Marantz SA-7001-KI Service Manual

SA7001KI

Service

SA7001KI /N1B/N1S

Manual

POWERON/OFF

SECTION 1 PAG E

1. TECHNICAL SPEC I FI CA TIONS AND UPDATE DISC ....................................................... 1-1

2. SERVICE HINTS AND TOOLS .......................................................................................... 1-2

3. WARNING AND LASER SAFETY IN STRUC TIONS .......................................................... 1-3

4. TAKING THE DISC OUT OF EMERGENCY ..................................................................... 1-4

5. UPDATA FIRMWARE ......................................................................................................... 1-5

6. SERVICE MODE ................................................................................................................ 1-6

7. BLOCK DIAGRAM ............................................................................................................. 1-7

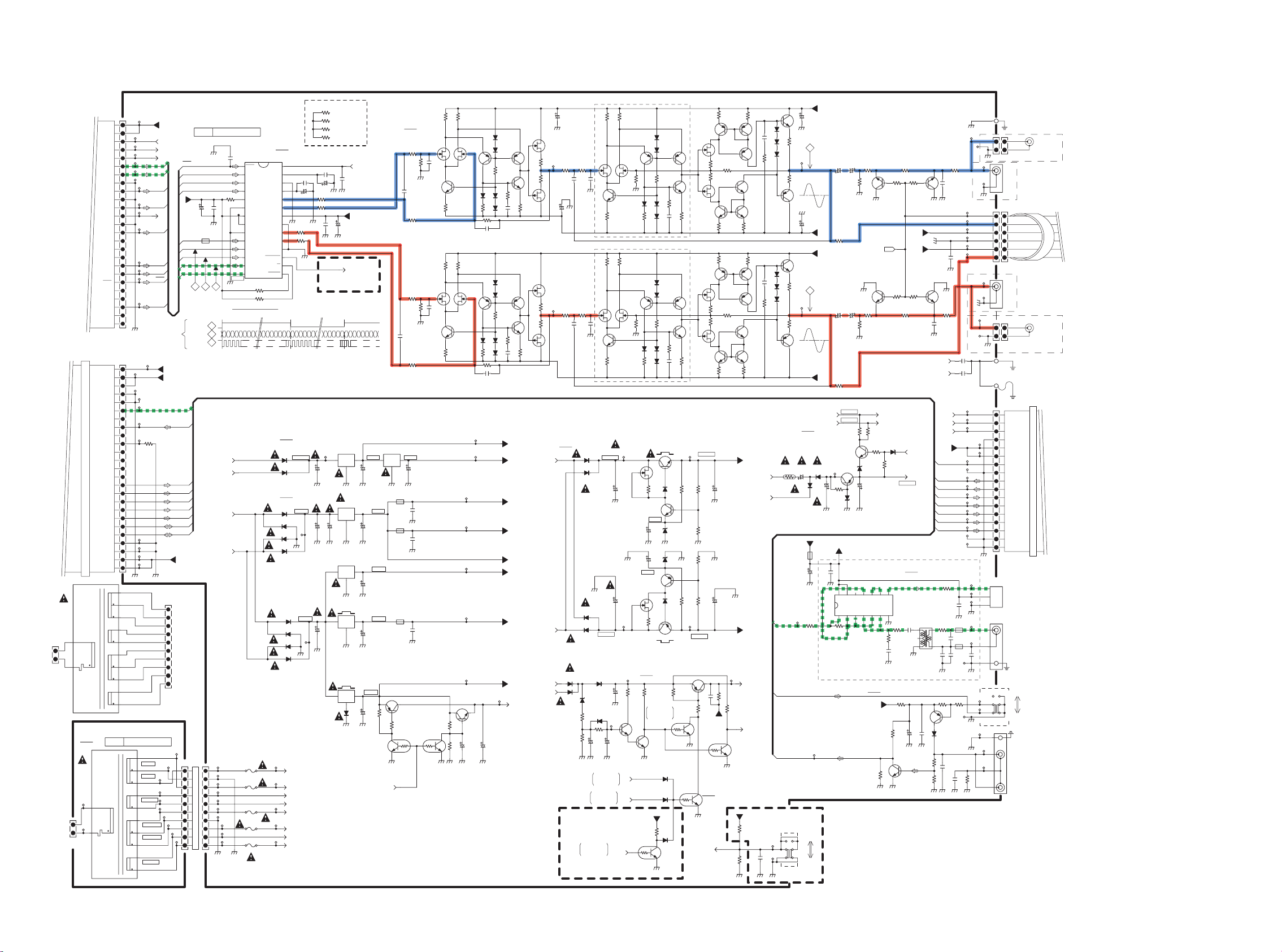

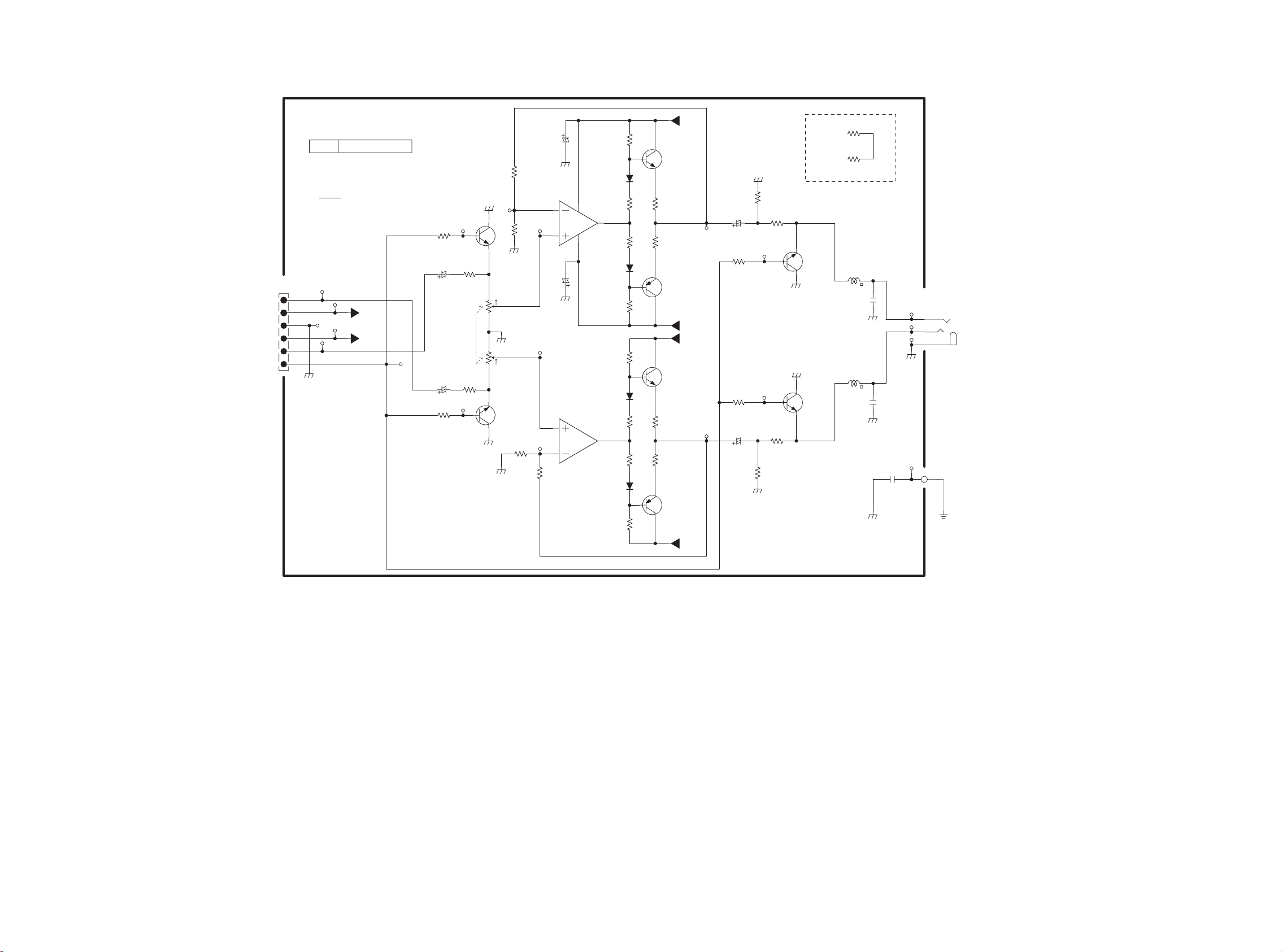

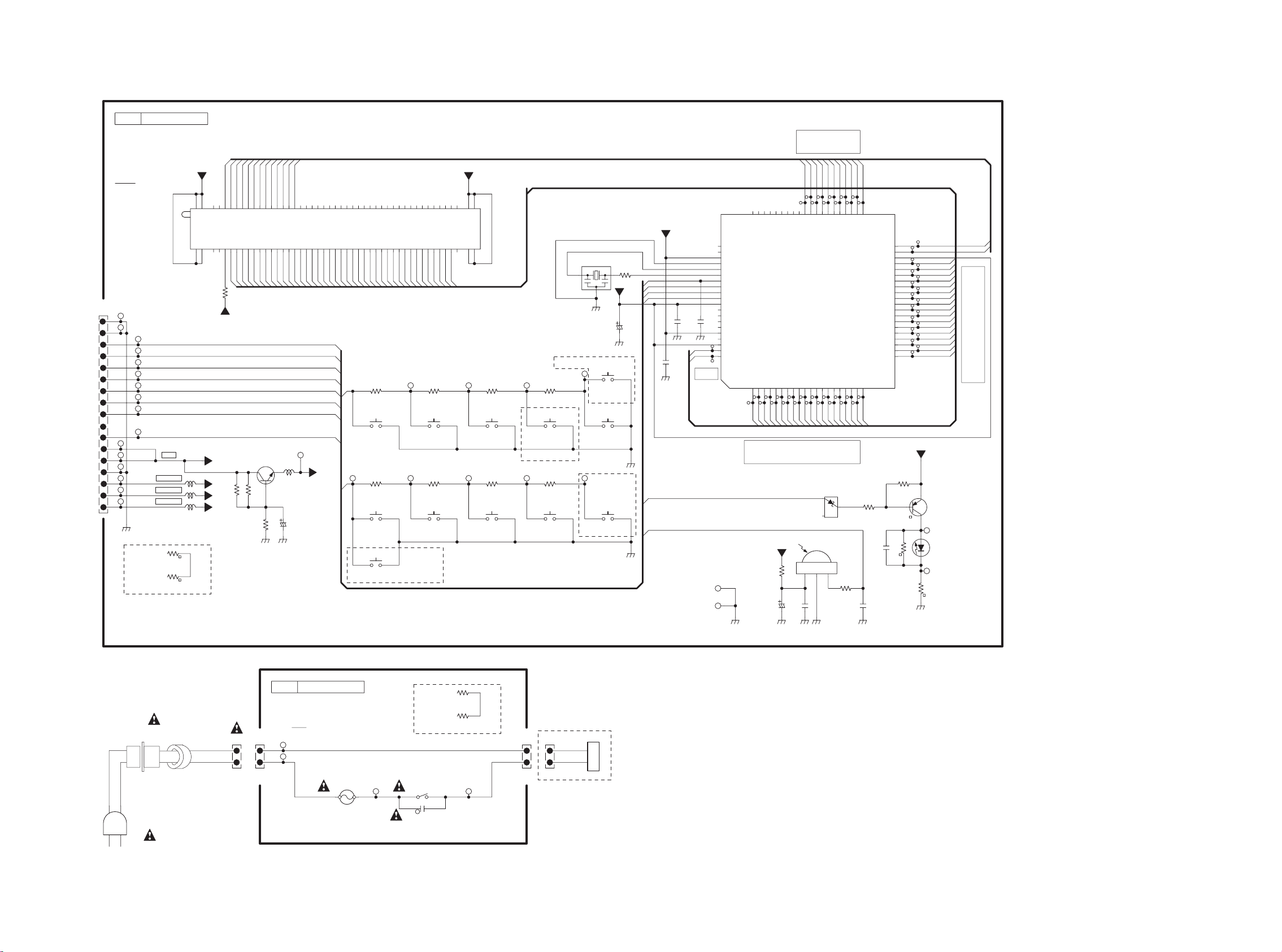

8. SCHEMATIC DIAGRAM ..................................................................................................... 1-9

