Page 1

INSTALLATION INSTRUCTIONS

COMMERCIAL WASHER

120-volt, 60-Hz Models

INSTRUCTIONS D’INSTALLATION DE LA

LAVEUSE COMMERCIALE

Modèles 120V,60Hz

COMMERCIAL WASHER INSTALLATION INSTRUCTIONS

220–240-VOLT, 50-HZ MODELS

INSTRUCTIONS D’INSTALLATION

DU LAVE-LINGE COMMERCIAL

MODÈLES 220–240 V, 50 HZ

LAVADORA COMERCIAL INSTRUCCIONES DE INSTALACIÓN

MODELOS DE 220 Y 240 VOLTIOS, 50 HZ

LAVATRICE COMMERCIALE ISTRUZIONI D’INSTALLAZIONE

MODELLI A 220-240 V, 50 HZ

MAT14PD

W10045627A

www.maytagcommerciallaundry.com

Page 2

Table of Contents

WASHER SAFETY ..................................................................... 3

WASHER DISPOSAL ................................................................. 3

INSTALLATION REQUIREMENTS ............................................ 4

Tools and Parts ................................................................... 4

Location Requirements ....................................................... 4

Drain System ....................................................................... 5

Electrical Requirements ...................................................... 5

Table des matières

SECURITE DU LAVE-LINGE ................................................... 14

ÉLIMINATION DU LAVE-LINGE ............................................. 14

EXIGENCES D’INSTALLATION .............................................. 15

Outillage et pièces ............................................................. 15

Exigences d’emplacement ................................................ 15

Système de vidange .......................................................... 16

Spécications électriques ................................................. 16

INSTALLATION INSTRUCTIONS .............................................. 6

Remove Shipping Strap ...................................................... 6

Connect the Hoses ............................................................. 6

Level the Washer ................................................................. 7

Complete Installation .......................................................... 8

Operating Tips ..................................................................... 8

ELECTRONIC CONTROLS SETUP ........................................... 9

WARRANTY .............................................................................. 13

INSTRUCTIONS D’INSTALLATION ........................................ 17

Enlever la sangle d’expédition .......................................... 17

Raccordement des tuyaux ................................................ 17

Réglage de l’aplomb du lave-linge .................................... 18

Achever l’installation .......................................................... 19

Conseils d’utilisation ......................................................... 19

PARAMÉTRAGE DES COMMANDES ÉLECTRONIQUES ..... 20

GARANTIE ................................................................................ 25

Índice

SEGURIDAD DE LA LAVADORA ............................................ 26

ELIMINACIÓN DE LA LAVADORA ......................................... 26

REQUISITOS DE INSTALACIÓN ............................................ 27

Piezas y herramientas ....................................................... 27

Requisitos de ubicación .................................................... 27

Sistema de desagüe ......................................................... 28

Requisitos eléctricos ......................................................... 28

Sommario

SICUREZZA DELLA LAVATRICE ........................................... 38

L’ELIMINAZIONE DELLA LAVATRICE ................................... 38

REQUISITI D’INSTALLAZIONE .............................................. 39

Attrezzi e componenti ....................................................... 39

Requisiti di posizionamento .............................................. 39

Sistema di scarico ............................................................. 40

Requisiti elettrici ................................................................ 40

INSTRUCCIONES DE INSTALACIÓN .................................... 29

Cómo quitar la correa de embalaje ................................... 29

Conecte las mangueras .................................................... 29

Nivelación de la lavadora .................................................. 30

Complete la instalación ..................................................... 31

Consejos para el funcionamiento ....................................... 31

PROGRAMACIÓN DE LOS CONTROLES

ELECTRÓNICOS ...................................................................... 32

GARANTIA ................................................................................ 37

ISTRUZIONI D’INSTALLAZIONE ............................................ 41

Rimozione delle fascette d’imballaggio ............................ 41

Collegamento dei tubi ....................................................... 41

Livellamento della lavatrice ............................................... 42

Installazione completa ....................................................... 43

Suggerimenti operativi ...................................................... 43

CONFIGURAZIONE DEI CONTROLLI ELETTRONICI ........... 44

GARANZIA ................................................................................ 52

2

Page 3

WASHER SAFETY

WASHER DISPOSAL

3

Page 4

INSTALLATION REQUIREMENTS

Tools and Parts

Gather the required tools and parts before starting installation.

Tools needed

n Level

n Utility knife

n Scissors

n 200 mm (8") or 250 mm

(10") adjustable wrench

n Flat-blade screwdriver

n Pliers

n Bucket

Parts supplied

Remove parts bag from washer. Check that all parts were

included.

n 1 Hose clamp

n 2 Inlet hoses

n 4 Flat water hose washers

Technical

Specications:

220 – 240 V, 50 Hz. AC MAT14PD: 5.9 Kg Max.

650 Watts

n 2 Front-leveling legs

with nuts

n 1 Drain hose

n Hose adapter

Clothes

Capacity:

Location Requirements

IMPORTANT: Do not install or store the washer where it will

be exposed to the weather. Do not store or operate the washer

in temperatures at or below 0°C (32°F). Some water can remain

in the washer and can cause damage in low temperatures.

Proper installation is your responsibility.

You will need:

n A water heater set to deliver 60°C (140°F) water to the washer.

n An earthed electrical outlet located within 1.2 m (4 ft) of where

the power cord is attached to the back of the washer. See

“Electrical Requirements.”

n Hot and cold water taps located within 1.2 m (4 ft) of the back

of the washer, and provide water pressure of 69–690 kPa

(10–100 psi). A pressure reduction valve should be used in the

supply line where inlet pressure entering the building exceeds

690 kPa (100 psi) to prevent damage to the washer mixing

valve.

n A level oor with a maximum slope of 25 mm (1") under entire

washer.

n A sturdy oor to support the washer weight (washer, water,

and load) of 143 kgs (315 lbs).

n A 300 mm (12") minimum riser to provide an air cushion and

prevent noise and damage to valves for a single washer

installation.

n A oor drain should be provided under the bulkhead.

Prefabricated bulkheads with electrical outlets, water

supply lines, and drain facilities should be used only

where local codes permit.

NOTE: Front access to the pump area is available by removing

No. T20 TORX

panel.

®†

security screws and then removing the front

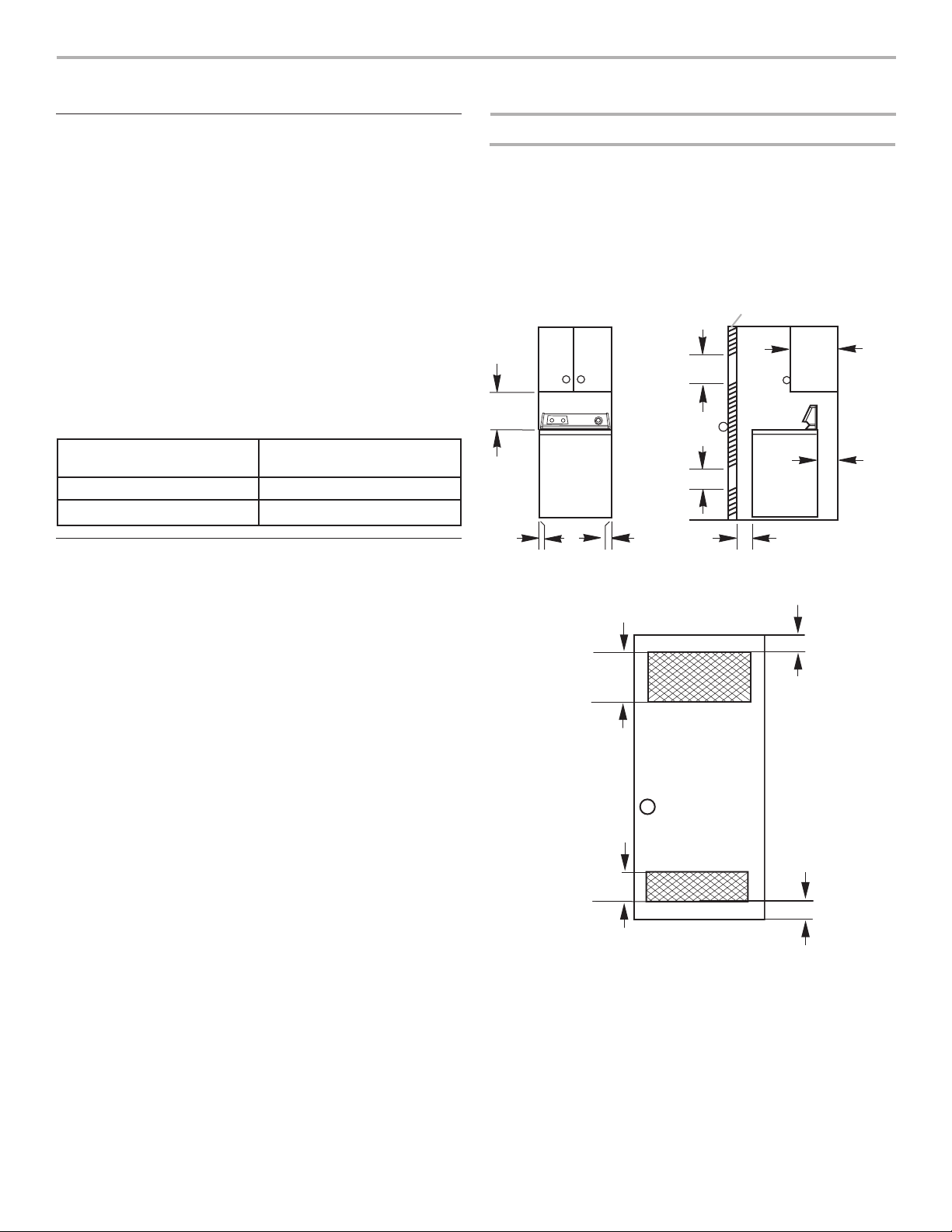

Recessed Area and Closet Installation Instructions

This washer may be installed in a recessed area or closet.

The installation spacing is in inches and is the minimum

allowable. Additional spacing should be considered for ease

of installation, servicing, and compliance with local codes

and ordinances.

If closet door is installed, the minimum unobstructed air

openings in the top and bottom are required. Louvered doors

with equivalent air openings are acceptable.

Closet door

2

3.10 m

(48 in2)*

432 mm

(17")

2

1.55 m

(24 in2)*

3.10 m

2

(48 in2)*

2

1.55 m

(24 in2)*

0 mm

2

2

(0")

Closet

door

25 mm (1") min.

76 mm

3"

(3")

(76 mm)

76 mm

3"

(76 mm)

(3")

0 mm

(0")

Recessed front view Closet side view

48 in.

(310 cm2)

Front

View

24 in.

(155 cm2)

* Opening is the minimum for a closet door.

Louvered doors with equivalent air openings are acceptable.

n Additional spacing should be considered for the ease of

installation and servicing.

n Additional clearances may be required for wall, door, and oor

mouldings.

n Additional spacing of 25 mm (1") on all sides of the washer is

recommended to reduce noise transfer.

n Companion spacing should also be considered.

356 mm

(14") max.

102 mm

(4") min.

®† Torx is a registered trademark of Saturn Fasteners, Inc.

