Marantz M-CR610 Service Manual

Service

M-CR610 /

N1B/N1W/U1B

Manual

NETWORK CD RECEIVER

For purposes of improvement, specications and design are subject to change without notice.

•

Please use this service manual with referring to the operating instructions without fail.

•

Some illustrations using in this service manual are slightly different from the actual set.

•

M-CR610

Copyright 2013 D&M Holdings Inc. All rights reserved.

S0723-0V02DM/DG1307

WARNING: Violators will be prosecuted to the maximum extent possible.

Ver. 2

Please refer to the

MODIFICATION NOTICE.

CONTENTS

ABOUT THIS MANUAL .............................................................3

What you can do with this manual ............................................3

Using Adobe Reader (Windows version) ..................................4

SAFETY PRECAUTIONS ..........................................................6

NOTE FOR SCHEMATIC DIAGRAM .........................................7

NOTE FOR PARTS LIST ...........................................................7

TECHNICAL SPECIFICATIONS ................................................9

DIMENSION ...............................................................................9

CAUTION IN SERVICING ........................................................10

Initializing NETWORK CD RECEIVER ...................................10

Service tools ............................................................................10

ABOUT REPLACE THE WLAN MODULE

WITH A NEW ONE ..................................................................10

Measurement of Board Test Points for Servicing ....................11

Note Handling and Replacement of the Laser pick-up .......13

1. Protection of the LD ...........................................................13

2. Precautions when handling the laser CD mechanism........13

3. Cautions on assembling and adjustment ...........................13

4. Determining whether the laser pick-up is defective ............13

DISASSEMBLY ........................................................................14

1. SIDE PANEL ......................................................................15

2. TOP COVER ASSY ............................................................15

3. CD MECHA ASSY ..............................................................16

4. CD PWB ASSY ..................................................................17

5. TUNER UNIT .....................................................................17

6. SHIELD CASE ...................................................................18

7. FRONT PANEL ASSY ........................................................18

8. SMPS PWB ASSY .............................................................19

9. INPUT PWB ASSY .............................................................19

10. ETHETNET PWB ASSY .....................................................20

11. MAIN PWB ASSY ...............................................................20

SPECIAL MODE ......................................................................21

1. Initialization mode (Factory Reset) .....................................22

