Page 1

Service

UD5007 /

U1B/K1B/S1B

N1SG/N1B

Manual

SUPER AUDIO CD/

BLU-RAY DISC PLAYER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

UD5007

S0690-0V07DM/DG1306

Ver. 7

Please refer to the

MODIFICATION NOTICE.

Page 2

CONTENTS

SAFETY PRECAUTIONS

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING AND LASER SAFETY INSTRUCTIONS

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS

AND OPTICAL UNIT

1. Ground for Human Body .......................................................7

2. Ground for Workbench ..........................................................7

TECHNICAL SPECIFICATIONS

DIMENSION

CAUTIONS IN SERVICING

Initializing BD player ..................................................................9

Service tools ..............................................................................9

DISASSEMBLY

1. FRONT PANEL ASSY .........................................................11

2. BD MECHA UNIT ASSY .....................................................12

3. MAIN PCB UNIT ASSY .......................................................13

4. POWER PCB UNIT ASSY ..................................................14

5. IR PCB UNIT ASSY ............................................................14

REMOVING DISCS .................................................................15

DIAGNOSTICS OF OPTICAL PICKUP

1. Iop checked Method ............................................................17

2. To clear the accumulated laser on time ...............................17

HOW TO REPLACE THE MAIN PCB & BD MECHA

OR BD MECHA

1. How to Replace the MAIN PCB & BD MECHA ..................18

2. How to Replace the BD MECHA .........................................18

HOW TO REPLACE THE MAIN PCB UNIT ASSY

SERVICE MODE

1. Initial setting mode ..............................................................25

2. Firmware version check mode ............................................25

3. Tray lock mode ....................................................................26

4. Remote lock mode ..............................................................26

5. All Lit / All Off mode for the FL tube .....................................26

6. Test mode ...........................................................................27

PROCEDURE FIRMWARE FOR UPGRADING

THE VERSION OF THE FIRMWARE

1. Update from the Internet .....................................................32

...............................................................................8

........................................................................10

........................................................................18

......................................................................25

..........................................................4

.........................................5

...........................................................5

.................6

..................................................................7

................................................8

.......................................................9

...................................16

................23

.....................................32

TROUBLE SHOOTING

1. Power (Power Board) ..........................................................33

2. LED blinking ........................................................................34

3. Power board ........................................................................34

4. DISPLAY (Display Board) ....................................................35

5. HDMI ...................................................................................36

6. Network ...............................................................................36

7. USB .....................................................................................37

8. No Audio output ...................................................................37

9. Disc playback error .............................................................38

BLOCK DIAGRAM

POWER BLOCK DIAGRAM

PRINTED WIRING BOARDS

MAIN ......................................................................................41

FRONT ...................................................................................42

FRONT ....................................................................................43

IRA1G ....................................................................................44

USE1G ...................................................................................44

SCHEMATIC DIAGRAMS (1/15)

POWER ...................................................................................45

DISPLAY_01 ...........................................................................46

DISPLAY_02 ...........................................................................47

IR 48

MAIN_01 .................................................................................49

MAIN_02 .................................................................................50

MAIN_03 .................................................................................51

MAIN_04 .................................................................................52

MAIN_05 .................................................................................53

MAIN_06 .................................................................................54

MAIN_07 .................................................................................55

MAIN_08 .................................................................................56

MAIN_09 .................................................................................57

MAIN_10 .................................................................................58

MAIN_11..................................................................................59

EXPLODED VIEW

PARTS LIST OF EXPLODED VIEW

PACKING VIEW

PARTS LIST OF PACKING VIEW

SEMICONDUCTORS

1. IC's ......................................................................................65

PARTS LIST OF PCB

............................................................33

...................................................................39

....................................................40

...................................................41

.............................................45

....................................................................60

.......................................61

......................................................................63

..........................................64

...............................................................65

.............................................................77

2

Page 3

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

marantz

parts can insure that your

marantz

marantz

product will continue to perform to the specications for which it

company has created the ultimate in stereo sound.

is famous.

Parts for your

marantz

equipment are generally available to our National

Marantz

Subsidiary or Agent.

ORDERING PARTS :

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specied.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

100 CORPORATE DRIVE

MAHWAH, NEW JERSEY 07430

USA

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

EUROPE / TRADING

D&M EUROPE B. V.

P. O. BOX 8744, BUILDING SILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE : +31 - 40 - 2507844

FAX : +31 - 40 - 2507860

CANADA

D&M Canada Inc.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE : 905 - 415 - 9292

FAX : 905 - 475 - 4159

KOREA

D&M SALES AND MARKETING KOREA LTD.

2F,YEON BLDG.,

88-5, BANPO-DONG, SEOCHO-GU,

SEOUL KOREA

PHONE : +82 - 2 - 715 - 9041

FAX : +82 - 2 - 715 - 9040

CHINA

D&M SALES AND MARKETING SHANGHAI LTD.

ROOM.808 SHANGHAI AIRPORT CITY TERMINAL

NO.1600 NANJING (WEST) ROAD, SHANGHAI,

CHINA. 200040

TEL : 021 - 6248 - 5151

FAX : 021 - 6248 - 4434

NOTE ON SAFETY :

Symbol z Fire or electrical shock hazard. Only original parts should be used to replaced any part marked with symbol z .

Any other component substitution (other than original type), may increase risk of re or electrical shock hazard.

安全上の注意:

がついている部品は、安全上重要な部品です。必ず指定されている部品番号のものを使用してください。

z

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary

AC cord connector pins (with unit NOT connected to AC mains and its Power switch ON), and the face or Front Panel of

product and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and veried before it is return to the user/customer.

Ref. UL Standard No. 60065.

In case of difculties, do not hesitate to contact the Technical

Department at above mentioned address.

3

091105DM/DG

Page 4

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

Heed the cautions!

◎

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

Cautions concerning electric shock!

◎

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

ngers are moved across them in some rare cases.

Wear gloves to protect your hands.

Use only designated parts!

◎

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

Make a safety check after servicing!

◎

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphones terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and

repaired.

CAUTION

Concerning important safety

parts

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

these properties are difcult to distinguish by sight, and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, res or other dangerous

situations.

4

Page 5

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts marked with this symbol z have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the unit to the customer, make sure you make either (1) a leakage current check or (2) a line to chassis resistance check. If the

leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the unit is defective.

WARNING:

DO NOT return the unit to the customer until the problem is located and corrected.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES IN MICRO FARAD. P=MICRO-MICRO FARAD EACH VOLTAGE AND CURRENT ARE MEASURED AT NO

SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT TO CHANGE WITHOUT PRIOR NOTICE.

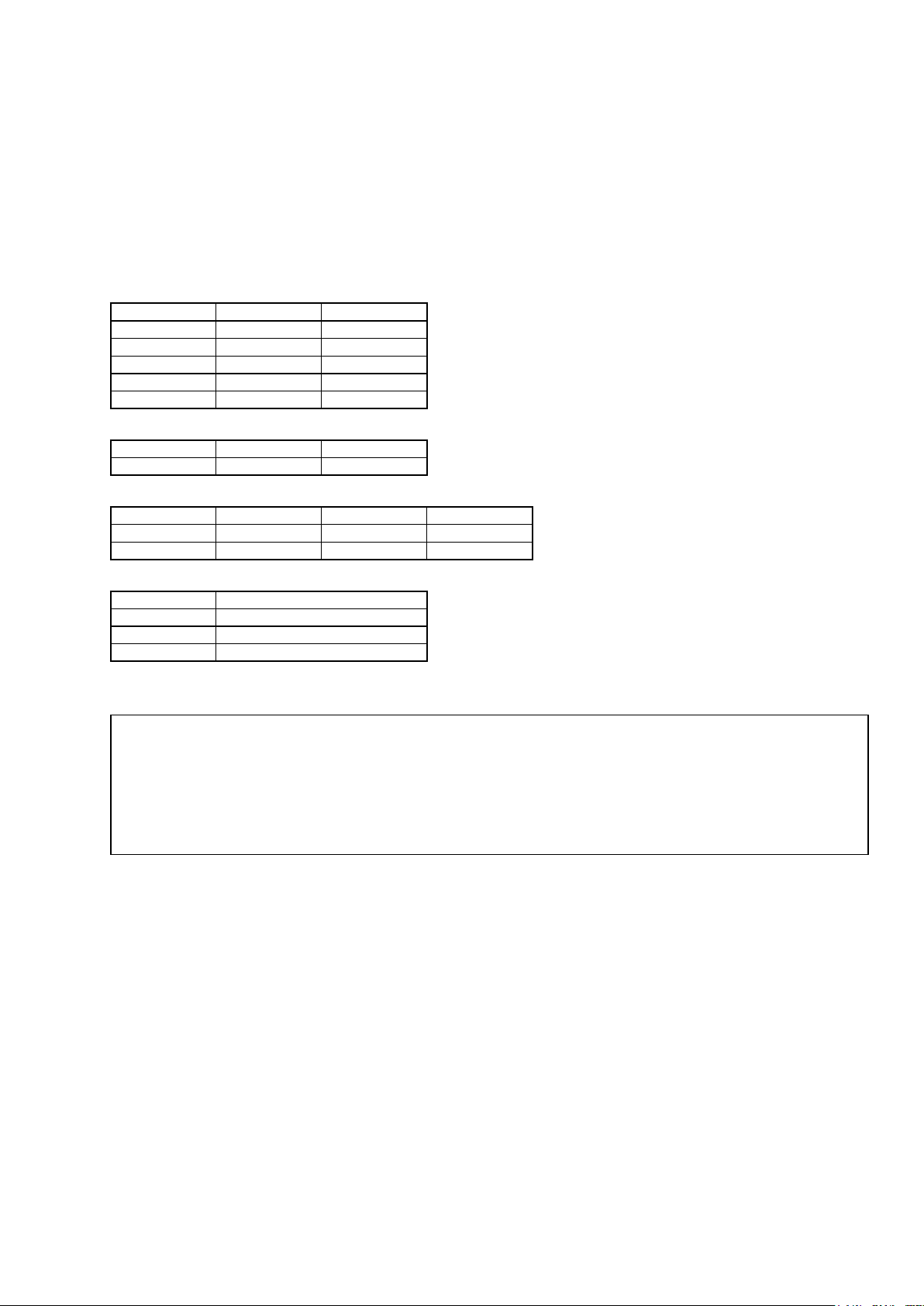

●Resistors

Value Tolerance Description

1Ω 5% 1

10Ω 5% 10

4.7KΩ 5% 4.7K

10KΩ 5% 10K

12.1KΩ 1% 12.1K/1%

●Electrolytic capacitor

Value Voltage Description

47μF 16V 47uF/16V

●Ceramic capacitor

Value Voltage Gread Description

0.1μF 25V Y5V 0.1uF/25V/Y5V

0.1μF 50V X7R 0.1uF/50V/X7R

●NC (not implemented)

Description Exsample

NC NC

*/NC 100uF/10V/NC

NC/* NC/0.1uF/25V/Y5V

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

5

Page 6

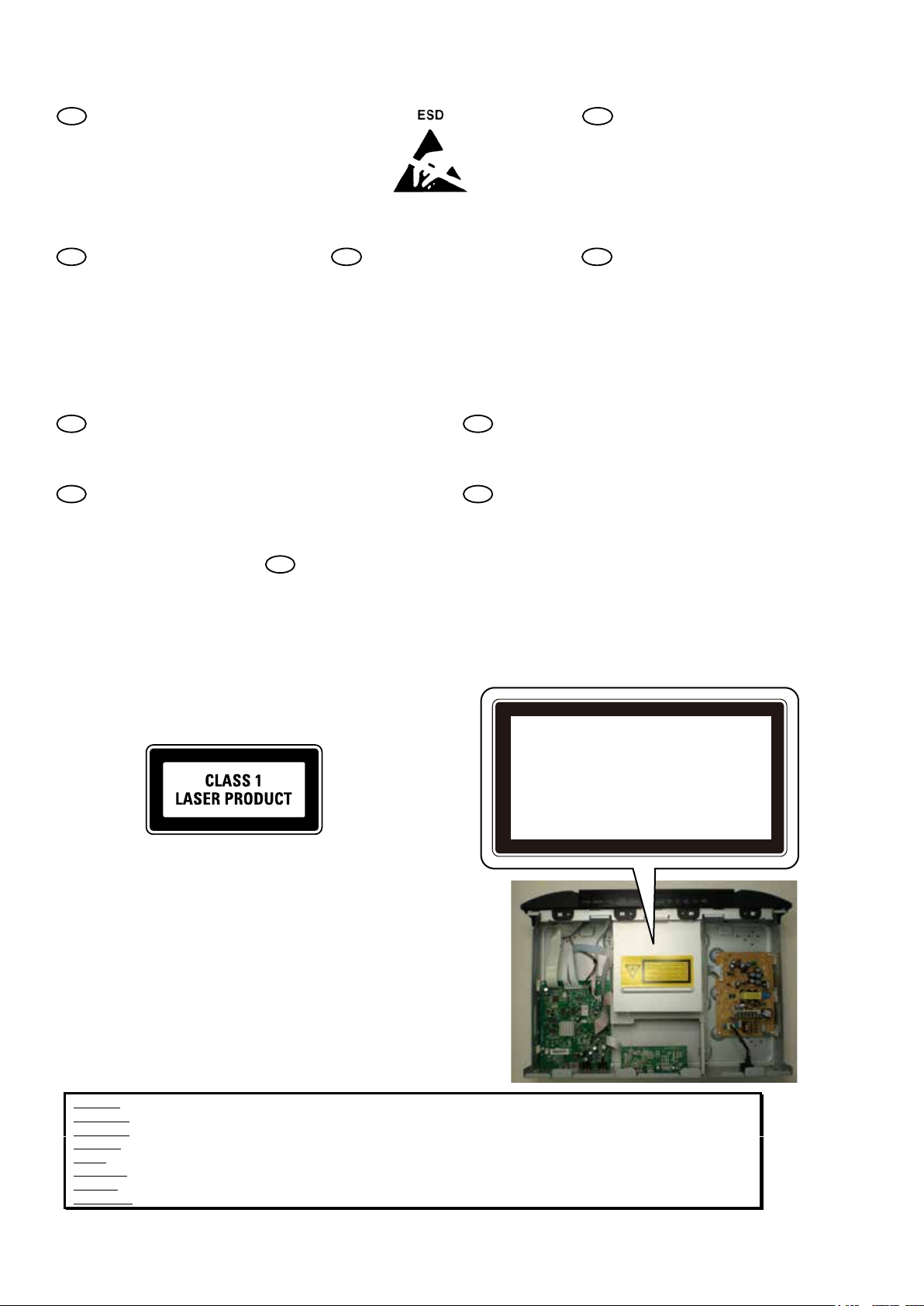

WARNING AND LASER SAFETY INSTRUCTIONS

ridatta

100301DM

WARNING AND LASER SAFETY INSTRUCTIONS

WARNING

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are connected

with the same potential as the mass of the set via a

wrist wrap with resistance.