4

Page 5

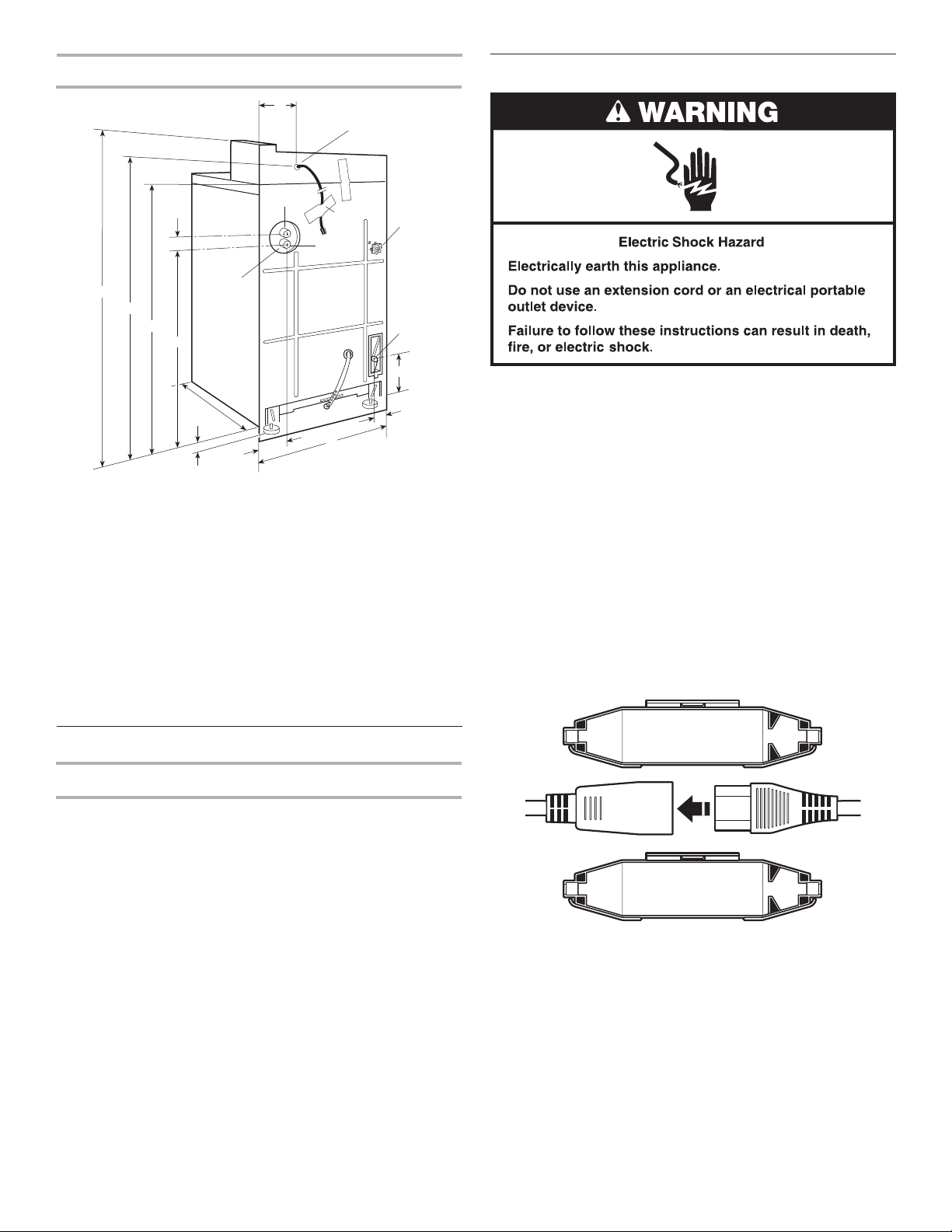

Product Dimensions

Electrical Requirements

H

I

D

A

B

C

E

F

N

A. 1.09 m (43") I. Power supply cord

B. 970 mm (381⁄8") J. Drain hose connector

C. 890 mm (35") K. Label

D. 38 mm (11⁄2") L. 685 mm (27")

E. 705 mm (273⁄4") M. 133 mm (51⁄4")

F. 650 mm (251⁄2") N. 25 mm (1")

G. Water inlets O. Water level switch and shaft

H. 180 mm (7") P. 127 mm (5")

Cold

G

M

Hot

K

L

J

O

P

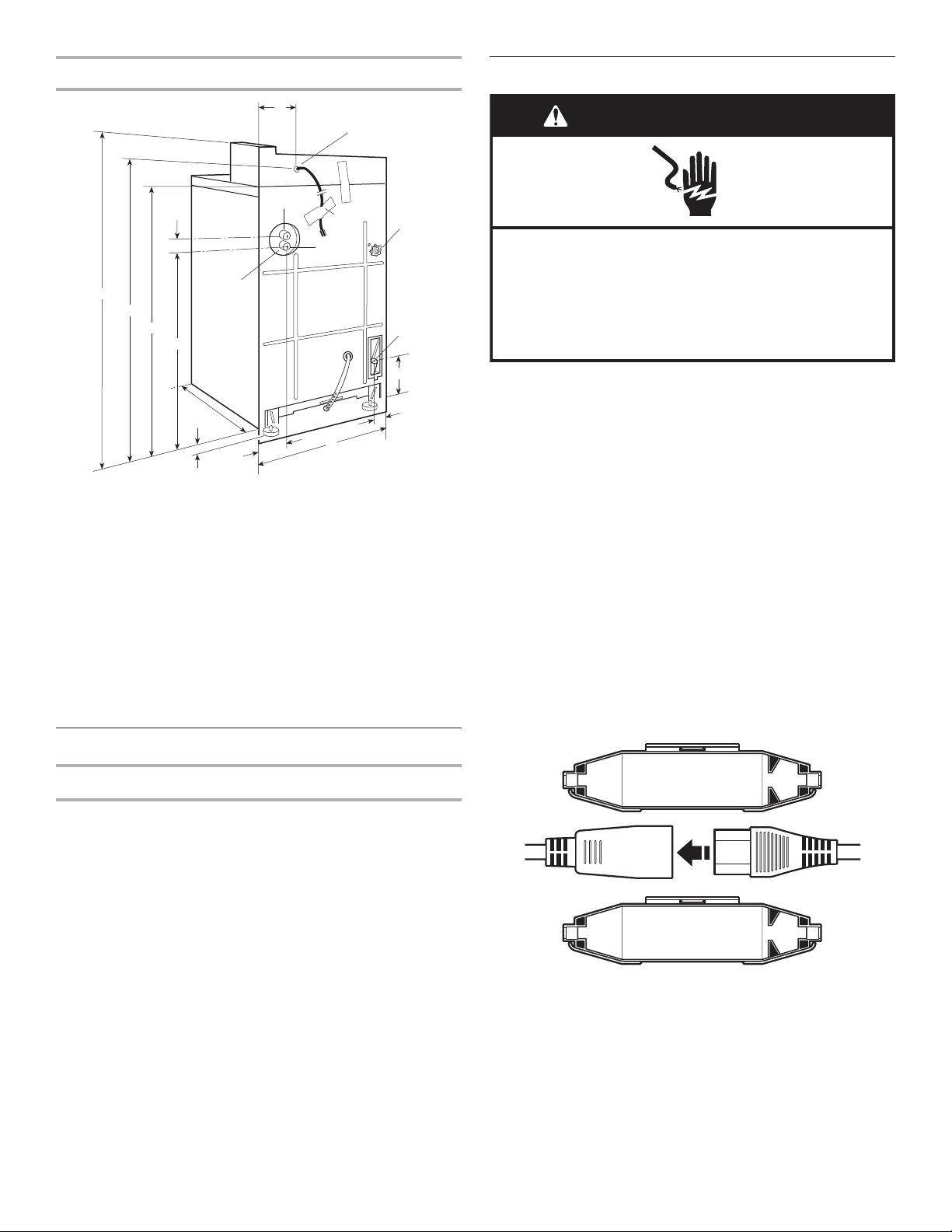

n A 220–240 volt, 50 Hz., AC only, 10-amp, fused electric

supply is required. A time-delay fuse or circuit breaker

is recommended. It is recommended that a separate circuit

serving only this appliance be provided.

n This washer is equipped with a power supply cord having

an earthing plug. The plug should be accessible for

disconnection from the supply.

n If the supply cord is damaged, it must be replaced by the

manufacturer, its service agent, or similarly qualied persons

in order to avoid a hazard.

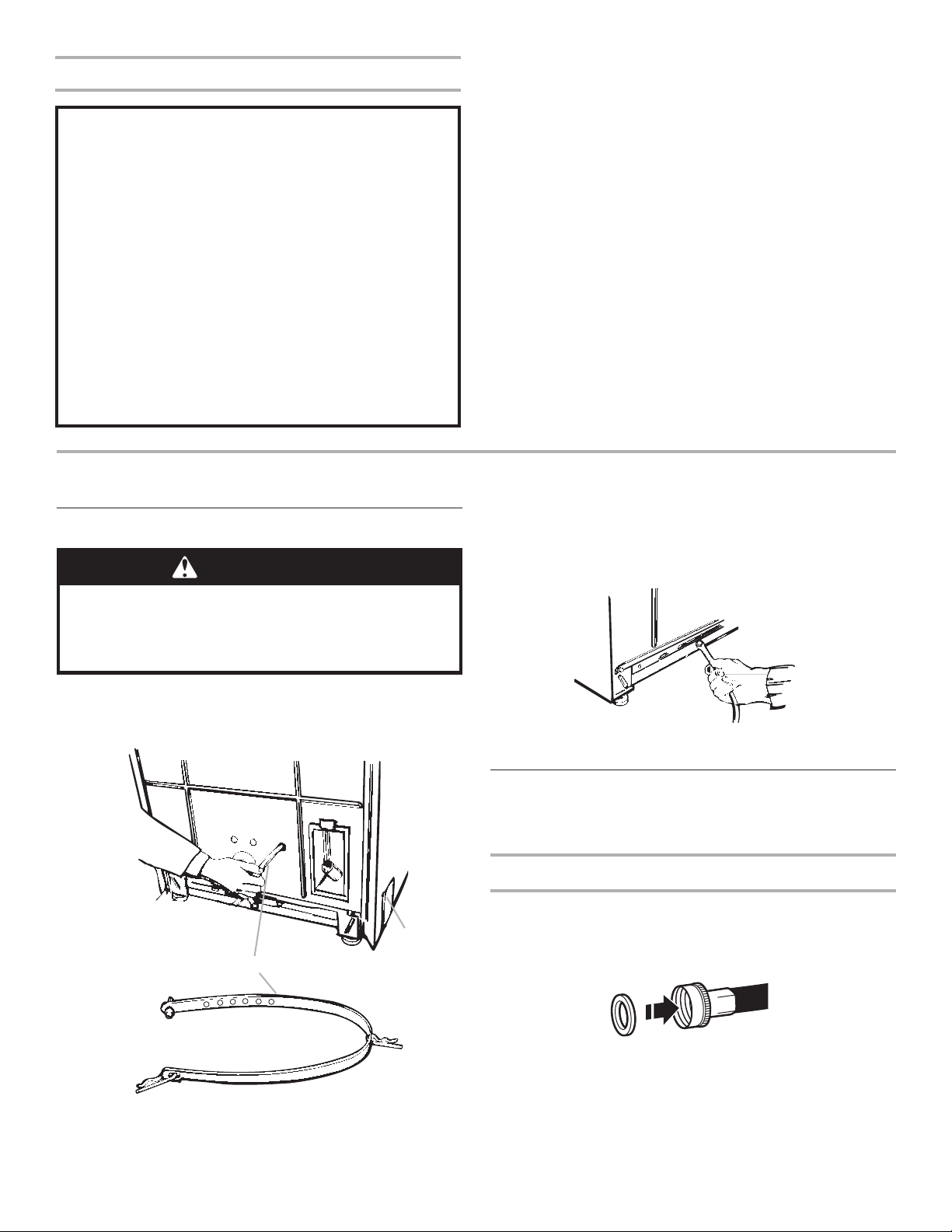

Using the universal cord included with this washer:

This washer is equipped with a universal cord with

interchangeable mains plugs.