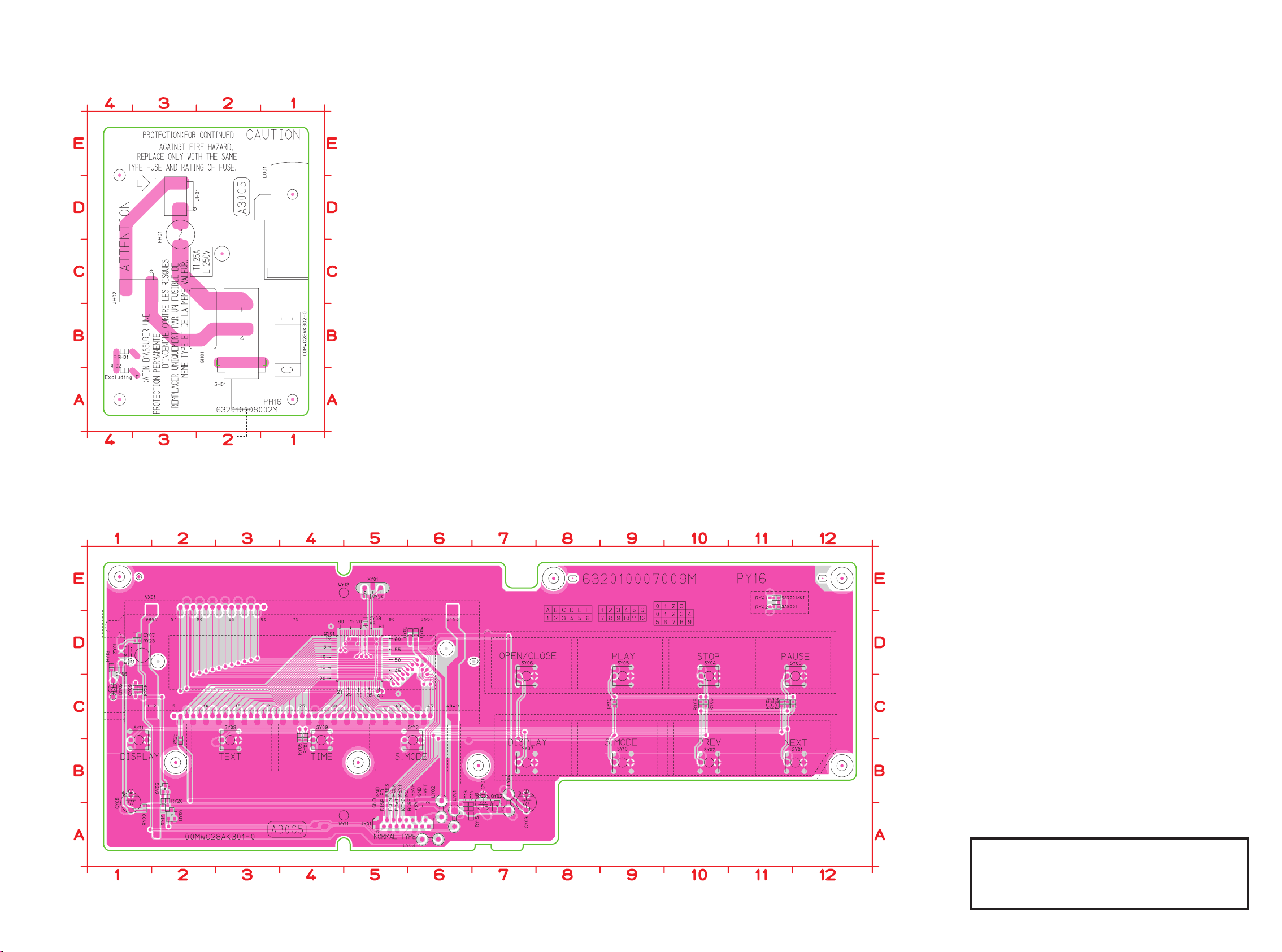

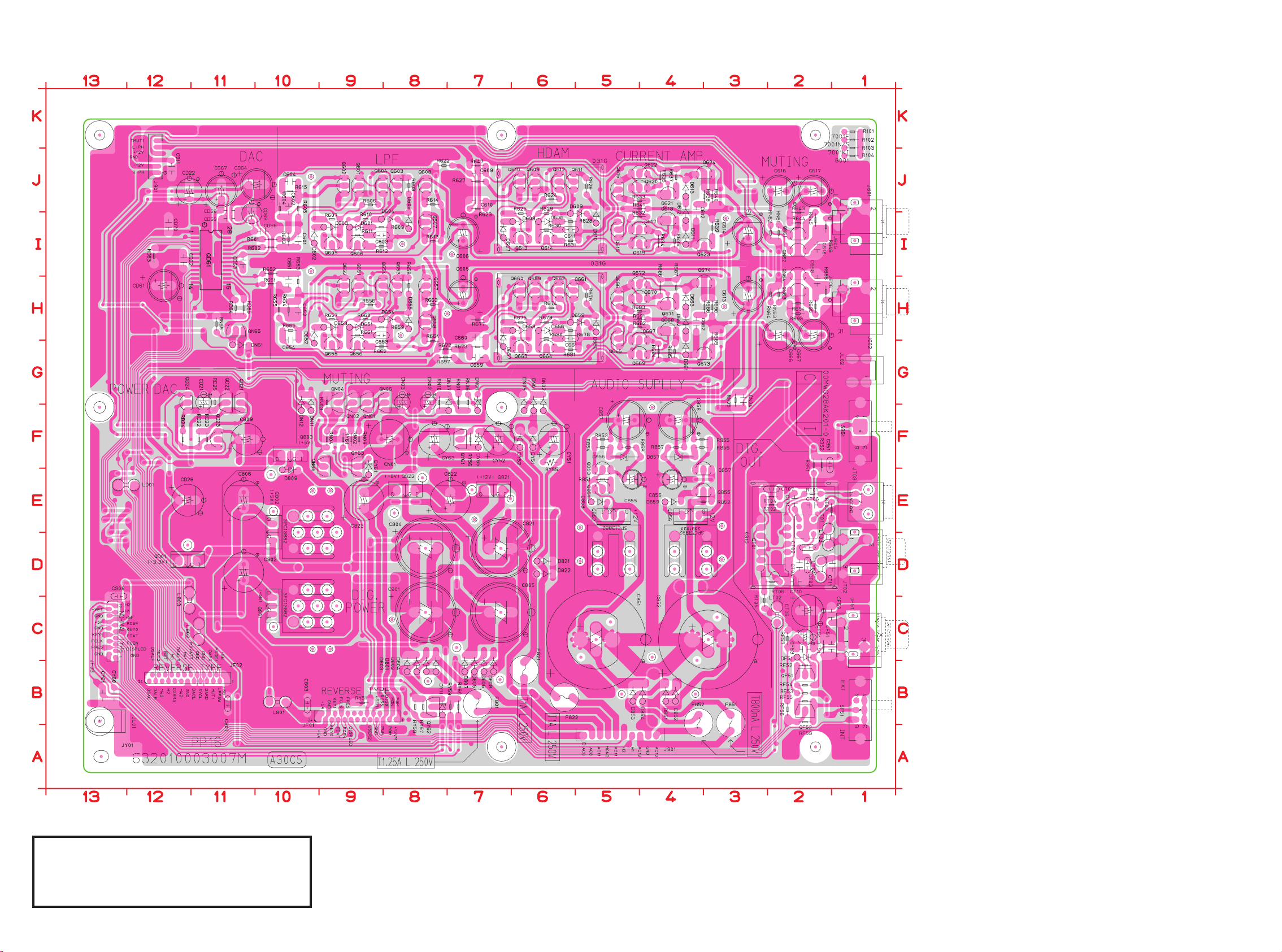

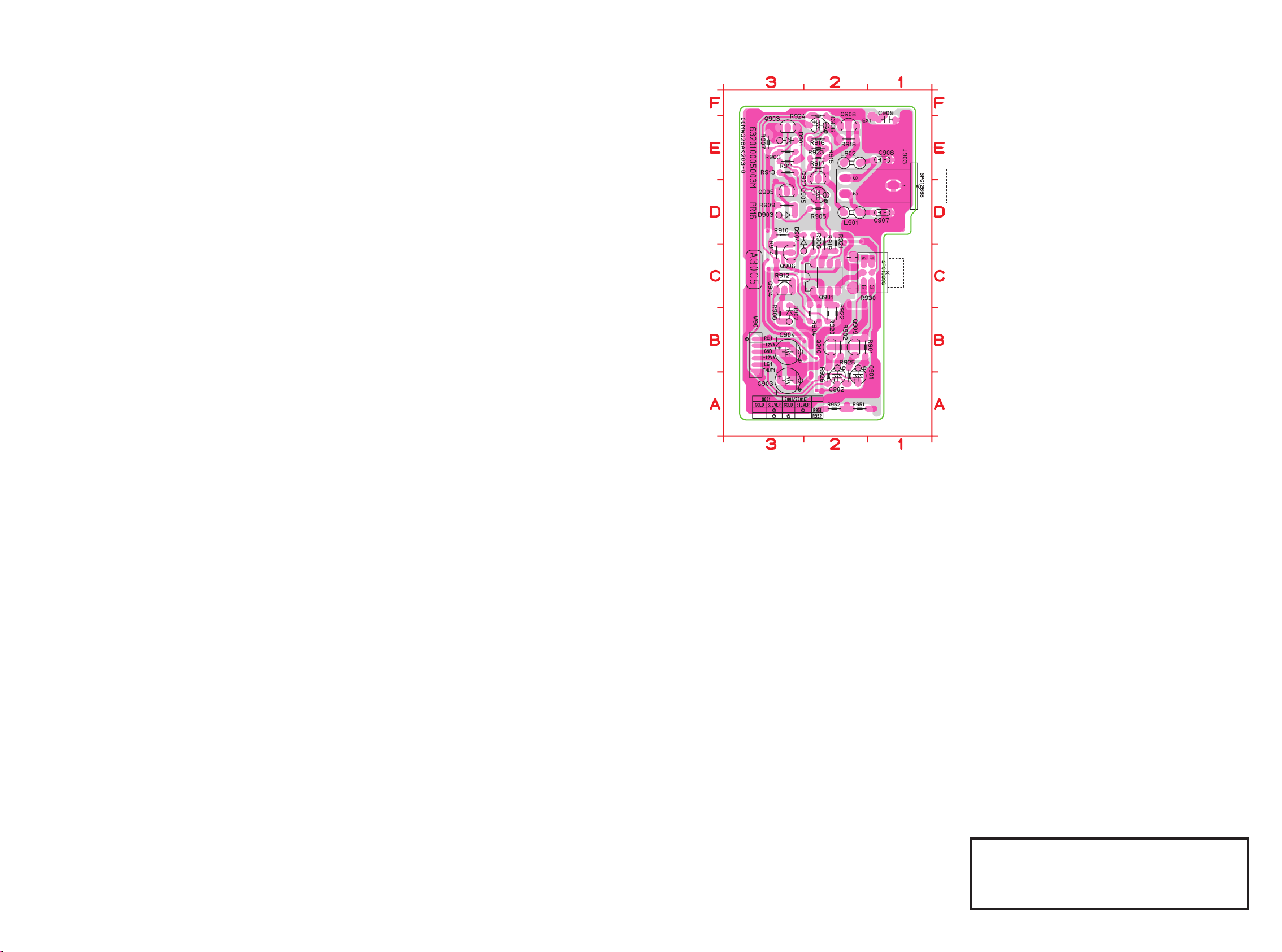

9. PARTS LOCATION ........................................................................................................... 1-15

10. MICROPROCESSOR AND IC DATA ................................................................................ 1-21

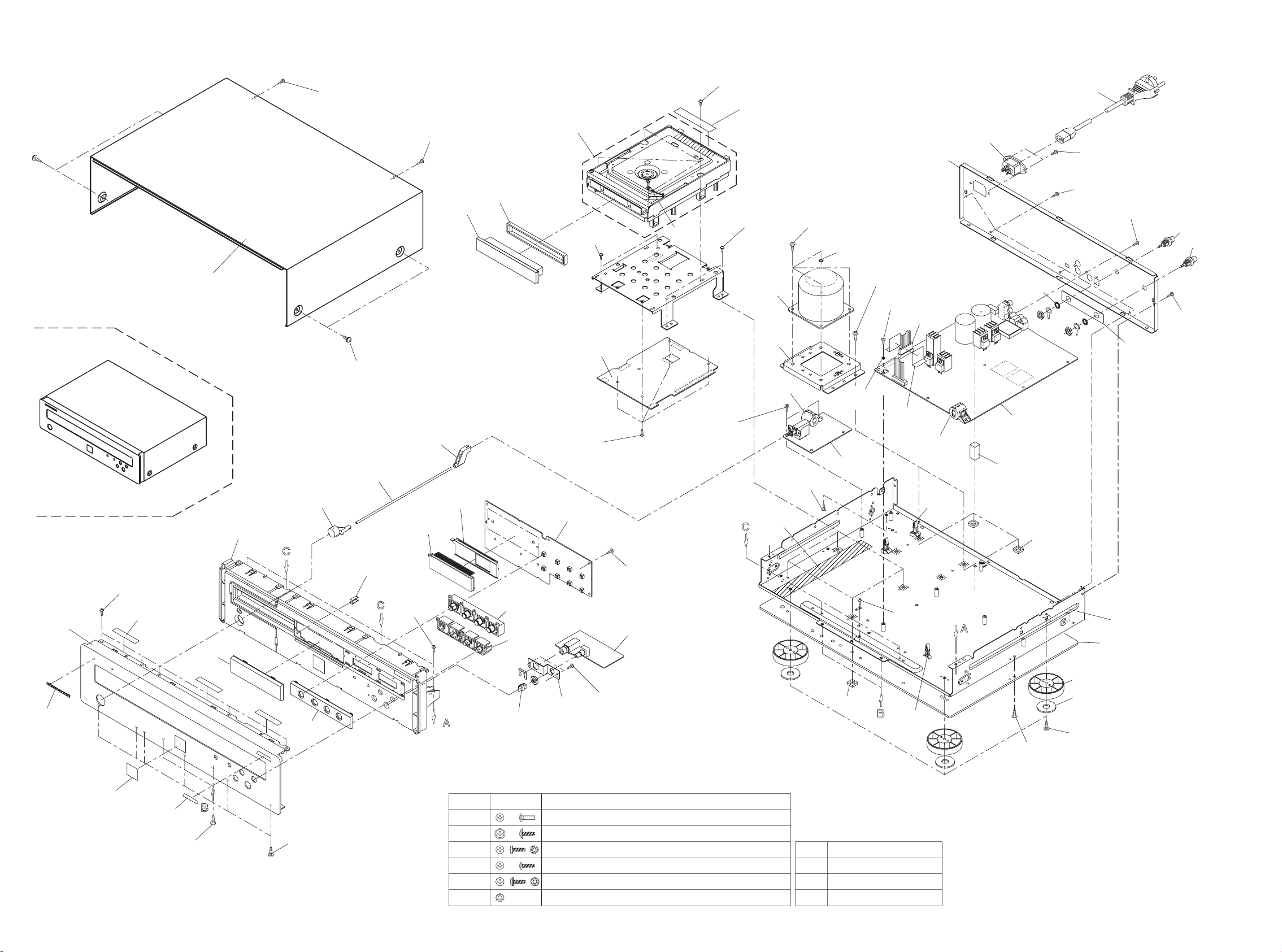

11. EXPLODED VIEW AND PARTS LIST .............................................................................. 1-25

12. ELECTRICAL PARTS LIST ............................................................................................. 1-28

SUPERAUDIO CD PLAYER SA7001

RNDM TRKAÐ

B

AMS

PROG

ALL TOTAL SING

REMAIN SACD

1

1

TEXT

2 3 4 5 6 78 9 10 1112 13 14 15 16 17 18 19 20

STEREO

TABLE OF CONTENTS

Super Audio CD Player

SOUNDMODEDISPLAY

SECTION 2 (MECHA LOADER AND MECHA TRAVERSE)

1. EXPLODED VIEW AND PARTS LIST ................................................................................ 2-2

SECTION 3 (SUPER AUDIO CD PWB MODULE)

1. IC DATA .............................................................................................................................. 3-2

2. BLOCK DI A GRAM ........................................................................................................... 3-23

3. SCHEMATIC DIAGRAM ................................................................................................... 3-25

4. PARTS LOCATION ........................................................................................................... 3-37

5. ELECTRICAL PARTS LIST .............................................................................................. 3-41

Please use this service manual with referring to the user guide ( D.F.U. ) without fail.