Keep components and tools also at this potential.

NL

Alle IC’s en vele andere halfgeleiders zijn gevoelig

voor elektrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de

levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een polsband

met weerstand verbonden bent met apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

WAARSCHUWING

F ATTENTION

Tous les IC et beaucoup d’autres semiconducteurs

sont sensibles aux décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est prise

a leur manipulation.

Lors de réparations, s’assurer de bien être relié au

même potentiel que la masse de l’appareil et enfiler

le bracelet serti d’une résistance de sécurité.

Veiller a ce que les composants ainsi que les outils

que l’on utilise soient également a ce potentiel.

D

WARNUNG

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

über ein Pulsarmband mit Widerstand mit auf

diesem Potential.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

F

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should

remove the cover or attempt to service this device, due to

possible eye injury.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono sensibili

alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

in caso di non osservazione della piu grande

cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto a

resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo potenziale.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

CAUTION-CLASS 2 VISIBLE AND INVISIBLE LASER

RADIATION WHEN OPEN. DO NOT STARE INTO THE BEAM.

VAROITUS-LUOKAN 2 NÄKYVÄÄ JA NÄKYMÄTÖNTÄ

LASERSÄTEILYÄ AVATUNA. ÄLÄ TUIJOTA SÄTEESEEN.

VARNING-KLASS 2 SYNLIG OCH OSYNLIG

LASERSTÅLNING VID ÖPPNING. STIRRA EJ NI I STRÅLEN.

ADVARSEL-KLASSE 2 SYNLIG OG USYNLIG LASERSTRÅLING

VED ÅBNING. SE IKKE IND I STRÅLEN.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE

OF PROCEDURE OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will

increase eye hazard.

Repair handling should take place as much as possible with

a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

Æ

TTELSE FOR STRÅLING

6

Page 7

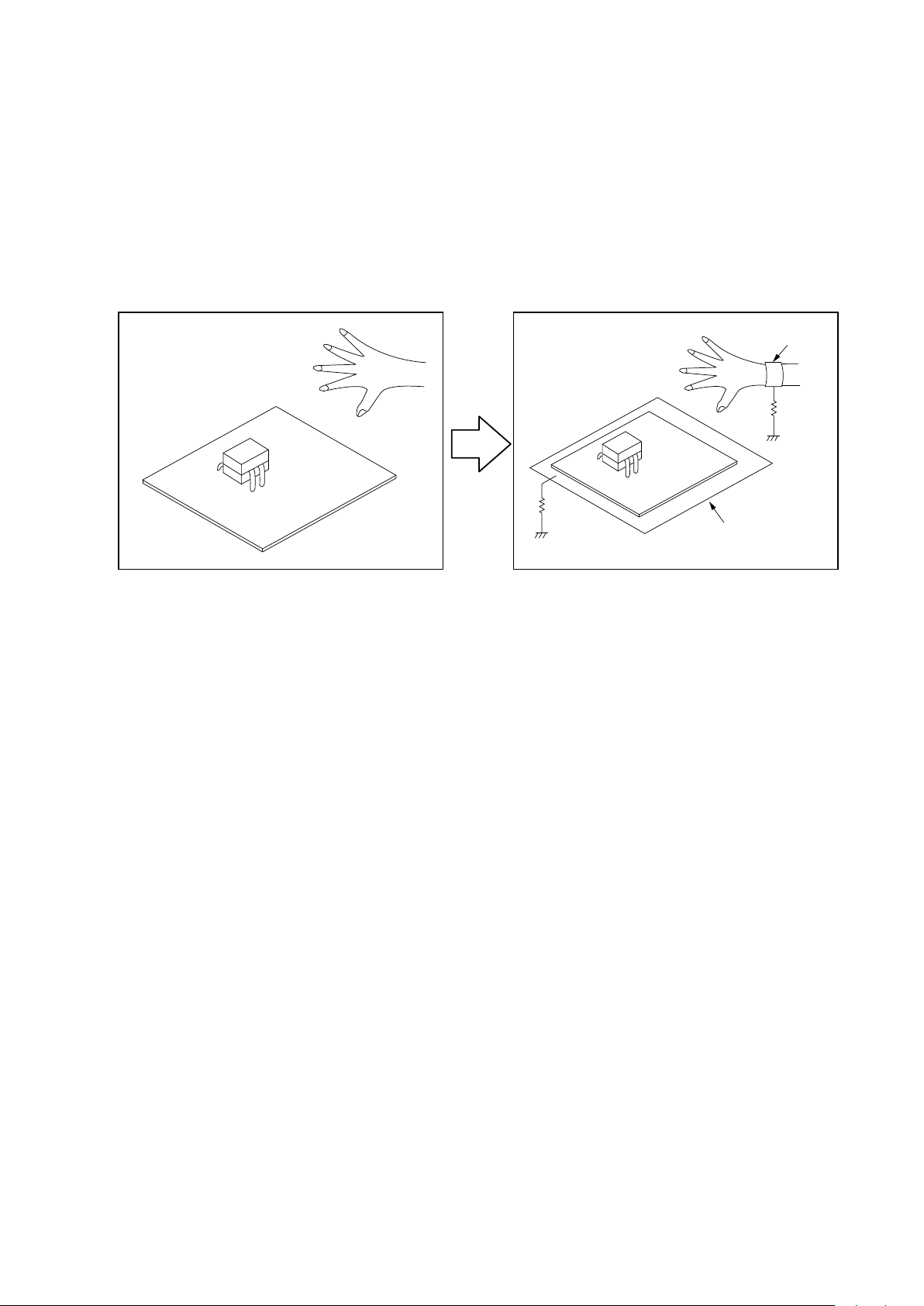

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential difference

caused by electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 MΩ) on the workbench or other surface, where the

semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through the body grounding band,

be careful to avoid contacting semi-conductors with your clothing

<Incorrect>

CBA

<Correct>

1MΩ

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

7

Page 8

TECHNICAL SPECIFICATIONS

Performance

n

Signal format : NTSC, PAL

Applicable discs /memory device :

(1) BD-Video disc :

12 cm, 1 side, 1 layer; 12 cm, 1 side, 2 layers

(2) DVD-Video / DVD-Audio disc :

12 cm, 1 side, 1 layer; 12 cm, 1 side, 2 layers /

12 cm, 2 sides, 2 layers (1 side, 1 layer)

8 cm, 1 side, 1 layer; 8 cm, 1 side, 2 layers /

8 cm, 2 sides, 2 layers (1 side, 1 layer)

(3) Super Audio CD :

12 cm, 1 layer / 12 cm, 2 layer / 12 cm, Hybrid

(4) Compact Disc (CD-DA) :

12 cm / 8 cm disc

(5) Memory device :

USB memory device (USB 2.0)

HDMI output :

Output terminal : 19-pin HDMI terminals, 1 set

(Deep Colour, Dolby Digital Plus, Dolby TrueHD, DTS-HD, 3D)

Analog audio output :

Output level : 2 Vrms (10 kΩ)

2 channels output terminal : Pin-jack, 1 set

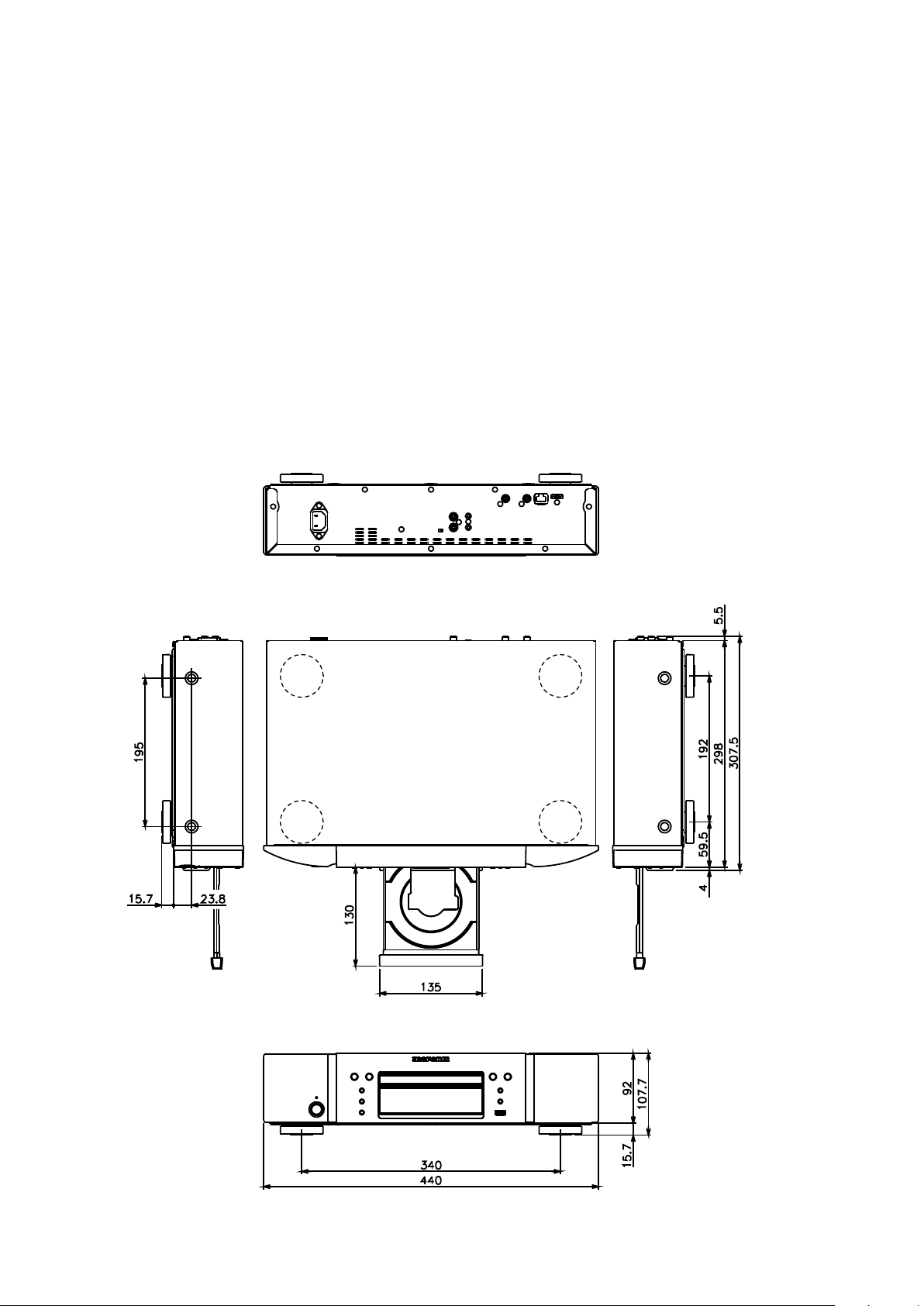

DIMENSION

Audio output characteristics :

(1) Frequency response

q BD (Linear PCM)

: 2Hz ~ 44kHz (96kHz sampling)

: 2Hz ~ 22kHz (48kHz sampling)

: 2Hz ~ 88kHz (192kHz sampling)

w DVD (Linear PCM)

: 2Hz ~ 44kHz (96kHz sampling)

: 2Hz ~ 22kHz (48kHz sampling)

: 2Hz ~ 88kHz (192kHz sampling)

e Super Audio CD

: 2Hz ~ 20kHz

r CD

(2) S/N ratio : 115dB (BD)

(3) Total harmonic distortion : 1kHz 0.0025% (BD)

(4) Dynamic range : 100dB (BD)

General

n

Power supply : AC 120 V, 60 Hz (for U)

AC 100 – 240 V, 50/60 Hz (for N, S)

AC 220 V, 50 Hz (for K)

Power consumption : 20W

0.3 W (Energy Saving Standby)

0.5 W (Normal Standby)

12 W (Quick Start)

: 2Hz ~ 40kHz

8

Page 9

CAUTIONS IN SERVICING

Initializing BD player

BD player initialization should be performed when the μcom, peripheral parts of μcom, and MAIN PCB. were replaced.

1. Turn on this model's power. "NO DISC" is displayed on the FL tube.

2. Press the this model's "1" and "9" buttons simultaneously. "INITIALIZING" is displayed on the FL tube.

3. The display on the FL tube switches to "INITIALIZED", the "NO DISC" display reappears and initialization is

completed.

NOTE : • If step 3 does not work, start over from step 1.

All user settings will be lost and this factory setting will be recovered after the set is initialized.

•

So make sure to note down your setting beforehand for restoring after the initialization.

91

ON/STANDBY (X)

Service tools

Measuring Disc: CD/TCD-784

DVD/VT502 or TDV-520A

BD/ABD-520 or BLX-108

Refer to "MEASURING METHOD AND WAVEFORMS".

z

When you repair the BD MECHA UNIT, you can use the following JIG.

Please order to Marantz Ofcial Service Distributor in your region if necessary.