1. Select the appropriate mains plug assembly from those

supplied and attach it to the mains cord connector.

2. Snap the 2 halves of the cord lock together over the

connector to retain it in position.

Drain System

Standpipe Drain System

The standpipe drain requires a minimum diameter standpipe of

50 mm (2"). The minimum carry-away capacity can be no less

than 64 L (17 gal.) per minute.

The top of the standpipe must be at least 990 mm (39") high

and no higher than 1.83 m (72") from the bottom of the washer.

5

Page 6

Recommended Earthing Method

EARTHING INSTRUCTIONS

This washer must be earthed. In the event of a malfunction

or breakdown, earthing will reduce the risk of electric

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-earthing conductor and an earthing plug. The

plug must be plugged into an appropriate outlet that is

properly installed and earthed in accordance with all local

codes and ordinances.

WARNING:

earthing conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly earthed.

Do not modify the plug provided with the appliance – if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

Improper connection of the equipment-

INSTALLATION INSTRUCTIONS

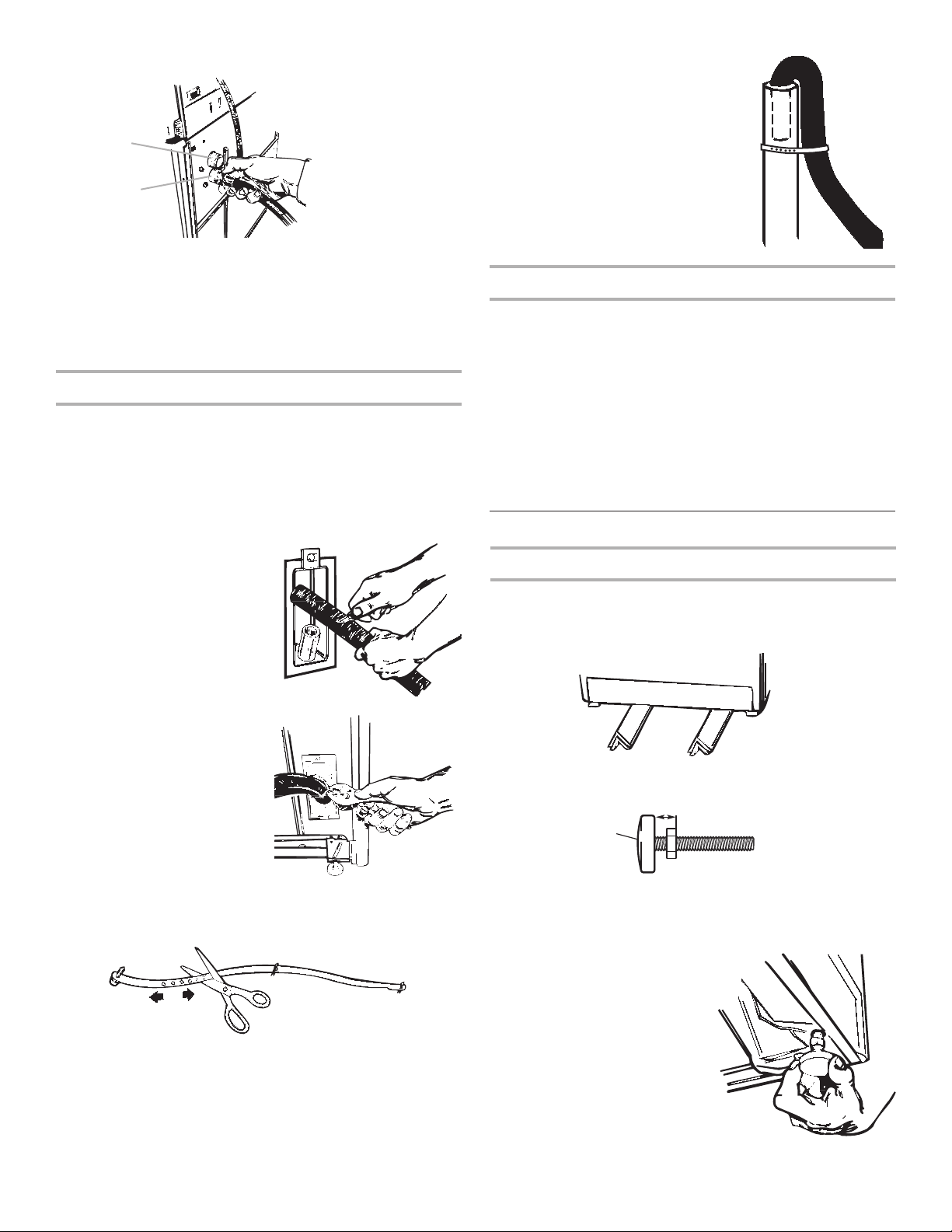

Remove Shipping Strap

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

1. Remove tape that covers the shipping strap. Pull to

completely remove the shipping strap with 2 cotter pins

from the inside of the washer.

2. Pull rmly to remove the end of shipping strap from the back

of the washer. The shipping strap plug must be completely

removed from the washer for the self-leveling legs to be

released.

Save the shipping strap for later use.

Connect the Hoses

Proper connection of the drain hose avoids damage to your

oors due to water leakage. Read and follow these instructions.

Connect the inlet hose

1. The washer must be connected to the water taps using the

A

B

A. Shipping tape

B. Shipping strap

6

new inlet hoses supplied with the washer. Do not re-use old

hoses. Insert new at washers (supplied) into each end of the

inlet hoses. Firmly seat the washers in the couplings.

B

A

A. Coupling

B. Washer

Page 7

2. Attach hose to bottom inlet valve opening rst.

A

A

B

A. Cold water inlet valve

B. Hot water inlet valve

3. Attach second hose to top inlet. Tighten couplings by hand;

then use pliers to make an additional two-thirds turn.

NOTE: Inlet valve threads are plastic. Do not strip or

cross-thread.

Connect the drain hose

NOTE: Slide washer onto cardboard or hardboard before

moving across oor.

1. Move washer close to nal position.

2. Put “hook” end of drain hose into laundry tub or standpipe.

3. Estimate the length of drain hose needed when washer is in

nal position. Hose must be cut exactly to length so “hook”

end is held tightly over edge of standpipe.

If drain hose is too long, cut

straight end of hose. (Do not

cut the “hook” shaped end

of the drain hose.)

NOTE: Do not force excess

length of drain hose down the

standpipe. This could cause

siphoning.

6. Check that hose is not twisted or kinked

and is securely in place.

Put “hook” end of drain hose into

standpipe. Tightly wrap the shipping

strap around the standpipe. Push plug

into the nearest hole in the shipping

strap.

Connect the inlet hoses to the water taps

1. Before attaching water inlet hoses to the water taps, run water

through both taps into a bucket. This will get rid of particles in

water lines that might clog hoses. Mark which is the hot water

tap.

2. Install a black plastic tap adapter on each inlet hose.

3. Attach bottom hose (inlet marked “H”) to hot water taps.

Tighten coupling to taps by hand.

4. Attach top hose (inlet marked “C”) to cold water taps. Tighten

coupling to taps by hand.

5. Use pliers to make an additional two-thirds turn to each

coupling.

Level the Washer

Install the front leveling feet

1. Stack two corner posts on top of each other. Tilt washer

backward and insert corner posts 76 mm (3") in from one side

of washer as shown. Repeat with other corner posts on other

side of washer.

4. Place the hose clamp over the

washer drain connector. Push

the drain hose onto the washer

connector. Use pliers to open

clamp and slide clamp over

drain hose. Check for good t.

5. Measure and mark a point approximately 406 mm (16") from

the plug end of the shipping strap. Cut shipping strap at this

point.

406 mm (16")

2. Use the leveling legs and nuts from parts package. Screw nut

down to within 13 mm (1/2") from base.

B

C

A. 13 mm (1/2")

B. Base

C. Nut

3. Insert legs into correct holes at

each front corner of washer until

nuts touch washer. Do not tighten

nuts until the washer is leveled.

4. Tilt washer backward and

remove corner posts. Gently

lower washer to oor.

5. Move washer to its permanent

location. Remove cardboard or

hardboard from under washer.

7

Page 8

Level the washer

1. Tilt washer forward, raising rear legs 25 mm (1") off of oor.

To adjust rear self-leveling legs, gently lower washer to oor.

2. Check levelness of the washer by

placing a carpenter’s level on top

of the washer, rst side to side;

then front to back.

3. If washer is not level, adjust the front legs up or down. Make

nal check with level.

4. When washer is level, use a wrench

to turn the nuts on front legs up tightly

against washer base. If nuts are not tight

against washer base, the washer may

vibrate.

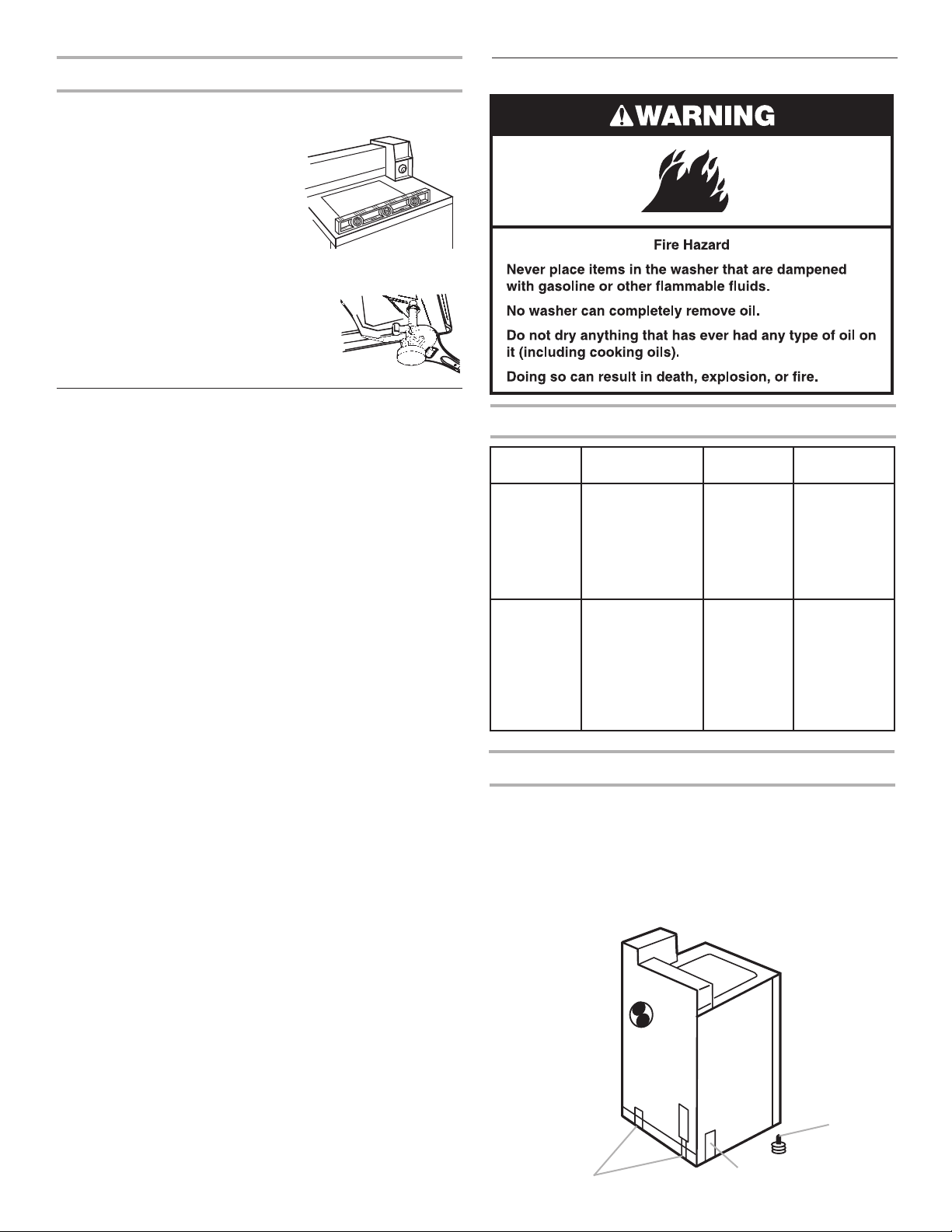

Operating Tips

Complete Installation

1. Check the electrical requirements. Be sure that you have

the correct electrical supply and the recommended earthing

method.

