washer is

recommended to reduce noise transfer.

• Companion spacing should also be considered.

0 Closet

door

3" (76mm)

A. 43" (1090 mm)

B. 38_"(970 mm)

C. 35" (890 mm)

D. 1Y2" (38 mm)

E. 27¼" (705 mm)

F. 25½" (650 mm)

G. Water inlets

H. 7" (180 mm)

I. Power supply cord

J. Drain hose connector

K. Label

L. 27" (685 mm)

M. 5V4" (133 mm)

N. 1"(25mm)

O. 5" (127mm)

Standpipe Drain System

The standpipe drain requires a minimum diameter standpipe of

2" (50 mm). The minimum carry-away capacity can be no less

than 17 gal. (64 L) per minute.

The top of the standpipe must be at least 39" (990 mm) high and

no higher than 72" (1.8 m) from the bottom of the washer.

Page 5

!iii!!iiilliiJ_ii:!!i__i::!i_i::__ii_'¸'!i_i:i__i!i_ii_:!!_i!il_i:!!!__i_iiiii_:_!ii_iii_?,i:!__ii_iiii_!!__i_i_:iiii:,_:i!i;

Recommended Ground Method

The washer, when installed, must be electrically grounded in

accordance with local codes, or in the absence of local codes,

with the National Electrical Code, ANSl/NFPA 70, latest edition,

and all local codes and ordinances.

GROUNDING INSTRUCTIONS

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

IMPORTANT : The washer must be electrically grounded in

accordance with local codes and ordinances or, in the absence of

local codes, with the National Electrical Code, ANSI/NFPA 70,

latest edition.

• If codes permit and a separate ground wire is used, it is

recommended that a qualified electrical installer determine

that the ground path is adequate.

• Do not ground to a gas pipe.

• Do not have a fuse in the neutral or ground circuit.

A copy of the above code standards can be obtained from:

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

• A 120 volt, 60 Hz, AC only, 15- or 20-amp, fused electrical

circuit is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this washer be provided.

• The washer is equipped with a power supply cord having a

3 prong grounding plug.

• To minimize possible shock hazard, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

5

Page 6

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

1=

Remove tape that covers shipping strap. Pull to completely

remove the shipping strap with 2 cotter pins from the inside of

the washer.

Proper connection of the drain hose avoids damage to your floor

due to water leakage. Read and follow these instructions.

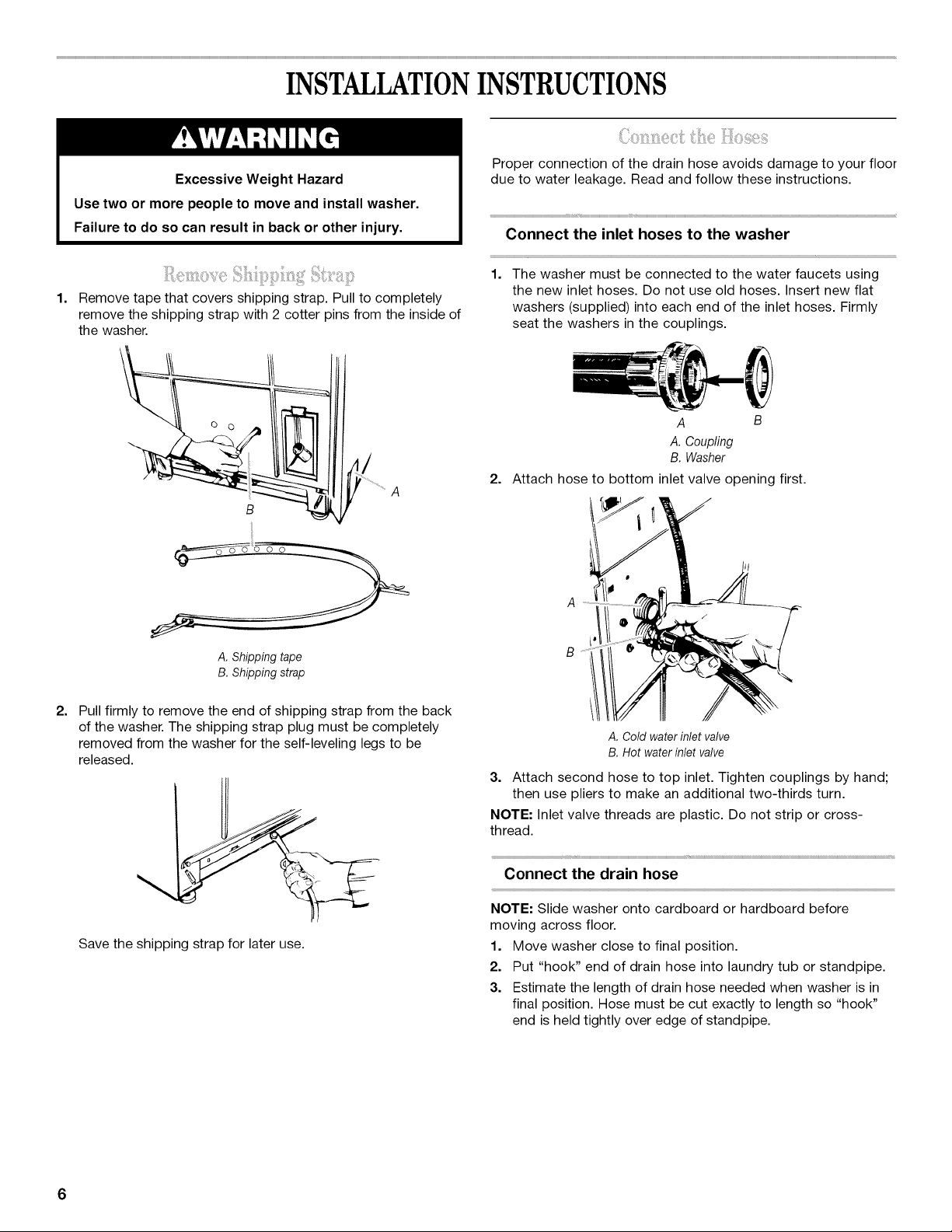

Connect the inlet hoses to the washer

1. The washer must be connected to the water faucets using

the new inlet hoses. Do not use old hoses. Insert new flat

washers (supplied) into each end of the inlet hoses. Firmly

seat the washers in the couplings.

A B

A. Coupling

B. Washer

2=

Attach hose to bottom inlet valve opening first.

A. Shipping tape

B. Shipping strap

2=

Pull firmly to remove the end of shipping strap from the back

of the washer. The shipping strap plug must be completely

removed from the washer for the self-leveling legs to be

released.

Save the shipping strap for later use.

A

B

A, Cold water inlet valve

B, Hot water inlet valve

3. Attach second hose to top inlet. Tighten couplings by hand;

then use pliers to make an additional two-thirds turn.

NOTE: Inlet valve threads are plastic. Do not strip or cross-

thread.

Connect the drain hose

NOTE: Slide washer onto cardboard or hardboard before

moving across floor.

1. Move washer close to final position.

2. Put "hook" end of drain hose into laundry tub or standpipe.

3. Estimate the length of drain hose needed when washer is in

final position. Hose must be cut exactly to length so "hook"

end is held tightly over edge of standpipe.

Page 7

If drain hose is too long, cut straight end of hose. (Do not cut

the "hook" shaped end of the drain hose.)

NOTE: Do not force excess length of drain hose down the

standpipe. This could cause siphoning.

4,

Place the hose clamp over the washer drain connector. Push

the drain hose onto the washer connector. Use pliers to open

clamp and slide clamp over drain hose. Check for good fit.

Connect the inlet hoses to the water faucets

1. Before attaching water inlet hoses, run water through both

faucets into a bucket. This will get rid of particles in the water

lines that might clog hoses. Mark which is the hot water

faucet.

2. Attach bottom hose (inlet marked "H") to hot water faucet.

Tighten coupling to faucet by hand.

3. Attach top hose (inlet marked "C") to cold water faucet.

Tighten coupling to faucet by hand.

4. Use pliers to make an additional two-thirds turn to each

coupling.