2. Initialization mode (User Reset) .........................................23

3. Version display ...................................................................23

4. CD test mode .....................................................................25

5. CD heat run mode ..............................................................28

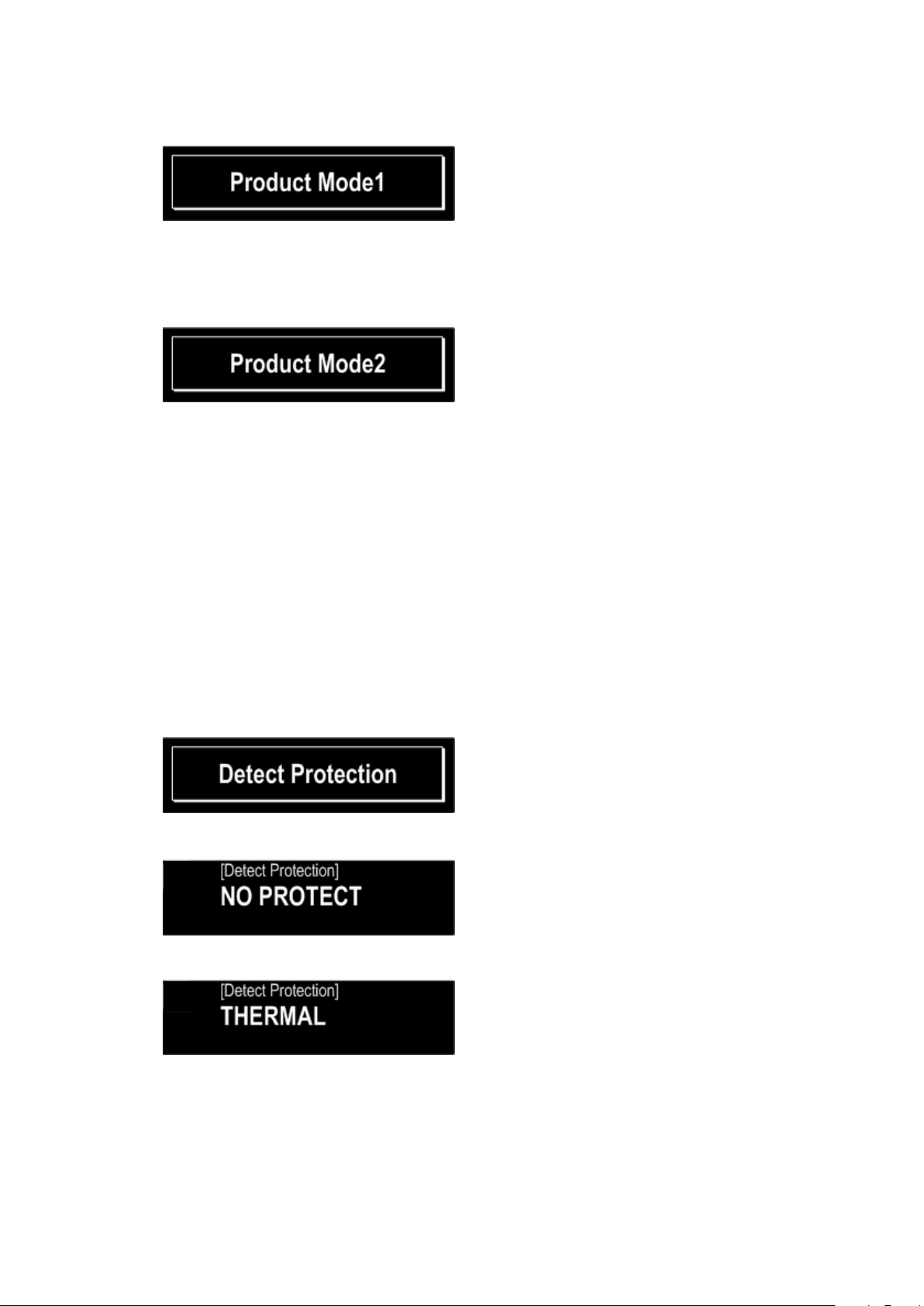

6. Product Mode 1 ..................................................................30

7. Product Mode 2 ..................................................................30

8. Protection history display mode .........................................30

9. USB UPDATE ....................................................................32

10. DPMS Update mode .........................................................33

11. MAC Address rewrite mode ...............................................34

12. Access to development server mode ................................34

ABOUT REPLACE THE MICROPROCESSOR

WITH A NEW ONE ...................................................................35

VERSION UPGRADE PROCEDURE OF FIRMWARE ............36

1. How to update by DPMS ....................................................36

2. How to update by USB Memory .........................................37

TROUBLE SHOOTING ............................................................39

1. OLED dosen't light .............................................................39

2. No Sound, Noise generated ...............................................40

MEASURING METHOD AND WAVEFORMS ..........................47

1. TEST POINT ...................................................................47

2. WAVEFORMS ....................................................................48

BLOCK DIAGRAM ...................................................................51

POWER DIAGRAM ..................................................................52

WIRING DIAGRAM ..................................................................53

PRINTED WIRING BOARDS ...................................................54

SCHEMATIC DIAGRAMS (1/6) ...............................................58

SCH01_NET_MCU .................................................................58

SCH02_NETWORK ................................................................59

SCH03_CD .............................................................................60

SCH04_AMP ...........................................................................61

SCH05_FRONT_TU-INPUT....................................................62

SCH06_SMPS ........................................................................63

EXPLODED VIEW ...................................................................64

PACKING VIEW .......................................................................65

SEMICONDUCTORS ...............................................................66

1. IC's .....................................................................................66

2. DISPLAY ............................................................................88

2

ABOUT THIS MANUAL

Read the following information before using the service manual.