2. Check that all parts are now installed. If there is an extra part,

go back through the steps to see which step was skipped.

3. Turn on water taps and check for leaks. Tighten couplings if

there is leaking. Do not overtighten; this could cause damage

to the taps.

4. Be sure you have all of your tools.

5. Check that the shipping strap was removed from the back

of the washer and used to secure the drain hose. If entire

strap is not removed, washer may vibrate and be noisy.

6. Plug power supply cord into an earthed outlet.

NOTE: On some models, during factory testing, the timer is

advanced partially into the cycle, causing the start button to be

depressed. Allow timer to advance to the end of the cycle. When

the cycle is complete, the timer will reset and the start button will

return to the start position. If the timer is not allowed to advance

to the end of the rst cycle and reset, the wash load will not be

completed.

Checklist for washer operation

Check the following if the washer is not operating properly:

1. Power supply cord is plugged in.

2. Circuit breaker is not tripped or fuse is not blown.

3. Timer has been advanced to start of a cycle.

4. Water taps are turned on.

5. Inlet and drain hoses are not kinked.

6. Washer lid is closed.

7. Inlet valve can freeze if not protected from the weather.

8. Suds level. Excess suds will slow the spin and cause poor

rinsing. Operate the washer through a complete cycle with

no detergent. Use less detergent or a controlled suds type

detergent in future loads.

If you need assistance:

Contact your authorized Maytag® Commercial Laundry

distributor. To locate your authorized Maytag® Commercial

Laundry distributor, or for web inquiries, visit

www.MaytagCommercialLaundry.com.

When you call, you will need the washer model number and

serial number. Both numbers can be found on the model/

serial-rating plate located under the lid.

8

Typical full load sizes

Load Type Loading

Mixed Load 3 double sheets

Permanent

Press

Suggestion

4 pillowcases

6 pair shorts

8 T-shirts

2 shirts

2 blouses

8 handkerchiefs

2 double or

1 king-size sheet

1 tablecloth

1 dress

1 blouse

2 slacks

3 shirts

2 pillowcases

Load Type Loading

Heavy Work

Clothes

Knits 3 blouses

Suggestion

3 pair pants

3 shirts

1 coverall

4 pair jeans

1 overall

4 slacks

6 shirts

4 tops

4 dresses

Moving the washer to a new location

n Remove the front legs from the base of the washer.

n Place both rear leveling legs in the upper position and tape

securely.

n Apply tape to the side and bottom of the cabinet near

the rear.

n Open washer lid and wedge a blanket between the tub ring

and the cabinet top to restrict the tub movement.

Front legs

Rear legs

Tape 2 sides.

Page 9

ELECTRONIC CONTROLS SETUP

BASIC OPERATION OF COMMERCIAL WASHER

n

For additional information, see www.MaytagCommercialLaundry.com.

n This tech sheet is not valid for models prior to series MAT14.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage

or weaken the electronic control assembly. The new control

assembly may appear to work well after repair is nished,

but failure may occur at a later date due to ESD stress.

n Use an anti-static wrist strap. Connect wrist strap

to green ground connection point or unpainted metal

in the appliance

-ORTouch your nger repeatedly to a green ground connection

point or unpainted metal in the appliance.

n Before removing the part from its package, touch the

antistatic bag to a green ground connection point or

unpainted metal in the appliance.

n Avoid touching electronic parts or terminal contacts;

handle electronic control assembly by edges only.

n When repackaging failed electronic control assembly

in antistatic bag, observe above instructions.

Warm Start (after power failure)

After a delay of up to 8 seconds, the washer is restored to the

state that existed at time of the power failure.

Free Cycles

This is established by setting the cycle price to zero. When this

happens, “SELECT CYCLE” will appear rather than a cycle price.

Debit Card Ready

This washer is debit card “cable” ready. It will accept a variety

of debit card systems, but does NOT come with a debit card

reader. Refer to the debit card reader manufacturer for proper

washer set-up. In models converted to a Generation 1 debit

card system, debit pulses represent the equivalent of one coin

(coin 1).

Display

After the washer has been installed and plugged in, the display

will show “0 MINUTES.” Once the washer has been plugged in

and the washer door opened and closed, the display will show

the price. In washers set for free cycles, the display will ash

“SELECT CYCLE.”

MINUTES

0

PRICE

2.00

GENERAL USER INFORMATION

Blank display

This condition indicates the appliance is inoperative. Enter

set-up mode to view diagnostic code.

“0 Minutes” showing in display

This condition indicates the appliance cannot be operated.

Coins dropped or debit inputs during this condition will be

stored in escrow but cannot be used until normal operation is

restored by opening and closing the door. If a door switch fails,

it must be replaced before normal operation can be restored.

Cold Start (initial rst use)

Washer is programmed at the factory as follows:

n 11-minute wash period

n 1 rinse and 2 minutes of rinse agitation

n $1.75 wash price (PD Models).

n $0.00 wash price (PR Models).

9

Page 10

CONTROL SET-UP PROCEDURES

IMPORTANT: Read all instructions before operating.

The lower fabric setting key pads and the digital display are

used to set up the controls. The display can contain 4 numbers

and/or letters and a decimal point. These are used to indicate

the set-up codes and related code values available for use in

programming the washer.

How to use the key pads to p;rogram the controls

1. The LOWER LEFT key pad is used to adjust the values

associated with set-up codes. Pressing the key pad will

increment the value. Rapid ajustment is possible by holding

down the key pad.

2. The LOWER MIDDLE key pad will advance you through the

set-up codes. Pressing the key pad will advance you to the

next available set-up code. Holding down the key pad will

automatically advance through the set-up codes at a rate

of one (1) per second.

3. The LOWER RIGHT key pad is used to select or deselect

options.

Start Operating Set-Up

n PD Models: Insert access door key, turn, and lift to remove

access door.

n PR Models: Once the debit card reader is installed (according

to the reader manufacturer’s instructions), the set-up mode

can be entered by inserting a set-up card (supplied by the

reader manufacturer) into the card slot. If a manual set-up

card is not available, manual set-up mode can be entered

by removing connector AA1 on the circuit board.

IMPORTANT: The console must not be opened unless power

is rst removed from the washer. To access connector AA1:

g Unplug washer or disconnect power.

g Open console, disconnect plug on AA1, close console.

g Plug in washer or reconnect power.

The washer is now in the set-up mode.

NOTE: The control does not need to be set up in order for

the washer to operate. These procedures are to be followed

only to customize the control as desired.

SET-UP CODES

n The LOWER MIDDLE key pad will advance from code

to code.

n The LOWER LEFT key pad will change the code value.

n The LOWER RIGHT key pad will select or deselect options.

FOR PR MODELS: The set-up codes are the same as for the PD

models, except where noted.

The set-up code is indicated by the one or two left-hand

characters. The set-up code value is indicated by the two

or three right-hand characters.

CODE EXPLANATION

6.07

6.07

REGULAR CYCLE PRICE

Represents the number of coins (coin 1); may adjust

from 0–39. (See VALUE OF COIN 1.) Advance from

0–39 by pressing the LOWER LEFT key pad. Factory

preset for 7 coins = $1.75.

PR MODELS ONLY: Factory preset for 0 coins.

g Press the LOWER MIDDLE key pad once to advance to next code.

10

CODE EXPLANATION

7.11

7.11

WASH LENGTH

This is the number of minutes for WASH.

Choose from 8–20 minutes by pressing the LOWER

LEFT key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

8.21

8.21

RINSE CYCLES

This is the length and total number of rinses. Each

rinse agitation is 1–4 minutes, with a choice of 1

or 2 rinses. The middle digit is the length of rinse

agitation and the right digit is the number of rinses.

The number is changed in the following sequence

(11, 21, 31, 41, 12, 22, 32, 42) by pressing the

LOWER LEFT key pad.

Press the LOWER MIDDLE key pad once to advance

to next code.

The DELICATES & KNITS cycle has a xed rinse

agitation length of one minute.

g Press the LOWER MIDDLE key pad once to advance to next code.

9.00

CYCLE COUNTER OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.”

9.00

9.0

Not Selected “OFF.”

Selected “ON” and not able to be deselected.

C

Press the LOWER RIGHT key pad 3 consecutive

times to select “ON.” Once selected “ON” it cannot

be deselected.

g Press the LOWER MIDDLE key pad once to advance to next code.

1.00

MONEY COUNTER OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.”

1.00

1.0

C

Not Selected “OFF.”

Selected “ON.”

Press the LOWER RIGHT key pad 3 consecutive

times to select “ON” and 3 consecutive times to

remove (Not Selected “OFF.”) Counter resets by

going from “OFF” to “ON.”

1.C0

Selected “ON” and not able to be deselected.

To select “ON” and not able to be deselected, rst

select “ON,” then within two seconds press the

LOWER RIGHT key pad twice, the LOWER LEFT

key pad once, and exit the set-up mode.

g Press the LOWER MIDDLE key pad once to advance to next code.

2.00

SPECIAL PRICING OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.”

2.00

2.5

Not Selected “OFF.”

Selected “ON.” Press the LOWER RIGHT key pad

P

once for this selection.

If SPECIAL PRICING OPTION is selected, you have access

to codes “3.” through “9.”.

g Press the LOWER MIDDLE key pad once to advance to next code.

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED:

3.07

3.07

SPECIAL CYCLE PRICE

Represents the number of quarters (coin 1): may

adjust from 0–39. (See VALUE OF COIN 1.) Advance

from 0–39 by pressing the LOWER LEFT key pad.

Factory preset for 7 coins = $1.75.

PR MODELS ONLY: Factory preset for 0 coins.

g Press the LOWER MIDDLE key pad once to advance to next code.

Page 11

CODE EXPLANATION

OPTIONS TO USE IF SPECIAL PRICING IS SELECTED (cont.):

5.00

5.00

TIME-OF-DAY CLOCK, MINUTES

This is the TIME-OF-DAY CLOCK, minute setting;

select 0–59 minutes by pressing the LOWER LEFT

key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

6.00

TIME-OF-DAY CLOCK, HOURS

NOTE: Uses military time or 24 hr. clock.

6.00

This is the TIME-OF-DAY CLOCK, hour setting;

select 0–23 hours by pressing the LOWER LEFT

key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

7.00

SPECIAL PRICE START HOUR

NOTE: Uses military time or 24 hr. clock.

