Page 1

Service

UD8004

UD8004 /

SUPER AUDIO CD/

K1B/S1B/N1B/U1B/R1B

Manual

SECTION PAGE

SERVICE HINTS AND TOOLS......................................................................................................ii

WARNING AND LASER SAFETY INSTRUCTIONS ....................................................................iii

SPECIFICATIONS .........................................................................................................................1

WIRE ARRANGEMENT ................................................................................................................2

DISASSEMBLY .............................................................................................................................3

DIAGNOSTICS OF OPTICAL PICKUP

AND REPLACING FE MAIN P.W.B AND BD MECHANISM UNIT ASSY

SERVICE MODE .........................................................................................................................14

VERSION UPGRADE PROCEDURE OF FIRMWARE ...............................................................25

TROUBLE SHOOTING ...............................................................................................................26

SEMICONDUCTORS ..................................................................................................................38

BLOCK DIAGRAM.......................................................................................................................51

PRINTED WIRING BOARDS ......................................................................................................52

NOTE FOR PARTS LIST .............................................................................................................59

PARTS LIST OF P.W.B. UNIT .....................................................................................................60

WIRING DIAGRAM .....................................................................................................................97

EXPLODED VIEW .......................................................................................................................98

PARTS LIST OF EXPLODED VIEW............................................................................................99

PACKING VIEW ........................................................................................................................101

PARTS LIST OF PACKING & ACCESSORIES .........................................................................102

MEASURING METHOD AND WAVEFORMS ............................................................................103

NOTE FOR SCHEMATIC DIAGRAM ........................................................................................108

SCHEMATIC DIAGRAMS .........................................................................................................109

BLU-RAY DISC PLAYER

TABLE OF CONTENTS

....................................12

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

X0446V01DM/DG0910

UD8004

Copyright 2009 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

Part no. 90M38AK855010

First Issue 2009.10

Page 2

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

MARANTZ

company has created the ultimate in stereo sound.

Only original

MARANTZ

parts can insure that your

MARANTZ

product will continue to perform to the specications for

which it is famous.

Parts for your

MARANTZ

equipment are generally available to our National Marantz Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and veried before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of difculties, do not hesitate to contact the Technical

Department at above mentioned address.

080702MZ

NOTE ON SAFETY :

Symbol Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol .

Any other component substitution (other than original type), may increase risk of re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用して下さい。

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

KOREA

D&M SALES AND MARKETING KOREA LTD.

CHUNG JIN B/D., #1001,

53-5, WONHYORO 3 GA, YONGSAN-GU,

SEOUL, 140-719, KOREA

PHONE : +82 - 2 - 323 - 2155

FAX : +82 - 2 - 323 - 2154

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

JAPAN

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

D&M Holdings Inc.

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

Page 3

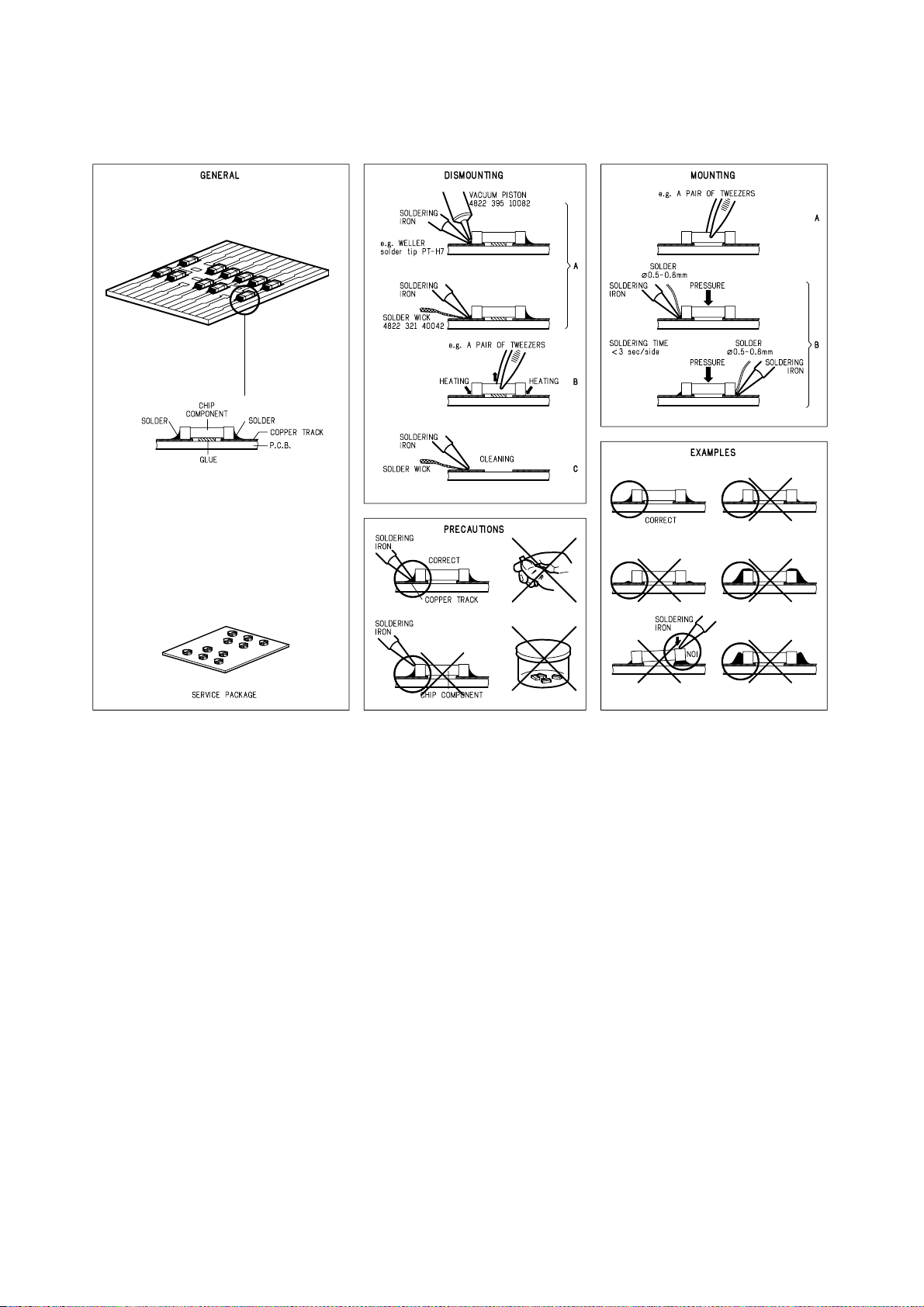

SERVICE HINTS AND TOOLS

2. SERVICE HINTS AND TOOLS

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184 or TCD-784

Disc without errors +

Disc with DO errors, black spots and fingerprints 4822 397 30245 (SBC444A) or TCD-726

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

070703MZ

Page 4

WARNING AND LASER SAFETY INSTRUCTIONS

03080

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composa

outils que l’on utilise soient également a ce

potentiel.

nts ainsi que les

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora s

questo potenziale.

iano anche a

.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service t

device, due to possible eye injury.

his

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄ

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

TEILYLLE. ÄLÄ KATSO SÄTEESEEN

4ecm

Page 5

SPECIFICATIONS

440.0

110.5

127

16.5

388

399

7

n Audio performance

Signal format : NTSC, PAL

Applicable discs /memory cards :

(1)BD-Video discs :

12 cm 1 side 1 layer, 12 cm 1 side 2 layers

(2)DVD-Video / DVD-Audio discs :

12 cm 1 side 1 layer, 12 cm 1 side 2 layers /

12 cm 2 sides 2 layers (1 side 1 layer)

8 cm 1 side 1 layer, 8 cm 1 side 2 layers /

8 cm 2 sides 2 layers (1 side 1 layer)

(3)Super Audio CDs :

12 cm 1 layer / 12 cm 2 layer / 12 cm Hybrid

(4)Compact Discs (CD-DA) :

12 cm / 8 cm discs

(5)Memory cards :

SD Memory Card / SDHC Memory Card / miniSD Card /

microSD Card

S-Video output :

Y output level : 1 Vp-p (75

C output level : 0.300 Vp-p

Output terminal : S-Video, 1 set

Video output :

Output level : 1 Vp-p (75

Output terminal : Pin-jack, 1 set

Component video output :

Y output level : 1 Vp-p (75 Ω/ohms)

Pb/Cb output level / Pr/Cr output level : 0.7 Vp-p (75 Ω/ohms)

Output terminal : Pin-jack, 1 set

HDMI output :

Output terminal : 19-pin HDMI terminals, 1 set

HDMI ver. 1.3a

(Deep Colour, Dolby Digital Plus, Dolby TrueHD, DTS-HD)

Analog audio output :

Output level : 2.3 Vrms (10 k

2 channels output terminal : Pin-jack, 1 set

7.1 channels output terminal : Pin-jack, 1 set

Audio output characteristics :

(1)Frequency response :

①BD (Multi linear PCM): 2 Hz ~ 22 kHz (48 kHz sampling)

②

DVD (Multi linear PCM)

③Super Audio CD : 2 Hz ~ 100 kHz

④Super Audio CD : 2 Hz ~ 20 kHz

(2)S/N ratio : 120 dB

(3)Total harmonic distortion : 1kHz 0.0015 %

(4)Dynamic range : 110 dB

(5)Channel separation : 110 dB

Digital audio output :

Optical digital output: Optical connector, 1 set

Coaxial digital output: Pin jack, 1 set

Ω

/ohms)

Ω

/ohms)

Ω

/kohms)

: 2 Hz ~ 44 kHz (96 kHz sampling)

:

2 Hz ~ 88 kHz (192 kHz sampling)

: 2 Hz ~ 22 kHz (48 kHz sampling)

: 2 Hz ~ 44 kHz (96 kHz sampling)

:

2 Hz ~ 88 kHz (192 kHz sampling)

n General

Power supply : AC 230 V, 50/60 Hz

Power consumption : 55W

• When in Power Saving Standby : 0.3 W

• When in Normal Standby : 0.8 W

• When in Quick Start Mode :

20 ~ 35 W (Changes according to connection status, etc.)

n Dimensions

n Weight : 8.5 kg

* For purposes of improvement, specifications and

design are subject to change without notice.

1

Page 6

WIRE ARRANGEMENT

If wire bundles are untied or moved to perform adjustment or parts replacement etc., be sure to rearrange them neatly as they

were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

Wire arrangement viewed from the top

Front Panel side

Back Panel side

2

Page 7

DISASSEMBLY

• Disassemble in order of the ar row of the figure of following flow.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling" it.

TOP COVER

FRONT PANEL ASSY MAIN UNIT ASSY POWER UNIT ASSY

Refer to "DISASSEMBLY Refer to "DISASSEMBLY Refer to "DISASSEMBLY

1.FRONT PANEL UNIT ASSY" 2.MAIN UNIT ASSY" 3.POWER UNIT ASSY"

FRONT UNIT ASSY MAIN UNIT ASSY POWER UNIT ASSY

(Ref. No. of EXPLODED VIEW : B-4) (Ref. No. of EXPLODED VIEW : C) (Ref. No. of EXPLODED VIEW : A-1)

POWER SW UNIT ASSY

(Ref. No. of EXPLODED VIEW : B-5)

ANALOG VIDEO UNIT ASSY MECHA ASSY AUDIO3 UNIT ASSY

(Ref. No. of EXPLODED VIEW : B-1) (Ref. No. of EXPLODED VIEW : D) (Ref. No. of EXPLODED VIEW : A-3)

and "EXPLODED VIEW" and "EXPLODED VIEW" and "EXPLODED VIEW"

ANALOG VIDEO UNIT ASSY MECHA ASSY AUDIO3 UNIT ASSY

Refer to "DISASSEMBLY Refer to "DISASSEMBLY Refer to "DISASSEMBLY

6.ANALOG VIDEO UNIT ASSY" 7.CHASSIS BACK" 4.AUDIO3 UNIT ASSY"

and "EXPLODED VIEW" and "EXPLODED VIEW" and "EXPLODED VIEW"

AUDIO2 UNIT ASSY

Refer to "DISASSEMBLY

5.AUDIO2 UNIT ASSY"

and "EXPLODED VIEW"

AUDIO2 UNIT ASSY

(Ref. No. of EXPLODED VIEW : A-2)

AUDIO UNIT ASSY

Refer to "DISASSEMBLY

6.AUDIO UNIT ASSY"

AUDIO UNIT ASSY

(Ref. No. of EXPLODED VIEW : B-7)

and "EXPLODED VIEW"

About the photos used for descriptions in the “DISASSEMBLY” section.

• Th e direction from which the photographs used herein were photographed is indicated at "Direction of photograph: ***" at

the left of the respective photographs.

• Refer to the table below for a description of the direction in which the photos were taken.

• Photographs for which no direction is indicated were taken from above the product.

• The photograph is UD8004.

The viewpoint of each photograph

(Photografy direction)

[View from above]

Direction of photograph: B

Front side

Direction of photograph: C

Direction of photograph: D

Direction of photograph: A

3

Page 8

1. FRONT PANEL ASSY

Proceeding : TOP COVER →→

(1) Remove the Loadr Panel.

Direction of photograph: B

(2) Remove the screws.

View from bottom

LOADER PANEL FRONT PANEL ASSY

(3) Cut the wire clampers. Disconnect the connector wire and FFC Cable.

cut

CX042

FFC Cable

cut

CY033

Please refer to "EXPLODED VIEW" for the disassembly method of each P.W.B included in FRONT PANEL ASSY.