What you can do with this manual

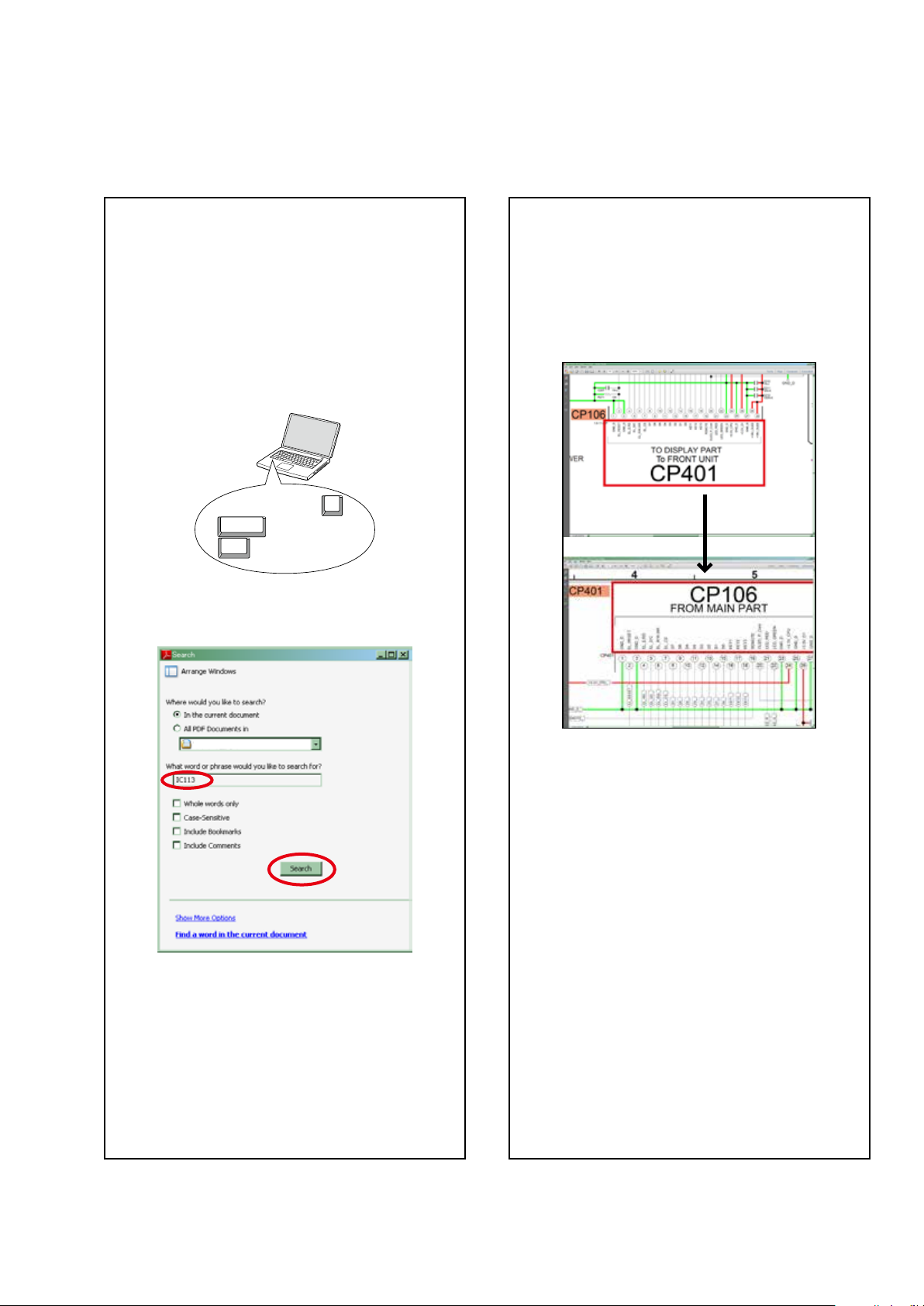

Search for a Ref. No. (phrase)

(Ctrl+Shift+F)

You can use the search function in Acrobat Reader to

search for a Ref. No. in schematic diagrams, printed

wiring board diagrams, block diagrams, and parts

lists.

1.Press Ctrl+Shift+F on the keyboard.

• The Search window appears.

F

Shift

Ctrl

2.Enter the Ref. No. you want to search for in the

Search window, and then click the Search button.

•A list of search results appears.

Jump to the target of a schematic

diagram connector

Click the Ref. No. of the target connector in the red

box around a schematic diagram connector.

•The screen jumps to the target connector.

3.Click an item on the list.

• The screen jumps to the page for that item, and the

search phrase is displayed.

• Page magnication stays the same as before the

jump.