7.00

This is the start hour, 0–23 hours. Select START

HOUR by pressing the LOWER LEFT key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

8.00

SPECIAL PRICE STOP HOUR

NOTE: Uses military time or 24 hr. clock.

8.00

This is the stop hour; 0–23 hours. Select STOP

HOUR by pressing the LOWER LEFT key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

9.10

9.10

SPECIAL PRICE DAY

This represents the day of the week and whether

special pricing is selected for that day. A number

followed by “0” indicates no selection that particular

day (9.10). A number followed by an “S” indicates

selected for that day (9.1S).

Days of the week (1–7) can be chosen by pressing the

LOWER LEFT key pad. Press LOWER LEFT key pad

once to select special pricing for each day chosen.

When exiting setup code “9.”, the display must show

current day of week:

DISPLAY DAY OF WEEK CODE (selected)

10 Day 1 = Sunday 1S

20 Day 2 = Monday 2S

30 Day 3 = Tuesday 3S

40 Day 4 = Wednesday 4S

50 Day 5 = Thursday 5S

60 Day 6 = Friday 6S

70 Day 7 = Saturday 7S

g Press the LOWER MIDDLE key pad once to advance to next code.

A

.00

VAULT VIEWING OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.”

A

.00

A.SC

Not Selected “OFF.”

Selected “ON.” Press LOWER RIGHT key pad once

for this selection. When selected, the money and/or

cycle counts will be viewable (if counting is selected)

when the coin box is removed.

g Press the LOWER MIDDLE key pad once to advance to next code.

6.05

6.05

VALUE OF COIN 1

This represents the value of coin 1 in number

of coins: 05 = $0.25.

By pressing the LOWER LEFT key pad, you have the

option of 1–199 coins.

g Press the LOWER MIDDLE key pad once to advance to next code.

CODE EXPLANATION

C

C

.20

.20

VALUE OF COIN 2

This represents the value of coin 2 in number of

coins: 20 = $1.00.

PR MODELS: Factory preset for $0.25.

By pressing the PERMANENT PRESS key pad, you

have the option of 1–199 coins.

g Press the LOWER MIDDLE key pad once to advance to next code.

8.00

COIN SLIDE OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.”

8.00

8.

CS

Not Selected “OFF.”

Selected “ON.” Press the LOWER RIGHT key pad

3 consecutive times for this selection.

When coin slide mode is selected, set “b.” equal to

value of slide in coins. Set step 6 (regular cycle price)

and step 3 (special cycle price) to number

of slide operations.

NOTE: If the installer sets up “CS” on a coin drop

model, it will not register coins.

g Press the LOWER MIDDLE key pad once to advance to next code.

E

.00

ADD COINS OPTION

This option is either SELECTED “ON” or NOT

SELECTED “OFF.” This option causes the customer

display to show the number of coins (coin 1) to enter,

rather than the dollars-and-cents amount.

E

.00

E.AC

Not Selected “OFF.”

Selected “ON.” Press the LOWER RIGHT key pad

3 consecutive times for this selection.

g Press the LOWER MIDDLE key pad once to advance to next code.

F

.00

F

.00

F.CP

ENHANCED PRICING OPTION

Not Selected “OFF.”

Cycle-Based pricing enables. This option allows

conguration of different prices for cold, warm, and

hot water cycles. Press the LOWER RIGHT key pad

for this selection.

F.S

Super Cycle pricing enabled. This option allows

u

customers to upgrade cycles by depositing extra

money. Set-up codes “H.” and “h.” will be displayed

only when this option is enabled. Press the LOWER

RIGHT key pad for this selection.

g Press the LOWER MIDDLE key pad once to advance to next code.

H

.01

SUPER CYCLE UPGRADE PRICE

(Skipped unless Super Cycle pricing is enabled.)

H

.01

This represents the number of coin 1 required to

upgrade a base cycle to a super cycle. Advance

from 0–39 by pressing the LOWER LEFT key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

h.01

SUPER CYCLE TYPE

(Skipped unless Super Cycle pricing is enabled.)

h.01

This represents the Super Cycle upgrade option.

Press the LOWER LEFT key pad to step through

upgrade options 1 through 3 as follows:

01 – enhanced wash, extra 3 minutes of wash tumble

in addition to the programmed wash time.

02 – extra rinse for all cycles.

03 – both 01 and 02.

g Press the LOWER MIDDLE key pad once to advance to next code.

11

Page 12

CODE EXPLANATION

EU - DECLARATION OF CONFORMITY

CE - DECLARATION DE CONFORMITE

WE (nous):

BAUKNECHT HAUSGERÄTE GmbH, D-73614 Schorndorf

representing (représentant):

WHIRLPOOL EUROPE S.r.l I-21025 COMERIO

declare under our sole responsibility that the product

déclarons sous notre propre responsabilité que le produit

washing machine

Maytag MAT14PD AGW

(machine à laver le linge):

to which this declaration relates is in conformity with the following standard(s) or other

normative document(s)

auquel se référe cette déclaration est conforme aux normes suivantes ou autres documents normatifs

EN 60335-1:2002+A1+A2+A11+A12+A13

EN 60335-2-7:2003+A1+A2

EN 62233:2008

EN 61770:2009

EN 55014-1:2006+A1:2009

EN 55014-2:1997+Corr.1997+A1:2001+A2:2008

EN 61000-3-2:2006+A1:2009+A1:2009

EN 61000-3-11:2000

following the provisions of Directive(s

):

suivant les prévisions des Directives:

2006/95/EC LOW VOLTAGE DIRECTIVE

(CEE Directive Basse Tension)

2004/108/EC ELECTROMAGNETIC COMPATIBILITY DIRECTIVE

(CEE Directive Compatibilité

Electro-magnétique)

represented by

Schorndorf, 15.11.2011

Franz Hartmann Karl-Dieter Klingenstein

Place and date:

Director PDC FC EMEA Product Approval

lieu et date

GPO, Schorndorf

Name and signature of aurthorised person

Basic Type: MAT14PD AGW Nom et signature de la personne autorisée

COIN/DEBIT OPTION

Both coin and debit selected.

Coins selected, debit disabled. Press LOWER RIGHT

key pad for this selection.

Debit Card selected, coins disabled. Press LOWER

RIGHT key pad for this selection.

Enhanced Debit is self-selected when a Generation

2 card reader is installed in the washer. The “Ed”

option cannot be manually selected or deselected.

g Press the LOWER MIDDLE key pad once to advance to next code.

PRICE SUPPRESSION OPTION

This option causes the customer display to show

“ADD” or “AVAILABLE” rather than the amount of

money to add. (Used mainly in debit installations.)

Not Selected “OFF.”

Selected “ON.” Press the LOWER RIGHT key pad

once for this selection.

g Press the LOWER MIDDLE key pad once to advance to next code.

CLEAR ESCROW OPTION

When selected,money held in escrow for 30 minutes

without further escrow or cycle activity will be cleared.

Selected “ON.”

Not selected “OFF.” Press the LOWER RIGHT key

pad once to deselect this selection.

g Press the LOWER MIDDLE key pad once to advance to next code.

PENNY INCREMENT OFFSET

This represents the penny increment price offset

used in Generation 2 (Enhanced Debit) PR models.

Choose from 0–4 pennies by pressing the LOWER

LEFT key pad.

g Press the LOWER MIDDLE key pad once to advance to next code.

If cycle counter (9.0C) is selected, the following is true:

100 Represents the number of cycles in HUNDREDS. 1 02 = 200

200 Represents the number of cycles in ONES. 2 25 = 25

TOTAL CYCLES = 225

This is “VIEW ONLY” and cannot be cleared.

Press the LOWER MIDDLE key pad once to advance to next

code.

If money counter (1.0C or 1.C0) is selected, the following

is true:

300 Currency amount in HUNDREDS. 3 01 = 100.00

400 Currency amount in ONES. 4 68 = 68.00

500 Currency amount of CENTS. 5 75 = .75

TOTAL = 168.75

END OF SET-UP PROCEDURES

EXIT FROM SET-UP MODE

n PD Models: Reinstall access door.

n PR Models:

g Unplug washer or disconnect power.

g Open console, reinsert plug into AA1, close console.

g Plug in washer or reconnect power.

Europe

12

Page 13

MAYTAG® COMMERCIAL SINGLE-LOAD AND VENDED

MULTI-LOAD WASHER AND DRYER

WARRANTY

LIMITED WARRANTY ON PARTS

For the first five years from the date of purchase, when this commercial appliance is installed, maintained and operated according to the

instructions attached to or furnished with the product, Maytag brand of Whirlpool Corporation (thereafter “Maytag”) will pay for factory

specified parts or original equipment manufacturer parts to correct defects in materials or workmanship. Proof of original purchase date

is required to obtain service under this warranty.

ITEMS MAYTAG WILL NOT PAY FOR

1. All other costs including labor, transportation, or custom duties.

2. Service calls to correct the installation of your commercial appliance, to instruct you how to use your commercial appliance, to

replace or repair fuses, or to correct external wiring or plumbing.

3. Repairs when your commercial appliance is used for other than normal, commercial use.

4. Damage resulting from improper handling of product during delivery, theft, accident, alteration, misuse, abuse, fire, flood, acts of

God, improper installation, installation not in accordance with local electrical or plumbing codes, or use of products not approved

by Maytag.

5. Pickup and Delivery. This commercial appliance is designed to be repaired on location.

6. Repairs to parts or systems resulting from unauthorized modifications made to the commercial appliance.

7. The removal and reinstallation of your commercial appliance if it is installed in an inaccessible location or is not installed in

accordance with published installation instructions.

8. Chemical damage is excluded from all warranty coverage.

9. Changes to the building, room, or location needed in order to make the commercial appliance operate correctly.

10. Repairs made by a non-Whirlpool authorized service technician.

DISCLAIMER OF IMPLIED WARRANTIES; LIMITATIONS OF REMEDIES

CUSTOMER'S SOLE AND EXCLUSIVE REMEDY UNDER THIS LIMITED WARRANTY SHALL BE PRODUCT REPAIR AS PROVIDED

HEREIN. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

ARE LIMITED TO ONE YEAR OR THE SHORTEST PERIOD ALLOWED BY LAW. WHIRLPOOL SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. SOME STATES AND PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, OR LIMITATIONS ON THE DURATION OF IMPLIED WARRANTIES OF

MERCHANTABILITY OR FITNESS, SO THESE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU. THIS WARRANTY GIVES

YOU SPECIFIC LEGAL RIGHTS AND YOU MAY ALSO HAVE OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE

TO PROVINCE.

If you need service, please contact your authorized Maytag® Commercial Laundry distributor. To locate your authorized Maytag®

Commercial Laundry distributor, or for web inquiries, visit www.MaytagCommercialLaundry.com.

3/10

For written correspondence:

®

Maytag

Commercial Laundry Service Department

2000 M-63 North

Benton Harbor, Michigan 49022 USA

13

Page 14

SECURITE DU LAVE-LINGE

ÉLIMINATION DU LAVE-LINGE

14

Page 15

EXIGENCES D’INSTALLATION

Outillage et pièces

Rassembler les outils et pièces nécessaires avant d’entreprendre

l’installation.