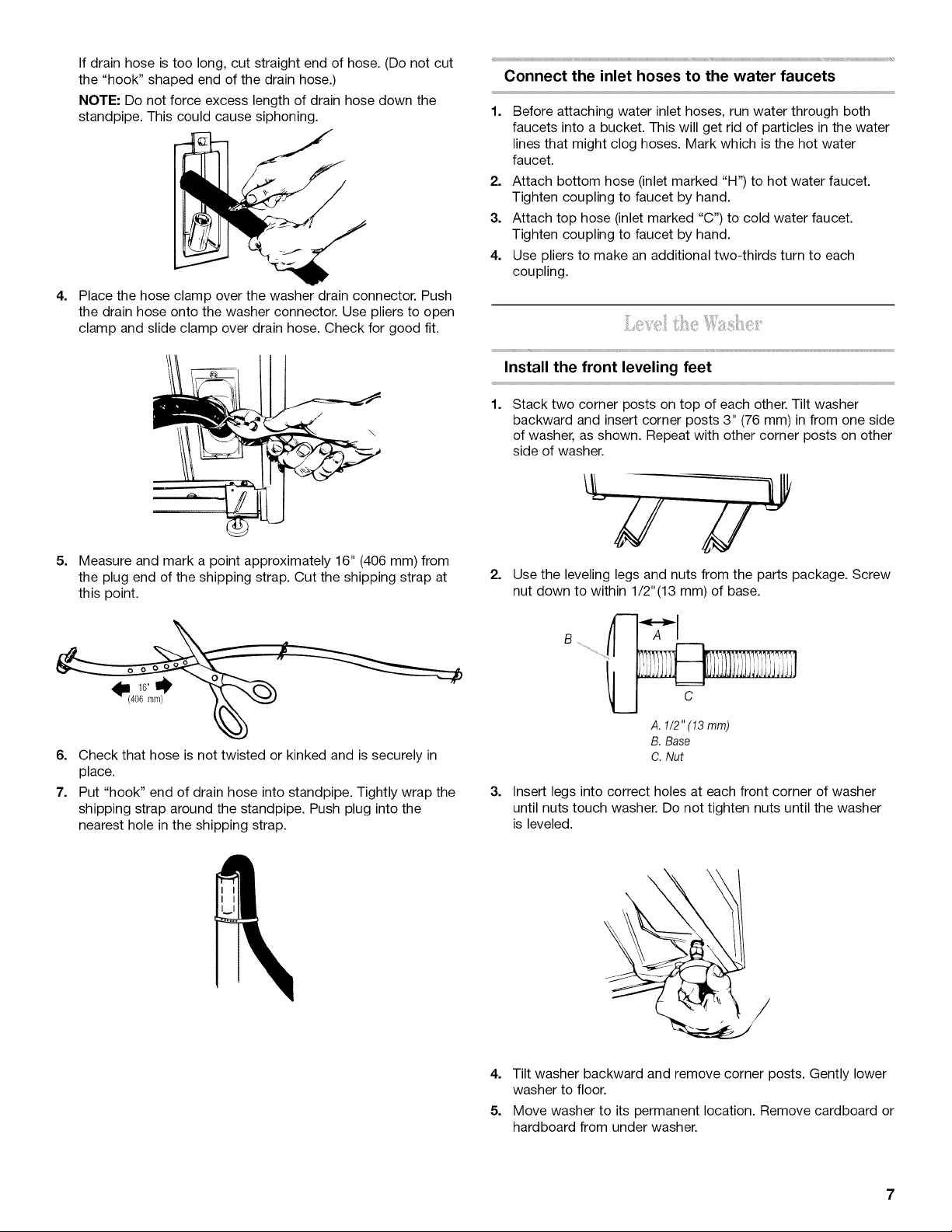

Install the front leveling feet

1,

Stack two corner posts on top of each other. Tilt washer

backward and insert corner posts 3" (76 mm) in from one side

of washer, as shown. Repeat with other corner posts on other

side of washer.

5. Measure and mark a point approximately 16" (406 mm) from

the plug end of the shipping strap. Cut the shipping strap at

this point.

" (406 mm) l_"_

6. Check that hose is not twisted or kinked and is securely in

place.

7. Put "hook" end of drain hose into standpipe. Tightly wrap the

shipping strap around the standpipe. Push plug into the

nearest hole inthe shipping strap.

2.

Use the leveling legs and nuts from the parts package. Screw

nut down to within 1/2" (13 mm) of base.

..................................__!_1

JJJJJJi JJii.'JJJi

A,1/2"(13mm)

B,Base

C. Nut

3.

Insert legs into correct holes at each front corner of washer

until nuts touch washer. Do not tighten nuts until the washer

is leveled.

\

4. Tilt washer backward and remove corner posts. Gently lower

washer to floor.

5. Move washer to its permanent location. Remove cardboard or

hardboard from under washer.

7

Page 8

Level the washer

1. Tilt washer forward raising back legs 1" (25 mm) off of floor, to

adjust rear self-leveling legs. Gently lower washer to floor.

2. Check levelness of the washer by placing a carpenter's level

on top of the washer, first side to side; then front to back.

3. If washer is not level, adjust the front legs up or down. Make

final check with level.

4. When washer is level, use a wrench to turn the nuts on front

legs up tightly against the washer base. If nuts are not tight

against washer base, the washer may vibrate.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

6. Plug power supply cord into a grounded 3 prong outlet.

NOTE: On some models, during factory testing, the timer is

advanced partially into the cycle causing the start button to be

depressed. Allow timer to advance to the end of the cycle.

When the cycle is complete, the timer will reset and the start

button will return to the start position. If the timer is not allowed

to advance to the end of the first cycle and reset, the wash load

will not be completed.

1. Check the electrical requirements. Be sure that you have the

correct electrical supply and the recommended grounding

method.

2. Check to be sure all parts are now installed. If there is an

extra part, go back through the steps to see which step was

skipped.

3. Turn on water faucets and check for leaks. Tighten

couplings if there is leaking. Do not overtighten; this could

cause damage to faucets.

4. Check to be sure you have all of your tools.

5. Check that the shipping strap was removed from the back of

the washer and used to secure the drain hose. If entire strap

is not removed, washer may vibrate and be noisy.

8

Page 9

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or electrical shock.

Checklist for washer operation:

Check the following if the washer is not operating properly:

1. Power supply cord is plugged in.

2. Circuit breaker is not tripped or fuse is not blown.

3. Timer has been advanced to start of a cycle.

4. Water faucets are turned on.

5. Inlet and drain hoses are not kinked.

6. Washer lid is closed.

7. Inlet valve is not frozen if not protected from the weather.

8. Suds level. Excess suds will slow the spin and cause poor

rinsing. Operate the washer through a complete cycle with no

detergent. Use less detergent or a controlled suds type

detergent in future loads.

If you need assistance:

Contact your authorized Maytag _ Commercial Laundry

distributor. To locate your authorized Maytag _ Commercial

Laundry distributor, or for web inquiries, visit

www.MaytagCommercialLaundry.com.

If you cannot locate your distributor, the Commercial Laundry

Support Center will answer any questions about operating

or maintaining your washer not covered in the Installation

Instructions.

Just dial 1-800 NO BELTS (1-800-662-3587)--the call is free.

When you call, you will need the washer model number and serial

number. Both numbers can be found on the serial-rating plate

located on your appliance.

Operating Tips

Fire Hazard

Never place items in the washer that are dampened

with gasoline or other flammable fluids.

No washer can completely remove oil.

Do not dry anything that has ever had any type of oil on

it (including cooking oils).

Doing so can result in death, explosion, or fire.

It is recommended that fiberglass items not be washed in coin-

operated washers. If these items are washed in the washer, run

the washer through a complete cycle to rinse any residue away

that might be left in the washer.