3

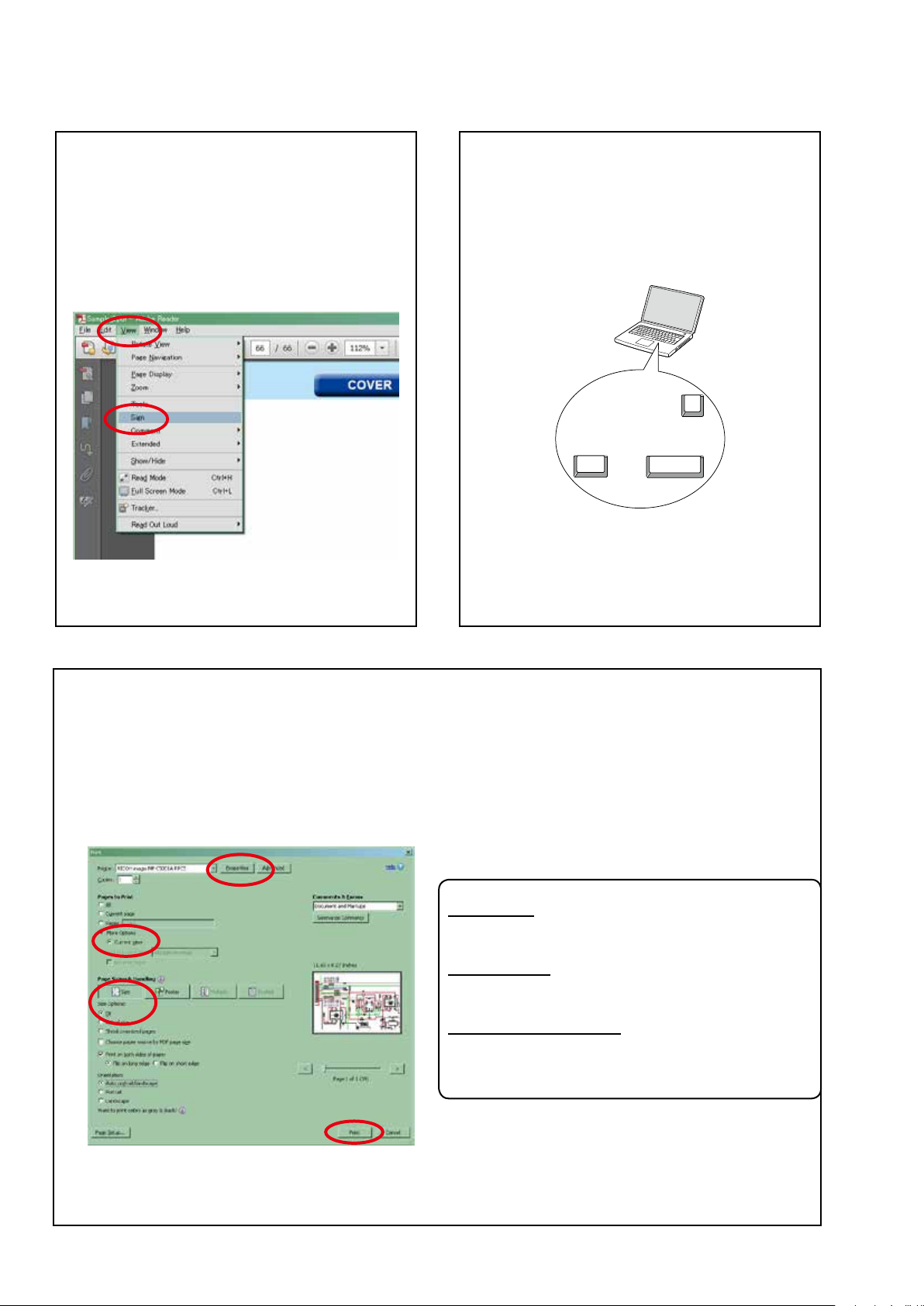

Using Adobe Reader (Windows version)

Add notes to this data (Sign)

The Sign function lets you add notes to the data in

this manual.

Save the le once you have nished adding notes.

[Example using Adobe Reader X]

On the "View" menu, click "Sign".

• The Sign pane appears.

[Example using Adobe Reader 9]

On the "Document" menu, click "Sign".

Magnify schematic / printed wiring

board diagrams - 1

(Ctrl+Space, mouse operation)

Press Ctrl+Space on the keyboard and drag the

mouse to select the area you want to view.

• The selected area is magnied.

0

Ctrl Space

• When you want to move the area shown, hold

down Space and drag the mouse.

• When you want to show a full page view, press

Ctrl+0 on the keyboard.

Printamagniedpartofthemanual

The Properties dialog box and functions will vary depending on your printer.

1. Drag the mouse to magnify the part you want to print.

2. On the "File" menu, click "Print".

3. Congure the following settings in the Print dialog box.

• Properties

Click this button and check that the printer is set to a

suitable paper size.

• Pagetoprint

Select the following checkbox.