Outils nécessaires

n Niveau

n Couteau utilitaire

n Ciseaux

n Clé à mollette de 200 mm

(8") ou 250 mm (10")

n Tournevis à lame plate

n Pince

n Seau

Pièces fournies

Retirer les pièces du lave-linge. Vérier la présence de toutes

les pièces.

n 1 bride de xation

n 2 tuyaux d’arrivée d’eau

n 4 rondelles plates de

tuyau d’arrivée d’eau

Spécications

techniques :

220 à 240 V, 50 Hz AC MAT14PD : 5,9 kg Max.

650 Watts

n 2 pieds de nivellement

avant avec écrous

n 1 tuyau de vidange

n Adaptateur de tuyau

Capacité de

vêtements :

Exigences d’emplacement

IMPORTANT : Ne pas installer ou remiser le lave-linge dans

un endroit où il sera exposé aux intempéries. Ne pas remiser

ou faire fonctionner le lave-linge à des températures inférieures

ou égales à 0°C (32°F). Une quantité d'eau peut demeurer dans

le lave-linge et causer des dommages à des températures

basses.

C’est à l’utilisateur qu’incombe la responsabilité de réaliser

une installation correcte.

Il vous faudra :

n Un chauffe-eau pour fournir de l’eau à 60°C (140°F)

au lave-linge.

n Une prise électrique reliée à la terre située à moins de 1,2 m

(4 pi) de la prise du cordon électrique se trouvant à l’arrière

du lave-linge. Voir “Spécications électriques”.

n Des robinets d’eau chaude et d’eau froide situés à 1,2 m (4 pi)

ou moins de l’arrière du lave-linge, et une pression d’eau

de 69 à 690 kPa (10 à 100 lb/po2). Lorsque la pression

d’alimentation à l’entrée du bâtiment est supérieure

à 690 kPa (100 lb/po2), on devrait installer une vanne

de réduction de la pression pour éviter une éventuelle

détérioration de la vanne de mixage du lave-linge.

n Un plancher de niveau ayant une pente maximale de 25 mm

(1") sous l’ensemble du lave-linge.

n Un plancher robuste pour supporter le lave-linge dont le poids

total (lave-linge, eau et charge) est de 143 kg (315 lb).

n Une colonne montante d’au moins 300 mm (12") destinée

à fournir un coussin d’air et à empêcher l’émission de bruit

et la détérioration des électrovannes lors de l’installation

d’un seul lave-linge.

n Un égout au plancher doit être installé sous le module

de la cloison. Les coffrages préfabriqués équipés de

prises électriques, de lignes d’arrivée d’eau et conduites

d’évacuation doivent être utilisés seulement là où les codes

locaux l’autorisent.

REMARQUE : On peut accéder à la zone avant de la pompe

en retirant les vis de sécurité No. T20 TORX

le panneau avant.

®† Torx est une marque déposée de Saturn Fasteners, Inc.

® †

puis en retirant

Instructions d’installation dans un encastrement

ou un placard

Ce lave-linge peut être installé dans un encastrement

ou un placard.

Les dimensions d’installation illustrées sont en centimètres et

constituent le minimum applicable. Un espace supplémentaire

peut être nécessaire pour faciliter l’installation, l’entretien et

pour observer les codes et règlements locaux en vigueur.

Si une porte de placard est installée, des ouvertures

d’évacuation de l’air minimales sont nécessaires dans les

parties supérieure et inférieure. Les portes à claire-voie offrant

des ouvertures équivalentes sont acceptables.

Porte du placard

2

3,10 m

(48 in2)*

432 mm

(17")

2

1,55 m

(24 in2)*

3,10 m

2

(48 in2)*

2

1,55 m

(24 in2)*

0 mm

2

2

(0")

Closet

Porte

door

du placard

25 mm (1") min.

Vue latérale

du placard

76 mm

3"

(3")

(76 mm)

76 mm

3"

(76 mm)

(3")

0 mm

(0")

Vue encastrée de face

du placard

48 in.

(310 cm2)

Vue de

Front

face

View

24 in.

(155 cm2)

* Dimension minimale pour une porte de placard. Les portes à claire-voie

offrant des ouvertures équivalentes sont acceptables.

n Un espace supplémentaire peut être nécessaire pour faciliter

l’installation et l’entretien.

n Un espace supplémentaire peut être requis pour les moulures

de porte et de plancher et pour les plinthes.

n Un espace supplémentaire de 25 mm (1 po) de tous

les côtés du lave-linge est recommandé pour réduire

le transfert du bruit.

n Il faut aussi prendre en compte l’espace requis entre

les appareils voisins.

356 mm

(14") max.

102 mm

(4") min.

15

Page 16

Dimensions du produit

Spécications électriques

H

I

AVERTISSEMENT

D

A

B

C

E

F

N

A. 1,09 m (43 po) I. Cordon d’alimentation électrique

B. 970 mm (381⁄8 po) J. Connecteur du tuyau de vidange

C. 890 mm (35 po) K. Étiquette

D. 38 mm (11⁄2 po) L. 685 mm (27 po)

E. 705 mm (273⁄4 po) M. 133 mm (51⁄4 po)

F. 650 mm (251⁄2 po) N. 25 mm (1 po)

G. Arrivées d’eau O. Commutateur du niveau d’eau

H. 180 mm (7 po) P. 127 mm (5 po)

Froid

G

M

et tige de réglage

K

Chaud

L

J

O

P

Risque de choc électrique

Brancher sur une prise reliée à la terre.

Ne pas utiliser un câble de rallonge ou un adaptateur.

Le non-respect de ces instructions peut causer un

décès, un incendie ou un choc électrique.

n L’appareil doit être alimenté par un circuit de 220-240 V, CA

seulement, 50 Hz, protégé par un fusible. On recommande

d’utiliser un fusible ou un disjoncteur temporisé. Il est

recommandé de raccorder le lave-linge sur un circuit

distinct exclusif à cet appareil.

n Ce lave-linge comporte un cordon d’alimentation électrique

pour liaison à la terre. La prise doit être accessible pour

pouvoir déconnecter l’appareil de l’alimentation électrique.

n Si le cordon d’alimentation est endommagé, il doit être

remplacé par le fabricant, son agent de service ou toute

autre personne qualiée an d’éviter tout danger.

À l’aide du cordon universel d’alimentation électrique

fourni avec ce lave-linge :

Ce lave-linge comporte un cordon universel avec des prises

principales interchangeables.

1. Sélectionner la prise principale appropriée parmi les prises

fournies et la xer au connecteur du cordon de câblage

principal.

2. Enclencher les deux moitiés du système de retenue

du cordon sur le connecteur pour le maintenir en place.

Système de vidange

Système de vidange avec tuyau de rejet à l’égout

Le système de rejet à l’égout nécessite un tuyau de diamètre

minimum de 50 mm (2 po). La capacité minimum de vidange

ne peut pas être inférieure à 64 L (17 gal.) par minute.

Le sommet du tuyau de rejet à l’égout doit être au moins

à 990 mm (39 po) de hauteur et au maximum à 1,83 m (72 po)

de la base du lave-linge.

16

Page 17

Méthode recommandée de mise à la terre

INSTRUCTIONS DE LIAISON À LA TERRE

Ce lave-linge doit être relié la terre. En cas d’anomalie de

fonctionnement ou de panne, la liaison à la terre réduira le

risque de choc électrique en offrant au courant électrique

un itinéraire d’évacuation de moindre résistance. Ce

leave-linge est alimenté par un cordon électrique

comportant un conducteur relié à la terre et une fiche

de branchement munie d’une broche de liaison à la terre.

La fiche doit être branchée sur une prise de courant

appropriée qui est bien installée et reliée la terre

conformément à tous les codes et règlements locaux.

AVERTISSEMENT : Le raccordement incorrect de cet

appareil au conducteur de liaison la terre peut susciter un

risque de choc électrique. En cas de doute quant à la

qualité de la liaison la terre de l’appareil, consulter un

électricien ou technicien d’entretien qualifié.

Ne pas modifier la fiche de branchement fournie avec

l’appareil si la fiche ne correspond pas à la configuration de

la prise de courant, demander à un électricien qualifié

d’installer une prise de courant convenable.

INSTRUCTIONS D’INSTALLATION

Enlever la sangle d’expédition

AVERTISSEMENT

Risque du poids excessif

Utiliser deux ou plus de personnes pour déplacer et

installer le lave-linge.

Le non-respect de cette instruction peut causer une

blessure au dos ou d'autre blessure.

1. Enlever le ruban adhésif qui recouvre la sangle d’expédition.

Tirer pour extraire complètement la sangle et les 2 goupilles

qui se trouvent à l’intérieur du lave-linge.

A

B

2. Tirer fermement pour extraire l’extrémité de la sangle

d’expédition de l’arrière du lave-linge. Pour la libérer les

pieds de réglage de l’aplomb, il faut que le piton de la sangle

d’expédition soit complètement extraite de la machine.

Conserver la sangle d’expédition pour réutilisation éventuelle.

Raccordement des tuyaux

Le bon acheminement du tuyau de vidange évite les dommages

à vos planchers imputables une fuite d’eau. Lire et suivre ces

instructions.

Connecter les tuyaux d’alimentation au lave-linge

1. Le lave-linge doit être raccordé aux robinets d’eau à l’aide

des nouveaux tuyaux d’arrivée d’eau fournis avec la machine.

Ne pas réutiliser de tuyaux usagés. Insérer les rondelles plates

neuves (fournies) dans chaque extrémité des tuyaux d’arrivée

d’eau. Insérer fermement les rondelles dans les raccords.

A. Ruban adhésif pour expédition

B. Sangle d’expédition

B

A

A. Raccord

B. Rondelle

17

Page 18

2. Fixer d’abord le tuyau à la valve d’arrivée d’eau inférieure.

A

A

B

A. Valve du tuyau d’alimentation d’eau froide

B. Valve du tuyau d’alimentation d’eau chaude

3. Fixer le second tuyau à la valve d’arrivée d’eau supérieure.

Serrer les raccords à la main, puis utiliser une pince et serrer

de deux tiers de tour en plus.

REMARQUE : Les ls des valves de tuyau d’arrivée d’eau sont

en plastique. Veiller à ne pas dénuder ou détériorer les letages

des raccords.

Connecter le tuyau de vidange

REMARQUE : Faire glisser le lave-linge sur un carton ou une

plaque de contreplaqué avant de la déplacer sur le plancher.

1. Placer la lave-linge près de son emplacement d’installation

nal.

2. Mettre l’extrémité en crochet du tuyau de vidange dans l’évier

de buanderie ou dans le tuyau de rejet à l’égout.

3. Estimer la longueur de tuyau de vidange nécessaire lorsque

le lave-linge est à son emplacement d’installation nal.

Il faut que le tuyau soit coupé à la longueur exacte qui

permettra à l’extrémité en crochet d’être fermement retenue

dans l’embouchure du tuyau de rejet à l’égout.

Si le tuyau de vidange est trop

long, couper l’extrémité droite

pour le raccourcir. (Ne jamais

couper l’extrémité recourbée

du tuyau de vidange.)

REMARQUE : Ne pas forcer

une section excessive du tuyau

de vidange à pénétrer dans

le tuyau de rejet à l’égout.

Ceci pourrait provoquer

un siphonnage.

4. Placer la bride de tuyau

sur le raccord de vidange

du lave-linge. Pousser le tuyau

de vidange pour l’engager sur

le raccord de connexion du

lave-linge. Utiliser une pince

pour ouvrir la bride de tuyau

et la placer à l’emplacement

approprié sur le tuyau de

vidange. Vérier que la bride est

correctement placée et serrée.

5. Mesurer et marquer un point à approximativement 406 mm

(16") de l’extrémité avec piton de la sangle d’expédition.