Typical full load sizes

Load Type Loading

Suggestion

Mixed Load 3 double sheets

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

2 blouses

8 handkerchiefs

Permanent 2 double or Knits

Press 1 king size sheet

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

Load Type

Heavy Work

Clothes

Loading

Suggestion

3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

3 blouses

4 slacks

6 shirts

4 tops

4 dresses

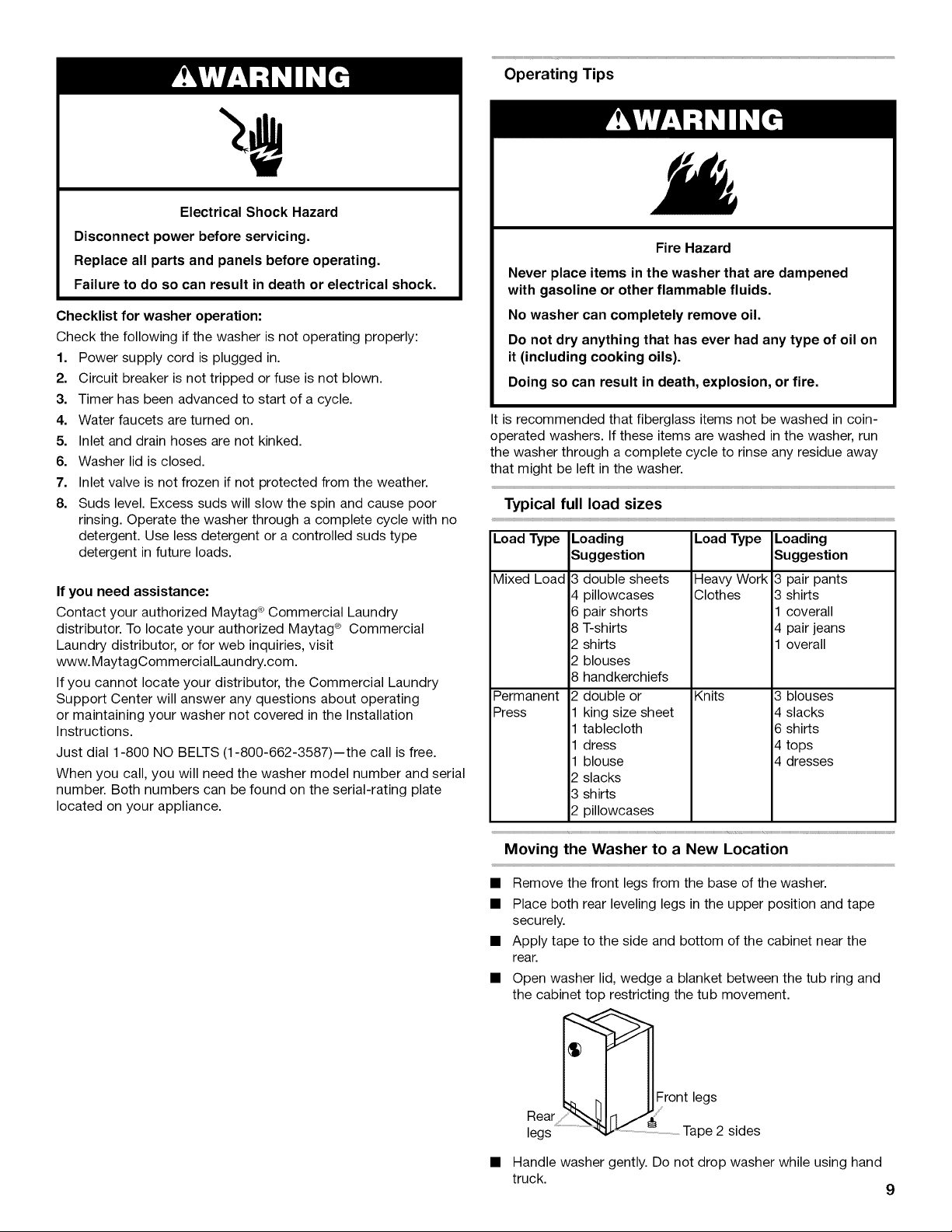

Moving the Washer to a New Location

• Remove the front legs from the base of the washer.

• Place both rear leveling legs in the upper position and tape

securely.

• Apply tape to the side and bottom of the cabinet near the

rear.

• Open washer lid, wedge a blanket between the tub ring and

the cabinet top restricting the tub movement.

_Front legs

Rear "_1__ H_ ....

legs ........Tape 2 sides

• Handle washer gently. Do not drop washer while using hand

truck.

9

Page 10

ELECTRONICCONTROLSSETUP

BASIC OPERATION OF COMMERCIAL WASHER

• For additional information,

see www. MaytagCommercialLaundry.com.

• This tech sheet is not valid for models prior to series MAT14.

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating,

Failure to do so can result in death or

electrical shock.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Elec_onics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is finished,

but failure may occur at a later date due to ESD stress.

• Use an anti-static wrist strap. Connect wrist strap to green

ground connection point or unpainted metal in the washer.

-OR-

Touch your finger repeatedly to a green ground connection point

or unpainted metal in the washer.

• Before removing the part from its package, touch the

anti-static bag to a green ground connection point or

unpainted metal in the washer.

• Avoid touching electronic parts or terminal contacts; handle

electronic control assembly by edges only.

• When repackaging failed electronic control assembly in

anti-static bag, observe above instructions.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, 'SELECT CYCLE' will appear rather than a cycle price.

Debit Card Ready

This washer is debit card 'cable' ready. It will accept a variety

of debit card systems, but does NOT come with a debit card reader.

Refer to the debit card reader manufacturer for proper washer

set-up. In models converted to a Generation 1 debit card system,

debit pulses represent the equivalent of one coin (coin 1).

Display

After the washer has been installed and plugged in, the display will

show '0 MINUTES'. Once the washer has been plugged in and the

washer door opened and closed, the display will show the price. In

washers set for free cycles, the display will flash 'SELECT CYCLE'.

WHITES COLORS SRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS BRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS SRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

GENERAl. USER INFORMATION

Blank Display

This condition indicate the washer is inoperative. Enter set-up mode

to view diagnostic code.

'0 Minutes' showing in display

This condition indicates the washer cannot be operated. Coins

dropped or debit inputs during this condition will be stored in escrow

but cannot be used until normal operation is restored by opening

and closing the door. If a door switch fails, it must be replaced before

normal operation can be restored.

Cold Start (initial first use)

Washer is programmed at the factory as follows:

• 11 minute wash period

• 1 rinses and 2 minutes of rinse agitation

• $1.75 wash price (PD models)

• $0.00 wash price (PR models)

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to the

state that existed at time of the power failure.

10

Page 11

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The lower fabric setting key pads and the digital display are used

to set up the controls. The display can contain 4 numbers and/or

letters and a decimal point. These are used to indicate the set-up

codes and related code values available for use in programming

the washer.

How to use the key pads to program the controls

1. The LOWER LEFT key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value.

Rapid adjustment is possible by holding the key pad down.

2. The LOWER MIDDLE key pad will advance you through the

set-up codes. Pressing the key pad will advance you to the

next available set-up code. Holding the key pad down will

automatically advance through the set-up codes at a rate of

one (1) per second.

3. The LOWER RIGHT key pad isusedto selector deselect options.

Start Operating Set-Up

• PD Models: Insertaccess door key,turn,and liftto removeaccess door.

• PR Models: Once the debit card reader is installed (according to the

reader manufacturer's instructions), the set-up mode can be entered

by inserting a set-up card (supplied by the reader manufacturer) into

the card slot. If a manual set-up card is not available, manual set-up

mode can be entered by removing connector AA1 on the circuit

board.

IMPORTANT: The console must not be opened unless power is first

removed from the washer. To access connector AA1:

Unplug washer or disconnect power.

Open console, disconnect plug on AA1, close console.

Plug in washer or reconnect power.

The washer is now in the set-up mode.

Before proceeding, it is worth noting that, despite all of the options

available, an owner can simply choose to uncrate a new commercial

washer, hook it up, plug it in, and have a unit that operates.

SET-UP CODES

• The LOWER MIDDLE key pad will advance from code to code.

• The LOWER LEFTkey pad will change the code value.

• The LOWER RIGHT key pad wilt select or deselect options.

FOR PR MODELS: The set-up codes are the same as for the 'PD'

models except where noted.

The set-up code is indicated by the one or two left-hand characters.The

set-up code value is indicated by the two or three right-hand characters.

REGULAR CYCLE PRICE

i-n'_

o___

Representsthenumberof quarters(coin1);mayadjustfrom0-39.

(SeeVALUEOFC01N1.)Advancefrom0-39bypressingtheLOWER

LEFTkeypad.Factorypresetfor7quarters= $1.75.

PRMODELSONLY:Factorypresetfor 0quarters.

PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

WASH LENGTH

Thisisthenumberof minutesforWASH.

Choosefrom 8-20minutesby pressingthe LOWERLEFTkeypad.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

n-_l I

RINSE CYCLES

o __, I Thisisthe lengthandtotalnumberof rinses.Eachrinseagitationi_

1-4minutes,withachoiceof1or2 rinses.Themiddledigitisthe

lengthofrinseagitationandtherightdigit isthenumberofrinses.

Thenumberischangedin thefollowingsequence(11,21,31,41,

12,22,32,42)bypressingtheLOWERLEFTkeypad.

PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

TheDELICATES&KNITScyclehasafixedrinseagitationlength

ofoneminute.

LOWERMIDDLEkeypadoncetoadvanceto nextcode.

CYCLE COUNTER OPTION

m

nnn

_'___

_nF"

_'___

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.

NotSelected'OFF'.

Selected'ON'andnotableto bedeselected.

Pressthe LOWERRIGHTkeypad3 consecutivetimes

toselect'ON'.Onceselected'ON'itcannotbedeselected.

_uu

inn

Pressthe

LOWERMIDDLEkeypadoncetoadvanceto nextcode.

MONEY COUNTER OPTION

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.

inn

I.Lr-r-r-r-r-r-r-r-_j

laP"

"_-E-E-E-E-E-E-E-E-_

NotSelected'OFF'.

Selected'ON'.

Pressthe LOWERRIGHTkeypad3 consecutivetimes

toselect'ON'and3 consecutivetimestoremove

(NotSelected'OFF'.)Counterresetsbygoingfrom'OFF'to 'ON'.

iFn

Selected'ON'andnotableto bedeselected.

Toselect'ON'andnotableto bedeselected,firstselect'ON',then

withintwo secondspressthe LOWERRIGHTkey padtwice,the

LOWERLEFTkeypadonce,andexittheset-upmode.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

SPECIAL PRICING OPTION

m

"_nn

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.

NotSelected'OFF'.

Selected'ON'.Pressthe LOWERRIGHTkeypadonce

forthis selection.

IfSPECIALPRICINGOPTIONis selected,youhaveaccesstocodes'3'

through'9.'.

PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

OPTIONSTOUSEIFSPECIALPRICINGISSELECTED:

_n

i_'_.lU 7

SPECIAL CYCLE PRICE

Representsthe numberofquarters(coin1):mayadjust

from0-39.(SeeVALUEOFC01N1.)Advancefrom0-39by

pressingtheLOWERLEFTkeypad.Factorypreset

for7 quarters= $1.75.

PRMODELSONLY:Factorypresetfor0 quarters.

Pressthe

LOWERMIDDLEkeypadoncetoadvanceto nextcode.

11

Page 12

OPTIONSTOUSEIFSPECIALPRICINGISSELECTED(cont.):

TIME-OF-DAY CLOCK, MINUTES

ThisistheTIME-OF-DAYCLOCK,minutesetting;

select0-59minutesbypressingthe LOWERLEFTkeypad.