SA7001KI

Printed on 100% Recycled Paper

Part no. 90M28AK855020

Printed in Japan

First Issue 2006.02

MZ

MARANTZ DESIGN AND SERVICE

Using superior design and selected high grade components,

Only original

MARANTZ

parts can insure that your

MARANTZ

MARANTZ

product will continue to perform to the specifi cations for which

company has created the ultimate in stereo sound.

it is famous.

Parts for your

MARANTZ

ORDERING PARTS :

equipment are generally available to our National Marantz Subsidiary or Agent.

Parts can be ordered either by mail or by Fax.. In both cases, the correct part number has to be specifi ed.

The following information must be supplied to eliminate delays in processing your order :

1. Complete address

2. Complete part numbers and quantities required

3. Description of parts

4. Model number for which part is required

5. Way of shipment

6. Signature : any order form or Fax. must be signed, otherwise such part order will be considered as null and void.

USA

MARANTZ AMERICA, INC

1100 MAPLEWOOD DRIVE

ITASCA, IL. 60143

USA

PHONE : 630 - 741 - 0300

FAX : 630 - 741 - 0301

AUSTRALIA

QualiFi Pty Ltd,

24 LIONEL ROAD,

MT. WAVERLEY VIC 3149

AUSTRALIA

PHONE : +61 - (0)3 - 9543 - 1522

FAX : +61 - (0)3 - 9543 - 3677

EUROPE / TRADING

MARANTZ EUROPE B.V.

P. O. BOX 8744, BUILDINGSILVERPOINT

BEEMDSTRAAT 11, 5653 MA EINDHOVEN

THE NETHERLANDS

PHONE:+31-40-2507844

FAX : +31 - 40 - 2507860

THAILAND

MRZ STANDARD CO., LTD

746 - 754 MAHACHAI ROAD.,

WANGBURAPAPIROM, PHRANAKORN,

BANGKOK, 10200 THAILAND

PHONE:+66-2-2229181

FAX : +66 - 2 - 224 6795

CANADA

MARANTZ CANADA INC.

5-505 APPLE CREEK BLVD.

MARKHAM, ONTARIO L3R 5B1

CANADA

PHONE:905-415-9292

FAX : 905 - 475 - 4159

SINGAPORE

WO KEE HONG DISTRIBUTION PTE LTD

No.1 JALAN KILANG TIMOR

#08-03 PACIFIC TECH CENTRE

SINGAPORE 159303

PHONE:+6563760338

FAX : +65 6376 0166

NEW ZEALAND

WILDASH AUDIO SYSTEMS NZ

14 MALVERN ROAD MT ALBERT

AUCKLAND NEW ZEALAND

PHONE :+64-9-8451958

FAX :+64-9-8463554

JAPAN

D&M Holdings Inc.

D&M BUILDING, 2-1 NISSHIN-CHO,

KAWASAKI-KU, KAWASAKI-SHI,

KANAGAWA, 210-8569 JAPAN

TAIWAN

PAI- YUING CO., LTD.

6THFLNO, 148 SUNGKIANG ROAD,

TAIPEI, 10429, TAIWAN R.O.C.

PHONE:+886 - 2 - 25221304

FAX : +886 - 2 - 25630415

MALAYSIA

WO KEE HONG ELECTRONICS SDN. BHD.

2ND FLOOR BANGUNAN INFINITE CENTRE

LOT 1, JALAN 13/6, 46200 PETALINGJAYA

SELANGOR DARUL EHSAN, MALAYSIA

PHONE:+60-3-79548088

FAX :+60-3-79547088

KOREA

MARANTZ KOREA CO., LTD.

ROOM 604, ELECTRO OFFICE, 16-58,

HANGGANG-RO 3GA, YONGSAN-KU,

SEOUL, 140-013, KOREA

PHONE:+82-2-323-2155

FAX : +82-2-323-2154

CHINA

MARANTZ SHANGHAI TRADING LTD.

ROOM.506 SHANGHAI LIGHT INDUSTRY MANSION

1578NANJING(WEST) ROAD SHANGHAI

CHINA

TEL : 021 - 6248 -1064

FAX : 021 - 6248 -3565

SHOCK, FIRE HAZARD SERVICE TEST :

CAUTION : After servicing this appliance and prior to returning to customer, measure the resistance between either primary AC

cord connector pins ( with unit NOT connected to AC mains and its Power switch ON ), and the face or Front Panel of product

and controls and chassis bottom.

Any resistance measurement less than 1 Megohms should cause unit to be repaired or corrected before AC power is applied,

and verifi ed before it is return to the user/customer.

In case of diffi culties, do not hesitate to contact the Technical

Department at above mentioned address.

060209MZ

1. TECHNICAL SPECIFICATIONS AND UPDATE DISC

Super Audio CD CD

Audio Characteristics

Analog output

Channels 2channels 2channels

Frequency range 2Hz — 100kHz 2Hz — 20kHz

Frequency characteristics 2Hz — 50kHz (-3dB) 2Hz — 20kHz

Dynamic range 112dB More than 100dB

THD (1kHz) 0.002% 0.002%

Wow & Flutter Precision of quartz Precision of quartz

Output level 2.3V RMS stereo 2.3V RMS stereo

Digital output

Output level (Cinch JACK) — 0.5Vp-p (75Ω)

Output level (Optical) — -19dBm

Headphone output level 0.5W / 32Ω (max, Vol.) 0.5W / 32Ω (max, Vol.)

Optical Readout System

Laser AlGaAs AlGaAs

Wave length 650nm 780nm

Signal format 1-bit DSD 16-bit linear PCM

Sampling frequency 2.8224MHz 44.1kHz

Power Supply

Input Voltage, Frequency [/N] ......................................................................... AC 230V 50Hz

Power Consumption ....................................................................................................... 19W

Cabinet, etc.

Dimensions ........................................................................................... 440 × 128 × 339mm

Net weight .....................................................................................................................7.7kg

Operating temperatures .................................................................................. +5°C ~ +35°C

Operating humidity .............................................................................5 ~ 90% (without dew)

Accessories

• Remote control unit (RC7001SA) ......................................................................................1

Dimensions (Width × Height × Depth) ............................................. 48 × 25.7 × 145mm

Net weight (without Batteries) ...................................................................................160g

• AAA (R03) Batteries ..........................................................................................................2

• AC Power cord ...................................................................................................................1

• Audio cable ...............................................................................................................1 pairs

• Remote connection Cable ................................................................................................1

• User’s Guide ......................................................................................................................1

Dimensions (unit: mm)

12

440

SUPER AUDIO CD PLAYER SA7001

RNDM TRKA–

PROG

1

TEXT

2 3 45 67 89 10 11121314 15161718 1920

B

ALL TOTAL SING

AMS

REMAIN SACD

1

STEREO

SOUND MODE

110 .0

SA7001: 126.5

22.5

SA7001: 331

SA7001 KI: 334.5

4.5

SA7001 KI: 128.0

SA7001: 335.5

SA7001 KI: 339.0

SA7001: 331

SA7001 KI: 334.5

SA7001: 16.5

SA7001 KI: 18.0

UPDATE DISC

Update of the CPU (IC731) ....................................................................... 90M-SA7001DVR

1-1

2. SERVICE HINTS AND TOOLS

SERVICE HINTS

SERVICE TOOLS

Audio signals disc 4822 397 30184

Disc without errors (SBC444)+

Disc with DO errors, black spots and fingerprints (SBC444A) 4822 397 30245

Disc (65 min 1kHz) without no pause 4822 397 30155

Max. diameter disc (58.0 mm) 4822 397 60141

Torx screwdrivers

Set (straight) 4822 395 50145

Set (square) 4822 395 50132

13th order filter 4822 395 30204

DVD test disc (PAL) 4822 397 10131

DVD test disc (NTSC) ALMEDIO TDV-540

1-2

3. WARNING AND LASER SAFETY INSTRUCTIONS

GB

WARNING

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce

life drastically.

When repairing, make sure that you are

connected with the same potential as the

mass of the set via a wrist wrap with

resistance.

Keep components and tools also at this

potential.

F

ATTENTION

D

WARNUNG

I

WAARSCHUWING

AVVERTIMENTO

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor elektrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie

kan de levensduur drastisch doen

verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tous les IC et beaucoup d’autres semiconducteurs sont sensibles aux décharges

statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution

n’est prise a leur manipulation.

Lors de réparations, s’assurer de bien être

relié au même potentiel que la masse de

l’appareil et enfiler le bracelet serti d’une

résistance de sécurité.

Veiller a ce que les composants ainsi que les

outils que l’on utilise soient également a ce

potentiel.

GB

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

NL

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

über ein Pulsarmband mit Widerstand mit

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

auf diesem Potential.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente

ridatta in caso di non osservazione della piu

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello

della massa dell’apparecchio tramite un

braccialetto a resistenza.

Assicurarsi che i componenti e anche gli

utensili con quali si lavora siano anche a

questo potenziale.

F

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

LASER SAFETY

This unit employs a laser. Only a qualified service person should remove the cover or attempt to service this

device, due to possible eye injury.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURE OTHER THAN THOSE

SPECIFIED HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will increase eye hazard.

Repair handling should take place as much as possible with a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

1-3

Æ

TTELSE FOR STRÅLING

030804ecm

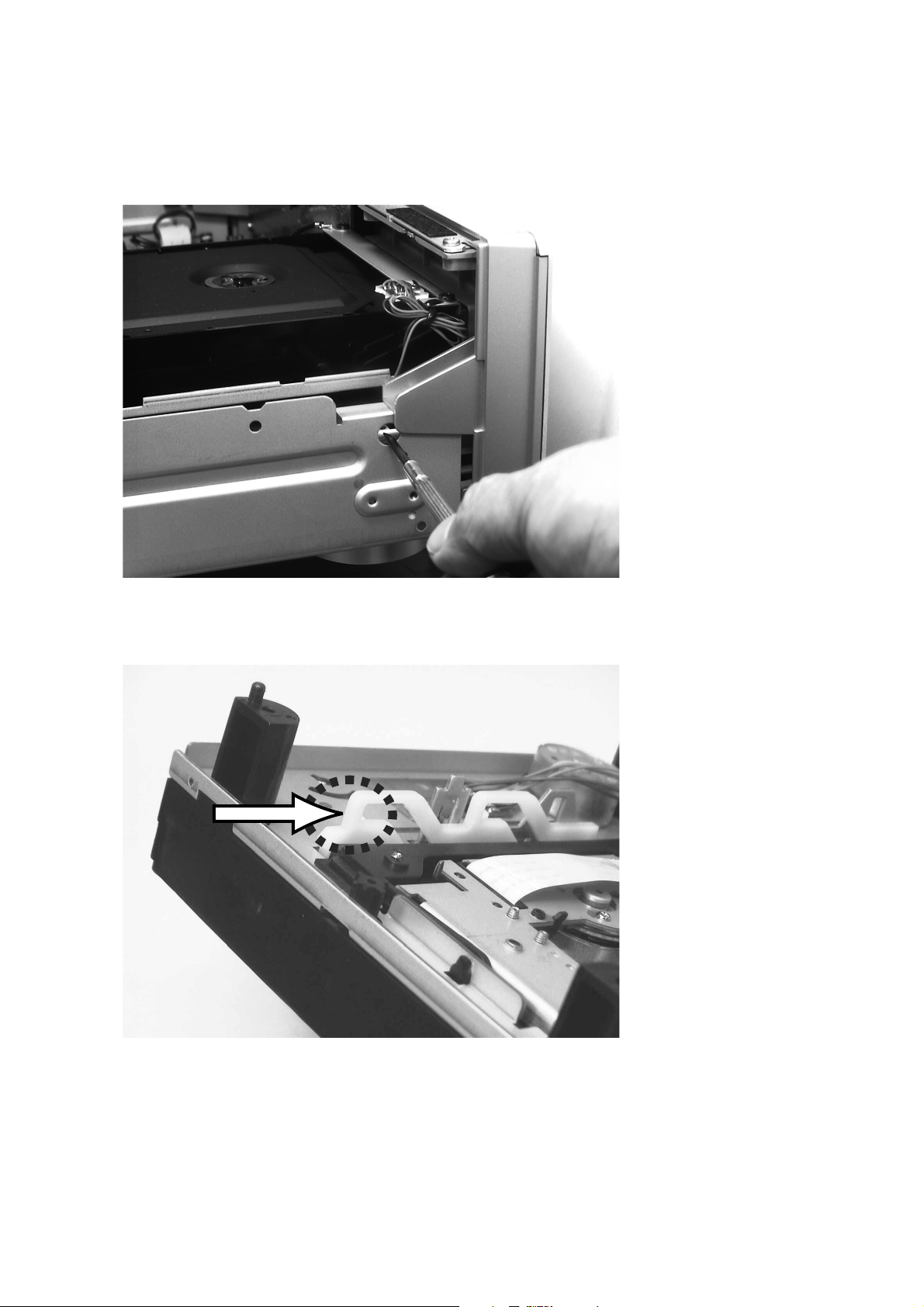

4. TAKING THE DISC OUT OF EMERGENCY

1. To open the stucked tray, insert a pin into the eject pinhole and push the eject lever.

2. Use a pin φ6mm or less.

This picture shows the unit upside down. The eject lever is pointed by the arrow.

The lever is thin so aim the narrow area carefully.

1-4

5. UPDATE FIRMWARE

ファームウエアのアップデート方法

Have UPDATE DISC. (90M-SA7001DVR)

Attention : Don't turn off the unit until disc tray opens

automatically during the updating. When the turn off the unit

halfway, The unit can't be operated any more.

1. Press the POWER button while pressing the PLAY and

OPEN/CLOSE buttons.

2. Press the OPEN/CLOSE button to open the tray, Insert the

update DVD-ROM (part No.:90M-SA7001DVR).

3. Press the SOUND MODE and STOP buttons.

The Display indicates " VERSION UP ".

4. Press the OPEN/CLOSE button to close the tray.

The Display indicates " TOC Reading " >>> " FILE CHECK

" >>> " ERASE " >>> " WRITING ".

5. Software updating will be done automatically.

When the updating is finished, The disc tray opens

automatically.

(Updating takes about 1 minute.)