Do not supply it : 232C (TTL) – USB conversion jig (Model: DUT-06635 by GeeeTech) : 1 Set

Part No. : 61205000300AS :

Refer to "HOW TO REPLACE THE MAIN PCB & BD MECHA OR BD MECHA".

z

4P RE-PH CONN CORD (1000mm) : 1 Set

9

Page 10

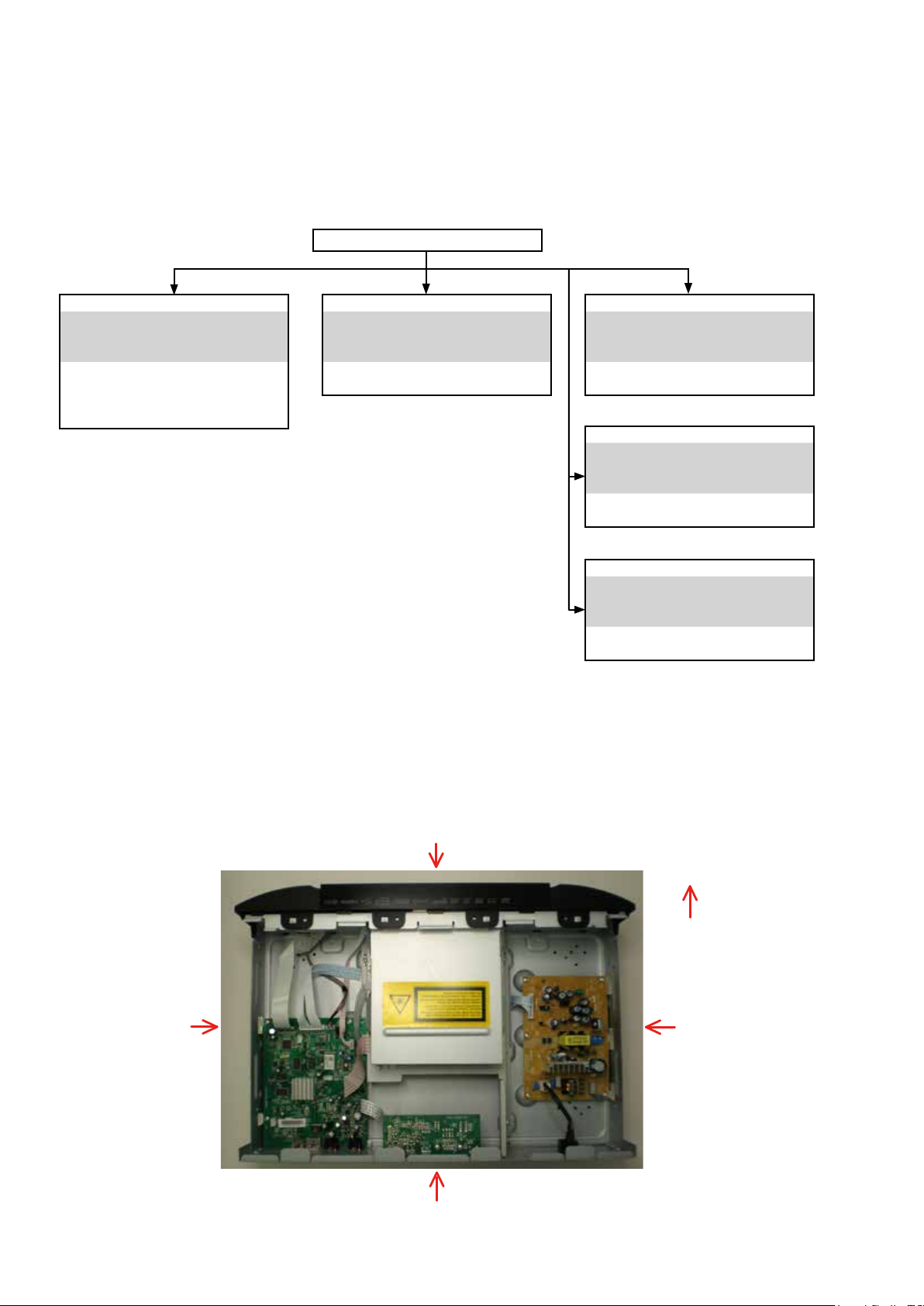

DISASSEMBLY

Shooting direction: C

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP COVER

FRONT PANEL ASSY

Refer to "DISASSEMBLY

1. FRONT PANEL ASSY"

and "EXPLODED VIEW"

FRONT PANEL ASSY

(Ref. No. of EXPLODED VIEW : 1a)

DISPLAY PCB UNIT

(Ref. No. of EXPLODED VIEW : 13)

BD MECHA UNIT ASS'Y

Refer to "DISASSEMBLY

2. BD MECHA UNIT ASSY"

and "EXPLODED VIEW"

MAIN PCB UNIT ASSY

(Ref. No. of EXPLODED VIEW : 21)

MAIN PCB UNIT ASS'Y

Refer to "DISASSEMBLY

3. MAIN PCB UNIT ASSY"

and "EXPLODED VIEW"

MAIN PCB UNIT

(Ref. No. of EXPLODED VIEW : 21)

POWER PCB UNIT ASS'Y

Refer to "DISASSEMBLY

5. POWER PCB UNIT"

and "EXPLODED VIEW"

POWER PCB UNIT

(Ref. No. of EXPLODED VIEW : 20)

IR PCB UNIT ASS'Y

Refer to "DISASSEMBLY

4. IR PCB UNIT"

and "EXPLODED VIEW"

IR PCB UNIT

(Ref. No. of EXPLODED VIEW : 19)

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction)

[View from the top]

Shooting direction: B

Front side

Shooting direction: D

Shooting direction: A

10

Page 11

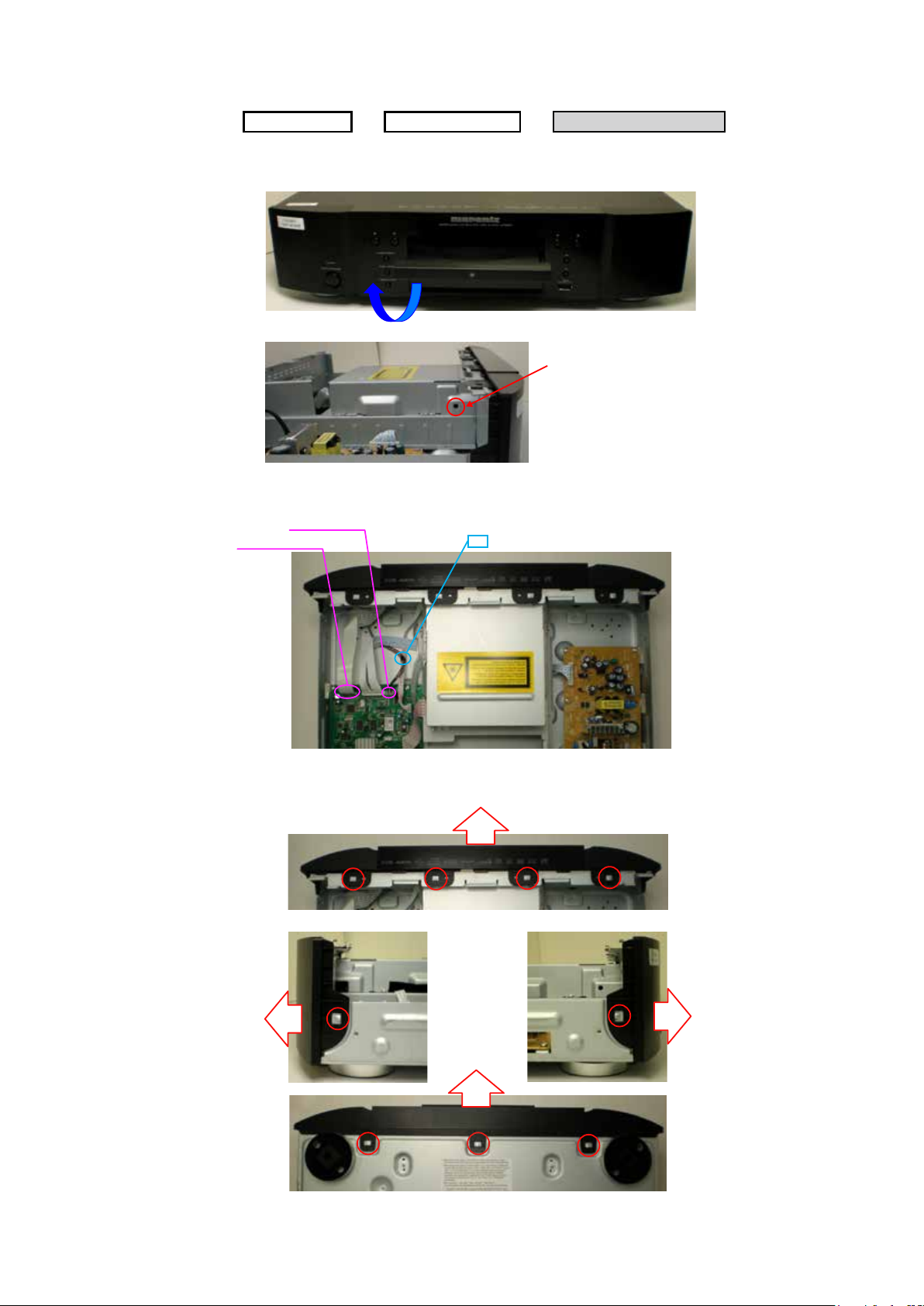

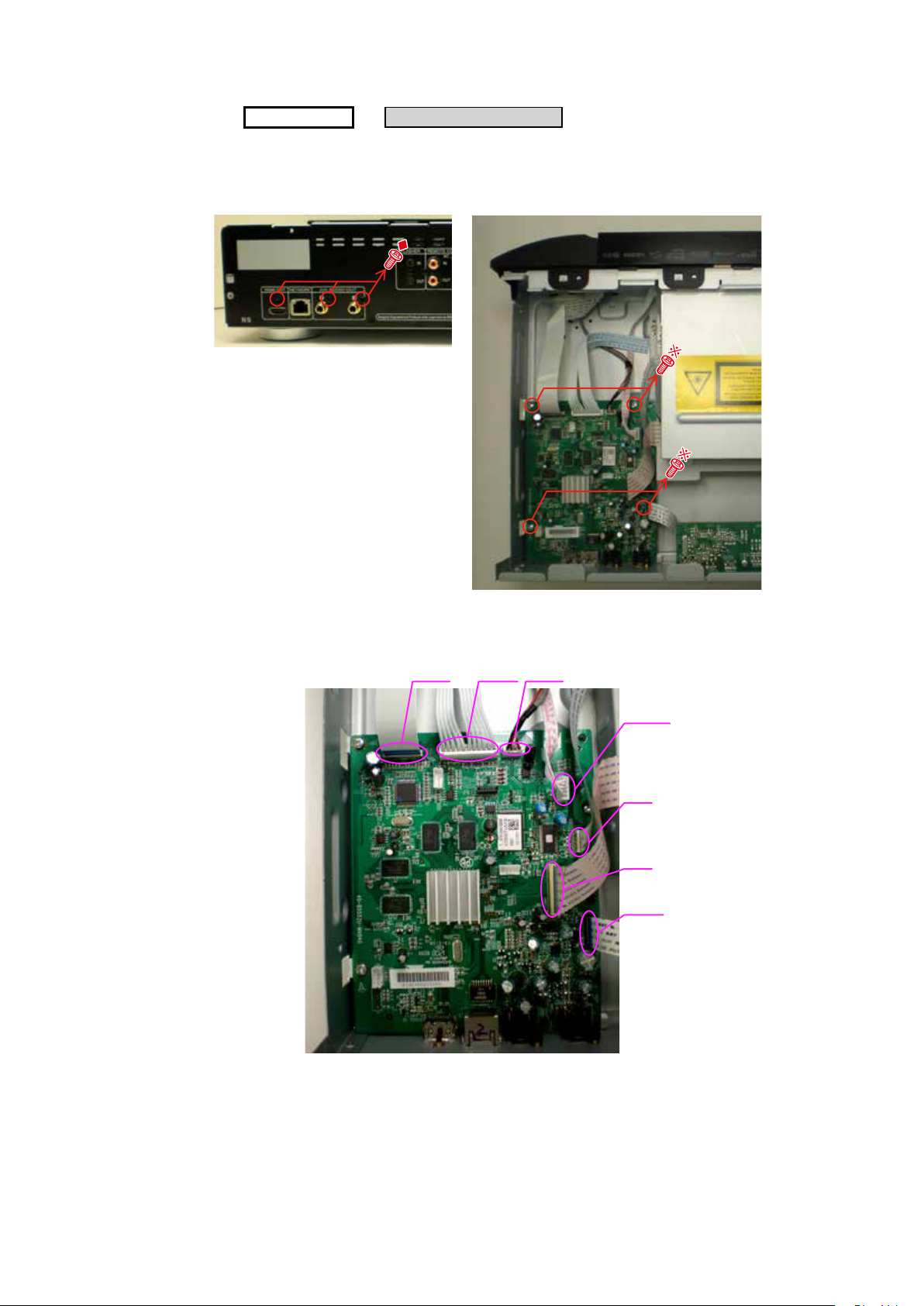

1. FRONT PANEL ASSY

Proceeding : TOP COVER

→

(1) Detach the LOADER PANEL.

Shooting direction: B

(2) Disconnect the connector wire and FFC.

4P-PH【XP3】

18P-FFC【XP4】

LOADER PANEL

cut

FRONT PANEL ASSY

→

Pressed in metal rod having a mechanism for

emergency open, stretched out like a small hole

on the left side of the clip to.

(3) Lift up to unhook the claw and move in the direction of arrow to gradually pull out the assembly.