-->PressmeLOWERMIDDLEkeypadoncetoadvanceto nextcode.

TIME-OF-DAY CLOCK, HOURS

NOTE:Usesmilitarytime or24 hr.clock.

ThisistheTIME-OF-DAYCLOCK,hourse_ng;select0-23hours

bypressingthe LOWERLEFTkeypad.

-->PressmeLOWERMIDDLEkeypadoncetoadvanceto nextcode.

"_ nn

u u SPECIAL PRICE START HOUR

NOTE:Usesmilitarytime or24 hr.clock.

"_ nn

i._ Thisisthe starthour;0-23 hours.SelectSTARTHOURbypressing

theLOWERLEFTkeypad.

Pressthe LOWERMIDDLEkey padoncetoadvanceto nextcode.

-->PressmeLOWERMIDDLEkeypadoncetoadvanceto nextcode.

SPECIAL PRICE STOP HOUR

NOTE:Usesmilitarytime or24 hr.clock.

Thisisthe stophour;0-23hours.SelectSTOPHOURby pressing

theLOWERLEFTkeypad.

-->PressmeLOWERMIDDLEkeypadoncetoadvanceto nextcode.

SPECIAL PRICE DAY

n i n Thisrepresentsthe dayoftheweekandwhetherspecialpricing

isselectedforthatday.Anumberfollowedby '0' indicatesno

selectionmatparticularday(9.10).Anumberfollowedbyan'S'

indicatesselectedfor thatday(9.1S).

Daysoftheweek(1-7)canbe chosenbypressingmeLOWER

LEFTkeypad.PresstheLOWERLEFTkeypadoncetoselect

.specialpricingforeachdaychosen.

Whenexitingset-upcode'9',thedisplaymustshowcurrentday

ofweek:

DISPLAY DAYOFWEEK CODE(selected)

10 Day1= Sunday 1S

20 Day2= Monday 2S

30 Day3=Tuesday 3S

40 Day4= Wednesday 4S

50 Day5=Thursday 5S

60 Day6= Friday 6S

70 Day7= Saturday 7S

-->Pressthe

_. nn

UU

LOWERMIDDLEkeypadoncetoadvancetonextcode.

VAULT VIEWING OPTION

ThisoptioniseimerSELECTED'ON'or NOTSELECTED'OFF'.

R nn

-IUUI

NotSelected'OFF'.

Selected'ON'.Pressthe LOWERRIGHTkeypadoncefor

thisselection.Whenselected,the moneyand/orcyclecounts

will beviewable(ifcountingisselected)whenthecoin

boxisremoved.

-->Pressme

LOWERMIDDLEkeypadoncetoadvanceto nextcode.

VALUE OF COIN 1

Thisrepresentsthe valueof coin1 in numberof nickels:

05 = $0.25.

BypressingtheLOWERLEFTkey pad,youhavetheop_on

of 1-199nickels.

-->Pressthe

LOWERMIDDLEkeypadoncetoadvanceto nextcode.

VALUE OF COIN 2

I- _n

Thisrepresentsthevalueof coin 2 in numberof nickels:

20= $1.00.

PRMODELSONLY:Factorypresetfor$0.25.

BypressingthePERMANENTPRESSkeypad,youhavetheoption

of 1-199nickels.

-->PresstheLOWERLEFTkey padoncetoadvancetonextcode.

COIN SLIDE OPTION

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.

inn

O._ NotSelected'OFF'.

Selected'ON'.Pressthe LOWERRIGHTkeypad3 conseculJve

_mesforthis selection.

Whencoinslidemodeisselected,set'b.' equaltovalueof slide

innickels.Setstep6(regularcycleprice)andstep3 (specialcycle

price)to numberofslideoperalJons.Ifmeinstallersetsup'CS'

ona coindropmodel,it willnotregistercoins.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

ADD COINS OPTION

ThisoptioniseitherSELECTED'ON'or NOTSELECTED'OFF'.This

optioncausesthe customerdisplaytoshowme numberofcoins

(coin1)to enter,ratherthanthedollars-and-centsamount

Cf3f3

_._ NotSelected'OFF'.

Selected'ON'.Pressthe LOWERRIGHTkeypad

3consecu'dvetimesforthis selection.

--) PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

ENHANCED PRICING OPTION

can

_._ NotSelected'OFF'.

/--._ Cycle-Basedpricingenabled.Thisoptionallowsconfiguration

ofdifferentpricesfor cold,warm,andhotwatercycles.Pressme

LOWERRIGHTkeypadforthis selection.

SuperCyclepricingenabled.Thisoptionallowscustomers

to upgradecyclesbydepositingextramoney.Set-upcodes

'H.'and'h.'will bedisplayedonlywhenthisoptionisenabled.

PressmeLOWERRIGHTkeypadforthisselection.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

_n,

u i SUPER CYCLE UPGRADE PRICE

(SkippedunlessSuperCyclepricingisenabled.)

/.( nl

._ Thisrepresentsthenumberof coin 1 requiredtoupgradea

basecycletoa supercycle.Advancefrom0-39 bypressing

the LOWERLEFTkeypad.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

_n,

u i SUPER CYCLE TYPE

(SkippedunlessSuperCyclepricingisenabled.)

/._nl

._ ThisrepresentstheSuperCycleupgradeoption.Pressthe

LOWERLEFTkeypadtostepthroughupgradeoptions1

through3asfollows:

01- enhancedwash,extra3minutesof washtumbleinaddition

tothe programmedwashtime.

02- extrarinseforallcycles.

03- both01and02.

-->PresstheLOWERMIDDLEkeypadoncetoadvanceto nextcode.

12

Page 13

COIN/DEBIT OPTION

Bothcoin&debitselected.

Coinsselected,debitdisabled.PresstheLOWERRIGHTkeypad

formis selec'don.

DebitCardselected,coinsdisabled.Pressthe LOWERRIGHTkey

padforthis selection.

EnhancedDebitisself-selectedwhena Generation2 card reader

isinstalledinthewasher.The Edoptioncannotbemanually

selectedordeselected.

Pressthe LOWERMIDDLEkeypadonceto advanceto nextcode.

PRICE SUPPRESSION OPTION

Thisoptioncausesme customerdisplaytoshow'ADD'or

'AVAILABLE'rathermanthe amountofmoneyto add.(Used

mainlyindebitinstallations.)

NotSelected'OFF'.

Selected'ON'.PressmeLOWERRIGHTkeypadonce

forthisselection.

Pressthe LOWERMIDDLEkeypadonceto advanceto nextcode.

CLEAR ESCROW OPTION

Whenselected,moneyheldin escrowfor 30 minuteswithout

furtherescroworcycleac'dvitywill becleared.

Selected'ON'.

Notselected'OFF'.Pressthe LOWERRIGHTkeypadoncetodeselecl

misselection.

Pressthe LOWERMIDDLEkeypadonceto advanceto nextcode.

PENNY INCREMENT OFFSET

Thisrepresentsthe pennyincrementpriceoffsetusedin

Generation2 (EnhancedDebit)PRmodels.Choosefrom0-4

penniesbypressingtheLOWERLEFTkeypad.

Pressthe LOWERMIDDLEkeypadonceto advanceto nextcode.

If cycle counter (90C) is selected, the following is true:

100 Represents the number of cycles in HUNDREDS. 1 02 = 200

200 Represents the number of cycles in ONES. 2 2.5 = 25

TOTAL CYCLES = 225

This is "VIEW ONLY" and cannot be cleared.

Press the LOWER MIDDLE key pad once to advance

to next code.

If money counter (1.0C or 1.C0) is selected, the following istrue:

300 Number of dollars in HUNDREDS. 3 01 = $100.00

400 Number of dollars in ONES. 4 68 = $ 68.00

500 Number of CENTS. 5 7.5= $ .75

TOTAL = $168.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

• PD Models: Reinstall access door.

• PR Models:

Unplug washer or disconnect power.

Open console, reinsert plug into AA1, close console.

Plug in washer or reconnect power.

13

Page 14

MAYTAG ®COMMERCIAL SINGLE-LOAD AND VENDED

MULTI-LOAD WASHER AND DRYER

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter "Maytag") will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR ORTHE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATESAND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag ® Commercial Laundry distributor. To locate your authorized Maytag ®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/10

For written correspondence:

Maytag ®Commercial Laundry Service Department

Benton Harbor, Michigan 49022 USA

2000 M-63 North

14

Page 15

P P

SECURITEDELALAVEUSE

Votre s6curite et celle des autres est tres importante.

Nous donnons de nombreux messages de securit6 importants dans ce manuel et sur votre appareil menager. Assurez-vous

de toujours lire tous les messages de securit6 et de vous y conformer.

Ce symbole d'alerte de securit6 vous signale les dangers potentiels de deces et de blessures graves a vous et

d'autres.

Voici le symbote d'alerte de securit6.

Tousles messages de securit6 suivront le symbole d'alerte de securit6 et le mot "DANGER" ou

"AVERTISSEMENT". Ces mots signifient :

Risque possible de deces ou de blessure grave si

vous ne suivez pas immediatement les instructions.