6. Remove the DVD-ROM from the disc tray.

Update is completed, Press the POWER button to turn off the

unit.

必要な物

注意) 書き換え中は、ディスクトレーが自動的にオープンする

まで絶対にセットの電源を切らないで下さい。途中で電源を切

ると通常の動作も出来なくなります。

: UPDATE DISC. (90M-SA7001DVR)

1. PLAY と OPEN/CLOSE ボタンを押しながら POWER ボタ

ンを押します。

2. OPEN/CLOSE ボタンを押し、トレイをオープンします。

アップデート

挿入します。

DVD-ROM ( 部品番号

90M-SA7001DVR

) を

3. SOUND MODE と STOP ボタンを同時に押します。

表示部には " VERSION UP " と表示されます。

4. OPEN/CLOSE ボタンを押します。トレイが閉じます。

表示部には " TOC Reading " >>> " FILE CHECK " >>> "

ERASE " >>> " WRITING "

ソフトの書き換えは自動的に行われます。書き換えが終了

5.

するとディスクトレーは自動的にオープンします。

の順に表示されます。.

(アップデートには約1分かかります .)

ディスクトレーから DVD-ROM を取り出します。

6.

以上で、ソフトウエアのアップデートは完了です。

ボタンを押し電源を切ります。

POWER

1-5

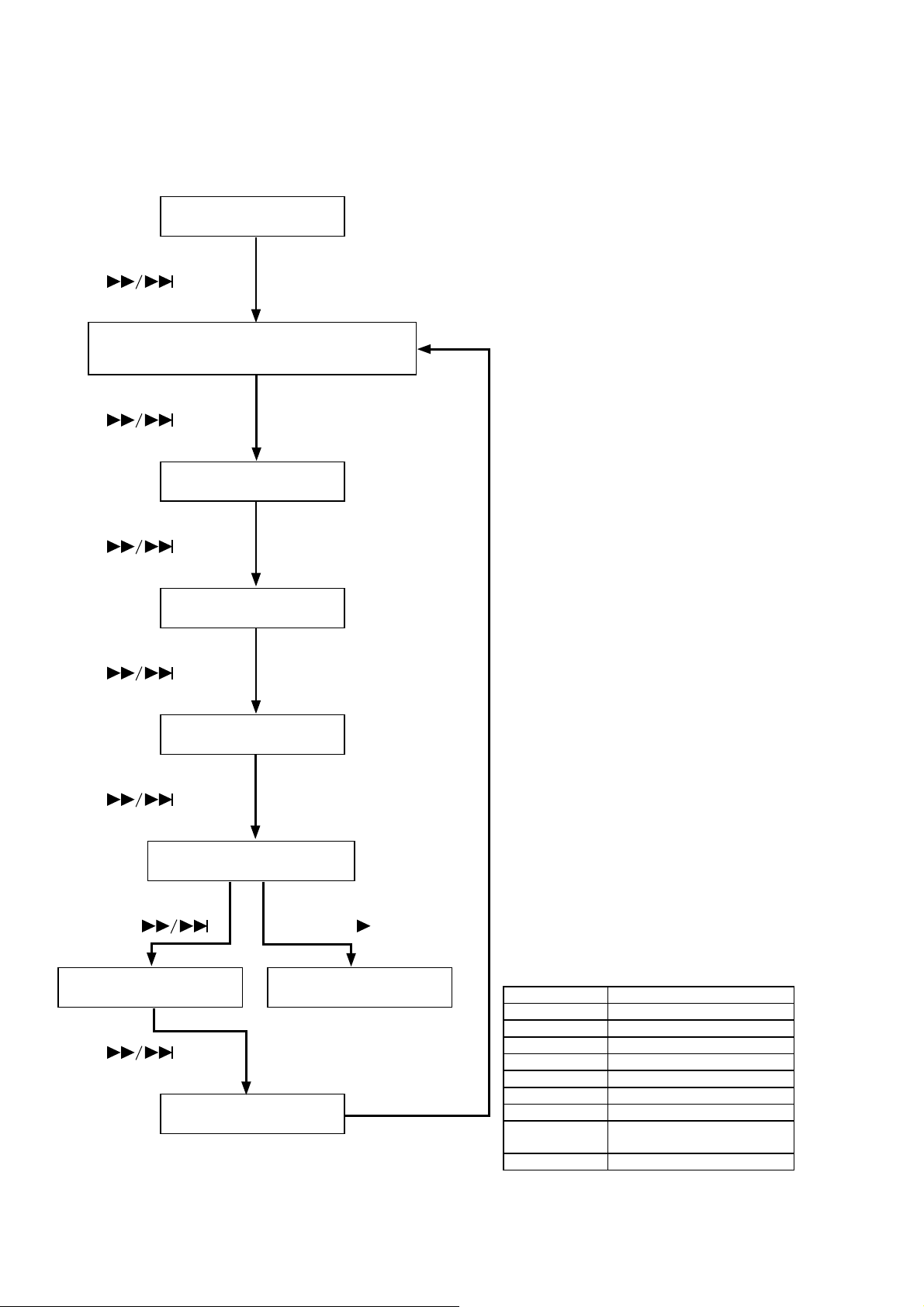

6. SERVICE MODE

The error code is indicated when a problem DISC is inserted fi rst.

Press the POWER button While pressing PLAY and OPEN/CLOSE button

Press<

Press<

Press<

"SA8400" is displayed

>

Version of Backend(IC731) µ-PRO is displayed

"B/E VXX.XX" is displayed

>

"DRV VXX.XX" is displayed

>

All area in the FLD light on

Press< >

Press<

Press<

All area in the FLD light off

>

"H.R.CHACKING" is displayed

> or Press PLAY< >

"H.R.SHORT" is displayed Appear Errer Code

(Ex:E1 0000)

Press<

>

"H.R.NORMAL" is displayed

Remove Mains cord from plug

Errer Code

Error Code Error

E1 XXXX Operation time Error

E2 XXXX T.O.C Error

E2 XXXX Focus Error

E2 XXXX Read Error

E4 XXXX Tracking Error

E5 XXXX Tray Error

E6 XXXX Navigation Pack Read Error

E7 XXXX Check Sum Eroor and

NonAcknow I edgmen

NO DISC XXXX NO disc

(XXXX: The Operation number of times to the error

occurrence)

1-6

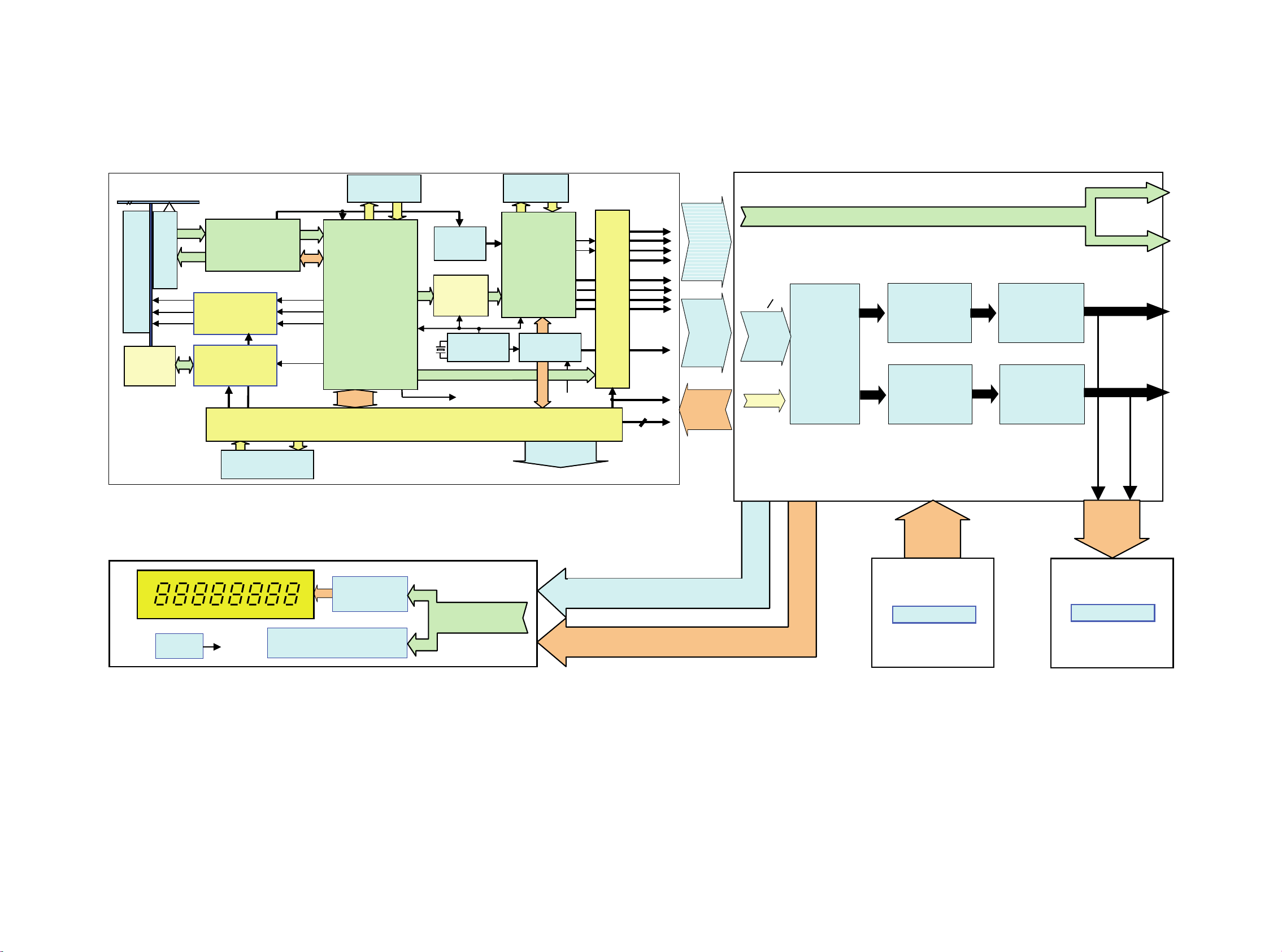

7. BLOCK DIAGRAM

SERVO BLOCK MAIN BLOCK

POWER HEADPHONE

SUPPLY BLOCK

FRONT UNIT BLOCK BLOCK

ML9207-01GP

CS4397

HDAM

HDAM

HDAM

HDAM

HEADPHONE

TRANSFORMER

L ch

R ch

COAX

OPT

DAC PART

DIG. OUT PART

AD6062

IC403

M11L16161SA-45T

IC503

CXD2753R

IC401

EM636165TS-7

IC402

DSD/CD

IC736

EPM33128

IC404

FAN8042

IC508

CXD1881AR

IC501

CXD1885Q

IC502

CLK SELECTOR

IC735

AN8471SA

IC505

T14L1024N

IC732

OSC IC734

M30624FGN

IC731

TURNTABLE

FOC,RAD,SLDG

3-AXICAL ACTUATOR

SPINDL

HOLL

MOTOR

photo

Laser

control

CD and DVD

LASER and MONITOR

LASER POWER CONT.

FOC,RAD,SLED

SPINDLE DRIVER

RF-AMP, AGC, EQ

DRIVER

RFAC

FOC

RAD

SLED

SPIN

SRAM(1M)

D-RAM(16M)

RF-AMP

DIGITAL SERVO

FIFO

and PLL,

DEMODURATOR

SYSTEM CLOCK

33.8688MHz

PCM DATA BUS LINE

DIGITAL I/O

FEATUR and LOADING for SERVO-DSP

IR sensor

RC-5

PLAY/STOP/PAUSE/NEXT/PREVI/etc

FTD DRIVER

KEYS

SDRAM(16M)

PSP DECORD

DSD MULTI-

CHANNL

DECODER

and

384/192fs

SYCLSW

DISPLAY and KEYS

DATA

LRCK

DAPC

DARD

DACL

DSALF

DSAC

DSALS

DSARS

DATA SWITCH

SYCL

384/192fs

MODE

DSCK

DSDO

DSCS1

DSRT1

ATT

MUTE1

DISPLAY and KEYS /RC-5 DATA

POWER SUPPLY

and

DAC CONTROL

PCM/DSD DATA

KEYS DATA

DISPLAY and

POWER

SUPPLY

DIGITAL I/O

DAPC/DARD

DACL/LRCK

SYCL

CONTROL

WOOFER/

CENTER

2CH DAC

Diffrencial AMP

&

2th-LPF

Diffrencial AMP

&

2th-LPF

POWER

SUPPLLY

Current

Feedback AMP

&

2th-LPF

Current

Feedback AMP

&

2th-LPF

HEADPHONE

L/R

1-7 1-8

8. SCHEMATIC DIAGRAM

25FMN-BTRK

WF05

+5B

+5B

LPFSW

MODE1

MUT1

DAPC

DARD

GND

SYCL

GND

DACL

M0/ATT

GND

M41

M42

TO SERVD PCB(PV16)

DSALS

DSARS

DSD DATA IN AND POWER OUT

M3

M2

RST

M43

MUT2

DALR

DSALF

DSAC

JF01

WF04

25FMN-BTRK

+12M

P8M

P8M

MGN

MGN

DIGO

GND

RC5S

USER2

USER1

CDLED

SALED

DSD DATA IN AND POWER OUT

L012

HF70SH28X2X10

4

2

MLTLED

LEY2

DISPLED

FRES

FCEN

FCLK

FDAT

KEY1

KEY0

GND

GND

+5A

+5A

8

9

10

11

12

13

14

15

16

17

TO SERVD PWB(PV16)

L001

2

1

(PH26) TRANSF.PWB

LPT

PH26

L001

TPF2G3

4

2

TPF2G2

2

1

JH04

00MWG28AK202-

(PP16)