"More Options" : "Current View"

• PageSizing&Handling

Select the following checkbox.

"Size" / "SizeOptions" : "Fit"

4. Click the Print button to start printing.

4

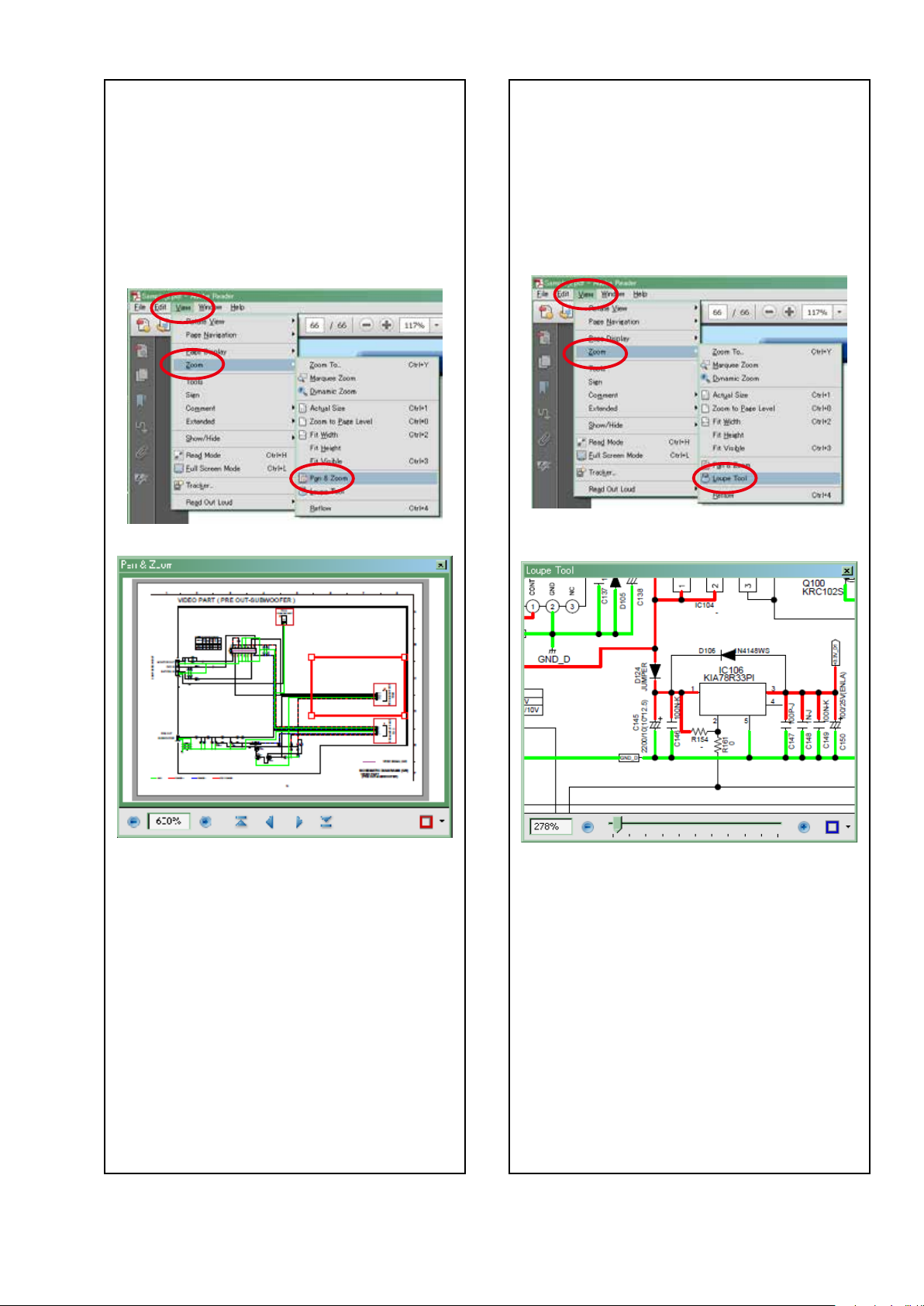

Magnify schematic / printed wiring

board diagrams - 2

(Pan&Zoomfunction)

The Pan & Zoom function lets you see which part of

a magnied diagram is being shown in a separate

window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Pan&Zoom".