Risque possible de deces ou de blessure grave si

vous ne suivez pas les instructions.

Tousles messages de securit6 vous diront quet est le danger potentiel et vous disent comment reduire le risque de blessure

et ce qui peut se produire en cas de non-respect des instructions.

IMPORTANTES INSTRUCTIONS DE SECURITE

AVERTISSEMENT : Pour reduire les risques d'incendie, de choc electrique ou de blessures Iors de I'utilisation de la

laveuse, suivre les precautions fondamentales dont les suivantes:

• Lire toutes les instructions avant d'utitiser la laveuse. •

• Ne pas laver des articles qui ont et6 nettoyes ou laves

avec de I'essence ou imbibes d'essence, sotvants de

nettoyage a sec, ou autres substances inflammables

ou explosives; ces substances peuvent emettre des

vapeurs susceptibles de s'enfiammer ou d'exptoser.

• Ne pas ajouter d'essence, solvant de nettoyage a sec ou

autre produit inflammable ou explosif dans l'eau de

lavage. Ces substances peuvent emettre des vapeurs

susceptibles de s'enflammer ou d'exploser.

• Dans certaines conditions, de I'hydrogene gazeux peut

se former dans un circuit d'eau chaude qui n'a pas et6

utilise pendant 2 semaines ou plus. LE GAZ

HYDROGC:NE EST EXPLOSlBLE. Si le circuit d'eau

chaude n'a pas et6 utilise pendant une tetle periode,

avant d'utiliser la taveuse, ouvrir tousles robinets

d'eau chaude et laisser I'eau s'ecouler pendant

plusieurs minutes par chaque robinet. Ceci permettra

I'evacuation de I'hydrogene gazeux accumule. Comme

ce gaz est inflammable, ne pas fumer ou utitiser une

fiamme nue au cours de cette periode.

CONSERVEZ CES INSTRUCTIONS

Ne pas taisser des enfants jouer sur ou a I'interieur de la

laveuse. Bien surveilter les enfants Iorsque la laveuse est

utilisee a_proximite d'enfants.

• Avant de mettre la taveuse au rebut ou hors de service, enlever

la porte ou le couvercte.

• Ne pas tenter d'atteindre un article a I'interieur de la cuve de la

laveuse Iorsque le tambour, la cuve ou I'agitateur est en

mouvement.

Ne pas installer ou remiser cette laveuse &un endroit o0 elle

serait exposee aux intemperies.

• Ne pas modifier les organes de commande.

• Ne pas reparer ou remptacer un composant quelconque de la

laveuse, ni entreprendre une operation de service, si ce n'est

specifiquement recommande dans ce manuel ou dans un

manuel d'instructions de reparations destine & I'utilisateur; it est

alors essentiet que la personne concernee comprenne ces

instructions et soit competente pour les executer.

• Voir "Specifications electriques" pour les instructions de liaison

la terre.

15

Page 16

EXIGENCESD'INSTALLATION

Rassembler les outils et pieces necessaires avant d'entreprendre

I'installation.

Outils n_cessaires

• Niveau

• Couteau utilitaire

• Ciseaux

• Cle &mollette de 8" ou 10"

• Tournevis & lame plate

• Pince

• Seau

Pi_ces fournies

Retirer les pieces de la laveuse. Verifier la presence de toutes les

pieces.

• 1 bride de fixation

• 2 tuyaux d'arrivee d'eau

• 4 rondelles plates de tuyau d'arrivee d'eau

• 2 pieds de nivellement avant avec ecrous

• 1 tuyau de vidange

IMPORTANT : Ne pas installer ou remiser la laveuse dans un

endroit oQ elle sera exposee aux intemperies. Ne pas remiser

ou faire fonctionner la laveuse & des temperatures inferieures

ou egales a 0°C (32°F). Une quantite d'eau peut demeurer dans

la laveuse et causer des dommages a des temperatures basses.

C'est a I'utilisateur qu'incombe la responsabilite de realiser une

installation correcte.

II vous faudra :

• Un chauffe-eau pour fournir de I'eau a 49°C (120°F) a la

laveuse.

• Une prise electrique reliee a laterre situ_e & moins de

1,2 m (4 pi) de la prise du cordon electrique se trouvant

I'arriere de la laveuse.

Voir "Specifications electriques".

• Des robinets d'eau chaude et d'eau froide situes a 1,2 m (4 pi)

de I'arriere de la laveuse, et une pression d'eau de 69 a 690

kPa (10 a100 Ib/po2). Lorsque la pression d'alimentation

I'entree du b&timent est superieure a 690 kPa (100 Ib/po2),

on devrait installer une vanne de reduction de la pression pour

eviter une eventuelle deterioration de la vanne de mixage de

la laveuse.

• Un plancher de niveau ayant une pente maximale de

25 mm (1") sous I'ensemble de la laveuse.

• Un plancher robuste pour supporter la laveuse dont le poids

total (laveuse, eau et charge) est de 143 kg (315 Ib).

• Une colonne montante d'au moins 300 mm (12") destinee

fournir un coussin d'air et a emp_cher I'emission de bruit et

la deterioration des electrovannes Iors de I'installation d'une

seule machine.

• Un siphon de plancher devrait _tre disponible sous la cloison.

On devra utiliser une cloison prefabriquee avec prises de

courant, canalisations d'eau et canalisations d'evacuation

seulement Iorsque le code local le permet.

REMARQUE : La zone de la pompe est accessible a I'avant

apres depose du panneau avant (maintenu en place par 2 vis

TORX®T n° T20).

16

1-®TORXest une marqued6pos6edeAcument IntellecualProperties,LLC.

Page 17

Instructions d'installation dans un encastrement ou

un placard

Cette laveuse peut _tre installee dans un encastrement ou un

placard.

Les dimensions d'installation illustrees sont en centimetres et

constituent le minimum applicable. Un espace supplementaire

peut _tre necessaire pour faciliter I'installation, I'entretien et pour

observer les codes et reglements Iocaux en vigueur.

Si une porte de placard est installee, des ouvertures d'evacuation

de Fair minimales sont necessaires dans les parties superieure et

inferieure. Les portes a claire-voie offrant des ouvertures

equivalentes sont acceptables.

D_gagements de s_paration minimums a respecter

j Porte de placard

Dimensions du produit

I

/

O0

432 mm

3,10m_ 356mm

(48"_),__ (14")max.

(17")

t_1- 25 mm.(l")

Vue encastree de

face du placard

3,10 m_ _-

(48"2)*__

Vue de face

Porte de

0 placard

Vue laterale du

placard

76 mm (3")

T

76 mm(3")

*Dimension minimale pour une porte de placard.

Les portes a claire-voie offrant des ouvertures equivalentes sont acceptables.

102mm

(4") min.

A. 1090 mm (43")

B. 970 mm (38-1/8',)

C. 890 mm (35 ")

D. 38 mm (1-1/2")

E. 705 mm (27-3/4',)

F. 650 mm (25-1/2',)

G. Arrivees d'eau

H. 180 mm (7'')

I. Cordon d'alimentation electrique

J. E-tiquette

K. 685 mm (27'')

L. 133 mm (5-1/4',)

M. 25 mm (1 ")

N. Tuyau de vidange

O. 127 mm (5'')

N

/

• Un espace supplementaire peut _tre necessaire pour faciliter

I'installation et I'entretien.

• Un espace supplementaire peut _tre requis pour les moulures

de porte et de plancher et pour les plinthes.

• Un espace supplementaire de 25 mm (1") de tousles c6tes

de la laveuse est recommande pour reduire le transfert du

bruit.

• IIfaut aussi prendre en compte I'espace requis entre les

appareils voisins.

Systbme de vidange avec tuyau de rejet _ I'_gout

Le systeme de rejet a I'egout necessite un tuyau de diametre

minimum de 50 mm (2"). La capacite minimum de vidange ne

peut pas _tre inferieure a 64 L (17 gal.) par minute.

Le sommet du tuyau de rejet a I'egout doit _tre au moins

990 mm (39") de hauteur et au maximum a 1,8 m (72") de

la base de la laveuse.

17

Page 18

Risque de choc dlectrique

Brancher sur une prise a 3 alvdoles relide & la terre.

Ne pas enlever la broche de liaison & la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un c&ble de rallonge.

Le non-respect de ces instructions peut causer

un ddc_s, un incendie ou un choc dlectrique.

IMPORTANT : La laveuse doit _tre correctement reliee & la terre

en conformite avec les codes et reglements Iocaux en vigueur ou,

en I'absence de tels codes, avec le National Electrical Code,

ANSI/NFPA 70 - derniere edition.

• Si les codes le permettent et si on utilise un conducteur

distinct de liaison & la terre, il est recommande qu'un

electricien qualifie verifie la qualite de la liaison & la terre.

• Ne pas utiliser une tuyauterie de gaz pour le raccordement &

la terre.

• Ne pas installer un fusible dans le conducteur neutre ou le

conducteur de liaison & la terre.