JF02

TPF245

1

2

TPF246

3

TPF247

4

TPF248

5

TPF249

6

TPF250

7

TPF251

8

TPF252

9

10

TPF253

11

TPF254

12

13

TPF255

14

15

16

17

TPF256

18

TPF257

19

TPF258

20

21

22

TPF259

23

24

25

GND

1

TPF260

2

TPF261

3

TPF263

4

TPF264

5

TPF265

6

7

TPF266

8

9

TPF267

10

RY51

11

100

12

13

14

15

16

17

18

19

20

21

TPF268

22

TPF269

23

TPF270

24

TPF271

25

M-GND GND

SA7001 ONLY

632010004000M

8

AC13V

9

AC13V

10

TPF2G

11

AC4.3V

12

13

AC11.8V

14

AC11.8V

15

16

AC7.3V

17

POWER SUPPLY,

DAC, AUDIO PWB

00MWG28AK201-

+5B

LPFSW

MODE1

MUT1

DAPC

DARD

SYCL

DACL

ATT

M41

M3

M2

RST

DALR

SA7001KI

SA8001

10

9

8

7

6

5

4

3

2

1

TPF2F8

TPF2F9

1

TPF2F7

TPF2F6

TPF2F5

TPF2F4

+12M

P8M

TPF2F3

DIGO

RC5S

DISPLED

FRES

FCEN

FCLK

FDAT

KEY1

KEY0

+5A

WH02

10

9

8

7

6

5

4

3

2

1

TPF2F2

TPF2F1

RST

M41

M3

M2

+3VDA

SYCL

DACL

DALR

DAPC

DARD

DAD1,3,5

PP16

CD61

100u/25V

LD01

12

14 15 16

DACK

SCLK

J801

GND

CD62

GND

15

16

14

10

R101

100

SA7001 F

R102

100

SA7001 N,S

R103

100

0.1

R104

CD68

CD67

100u/25V

R601

1.2K

R602

1.2K

GND GND

SA7001KI

100

SA8001

0.1

CD69

GNDGND

+5.6VA

CD64

0.1

100u/25V (SA70001/SA7001KI)

CD63

100u/10V (SA8001)

MUTEC

No Connect

VREF

0.1

632010003007M

LDA

QD61

CS4397

CD70

1000p

1

RST

2

M4/ADD

3

M3/AD0

4

M2/SC1

RD63

10K

5

M0/SDA

6

0.1

DGND

7

VD

8

VD

9

DGND

10

MCLK

11

SCLK

12

CMOD

13

SDAT

14 15

M1 MUTE

CD=H

GND

RD64

RD65

DAC DATA INPUT FIG

L.CH R.CH

MLMLM

18K

18K

VREF

FILT+

FILT-

CMOUT

GND

GND

MUTEC

-LD

+LD

VA

+RD

-RD

c/H

28

27

CD66

26

25

10u/50V

24

23

22

21

GND GND

R652

20

R651

19

18

17

16

CD65

GND

1.2K

1.2K

LPS

Q821

3AC11

5AC11

1AC8

2AC8

TPF272

TPF273

9

TPF274

8

TPF275

7

TPF276

6

TPF277

5

TPF278

4

TPF279

3

TPF280

2

TPF281

1

M-GND GND

F852

T800mA L 250V

F851

T800mA L 250V

F822

T1A L 250V

F821

T1A L 250V

F801

T1.25A L 250V

TPF284

11EQS10

11EQS10

TPF282

TPF283

TPF285

TPF286

D822

ID3

D821

ID3

LPS

D803

D802

11EQS10

D804

D801

11EQS10

D807

11EQS10

D806

11EQS10

D808

11EQS10

D805

11EQS10

GND

10AC12

8AC12

H1

H2

5AC11

3AC11

2AC8

1AC8

+15.1V

+7.9V

TPF2B2

+8V

GND

BA12T

TPF2B1

OUT

COM

C821

4700u/25V

M-GND

Q801

BA05T

321

IN

OUT

COM

C804

C801

6800u/16V

3300u/16V

GNDGND GND

QD01

BA033T

321

IN

OUT

COM

GND

32112

IN

OUT

COM

Q802

C805

BA05T

TPF2B3

6800u/16V

GND

TR SHILED

(KI/8001 ONLY)

321

IN

OUT

COM

Q803

BA05T

D809

Q822

NJM7808F

+12V

321321

IN

C822

220u/25V

M-GNDM-GND M-GND

5V

+5V

C802

1000u/10V

GND

3.3V

CD26

220u/25V (SA7001/SA7001KI)

1000u/10V (SA80001)

GND

035G

TR SHILED

(KI/8001 ONLY)

+5V

C806

1000u/10V

GNDGND

035G

+5.6V

12

EC

RD22

C809

4.7K

11EQS10

1000u/10V

GNDGND

RD23

MODE1

120

C651

+8V

R603

R605

R653

R655

GND

GND

GND

560

3.9K

560

3.9K

1.8K

R604

GND

C601

1800p

R654

GND

1800p

C823

2200u/16V

2SK369 BL

Q603

2SC2240

GR,BL

2SK369 BL

Q651

1.8K

Q653

2SC2240

GR,BL

0.10.1

C807

C808

0.1

C803

DTC114TS

Q601

+

+

2

G

C602

R608

R656

2

G

C652

R658

GNDGND

R606

330p

330p

D

S

2

1

68

120

D

S

2

1

68

RD24

LFB

OUTIN

COM

M-GND

L802

12

L803

12

L801

QD23

BEC

3

2SA970

Y,GR

1.2K

QD21 QD22

DTC114TS

GND

7

1

D

1

3

S

3

Q602

2SK369 BL

C

3

B

E

1

D

1

S

3

3

Q652

2SK369 BL

C

3

B

E

TPF2A4

TPF2A5

TPF2A6

TPF2A7

TPF2A8

TO DAC(5.5/3.5V)

3

B

1.5K

3.9K

RD25

GND GND

DIFFERENCIAL

120

R60

Q604

2SA970

-

GR,BL

E

2

1

B

G

3

2

C

R610

D601

560

R609

5.1K

R615

120p

C604

120

R657

Q654

2SA970

GR,BL

E

2

1

B

G

3

2

C

R660

D651

560

R659

5.1K

R665

120p

C654

TPF2A2

TO SERVO

TPF2A3

TO SERVO

TO SERVO

TO FRON

TO DIG.OUT

TO DAC

TO SERVO

TO DAC

TPF2A9

12

QD24

2SC2828

CD22

100u/25V (SA7001/SA7001KI)

CD21

100u/10V (SA8001)

10u/50V

33K

33K

D602D603

2SC2240

GR,BL

D604

D605

D652

D653

Q656

2SC2240

GR,BL

D654D655

T

Q605

2SA970

GR,BL

Q606

Q655

2SA970

GR,BL

B

3

3

B

B

3

3

B

+12M

P8M

+5B

+5F

+5VD

+3VDA

+5A

VREF

E

C

C

E

R611

C603

E

C

C

E

R661

C653

+5.6VA

CURRENT LPF

Q618

270

2SA970

Q615

2SK170

2

1

G

2

2

G

1

Q616

2SJ74

V

2SC2240

560

R631

Q665

2SK170

2

1

G

2

2

2

G

1

Q666

2SJ74

V

2SC2240

560

R681

TPF294

3.3K

R858

GND

TPF296

-11.4V

12

EC

B

3

47K

RN04

2

1

M-GND

QN66

2

1

M-GND

LPFSW

V

D

S

R632

S

2

D

Q620

GR,BL

D

V

S

R682

S

D

Q670

GR,BL

11.4V

R853

R854

R856

R855

0.1

CN04

DTC114TS

3

LFB

100

100

2.7K

GND

3.3K

3.3K

2.7K

QY63

1

3

3

1

R636

1

3

3

1

R686

R634

1

2

2

1

270

R684

1

2

2

1

-12V

E

C

Q617

2SA970

GR,BL

Q619

2SA970

R641

100

120

R633

C

E

270

E

C

Q667

2SA970

GR,BL

Q669

2SA970

R691

100

120

R683

C

E

270

TO AUDIO

C857

C858

470u/16V

TO AUDIO

100K

RN05

M-GND

GR,BL

B

3

GR,BL

3

B

3

3

B

B

Q668

2SA970

GR,BL

B

3

GR,BL

3

B

3

3

B

B

470u/16V

GND

TPF298

RY61

2

1

+5VD2

R352 R351

220u/25V

R623

3.3K

560p

C609

C610

1200p

GND

R673

3.3K

560p

C659

C660

1200p

GND

D854

11EQS10

D853

11EQS10

GND

D852

11EQS10

D851

11EQS10

DN05

ID3

ID3

4.7V

DN06

DN07

RN10

2.2M

15K 1.2K

RN01 RN06

H:MUTE ON

L:MUTE OFF

H:MUTE ON

L:MUTE OFF

No Connect

H:MUTE OFF

L:MUTE ON

R624

R625

Q612

2SA970

GR,BL

E

1

2SK369 BL

B

Q610

D

3

2

C

2

G

S

270

R629

R627

GND

D606

560

R628

Q662

2SA970

GR,BL

E

1

2SK369 BL

B

Q660

D

3

2

C

2

G

S

270

R679

R677

GND

D656

560

R678

TPF295

S

3

G

2

D

1

Q851

GR

2SK246

3300u/25V

(SA7001KI/SA8001)

Q853

2SC2240

GR,BL

6.2V

C855

10u/50V

C856

GND GND GND

ARA

10u/50V

6.2V

Q857

2SA970

GR,BL

Q855

2SK246

S

GR

3

G

2

3300u/25v

D

1

(SA7001KI/SA8001)

100

R852

TPF297

Q856

LMU

TPF299

10K

47K

RN02

RN09

H:MUTE ON

L:MUTE OFF

C

2

C

2

E

1

3

QN01

B

2SC2458

E

1

Y,GR

M-GND

ATT

+3VDA

N.P.

RN65

QN65

N.P.

3

GND

2

G

+

2

G

ID3

+

CN02

D

S

2

1

R626

R674

D

S

2

1

R676

C851

C852

-12.6V

1u/50V

M-GNDM-GNDM-GND

1

3

C

E

68

120

1

3

C

E

68

12.6V

(SA7001)

(SA7001)

CN01

QN06

2SC2458

TPF2A1

MUTEC

Q609

1

2SK369 BL

3

3

B

Q611

2SC2240

GR,BL

120

R675

Q659

1

2SK369 BL

3

3

B

Q661

2SC2240

GR,BL

1000u/35V

GND

1000u/35V

1000u/25V

M-GND

Y,GR

3

B

CN03

4.7u/50V

MUT1

Q613

D607

2SA970

GR,BL

D608

B

3

Q614

2SC2240

33K

GR,BL

3

B

D609

D610

Q663

D657

2SA970

GR,BL

D658

B

3

Q664

2SC2240

33K

GR,BL

3

B

D659

D660

035G

TR SHILED

(KI/8001 ONLY)

12

EC

B

3

100

D858

R851

C

2

E

1

D856

GNDGND

D857

HZ6L-3

E

1

C

2

D859

B

3

12

2SB1020A

035G

TR SHILED

(KI/8001 ONLY)

47K

RN03

DTC114TS

3

DN12

DN11

DN61

N.P.

2

1

E

C

C

E

47

R630

33p

C611

E

C

C

E

47

R680

33p

C661

Q852

2SD1415A

3

B

HZ6L-3

B

3

3.3K

R857

EC

QN04

2SA1048

Y,GR

QN02

DTC114TS

3

Q607

2SK170

2

G

1

2

2

1

2

G

100

560

Q608

2SJ74

47p

R612

Q657

2SK170

2

G

1

2

2

1

2

G

100

560

Q658

2SJ74

47p

R662

C605

GND

D

V

1

3

S

R622

TPF287

3333

R613R614

2.2K

S

3

1

D

GND

C606

220u/25V

V

D

V

1

3

S

R672

TPF288

33

R663

2.2K

33

R664

S

3

1

D

V

LPS

8AC12

10AC12

DN02

5AC11

3AC11

DN01

120

120

B

3

B

3

R637

B

3

B

3

R687

4.7K

100 N.P.

C

E

C

E

270

C

E

C

E

270

E

C

E

C

2

1

2

1

E

C

E

C

2

1

2

+12V

-12V

TMUT1

DSOF

270

R635

1

2

C612

1

2

Q622

2SC2240

GR,BL

Q621

2SC2240

GR,BL

2SC2240

270

R685

1

2

C662

1

2

Q672

2SC2240

GR,BL

Q671

2SC2240

1

GR,BL

5AC11

3AC11

No Connect

N.P.

C351

Q623

2SC2240

GR,BL

680p

R638

2SA970

GR,BL

Q673

GR,BL

680p

R688

2SA970

GR,BL

TPF243

TPF244

GNDGNDGND

47

Q624

47

Q674

10 1/4W

3

B

D611D612D613

B

3

3

B

D661

D662

D663

B

3

RY55

DIGO

RC5F

RC5S

S351

4

5

6

C

E

E

C

C

E

E

C

2

1

TPF289

1

2

2

1

TPF290

1

2

220u/50V

TPF292

N.P.

1

2

3

GND

3333

R639R640

GND

3333

R689

R690

LLM

CY51

DY51

CT05

STANDARD

CUSTOM

+12V

C613

220u/25V

66

C616

220u/16V

(F ONLY)

100u/25V

220u/16V

(F ONLY

JUMMPER

C614

220u/25V

R647

-12V

100

+12V

66

C666

220u/16V

(F ONLY)

100u/25V

220u/16V

(F ONLY)

JUMMPER

R697

-12V

100

H1

H2

2SC2458

QY61

2SA1048

Y,GR,ETC

DY52

TPF291

ID3

ID3

CY52

RY56

4.7K

220u/50V

M-GND

M-GND

+5VD

+5VD2

LT02

12

0.1

CT10

100u/25V

GND

GND

QT01

74HC04

1234567

RT06

RT05

1.2K

100K

RC-5 IN/OUT

TPF293

R644

75

C617

R643

47K

)

GND

GND GND

R694

75

C667

R693

47K

GND

QN61

E

1

2SC2878

B

3

C

2

GND

TMUT1

QN63 QN64

2SC2240

C

2

3

B

1

E

R645

75

RN61 RN62

4.7K 4.7K

RN63

4.7K

R695

75

FOR DAC (BUS LINE)

AC4.3V

AC4.3V

QY62

Y,GR

3

H1

H2

47

47

RY59

RY60

DY61

RY57

C

2

27V

10K

3

B

E

1

12

EC

B

27V

DY65

M-GND

4.7V

DY11

CY63

100u/50V

RY58

47K

-26.8V

031G SHILED (KI/8001 ONLY)

DIG OUT

891011121314

NC

GND

RT04

33

CT07

220

GND

LPA

+5VD2

RF57

100

4.7K

RF56

CF54

C

2

3

B

8.2K

RF58

1

QF52

E

2SC2458

GNDGND

2SC2878

QN62

+12V

-12V

2SC2240

RN64

4.7K

DSOF

-VFT

LTD

CT01RT02

0.133

3

2

15

GND

0.1

10/50V

CF53

GNDGND

C668

N.P.