Couper la sangle à cet endroit.

406 mm (16")

18

6. Vérier que le tuyau n’est pas vrillé ou

déformé et qu’il est fermement maintenu

en place.

Introduire l’extrémité recourbée du tuyau

de vidange dans le tuyau de rejet à

l’égout. Enlacer les deux tuyaux avec

la sangle de transport. Introduire le piton

dans le trou le plus proche de la sangle.

Connecter les tuyaux d’alimentation aux robinets d’eau

1. Avant de xer les tuyaux d’alimentation, faire s’écouler l’eau

des deux robinets dans un seau. Ceci éliminera les particules

se trouvant dans les canalisations d’eau qui pourraient

obstruer les tuyaux. Marquer le robinet d’eau chaude.

2. Installer une rondelle sur le robinet de chaque tuyau d’arrivée

d’eau.

3. Fixer le tuyau d’alimentation inférieur (marqué “H”) au robinet

d’eau chaude. Serrer à la main les raccords au robinet.

4. Fixer le tuyau d’alimentation supérieur (marqué “C”) au robinet

d’eau froide. Serrer à la main les raccords au robinet.

5. Utiliser une pince et tourner chaque raccord de deux tiers

de tour en plus.

Réglage de l’aplomb du lave-linge

Installation des pieds de réglage de l’aplomb avant

1. Superposer deux cornières de carton d’emballage. Incliner

le lave-linge vers l’arrière et insérer les cornières sous le

lave-linge à 76 mm (3") de chaque côté – voir l’illustration.

2. Trouver les pieds de réglage de l’aplomb et les écrous dans

le sachet de pièces. Visser l’écrou jusqu’à de 13 mm (1/2")

ou moins de la base.

B

C

A. 13 mm (1/2")

B. Base

C. Écrou

3. Insérer un pied dans le trou

approprié dans chaque angle

avant du lave-linge jusqu’à ce

que l’écrou soit au contact de

la base du lave-linge. Ne pas

serrer les écrous avant que

l’aplomb du lave-linge n’ait

été établi.

4. Incliner le lave-linge vers l’arrière

et retirer les cornières de carton.

Abaisser doucement le lave-linge

pour le reposer au sol.

5. Déplacer le lave-linge jusqu’à son emplacement dénitif.

Retirer le carton ou la plaque de contreplaqué de dessous

le lave-linge.

Page 19

Réglage de l’aplomb du lave-linge

1. Incliner le lave-linge vers l’avant pour soulever les pieds

arrière de 25 mm (1") pour

l’ajustement des pieds arrière

de réglage automatique de l’aplomb.

Abaisser doucement le lave-linge

jusqu’au sol.

2. Utiliser un niveau pour contrôler

l’aplomb du lave-linge dans les

deux directions, transversalement

et avant-arrière.

3. Si le lave-linge n’est pas d’aplomb, régler la longueur

de déploiement des pieds avant. Utiliser le niveau pour

uncontrôle nal.

4. Lorsque le lave-linge est d’aplomb, utiliser

une clé pour serrer chaque écrou des

pieds avant au contact de la base du

lave-linge. Si les écrous ne sont pas

sufsamment serrés contre la base,

le lave-linge pourrait vibrer.

Achever l’installation

1. Consulter les spécications électriques. Vérier que la tension

électrique disponible est correcte et que la prise de courant

est convenablement reliée à la terre.

2. Vérier que toutes les pièces sont maintenant installées. S’il

reste une pièce, passer en revue les différentes étapes pour

découvrir laquelle aurait été oubliée.

3. Ouvrir les robinets d’eau et vérier s’il y a des fuites. Serrer

les raccords en cas de fuites. Ne pas serrer excessivement,

ceci pourrait endommager les robinets.

4. S’assurer d’avoir récupéré tous vos outils.

5. Vérier que la sangle d’expédition a été retirée à l’arrière

du lave-linge et qu’il a été utilisé pour l’arrimage du tuyau

de vidange. Si la sangle n’a pas été totalement retirée,

le lave-linge peut vibrer et être bruyant.

6. Brancher le cordon électrique dans une prise reliée à la terre.

REMARQUE : Sur certains modèles, lors des tests à l’usine,

le bouton de la minuterie est engagé (exécution partielle

d’un programme) et le bouton de mise en marche est enfoncé.

Laisser la minuterie provoquer la poursuite du programme

jusqu’à la n. Lorsque le programme est terminé, la minuterie

se réarme et le bouton reprend sa position de mise en marche.

Si on ne laisse pas la minuterie commander le déroulement

du programme jusqu’à la n et le réarmement, le lavage

de la première charge ne sera pas exécuté correctement.

Liste de contrôle pour le fonctionnement du lave-linge :

Si le lave-linge ne fonctionne pas correctement, vérier

ce qui suit :

1. Le cordon d’alimentation est branché.

2. Le disjoncteur ne s’est pas déclenché ou aucun fusible n’est

grillé.

3. La minuterie a été avancée pour commencer un programme.

4. Les robinets d’eau chaude et d’eau froide sont ouverts.

5. Les tuyaux d’arrivée d’eau et de vidange ne sont pas

déformés.

6. Le couvercle du lave-linge est fermé.

7. La valve d’arrivée d’eau n’est pas gelée si elle n’est pas

protégée des intempéries.

8. Niveau de mousse. Une quantité excessive de mousse

ralentira l’essorage et produira un rinçage médiocre. Exécuter

un programme complet sans utiliser de détergent. Utiliser

moins de détergent ou un détergent au niveau de mousse

contrôlé pour les prochaines charges.

Si vous avez besoin d’assistance :

Communiquer avec votre distributeur d’ensemble de buanderie

commercial Maytag® autorisé. Pour localiser votre distributeur

d’ensemble de buanderie commercial Maytag® autorisé, ou

pour des demandes de renseignements sur Internet, visitez

le site Web www.MaytagCommercialLaundry.com.

Lors de l’appel, vous aurez besoin des numéros de modèle

et de série du lave-linge. Vous trouverez ces deux numéros

sur la plaque signalétique située sous le couvercle.

Conseils d’utilisation

Tailles typiques de chargement complet

Type de

chargement

Charge

mixte

Pressage

permanent

En cas de déplacement du lave-linge à un nouvel

emplacement

n Retirer les pieds avant de la base du lave-linge.

n Placer les deux pieds de nivellement arrière en position

élevée et xer à l’aide de ruban adhésif.

n Appliquer du ruban adhésif sur les côtés et le bas du placard

à l’arrière de celui-ci.

n Ouvrir le couvercle du lave-linge; insérer une couverture entre

la couronne de la cuve et le sommet de la caisse pour limiter

les mouvements de la cuve.

Pieds arrière

Suggestion

de chargement

3 draps doubles

4 taies d’oreiller

6 shorts

8 tee-shirts

2 chemises

2 chemisiers

8 mouchoirs

2 draps simples

ou 1 très grand

1 nappe

1 robe

1 chemisier

2 pantalons

décontractés

3 chemises

2 taies d’oreiller

Type de

chargement

Vêtements

de travail

lourds

Tricots 3 chemisiers

Ruban adhésif double face

Suggestion

de chargement

3 pantalons

3 chemises

1 salopette

4 jeans

1 ensemble

4 pantalons

décontractés

6 chemises

4 hauts

4 robes

Pieds avant

19

Page 20

PARAMÉTRAGE DES COMMANDES ÉLECTRONIQUES

UTILISATION BASIQUE DU LAVE-LINGE À USAGE

COMMERCIAL

n

Pour des renseignements supplémentaires,

voir www.MaytagCommercialLaundry.com.

n Cette che technique n’est pas destinée aux modèles

antérieurs à la série MAT14.

IMPORTANT

Circuits électroniques sensibles

aux décharges électrostatiques

Le risque de décharge électrostatique est permanent.

Une décharge électrostatique peut détruire ou détériorer les

circuits électroniques de la machine. La nouvelle carte peut

sembler fonctionner correctement après la réparation, mais

une décharge électrostatique peut lui avoir fait subir des

contraintes qui provoqueront une défaillance plus tard.

n Utiliser un bracelet de décharge électrostatique.

Connecter le bracelet de décharge électrostatique

au point vert de raccordement à la terre ou à une surface

métallique non peinte à l’intérieur de l’appareil.

-OUToucher plusieurs fois de suite avec le doigt un point vert

de raccordement à la terre ou une surface métallique non

peinte à l’intérieur de l’appareil.

n Avant de retirer la pièce de son sachet, placer le sachet

antistatique en contact avec la vis verte de liaison à la

terre ou une surface métallique non peinte de l’appareil.

n Éviter de toucher les composants électroniques ou les

broches de contact ; manipuler les circuits électroniques

de la machine uniquement par les bords.

n Lors du ré-emballage des circuits électroniques de la

machine défaillante dans le sachet antistatique, observer

les instructions ci-dessus.

Remise en marche (après une interruption de l’alimentation)

Après un délai qui peut atteindre 8 secondes, l’état initial du

lave-linge (au moment de l’interruption de l’alimentation) est

restauré.

Programmes gratuits

Pour ceci, on règle le prix de l’utilisation à zéro ; l’afcheur

présente alors “SELECT CYCLE” (sélectionner un programme)

plutôt que le prix d’un programme.

Prêt pour carte de débit

Ce lave-linge est préconguré pour l’utilisation des cartes

de débit. Il accepte une variété de systèmes de paiement

par carte de débit, mais il n’est PAS fourni avec un lecteur de

cartes de débit. Voir les instructions fournies par le fabricant

du lecteur de cartes de débit pour connaître le réglage adéquat

du lave-linge. Pour les modèles convertis au système de carte

de débit Génération 1, les pulsations de débit représentent

l’équivalent d’une pièce (pièce 1).

Afcheur

Après l’installation initiale et le branchement du lave-linge,

l’afcheur présente “0 MINUTES”. Après le branchement

du lave-linge et l’ouverture et la fermeture de la porte du

lave-linge, l’afcheur présente le prix. Si le lave-linge est réglé

pour l’utilisation gratuite, l’afcheur présente “SELECT CYCLE”

(sélectionner un programme) avec clignotement.

MINUTES

0

INFORMATIONS GÉNÉRALES POUR L’UTILISATEUR

Afchage vide

Ce problème indique que la machine est défectueuse. Entrer

au mode de réglage pour voir le code de diagnostique.

“0 Minutes” apparaît sur l’afchage

Ce problème indique qu’il n’est pas possible de faire fonctionner

la machine. Les pièces introduites ou le débit par carte engagé

pendant cette phase sont stockés en avoir, mais ne sont pas

utilisables tant que le fonctionnement normal n’est pas rétabli

par l’ouverture et la fermeture de la porte. Si un commutateur de

porte échoue, il doit être remplacé pour que le fonctionnement

normal soit rétabli.

Démarrage à froid (première utilisation)

Le lave-linge est programmé à l’usine comme suit :

n Période de lavage de 11 minutes

n 1 rinçage et 2 minutes d’agitation (rinçage)

n Prix du lavage : 1,75 $ (modèles PD)

n Prix du lavage : 0,00 $ (modèles PR)

20

PRICE

2.00

Page 21

PROCÉDURES DE RÉGLAGE DES SYSTÈMES

DE COMMANDE

IMPORTANT : Lire la totalité des instructions avant l’utilisation.

Pour le réglage des systèmes de commande, on utilise les

touches de réglage inférieures (tissu) et l’afcheur numérique.

L’afcheur peut présenter 4 chiffres et/ou lettres et un point

décimal. Ils indiquent les codes de paramétrage et les valeurs

connexes disponibles pour la programmation du lave-linge.