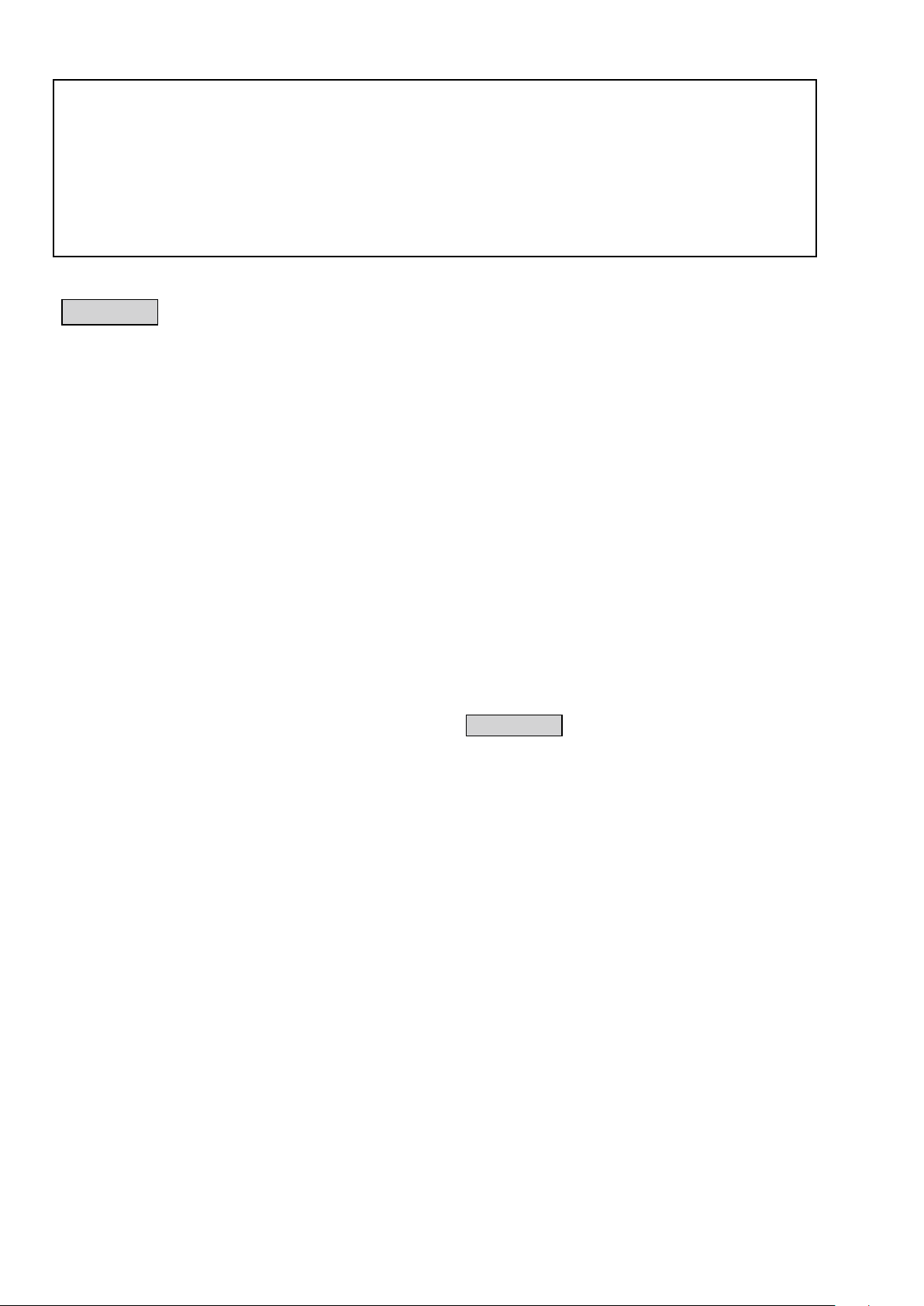

Magnify schematic / printed wiring

board diagrams - 3

(Loupe Tool function)

The Loupe Tool function lets you magnify a specic

part of a diagram in a separate window.

[Example using Adobe Reader X]

On the "View" menu, point to "Zoom", and then click

"Loupe Tool".

• The Pan & Zoom window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select&Zoom", and

then click "Pan&ZoomWindow".

• The Loupe Tool window appears on the screen.

[Example using Adobe Reader 9]

On the "Tools" menu, point to "Select&Zoom", and

then click "Loupe Tool Window".

5

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

leakage current check

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state

(on, off and standby mode), if applicable.

CAUTION

Please heed the following cautions and instructions during servicing and

inspection.