Pour obtenir un exemplaire de la norme des codes ci-dessus,

contacter :

National Fire Protection Association

One Batterymarch Park, Quincy, MA 02269

• L'appareil doit _tre alimente par un circuit de 120 V, CA

seulement, 60 Hz, 15 ou 20 A, proteg6 par un fusible. On

recommande d'utiliser un fusible ou un disjoncteur temporis&

IIest recommande de raccorder la laveuse sur un circuit

distinct exclusif & cet appareil.

• Cette laveuse comporte un cordon d'alimentation electrique &

trois broches pour liaison & la terre.

• Pour minimiser les risques de choc electrique, on doit

brancher le cordon sur une prise de courant de configuration

correspondante, & 3 alveoles, reliee & la terre et installee

conformement & tous les codes et reglements Iocaux en

vigueur. Si une prise de courant de configuration

correspondante n'est pas disponible, le client a la

responsabilite et I'obligation de faire installer par un electricien

qualifie une prise de courant correctement reliee & la terre.

M_thode recommand_e de mise _ la terre

La laveuse doit _tre correctement reliee & la terre en conformite

avec les codes et reglements Iocaux en vigueur ou, en I'absence

de tels codes, avec le National Electrical Code, ANSI/NFPA 70 -

derniere edition, et aux codes et reglements Iocaux.

INSTRUCTIONS DE LIAISON A LA TERRE

Pour une laveuse reliee a la terre et connectee par

un cordon :

Cette laveuse dolt _tre reliee la terre. En cas d'anomalie de

fonctionnement ou de panne, la liaison & la terre reduira le

risque de choc electrique en offrant au courant electrique un

itineraire d'evacuation de moindre resistance. Cette laveuse

est alimentee par un cordon etectrique comportant un

conducteur retie & la terre et une fiche de branchement

munie d'une broche de liaison & la terre. La fiche dolt _tre

branchee sur une prise de courant appropriee qui est bien

installee et reliee la terre conformement & tousles codes et

regtements Iocaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareil au conducteur de liaison ta terre peut susciter un

risque de choc electrique. En cas de doute quant & la qualite

de la liaison la terre de I'appareil, consulter un electricien ou

technicien d'entretien qualifi&

Ne pas modifier la fiche de branchement fournie avec

I'appareil si la fiche ne correspond pas & la configuration de

la prise de courant, demander & un electricien qualifie

d'installer une prise de courant convenable.

Pour une laveuse raccordee en permanence :

Cette laveuse dolt _tre raccordee & un systeme de c&blage

permanent en metal retie & ta terre ou un conducteur retie &

la terre dolt _tre en fonction avec les conducteurs de circuit

et raccordes & ta borne de liaison la terre ou la borne sur

I'appareil menager.

18

Page 19

INSTRUCTIONSD'INSTALLATION

Risque du poids excessif

Utiliser deux ou plus de personnes pour deplacer et

installer la laveuse.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

1.

Enlever le ruban adhesif qui recouvre la sangle d'expedition.

Tirer pour extraire completement la sangle et les 2 goupilles

qui se trouvent &I'interieur de la laveuse.

B

Le bon acheminement du tuyau de vidange evite d'endommager

vos planchers imputables & une fuite d'eau. Lire et suivre

ces instructions.

Connecter les tuyaux d'alimentation _ la laveuse

1. La laveuse doit _tre connectee aux robinets d'eau & I'aide

des nouveaux tuyaux d'arrivee d'eau. Ne pas utiliser de tuyaux

usages. Inserer les rondelles plates neuves (fournies) dans

chaque extremit6 des tuyaux d'arrivee d'eau. Inserer fermement

les rondelles dans les raccords.

A B

A. Raccord

B.Rondelle

2=

Fixer d'abord le tuyau & la valve d'arrivee d'eau inferieure.

A, Ruban adh6sif pour expedition

B, Sangle d'exp6dition

2=

Tirer fermement pour extraire I'extremit6 de la sangle

d'expedition de I'arriere de la laveuse. Pour la liberer les pieds

de reglage de I'aplomb, il faut que la sangle d'expedition soit

completement extraite de la machine.

Conserver la sangle d'expedition pour reutilisation eventuelle.

A

B

A. Valve du tuyau d'alimentation d'eau froide

B. Valve du tuyau d'alimentation d'eau chaude

3. Fixer le second tuyau &la valve d'arrivee d'eau superieure.

Serrer les raccords & la main, puis utiliser une pince et serrer

de deux tiers de tour en plus.

REMARQUE : Les ills des valves de tuyau d'arrivee d'eau sont

en plastique. Veiller &ne pas det6riorer les filetages des

raccords.

Connecter le tuyau de vidange

REMARQUE : Faire glisser la laveuse sur un carton ou une

plaque de contreplaqu_ avant de la deplacer sur le plancher.

1. Placer la laveuse pres de son emplacement d'installation final.

2. Mettre I'extremite en crochet du tuyau de vidange dans

I%vier de buanderie ou dans le tuyau de rejet & I'egout.

3. Estimer la Iongueur de tuyau de vidange necessaire Iorsque la

laveuse est & son emplacement d'installation final. II faut que

le tuyau soit coupe & la Iongueur exacte qui permettra &

I'extremite en crochet d'etre fermement retenue dans

I'embouchure du tuyau de rejet & I'egout.

19

Page 20

Si le tuyau de vidange est trop long, couper I'extremit6 droite

pour le raccourcir. (Ne jamais couper I'extremit6 recourbee du

tuyau de vidange.)

REMARQUE • Ne pas forcer une section excessive du tuyau

de vidange & pen6trer dans letuyau de rejet & I'egout, ceci

pourrait provoquer un siphonnage.

4.

Placer la bride de tuyau sur le raccord de vidange de la

laveuse. Pousser le tuyau de vidange pour I'engager sur le

raccord de connexion de la laveuse. Utiliser une pince pour

ouvrir la bride de tuyau et la placer & I'emplacement approprie

sur le tuyau de vidange. Verifier que la bride est correctement

placee et serree.

Connecter les tuyaux d'alimentation aux

robinets d'eau

1. Avant de fixer les tuyaux d'alimentation, faire s'ecouler I'eau

des deux robinets dans un seau. Ceci eliminera les particules

se trouvant dans les canalisations d'eau qui pourraient

obstruer les tuyaux. Marquer le robinet d'eau chaude.

2. Fixer le tuyau d'alimentation inferieur (marqu_ "H") au

robinet d'eau chaude.

Serrer & la main les raccords au robinet.

3. Fixer le tuyau d'alimentation superieur (marqu_ "C") au robinet

d'eau froide.

Serrer & la main les raccords aux robinets.

4. Utiliser une pince et tourner chaque raccord de deux tiers de

tour en plus.

Installation des pieds de r_glage de I'aplomb avant

1. Superposer deux cornieres de carton d'emballage. Incliner la

laveuse vers I'arriere et inserer les cornieres sous la laveuse &

76 mm (3") de chaque c6te - voir I'illustration.

5. Mesurer et marquer un point & approximativement

406 mm (16") de I'extremite avec piton de la sangle

d'expedition. Couper la sangle & cet endroit.

6.

Verifier que le tuyau n'est pas vrille ou deforme et qu'il est

fermement maintenu en place.

7.

Introduire I'extremite recourbee du tuyau de vidange dans le

tuyau de rejet &I'egout. Enlacer les deux tuyaux avec la

sangle d'expedition. Introduire le piton dans le trou le plus

proche de la sangle.

Irouver les pleas ae reglage ae raplomo et _esecrous aans

le sachet de pieces. Visser I'ecrou jusqu'& moins de 13 mm

(1/2") de la base.

P_i____1_!_1_!_1"_ _ 1

JJ;JJJJJJ,;J.JJJij,jJ

A, 13mm (1/2")

B,Base

C,E-crou

3.

Inserer un pied dans le trou approprie dans chaque angle

avant de la laveuse jusqu'& ce que I'ecrou soit au contact

de la base de la laveuse. Ne pas serrer les ecrous avant

que I'aplomb de la laveuse n'ait ete etabli.

\

/

20

4. Incliner la laveuse vers I'arriere et retirer les cornieres de

carton. Abaisser doucement la laveuse pour la reposer au sol.

5. Deplacer la laveuse jusqu'& son emplacement definitif. Retirer

le carton ou la plaque de contreplaqu6 de dessous la laveuse.

Page 21

R_glage de I'aplomb de la laveuse

1. Incliner la laveuse vers I'avant pour soulever les pieds arriere

de 2,5 mm (1") pour I'ajustement des pieds arriere de reglage

automatique de I'aplomb. Abaisser doucement la laveuse

jusqu'au sol.

2. Utiliser un niveau pour contr61er I'aplomb de la machine dans

les deux directions, transversalement et avant-arriere.

3,

Si la laveuse n'est pas d'aplomb, regler la Iongueur de

deploiement des pieds avant. Utiliser le niveau pour un

contr61e final.

4,

Lorsque la laveuse est d'aplomb, utiliser une cle pour serrer

chaque ecrou au contact de la base de la laveuse. Si les

ecrous ne sont pas suffisamment serres contre la base, la

laveuse pourrait vibrer.

\

Risque de choc electrique

Brancher sur une prise & 3 alveoles reliee & la terre.

Ne pas enlever la broche de liaison _ la terre.