Top side ×4, Side ×2 (Left and right), Bottom ×3

Top side

Shooting direction: C

Side

Bottom side

Shooting direction: D

11

Page 12

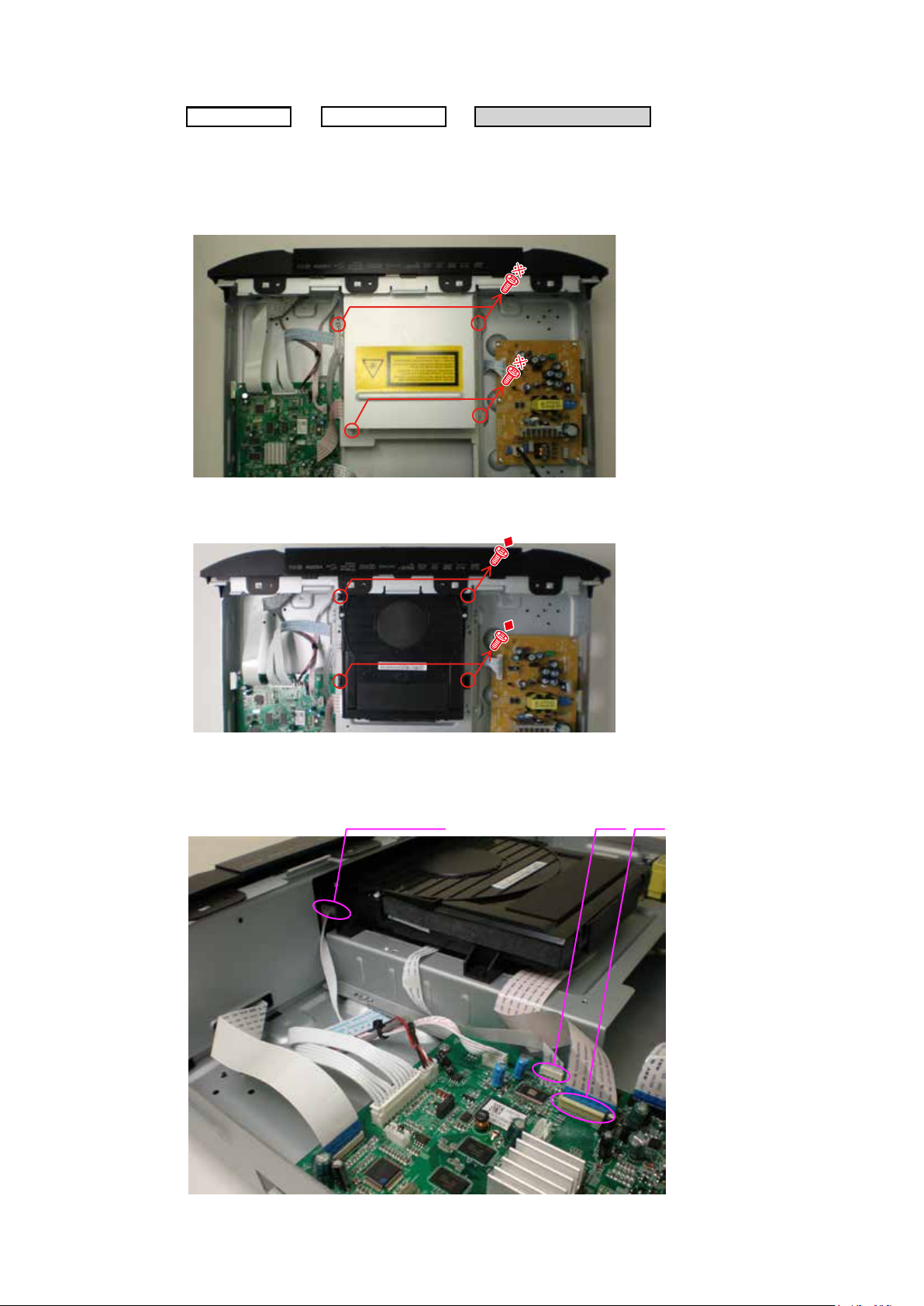

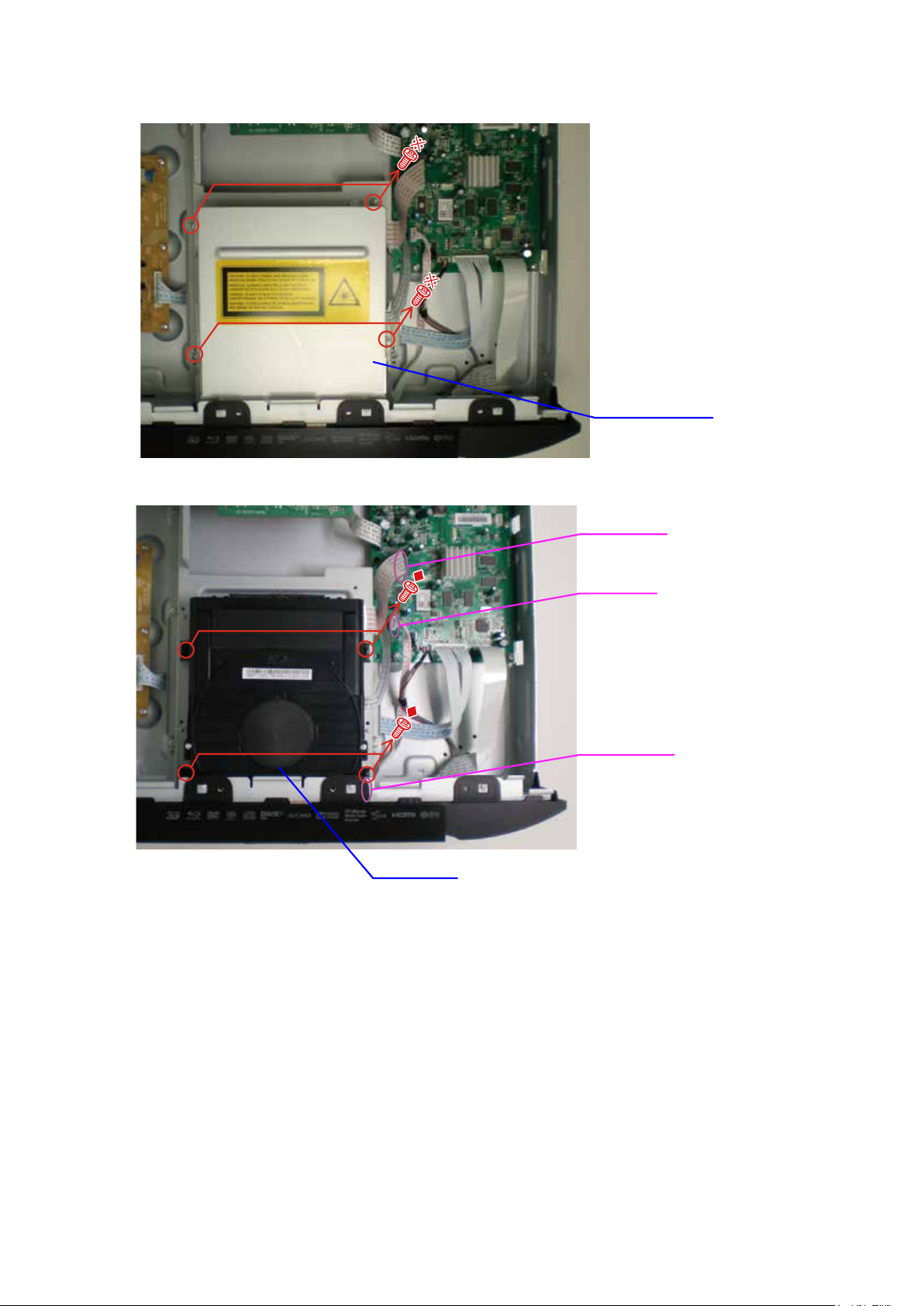

2. BD MECHA UNIT ASSY

Proceeding : TOP COVER

Please ensure ESD protection prior to handling the BD MECHA.

※

(1) Remove the screws.

Screw of Mecha cover ×4

(2) Remove the screws.

Screw of BD's Mecha ×4

MECHA COVER

→

BD MECHA UNIT ASSY

→

(3) Disconnect the connector wire and FFC.

45P-FFC【J2】, 9P-FFC【J4】

From the left side of the BD's Mecha, remove the screw.

【J2】【J4】【5P-PH CORD】

12

Page 13

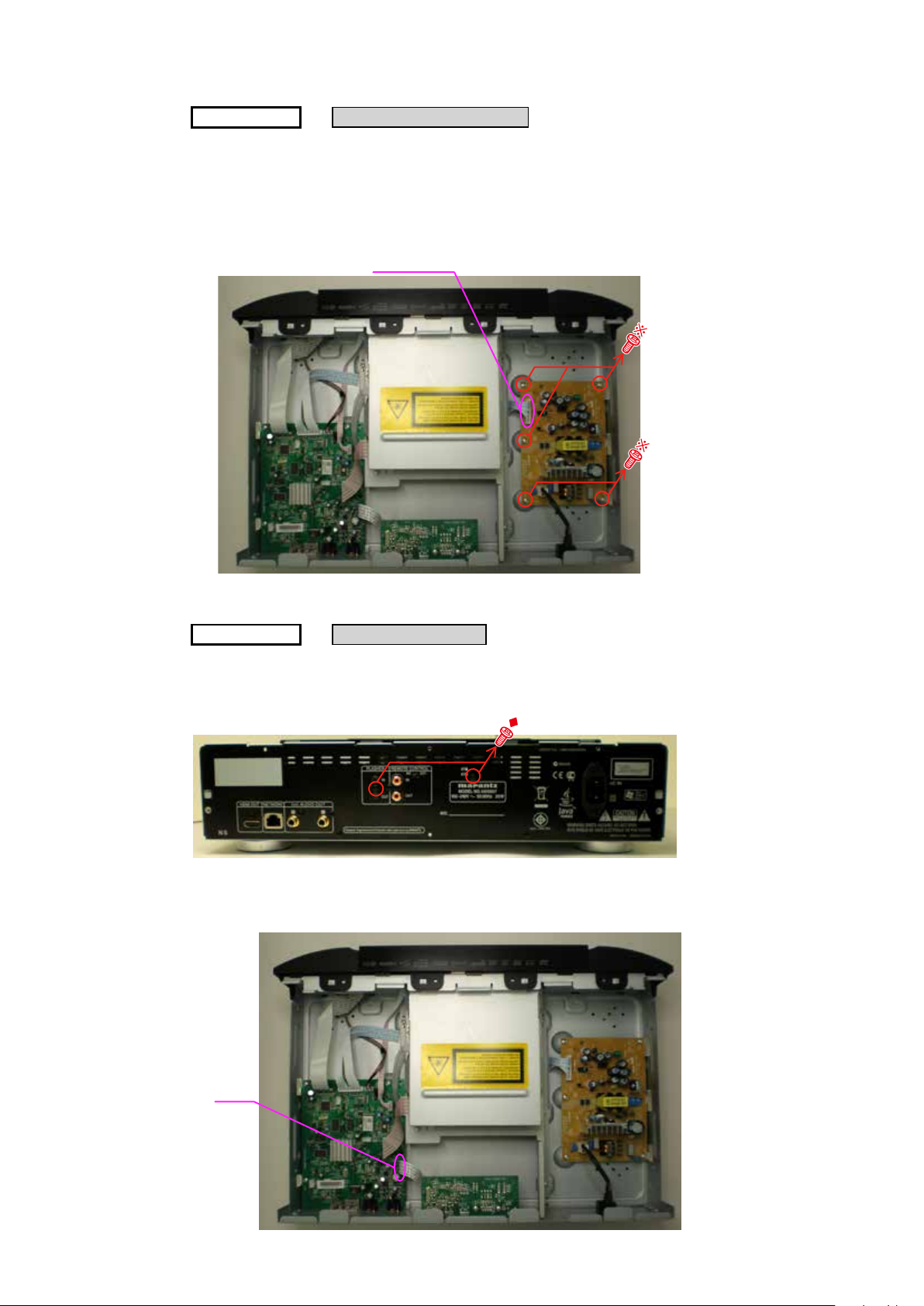

3. MAIN PCB UNIT ASSY

Proceeding : TOP COVER

(1) Remove the screws.

Remove the screws from REAR PANEL ×2

Remove the screws from TOP PANEL ×4

MAIN PCB UNIT ASSY

→

(2) Disconnect the connector wire and FFC.

Disconnect 13P-FFC【XP8】, 12P-PH【XP1

】

【XP4】 【XP1】【XP3】

【XP10】

【J4】

【J2】

【XP8】

13

Page 14

4. POWER PCB UNIT ASSY

Proceeding : TOP COVER

(1) Remove the screws.

Remove the screws from TOP ×5

(2) Disconnect the connector wire and FFC.

Disconnect 12P-PH【CN502/503】, 3P-VH【CN501

POWER PCB UNIT ASSY

→

】

【CN502/503】

5. IR PCB UNIT ASSY

Proceeding : TOP COVER

(1) Remove the screws.

Remove the screws from REAR PANEL ×2

(2) Disconnect the connector wire and FFC.

Disconnect 13P-FFC【XP8

→

】

IR PCB UNIT ASSY

【XP8】

14

Page 15

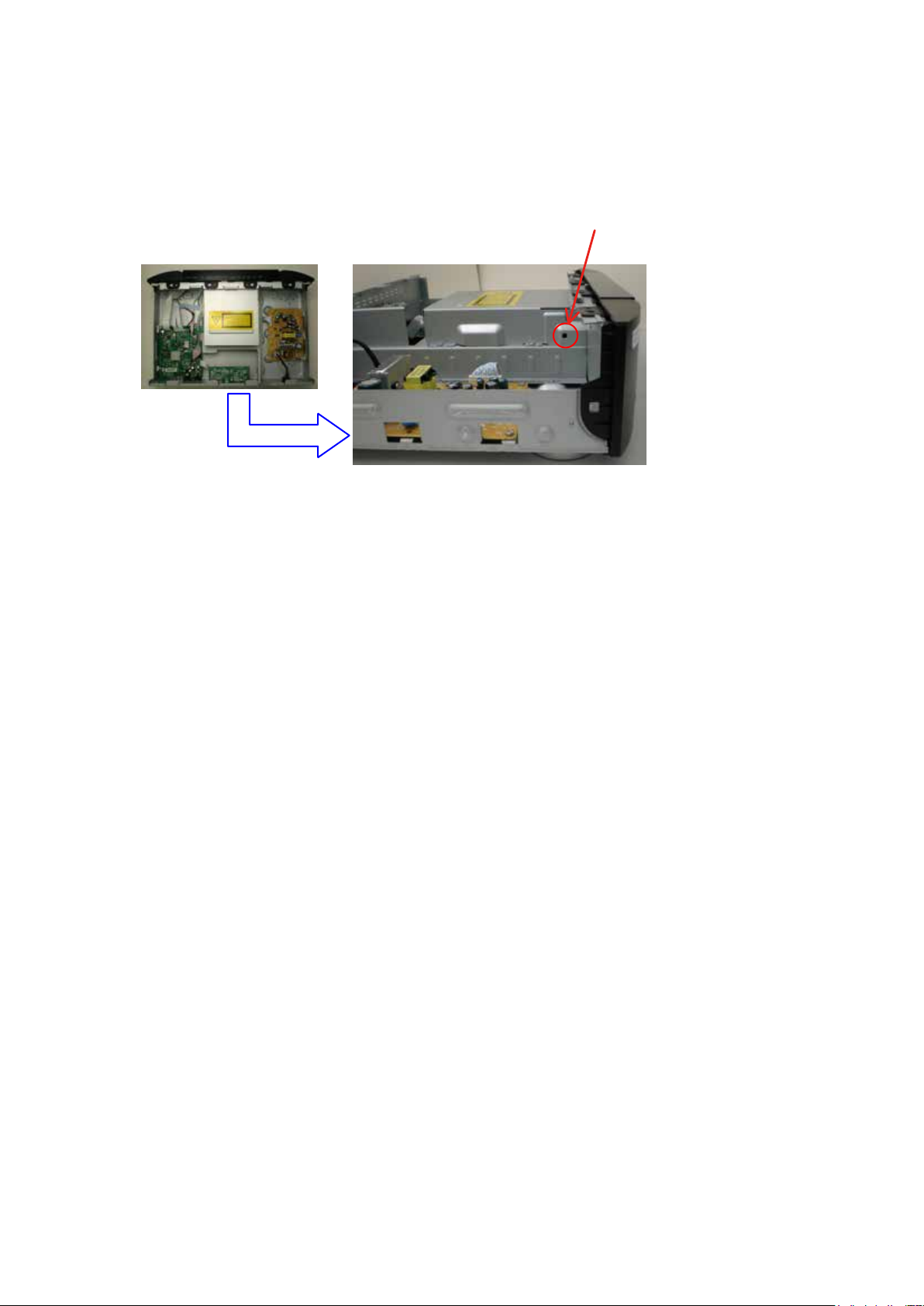

REMOVING DISCS

(1) Remove the Top Cover.