Utilisation des touches pour la programmation des systèmes

de commande

1. La touche INFÉRIEURE DE GAUCHE permet la sélection des

valeurs associées aux codes de paramétrage. Une pression

sur la touche fait augmenter la valeur. Une pression constante

sur la touche permet un ajustement rapide.

2. La touche INFÉRIEURE CENTRALE commande

la progression parmi les codes de paramétrage. Une pression

sur la touche provoque le passage au code de paramétrage

suivant. Une pression constante sur la touche commande

le délement automatique des codes à raison d’un (1) code

par seconde.

3. La touche INFÉRIEURE DE DROITE permet de sélectionner/

désélectionner les options.

Paramétrage pour la mise en marche

n Modèles PD : Insérer la clé de la porte d’accès ; ensuite

tourner et soulever pour enlever la porte d’accès.

n Modèles PR : Après installation du lecteur de cartes de débit

(conformément aux instructions du fabricant du lecteur

de cartes), pour accéder au mode de paramétrage, insérer

la carte de paramétrage manuel (fournie par le fabricant

du lecteur de cartes) dans le lecteur de cartes. Si une carte de

paramétrage manuel n’est pas disponible, on peut également

enlever le connecteur AA1 sur la plaquette de circuits imprimés

pour accéder au mode de paramétrage manuel.

IMPORTANT : Ne pas ouvrir la console avant d’avoir débranché

le lave-linge de toute source de courant électrique. Pour accéder

au connecteur AA1 :

g Débrancher le lave-linge ou déconnecter la source de courant

électrique.

g Ouvrir la console, débrancher le connecteur AA1 ; refermer

la console.

g Brancher le lave-linge ou reconnecter la source de courant

électrique.

Le lave-linge est maintenant en mode de paramétrage.

REMARQUE : Il n’est pas nécessaire de congurer

le système de commande pour faire fonctionner le lave-linge.

Ces procédures ne sont nécessaires que lorsqu’on désire

personnaliser le système de commande.

CODES DE PARAMÉTRAGE

n La touche INFÉRIEURE CENTRALE permet de passer

de code en code.

n La touche INFÉRIEURE DE GAUCHE permet de changer

la valeur du code.

n La touche INFÉRIEURE DE DROITE permet de sélectionner

ou désélectionner les options.

POUR LES MODÈLES PR : Les codes de paramétrage sont

identiques au modèle PD, sauf indication contraire.

Le code de paramétrage est indiqué par un ou deux caractères

à gauche. La valeur du code de paramétrage est indiquée par

2 ou 3 caractères à droite.

CODE EXPLICATION

6.07

6.07

PRIX POUR PROGRAMME RÉGULIER

Ceci représente le nombre de pièces de 0,25 $

(pièce 1) ; réglage de 0 à 39. (Voir VALEUR POUR

PIÈCE 1.) Sélectionner une valeur de 0 à 39 :

appuyer sur la touche INFÉRIEURE DE GAUCHE.

Conguré à l’usine pour 7 pièces de 0,25 $ = 1,75 $.

MODÈLES PR SEULEMENT : Conguré à l’usine

pour 0 pièce.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

7.11

7.11

DURÉE DU LAVAGE

Nombre de minutes de la période de LAVAGE.

Sélectionner une valeur entre 8 et 20 minutes en

appuyant sur la touche INFÉRIEURE DE GAUCHE.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

8.21

8.21

PROGRAMMES DE RINÇAGE

Il s’agit de la durée et du nombre total de de rinçages.

La durée de chaque période d’agitation (rinçage) est

de 1à 4 minutes ; on peut choisir 1 ou 2 rinçages.

Le chiffre du milieu représente la durée de la période

d’agitation (rinçage) et le chiffre de droite représente

le nombre de rinçages.

On fait changer la valeur afchée selon la séquence

suivante (11, 21, 31, 41, 12, 22, 32, 42) par des

pressions sur la touche INFÉRIEURE DE GAUCHE.

Appuyer une fois sur la touche INFÉRIEURE

CENTRALE pour passer au code suivant.

Pour le programme DELICATES & KNITS (articles

délicats/tricots), la durée xe de période d’agitation

(rinçage) est d’une minute.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

9.00

OPTION DE COMPTAGE DU NOMBRE DE

PROGRAMMES

Cette option peut être SÉLECTIONNÉE “ON” (active)

ou DÉSÉLECTIONNÉE “OFF” (inactive).

9.00

9.0

Désélectionnée “OFF”.

Option sélectionnée “ON” et impossible

C

à désélectionner.

Appuyer 3 fois consécutives sur la touche

INFÉRIEURE DE DROITE pour sélectionner “ON”

(active). Une fois “ON” sélectionnée, on ne peut plus

la désélectionner.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

21

Page 22

CODE EXPLICATION

1.00

OPTION COMPTEUR DE MONNAIE

Cette option peut être SÉLECTIONNÉE “ON” (active)

ou DÉSÉLECTIONNÉE “OFF” (inactive).

1.00

1.0

C

Désélectionnée “OFF”.

Sélectionnée “ON”.

Appuyer 3 fois consécutives sur la touche

INFÉRIEURE DE DROITE pour sélectionner

“ON” (active); appuyer 3 fois sur la touche

pour désélectionner l’option. Le compteur

passe de “OFF” (inactive) à “ON” (active).

1.C0

Option “ON” sélectionnée et impossible

à désélectionner.

Pour sélectionner “ON” avec impossibilité

de désélection, sélectionner d’abord “ON”. Puis

en moins de deux secondes appuyer deux fois sur

la touche INFÉRIEURE DE DROITE et une fois sur

la touche INFÉRIEURE DE GAUCHE, et quitter

le mode de paramétrage.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

2.00

OPTION DE PRIX SPÉCIAL

Cette option peut être SÉLECTIONNÉE “ON” (active)

ou DÉSÉLECTIONNÉE “OFF” (inactive).

2.00

2.5

Désélectionnée “OFF”.

Sélectionnée “ON”. Appuyer une fois sur la touche

P

INFÉRIEURE DE DROITE pour cette sélection.

Si l’OPTION DE PRIX SPÉCIAL est sélectionnée,

on a accès aux codes « 3. » à « 9. ».

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

OPTIONS DISPONIBLES SI L’OPTION DE PRIX SPÉCIAL

A ÉTÉ SÉLECTIONNÉE :

3.07

3.07

PRIX POUR PROGRAMME SPÉCIAL

Ceci représente le nombre de pièces de 0,25 $

(pièce 1) ; réglage de 0 à 39. (Voir VALEUR POUR

PIÈCE 1.) Sélectionner une valeur de 0 à 39 :

appuyer sur la touche INFÉRIEURE DE GAUCHE.

Conguré à l’usine pour 7 pièces de 0,25 $ = 1,75 $.

MODÈLES PR SEULEMENT : Conguré à l’usine

pour 0 pièce.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

OPTIONS DISPONIBLES SI L’OPTION DE PRIX

SPÉCIAL A ÉTÉ SÉLECTIONNÉE (suite) :

5.00

5.00

HORLOGE – MINUTES

Sélection du nombre de minutes pour l’HORLOGE ;

sélectionner une valeur de 0 à 59 minutes : appuyer

sur la touche INFÉRIEURE DE GAUCHE.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

6.00

HORLOGE – HEURES

REMARQUE : Utilisation du format 24 h (heure

militaire).

6.00

Sélection du nombre d’heures pour l’HORLOGE ;

sélectionner une valeur de 0 à 23 heures en

appuyant sur la touche INFÉRIEURE DE GAUCHE.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

CODE EXPLICATION

7.00

PRIX SPÉCIAL – HEURE DE COMMENCEMENT

REMARQUE : Utilisation du format 24 h.

7.00

C’est l’heure de commencement de cette tarication ;

0 à 23 heures. Sélectionner START HOUR (heure de

commencement) : appuyer sur la touche INFÉRIEURE

DE GAUCHE.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

8.00

PRIX SPÉCIAL – HEURE D’EXPIRATION

REMARQUE : Utilisation du format 24 h

(heure militaire).

8.00

Sélection de l’heure d’expiration pour cette

tarication ; 0 à 23 heures. Sélectionner START

HOUR (heure de commencement) : appuyer sur

la touche INFÉRIEURE DE GAUCHE.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

9.10

9.10

JOUR POUR PRIX SPÉCIAL

Ceci représente le jour de la semaine sélectionné,

et la sélection de la tarication spéciale pour ce jour.

Un chiffre suivi de “0” indique que cette option n’est

pas sélectionnée pour le jour particulier concerné

(9.10). Un chiffre suivi d’un “S” indique que cette

option est sélectionnée pour le jour concerné (9.1S).

Pour sélectionner le jour de la semaine (1 à 7),

appuyer sur la touche INFÉRIEURE DE GAUCHE.

Appuyer une fois sur la touche INFÉRIEURE DE

GAUCHE pour sélectionner l’option de prix spécial

pour chaque jour choisi.

Le jour de la semaine doit apparaître sur l’afcheur

au moment de sortir du code de paramétrage “9.” :

AFFICHAGE

10 Jour 1 = Dimanche 1S

20 Jour 2 = Lundi 2S

30 Jour 3 = Mardi 3S

40 Jour 4 = Mercredi 4S

50 Jour 5 = Jeudi 5S

60 Jour 6 = Vendredi 6S

70 Jour 7 = Samedi 7S

JOUR DE LA SEMAINE

CODE (sélectionné)

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

A

.00

OPTION AFFICHAGE DU CONTENU DU COFFRE

Cette option peut être SÉLECTIONNÉE “ON”

ou DÉSÉLECTIONNÉE “OFF”.

A

.00

A.SC

Désélectionnée “OFF”.

Sélectionnée “ON”. Appuyer une fois sur la touche

INFÉRIEURE DE DROITE pour cette sélection. Lorsque

l’option est sélectionnée, le montant d’argent et/

ou le nombre de programmes (si on a sélectionné le

comptage) sont visibles lorsque la boîte à pièces a été

enlevée.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

6.05

6.05

VALEUR DE LA PIÈCE 1

Ceci représente la valeur de la pièce 1, en multiples

de 0,05 $ : 05 = 0,25 $.

Par des pressions sur la touche INFÉRIEURE

DE GAUCHE, on peut sélectionner une valeur

de 1 à 199 pièces.

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

pour passer au code suivant.

22

Page 23

CODE EXPLICATION

C

.20

C

.20

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

8.00

8.00

8.

CS

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

E

.00

E

.00

E.AC

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

F

.00

F

.00

F.CP

F.S

g Appuyer une fois sur la touche INFÉRIEURE CENTRALE

VALEUR DE LA PIÈCE 2

Ceci représente la valeur de la pièce 2, en nombre

de pièces : 20 = 1 $.

Modèles PR : Conguré à l’usine pour 0,25 $.

En appuyant sur la touche À PRESSION

PERMANENTE, on peut sélectionner une valeur

de 1 à 199 pièces.

pour passer au code suivant.

OPTION GLISSIÈRE À PIÈCES

Cette option peut être SÉLECTIONNÉE “ON”

ou DÉSÉLECTIONNÉE “OFF”.

Désélectionnée “OFF”.

Sélectionnée “ON”. Appuyer 3 fois consécutives

sur la touche INFÉRIEURE DE DROITE pour cette

sélection.

Lorsqu’on sélectionne le mode de glissière à

pièces, sélectionner une valeur ‘b.’ égale à la valeur