Ne pas utiliser un adaptateur.

Ne pas utiliser un cable de rallonge.

Le non-respect de ces instructions peut causer un

deces, un incendie ou un choc electrique.

6. Brancher le cordon electrique dans une prise & 3 alveoles

reliee &la terre.

REMARQUE : Sur certains modeles, Iors des tests & I'usine, le

bouton de la minuterie est engage (execution partielle d'un

programme) et le bouton de mise en marche est enfonc&

Laisser la minuterie provoquer la poursuite du programme

jusqu'& la fin. Lorsque le programme est termine, la minuterie se

rearme et le bouton reprend sa position de mise en marche. Si

on ne laisse pas la minuterie commander le deroulement du

programme jusqu'& la fin et le rearmement, le lavage de la

3remiere charge ne sera pas execute correctement.

1. Consulter les specifications electriques. Verifier que la tension

electrique disponible est correcte et que la prise de courant

est convenablement reliee &la terre.

2. Verifier que toutes les pieces sont maintenant installees. S'il

reste une piece, passer en revue les differentes etapes pour

decouvrir laquelle aurait ete oubliee.

3. Ouvrir les robinets d'eau et verifier s'il y a des fuites. Serrer les

raccords en cas de fuites. Ne pas serrer excessivement, ceci

pourrait endommager les robinets.

4. S'assurer d'avoir recupere tous vos outils.

5. Verifier que la sangle d'expedition a ete retiree & I'arriere de la

laveuse et qu'elle a ete utilisee pour I'arrimage du tuyau de

vidange. Si la sangle n'a pas ete totalement retiree, la laveuse

peut vibrer et etre bruyante.

Risque de choc electrique

Deconnecter la source de courant electrique avant

I'entretien.

Replacer pieces et panneaux avant de faire la remise

en marche.

Le non-respect de ces instructions peut causer un

deces ou un choc electrique.

Liste de contr61e pour le fonctionnement de la laveuse :

Si la laveuse ne fonctionne pas correctement, verifier ce qui suit :

1. Le cordon d'alimentation est branch&

2. Le disjoncteur ne s'est pas declenche ou aucun fusible

n'est grille.

3. La minuterie a ete avancee pour commencer un programme.

4. Les robinets d'eau chaude et d'eau froide sont ouverts.

5. Les tuyaux d'arrivee d'eau et de vidange ne sont pas

deformes.

6. Le couvercle de la laveuse est ferm&

7. La valve d'arrivee d'eau n'est pas gelee si elle n'est pas

protegee des intemperies.

8. Niveau de mousse. Une quantite excessive de mousse

ralentira I'essorage et produira un rin£;age mediocre. Executer

un programme complet sans utiliser de detergent. Utiliser

moins de detergent ou un detergent au niveau de mousse

contr61e pour les prochaines charges. 21

Page 22

Si vous avez besoin d'assistance :

Communiquer avec votre distributeur d'ensemble de buanderie

Maytag _ autoris& Pour Iocaliser votre distributeur d'ensemble

de buanderie Maytag _*autorise, ou pour des demandes

de renseignements sur Internet, visitez le site Web

www.MaytagCommercialLaundry.com.

Si vous ne pouvez pas Iocaliser votre distributeur, le Centre

d'assistance d'appareils de buanderie commerciaux repondra &

toute question concernant le fonctionnement et I'entretien de la

laveuse non abordee dans les instructions d'installation.

IIsuffit de composer le 1-800 NO BELTS (1-800-662-3587).

La communication est gratuite.

Lors de I'appel, vous aurez besoin des numeros de modele et de

serie de la laveuse. Les deux numeros sont indiqu6s sur la plaque

signaletique de I'appareil.

Conseils de fonctionnement

Tailles de charges completes classiques

Type de

charge

Charge

mixte

Pressage

3ermanent

Suggestion de

chargement

3 draps a 2 places

4 taies d'oreiller

6 shorts

8 tee-shirts

2 chemises

2 chemisiers

8 mouchoirs

2 draps a 2 places

ou 1 drap de tres

grande taille

1 nappe

1 robe

1 chemisier

2 pantalons tout-

aller

3 chemises

2 taies d'oreiller

Type de

charge

V_tements

de travail

epais

Tricots

Suggestion de

chargement

3 pantalons

3 chemises

1 salopette

4 jeans

1 ensemble

3 chemisiers

4 pantalons tout-

aller

6 chemises

4 hauts

4 robes

Risque d'incendie

Ne jamais mettre des articles humectes

d'essence ou d'autres fluides inflammables dans la

laveuse.

Aucune laveuse ne peut compl_tement enlever I'huile.

Ne pas faire s_cher des articles qui ont _t_ salis par

tout genre d'huile (y compris les huiles

de cuisson).

Le non-respect de ces instructions peut causer un

d_c_s, une explosion ou un incendie.

On deconseille le lavage d'articles de fibre de verre dans une

laveuse commandee par piece de monnaie. Si de tels articles ont

et6 laves dans la machine, commander I'execution d'un

programme complet pour I'elimination de tout residu qui pourrait

encore se trouver dans la machine.

En cas de d_placement de la laveuse

un nouvel emplacement

• Retirer les pieds avant de la base de la laveuse.

• Placer les deux pieds de nivellement arriere en position elev6e

et fixer & I'aide de ruban adhesif.

• Appliquer du ruban adhesif sur les c6tes et le bas du placard

& I'arriere de celui-ci.

Ouvrir le couvercle de la laveuse; inserer une couverture entre

la couronne de la cuve et le sommet de la caisse pour limiter

les mouvements de la cuve.

Pieds _Pieds avant

arriere "£1_-_" - Ruban adhes f double face

Manipuler doucement la laveuse. Faire attention de ne pas

laisser tomber la laveuse en cas d'utilisation d'un chariot &

bras.

22

Page 23

P P

REGLAGEDELACOMMANDEELECTRONIQUE

LAVEUSE COMMERCIALE. OPERATIONS DE BASE

• Pourd'autresrenseignements,consulterwww.MaytagCommercialLaundry.com.

• Cetfichetechniquen'estpasvalablepourlesmodelesanterleursauxmodelesseriesMAT14.

Risque de choc electrique

Deconnecter la source de courant electrique avant

I'entretien,

Replacer pieces et panneaux avant defaire la

remise en marche,

Le non-respect de ces instructions peut causer un

deces ou un choc electrique.

IMPORTANT

Circuits electroniques sensibles

aux decharges electrostatiques

Lerisquededechargedectrostatiqueestpermanent.Unedechargedectrostatiquepeut

endommagerouaffaibtirlescomposantsdectroniques.Lanouvellecartepeut donner

I'impressionqu'dle fonctlennecorrectementapresla reparation,maisunedecharge

dectrostatiquepeutluiavoirfait subirdesdommagesquiprovoquemntuneddaillance

plustard.

• Utitiserunbraceletdedechargedectrostatique.Connecterlebraceletb lavis vertede

liaisonala terreousurunesurfacemetalliquenonpeintede I'appareil

-OU-

Toucherplusleursfob du doigtla vis vertedeliaisonblaterreou unesurface

metalliquenonpeintedelalaveuse.

• Avantderetirerlapiecedesonsachet,placerle sachetantistatiqueencontactavec

la vis vertedeliaisonblaterreou unesurfacemetaltiquenonpeintedela laveuse.

• Eviterde toucherles composantselectroniquesoulesbrochesdecontact,tenirla

cartedecircuitsdectroniquespar lesbordsseulementlersdesmanipulations.

• Lorsdureemballaged'unecartedecircuitselectroniquesddaillantedanslesachet

antistatique,observerlesinstructionsci-dessus.

Programmes gratuits

Pourceci, on regle le prix deI'utilisation a zero; I'afficheur presente alors

'SELECTCYCLE'(sdectionner le programme) plutCtque le prix d'une utilisation.

Pr_t pour carte de debit

Cettelaveuseest preoconfigu_e pour I'udisation des cartes de debit; Nest compatib/

avecune varie_ desystemesdepaiement par earle dedebit, mab il n'est MS

burni avecun lecteur de carte ryed'ebit.,Dourlereg/agea_pro?rie de la machine,

volt les instructions foumies par le bbricant W lectew d_ carte de debit. Pourun

modele converti pour I'uti/isaL/ond'une carte dec_bit OenerationI, les in_ou/sions

de d#,,bitsont equivalentesa I'insertion d'une piece (,obce I).

Afficheur

ApresI'installation initiale et le branchementde I'appareil, I'afficheur presente

'0 MINUTES'.Apresle branchement dela laveuseet I'ouverture du couvercle,

I'afficheur presente le prix. Si la laveuse est regleepour I'utilisation gratuite,

I'afficheur presente 'SELECTCYCLE'(sdectionner leprogramme) avec clignotement.

WHITES COLORS BRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS BRIGHTS

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

WHITES COLORS BRIGHTS

INFORMATION GENERALE POUR UUTILISATEUR

Afficheur vierge

Cettesituationindiqueque/a/aveusen'estpasoperationne/le.Accederaumodede

configurationpourvoirle codedediagnostic.