4

Page 9

2. MAIN UNIT SUB ASSY

Proceeding : TOP COVER → MAIN UNIT ASSY

(1) Remove the screws.

◆

Direction of photograph: A

◆◆

(2) Remove the screws. Disconnect the connector wires and FFC cables.

FFC Cable

◆

FFC Cable

CY151

MAIN UNIT

5

Page 10

3.POWER UNIT ASSY

Proceeding : TOP COVER →

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws. Disconnect the connector wire.

CY063

POWER UNIT ASSY

◆

CX042

CY151

CY032

CX022

CX021

POWER UNIT

6

Page 11

4. AUDIO3 UNIT ASSY

Proceeding : TOP COVER →

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws. Disconnect the HOCK, connector wire and FFC Cable.

HOCK

AUDIO3 UNIT ASSY

FFC Cable

FFC Cable

AUDIO3 UNIT

CX067

7

Page 12

5. AUDIO2 UNIT ASSY

Proceeding : TOP COVER →→

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws. Disconnect the HOCK, connector wire and FFC Cable.

HOCK

AUDIO3 UNIT ASSY AUDIO2 UNIT ASSY

FFC Cable

AUDIO2 UNIT

CX065

8

Page 13

6. AUDIO UNIT ASSY

Proceeding : TOP COVER →

AUDIO UNIT ASSY

→

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws.

AUDIO3 UNIT ASSY

AUDIO2 UNIT ASSY

→

(3) Remove the screws.

AUDIO UNIT

CY022

FFC Cable

9

Page 14

7. ANALOG VIDEO UNIT ASSY

Proceeding : TOP COVER →→ MAIN UNIT ASSY ANALOG VIDEO UNIT ASSY

(1) Remove the screws.

Direction of photograph: A

(2) Remove the screws.

ANALOG VIDEO UNIT

8. MECHA ASSY

Proceeding : TOP COVER →→ MAIN UNIT ASSY MECHA ASSY

(1) Remove the screws. Disconnect the connector wire.

CY063

10

Page 15

Removing discs

Proceeding : INSIDE PLATE → SLIDE CAM

(1) Remove the screws and FOOTs.

View from bottom

(2) Slide the SLIDE CAM in the direction of the arrow.

Direction of photograph: A

(3) Draw out the LOADER TRAY, then remove the disc.

11

Page 16

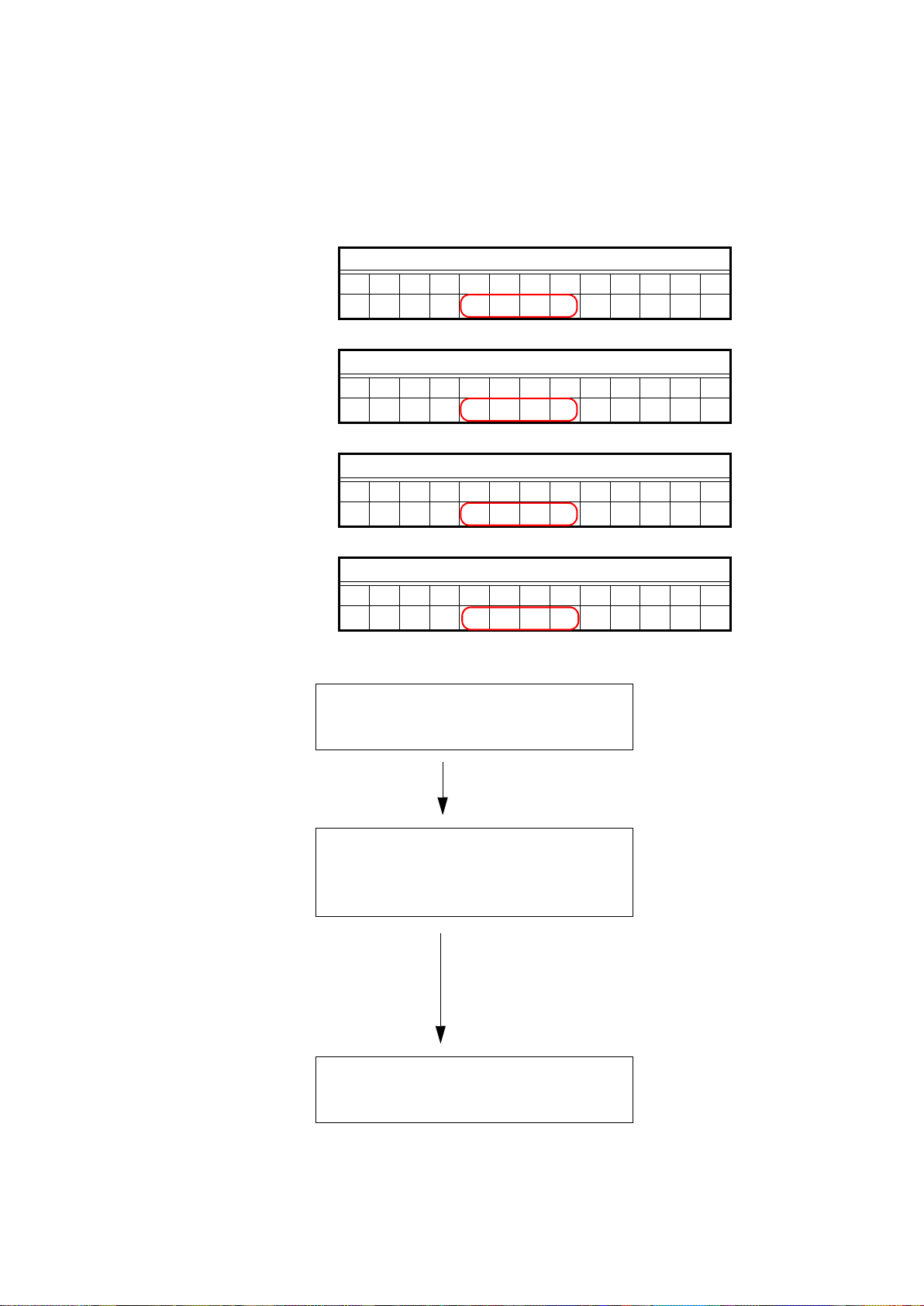

DIAGNOSTICS OF OPTICAL PICKUP

DIAGNOSTICS OF OPTICAL PICKUP AND REPLACING FE MAIN P.W.B AND BD MECHANISM UNIT ASSY

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than ± 12[mA] of the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked Method" of next page.

In case of replacing the Pickup, change the whole part of the FE Main P.W.B and BD Mechanism Unit Assy.

No mechanical adjustment is necessary after the replacement.

Laser drive current initial value:

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 1 - m m m m - n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 2 - m m m m - n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 3 - m m m m - n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 4 - m m m m - n n n n

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check

HF wave form check

(Refer to WAVE FORMS)

FE Main P.W.B. and BD Mechanism Unit

Assy replacing

Current value of the BD, DVD or CD IOP is

± 12[mA] or more the initial value.

CD:

DVD:

BD(SL):

BD(DL):

AND REPLACING FE MAIN P.W.B AND BD MEChANISM UNIT ASSy

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than ±12[mA] of the initial value, the Optical Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked Method" of next page.

In case of replacing the Pickup, change the whole part of the FE Main P.W.B and BD Mechanism Unit Assy.

No mechanical adjustment is necessary after the replacement.

Laser drive current initial value:

12

Page 17

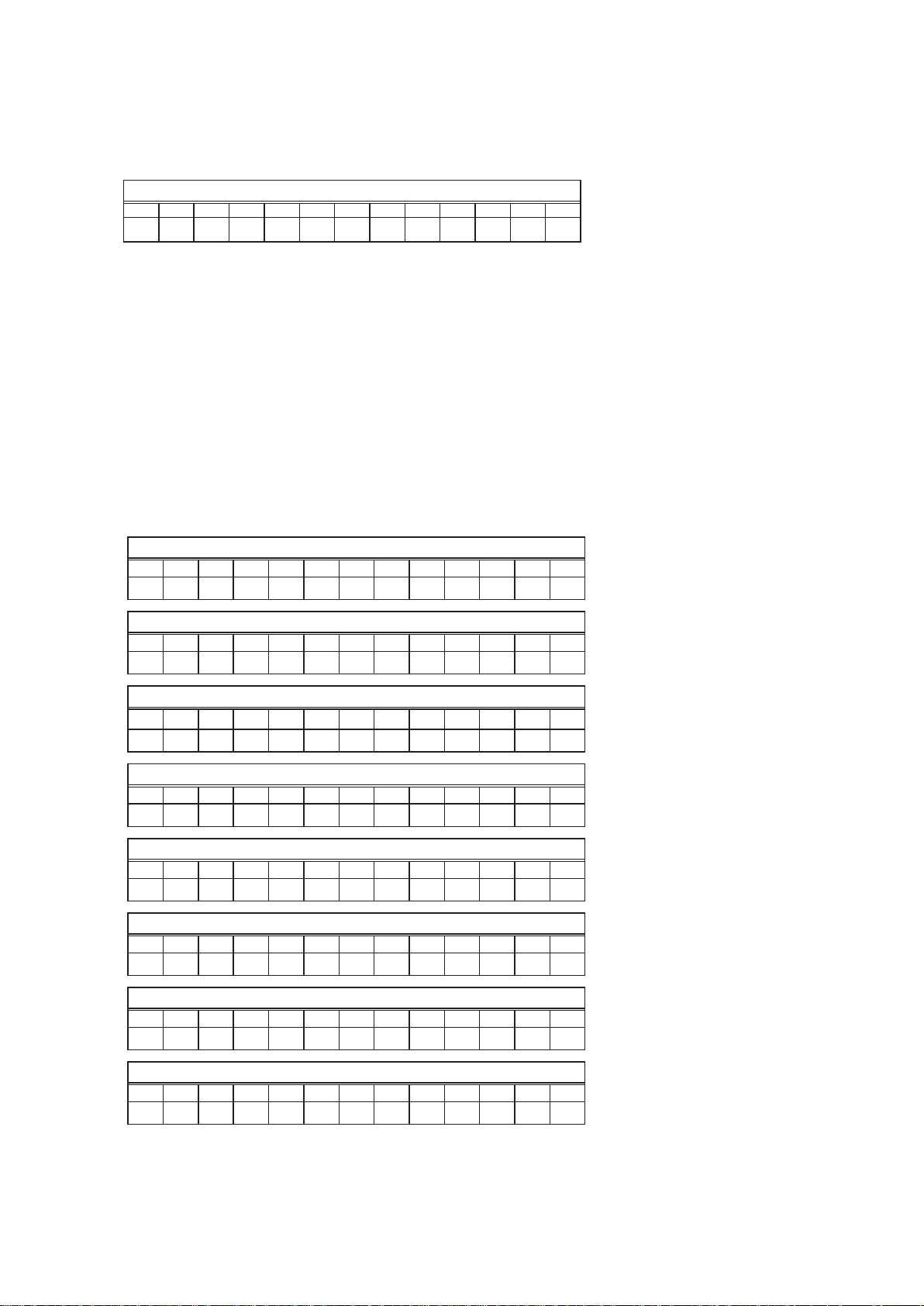

Iop checked Method

1.Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser.

(See page 19 for test mode.)

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

1.Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser.

(See page 19 for test mode.)

DVDlasercurrentcheck

Press the 8 or 9 button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn).

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X - m m m m - n n n n

1.Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser.

(See page 19 for test mode.)

DVDlasercurrentcheck

Press the 8 or 9 button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn).

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

2. To clear the accumulated laser on time

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until " * " appears at the fourth

position. Press the 8 or 9 button to select "TC4".If the 1 button is pressed while "TC1" is displayed, the accumu-

lated laser on time of CD, DVD and BD is cleared.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X - m m m m - n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 4 * - - - - - - - - -

1.Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser.

(See page 19 for test mode.)

DVDlasercurrentcheck

Press the 8 or 9 button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn).

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

2. To clear the accumulated laser on time

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until " * " appears at the fourth

position. Press the 8 or 9 button to select "TC4".If the 1 button is pressed while "TC1" is displayed, the accumu-

lated laser on time of CD, DVD and BD is cleared.

When “TC1”, “TC2” or “TC3” is selected with the 8 or 9 button, "mmmmmm" is displayed as “0” so you can check.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X - m m m m - n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 4 * - - - - - - - - -

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C Y - - - m m m m m m h

1.

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the IOP value of CD laser, DVD laser or BD

laser.

(See page 19 for test mode.)

DVD laser current check

Press the 8 or 9 button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn)

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

To clear the accumulated laser on time

2.

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "*" appears at the

fourth position. Press the 8 or 9 button to select "TC4". If the 1 button is pressed while "TC1" is displayed, the

accumulated laser on time of CD, DVD and BD is cleared

When "TC1", "TC2" or "TC3" is selected with the 8 or 9 button, "mmmmmm" is displayed as "0" so you can check.

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time(Fractions of hours are counted up one hour on the display.)

13

Page 18

SERVICE MODE

1. Heat run mode

1.1. preparation

(1) Equipment used : Heat run disc (This operation may not work with any discs other than the heat run discs listed

below.)

CD

CD TEST DISC (TCD-HR01)

:

DVD :DVD TEST DISC (TDV-HR01)

BD :BD TEST DISC (TBD-HR01)

(2) Unit setting : No spec other than the following procedure.

1.2. procedure

<Playback mode>

(1) Pressing the 5 and 1 buttons simultaneously, plug the AC cord into a power outlet.

When the heat run mode is set, the "1" and "3" indicators light.

(2) Press the 5 button and open a tray.