LT01

B

3

3

B

E

C

GNDGND

C

E

GND

CT03

2200p

1

2

DF51

47K18K

RF54RF55

4

1

(JUMMPER)

2

GND

C911

0.1

GND

2

1

R696

0

(JUMMPER)

H1

H2

H2

-VFT

H1

+5F

RC5F

KEY0

KEY1

FDAT

FCLK

FCEN

FRES

DISPLED

RT01

100

RT0

3

75

CT02

47

CT04

0.1

RF52

E

4.7K

B

3

QF51

C

2SA1048

CF51

R646

0

N.P.

C618

CY61

TPF215

TPF219

TPF220

TPF221

TPF222

TPF223

TPF224

TPF225

TPF226

TPF227

TPF228

TPF229

0.1

CT06

GND

LT03

12

(JAMPER)

LT04

12

(JAMPER)

CT11

TPF236

RF53

4.7K

TPF239

470p

CF52

0.1

CY60

0.1

0.1

TPF216

TPF217

TPF231

TPF232

TPF233

TPF234

TPF235

0.1

22

RF51

GNDGNDGNDGND

GND

TPF201

TPF203

TPF204

TPF205

TPF206

TPF207

TPF208

TPF209

TPF210

TPF211

TPF212

TPF213

TPF214

17FMF-BTK

TPF218

TPF230

GND

GNDGND

TPF237

TPF238

GND

TPF240

GND

TPF202

GND

GND

JF03

GND

SF51

TPF241

TPF242

GND

J901

PH6P

J606

GND

JL02

JL01

JY01

JT02

1

2

1

2

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

JT03

3

2

1

1

2

3

4

5

6

JF51

EARTH

1

2

J605

W901

6

5

4

3

2

1

2

FRONT

1

2

3

4

2

3

1

SA7001KI/SA8001

W601

1

1

2

2

FRONT

L.CH

SA7001 ONLY

J601

FRONT L.CH

PH6P

TFCK-16813

6

5

4

3

2

1

SA7001 ONLY

J602

SA7001KI/SA8001

J608

W602

121

1

2

R.CH

EARTH

WY01

EARTH

WF07

H2

-VFT

H1

GND

+5F

+5F

RC5F

GND

KEY0

KEY1

FDAT

FCLK

FCEN

FRES

DISPLED

GND

GND

L013 (SA8001 ONLY)

HF70SH28X2X10

DIG OUT

OPTICAL

COAX

EXT

RC-5

INT/EXT SW

INT

RC-5

IN OUT

J607

FRONT L.CH

(WHT)

L011

TO PHONE PWB

FRONT R.CH

FRONT R.CH

(RED)

TO FRONT PWB(PY16)

COMMAND INTERFACE

1-101-9

RCH

-12VA

GND

+12VA

LCH

TMUT1

(PR16)

HEADPHONE PWB

00MWG28AK203-

PR16

W901

1

2

3

4

5

6

TPF2J1

TPF2J2

TPF2J3

A-GND

B6B-PH-K-S

632010005003M

LHP

TPF2J4

TPF2J5

-12VA

+12VA

TPF2J6

R925

4.7k

C901

47u/25

C902

47u/25

R926

4.7k

2SC2878

TPF2J7

R901

100

R930

10k

R902

100

TPF2J8

Q909

R919

4.7K

A-GND

R921

4.7k

13

A-GND

46

Q910

2SC2878

A-GND

A-GND

2

5

TPF2K3

A-GND

R922

4.7k

TPF2K2

TPF2K1

TPF2J9

R920

4.7K

A-GND

Q901

2

3

C904

5

6

NJM4560D

220u/25

A-GND

Q901

NJM4560D

1SS133T-77

8

1

4

1SS133T-77

1SS133T-77

7

1SS133T-77

R907C903

1.5k220u/25

D901

R903

R905

D903

R909

1.5k

R908

1.5k

D902

R904

R906

D904

+12VA

GOLD

Q903

2SC2120-Y

TPE2

A-GND

R915

R911

3

33

R913

33

Q905

1

2SA950-O_Y

TPE2

2

Q904

2SC2120-Y

TPE2

R912

33

R914

33

Q906

2SA950-O_Y

TPE2

-12VA

+12VA

TPF2K8

47u/25

TPF2K4

47u/25

33

33

33

33

C905

R923

4.7k

R924

4.7k

C906

R916

100k

TPF2K5

TPF2K6

A-GND

100k

R918

R917

100

100

A-GND

A-GND

SILVER

Q907

2SC2878

Q908

2SC2878

R951

R952

L901

BL02RN2

C907

1000p

L902

BL02RN2

C908

1000p

100

100

A-GND

A-GND

C909

NP

TPF2K7

TPF2K9

TPF2L1

A-GND

TPF2L2

J903

2

3

1

H.P JACK

R910

1.5k

-12VA

A-GND

EARTH

1-11 1-12

PY16

632010007009M

GND

GND

DISPLED

FRES

FCEN

FCLK

FDAT

KEY1

KEY0

NC

RC5F

+5VF

+5VF

GND

-VFT

( PY16) FRONT PWB

00MWG28AK301-

LLM

JY01

17FMN-BTK-A

17

TPF301

16

TPF302

15

TPF307

14

TPF308

13

TPF309

12

TPF310

11

TPF311

10

TPF312

9

TPF313

8

7

TPF314

6

TPF303

5

TPF304

4

TPF305

3

2

1

TPF306

TPF315

TPF316

D-GND

SA7001/KI

SA8001

H1

H2

+5V

AC4.3V

-26.8V

AC4.3V

RY41

100

RY42

100

H1 H2

G[2]

G[3]

G[1]

95

97

98

G[4]

G[5]

G[6]

G[7]

G[8]

G[9]

G[10]

G[11]

G[12]

G[13]

58596061626364656667686970717273747576777879808182838485868788899091929394

57

VX01

CH2163B

1256789

RY25

150k

4

101112131415161718192021222324252627282930313233343536373839404142434445464849

S[2]

S[3]

S[4]

S[5]

S[6]

S[7]

S[8]

S[9]

S[10]

S[11]

S[12]

S[13]

S[14]

S[15]

S[16]

S[17]

S[18]

S[19]

S[20]

S[21]

S[22]

S[23]

S[24]

S[25]

S[26]

S[27]

S[28]

S[29]

S[30]

S[31]

S[32]

S[33]

S[34]

S[35]

S[36]

S[37]

-VFT

DISPLED

FRES

FCEN

FCLK

FDAT

KEY0

RY06

150

RY04 RY01

180 270

KEY1

KEY0

RC-5

SY06 SY04

1212

SKHVBF 260GF

RED

SKHVBF 260GF

RED

TPF317

LY04

QY02

2SC4081

312000451210

D-GND D-GND

CY01

47u/25

+3.3VF

KEY1

TPF318

RY10

150

SY10

SKHVBF 260GF

RED

SY12

SKHVBF 260GF RED

TPF320 TPF322 TPF324

RY05 RY02

180 270

12

SKHVBF 260GF

RED

12

SA8001 ONLY

LY03

LY02

LY01

+5VF

H1

-VFT

H2

1k

RY13

10k

RY14

RY15

3.3k

56

S[38]

55

S[39]

54

S[40]

515350

SKHVBF 260GF

RED

SY02SY05

SKHVBF 260GF

RED

1212

TPF323TPF321TPF319

SKHVBF 260GF

SA8001 ONLY

SKHVBF 260GF

RY09

SY09

RY03

390

SY03

RED

390

RED

XY01

CST4.00MGW

12

3

D-GND

47u/25

SA8001 ONLY

TPF325

SKHVBF 260GF

12

SKHVBF 260GF

TPF326

SA8001 ONLY

12

SKHVBF 260GF

4MHz

CY03

SY11

SY07SY01

RED

SY08

RED

RED

RY24

680

+3.3VF

D-GND

12

1212

D-GND

12

D-GND

-VFT

FRES

FCEN

FCLK

FDAT

D-GND

DISPLED

RC-5

D-GND

CY04

0.047u

CY02

0.1u

CY08

D-GND

S[39]

S[40]

TPZ351

TPZ352

WY11

WY13

0.1u

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

COM23

COM24

VFL1

GND

OSC0

OSC1

XRESET

XCS

XCP

DA

VDD

P1

P2

P3

P4

VFL2

NC

VDISP2

AD1

AD2

60

COM17

COM18

COM19

COM20

COM21

COM22

ML9207-01GP

AD3

AD4

SEG1

SEG2

SEG3

SEG4

123456789

S[2]

S[3]

S[4]

S[5]

S[6]

S[7]

S[8]

TPZ301

TPZ302

TPZ303

TPZ304

TPZ305

TPZ306

TPZ307

+5VF

RY22

100

CY05

220u/10

TPZ350

TPZ349

TPZ348

TPZ347

TPZ346

TPZ345

TPZ344

TPZ343

TPZ342

TPZ341

TPZ340

G[9]

G[8]

G[7]

G[6]

G[5]

G[4]

G[13]

G[12]

G[11]

G[10]

G[3]

41424344454647484950515253545556575859

COM3

COM4

COM5

COM6

COM7

COM8

COM9

COM10

COM11

COM12

COM13

COM14

COM15

COM16

QY01

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

SEG16

SEG17

S[16]

S[17]

TPZ316

RY23

S[18]

S[19]

TPZ317

TPZ318

2

1k

SEG18

S[20]

S[21]

TPZ319

TPZ320

RY19

1k

1011121314151617181920

S[9]

S[10]

S[11]

S[12]

S[13]

S[14]

S[15]

TPZ308

TPZ309

TPZ310

TPZ311

TPZ312

TPZ313

TPZ314

TPZ315

DY07

02CZ3.9-X(TE85L)

3

1

ZY01

RPM-6936-V4

IR SENSER

123

CY06

0.1u 330p

D-GND D-GNDD-GND

D-GNDD-GND

COM2

COM1

VDISP1

SEG35

SEG34

SEG33

SEG32

SEG31

SEG30

SEG29

SEG28

SEG27

SEG26

SEG25

SEG24

SEG23

SEG22

SEG21

SEG20

SEG19

CY07

CY09

0.1u

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

RY20

1k

RY26

10k

+5VF

QY05

2SA1586

12

RY18

470

D-GND

S[38]

S[37]

S[36]

S[35]

S[34]

S[33]

S[32]

S[31]

S[30]

S[29]

S[28]

S[27]

S[26]

S[25]

S[24]

S[23]

S[22]

TPF327

DY02

LT3D8B

TPF328

G[2]

G[1]

TPZ331

TPZ321

TPZ322

TPZ332

TPZ323

TPZ333

TPZ324

TPZ334

TPZ325

TPZ335

TPZ326

TPZ336

TPZ327

TPZ337

TPZ328

TPZ338

TPZ329

TPZ339

TPZ330

PH16

632010008002M

(PH16) POWER SW PWB

00MWG28AK302-

J001

HF-301

B2P3-VH

2

1

L003

TFCK-23-11-14

1

2

JH01 JH02W003

LPT

TPF351

2

TPF352

1

FH01

250V1.25A

TPF353 TPF354

JUMPER (F only)

SH01

ESB92S94B

M

GH01

0.01u

RH01

ONLY F

RH02

EXCLUDING F

21

100

100

B2P3-VH

2

1

SA7001 ONLY

WH01

2

1

2

1

W001

1-141-13

鉛フリー半田

9. PARTS LOCATION

PH16 B

FH01 C3

GH01 B2

JH01 D3

JH02 C3

RH01 B4

RH02 A4

SH01 B2

PY16 A

CY01 A7

CY02 D6

CY03 A7

CY04 D6

CY05 A1

CY06 D1

CY07 D1

CY08 D5

CY09 C1

DY02 C1

DY07 A2

JY01 A6

LY0 1 A 6

LY0 2 A 6

LY0 3 A 6

LY0 4 A 7

QY01 D5

QY02 A7

QY05 B2

RY01 C4

RY02 C11

RY03 C11

RY04 C12

RY05 C10

RY06 C10

RY09 C4

RY10 C9

RY13 A6

RY14 A6

RY15 A6

RY18 D1

RY19 A2

RY20 B2

RY22 A1

RY23 D1

RY24 E5

RY25 B2

RY26 C1

鉛フリー半田

半田付けには、鉛フリー半田

RY41 E11

RY42 E11

SY01 B12

SY02 B10

SY03 C12

SY04 C10

SY05 C9

SY06 C7

SY07 B7

SY08 B3

SY09 B4

SY10 B9

SY11 B1

SY12 B6

VX01 D4

WY11 A5

WY13 E5

XY01 E5

ZY01 D1

(Sn-Ag-Cu)

を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

1-15 1-16

鉛フリー半田

PP16 B

C351 E2

C601 I10

C602 J10

C603 I8

C604 J10

C605 H7

C606 I7

C609 J7

C610 J7

C611 I5

C612 I4

C613 H3

C614 I3

C616 J2

C617 J2

C618 I2

C651 H10

C652 H10

C653 H8

C654 H10

C659 G7

C660 H7

C661 H5

C662 H4

C666 H2

C667 H2

C668 H2

C801 C8

C802 D11

C803 B10

C804 D8

C805 C7

C806 E11

C807 B11

C808 D13

C809 F11

C821 D7

C822 E7

C823 E9

C851 C5

C852 C4

C855 E5

C856 E4

C857 F5

C858 F4

C911 J12

CD21 F11

CD22 J12

CD26 E12

CD61 H12

CD62 I12

CD63 I11

CD64 J11

CD65 I11

CD66 I10

CD67 J11

CD68 J11

CD69 I11

CD70 I12

CF51 C2

CF52 C2

CF53 C2

CF54 C2

CN01 F9

CN02 F8

CN03 F8

CN04 F3

CT01 E2

CT02 D2

CT03 D2

CT04 D2

CT05 C2

CT06 E2

CT07 E3

CT10 D2

CT11 D1

CY51 F6

CY52 F7

CY60 B13

CY61 B13

CY63 F8

D601 I9

D602 I10

D603 I9

D604 I9

D605 I8

D606 I6

D607 I7

D608 I6

D609 I6

D610 I5

D611 I4

D612 I4

D613 J4

D651 H9

D652 G10

D653 H9

D654 H9

D655 H8

D656 H6

D657 G7

D658 H6

D659 H6

D660 H5

D661 G4

D662 H4

D663 H4

D801 B8

D802 B8

D803 B8

D804 B8

D805 B7

D806 B7

D807 B7

D808 B7

D809 E10

D821 D6

D822 D6

D851 B4

D852 B4

D853 B5

D854 B4

D856 F5

D857 F4

D858 E5

D859 E4

DF51 C2

DN01 F6

DN02 F6

DN05 F6

DN06 F7

DN07 F7

DN11 F10

DN12 F10

DN61 G11

DY11 B8

DY51 F6

DY52 F6

DY61 E9

DY65 F7

F801 B7

F821 B6

F822 B6

F851 A3

F852 A4

J601 I1

J602 H1

鉛フリー半田

半田付けには、鉛フリー半田

(Sn-Ag-Cu)