Affichage de '0 Minute'

Ceciindiquequ'i!n'estpaspossibledefairefonctionner/a laveuse.L'informationsurles

pbcesinsereesoulesentreesdedebitseramemoriseemaisnepeut#treutitiseeavant/e

retabtissementdu fonctionnementnorma/parunemancauvred'ouverture/fermeturedu

couvercle.Encasdedalai/lanceducontacteurducouverc/e,on doltleremp/acerpourpouvoir

retabtirlefonctionnementnormal

Mise en marche pour la premiere utilisation

Lalaveusea ere programme aI'usine comme suit :

• Periodedelavage de 11minutes

m 1 rinqageet 2 minutes d'agitation (rinqage)

m Prixdu lavage : 1,75 $ (modeles PD)

m Prixdu lavage : 0,00 $ (modeles PR)

Remise en marche apres une interruption de I'alimentation

Apres un dalai qui peut atteindre 8 secondes, I'etat initial dela laveuse (aumoment

de/'interruption de I'alimentation) est restauree.

Prix de I'utilisation

Apres I'ouverture du couvercle aI'achevement d'un programme, I'afficheur presente

le prix d'utilisation (sauf si I'appareil est reglepour I'utilisation gratuite). Lots de

I'enregistrement de/'introduction depieces oud'un debit,/'information affichee

changeet guideI'utilisateur pour le lancement d'un programme.

PERM. DELICATES SMALL

PRESS AND KNITS LOAD

PROCJEDURES DE RJEGLAGE DES SYSTEMES

DE COMMANDE

IMPORTANT: Lirela totalite des instructions avantI'utilisation.

Pourle reglage des systemes de commande, on utilise les touches dereglage

inferleures (tissu) etI'afficheur numerique. Eafficheurpeut presenter 4 chiffres

et/ou lettres etun point decimal,qui indiquentles codes de parametrage et des

valeursconnexesdisponiblespour laprogrammation de la laveuse.

Utilisation des touches pour la programmation des

systemes de commande

1. La touche INFERIEUREDEGAUCHEpermet la sdection des valeurs associees

aux codes deparametrage. Linepression sur la touche fair augmenterla valeur;

si on maintient la pression sur la touche, la valeurafficheeaugmenterapidement.

2. Latouche INFERIEURECENTRALEcommande la progression parmi les codes de

parametrage.Linepression sur la touche provoque le passage au code de

parametragesuivant; une pression constante sur la touche commande le

ddilement automatiquedes codes a raisonde un code par seconde.

3. La touche INFERIEUREDEDROITEpermet deselectionner/desdectionner

les options.

23

Page 24

Parametrage pour mise en marche

• Modde PD:Insererla cb de la porte d'acces; toumer et souleverpour enlever

la porte d'acces.

• Modde PR: Apres installationdu lecteur de carte de debit (conformementaux

instructions du fabricantdu lecteur decarte), pour acceder aumode de

parametrage,inserer la carte de parametragemanuel(foumie par le fabricant du

lecteur de carte) dansle lecteur decarte. Siune carte deparametragemanuel

n'est pas disponble, onpeut egalementenleverle connecteur AA1sur la carte

des circuits pour accederau mode deparametragemanuel

IMPORTANT:Nepas ouvrir la console avant d'avoir deconnecteI'appareil detoute

source d'energie. Pour acceder auconnecteur AA1 :

-.>Debrancherla laveuseou deconnecterla sourcede courant dectrique.

-> Ouvrirla console, debrancherle connecteurAA1;refermer la console.

Brancherla laveuseou reconnecterla source decourant dectrique.

L'appareilest maintenant aumode de parametrage.

Avantde poursuivre, noter quemalgre le grand nombre d'options disponibles,

le propfietaire de I'appareflpeut deciderde simplement debater sa nouveflemachine

commerciale,la brancher et la raccorder; eriesera alors parfaitementoperationnelle.

CODES DE PARAMETRAGE

• LatoucheINFERIEURECENTRALEpermetde passerdecodeencode.

• LatoucheINFERIEUREDEGAUCHEpermetdechangerlavaleurducode.

• LatoucheINFERIEUREDEDROITEpermetdeseleetionnerou desdectionnerlesoptions.

POURLESMODELESPR: LescodesdeparametragesontidentiquesaumodelePD,sauf

quandspecifie.

Unoudeuxcaracteresagauchecorrespond(ent)aucode deconfiguration.Lavaleurdu

codeestindiqueepar les 2ou3 caracteresde droite.

_L_n 7 PRIXPOURPROGRAMMEREGULIER

_ O_j Cecirepresentelenom.bredepiecesde0,25$(piece1),reglagedanslaplage0-39.

'VoirVALEURPOURPIECE1.)Pourhireaugmenterle chiffreafficMentre0-39,appwer

surlatoucheINFERIEUREDEGAUCHE.Configurea I'usinepour7pbcesde8,25$ =

1,75$.

MODELESPRSEULEMENT: Configureal'usinepour0 piecede0,25$.

e AppwerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

"1 t I

L_JI I DUREEDULAVAGE

"t I 1

' LLJJ NombredeminutesdelaperiodedeLAVAGE.Sdectionnerunevaleurde8-20minutes:

appuyersurlatoucheINFERIEUREDEGAUCHE.

AppwerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_ / PERIODESDE RINgAGE

B _L_j IIs'agitdeladureeetdunombretotaldeperiodesderin_age.Ladureedechaque

pefioded'agitation(rin_age)estde1-4minutes,onpeutohoisir1ou2 rin_ages.Le

chiffredumilieurepresenteladureedelapefioded'agitation(rin_age)etleohiffrede

droiterepresentelenombrederin_ages.

Onbitohangerlavaleuraffioheeselonlasequencesuivante(11,21,31,41,12,22,32,

42)pardespressionssurlatoucheINFERIEUREDEGAUCHE.

AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

PourleprogrammeDELICATES&KNITS(articlesddicats/tficots),ladureefixedepefiode

d'agitation(rin_age)estdeuneminute.

•e AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_ OPTIONDECOMPTAGEDUNOMBREDEPROGRAMMES

Cetteoptionpeut_treSELECT!ONNEE('ON')ouPASSELECT!ONNEE('OFF').

Passe ection,!e!OEE') ..................................

_ nu_j Optionsdectionneeetimpossibilitededesdection.

Appuyer3fob consecutivessurlatoucheINFERIEUREDEDROITEpoursdeotionner'ON'

(active).Lorsque'ON'aeresdectionne,onnepeutdesdeotionnerI'option.

e AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_juu OPTIONCOMPTEURDEMONNAIE

Cetteoptionpeut_treSELECTIONNEE('ON')ouPASSELECTIONNEE('OFF').

nn Passdectionnee('OFF').

_.u_ Optionsdectionnee('ON').

Appuyer3foisconsecutivessurlatoucheINFERIEUREDEDROITEpoursdectionner'ON'

(active);appuyer3foissurlatouchepourdesdectionnerI'option.Lecompteurpassede

'OFF'(inactive)a 'ON'(active).

_._£j Optionsdectionnee('ON')etimpossibilitededesdection.

Poursdectionner'ON'avecimpossibilitededesdection,sdectionnerd'abord'ON'.Puis

enmoinsdedeuxsecondesappuyerdeuxfoissurlatoucheINFERIEUREDEDROITEet

unefoissurlatoucheINFERIEUREDEGAUCHE,etquitterlemodedeparametrage.

AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_L_nn OPTIONDEPRIXsPECIAL

Cetteoptionpeut_treSELECTIONNEE('ON')ouPASSELECTIONNEE('OFF').

PassG ectionnee .................................................

2._jP Optionsdectionnee('ON').AppuyerunefoissurlatoucheINFERIEUREDEDROITEpour

cettesdection.

Si/'OPtiONDEPRIXSPECIALestselectionnee,onaaccesauxcodes'3/a '9.'.

•e AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

OPtiONSDISPONIBLESSIL'OPTIONDEPRIXSPECIALAETESELECT/ONNEE:

-__j Cecirepresentelenombredepbcesde0,25$(piece1),reglagedanslaplage0-39.

(VoirVALEURPOURPIECE1.)Pourfaireaugmenterlechiffreafficheentre0-39,appuyer

surlatoucheINFERIEUREDEGAUCHE.ConfigureaI'usinepour7pbcesde0,25$ =

1,75$.

MODELEPRSEULEMENT: ConfigureaI'usinepour0piecede0,25$.

-->AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_._ SdectiondunombredeminutespourI'HORLOGE;sdectionnerunevaleurde

0-59minutes:appuyersurlatoucheINFERIEUREDEGAUCHE.

-_ AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

_nnu HORLOGE-HEURES

NOTE:Utilisationduformat24h.

appuyersurlatoucheINFERIEUREDEGAUCHE.

e AppuyerunefoissurlatoucheINFERIEURECENTRALEpourpasseraucodesuivant.

"_nn PRIXsPECIAL- NEUREDE COMMENCEMENT

L_UU

NOTE:Utilisationduformat24h.

"3 mn

_.u_j SdectiondeI'heuredecommencementpourcettetarification;0-23heures.Sdectionner

STARTHOUR(heuredecommencement): appuyersurlatoucheINFERIEUREDEGAUCHE,