(3) Set a disc to the tray and press the 1 button once. The "1" and "3" indicators blink at the same time and heat run

operation starts.

DVD : After playback title-1 and title-10 of the disc, the tray opens and closes automatically, then playback the

title-1 and title-10 again.

CD/BD : The disc is played through once from title 1 through the last title, the tray opens and closes automatically,

then the disc is played through again from title 1 through the last title.

(4) This heat run operation continues automatically or it stops caused by an error. In case of some error, the following

error messages are displayed on the FL tube.

<Tray open/close mode>

(1) Pressing the 5 and 1 buttons simultaneously, plug the AC cord into a power outlet.

When the heat run mode is set, the "1" and "3" indicators light.

(2) Press the 5 button and open a tray.

(3) Set a disc to the tray and press the 1 button twice. The "1" and "3" indicators blinks alternately and heat run

operation starts.

CD/DVD/BD : After disc loading is complete, the tray opens and closes automatically, and disc loading is carried out

again.

(4) This heat run operation continues automatically or it stops caused by an error. In case of some error, the following

error messages are displayed on the FL tube.

If the PURE DIRECT button is pressed during heat run, the repeat count of heat run operations is displayed as (Cnt

b

*********). Press the PURE DIRECT button once more and the display returns to its original state.

No. Error contents FL display

1

Tray Error ERROR 01

2 Bad Disc ERROR 02

3 Search Error ERROR 03

4 Read Error ERROR 04

5 Communications error ERROR 05

6 Other (Front end error) ERROR 06

14

Page 19

2. Initial setting mode

2.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

2.2. procedure

Initialize the BD player when µcom, peripheral parts of µcom, or MAIN P.W.B. unit has been replaced in servicing.

b

All user setting will be lost and its factory setting will be restored when this initialization is made. Be sure to memorize

b

your setting for restoring again after the initialization.

(1)TurnontheUD8004'spower."NODISC"isdisplayedontheuorescenttube.

(2) Press the UD8004's PLAY, EJECT and SOUND MODE buttons simultaneously. "INITIALIZING" is displayed on the

uorescenttube.

(3)Thedisplayontheuorescenttubeswitchesto"INITIALIZED",the"NODISC"displayreappearsandinitializationis

completed.

3. µcomrm,H/Wversion,andSerealnumbermode

3.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

3.2. procedure

Systemµcomandotherµcomrmcheckmode.

b

This mode is for displaying the status of each µcom employed.

(1) Pressing the 5 and 1 buttons simultaneously, plug the AC cord into a power outlet.

(2)"NODISC"isdisplayedontheuorescenttube.

(3) Press remote contraller "3265".

(4) Each time the POP UP MENU button or Cursor buttons(d or f) on the remote control unit is pressed, version

informationofµcomrm,versionofH/Wandserialnumberisdisplayedoneafteranother.

Ex.: [Sys Ver000103, Sys Day090219, Sys GEN100000………, H/W Ver000000, S/N ***************]

4. Tray lock mode

4.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

4.2. procedure

[Setting]

(1) Pressing the 1 and 3 buttons for simultaneously, plug the AC cord into a power outlet.

(2)"TRAYLOCK"isdisplayedontheuorescenttubeandtrayopening/closingisinvalidated.

[Cancel]

(1) Unplug the UD8004's AC cord from the power outlet.

(2) Pressing the 1 and 3 buttons simultaneously, plug the AC cord into a power outlet.

(3)"PLEASEWAIT"isdisplayedontheuorescenttubeandtrayopening/closingisenabled.

The tray lock mode is also canceled when the product is initialized.

b

15

Page 20

All Lit / All Off mode for the FL tube

5.

5.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

5.2. procedure

[Setting]

(1) Pressing the HDMI RESOLUTION and 1 buttons for simultaneously, plug the AC cord into a power outlet.

If All Lit / All Off mode is set for the FL tube, the FL tube’s display area is fully lit.

(2) Press the Pure Direct button to switch between ‘all lit’ and ‘all off’ display.

[Cancel]

(1) Remove the power cable for 5 seconds or more to cancel All Lit / All Off mode for the FL tube.

Forced Tray Open mode.

6.

7.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

Operation cannot be guaranteed after executing Forced Tray Open mode.

b

6.2. procedure

[Setting]

To forcibly open the tray, press the 5 for 5 seconds or more.

(1)

[Cancel]

(1) Remove the power cable for 5 seconds or more to cancel Forced Tray Open mode.

16

Page 21

7. Test mode

7.1. Entering the test mode

The test mode is entered by pressing the 5 and 2 buttons simultaneously, plug the AC cord into a power outlet.

When the test mode is set, the "1" and "3" indicators light.

FL tube display when test mode entered

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T E S T M O D E

When the test mode is set, a color bar appears on the monitor.

7.2. Selecting the mode

The following modes are available.

・

(1) Laser on/off (CD/DVD/BD) mode : T2

(2) Servo adjustment value display mode : T3

(3) Error rate (skew) measurement mode : T7

(4) Accumulated laser on time display mode : TC

(5) Track buffer output mode : TE

(6) Picking up No. display mode : TG

(7) Error log display mode : TH

(8) Test mode cancel : TI

When the 9 button is pressed after entering the test mode, the display switches in the order: "T2, T3, T7, TC, TE,

q

TG, TH, TI, T2 …"

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 3 S e r v o A d j .

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 7 E r r o r R a t e

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C L a s e r O n T i m

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T E T r a c k B u f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T G O P U N u m b e r

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T H E r r o r L o g

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T I T e s t E x i t

When the 8 button is pressed, the display switches in the opposite order fromq above, starting from the current

w

position (for example, if currently at "TA", it switches as follows: "T2, T3, T7, TC, TE, TG, TH, TI, T2 …").

17

Page 22

7.3. About each mode

With the mode selected, press the 1 button to set that mode.

・

(1) Laser on/off (CD/DVD/BD) mode

Press the 8 or 9 button to select [X] and press the 1 button to set it.

Laser on/off control is executed and the laser current is displayed.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X m m m m n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(mm.mm[mA] : Stored data, nn.nn[mA] : Current value)

When the current value is more that ± 12.00[mA] of saved data, it becomes the pickup transducer's target.

b

In this case, replace the mechanism unit.

If stored value is not

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X

― ― ― ― ― ―

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode, 4 : BD(DL) laser mode)

(nn.nn[mA] : Current value)

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

n n n n

(2) Servo adjustment value display mode

Press the 8 or 9 button to select [XXX]. Refer to [Table 1 - Servo adjustment value display mode details] (page

21).

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T X X X

(XXX : Servo adjustment value

Press the 1 button to set. The contents indicated on "Table 1: Details of the servo adjustment value display mode"

(page 21) are displayed.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

)

T X X X m m m m m m n n

(XXX : Selection mode, mmmmmm : Address(HEX), nn:Data(HEX))

Thersttime,theaddressspeciciationpositionistheuppermostposition(5thplace).Theaddressspeciciation

position moves downwards each time the 1 button is pressed.

Theaddressspeciciationpositionashes(atanintervalofabout0.5seconds).Ifthe1buttonispressedafter

moving to the lowermost position (10th place), the position moves to the uppermost position

Use the 8 or

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

buttontochangethedisplayattheaddressspecicationposition.

9

18

Page 23

(3) Error rate measurement mode

Press the 8 or 9 button to select [YY] .

Refer to [Table 2 - Error rate details]. (page 22)

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T Y Y F F F F F F F F F F

(X : measurement mode, F : Address and error rate (When not set, "F" is displayed.)

Press the 1 button to begin error rate measurement. The address and error rate are displayed.

For a description of the displayed measurement results, see "Table 2: Error rate details" (page 22).

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T Y Y m m m m m m

(YY : selection mode [71 to 94], m : address [PBA][HEX], l : error rate [COUNT/SEC] [HEX])

(Note) CD (4x-speed) : Renewal of data is carried out for every 300 frame.

Error rate of 75 frames is displayed.

DVD (2x-speed) : Renewal of data is carried out for every 80ECC block.

Error rate of 8ECC block is displayed.

BD (2x-speed) : Renewal of data is carried out for every 136LDC clusters block.

Error rate of 8LDC clusters block is displayed.

The mode chosen when selection mode was changed into the trace execution and the 1 button was pushed is

performed from the beginning.

When the 1 button is pushed without changing selection mode, the mode under selection is performed from the

beginning.

(If the 1 button is pushed, the address corresponding to the chosen mode will be searched again.)

The pause mode is set after tracing is completed.

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

l l l l

(4) Accumulated laser on time display mode

Press the 8 or 9 button to select [Y] and press the 1 button to set it.

The accumulated laser on time is displayed.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C Y m m m m m m h

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time(Fractions of hours are counted up one hour on the display.)

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21)

---To clear the accumulated laser on time---

Press the 1 button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "*" appears at

the fourth position.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C Y * m m m m m m

Press the 8 or 9 button to select "TC4"

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 4 *

If the 1 button is pressed while "TC4" is displayed, the accumulated laser on time of CD, DVD and BD is cleared.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 1 0 0 0 0 0 0 h

When "TC1", "TC2" or "TC3" is selected with the 8 or 9 button, "mmmmmm" is displayed as "0" so you can

check.

19

Page 24

(5) Track buffer output mode

Press the 8 or 9 button to select "Y" and switch the track buffer output.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T E Y T r a c k B u f f

(Y=1 : Track buffer being output, 0 : Track buffer output off )

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

(6) Picking up No. display mode

Press the 8 or 9 button to switch to the pickup number display.

The pickup number is a 14-digit number, so it is displayed in two sections.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T G X Y Y Y Y Y Y Y

(X (display position) = 1 : Lower digits, 2 : Upper digits. YYYYYYY: Pickup number)

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

(7) Error log display mode

Press the 8 or 9 button to switch to the error log display.

For Error log No. and description of the displayed measurement results, see "Table 3: Error log details" (page 24).

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

n T H X

(n : Error information No.(1~5), X : Error log No.)

Display when there is no error

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

n T H 1 N o E r r o r

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

(8) Test mode cancel

Aconrmationmessageisdisplayed.Pressthe

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

button to set, canceling the test mode.

1

T I 1 R e a l l y ?

When the 2 button is pressed, the layer above the current layer is displayed. See "7.4 Stopping the mode" (page

21).

20

Page 25

7.4. Stopping the mode

When the 2 button is pressed, the layer above the current layer is displayed. The relationship between the different

modes and the display of the different layers is shown on the table below.

Mode 1 layer 2 layer 3 layer

Laser on/off (CD/DVD/BD) mode T2 LaserOnOff T2X mmmm nnnn Non

Servo adjustment value display mode T3 Servo Adj. TXXX TXXXmmmmmm nn

Error rate (skew) measurement mode T7 Error Rate TYYFFFFFFFFFF TYYmmmmmmllll

Accumulated laser on time display mode TC LaserOnTim TCY mmmmmmh

Track buffer output mode TE Track Buf TEYTrack Buff Non

Picking up No. display mode TG OPU Number TGX YYYYYYY Non

Error log display mode TH Error Log

Test mode cancel TI Test Exit TI1 Really? Non

nTHX

nTH1 No Error

TCY* mmmmmmh

TC4*

nTHX dddddd

nTHAyyy dddd

7.5. About the OPEN/CLOSE (5)button

Even during the test mode, the tray is opened and closed when the 5 button is pressed.

7.6. Test mode detailed table

Table 1: Servo adjustment value display mode details

No XXX Name Address range Meaning

0 T30 BUF_ID_SDRAM 0x000000~0x3FFFFF SDRAM

1 T31 BUF_ID_MPU_ALL 0x000000~0xBEFF3F

2 T32 BUF_ID_MPU_RMCR 0x000000~0x00FFFF ROMCOR

3 T33 BUF_ID_MPU_SYSCFG 0x000000~0x000FFF SystemCongration

4 T34 BUF_ID_MPU_DMAC 0x000000~0x0004FF DMAC

5 T35A BUF_ID_MPU_ITIM0 0x000000~0x0000FF

6 T35B BUF_ID_MPU_ITIM1 0x000000~0x0000FF ITIM 1

7 T35C BUF_ID_MPU_ITIM2 0x000000~0x0000FF ITIM 2

8 T35D BUF_ID_MPU_ITIM3 0x000000~0x0000FF ITIM 3

9 T35E BUF_ID_MPU_ITIM4 0x000000~0x0000FF ITIM 4

10 T35F BUF_ID_MPU_ITIM5 0x000000~0x0000FF ITIM 5

11 T36 BUF_ID_MPU_RSV2 0x000000~0x0079FF Reserved

12 T37 BUF_ID_MPU_WDT 0x000000~0x000FFF WDT

13 T38 BUF_ID_MPU_UART0 0x000000~0x0000FF

14 T39 BUF_ID_MPU_UART1 0x000000~0x0000FF UART 1

15 T40 BUF_ID_MPU_CSIO0 0x000000~0x0000FF CSIO 0

16 T41 BUF_ID_MPU_CSIO1 0x000000~0x0000FF CSIO 1

17 T42 BUF_ID_MPU_GPIO0 0x000000~0x0000FF GPIO 0

18 T43 BUF_ID_MPU_GPIO1 0x000000~0x0000FF GPIO 1

19 T44 BUF_ID_MPU_GPIO2 0x000000~0x0000FF GPIO 2

20 T45 BUF_ID_MPU_RSV5 0x000000~0x00BCFF Reserved

21 T46 BUF_ID_MPU_HEXBIU 0x000000~0x000FFF HEXBIU

22 T47 BUF_ID_MPU_HCSC 0x000000~0x000FFF HCSC

23 T48 BUF_ID_MPU_RSV6 0x000000~0x7DDFFF Reserved

24 T49 BUF_ID_MPU_RSV7 0x000000~0x3DFEFF Reserved

25 T50 BUF_ID_MPU_INT 0x000000~0x00003F INT

26 T51 BUF_ID_IRAM 0x000000~0x003FFF

27 T52 BUF_ID_DSP 0x000000~0x001FFF DSP Register

28 T53 BUF_ID_AFE 0x000000~0x0000FF AFE Register

29 T54 BUF_ID_SVO_ALL 0x000000~0x001FFF SVO REG ABS ACCESS

30 T55 BUF_ID_SVO_REG 0x000000~0x0007FF SVERVO REG

MPU(Abs Access)