(2) Open the CD tray.

Shooting direction: D

Pressed in metal rod having

a mechanism for emergency

open, stretched out like a small

hole on the left side of the clip to.

15

Page 16

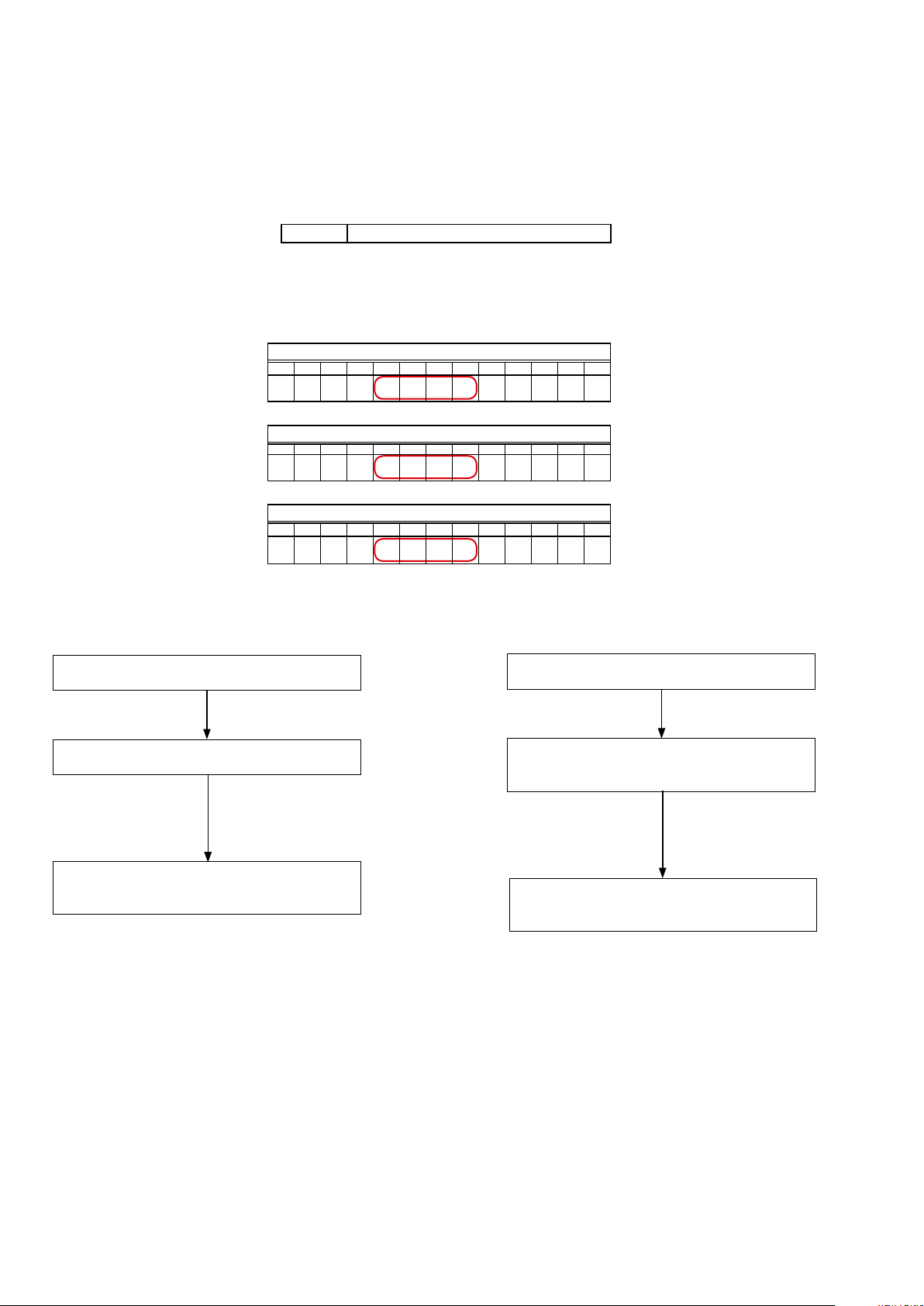

DIAGNOSTICS OF OPTICAL PICKUP

Make failure diagnostics of the Optical Pickup as follows.

If the laser drive current (Iop) becomes more than BD : ± 6 [mA], DVD or CD : ±12 [mA] of the initial value, the Optical

q

Pickup should be replaced.

The laser drive current initial value is checked by "Iop checked Method" of next page.

Load ve times of following disc again and playing it for one minute. It becomes the aim of the Optical Pickup

w

exchange when it cannot play.

BD-RE ABD-RE540W(made by ALMEDIO)

In case of replacing the Pickup, change the whole part of the MAIN PCB & BD MECHA or BD MECHA.

No mechanical adjustment is necessary after the replacement. (HOW TO REPLACE THE MAIN PCB & BD MECHA OR

BD MECHA (page 17))

Laser drive current initial value:

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

CD :

T 2 1 : m m m m : n n n n

FL Display (The display part of 13 digits)

DVD :

BD(SL) :

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 2 : m m m m : n n n n

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 3 : m m m m : n n n n

Check the laser drive current value

q

Disc no read, unsteady playback, etc.

Laser drive current (Iop) check.

Current value of the BD Iop is ±6[mA],

DVD or CD Iop is ±12[mA] or more the

initial value.

The MAIN PCB & BD MECHA

or the BD MECHA replacing.

Check the playability disc

w

Disc no read, unsteady playback, etc.

ABD-RE540W disc playability check

(Load ve times of following disc)

Disc cannot play.

The MAIN PCB & BD MECHA

or the BD MECHA replacing.

16

Page 17

1. Iop checked Method

Select the laser ON/OFF(CD/DVD/BD)mode of the test mode, and check the Iop value of CD laser, DVD laser or BD

laser. (Refer to "6. Test mode")

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

Laser current check

Press the "8" or "9" button to display the laser current value, and then select [X].

Check the current value of Iop (nnnn)

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X : m m m m : n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode

(mmmm[mA] : Initial value, nnnn[mA] : Current value)

2. To clear the accumulated laser on time

Press the "1" button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "TC4*clear??"

appears at the display. If the "1" button is pressed, the accumulated laser on time of CD, DVD and BD is cleared

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 4 * - - c l e a r ? ?

When "TC1", "TC2" or "TC3" is selected with the "8" or "9" button, "mmmmmm" is displayed as "0" so you can

check.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C Y - - - m m m m m m h

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time)

17

Page 18

HOW TO REPLACE THE MAIN PCB & BD MECHA OR BD MECHA

NOTE: The optical pick-up laser diode (LD) is instantly degraded or damaged by static electricity or a power

surge. When handling the BD MECHA UNIT, always be sure to earth yourself, and use an earth mat on the

workbench and oor for grounding.

• BD MECHA UNIT Replacement Conditions

If the laser amperage (Iop) exceeds the stipulated range (see the laser on/off mode in test mode (page 25)), replace the

BD MECHA or replace the MAIN PCB & BD MECHA. If other problems occur, replace the MAIN PCB & BD MECHA.

Stipulated range: For BD, within ±6 [mA] of the initial value; for DVD/CD, within ±12 [mA] of the initial value.

• The following two parts are specied as service parts for the MECHA UNIT.

1. MAIN PCB & BD MECHA : (Part No. : 919304100210M)

2. BD MECHA : (Part No. : 919304100230S)

1. How to Replace the MAIN PCB & BD MECHA

(1) Refer to the removal procedure, and remove and replace the MAIN PCB & BD MECHA. (see "DISASSEMBLY")

(2) Follow the rmware update procedure, and update the rmware to the latest version.

(see "VERSION UPGRADE PROCEDURE OF FIRMWARE")

2. How to Replace the BD MECHA

2.1. Devices Used

1. PC

2. USB - 232C (TTL) conversion jig (Model: DUT-06635 by GeeeTech) (Do not supply)

3. 4P RE-PH CONN CORD (1000mm) (Part No. : 61205000300AS)

4. Write software (5.12.71(8550+KES470)_1Dscan.zip)

2.2. Replacement Overview

(1) Before replacing the UNIT, write all of the UNIT data of the unit to be replaced onto the set.

(2) After performing (1), replace the UNIT.

(3) Congure the settings for the set in which the UNIT was replaced.

2.3. Before replacing

[Preparation]

1. Set unit before replacing the UNIT

2. PC with write software (5.12.71(8550+KES470)_1Dscan.zip) installed

3. USB - 232C (TTL) conversion jig

4. UNIT for replacement

18

Page 19

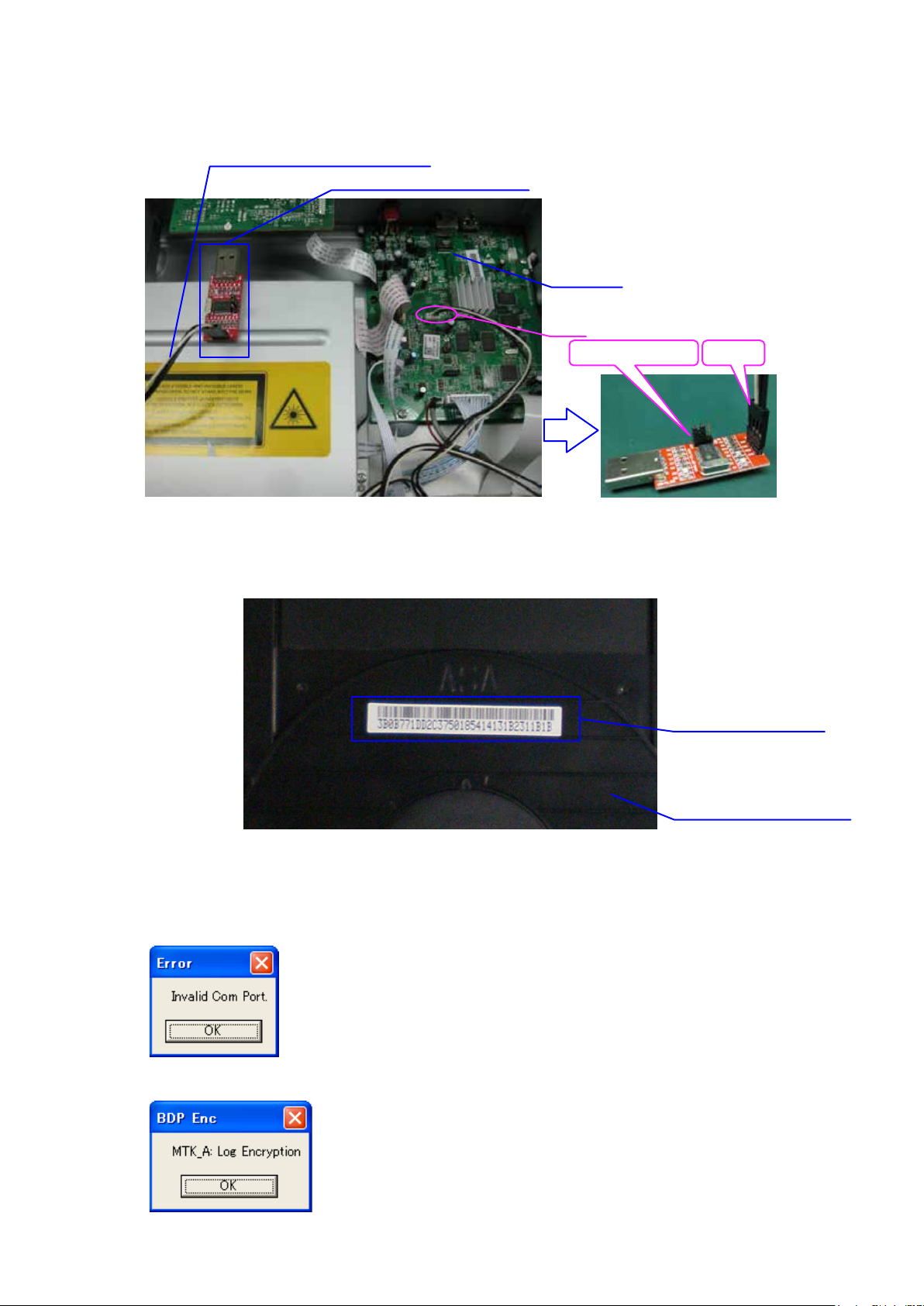

[Connection]

(1) Connect the 232C (TTL) side 4P PH connector of the USB - 232C (TTL) conversion jig to the MAIN PCB of the set.

(2) Connect the USB side of the USB - 232C (TTL) conversion jig to the PC.