を使用してください。

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

1-181-17

鉛フリー半田

PP16 B

J605 I1

J606 H1

J801 A5

J901 J12

JF01 B8

JF02 B11

JF03 C13

JF51 C1

JL01 B13

JL02 G1

JT02 D1

JT03 E1

JY01 A12

L801 B10

L802 C11

L803 C12

LD01 E12

LT01 E2

LT02 C2

LT03 D2

LT04 D2

Q601 J9

Q602 J9

Q603 J8

Q604 J9

Q605 I9

Q606 I9

Q607 I8

Q608 J8

Q609 J6

Q610 J6

Q611 J6

Q612 J6

Q613 I6

Q614 I6

Q615 I5

Q616 J5

Q617 I5

Q618 I4

Q619 I5

Q620 J5

Q621 J4

Q622 J5

Q623 I3

Q624 J3

Q651 H9

Q652 H9

Q653 H8

Q654 H9

Q655 G9

Q656 G9

Q657 H8

Q658 H8

Q659 H6

Q660 H6

Q661 H6

Q662 H6

Q663 G6

Q664 G6

Q665 H5

Q666 H5

Q667 H5

Q668 H4

Q669 G5

Q670 H5

Q671 H4

Q672 H5

Q673 G3

Q674 H3

Q801 C10

Q802 E10

Q803 F10

Q821 E7

Q822 E8

Q851 E5

Q852 E5

Q853 E5

Q855 E4

Q856 E4

Q857 E4

QD01 D12

QD21 G11

QD22 G11

QD23 F11

QD24 G12

QD61 I11

QF51 B2

QF52 B2

QN01 G9

QN02 G9

QN04 G9

QN06 G8

QN61 I2

QN62 I2

QN63 H2

QN64 I2

QN65 H11

QN66 F9

QT01 D3

QY61 F7

QY62 B8

QY63 F9

R101 K1

R102 K1

R103 K1

R104 J1

R351 E2

R352 E2

R601 I10

R602 I10

R603 I10

R604 I10

R605 I10

R606 J9

R607 I9

R608 J8

R609 I8

R610 I9

R611 I9

R612 I8

R613 I8

R614 J8

R615 J10

R622 J7

R623 J7

R624 J6

R625 I6

R626 J5

R627 J7

R628 I5

R629 I6

R630 I6

R631 I5

R632 I4

R633 J4

R634 I4

R635 I4

R636 J4

R637 J4

R638 J3

R639 I3

R640 J3

R641 J4

R643 I2

R644 I2

R645 I2

R646 I2

R647 J7

R651 H10

R652 I10

R653 H10

R654 H10

R655 H10

R656 H9

R657 H9

R658 H8

R659 H8

R660 H9

R661 H9

R662 G8

R663 H8

R664 G8

R665 H10

R672 G7

R673 G7

R674 H6

R675 H6

R676 H5

R677 H7

R678 H5

R679 H6

R680 H6

R681 G5

R682 H4

R683 H4

R684 G4

R685 G4

R686 H4

R687 H4

R688 H3

R689 G3

R690 H3

R691 H4

R693 H2

R694 H2

R695 H2

R696 H2

R697 G7

R851 E5

R852 E3

R853 F5

R854 F5

R855 F4

R856 F4

R857 F4

R858 F5

RD22 F11

RD23 F11

RD24 F12

RD25 F11

RD63 I12

RD64 H11

RD65 H11

RF51 C2

RF52 B2

RF53 B2

RF54 B2

RF55 B2

RF56 B2

RF57 C2

RF58 B2

RN01 F7

RN02 F9

RN03 F9

RN04 F9

RN05 F3

RN06 F7

RN09 F9

RN10 F8

RN61 I2

RN62 I2

RN63 H2

RN64 H2

RN65 H11

RT01 E2

RT02 E3

RT03 E2

RT04 E3

RT05 C3

RT06 D2

RY51 B9

RY55 F6

RY56 F7

RY57 B8

RY58 B8

RY59 B7

RY60 B7

RY61 F9

S351 F1

SF51 B1

PR16 B

C901 A2

C902 A2

C903 A3

C904 B3

C905 D2

C906 E2

C907 D1

C908 E1

C909 E1

D901 E3

D902 B3

D903 D3

D904 C3

EX1 E1

J903 D1

L901 D2

L902 E2

Q901 C2

Q903 E3

Q904 C3

Q905 D3

Q906 C3

Q907 E2

Q908 E2

Q909 B2

Q910 B2

R901 B2

R902 B2

R903 E3

R904 B2

R905 D2

R906 C2

R907 E3

R908 B3

R909 D3

R910 D3

R911 E3

R912 C3

R913 E3

R914 C3

R915 E2

R916 E2

R917 E2

R918 E2

R919 C2

R920 B2

R921 C2

R922 B2

R923 E2

R924 F2

R925 A2

R926 A2

R930 C1

R951 A2

R952 A2

W901 B3

鉛フリー半田

半田付けには、鉛フリー半田

Lead-free Solder

When soldering, use the Lead-free Solder (Sn-Ag-Cu).

1-19 1-20

(Sn-Ag-Cu)

を使用してください。

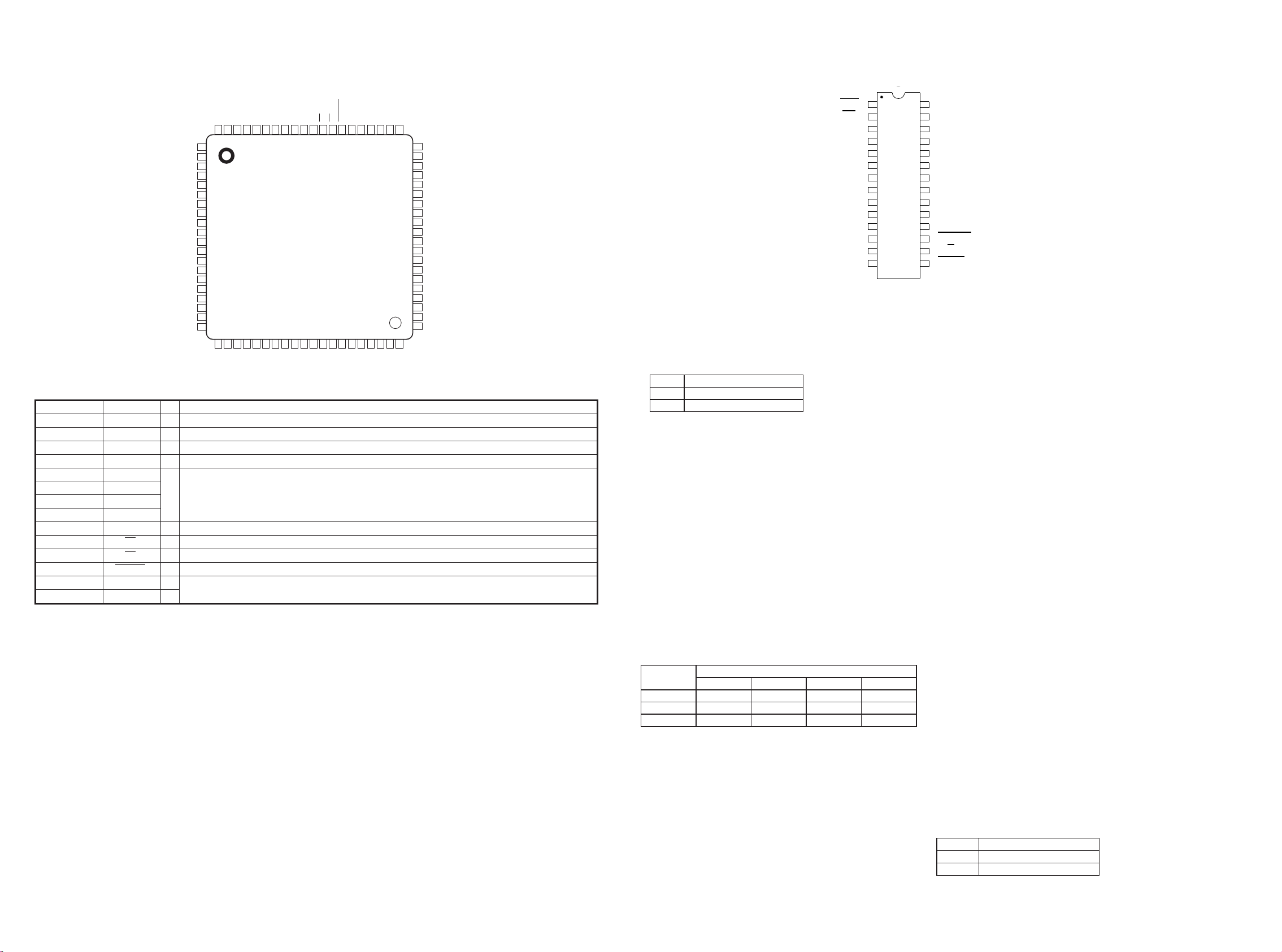

10. MICROPROCESSOR AND IC DATA

QY01 : ML9207-01

FL2

DISP2

NC

V

AD1

AD2

77

78

79

80

1

AD3

2

AD4

3

SEG1

4

SEG2

5

SEG3

6

SEG4

7

SEG5

8

SEG6

9

SEG7

10

SEG8

11

SEG9

12

SEG10

13

SEG11

14

SEG12

15

SEG13

16

SEG14

17

SEG15

18

SEG16

19

SEG17

20

SEG18

24

23

22

21

SEG22

SEG21

SEG20

SEG19

ML9207-01 Terminal Function

Pin Name FunctionPin No. I/O

3~37 SEG1~35 O FL display anode drive output pin

39~62 COM1~24 O FL display grid drive output pin

1,2, 79, 80 AD1~4 O FL display anode drive output pin

72~75 P1~4 O General port output pin

71 VDD

38, 78 VDISP1~2

64 GND

63, 76 VFL1~2

70 DA I Serial data input pin (positive logic)

69 CP I Shift clock input pin

68 CS I Chip select input pin

67 RESET I Reset input pin

65 OSC0 I

66 OSC1 O

VDD-GND: Power supply for logic block

VDISP-VFL: Power supply for FL display drive

DD and VDISP, apply from same power source

For V

Pin for self-oscillation

P4

V

75

76

26

25

SEG23

SEG24

P2

P3

73

74

28

27

SEG26

SEG25

VDDP1

71

72

30

29

SEG28

SEG27

CP

DA

69

70

32

31

SEG30

SEG29

RESET

CS

67

68

34

33

SEG32

SEG31

OSC0

OSC1

65

66

36

35

SEG34

SEG33

FL1

GND

V

63

64

38

37

DISP1

V

SEG35

QD61 : CS4397

PCM MODE

Reset RST

COM23

COM24

61

62

60

COM22

59

COM21

58

COM20

57

COM19

56

COM18

55

COM17

54

COM16

53

COM15

52

COM14

51

COM13

50

COM12

49

COM11

48

COM10

47

COM9

46

COM8

45

COM7

44

COM6

43

COM5

42

COM4

41

COM3

40

39

Reset - RST

Pin 1, Input

Function:

The device enters a low power mode and all internal state

machines registers are reset when low. When

See Description M4(AD0/CS

See Description M3(AD1/CDIN) FILT- Reference Ground

See Description M2(SCL/CCLK) CMOUT Common ModeS Voltage

See Description M0(SDA/CDOUT) AOUTL- Differential Output

Digital Ground DGND AOUTL+ Differential Output

Digital Power VD VA Analog Power

Digital Power VD AGND Analog Ground

Digital Ground DGND AOUTR+ Differential Output

Master Clock MCLK AOUTR- Differential Output

Serial Clock SCLK AGND Analog Ground

Left/Right Clock LRCK MUTEC

Serial Data SDATA C/H

See Description M1 MUTE

1

1

) FILT+ Reference Filter

2

2

3

4

5

5

6

6

7

8

9

10

11

12

131416

high, the device will be in a normal operation mode .

COM2

COM1

RST DESCRIPTION

0 Enabled

1 Normal operation mode

Digital Ground - DGND

Pins 6 and 9, Inputs

Function:

Digital ground reference.

Digital Power - VD

Pins 7 and 8, Input

Function:

Digital power supply. Typically 5.0 to 3.0 VDC.

Master Clock - MCLK

Pin 10, Input

Function:

The master clock frequency must be either 256x, 384x, 512x or

768x the input sample rate in Single

Speed Mode; either 128x, 192x 256x or 384x the input sample

rate in Double Speed Mode; or 64x, 96x

128x or 192x the input sample rate in Quad Speed Mode. Tables

4-6 illustrate the standard audio sample

rates and the required master clock frequencies.

Sample

Rate (kHz)

256x 384x 512x 768x

MCLK (MHz)

32 8.1920 12.2880 16.3840 24.5760

44.1 11.2896 16.9344 22.5792 33.8688

48 12.2880 18.4320 24.5760 36.8640

Table 4. Single Speed (16 to 50 kHz sample rates) Common Clock

Frequencies

Serial Clock - SCLK

Pin 11, Input

Function:

Clocks individual bits of serial data into the SDATA pin. The

required relationship between the Left/Right

clock, serial clock and serial data is defi ned by either the Mode

Control Byte in Control Port Mode or the

M0 - M4 pins in Hardware Mode. The options are detailed in

Figures 29-33

VREF Voltage Reference

28

27

26

25

24

23

22

21

20

19

18

17

Mute Control

Control port/Hardware select

15

Soft Mute

Left/Right Clock - LRCK

Pin 12, Input

Function:

The Left/Right clock determines which channel is currently being

input on the serial audio data input,

SDATA. The frequency of the Left/Right clock must be at the input

sample rate. Audio samples in

Left/Right sample pairs will be simultaneously output from the

digital-to-analog converter whereas

Right/Left pairs will exhibit a one sample period difference. The

required relationship between the

Left/Right clock, serial clock and serial data is defi ned by the

Mode Control Byte and the options are de-

tailed in Figures 29-33

Serial Audio Data - SDATA

Pin 13, Input

Function:

Serial audio data is input on this pin. The selection of the Digital

Interface Format is determined by set-

tings of the Mode select as detailed in Figures 29-33. The data is

clocked into SDATA via the serial clock

and the channel is determined by the Left/Right clock. The

required relationship between the Left/Right

clock, serial clock and serial data is defi ned by the Mode Control

Byte and the options are detailed inin

Figures 29-33

Soft Mute - MUTE

Pin 15, Input

Function:

The analog outputs will ramp to a muted state when enabled. The

ramp requires 1152 left/right clock cy-

cles in Single Speed, 2304 cycles in Double Speed and 4608

cycles in Quad Speed mode. The bias volt-

age on the outputs will be retained and MUTEC will go active at

the completion of the ramp period.