ITIM 0

UART 0

IRAM(internal SRAM))

21

Page 26

No XXX Name Address range Meaning

31 T56 BUF_ID_SVO_SVRAM 0x000000~0x0005FF SVRAM

32 T57A BUF_ID_SVO_CRAM0 0x000000~0x0001FF CRAM0

33 T57B BUF_ID_SVO_CRAM1 0x000000~0x0001FF CRAM1

34 T57C BUF_ID_SVO_CRAM2 0x000000~0x0001FF CRAM2

35 T57D BUF_ID_SVO_CRAM3 0x000000~0x0001FF CRAM3

36 T58A BUF_ID_SVO_ZRAM0 0x000000~0x0001FF ZRAM0

37 T58B BUF_ID_SVO_ZRAM1 0x000000~0x0001FF ZRAM1

38 T58C BUF_ID_SVO_ZRAM2 0x000000~0x0001FF ZRAM2

39 T58D BUF_ID_SVO_ZRAM3 0x000000~0x0001FF ZRAM3

40 T59 BUF_ID_EPRM 0x000000~0x000FFF EEPROM

41 T60 BUF_ID_PUCONT_LDD 0x000000~0x000007 LDD

42 T61 BUF_ID_SVRESULT 0x000000~0x0002C3 SvResult

43 T62 BUF_ID_LD_TIME 0x000000~0x00000D

44 T63 BUF_ID_IOP 0x000000~0x000007 IOP(Stored value)

LD ON Time Integrated value

Table 2: Error rate details

Measurement

YY

71

72 The inner

73 The inner

74 The inner

75 The central

76 The central

77 The central

78 The central

79 The outer

80 The outer

81 The outer

82 The outer

position

The inner

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

Error rate display details for each media type

BD DVD CD

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

Remarks

It is invalid. It is invalid. When this is selected for DVD or CD,

it shifts to YY=73.

It is invalid. It is invalid. When this is selected for DVD or CD,

it shifts to YY=73.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid. When this is selected for DVD or CD,

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid. When this is selected for DVD or CD,

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

PO uncorrectable

error number

C1 error

detection number

C2 uncorrectable

error number

it shifts to YY=77.

it shifts to YY=77.

C1 error

detection number

C2 uncorrectable

error number

it shifts to YY=81.

it shifts to YY=81.

C1 error

detection number

C2 uncorrectable

error number

22

Page 27

Measurement

YY

83

84 The inner

85 The inner

86 The inner

87 The central

88 The central

89 The central

90 The central

91 The outer

92 The outer

93 The outer

94 The outer

position

The inner

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

Error rate display details for each media type

BD DVD CD

BIS error detection

signed number

BIS error uncorrectable

signed number

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

BIS error detection

signed number

BIS error uncorrectable

signed numbe

LDC error detection

signed number

LDC error uncorrectable

signed numbe

Remarks

It is invalid. It is invalid. When this is selected for 2-layer DVD,

it shifts to YY=85.

When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

It is invalid. It is invalid. When this is selected for DVD 2-layer,

it shifts to YY=85.

When this is selected for DVD 1-layer

or CD, it shifts to YY=73.

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid. When this is selected for DVD

It is invalid. It is invalid. When this is selected for DVD 2-layer,

PI error detection

number

PO uncorrectable

error number

It is invalid. It is invalid. When this is selected for DVD 2-layer,

It is invalid. It is invalid. When this is selected for DVD 2-layer,

PI error detection

number

PO uncorrectable

error number

It is invalid. When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

It is invalid. When this is selected for 1-layer DVD

or CD, it shifts to YY=73.

2-layer, it shifts to YY=89.When this

is selected for DVD 1-layer or CD, it

shifts to YY=77.

it shifts to YY=89.

When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

It is invalid. When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

It is invalid. When this is selected for DVD 1-layer

or CD, it shifts to YY=77.

it shifts to YY=93.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

it shifts to YY=93.

When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

It is invalid. When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

It is invalid. When this is selected for DVD 1-layer

or CD, it shifts to YY=81.

* The inner circumference of the layer refers to the physical inner circumference for DVD parallel, the physical outer

circumference for the opposite case.

* The inner circumference of the layer refers to the physical outer circumference for DVD parallel, the physical inner

circumference for the opposite case.

23

Page 28

Table 3: Error log details

Error log No.

1 LD On Time (4Byte)

2 Error type (2Byte) See "Table 3-1: Error type details"

3 (31 to 34 displayed in 4-byte units) Reserve (16Byte)

4 Media type (2Byte) See "Table 3-2: Media type details"

5 Reserve (4Byte)

6 Reserve (4Byte)

7 Reserve (2Byte)

8 HyBrid SOUND MODE (2Byte) See "Table 3-3: HyBrid Disc current layer details"

9 (91 to 92 displayed in 7-digit units)

(Matched to TG pickup number display)

A (A000 to A161 displayed in 2-digit units) Reserve (708Byte)

B (B1 to B3 displayed in 4-digit units) Reserve (11Byte)

C Reserve (1Byte)

D (D1 to D3 displayed in 4-digit units) Reserve (12Byte)

PU# (16Byte)

Table 3-1: Error type details

Contents

(Errorlogoveralllayout)

Table 3-2: Media type details

Remarks

Error type Error code

NoError 0x0000

Focus does not turn on. 0x0001

Tracking does not turn on. 0x0002

CLV does not turn on. 0x0003

ID cannot be read. 0x0004

Loader error 0x0005

Thread error 0x0006

Expander error 0x0007

Other error 0x0008

Error disc (Failure to recognition of disc) 0x0009

Seek error 0x0010

Lead error 0x0020

Other Reserved

Table 3-3: HyBrid Disc current layer details

HyBrid Disc current layer Current layer code

SACD layer 0x0000

CD layer 0x0001

DVD layer 0x0002

BD layer 0x0003

Other Reserved

Media type Media code

DVD-ROM 0x0001

DVD-R 0x0002

DVD-RW 0x0003

DVD-PLUS-R 0x0004

DVD-PLUS-RW 0x0005

DVD-ROM DL 0x0006

DVD+R DL 0x0007

DVD-R DL 0x0008

DVD+RW DL 0x0009

DVD-RW DL 0x000A

CD-ROM 0x000B

CD-R 0x000C

CD-RW 0x000D

BD-RE SL 0x000E

BD-RE DL 0x000F

BD-R SL 0x0010

BD-R DL 0x0011

BD-R SL LTH 0x0012

BD-ROM SL 0x0013

BD-ROM DL 0x0014

BD-Hybrid 0x0015

SACD-Hybrid 0x0016

SACD DL 0x0017

SACD SL 0x0018

DVD-Hybrid 0v0019

Unknown 0xFFFF

Other Reserved

24

Page 29

VERSION UPGRADE PROCEDURE OF FIRMWARE

Modem

Internet

Computer

LAN port/

Ethernet

connector

ETHERNET

connector

Router

To WAN port

To LAN port

To LAN port

You can update by downloading the latest firmware from the Internet.

To update the IP ROM, refer to "Updating the IP ROM" on page 30.

1.Update from the Internet

1.1. Connecting to the Network

(1) System Requirement

• Internet Connection by Broadband Circuit

• Modem

• Router

• Ethernet cable (CAT-5 or greater recommended)

(2) Setting

1.2. Check for Update and Update

Check if the latest firmware exists. You can also check approximately how long it will take to complete an update.

(1) Press the SETUP button on the remote control to display the GUI menu.

(2) Use the cursor buttons to select "Other settings" → "Firmware update" → "Update check".

(3) Press the ENTER buttom.

• The latest version of the firmware uploaded to the web is displayed.

• If the latest firmware version is on the web, proceed to (4).

• If the latest firmware is already installed, press the SETUP button to close the menu.

(4) Use the cursor buttons to select "Update" , then pre ss the ENTER button.

• During update, the power indicator lights red and the GUI screenis shut down. And a rough remaining time is

indicated on the display.

• When updating is complete the power indicator lights green and normal

• status is resumed.

(5) Press the SETUP button to close the menu.

--- Cautions on Firmware Update ---

• In order to use these functions, you must have the correct system requirements and settings for a broadband Internet

connection.

• Do not turn off the power until updating is completed.

Even with a broadband connection to the Internet, approximately about 1 hour is required for the updating procedure to be

completed.

Once updating starts, normal operations on the UD8004 cannot be performed until updating is completed. Also, setting

items of the GUI menu of DVD-A1UD or setting items of the image adjustment may be initialized.

Make a note of the settings before updating, and set them again after updating.

25

Page 30

TROUBLE SHOOTING

㪚㪿㪼㪺㫂㩷㪺㫆㫅㫅㪼㪺㫋㫀㫆㫅㩷㪙㪆㪜㩷㩷㪧㪮㪙㩷㪬㪥㪠㪫 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪃㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼

㪏㪬㪄㪊㪈㪇㪇㪋㪈㩿㪙㪆㪜㩷㪬㪥㪠㪫㪀

㪥㪅㪞㪅

䊶㪲㪚㪯㪊㪊㪈㪴㪑㪏㪬㪄㪊㪈㪇㪇㪋㪈

䊶㪲㪚㪯㪊㪊㪈㪴㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅 䊶㪲㪚㪯㪊㪊㪉㪴㪑㪏㪬㪄㪊㪈㪇㪇㪋㪈

䊶㪲㪚㪯㪊㪊㪉㪴㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㪅 䊶㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪛㪘㪫㪘㩷㪪㫀㪾㫅㪸㫃 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪃㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀 䊶㪲㪚㪰㪊㪊㪈㪴㪲㪚㪯㪉㪈㪈㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎

䊶㪲㪠㪚㪊㪇㪈㪴㩿㪛㪘㪚㩷㪽㫆㫉㩷㪉㪺㪿㩿㪤㫀㫏㪀㩷㪣㪆㪩㪀 䊶㪲㪚㪰㪉㪈㪈㪴㪲㪚㪰㪈㪎㪏㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉

㪈㪃㪉㪃㪋㪃㪍㪃㪎㫇㫀㫅㩿㪮㪚㪢㪔㪈㪍㪆㪏㪆㪋㪽㫊㪃 䊶㪲㪚㪰㪊㪊㪉㪴㪲㪚㪯㪈㪎㪏㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊

㩷㪙㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪃 䊶㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅

㩷㪛㪘㪫㪘㪃㪤㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪀

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉㩿㪘㪬㪛㪠㪦㪉㩷㪬㪥㪠㪫㪀

䊶㪲㪠㪚㪍㪇㪈㪴㩿㪛㪘㪚㩷㪽㫆㫉㩷㪝㪣㪆㪝㪩㪀

㪥㪅㪞㪅

䊶㪲㪠㪚㪎㪇㪈㪴㩿㪛㪘㪚㩷㪽㫆㫉㩷㪚㪆㪪㪮㪀

㪈㪃㪉㪃㪋㪃㪍㪃㪎㫇㫀㫅㩿㪮㪚㪢㪔㪈㪍㪆㪏㪆㪋㪽㫊㪃

㩷㪙㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪃

㩷㪛㪘㪫㪘㪃㪤㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪀

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊㩿㪘㪬㪛㪠㪦㪊㩷㪬㪥㪠㪫㪀

䊶㪲㪠㪚㪏㪇㪈㪴㩿㪛㪘㪚㩷㪽㫆㫉㩷㪪㪣㪆㪪㪩㪀

䊶㪲㪠㪚㪐㪇㪈㪴㩿㪛㪘㪚㩷㪽㫆㫉㩷㪪㪙㪩㪆㪪㪙㪣㪀

㪈㪃㪉㪃㪋㪃㪍㪃㪎㫇㫀㫅㩿㪮㪚㪢㪔㪈㪍㪆㪏㪆㪋㪽㫊㪃

㩷㪙㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪃

㩷㪛㪘㪫㪘㪃㪤㪚㪢㪔㪌㪈㪉㪆㪉㪌㪍㪆㪈㪉㪏㪽㫊㪀

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪛㪘㪚㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀 䊶㪲㪠㪚㪊㪇㪈㪴㪲㪠㪚㪍㪇㪈㪴㪲㪠㪚㪎㪇㪈㪴

䊶㪲㪠㪚㪊㪇㪈㪴㪑㫆㫌㫋㫇㫌㫋 䇭㪈㪇㪃㪈㪈㪃㪈㪉㫇㫀㫅㩿㪺㫆㫅㫋㫉㫆㫃㩷㫃㫀㫅㪼㪀

䊶㪲㪠㪚㪏㪇㪈㪴㪲㪠㪚㪐㪇㪈㪴

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉㩿㪘㪬㪛㪠㪦㪉㩷㪬㪥㪠㪫㪀 䇭㪈㪇㪃㪈㪈㪃㪈㪉㫇㫀㫅㩿㪺㫆㫅㫋㫉㫆㫃㩷㫃㫀㫅㪼㪀

䊶㪲㪠㪚㪍㪇㪈㪴㪲㪠㪚㪎㪇㪈㪴㪑㫆㫌㫋㫇㫌㫋

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㪭㫆㫃㫋㪸㪾㪼

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊㩿㪘㪬㪛㪠㪦㪊㩷㪬㪥㪠㪫㪀 㪥㪅㪞㪅 䊶㪲㪚㪯㪇㪍㪈㪴㪲㪚㪯㪇㪍㪉㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎

䊶㪲㪠㪚㪏㪇㪈㪴㪲㪠㪚㪐㪇㪈㪴㪑㫆㫌㫋㫇㫌㫋 㩷㪈㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪈㪈㪭㪆㩷㪊㫇㫀㫅㪑㪸㪹㫆㫌㫋㪄㪈㪈㪭㪃

㩷㪌㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪌㪭㪆㩷㪍㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪊㪅㪊㪭

䊶㪲㪚㪰㪇㪍㪉㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉

㩷㪈㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪈㪈㪭㪆㩷㪊㫇㫀㫅㪑㪸㪹㫆㫌㫋㪄㪐㪭㪃

㩷㪌㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪌㪭㪆㩷㪍㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪊㪅㪊㪭

䊶㪲㪚㪰㪇㪍㪈㪴㪑㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊

㩷㪈㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪈㪈㪭㪆㩷㪊㫇㫀㫅㪑㪸㪹㫆㫌㫋㪄㪐㪭㪃

㩷㪌㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪌㪭㪆㩷㪍㫇㫀㫅㪑㪸㪹㫆㫌㫋㪂㪊㪅㪊㪭

䊶㪚㪿㪼㪺㫂㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪃㩷㪸㫅㪻㩷㫊㫆㫃㪻㪼㫉㫀㫅㪾

䊶㪚㪿㪼㪺㫂㩷㪝㫌㫊㪼

㪝㪊㪇㪈㪄㪝㪊㪇㪋

㪦㪅㪢㪅

1.