4P RE-PH CONN CORD (1000mm)

USB - 232C(TTL) conversion jig

MAIN PCB

CON1

Jumper pin : 3.3V

[Writing new optical pick-up data ]

• Barcode position of optical pick-up unit

f mark

View from the top

(1) Switch on the power on of the set before the BD MECHA is replaced.

(2) Decompress the 5.12.71(8550+KES470)_1Dscan.zip folder and start the "Rpower.exe".

(3) A pop-up is displayed. Click "OK".

(4) Click "OK".

1Dimensional Bar Code

BD MECHA for replacement

19

Page 20

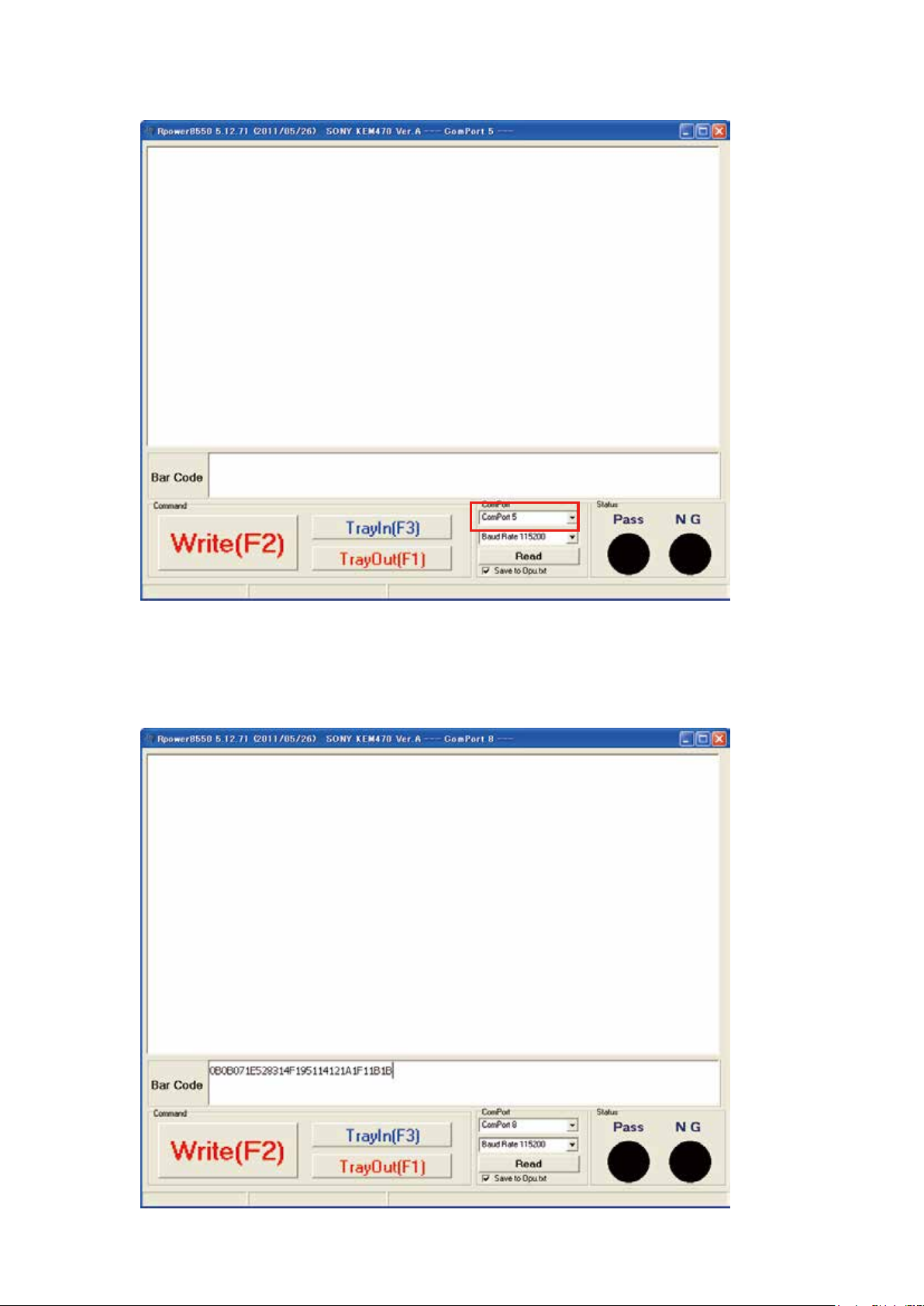

(5) On the screen below, select "ComPort XX".

Select the USB - 232C (TTL) conversion jig port.

(6) Enter the Bar Code BOX 32-digit hexadecimal number listed at the bottom of one-dimensional bar code

replacement for the BD MECHA.

One dimension of bar code data can stick to reading, Bar Code BOX in bar code leaders and can input.

NOTE: The bar code data of the optical pickup, please do not enter the wrong data. Please do not confused

with other data of the optical pickup also.

20

Page 21

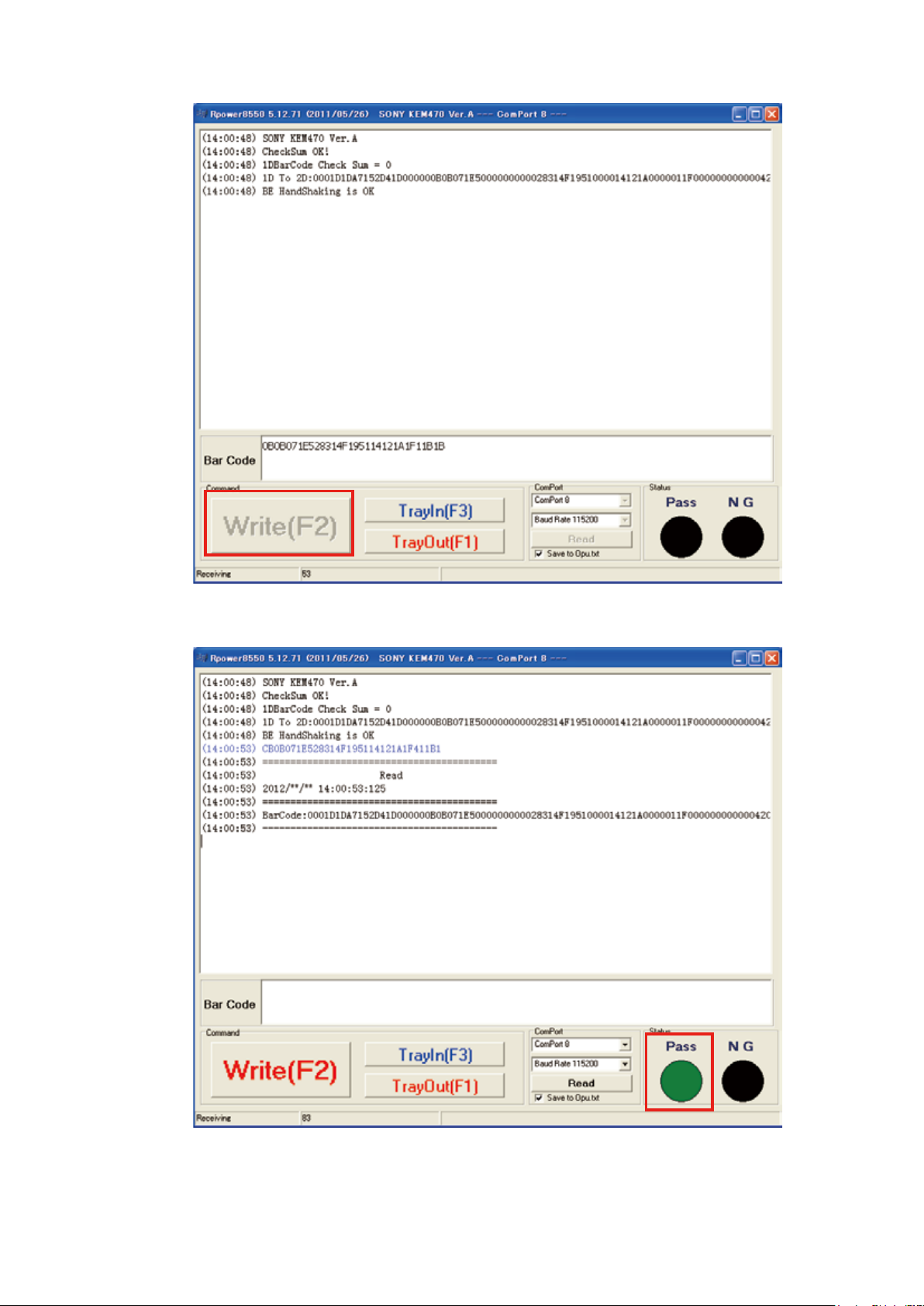

(7) Click Write(F2).

(8) When “Pass” changes to green, writing to the Flash ROM of the MAIN PCB is complete.

(9) Switch off the set unit power, and remove the 232C (TTL) side 4P PH connector of the USB - 232C (TTL)

conversion jig from the MAIN PCB (CON1).

21

Page 22

2.4. Replace the BD MECHA UNIT ASSY

(1) Remove the MECHA COVER.

MECHA COVER

(2) Move the optical pickup to the outer circumference, remove the FFC, and remove the screws.

J2 45P-FFC

J4 9P-FFC

5P-PH CORD

BD MECHA

(3) Attach the BD MECHA for replacement to the set unit. (When assembling the unit, perform the steps in reverse

order.)

(4) Check that the 45P-FFC, 9P-FFC and 5P-PH connector cords have been connected.

2.5. Congure the settings of the set that contains the new BD MECHA

(1) Check the laser amperage (see laser on/off mode in the test mode (page 25)).

Check that the values are ±6 [mA] from the initial value for BD, and ±12 [mA] from the initial value for DVD/CD.

(2) Clear the total laser usage time (see the procedure for clearing the accumulated laser on time in test mode (page

26)).

(3) Check BD, DVD, and CD media playback.

(4) If there are no problems with playback, remove the disc, press the "ON/STANDBY" button to switch to standby

status, and remove the AC plug from the AC socket.

(5) Attach the top cover, and this completes the replacement procedure.

22

Page 23

HOW TO REPLACE THE MAIN PCB UNIT ASSY

Service Part for the MAIN PCB UNIT ASSY

・

MAIN PCB: (Part No. :919639100340M)

s

1.1. Devices Used

(1) PC

(2) USB - 232C (TTL) conversion jig (Model: DUT-06635 by GeeeTech) (Do not supply)

(3) 4P RE-PH CONN CORD (1000mm) (Part No. : 61205000300AS)

(4) Write software (5.12.71(8550+KES470)_1Dscan.zip)

1.2. Replacement Overview

(1) Replace the MAIN PCB UNIT ASSY. (Disconnected J2 45P FFC)

(2) Writing Mecha's data to the replacement MAIN PCB UNIT.

(3) Turn off the unit, then connect 45P FFC of J2.

(4) To conrm the operation.

1.3. Before replacing

[Preparation]

(1) The unit of before replacement.

(2) Replacement MAIN PCB UNIT ASSY

(3) PC with write software (5.12.71(8550+KES470)_1Dscan.zip) installed

(4) USB - 232C (TTL) conversion jig

1.4. Replace the MAIN PCB UNIT ASSY

(1) Replacement MAIN PCB UNIT ASSY. (Refer to "DISASSEMBLY 3. MAIN PCB UNIT ASSY ")

(45P FFC J2 does not connect at this time.)

(2) Remove the MECHA COVER.

(3) Fixed to the MECHA UNIT to prevent short circuit. (J2 45P FFC)

J2 45P FFC

J2 45P FFC BASE

1.5. Connection and Writing optical pick-up data

(1) Refer to "HOW TO REPLACE THE MAIN PCB & BD MECHA OR BD MECHA,

[Connection] and [Writing new optical pick-up data ]"(P.19) , then writing new optical

pick-up data to MAIN PCB UNIT.

23

Page 24

1.6. Operation check

(1) Connect the 45P FFC of J2

J2 45P FFC

(2) Attach the MECHA COVER.

(3) Attach the TOP COVER.

(4) Follow the rmware update procedure, and update the rmware to the latest version.

(see "VERSION UPGRADE PROCEDURE OF FIRMWARE")

(5) Check the laser amperage (see laser on/off mode in the test mode (page 28)).

Check that the values are ±6 [mA] from the initial value for BD, and ±12 [mA] from the initial value for DVD/CD.

(6) Check BD, DVD, and CD media playback and operation.

(7) If there are no problems with playback, remove the disc, press the ON/STANDBY button to switch to standby

status,and remove the AC plug from the AC socket.

(8) Completes the replacement procedure.

Note: In the case of exchange, only MAIN PCB UNIT is cleared in the laser total use time.

24

Page 25

SERVICE MODE

Front-end version

1. Initial setting mode

1.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

1.2. procedure

Initialize the BD player when µcom, peripheral parts of µcom, or MAIN PCB. unit has been replaced in servicing.

b

All user setting will be lost and its factory setting will be restored when this initialization is made. Be sure to memorize

b

your setting for restoring again after the initialization.

(1) Turn on this model's power. "NO DISC" is displayed on the FL tube.

(2) Press the this model's "1" and "9" buttons simultaneously. "INITIALIZING" is displayed on the FL tube.

(3) The display on the FL tube switches to "INITIALIZED", the "NO DISC" display reappears and initialization is

completed.

2. Firmware version check mode

2.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

2.2. procedure

Front-end and Back-end and SYS com version check mode.

b

(1) Press the "SETUP" button on the remote controller to display the SETUP menu.

(2) Press remote controller "3265".

(3) The version is displayed on the TV screen as follows.

marantz

General Setting

System

Language

Ratings

Network

Others

Select

Factory Page

HQ 00003604,HF 00000000, MCU007

Version

JVM CDCA_JVM100311_2586

Loader: CV0017 8530

DVD Region Cod

BD Region Code

Reset Password

ENTER

Confirm

Reset

0

1

SETUP

Version

Version

Fmt buda

Fmt buda

Loader: 4Fxxxx

Exit

HQ 0000xxxx

MCUxxx

Back-end version

SYS com version

25

Page 26

3. Tray lock mode

3.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

3.2. procedure

[Setting]

(1) Pressing the "1" and "8" buttons for simultaneously, plug the AC cord into a power outlet.