The analog outputs will ramp to a normal state when this function

transitions from the enabled to disabled

state. The ramp requires 1152 left/right clock cycles in Single

Speed, 2304 cycles in Double Speed and

4608 cycles in Quad Speed mode. The MUTEC will release

immediately on setting MUTE = 1.

The converter analog outputs will mute when enabled. The bias

voltage on the outputs will be retained

and MUTEC will go active during the mute period.

Mute DESCRIPTION

0 Enabled

1 Normal operation mode

1-221-21

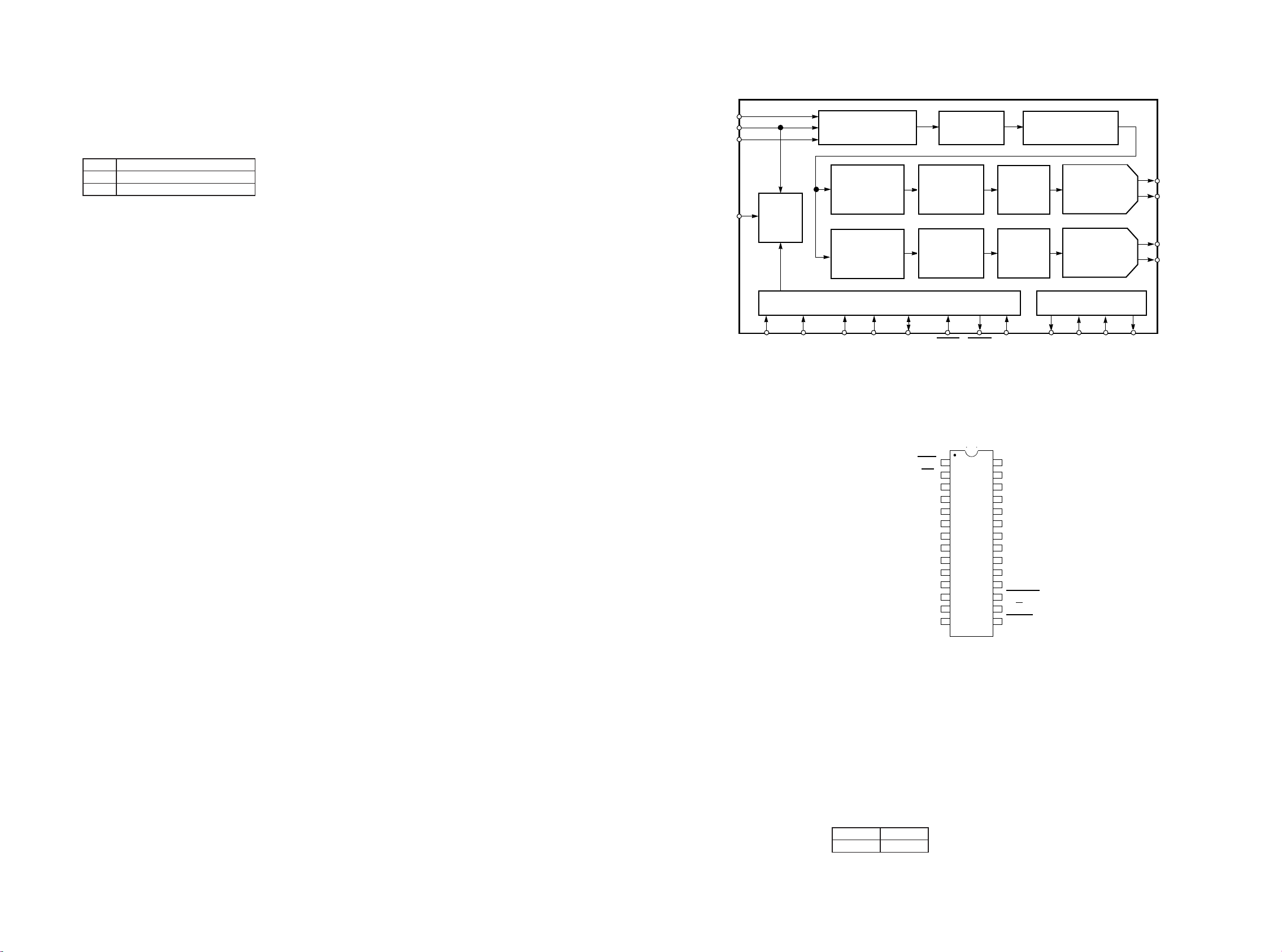

QD61 : CS4397

QD61 : CS4397

Control Port / Hardware Mode Select - C/H

Pin 16, Input

Function:

Determines if the device will operate in either the Hardware Mode

or Control Port Mode.

C/H DESCRIPTION

0 Hardware Mode Enabled

1 Control Port Mode Enabled

Mute Control - MUTEC

Pin 17, Output

Function:

The Mute Control pin goes low during power-up initialization,

reset, muting, master clock to left/right clock

frequency ratio is incorrect or power-down. This pin is intended to

be used as a control for an external mute

circuit to prevent the clicks and pops that can occur in any single

supply system. Use of Mute Control is not

mandatory but recommended for designs requiring the absolute

minimum in extraneous clicks and pops.

Analog Ground - AGND

Pins 18 and 21, Inputs

Function:

Analog ground reference.

Differential Analog Outpus - AOUTR- , AOUTR+ and AOUTL- ,

AOUTL+

Pins 19, 20, 23 and 24, Outputs

Function:

The full scale differential analog output level is specifi ed in the

Analog Characteristics specifi cations table.

Analog Power - VA

Pin 22, Input

Function:

Power for the analog and reference circuits. Typically 5VDC.

Common Mode Voltage - CMOUT

Pin 25, Output Function:

Filter connection for internal bias voltage, typically 50% of VREF.

Capacitors must be connected from CMOUT to analog ground,

as shown in Figure 6. CMOUT has a typical source impedence

of 25 kΩ and any current drawn from this pin will alter device

performance

Reference Ground - FILT-

Pin 26, Input Function:

Ground reference for the internal sampling circuits. Must be

connected to analog ground.

Reference Filter - FILT+

Pin 27, Output Function:

Positive reference for internal sampling circuits. External

capacitors are required from FILT+ to analog ground, as shown in

Figure 6. FILT+ is not intended to supply external current.

Voltage Reference Input- VREF

Pin 28, Input Function:

Analog voltage reference. Typically 5VDC.

HARDWARE MODE

Mode Select - M0, M1, M2, M3, M4

Pins 2, 3, 4, 5 and 14, Inputs Function:

The Mode Select pins determine the operational mode of the

device as detailed in Tables 9-14. The op-tions include;

Selection of the Digital Interface Format which determines the

required relationship between the Left/Right clock, serial clock

and serial data as detailed in Figures 29-33 Selection of the

standard 15 μs/50 μs digital de-emphasis fi lter response, Figure

28, which requires re-confi guration of the digital fi lter to maintain

the proper fi lter response for 32, 44.1 or 48 kHz sample rates.

Selection of the appropriate clocking mode to match the input

sample rates. Access to the Direct Stream Digital Mode Access

to the 8x Interpolation Input Mode

CONTROL PORT MODE

Address Bit 0 / Chip Select - AD0 / CS

Pin 2, Input Function:

2

C mode, AD0 is a chip address bit. CS is used to enable the

In I

control port interface in SPI mode. The device will enter the SPI

mode at anytime a high to low transition is detected on this pin.

Once the device has entered the SPI mode, it will remain until

either the part is reset or undergoes a power-down cycle.

Address Bit 1 / Control Data Input - AD1/CDIN

Pin 3, Input Function:

In I2C mode, AD1 is a chip address bit. CDIN is the control data

input line for the control port interface in SPI mode.

Serial Control Interface Clock - SCL/CCLK

Pin 4, Input Function:

2

C mode, SCL clocks the serial control data into or from

In I

SDA/CDOUT.

In SPI mode, CCLK clocks the serial data into AD1/CDIN and out

of SDA/CDOUT.

Serial Control Data I/O - SDA/CDOUT

Pin 5, Input/Output Function:

2

C mode, SDA is a data input/output. CDOUT is the control

In I

data output for the control port interface in SPI mode.

M1 - Mode Select

Pin 14, Input Function:

This pin is not used in Control Port Mode and must be terminated

to ground.

SCLK

LRCK

SDATA

MCLK

CLOCK

DIVIDER

M4

(AD0/CS)

(AD1/CDIN) (SCL/CCLK)

M3 M2

SERIAL INTERFACE

AND FORMAT SELECT

INTERPOLATION

FILTER

INTERPOLATION

FILTER

HARDWARE MODE CONTROL

(CONTROL PORT)

M1

M0

(SDA/CDOUT)

SOFT MUTE

MULTI-BIT

ΔΣ

MODULATOR

MULTI-BIT

ΔΣ

MODULATOR

RESET MUTEC MUTE

DSD MODE

Refer to PCM mode RST VREF Refer to PCM mode

Refer to PCM mode M4(ADO/CS

Refer to PCM mode M3(AD1/CDIN) FILT- Refer to PCM mode

Refer to PCM mode M2(SCL/CCLK) CMOUT Refer to PCM mode

Refer to PCM mode M0(SDA/CDOUT) AOUTL- Refer to PCM mode

Refer to PCM mode DGND AOUTL+ Refer to PCM mode

Refer to PCM mode VD VA Refer to PCM mode

Refer to PCM mode VD AGND Refer to PCM mode

Refer to PCM mode DGND AOUTR+ Refer to PCM mode

Master Clock MCLK AOUTR- Refer to PCM mode

DSD Serial Clock DSD_SCLK AGND Refer to PCM mode

Master Clock Mode CLKMODE MUTEC

Left Channel Data DSD_L C/H

Right Channel Data DSD_R MUTE

Master Clock - MCLK

Pin 10, Input

Function:

The master clock frequency must be either 4x or 6x the DSD data

rate for 64x oversampled DSD data and 2x or 3x the DSD data

rate for 128x oversampled DSD data, refer to Table 7.

CLKMODE

Pin 12, Input

Function:

This pin determines the allowable Master Clock to DSD data ratio

as defi ned in Table 7.

1

1

) FILT+ Refer to PCM mode

2

2

3

4

5

5

6

6

7

8

9

10

11

12

131416

DE-EMPHASIS

FILTER

DYNAMIC

ELEME NT

MATCHING

LOGIC

DYNAMIC

ELEME NT

MATCHING

LOGIC

FILT+

SWITCHED

CAPACITOR-DAC

AND FILTER

SWITCHED

CAPACITOR-DAC

AND FILTER

VOLTAGE REFERENCE

VREF CMO UTFILT-

AOUTL+

AOUTL-

AOUTR+

AOUTR-

28

27

26

25

24

23

22

21

20

19

18

17

Refer to PCM mode

Refer to PCM mode

15

Refer to PCM mode

DSD Serial Clock -DSD_SCLK

Pin 11, Input

Function:

Clocks the individual bits of the DSD audio data into the DSD_L

and DSD_R pins.

Audio Data -DSD_L and DSD_R

Pins 13 and 14, Inputs

Function:

Direct Stream Digital audio data is clocked into DSD_L and

DSD_R via the DSD serial clock.

CLKMODE

01

DSD Over-Sampling

Ratio

64x 4x 6x

128x 2x 3x

Table 7. MCLK to DSD Data Rate Clock Ratios

1-23 1-24

11. EXPLODED VIEW AND PARTS LIST

101D

010B

5127

Ø 3 X 8(M)

112B

5126

Ø3X8(M)X4

111B

5126

Ø3X8(M)

110B

VX01

135B

013B

130B

Mecha Loader and

Mecha Traverse

014M

5129

Ø3X8(M)

X2

Super Audio CD

PWB Module

(5110)

Ø3X6(M)X4

PY16

W005

(5159)

Ø2.6X6(B)

X4

(544010001002S)

5110

Ø3X8(M)

X2

TEFLON TAPE

5126

Ø3X8(M)

X2

L001

070G

L003

Ø3X8(M)

100G

5128

Ø4X8(M)X4

5129

5405

Ø 4 (M)

5405

Ø3(M)

PH16

5128

Ø4X8(M)X4

5110

Ø3X6(M)X7

L012

110G X 2

020G

L011

030G

X2

J001

/N Only

W001

5128

Ø3X8(M)X2

5127

Ø 3 X 8(M) X 4

5127

Ø3X8(M)X3

J608

J607

068G X 2

5126

Ø3X8(M)

065G

PP16

045G

095G X 4

003B

001B

5128

Ø3X8(M)X5

005B

100D X 3

008B

025B

5129

Ø3X8(M)X2

030B

5128

Ø3X8(M)X6

040B

5128

Ø 3 X 8(M)

X4

050B

060B

093G

SYMBOL STYLE

5110

5126

5127

5128

5129

5405

5128

Ø3X8(M)

X7

PR16

5128

090G

+B.H.M.SCREW

+B.H.TAP TITE SCREW W/ WASHER

+B.H.TAP TITE SCREW(W/)

+B.H.TAP TITE SCREW(B TYPE )

+B.H.TAP TITE SCREW(W/T.L.WASHER)

TOOTHED LOCK WASHERS

Ø3X6(M)

X2

PARTS NAME

095G X 3

MARK

MATERIAL/FINISH

STEEL/COPPER(M)

STEEL/BLACK(U)

(K) STEEL/NICKEL

5129

Ø3X8(M)

050G

5128

Ø3X8(M)X8

001G

001G

002G