8U-210095-7 (AUDIO UNIT)/ 8U-210094-2 (AUDIO2 UNIT)/ 8U-210094-3 (AUDIO3 UNIT)

26

Page 31

㪚㪿㪼㪺㫂㩷㪘㪤㪧䊶㪦㪧㩷㪘㪤㪧㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀 䊶㪲㪠㪚㪊㪇㪉㪴㪲㪠㪚㪊㪇㪍㪴㪲㪠㪚㪊㪇㪊㪴㪲㪠㪚㪊㪇㪎㪴

䊶㪲㪠㪚㪊㪇㪉㪴㪲㪠㪚㪊㪇㪍㪴㪲㪠㪚㪊㪇㪊㪴㪲㪠㪚㪊㪇㪎㪴 䊶㪲㪠㪚㪍㪇㪌㪴㪲㪠㪚㪍㪇㪋㪴㪲㪠㪚㪍㪇㪍㪴

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪋㪈㪌㪴㩷㪸㫅㪻㩷㪲㪩㪋㪈㪎㪴㩷

㪥㪅㪞㪅

䊶㪲㪠㪚㪍㪇㪉㪴㪲㪠㪚㪍㪇㪊㪴㪲㪠㪚㪍㪇㪎㪴

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪊㪍㪋㪴㩷㪸㫅㪻㩷㪲㪩㪊㪍㪍㪴㩷 䊶㪲㪠㪚㪏㪇㪉㪴㪲㪠㪚㪏㪇㪊㪴㪲㪠㪚㪏㪇㪋㪴

䊶㪲㪠㪚㪐㪇㪉㪴㪲㪠㪚㪐㪇㪊㪴㪲㪠㪚㪐㪇㪋㪴

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉㩿㪘㪬㪛㪠㪦㪉㩷㪬㪥㪠㪫㪀

䊶㪲㪠㪚㪍㪇㪌㪴㪲㪠㪚㪍㪇㪋㪴㪲㪠㪚㪍㪇㪍㪴 㩷㪧㪦㪮㪜㪩㩷㪚㪃㪩㪃㩷㪫㪩

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪍㪎㪐㪴㩷㪸㫅㪻㩷㪲㪩㪍㪏㪈㪴㩷

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪍㪏㪇㪴㩷㪸㫅㪻㩷㪲㪩㪍㪏㪉㪴㩷

䊶㪲㪠㪚㪍㪇㪉㪴㪲㪠㪚㪍㪇㪊㪴㪲㪠㪚㪍㪇㪎㪴

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪎㪏㪊㪴㩷㪸㫅㪻㩷㪲㪩㪎㪏㪌㪴㩷

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪎㪎㪏㪴㩷㪸㫅㪻㩷㪲㪩㪎㪏㪇㪴㩷

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊㩿㪘㪬㪛㪠㪦㪊㩷㪬㪥㪠㪫㪀

䊶㪲㪠㪚㪏㪇㪉㪴㪲㪠㪚㪏㪇㪊㪴㪲㪠㪚㪏㪇㪋㪴

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪏㪐㪈㪴㩷㪸㫅㪻㩷㪲㪩㪏㪐㪊㪴㩷

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪏㪐㪉㪴㩷㪸㫅㪻㩷㪲㪩㪏㪐㪋㪴㩷

䊶㪲㪠㪚㪐㪇㪉㪴㪲㪠㪚㪐㪇㪊㪴㪲㪠㪚㪐㪇㪋㪴

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪐㪍㪎㪴㩷㪸㫅㪻㩷㪲㪩㪐㪍㪐㪴㩷

䊶㪚㫆㫅㫅㪼㪺㫋㫀㫆㫅㫊㩷㫆㪽㩷㪲㪩㪐㪍㪍㪴㩷㪸㫅㪻㩷㪲㪩㪐㪍㪏㪴㩷

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪦㪬㪫㪧㪬㪫㩷㫋㪼㫉㫄㫀㫅㪸㫃 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀 㪤㪬㪫㪜㩷㪺㫀㫉㪺㫌㫀㫋㪑㪤㪬㪫㪜㩷㪫㪩

䊶㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫉㫆㫄㩷㪦㪬㪫㪧㪬㪫㩷㫋㪼㫉㫄㫀㫅㪸㫃 㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪎㩿㪘㪬㪛㪠㪦㩷㪬㪥㪠㪫㪀

䇭㩿㪜㪸㪺㪿㩷㪺㪿㪸㫅㫅㪼㫃㫊㪀 䊶㪫㪩㪊㪉㪌䌾㪫㪩㪊㪉㪏

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉㩿㪘㪬㪛㪠㪦㪉㩷㪬㪥㪠㪫㪀 㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪉㩿㪘㪬㪛㪠㪦㪉㩷㪬㪥㪠㪫㪀

䊶㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫉㫆㫄㩷㪦㪬㪫㪧㪬㪫㩷㫋㪼㫉㫄㫀㫅㪸㫃 䊶㪫㪩㪍㪉㪏䌾㪫㪩㪍㪊㪈

䇭㩿㪜㪸㪺㪿㩷㪺㪿㪸㫅㫅㪼㫃㫊㪀 㪥㪅㪞㪅 䊶㪫㪩㪎㪊㪇㪃㪫㪩㪎㪊㪉㪃㪫㪩㪎㪊㪊㪃㪫㪩㪎㪊㪌㪃

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊㩿㪘㪬㪛㪠㪦㪊㩷㪬㪥㪠㪫㪀 㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪊㩿㪘㪬㪛㪠㪦㪊㩷㪬㪥㪠㪫㪀

䊶㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫉㫆㫄㩷㪦㪬㪫㪧㪬㪫㩷㫋㪼㫉㫄㫀㫅㪸㫃 䊶㪫㪩㪏㪉㪐䌾㪫㪩㪏㪊㪉㪃㪫㪩㪐㪉㪌䌾㪫㪩㪐㪉㪏

䇭㩿㪜㪸㪺㪿㩷㪺㪿㪸㫅㫅㪼㫃㫊㪀

㪫㪩㪄㪙㪘㪪㪜㩷㫋㪼㫉㫄㫀㫅㪸㫃㪑㪸㪹㫆㫌㫋㪄㪈㪉㪭㩿㪸㫋㩷㪤㪬㪫㪜㩷㫆㪽㪽㪀

䊶㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪃㩷㪦㫌㫋㫇㫌㫋㩷㫋㪼㫉㫄㫀㫅㪸㫃

㪦㪅㪢㪅

㪜㪥㪛

27

Page 32

2. 8U-210094-1 (POWER UNIT)

㪚㪿㪼㪺㫂㩷㪝㪬㪪㪜㩷㪚㫆㫅㪻㫀㫋㫀㫆㫅

㪛㪼㪽㪼㪺㫋㩷㫆㪽㩷㫇㫉㫀㫄㪸㫉㫐㩷㪺㫀㫉㪺㫌㫀㫋㩷㪺㫆㫄㫇㫆㫅㪼㫅㫋㪅

䊶㪝㪬㪪㪜㩷㪲㪝㪈㪇㪈㪴㩷㪦㪧㪜㪥㪖

䊶㪲㪛㪈㪇㪈㪴 㩿㪩㪙㪭㪄㪋㪇㪍㪀

㪥㪅㪞㪅 䊶㪲㪠㪚㪈㪇㪉㪴 㩿㪪㪫㪩㪄㪰㪍㪋㪌㪊䇭㩿㪈㪇㪇㪭㩷㫊㫐㫋㪼㫄㪀㪀

㩿㪪㪫㪩㪄㪰㪍㪋㪎㪊䇭㩿㪉㪇㪇㪭㩷㫊㫐㫋㪼㫄㪀㪀

䊶㪲㪫㪈㪇㪈㪴 㩿㪪㪮㪶㪫㪩㪘㪥㪪㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪂㪍㪭㪶㪥㪪㪮㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 䊶㪲㪫㪈㪇㪉㪴 㩿㪧㪦㪮㪜㪩㪶㪫㪩㪘㪥㪪㪀

㩷㩷㪂㪍㪭㩷㪛㪚㩷㩿㫅㫆㫅㪄㫊㫎㫀㫋㪺㪿㪼㪻㪀㩷㪭㫆㫃㫋㪸㪾㪼㩷㫀㫊㩷㪦㪅㪢㪅㪖 㪥㪅㪞㪅 䊶㪲㪛㪈㪈㪇䌾㪛㪈㪈㪊㪴 㩿㪩㪙㪌㪉㪈㪪㪀

㩷㩷㪲㪚㪯㪈㪌㪈㪴㩷㪈㪊㫇㫀㫅

㶎㩷㪩㪸㫅㪾㪼㩷㪽㫉㫆㫄㩷㪍㩷㫋㫆㩷㪈㪍㪭

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪂㪌㪭㪶㪥㪪㪮㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

㩷㩷㪌㪭㩷㪛㪚㩷㩿㫊㫎㫀㫋㪺㪿㪼㪻㪀㩷㪭㫆㫃㫋㪸㪾㪼㩷㫀㫊㩷㪦㪅㪢㪅㪖 㪥㪅㪞㪅 䊶㪲㪠㪚㪐㪉㪈㪴 㩿㪙㪘㪊㪊㪙㪇㪇㪝㪧㪀

㩷㩷㪲㪚㪯㪈㪌㪈㪴㩷㪈㪋㫇㫀㫅㩷㫆㫌㫋㫇㫌㫋

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪚㪣㪢㪶㪌㪇㪆㪍㪇㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 䊶㪲㪫㪈㪇㪉㪴 㩿㪧㪦㪮㪜㪩㪶㪫㪩㪘㪥㪪㪀

㩷㩷㪲㪚㪯㪈㪌㪈㪴㩷㪍㫇㫀㫅㩷㫆㫌㫋㫇㫌㫋 㪥㪅㪞㪅 䊶㪲㪛㪈㪇㪏㪃㪛㪈㪇㪐㪴 㩿㪩㪙㪌㪉㪈㪪㪀

㩷㩷㩿㪘㪚㪌㪇㪟㫑㩷㪈㪇㪇㪟㫑㪀 䊶㪲㪫㪩㪈㪇㪉㪴 㩿㪢㪫㪚㪊㪏㪎㪌㪪㪀

㩷㩷㩿㪘㪚㪍㪇㪟㫑㩷㪈㪉㪇㪟㫑㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪦㪥㪆㪪㪫㪘㪥㪛㪙㪰㩷㪠㫅㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 䊶㪲㪚㪯㪈㪌㪈㪴 㩿㪈㪌㪧㪄㪧㪟㪄㪪㪘㪥㪀

㩷㩷㪲㪚㪯㪈㪌㪈㪴㩷㪎㫇㫀㫅㩷㫆㫌㫋㫇㫌㫋 㪥㪅㪞㪅 㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

㶎㪧㫉㪼㫊㫊㩷㩹㪦㪥㪆㪪㪫㪘㪥㪛㪙㪰㩹㩷㫋㫆㩷㪺㪿㪼㪺㫂㪅 䇭䊶㪲㪠㪚㪏㪌㪊㪴 㩿㪩㪌㪝㪊㪍㪋㪭㪛㪥㪝㪙㪀

㩷㩷㪥㫆㫉㫄㪸㫃㫃㫐㩷㪂㪊㪅㪊㪭㩷㫀㫊㩷㫆㫌㫋㫇㫌㫋

㶎㪦㪢㩷㫀㪽㩷㪂㪊㪅㪊㪭㩷㫀㫊㩷㫆㫌㫋㫇㫌㫋㩷㪼㫍㪼㫅㩷㫄㫆㫄㪼㫅㫋㪸㫉㫀㫃㫐㪅 㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪧㫆㫎㪼㫉㩷㪩㪼㫃㪸㫐

㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪠㫊㩷㪲㪩㪣㪈㪇㪈㪴㩷㫊㫎㫀㫋㪺㪿㪼㪻㪖

䊶㪲㪫㪩㪈㪇㪌㪴 㩿㪢㪫㪚㪊㪈㪐㪐㪀

㪥㪅㪞㪅

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

2.1. The power cannot be turned on.

28

Page 33

㪚㪿㪼㪺㫂㩷㪂㪌㪭㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 㪥㪅㪞㪅 䊶㪲㪠㪚㪈㪇㪌㪴 㩿㪪㪠㪄㪏㪇㪇㪌㪨㪄㪫㪣㪀

㩷㩷㪂㪌㪭㩷㪛㪚㩷㩿㫊㫎㫀㫋㪺㪿㪼㪻㪀㩷㪭㫆㫃㫋㪸㪾㪼㩷㫀㫊㩷㪦㪅㪢㪅㪖

㩷㩷㪲㪣㪈㪇㪊㪴㩷㪠㪚㪈㪇㪌㩷㫆㫋㪿㪼㫉㩷㫊㫀㪻㪼㩷㫆㫌㫋㫇㫌㫋 㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪲㪫㪩㪊㪇㪋㪴 㩿㪉㪪㪛㪈㪏㪌㪏㪀

䊶㪲㪱㪛㪊㪇㪉㪴 㩿㪤㪫㪱㪡㪐㪅㪈㪙㪀

㪠㫊㩷㫋㪿㪼㩷㫉㪼㪸㫉㩷㫊㫀㪻㪼㩷㪽㪸㫅㩷㫋㫌㫉㫅㫀㫅㪾㪖 㪥㪅㪞㪅

㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

䇭䊶㪲㪠㪚㪏㪌㪊㪴 㩿㪩㪌㪝㪊㪍㪋㪭㪛㪥㪝㪙㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪜㪥㪛

29

Page 34

3. 8U-210095-4 (FRONT UNIT)

㪚㪿㪼㪺㫂㩷㫧㩷㪝㩷㫆㫌㫋㫇㫌㫋㩷䋨㪌㪭䋩 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪲㪚㪰㪇㪋㪉㪴㩷㪊㪄㪋㫇㫀㫅 䊶㪲㪝㪣㪈㪇㪈㪴

䇭䇭䇭䇭䇭㩿㪝㪣㪄㪫㪬㪙㪜㩿㪈㪌㪄㪙㪫㪄㪈㪈㪋㪞㪥㪢㪀䇭䇭

㪥㪅㪞㪅

㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪈㩷㩿㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

䇭䊶㪲䌔㪈㪇㪈㪴 㩿㪪㪮㪶㪫㪩㪘㪥㪪㪀

䇭䊶㪲㪛㪈㪇㪋㪴 㩿㪘㪣㪇㪈㪱㪀

䇭䊶㪲㪱㪛㪈㪇㪌㪴 㩿㪤㪫㪱㪡㪊㪅㪍㪙㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪄㪊㪉㪭㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 䊶㪲㪠㪚㪈㪇㪈㪴䇭 㩿㪧㪫㪍㪊㪇㪉㪄㪪㪪㪦㪧㪀

㩷㩷㪄㪊㪉㪭㩷㪛㪚㩷㩿㫅㫆㫅㪄㫊㫎㫀㫋㪺㪿㪼㪻㪀㩷㪭㫆㫃㫋㪸㪾㪼㩷㫀㫊㩷㪦㪅㪢㪅㪖

㩷㩷㪲㪚㪰㪇㪋㪉㪴㩷㪉㫇㫀㫅㩷㫆㫌㫋㫇㫌㫋 㪏㪬㪄㪉㪈㪇㪇㪐㪋㪄㪈㩷㩿㪧㪦㪮㪜㪩㩷㪬㪥㪠㪫㪀

㪥㪅㪞㪅

䇭䊶㪲䌔㪈㪇㪈㪴 㩿㪪㪮㪶㪫㪩㪘㪥㪪㪀

䇭䊶㪲㪫㪩㪈㪇㪊㪴 㩿㪉㪪㪙㪌㪍㪉㪀

䇭䊶㪲㪱㪛㪈㪇㪋䇮㪱㪛㪈㪇㪎㪴 㩿㪤㪫㪱㪡㪈㪍㪙㪀

䇭䊶㪲㪛㪈㪇㪍㪴 㩿㪘㪣㪇㪈㪱㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪂㪊㪅㪊㪭㩷㫆㫌㫋㫇㫌㫋 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㵶㩷㪭㫆㫃㫋㪸㪾㪼㩷㪚㪿㪼㪺㫂 䊶㪲㪠㪚㪈㪇㪈㪴䇭 㩿㪧㪫㪍㪊㪇㪉㪄㪪㪪㪦㪧㪀

㩷㩷㪊㪅㪊㪭㩷㪛㪚㩷㩿㫊㫎㫀㫋㪺㪿㪼㪻㪀㩷㪭㫆㫃㫋㪸㪾㪼㩷㫀㫊㩷㪦㪅㪢㪅㪖

㪥㪅㪞㪅

䊶㪲㪚㪰㪉㪋㪈㪴䇭 㩿㪉㪋㪧㪄㪝㪤㪥㪀

㩷㩷㪲㪚㪰㪉㪋㪈㪴㩷㪈㪏㫇㫀㫅㩷㫆㫌㫋㫇㫌㫋 䊶㪝㪝㪚㩷㪺㪸㪹㫃㪼

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪲㪠㪚㪈㪇㪈㪴䇭 㩿㪧㪫㪍㪊㪇㪉㪄㪪㪪㪦㪧㪀

䊶㪲㪝㪣㪈㪇㪈㪴

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪋㩷㩿㪝㪩㪦㪥㪫㩷㪬㪥㪠㪫㪀

䊶㪲㪚㪰㪉㪋㪈㪴䇭 㩿㪉㪋㪧㪄㪝㪤㪥㪀

䊶㪝㪝㪚㩷㪺㪸㪹㫃㪼

䊶㪲㪚㪰㪉㪋㪈㪴䇭 㩿㪉㪋㪧㩷㪝㪤㪥㪀

䇭䇭䇭䇭䇭㩿㪝㪣㪄㪫㪬㪙㪜㩿㪈㪌㪄㪙㪫㪄㪈㪈㪋㪞㪥㪢㪀㪀

㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

䇭䊶㪲㪠㪚㪏㪌㪊㪴 㩿㪩㪌㪝㪊㪍㪋㪭㪛㪥㪝㪙㪀

㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪅㪢㪅

㪜㪥㪛

3.1. FL TUBE dosen't light

30

Page 35

4. 8U-310041 (MAIN UNIT)

㫇

㪚㪿㪼㪺㫂㩷㪪㫌㫇㫇㫃㫐㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪽㫉㫆㫄㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㪬㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㩷㪸㫅㪻㩷㪮㫀㫉㪼㫊㩷㪽㫉㫆㫄㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㪬㫅㫀㫋

䍃㪂㪈㪉㪭㪶㪛㪃㩷㪂㪈㪈㪭㪶㪥㪪㪮㪃㩷㪂㪌㪭㪶㪥㪪㪮 䍃㪲㪚㪰㪈㪌㪈㪴㩷㪈㪃㩷㪉㪃㩷㪈㪊㪃㩷㪈㪋㪧㫀㫅

㪚㪿㪼㪺㫂㩷㪪㫌㫇㫇㫃㫐㩷㪚㫆㫅㫋㫉㫆㫃㩷㫊㫀㪾㫅㪸㫃㩷㫋㫆㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㫌㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㩷

䍃㪦㪥㪆㪪㪫㪘㪥㪛㪙㪰 䍃㪲㪚㪰㪈㪌㪈㪴㩷㪎㪧㫀㫅

㪚㪿㪼㪺㫂㩷㪪㫌㫇㫇㫃㫐㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪸㫋㩷㪛㪚㪛㪚㩷㫆㫌㫋㫇㫌㫋㪅 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䍃㪂㪌㪭㪶㪛㪃㩷㪂㪊㪅㪊㪭㪶㪛㪃㩷㪂㪈㪅㪏㪭㪶㪛㪃㩷㪂㪈㪅㪈㪭㪶㪛㪋㪃㩷㪂㪈㪅㪉㪭㪶㪛㪃㩷㪂㪈㪅㪇㪭㪶㪛㪭 䍃㪲㪠㪚㪉㪇㪐㪴㪃㩷㪲㪠㪚㪉㪇㪎㪴㪃㩷㪲㪠㪚㪉㪇㪍㪴㪃㩷㪲㪠㪚㪉㪇㪏㪴㪃㩷㪲㪠㪚㪉㪇㪌㪴㪃㩷㪲㪠㪚㪎㪇㪉㪴

㪚㪿㪼㪺㫂㩷㪪㫌㫇㫇㫃㫐㩷㪚㫆㫅㫋㫉㫆㫃㩷㫊㫀㪾㫅㪸㫃㩷㫋㫆㩷㪛㪚㪛㪚 㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

䍃㪙㪜㪶㪪㪫㪘㪥㪛㪙㪰㪃㩷㪙㪜㪶㪧㪦㪮㪜㪩㪶㪚㪦㪩㪜㪃㩷㪤㪭㪶㪧㪦㪮㪜㪩 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㩷

䍃㪲㪠㪚㪏㪌㪊㪴㩷㪎㪎㪃㪍㪊㪃㪌㪏㪧㫀㫅㩷㪸㫅㪻㩷㪲㪚㪰㪈㪌㪈㪴㩷㪈㪌㪧㫀㫅㪃㩷㪲㪩㪏㪐㪊㪴㪃㩷㪲㪫㪩㪏㪌㪍㪴㪃

㩷㪲㪩㪌㪎㪐㪴㪃㩷㪲㪫㪩㪏㪌㪎㪴㪃㩷㪲㪩㪌㪎㪎㪴㪃㩷㪲㪩㪌㪏㪈㪴㪃㪲㪩㪩㪍㪇㪋㪴㪃㩷㪲㪩㪩㪍㪍㪇㪴

㪚㪿㪼㪺㫂㩷㪩㪼㫊㪼㫋㩷㫊㫀㪾㫅㪸㫃㫊 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䍃㪥㪩㪪㪫 㩷㪲㪠㪚㪏㪌㪈㪴㩷㪋㪧㫀㫅

䍃㪝㪣㪶㪩㪪㪫㪃㩷㪧㪣㪣㪶㪩㪪㪫㪃㩷㪙㪜㪶㪩㪪㪫 㩷㪲㪠㪚㪏㪌㪊㪴㩷㪉㪊㪃㪉㪋㪃㪍㪈㪧㫀㫅

㪚㪿㪼㪺㫂㩷㪦㫊㪺㫃㫃㪸㫋㫀㫆㫅㩷㫎㪸㫍㪼㪽㫆㫉㫄 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䍃㪭㪤㪚㪣㪢㪃㩷㪘㪤㪚㪣㪢㪈㪃㩷㪘㪤㪚㪣㪢㪉 䍃㪲㪩㪐㪈㪊㪴㪃㩷㪲㪩㪩㪐㪌㪍㪴㩷㪸㫅㪻㩷㪲㪩㪩㪐㪌㪎㪴

㪚㪿㪼㪺㫂㩷㪧㪦㪮㪜㪩㩷㪪㪜㪥㪪㪜㩷㪪㫀㪾㫅㪸㫃 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䍃㪧㪦㪮㪜㪩㪶㪪㪜㪥㪪 㩷㪲㪠㪚㪏㪌㪊㪴㩷㪐㪉㪧㫀㫅㪃㩷㪲㪩㪏㪏㪐㪴

㪚㪿㪼㪺㫂㩷㪘㪫㪈㪛㪘㪫㪘㪲㪇㪑㪈㪌㪴㩷㫊㫀㪾㫅㪸㫃㫊㩷㪽㫉㫆㫄㩷㪝㪜㩷㪬㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䊶㪲㪚㪰㪋㪌㪉㪴㩷㪉㪐㪄㪋㪋㪧㫀㫅 䍃㪲㪚㪰㪋㪌㪉㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㪛㪪㪛㩷㪛㪸㫋㪸㩷㪸㫅㪻㩷㪚㫃㫆㪺㫂㩷㫊㫀㪾㫅㪸㫃㫊㩷㪽㫉㫆㫄㩷㪝㪜㩷㪬㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾

䊶㪲㪚㪰㪋㪇㪉㪴㩷㪐㪄㪈㪍㪃㩷㪉㪃㩷㪋㪃㩷㪍㪧㫀㫅 䍃㪲㪚㪰㪋㪇㪉㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㪭㫀㪻㪼㫆㩷㪛㪸㫋㪸㩷㪸㫅㪻㩷㪚㫃㫆㪺㫂㩷㫊㫀㪾㫅㪸㫃㫊㩷㫋㫆㩷㪘㫅㪸㫃㫆㪾㩷㪭㫀㪻㪼㫆㩷㪬㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪚㫆㫄㫇㫆㫊㫀㫋㩷㪪㫀㪾㫅㪸㫃㩷㪲㪚㪯㪈㪌㪈㪴㩷㪋㪄㪈㪈㪃㩷㪉㪃㩷㪈㪊㪃㩷㪈㪋㪧㫀㫅 䊶㪲㪚㪯㪈㪌㪈㪴㪃㩷㪲㪚㪯㪌㪇㪈㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