(2) "TRAY LOCK" is displayed on the FL tube and tray opening/closing is invalidated.

[Cancel]

(1) Unplug this model's AC cord from the power outlet.

(2) Pressing the "1" and "8" buttons for simultaneously, plug the AC cord into a power outlet.

(3) "PLEASE WAIT" is displayed on the FL tube and tray opening/closing is enabled.

The tray lock mode is also canceled when the product is initialized.

b

4. Remote lock mode

4.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

4.2. procedure

[Setting]

(1) Pressing the

(2) “Lock-On” is displayed on the FL tube, and operations with the remote control and the REMOTE CONTROL input

terminal on the back of the UD5007 are disabled.

"PURE DIRECT" and "9" buttons for simultaneously.

[Cancel]

(1) Pressing the

(2) "Lock-Off" is displayed on the FL tube and remote lock mode is made canceled.

"PURE DIRECT" and "9" buttons for simultaneously.

5. All Lit / All Off mode for the FL tube

5.1. preparation

(1) Equipment used: None

(2) Unit setting: No spec other than the following procedure.

5.2. procedure

[Setting]

(1) Pressing the "PURE DIRECT" and "8" buttons for simultaneously, plug the AC cord into a power outlet.

If All Lit / All Off mode is set for the FL tube, the FL tube’s display area is fully lit.

(2) Press the "PURE DIRECT" button to ‘all off’ display.

[Cancel]

(1) Remove the power cable for 5 seconds or more to cancel All Lit / All Off mode for the FL tube.

26

Page 27

6. Test mode

6.1. Entering the test mode

The test mode is entered by pressing the "5" and "8" buttons simultaneously, plug the AC cord into a power outlet.

When the test mode is set, the "1" and "3" indicators light.

FL tube display when test mode entered

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T E S T M O D E

When the test mode is set, the choice screen of the mode appears on the monitor.

6.2. Selecting the mode

The following modes are available.

・

(1) Laser on/off (CD/DVD/BD) mode : T2

(2) Error rate (skew) measurement mode : T7

(3) Accumulated laser on time display mode : TC

(4) Test mode cancel : TI

When the "9" button is pressed after entering the test mode, the display switches in the order: "T2, T7, TC, TI, T2

q

…"

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 L a s e r O n O f f

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 7 E r r o r R a t e

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C L a s e r O n T i m

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T I T e s t E x i t

When the "8" button is pressed, the display switches in the opposite order from q above, starting from the

w

current position (for example, if currently at "TC", it switches as follows: "T7, T2 ").

27

Page 28

6.3. About each mode

With the mode selected, press the "1" button to set that mode.

・

(1) Laser on/off (CD/DVD/BD) mode

Press the "8" or "9" button to select [X] and press the "1" button to set it.

Laser on/off control is executed and the laser current is displayed.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T 2 X : m m m m : n n n n

(X=1 : CD laser mode, 2 : DVD laser mode, 3 : BD(SL) laser mode)

(mmmm[mA] : Stored data, nnnn[mA] : Current value)

When the current value is more that BD: ±6[mA], DVD or CD: ± 12[mA] of saved data, it becomes the pickup

b

transducer's target.

In this case, replace the mechanism unit.

When the "2" button is pressed, the layer above the current layer is displayed. See "6.4 Stopping the mode".

(2) Error rate measurement mode

Press the "8" or "9" button to select [YY] .

Refer to [Table 1 - Error rate details].

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T Y Y F F F F F F F F F F

(YY : measurement mode, F : Address and error rate (When not set, "F" is displayed.)

Press the "1" button to begin error rate measurement. The address and error rate are displayed.

For a description of the displayed measurement results, see "Table 1: Error rate details".

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T Y Y m m m m m m

(YY : selection mode [71 to 94], m : address [PBA][HEX], l : error rate [COUNT/SEC] [DEC])

(Note) CD (4x-speed) : Renewal of data is carried out for every 300 frame.

Error rate of 75 frames is displayed.

DVD (1.6x-speed) : Renewal of data is carried out for every 80ECC block.

Error rate of 8ECC block is displayed.

BD (1.6x-speed) : Renewal of data is carried out for every 136LDC clusters block.

Error rate of 8LDC clusters block is displayed.

The mode chosen when selection mode was changed into the trace execution and the "1" button was pressed is

performed from the beginning.

When the "1" button is pressed without changing selection mode, the mode under selection is performed from the

beginning.

(If the "1" button is pressed, the address corresponding to the chosen mode will be searched again.)

The pause mode is set after tracing is completed.

When the "2" button is pressed, the layer above the current layer is displayed. See "6.4 Stopping the mode".

l l l l

28

Page 29

(3) Accumulated laser on time display mode

Press the "8" or "9" button to select [Y] and press the "1" button to set it.

The accumulated laser on time is displayed.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C Y m m m m m m h

(Y=1 : CD, 2 : DVD , 3 : BD, mmmmmm : Time(Fractions of hours are counted up one hour on the display.)

When the "2" button is pressed, the layer above the current layer is displayed. See "6.4 Stopping the mode".

---To clear the accumulated laser on time---

Press the "1" button while the accumulated laser on time is displayed ("TC1, "TC2", "TC3" ) until "TC4*clear??"

appears at the display.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 4 * c l e a r ? ?

If the "1" button is pressed, the accumulated laser on time of CD, DVD and BD is cleared.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T C 1 0 h

When "TC1", "TC2" or "TC3" is selected with the "8" or "9" button, "mmmmmm" is displayed as "0" so you

can check.

(4) Test mode cancel

A conrmation message is displayed. Press the "1" button to set, canceling the test mode.

FL Display (The display part of 13 digits)

1 2 3 4 5 6 7 8 9 10 11 12 13

T I 1 R e a l l y ?

When the "2" button is pressed, the layer above the current layer is displayed. See "6.4 Stopping the mode".

29

Page 30

6.4. Stopping the mode

When the "2" button is pressed, the layer above the current layer is displayed. The relationship between the different

modes and the display of the different layers is shown on the table below.

Mode 1 layer 2 layer 3 layer

Laser on/off (CD/DVD/BD) mode T2 LaserOnOff T2X mmmm nnnn Non

Error rate measurement mode T7 Error Rate TYYFFFFFFFFFF TYYmmmmmmllll

Accumulated laser on time display mode TC LaserOnTim TCY mmmmmmh TC4* clear??

Test mode cancel TI Test Exit TI1 Really? Non

6.5. About the OPEN/CLOSE (

) button

5

Even during the test mode, the tray is opened and closed when the "5" button is pressed.

6.6. Test mode detailed table

Table 1: Error rate details

Measurement

YY

71 The inner

72 The inner

73 The inner

74 The inner

75 The central

76 The central

77 The central

78 The central

79 The outer

80 The outer

81 The outer

82 The outer

83 The inner

position

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

2-layer

BIS error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. C2 uncorrectable

BIS error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. C2 uncorrectable

BIS error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. C2 uncorrectable

BIS error detection

signed number

Error rate display details for each media type

BD DVD CD

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

It is invalid. It is invalid. When this is selected for DVD or CD,

C1 error

detection number

error number

C1 error

detection number

error number

C1 error

detection number

error number

Remarks

T71 FFFFFFFFFF display.

CD, T72 FFFFFFFFFF display.

When this is selected for BD or DVD,

T74 FFFFFFFFFF display.

T75 FFFFFFFFFF display.

CD, T76 FFFFFFFFFF display.

When this is selected for BD or DVD,

T78 FFFFFFFFFF display.

T79 FFFFFFFFFF display.

CD, T80 FFFFFFFFFF display.

When this is selected for BD or DVD,

T82 FFFFFFFFFF display.

T83 FFFFFFFFFF display.

30

Page 31

Measurement

YY

84 The inner

85 The inner

86 The inner

87 The central

88 The central

89 The central

90 The central

91 The outer

92 The outer

93 The outer

94 The outer

position

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

2-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

circumference of

1-layer

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

BIS error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

BIS error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

LDC error detection

signed number

It is invalid. It is invalid. It is invalid. When this is selected for BD, DVD or

Error rate display details for each media type

BD DVD CD

PI error detection

number

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

It is invalid. It is invalid. When this is selected for DVD or CD,

PI error detection

number

It is invalid. When this is selected for 1-layer DVD

It is invalid. When this is selected for DVD 1-layer

It is invalid. When this is selected for DVD 1-layer

Remarks

CD, T84 FFFFFFFFFF display.

or CD, T85 FFFFFFFFFF display.

CD, T86 FFFFFFFFFF display.

T87 FFFFFFFFFF display.

CD, T88 FFFFFFFFFF display.

or CD, T89 FFFFFFFFFF display.

CD, T90 FFFFFFFFFF display.

T91 FFFFFFFFFF display.

CD, T92 FFFFFFFFFF display.

or CD, T93 FFFFFFFFFF display.

CD, T94 FFFFFFFFFF display.

* The inner circumference of the layer refers to the physical inner circumference for DVD parallel, the physical outer

circumference for the opposite case.

* The inner circumference of the layer refers to the physical outer circumference for DVD parallel, the physical inner

circumference for the opposite case.

31

Page 32

PROCEDURE FIRMWARE FOR UPGRADING THE VERSION OF THE FIRMWARE

You can update by downloading the latest version from the Internet.

1. Update from the Internet

1.1. preparation

(1) System requirements

• Internet Connection by Broadband Circuit

• Modem

• Router

• Ethernet cable (CAT-5 or greater recommended)

(2) Setting

Internet

Computer

Router

Modem

To WAN port

To LAN port

To LAN port

NET WORK

connector

LAN port/Ethernet connector

1.2. Checking and updating the rmware

Check if the latest rmware exists. You can also check approximately time required to complete an update.

(1) Press the "SETUP" button on the remote control to display the GUI menu.

(2) Use the cursor buttons to select "General Setting" → "System" → "Firmware Update" → "Update check".

(3) Press the "ENTER" button.

• If the rmware on the website is latest, proceed to (4) Press "Enter" Button.

• If the latest rmware has been already installed, press the "RETURN" button to return to SETUP menu.

(4) Press the "ENTER" button.

• When updating is completed, return to normal status about 20 seconds later.

--- Cautions on Firmware Update ---

• In order to update the rmware, you must have the correct system requirements and settings for a broadband Internet

connection.

• Do not turn off the power until updating is completed.

• Once updating starts, normal operations on this unit cannot be performed until updating is completed. Also, setting

items of the GUI menu of this unit or setting items of the image adjustment may be initialized.

Note down of the settings before updating, and set them again after updating.

32

Page 33

TROUBLE SHOOTING

1. Power (Power Board)

1. Power does not turn on.

Power does not turn on.

POWER_LED is not blinking red. Refer to "2. LED blinking".

Yes

Is the fuse of F501 normal?

Yes

Check 5VSTB(CN502#1).

Is output voltage about 5.2V?

Yes

Check PCON(CN502#2).

Is input voltage about 2V?

Yes

Check +5V(CN502#3).

Is outut voltage about 5.1V?

Yes

Check +12VA(CN502#9).

Is output voltage about +12V?

Yes

Check -12VA(CN502#11).

Is ouput about -12V?

Yes

Check +12VM(CN502#7).

Is output about +12V?

Yes

No

No

No

No

No

No

No

No

Check abnormalities of the circuit of a primary side.

(Such as D501,D502,D503,D504,Ce501,Q501,U501)

Defect parts should be exchanged.

After-repair Hughes is exchanged.

Refer to "3. Power board".

Check abnormalities of the connection circuit of

PCON. (Such as Q506)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Check abnormalities of the connection circuit of +5V.

(Such as Q512,Q505)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Check abnormalities of the connection circuit of +12V.

(Such as D511,Q510,Q509,Q508,Q507,ZD503)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Check abnormalities of the connection circuit of -12V.

(Such as D512,Q511,ZD504,U512)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Check abnormalities of the connection circuit of +12V.

(Such as Q507,Q508)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Abnormality of the board for MAIN, replace the MAIN

PCB.

33

Page 34

2. LED blinking

POWER_LED is blinking red.

PC0N (CN502#2) and +5V (CN502#3) are measured

simultaneously.

Before PCON is set to "L", +5V has not carried out

voltage drops.

Yes

PC0N (CN502#2) and +12VA (CN502#9) are

measured simultaneously.

Before PCON is set to "L", +5V has not carried out

voltage drops.

Yes

Abnormality of the board for MAIN, replace the MAIN

board.

3. Power board

No output +5VSTB(CN502#1).

No

No

Check abnormalities of the connection circuit of +5V.

(Such as Q512,Q505)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Check abnormalities of the connection circuit of +12V.

(Such as D511,Q510,Q509,Q508,Q507,ZD503)

Defect parts should be exchanged.

When there are no abnormalities in a POWER board,

MAIN PCB can be exchanged.

Where CN502 is removed, 5VSTB (CN502#1) is not

outputted.

Yes

There are no abnormalities in the connection circuit of

+5VSTB.

(Such as D509,U503,U502,U505,L550)

Yes

Check abnormalities of the circuit of a primary side.

(Such as D501,D502,D503,D504,Ce501,Q501,U501)

Defect parts should be exchanged.

No

No

Abnormality of the board for MAIN, replace the MAIN

board

Abnormality of the board for MAIN, replace the MAIN

board

34

Page 35

4. DISPLAY (Display Board)

FL TUBE doesn't light.

Does not appear when press the "DIMMER" on the

remote control.

Yes

CHeck VFD_RST(U2#9).

Is voltage more than 2.6V ?

Yes

Is VH(U2#6) set to the 29V~35V?

Yes

Check Between F-(U2#52) and F+(U2#1) .

Is voltage 3.78V~4.62V?

No

No

No

No

May be DIMMER was working.

Also, May be "PURE DIRECT" was working.

To replace the parts to check there is nothing wrong

with the connection circuit VFD_RST. (Such as a cable

of Q19, Q17, XP4, XP4) Abnormal when there is no

substrate to replace the MAIN PCB.

To replace the parts to check there is nothing wrong

with the circuit connection of VH. Such as cable, XP4

(ZD602, D609, Q16, U1, +12 V, XP4

Yes

Check F-(U2#52).

Is voltage 2.0V~3.0V?

Yes

Chek VDD(U2#7).