䊶㪚㫆㫄㫇㫆㫅㪼㫅㫋㩷㪪㫀㪾㫅㪸㫃㩷㪲㪚㪯㪌㪇㪈㪴㩷㪌㪄㪈㪉㪃㩷㪈㪌㪄㪉㪉㪃㩷㪉㪌㪄㪊㪉㪧㫀㫅

㩷㪊㪋㪃㩷㪊㪍㪄㪊㪏㪧㫀㫅

㪚㪿㪼㪺㫂㩷㪘㫌㪻㫀㫆㩷㪛㪸㫋㪸㩷㪸㫅㪻㩷㪚㫃㫆㪺㫂㩷㪪㫀㪾㫅㪸㫃㫊㩷㫋㫆㩷㪘㫅㪸㫃㫆㪾㩷㪘㫌㪻㫀㫆㩷㪬㫅㫀㫋 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪲㪚㪯㪊㪊㪈㪴㩷㪈㪈㪃㩷㪈㪊㪃㩷㪈㪌㪄㪈㪏㪃㩷㪉㪊㪃㩷㪉㪌㪃㩷㪉㪎㪄㪊㪇㪧㫀㫅 䊶㪲㪚㪯㪊㪊㪈㪴㪃㩷㪲㪚㪯㪊㪊㪉㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

䊶㪲㪚㪯㪊㪊㪉㪴㩷㪈㪇㪄㪈㪉㪃㩷㪈㪌㪄㪈㪏㪃㩷㪉㪊㪃㩷㪉㪌㪃㩷㪉㪎㪄㪊㪇㪧㫀㫅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂

㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽㩷㪘㫅㪸㫃㫆㪾㩷㪭㫀㪻㪼㫆

㫆㫉㩷㪘㫅㪸㫃㫆㪾㩷㪘㫌㪻㫀㫆㩷㪬㫅㫀㫋

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

4.1. No System Power up or Loading

No Video or Audio Output

31

Page 36

4.2. No Ether-net Operation

㪚㪿㪼㪺㫂㩷㪣㪜㪛㩷㫊㫋㪸㫋㫌㫊㩷㫆㫅㩷㪣㪘㪥㩷㪺㫆㫅㫅㪼㪺㫋㪼㫉㩷㫀㫅㩷㪸㪺㪺㪼㫊㫊㩷㫄㫆㪻㪼 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪞㫉㪼㪼㫅㪑㩷㪦㪥 䍃㪲㪯㪈㪇㪉㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪦㫉㪸㫅㪾㪼㪑㩷㪙㫉㫀㫅㫂㫀㫅㪾 䍃㪲㪡㪢㪈㪇㪈㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䍃㪲㪠㪚㪐㪇㪈㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪥㪅㪞㪅

㪦㪅㪢㪅

㪚㪿㪼㪺㫂㩷㪪㪛㪛㪘㪫㪇㪄㪊㪃㩷㪪㪛㪚㪣㪢㪃㩷㪪㪛㪚㪛㪃㩷㪸㫅㪻㩷㪪㪛㪶㪭㪛㪛㪊㪊 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪲㪚㪰㪈㪏㪊㪴㩷㪉㪃㩷㪋㪃㩷㪏㪃㩷㪐㪃㩷㪈㪇㪃㩷㪈㪉㪃㩷㪈㪋㪃㩷㪈㪍㪧㫀㫅 䍃㪲㪚㪰㪈㪏㪊㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪥㪅㪞㪅

㪦㪅㪢㪅

㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂

㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽㩷㪪㪛㩷㪚㪸㫉㪻㩷㪬㫅㫀㫋

4.3. No SD Card Operation

32

Page 37

5. 8U-210095-1 (ANALOG VIDEO UNIT)

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪈㩷㩿㪘㪥㪘㪣㪦㪞㩷㪭㪠㪛㪜㪦㩷㪬㪥㪠㪫㪀㩷

㩿㪈㪀㩷㪭㫀㪻㪼㫆㪆㪪㪄㪭㫀㪻㪼㫆㩷㪦㫌㫋㩷㪻㫆㪼㫊㩷㫅㫆㫋㩷㪹㪼㩷㫆㫌㫋 㫌㫋㫋㪼㪻

㪚㪿㪼㪺㫂㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪚㪯㪈㪌㪌㪴 㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪅

䊶㪭㪜㪥㪚㪄㪚㪭㪶㪚㪣㪢㪃㩷㪭㪜㪥㪚㪄㪚㪭㪶㪪㪲㪉㪑㪐㪴㪃㩷㪭㪜㪥㪚㪶㪚㪭㪶㪟㪪 㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽

䊶㪭㪜㪥㪚㪄㪚㪭㪶㪭㪪㪃㩷 㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

㪚㪿㪼㪺㫂㩷㪚㫆㫅㫋㫉㫆㫃㩷㪪㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㪽㫆㫉㩷㪲㪚㪯㪌㪇㪌㪴 㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪅

䊶㪂㪌㪭㪶㪛㪭㪃㩷㪭㪶㪧㪮㪩㪃㩷㪘㪙㪫㪶㪪㪛㪘㪃㩷㪘㪙㪫㪶㪪㪚㪣 㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽

㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪽㫆㫉㩷㪲㪠㪚㪏㪈㪉㪴 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪂㪊㪅㪊㪭㪶㪘㪭 㪠㪚㪏㪈㪉㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪽㫆㫉㩷㪲㪠㪚㪏㪈㪈㪴 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪂㪈㪅㪏㪭㪶㪘㪭 㪠㪚㪏㪈㪈㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪠㪚㪏㪇㪏㪴㩿㪘㪛㪭㪎㪊㪋㪇㪙㪪㪫㪱㪄㪊㪀 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪘㪙㪫㪶㪪㪛㪘㪃㩷㪘㪙㪫㪶㪪㪚㪣 䊶㪲㪩㪪㪋㪇㪍㪄㪩㪪㪋㪇㪎㪴

䊶㪚㪣㪢㪠㪥㪄㪘㪃㩷㪭㪜㪥㪚㪄㪚㪭㪶䌖㪪㪃㩷㪭㪜㪥㪚㪄㪚㪭㪶㪟㪪 䊶㪲㪩㪪㪋㪇㪏㪄㪩㪪㪋㪇㪐㪴

䊶㪭㪜㪥㪚㪄㪚㪭㪶㪪㪲㪉㪑㪐㪴 䊶㪲㪚㪯㪈㪌㪌㪴

䊶㪪㪰㪃㩷㪪㪚 䊶㪲㪩㪪㪋㪊㪌㪄㪩㪪㪋㪊㪍㪴㪃㩷㪲㪩㪪㪋㪌㪉㪄㪩㪪㪋㪌㪊㪴㪃㩷㪲㪚㪚㪏㪌㪇㪄㪚㪚㪏㪌㪈㪴

䊶㪲㪠㪚㪏㪇㪏㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪠㪚㪏㪇㪐㪴㩿㪥㪡㪤㪉㪌㪍㪍㪘㪭㪀 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪭㪦㪬㪫 䊶㪲㪩㪜㪐㪉㪊㪴㪃㩷㪲㪚㪚㪐㪎㪌㪴㪃㩷㪲㪩㪜㪐㪊㪋㪴

䊶㪪㪰㪦㪬㪫 䊶㪲㪩㪜㪐㪉㪌㪴㪃㩷㪲㪚㪚㪐㪏㪇㪴㪃㩷㩷㪲㪩㪜㪐㪊㪌㪴

䊶㪪㪚㪦㪬㪫 䊶㪲㪚㪚㪏㪍㪊㪴㪃㩷㪲㪩㪜㪐㪉㪈㪴㪃㩷㩷㪲㪩㪜㪐㪊㪊㪴

䊶㪲㪠㪚㪏㪇㪐㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪩㪼㫇㫃㪸㪺㪼㩷㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪈㩷㩿㪘㪥㪘㪣㪦㪞㩷㪭㪠㪛㪜㪦㩷㪬㪥㪠㪫㪀

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

5.1. Video/S-Video Out does not be outputted.

33

Page 38

5.2. Component Out does not be outputted

㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪈㩷㩿㪘㪥㪘㪣㪦㪞㩷㪭㪠㪛㪜㪦㩷㪬㪥㪠㪫㪀㩷

㩿㪈㪀㩷㪚㫆㫄 㫆㫅㪼㫅㫋㩷㪦㫌㫋㩷㪻㫆㪼㫊㩷㫅㫆㫋㩷㪹㪼㩷㫆㫌㫋 㫌㫋㫋㪼㪻

㪚㪿㪼㪺㫂㩷㫀㫅㫇㫌㫋㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪚㪯㪌㪇㪌㪴 㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪅

䊶㪭㪜㪥㪄㪚㪤㪧㪶㪚㪣㪢㪃㩷㪭㪜㪥㪶㪚㪤㪧㪶㪟㪪㪃㩷㪭㪜㪥㪄㪚㪤㪧㪶㪭㪪 㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽

䊶㪭㪜㪥㪄㪚㪤㪧㪶㪛㪜㪃㩷㪭㪜㪥㪄㪚㪤㪧㪶㪰㪲㪇㪑㪎㪴㪃㩷㩷 㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

䊶㪭㪜㪥㪄㪚㪤㪧㪶㪚㪹㪲㪇㪑㪎㪴㪃䇭㪭㪜㪥㪄㪚㪤㪧㪶㪚㫉㪲㪇㪑㪎㪴

㪚㪿㪼㪺㫂㩷㪚㫆㫅㫋㫉㫆㫃㩷㪪㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪧㫆㫎㪼㫉㩷㪪㫌㫇㫇㫃㫐㩷㪽㫆㫉㩷㪲㪚㪯㪌㪇㪌㪴 㪚㪿㪼㪺㫂㩷㪝㪝㪚㩷㪺㪸㪹㫃㪼㩷㫀㫅㫊㪼㫉㫋㫀㫆㫅㪅

䊶㪂㪌㪭㪶㪛㪭㪃㩷㪭㪶㪧㪮㪩㪃㩷㪘㪙㪫㪶㪪㪛㪘㪃㩷㪘㪙㪫㪶㪪㪚㪣 㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽

㪏㪬㪄㪊㪈㪇㪇㪋㪈㩷㩿㪤㪘㪠㪥㩷㪬㪥㪠㪫㪀

㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪽㫆㫉㩷㪲㪠㪚㪏㪈㪉㪴 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪂㪊㪅㪊㪭㪶㪘㪭 㪠㪚㪏㪈㪉㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫆㫌㫋㫇㫌㫋㩷㪭㫆㫃㫋㪸㪾㪼㫊㩷㪽㫆㫉㩷㪲㪠㪚㪏㪈㪈㪴 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪂㪈㪅㪏㪭㪶㪘㪭 㪠㪚㪏㪈㪈㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪠㪚㪏㪈㪇㪴㩿㪘㪛㪭㪎㪊㪋㪇㪙㪪㪫㪱㪄㪊㪀 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪘㪙㪫㪶㪪㪛㪘㪃㩷㪘㪙㪫㪶㪪㪚㪣 䊶㪲㪩㪪㪋㪇㪏㪄㪩㪪㪋㪇㪐㪴

䊶㪚㪣㪢㪠㪥㪄㪘㪃㩷㪭㪜㪥㪄㪚㪤㪧㪶䌖㪪㪃㩷㪭㪜㪥㪄㪚㪤㪧㪶㪟㪪 䊶㪲㪩㪪㪊㪎㪈㪄㪩㪪㪊㪎㪉㪴

䊶㪭㪜㪥㪄㪚㪤㪧㪶㪰㪲㪇㪑㪎㪴㪃㩷㪭㪜㪥㪄㪚㪤㪧㪶㪚㪹㪲㪇㪑㪎㪴 䊶㪲㪚㪯㪌㪇㪌㪴

䊶㪭㪜㪥㪄㪚㪤㪧㪶㪚㫉㪲㪇㪑㪎㪴㪃㩷㪰㫇㪆㪰㫀㪃㩷㩷㪧㪹㪆㪚㪹㪃㩷㪧㫉㪆㪚㫉 䊶㪲㪩㪪㪊㪊㪈㪄㪩㪪㪊㪊㪊㪴㪃㩷㪲㪩㪪㪊㪍㪌㪄㪩㪪㪊㪍㪎㪴㪃㩷㪲㪚㪚㪏㪌㪉㪄㪚㪚㪏㪌㪋㪴

䊶㪲㪠㪚㪏㪈㪇㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㪽㫆㫉㩷㪲㪠㪚㪏㪇㪐㪴㩿㪥㪡㪤㪉㪌㪍㪍㪘㪭㪀 㪚㪿㪼㪺㫂㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

䊶㪰㪦㪬㪫 䊶㪲㪚㪚㪐㪏㪉㪴㪃㩷㪲㪩㪜㪐㪉㪎㪴㪃㩷㪲㪩㪜㪐㪊㪍㪴

䊶㪧㪙㪦㪬㪫 䊶㪲㪚㪚㪐㪏㪋㪴㪃㩷㪲㪩㪜㪐㪉㪐㪴㪃㩷㩷㪲㪩㪜㪐㪊㪎㪴

䊶㪧㪩㪦㪬㪫 䊶㪲㪚㪚㪐㪏㪎㪴㪃㩷㪲㪩㪜㪐㪊㪈㪴㪃㩷㩷㪲㪩㪜㪐㪊㪏㪴

䊶㪲㪠㪚㪏㪇㪐㪴㩷㪸㫅㪻㩷㪚㫀㫉㪺㫌㫄㪽㪼㫉㪼㫅㪺㪼

㪩㪼㫇㫃㪸㪺㪼㩷㪏㪬㪄㪉㪈㪇㪇㪐㪌㪄㪈㩷㩿㪘㪥㪘㪣㪦㪞㩷㪭㪠㪛㪜㪦㩷㪬㪥㪠㪫㪀

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

㪦㪅㪢㪅

㪥㪅㪞㪅

㪦㪅㪢㪅

34

Page 39

6. 8U-310037 (FE/SACD UNIT)