Is voltage 3.0V~3.6V?

Yes

Check the output signal to VSTB(U2#10),

VCLK(U211), VDATA(U2#12).

Is voltage set to "H"(more than 2.6V)

Yes

No

No

No

To replace the parts to check there is nothing wrong

with the connection circuit F +, of F-. Such as cable,

XP4 (U700, D610, D611, D612, +12 V, XP4

To replace the parts to check there is nothing wrong

with the connection circuit of VDD. (Such as a cable

of XP4, XP4)Abnormal when there is no substrate to

replace the MAIN PCB.

(U2 # 10), VCLK (U211), to replace the parts to check

there is nothing wrong with the connection circuit (U2

# 12) VDATA VSTB. (Such as a cable of XP4, XP4)

Abnormal when there is no substrate to replace the

MAIN PCB.

VFD and (U2), abnormality of the peripheral circuits.

Check the location of the abnormality, and correct it.

35

Page 36

5. HDMI

No picture or sound is output.

Is the set in "PURE DIRECT MODE" "Off"?

Yes

Is a contact part of HDMI JACK J1 normal?

Is there no damage around the contact where HDMI

cable are inserted?

Are there no bad soldering?

Yes

Is that the cable correctly inserted into the connector

XP1 11p of Main PCB?

Yes

Is that supplied from 5V 3pin of XP1 of Main PCB?

Yes

Replace Main PCB.

No

Set the "PURE DIRECT MODE" "Off".

No

Replace the HDMI JACK.

No

To be inserted into the XP1 the "11p" cable

No

Refer to 2.LED blinking.

6. Network

Cannot connect to Internet

Is there nothing wrong with the ETHER JACK P1 of

Main PCB?

Is there no damage around the contact where

Ethernet cable are inserted.

Are there no bad solder joints?

Yes

Is that the cable correctly inserted into the connector

XP1 11p of Main PCB?

Yes

Is that is supplied from 5V 3pin of XP1 of Main PCB?

Yes

No

Replace the ETHER JACK.

No

To be inserted into the XP1 the 11p cable.

No

Refer to 2.LED blinking.

Replace Main PCB.

36

Page 37

7. USB

Does not recognize the USB.

Is there nothing wrong with the USB connector P1 of

the Display PCB?

Is there no damage around the contact where USB

cable are inserted.

Are there no bad solder joints?

Yes

No

Replace the F.PANEL ASSY

Is there is nothing wrong with the 4P cable JP1 of

Display PCB?

Does disconnection of the cable?

Are there bad solder joints?

Yes

Is the cable correctly inserted into the connector 4P

XP3 of Main PCB?

Yes

Is that supplied from 5V 3pin of XP1 of Main PCB?

Yes

Replace Main PCB.

8. No Audio output

There is no output from the (2P RCA) ANALOG

output.

No

Replace the F.PANEL ASSY

No

4p cable to be inserted into the XP3.

No

Refer to No.2 LED blinking.

Terminal P2 pin jack on the Main PCB (or P3, P4)

There is nothing wrong with the. Not bad, abnormal

soldering or the like.

Yes

Is 11p cable inserted properly to XP1 of Main PCB?

Yes

Does XP1 of Main PCB(#9:+12 V, #11:-12V) supply

voltage?

Yes

Replace Main PCB.

No

No

No

37

Replace the RCA PIN JACK.

11p cable to be inserted into the XP1.

Refer to Power Board

No.2 LED blinking.

Page 38

9. Disc playback error

Disc playback error

Is 45P FFC inserted properly to J2 of Main PCB? 45P FFC inserted into the J2.

Yes

Is 9P FFC inserted properly to J4 of Main PCB? 9P FFC inserted into J4.

Yes

Is 5P PH connector inserted properly to X10 of Main

PCB?

Yes

Is that 12V supplied from the XP10 7pin of Main PCB

No

No

No

No

5P PH connector to be inserted into theX10.

Refer to 1.Power Board

Check +12VM(CN502#7). Is it output about +12V?

Yes

Is that output of 8V from 2pin of U17 Main PCB?

Yes

Refer to "HOW TO REPLACE THE MAIN PCB &BD

MECHA OR BD MECHA"

No

Replace Main PCB.

38

Page 39

BLOCK DIAGRAM

A

4 4

B

P2

R

L

RCA

Audio AMP&LPF

NJM4565

AUDIO DAC

+12VA

-12V

AUDIO_5V

L

FOR UD5007

C

+5V_STBY

R

HDMI_5V

NJM2882

HDMI OUTPUT

HDMI

PESD_TPD4S010B

PM1781

J1

D

Ethernet

LFE8634

P1

E

OUT

IN

W.remote

OUT

IN

IR SWITCH BOARD

100-240V 50/60Hz

POWER AC IN

RC5

FOR UD5007

W.remote

1.1V

1.5V

3.3V

IIS

IIS

3

IIC

MCU

CS8966

MCU_3.3V

G9091-330T11U

MT8555/DPBG

J2

45PIN*0.5

3.3V

DVD LOADER

2 2

ASA F-9829D1+Cover + SONY470AAB

J3

9PIN*1.0

AA+

BB+

GND

W

V

U

COMMON

LOADLOAD+

GND

TRAYIN#

XP4

4PIN*2.0

+12V

VCC

MOTER

DRIVER

TI2050G4

1 914

VCC

A3.3V

G556B1

8Gb

N FLASH

VCC

USB_5V

1 4

XP2 USB

4PIN*2.0

1Gbit

DDR3

1Gbit

DDR3

1Gbit

DDR3

1Gbit

DDR3

1.5V

18PIN*1.0

XP3

18

EEPROM

POWER_K

3.3V

1.5V

1.1V

AUDIO_5V

3.3V LDO

G966A-25ADJ

DC-DC

EUP3485

DC-DC

AT1526

78L05

1

+5V_STBY

5V

12V

XP1

11PIN*2.5

11

NCP1271

POWER

SUPPLY

1

+5V_STBY

PS_ON#

5V

5V

GND

GND

+12V

GND

+12VA

GND

-12V

1

XS201

11PIN*2.5

11

3

MAIN BOARD(MP1)

1

1 1

A

GREEN RED

ON / STANDBY

PURE DIRECT

B

VFD

VFD WITH DRIVER IC

SPI

(Futaba:014BT102GINK)

IR

38kHz

C

3.3V

GND

KEY_IN_A

KEY_IN_B

STANDBY_KEY

MCU_LED_CTRL_1

MCU_LED_CTRL_2

VSTB

VCLK

+12V

VDATA

+5V_STBY

PLAY STOP

OPEN/CLOSE

DISPLAY

D

VFD_RST

IR_IN

W_REMOTE

18

16PIN*2.0MM

PREV

BOARD

NEXT

XS304 4PIN*2.0

USB

USB

BOARD

E

39

Page 40

POWER BLOCK DIAGRAM

+12VM

(U501)

NCP1271

PCON

PCON

(U512)

L79L12ACZ

+12VA

-12VA

+5VSTB

MAIN

BOARD

+5V(VCC

40

PCON

(U503)

TL431

PCON

STANDBY ON/OFF

Page 41

PRINTED WIRING BOARDS

181716151413121110987654321

MAIN

(COMPONENT SIDE)

MAIN

(FOIL SIDE)

A

B

C

D

E

F

G

H

I

J

K

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

L

M

41

Page 42

FRONT

(COMPONENT SIDE)

181716151413121110987654321

A

B

C

D

E

PWD1G

(COMPONENT SIDE)

F

G

H

I

J

42

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

K

L

M

Page 43

FRONT

(FOIL SIDE)

181716151413121110987654321

A

B

C

D

E

PWDG1

(FOIL SIDE)

F

G

H

I

J

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

K

L

M

43

Page 44

181716151413121110987654321

IRA1G

(COMPONENT SIDE)

USE1G

(COMPONENT SIDE)

IRA1G

(FOIL SIDE)

USE1G

(FOIL SIDE)

A

B

C

D

E

F

G

H

I

J

K

L

44

鉛フリー半田

半田付けには、鉛フリー半田 (Sn-Ag-Cu) を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

M

Page 45

87654321

+12VA/0.1A

CE560

CE560

+

+

470uF/16V

470uF/16V

+12VM

R573NCR573

NC

0.1uF/50V/X7R

0.1uF/50V/X7R

MAIN

BOARD

1

2

3

4

5

6

7

8

9

10

11

12

12PIN/2.5mm

12PIN/2.5mm

R572NCR572

NC

0.1uF/50V/X7R

0.1uF/50V/X7R

C557

C557

01 +5VSTB

02 PCON

03 +5V

04 +5V

05 GND

06 GND

07 +12VM

08 GND

09 +12VA

10 GND

11 -12VA

12 GND

+12VA

C559

C559

+12VM/0.5A

+5VSTB

PCON

+5V

+12VM

+12VA

-12VA

CN503

CN503

7PIN/2.5mm

7PIN/2.5mm

1

2

3

4

5

6

7

1

2

3

4

CN504

CN504

4PIN/2.5mm

4PIN/2.5mm

1

2

3

4

5

6

7

1

2

3

4

Upper model

01 +5VSTB

02 PCON

03 +5V

04 +5V

05 GND

06 GND

07 +12VM

01 +12VA

02 GND

03 -12VA

04 GND

A

B

C

D

L552 3.3uH/3AL552 3.3uH/3A

CY503

CY503

470pF/250VAC

470pF/250VAC

11

10

10

12

8

D509

D509

10A60V

10A60V

9

U502

U502

R5271KR527

JP507NCJP507

NC

D511

D511

SR3100/3A/100V

SR3100/3A/100V

D512 FR107/1A/1000VD512 FR107/1A/1000V

C550

C550

2200pF/50V/X7R

2200pF/50V/X7R

R55022R550

22

+

+

CE550

CE550

1500uF/16V

1500uF/16V

R551

R551

470

470

R552

R552

2.2K

2.2K

3

U503

U503

1

H431

H431

2

+M12V

ZD505

ZD505

BZX79C15

BZX79C15

1K

R56222R562

22

C555

C555

1000pF/1KV

1000pF/1KV

L550 3.3uH/3AL550 3.3uH/3A

CE551

CE551

1500uF/16V

1500uF/16V

+

+

C551

C551

0.1uF/50V/X7R

0.1uF/50V/X7R

R576NCR576

-12VA

BZX79C15

BZX79C15

ZD506

ZD506

CE555

CE555

+

+

1000UF/25V

1000UF/25V

CE558

CE558

+

+

220uF/25V

220uF/25V

NC

CE561

CE561

+

+

1000UF/25V

1000UF/25V

R569

R569

100K

100K

Q511

Q511

NPN_MMBT8050C

NPN_MMBT8050C

+

+

CE552

CE552

1000uF/16V

1000uF/16V

R553

R553

10K

10K

R555

R555

11.3K/1%

11.3K/1%

R563 10KR563 10K

R554

R554

12.1K/1%

12.1K/1%

R565

2.2K

2.2K

Q509

Q509

NPN_3DG3904M

NPN_3DG3904M

R570 2.2KR570 2.2K

R571 0R571 0

0.1uF/50V/X7R

0.1uF/50V/X7R

R556

R556

10K

10K

Q505

Q505

NPN_3DG3904M

NPN_3DG3904M

R557 1KR557 1K

Q506

Q506

NPN_3DG3904M

NPN_3DG3904M

R558

R558

10K

10K

C556 2200pF/50V/X7RC556 2200pF/50V/X7R

ZD504 20HSCZD504 20HSC

U512 L79L12ACZU512 L79L12ACZ

2

VIN

+5VSTB

C561

C561

D510

D510

MBRX140/40V/1A

MBRX140/40V/1A

R559 4.7KR559 4.7K

C552

C552

0.1uF/50V/X7R

0.1uF/50V/X7R

Q508

Q508

PNP_3CG3906M

PNP_3CG3906M

R566 2.2KR566 2.2K

Q510

Q510

NPN_3DG3904M

NPN_3DG3904M

VOUT

GND

1

R564

R564

10K

10K

12-S

L553 7.5mmL553 7.5mm

3

CE559

CE559

+

+

100uF/16V

100uF/16V

Q512

Q512

P_PMK35EP

P_PMK35EP

1

2

3

4

C560 1uF/63VC560 1uF/63V

PCON

Q507 P_AP6679GIQ507 P_AP6679GI

DS

G

C562

C562

1uF//50V/X7R

1uF//50V/X7R

+12VA

-12VA

R574NCR574

C558

C558

NC

0.1uF/50V/X7R

0.1uF/50V/X7R

8

7

6

5

CE554

CE554

470uF/16V

470uF/16V

+

+

R560

R560

22K

22K

R561

R561

10K

10K

+M12V

ZD503

ZD503

BZX79C11

BZX79C11

R567

R567

150

150

R568

R568

200

200

-12VA/0.1A

+5V

C554

C554

0.1uF/50V/X7R

0.1uF/50V/X7RR518

R575NCR575

NC

12-S

C553

C553

0.1uF/50V/X7R

0.1uF/50V/X7R

L551 3.3uH/3AL551 3.3uH/3A

CE557

CE557R565

CE556

CE556

+

+

+

+

470uF/16V

470uF/16V

1000uF/16V

1000uF/16V

1

+5VSTB

2

PCON

+5V/2.5A

+12VM

+12VA

-12VA

3

4

5

6

7

8

9

10

11

12

CN502

CN502

CY505NCCY505

NC

D504

D504

D503

D503

RL207/2A/1000V

RL207/2A/1000V

RL207/2A/1000V

D501

D501

RL207/2A/1000V

RL207/2A/1000V

R503 NCR503 NC

R501 NCR501 NC

CX501 0.1uF/275VACCX501 0.1uF/275VAC

CX502 NCCX502 NC

CY501

CY501

100pF/250VAC

100pF/250VAC

RV501 VDR/470VRV501 VDR/470V

F501

F501

FUSE_T2AL/250V

FUSE_T2AL/250V

CN501

CN501

2PIN/7.92mm

2PIN/7.92mm

90-264VAC&50/60Hz INPUT

RL207/2A/1000V

RL207/2A/1000V

RL207/2A/1000V

LF501

LF501

30mH

30mH

112

D502

D502

optional

2

0.1uF/275VAC

0.1uF/275VAC