㪚㪿㪼㪺㫂㩷㪟㪝㩷㫊㫀㪾㫅㪸㫃 㪛㪼㪽㪼㪺㫋㩷㫆㪽㩷㫇㫉㫀㫄㪸㫉㫐㩷㪺㫀㫉㪺㫌㫀㫋㩷㪺㫆㫄㫇㫆㫅㪼㫅㫋㪅

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㪥㪞

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㪤㪜㪘㪪㪬㪩㪠㪥㪞㩷㪤㪜㪫㪟㪦㪛㩷㪘㪥㪛㩷㪮㪘㪭㪜㪝㪦㪩㪤㪪 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪚㪯㪋㪌㪈㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㵶㩷㪚㪼㪺㫂㩷㽲㪟㪝㩷㪮㪸㫍㪼㪽㫆㫉㫄

㪦㪢

㪚㪿㪼㪺㫂㩷㪤㪬㪫㪜㩷㫊㫀㪾㫅㪸㫃 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㪥㪞

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㵶㩷㪲㪠㪚㪈㪇㪇㪴㩷㪊㪋㫇㫀㫅㩷㪲㪚㪫㪣㪉㪴㪑㩷㵰㪟㵱㩷㫃㪼㫍㪼㫃㪖 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪠㪚㪈㪌㪈㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪢

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪝㫆㪺㫌㫊㩷㫊㫐㫊㫋㪼㫄

㪥㪞

㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪤㪜㪘㪪㪬㪩㪠㪥㪞㩷㪤㪜㪫㪟㪦㪛㩷㪘㪥㪛㩷㪮㪘㪭㪜㪝㪦㪩㪤㪪 㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㵶㩷㪚㪿㪼㪺㫂㩷㽳䌾㽵㪃㽶䌾㽷㪅 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪠㪚㪈㪌㪈㪴㪲㪚㪯㪋㪌㪈㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪢

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪫㫉㪸㪺㫂㫀㫅㪾㩷㫊㫐㫊㫋㪼㫄 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪤㪜㪘㪪㪬㪩㪠㪥㪞㩷㪤㪜㪫㪟㪦㪛㩷㪘㪥㪛㩷㪮㪘㪭㪜㪝㪦㪩㪤㪪

㪥㪞

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㵶㩷㪚㪿㪼㪺㫂㩷㽹䌾㽻㪅 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪠㪚㪈㪌㪈㪴㪲㪚㪯㪋㪌㪈㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪢

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪪㫇㫀㫅㪻㫃㪼㩷㫊㫐㫊㫋㪼㫄 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪤㪜㪘㪪㪬㪩㪠㪥㪞㩷㪤㪜㪫㪟㪦㪛㩷㪘㪥㪛㩷㪮㪘㪭㪜㪝㪦㪩㪤㪪

㪥㪞

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㵶㩷㪚㪿㪼㪺㫂㩷㽼㪃㩷㽽㪅 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪠㪚㪈㪌㪈㪴㪲㪚㪯㪈㪏㪉㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪢

㪚㪿㪼㪺㫂㩷㫊㫀㪾㫅㪸㫃㩷㫆㪽㩷㪫㪿㫉㪼㪸㪻㩷㫊㫐㫊㫋㪼㫄 㪚㪿㪼㪺㫂㩷㪧㪸㫉㫋㫊㩷㪸㫅㪻㩷㪪㫆㫃㪻㪼㫉㫀㫅㪾㪅

㪤㪜㪘㪪㪬㪩㪠㪥㪞㩷㪤㪜㪫㪟㪦㪛㩷㪘㪥㪛㩷㪮㪘㪭㪜㪝㪦㪩㪤㪪

㪥㪞

㪏㪬㪄㪊㪈㪇㪇㪊㪎㩷㩿㪝㪜㪆㪪㪘㪚㪛㩷㪬㪥㪠㪫㪀

㵶㩷㪚㪿㪼㪺㫂㩷㽾䌾㽿㪅 㵶㩷㪲㪠㪚㪈㪇㪇㪴㪲㪠㪚㪈㪌㪈㪴㪲㪚㪯㪈㪏㪉㪴㩷㪸㫅㪻㩷㪦㫋㪿㪼㫉㩷㪚㫀㫉㪺㫌㫀㫋㫊

㪦㪢

㪚㫆㫅㫋㫀㫅㫌㪼㩷㫋㫆㩷㫋㪿㪼㩷㪺㪿㪼㪺㫂㩷㫇㫉㫆㪺㪼㫊㫊㩷㫆㪽

㪤㪘㪠㪥㩷㪬㪥㪠㪫㩷㪏㪬㪄㪊㪈㪇㪇㪋㪈

6.1. BD or DVD or CD or SACD check

35

Page 40

SEMICONDUCTORS

Only major semiconductors are shown, general semiconductors etc. are omitted to list.

The semiconductor which described a detailed drawing in a schematic diagram are omitted to list.

1. IC’s

SII9134CTU (8U-310041 : IC502)

SII9134CTU Block Diagram

CSDA

CSCL

CI2CA

RESET #

IDCK

D[35:0]

HSYNC

VSYNC

DE

2

I C

Slave

Video Data

Capture /

DE Gen /

656

Logic

Block

DCLK

SPDIF

MCLK

SCK

WS

SD[3:0]

DL[3:0]

DR[3:0]

Audio Data

Capture

Logic

Block

Registers

---------------

Configuration

Logic Block

Video

Processing

control signals

audio data

HDCP

Keys

ROM

Packetizer

E-DDC

Master

Receiver Sense + Interrupt Logic

encrypted

data

XOR

VastLane

TMDS

Digital

Core

5V

DSDA

DSCL

INT

HPD

EXT_SWING

TXC

±

TX0

±

TX1

±

±

TX2

36

Page 41

SII9134CTU Pin Function

Pin

Name

D0 98 LVTTL Input These are the lower 12 bits of the 36-bit pixel bus. These pins are highly conD1 97 LVTTL Input

D2 96 LVTTL Input

D3 95 LVTTL Input

D4 94 LVTTL Input

D5 93 LVTTL Input

D6 92 LVTTL Input

D7 91 LVTTL Input

D8 90 LVTTL Input

D9 86 LVTTL Input

D10 85 LVTTL Input

D11 84 LVTTL Input

D12 83 LVTTL Input These are the middle 12 bits of the 36-bit pixel bus.

D13 82 LVTTL Input

D14 81 LVTTL Input

D15 80 LVTTL Input

D16 79 LVTTL Input

D17 78 LVTTL Input

D18 77 LVTTL Input

D19 75 LVTTL Input

D20 74 LVTTL Input

D21 73 LVTTL Input

D22 72 LVTTL Input

D23 71 LVTTL Input

D24 70 LVTTL Input These are the middle 12 bits of the 36-bit pixel bus.

D25 69 LVTTL Input

D26 68 LVTTL Input

D27 67 LVTTL Input

D28 63 LVTTL Input

D29 62 LVTTL Input

D30 61 LVTTL Input

D31 60 LVTTL Input

D32 59 LVTTL Input

D33 58 LVTTL Input

D34 57 LVTTL Input

D35 56 LVTTL Input

IDCK 88 LVTTL Input Input Data Clock

DE 1 LVTTL Input Data enable

HSYNC 2 LVTTL Input Horizontal Sync input control signal

VSYNC 3 LVTTL Input Vertical Sync input control signal

SCK 11 LVTTL Input I2S Serial Clock

WS 10 LVTTL Input I2S Word Select

SD0 9 LVTTL Input I2S Serial Data

SD1 8 LVTTL Input I2S Serial Data

SD2 7 LVTTL Input I2S Serial Data

SD3 6 LVTTL Input I2S Serial Data

DL0 17 LVTTL Input One-bit Audio Data Left 0

DR0 16 LVTTL Input One-bit Audio Data Right 0

DL1 19 LVTTL Input One-bit Audio Data Left 1

DR1 18 LVTTL Input One-bit Audio Data Right 1

DL2 21 LVTTL Input One-bit Audio Data Left 2

DR2 20 LVTTL Input One-bit Audio Data Right 2

DL3 23 LVTTL Input One-bit Audio Data Left 3

DR3 22 LVTTL Input One-bit Audio Data Right 3

DCLK 15 LVTTL Input One-bit Audio Clock Input

MCLK 5 LVTTL Input Audio Input Master Clock

SPDIF 4 LVTTL Input S/PDIF Audio Input

Pin # Type Dir Description

figurable and support multiple RGB and YCbCr formats. See Data Bus Mappings on page 30 for complete information.

37

Page 42

R5F364VDNFB (8U-310041 : IC853)

R5F364VDNFB Block Diagram

38

Page 43

R5F364VDNFB Pin Function

39

Page 44

40

Page 45

ADV7340BSTZ-3 (8U-210095-1 : IC808, IC810)

ADV7340BSTZ-3 Block Diagram

DGND (2) VDD (2)

GND_IO

VDD_IO

10-BIT

VIDEO

DATA

20-BIT

ED/HD

VIDEO

DATA

SD

VBI DATA SERVI CE

INSERTION

4:2:2 TO 4:4:4

HD DDR

DEINTERLEAVE

R

G/B

ED/HD INPUT

DEINTERLEAVE

RGB/YCrC b

TO

YUV

MATRIX

RGB

ASYNC

BYPASS

YCbCr

HDTV

TEST

PATTERN

GENERATOR

V

DD_IO

DGND

TOP VIEW

(Not to Scale)

24

25

P_VSYNC

P_HSYNC

P_BLANK

FILTER

FILTER

DD

55S454S353S252S151S050

26

C6

C527C728C829C9

SUBCARRIER FREQUENCY

YCbCr

TO

RGB MATRIX

S_HSYNC49S_VSYNC

30

31 32

EXT_LF2

CLKIN_A

SFL/

MISO

LOCK (SFL )

YUV

TO

YCrCb/

RGB

SIN/COS DDS

BLOCK

PGND

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

SFL/MISO

R

SET1

V

REF

COMP1

DAC 1

DAC 2

DAC 3

V

AA

AGND

DAC 4

DAC 5

DAC 6

R

SET2

COMP2

PV

DD

EXT_LF1

16×

FILTER

16×

FILTER

4×

FILTER

ADV7344

MULTIPLEXER

AGND

14-BIT

DAC 1

14-BIT

DAC 2

14-BIT

DAC 3

14-BIT

DAC 4

14-BIT

DAC 5

14-BIT

DAC 6

V

AA

DAC 1

DAC 2

DAC 3

DAC 4

DAC 5

DAC 6

GND_IO63CLKIN_B62S961S860S759S658S557DGND56V

64

1

PIN 1

2

Y0

3

Y1

4

Y2

5

Y3

6

Y4

7

Y5

8

Y6

9

Y7

10

V

DD

11

12

Y8

13

Y9

14

C0

15

C1

16

C2

17C318C419

SCL/

MOSI

ADV7340/ADV7341

20

21

22 23

SCL/MOSI

SDA/SCLK

ALSB/SPI_SS

ALSB/

SDA/

SPI_SS

SCLK

MPU PORT

ADD

SYNC

ADD

BURST

PROGRAMMABLE

LUMINANCE

PROGRAMMABLE

CHROMINANCE

RGB

PROGRAMMABLE

HDTV FILT ERS

SHARPNESS AND

ADAPTIVE FIL TER

CONTROL

POWER

MANAGEMENT

CONTROL

VIDEO TIMING GENERATOR

RESET S_HSYNCP_HSYNC P_VSYNC P_BLANK S_VSYNC

41

16x/4x OVERSAM PLING

DAC PLL

CLKIN (2) PV

DD

PGND EXT_LF V

REFERENCE

AND CABLE

DETECT

COMP (2)

REF

(2)

R

SET

Page 46

ADV7340BSTZ-3 Pin Function

Input/

Pin No. Mnemonic

13, 12,

Y9 to Y0 I 10-Bit Pixel Port (Y9 to Y0). Y0 is the LSB. Refer to Table 31 for input modes.

9 to 2

29 to 25,

C9 to C0 I 10-Bit Pixel Port (C9 to C0). C0 is the LSB. Refer to Table 31 for input modes.

18 to 14

62 to 58,

S9 to S0 I 10-Bit Pixel Port (S9 to S0). S0 is the LSB. Refer to Table 31 for input modes.

55 to 51

30 CLKIN_A I Pixel Clock Input for HD Only (74.25 MHz), ED1 Only (27 MHz or 54 MHz), or SD Only (27 MHz).

63 CLKIN_B I

50

49

22

23

24

S_HSYNC

S_VSYNC

P_HSYNC

P_VSYNC

P_BLANK

48 SFL/MISO I/O

47 R

36 R

I

SET1

I

SET2

Output

Description

Pixel Clock Input for Dual Modes Only. Requires a 27 MHz reference clock for ED operation or a

74.25 MHz reference clock for HD operation.

I/O

SD Horizontal Synchronization Signal. This pin can also be configured to output an SD, ED, or HD

horizontal synchronization signal. See the External Horizontal and Vertical Synchronization

Control section.

I/O

SD Vertical Synchronization Signal. This pin can also be configured to output an SD, ED, or HD

vertical synchronization signal. See the External Horizontal and Vertical Synchronization Control

section.

I

ED/HD Horizontal Synchronization Signal. See the External Horizontal and Vertical

Synchronization Control section.

I

ED/HD Vertical Synchronization Signal. See the External Horizontal and Vertical Synchronization