◎Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if you

touch internal metal parts when the set is energized,

you may get an electric shock. Avoid getting an

electric shock, by using an isolating transformer

and wearing gloves when servicing while the set is

energized, or by unplugging the power cord when

replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs on

the edges of parts. The burrs could cause injury if ngers

are moved across them in some rare cases. Wear gloves

to protect your hands.

◎Use only designated parts!

The set's parts have specic safety properties (re

resistance, voltage resistance, etc.). Be sure to use parts

which have the same properties for replacement. The

burrs have the same properties. In particular, for the

important safety parts that are indicated by the z mark

on schematic diagrams and parts lists, be sure to use

the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or other

insulating materials, and some parts are mounted away

from the surface of printed circuit boards. Care is also

taken with the positions of the wires by arranging them

and using clamps to keep them away from heating and

high voltage parts, so be sure to set everything back as

it was originally placed.

◎Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in their

original positions, check that no serviced parts have

deteriorate the area around. Then make an insulation

check on the external metal connectors and between

the blades of the power plug, and otherwise check that

safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet, disconnect

the antenna, plugs, etc., and on the power. Using a 500V

insulation resistance tester, check that the insulation

resistance value between the inplug and the externally

exposed metal parts (antenna terminal, headphones

terminal, input terminal, etc.) is 1MΩ or greater. If it is

less, the set must be inspected and repaired.

CAUTION

Concerning important

safety parts

Many of the electric and the structural parts used in the

set have special safety properties. In most cases these

properties are difcult to distinguish by sight, and the use

of replacement parts with higher ratings (rated power

and withstand voltage) does not necessarily guarantee

that safety performance will be preserved. Parts with

safety properties are indicated as shown below on the

wiring diagrams and the parts list in this service manual.

Be sure to replace them with the parts which have the

designated part number.

(1) Schematic diagrams .......Indicated by the z mark.

(2) Parts lists .......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, res or other dangerous

situations.

6

NOTE FOR SCHEMATIC DIAGRAM

NOTE FOR PARTS LIST

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identied and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

NOTE FOR PARTS LIST

1.

Parts indicated by "nsp" on this table cannot be supplied.

2.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

3.

A part ordered without specifying its part number can not be supplied.

4.

Part indicated by "★" mark is not illustrated in the exploded view.

5.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

6.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

WARNING:

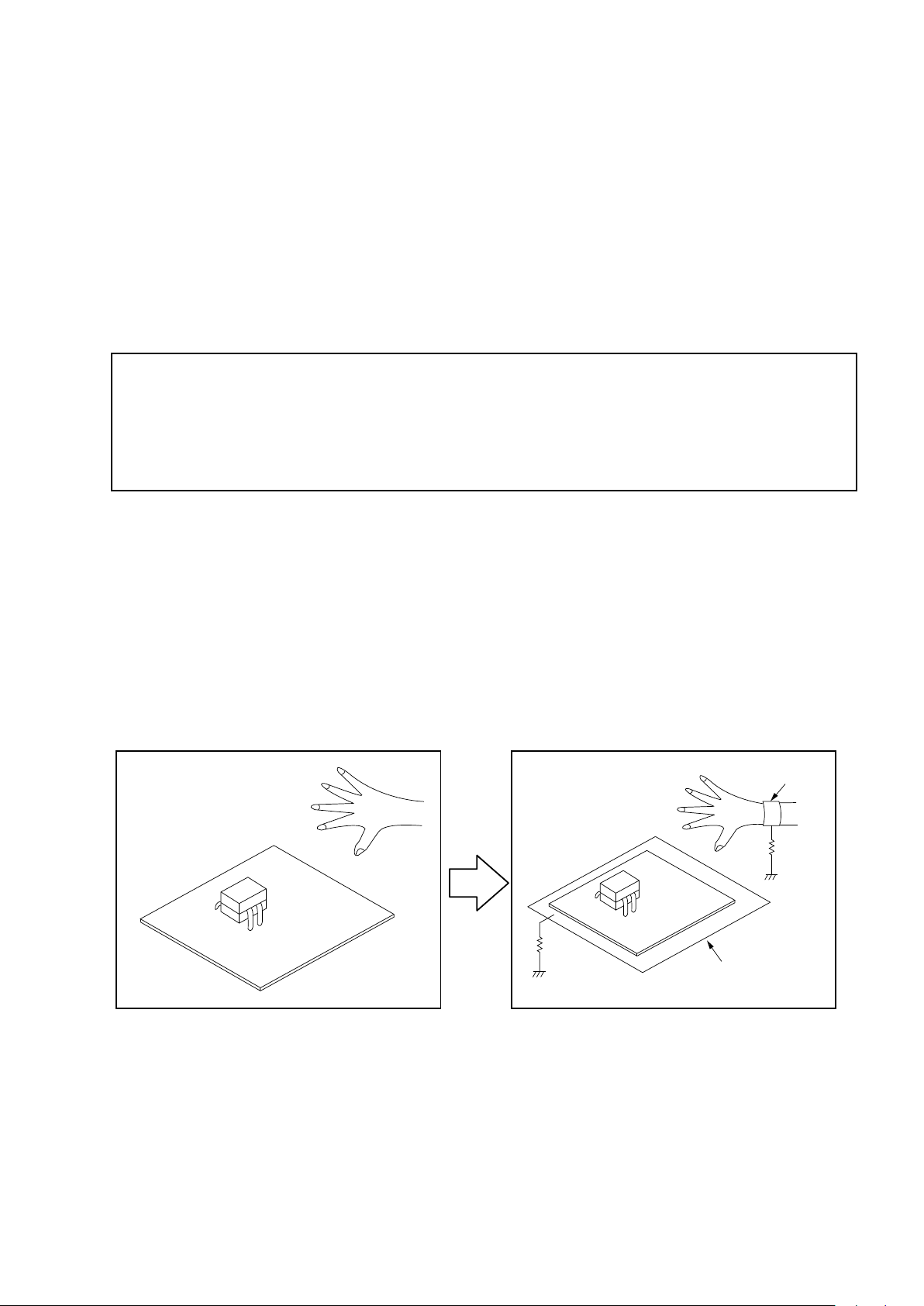

INSTRUCTIONS FOR HANDLING SEMI-CONDUCTORS AND OPTICAL UNIT

Electrostatic breakdown of the semi-conductors or optical pickup may occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is properly grounded to remove any static electricity that may be

charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate with proper grounding (1 MΩ) on the workbench or other surface,

where the semi-conductors are to be placed. Because the static electricity charge on clothing will not escape through

the body grounding band, be careful to avoid contacting semi-conductors with your clothing

<Incorrect>

<Correct>

CBA

CBA

1MΩ

Grounding Band

1MΩ

Conductive Sheet or

Copper Plate

7

WARNING AND LASER SAFETY INSTRUCTIONS

F ATTENTION

D

WARNUNG

WAARSCHUWING

AVVERTIMENTO

WARNING

Safety regulations require that the set be restored to its original condition

and that parts which are identical with those specified be used.

Veiligheidsbepalingen vereisen, dat het apparaat in zijn oorspronkelijke

toestand wordt terug gebracht en dat onderdelen, identiek aan de

gespecifieerde worden toegepast.

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu beachten.

Der Originalzustand des Gerats darf nicht verandert werden.

Fur Reparaturen sind Original-Ersatzteile zu verwenden.

Le norme di sicurezza esigono che l’apparecchio venga rimesso nelle

condizioni originali e che siano utilizzati pezzi di ricambiago idetici a quelli

specificati.

Les normes de sécurité exigent que l’appareil soit remis a l’état d’origine et

que soient utilisées les pièces de rechange identiques à celles spécifiées.

“Pour votre sécurité, ces documents

doivent être utilisés par des

spécialistes agrées, seuls habilités à

réparer votre appareil en panne.”

GB

NL

I

D

I

F

GB

NL

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are connected

with the same potential as the mass of the set via a

wrist wrap with resistance.

Keep components and tools also at this potential.

Tous les IC et beaucoup d’autres semiconducteurs

sont sensibles aux décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est prise

a leur manipulation.

Lors de réparations, s’assurer de bien être relié au

même potentiel que la masse de l’appareil et enfiler

le bracelet serti d’une résistance de sécurité.

Veiller a ce que les composants ainsi que les outils

que l’on utilise soient également a ce potentiel.

Alle IC und viele andere Halbleiter sind

empfindlich gegen elektrostatische

Entladungen (ESD).

Unsorgfältige Behandlung bei der Reparatur

kann die Lebensdauer drastisch vermindern.

Sorgen sie dafür, das Sie im Reparaturfall

dem Massepotential des Gerätes verbunden

sind.

Halten Sie Bauteile und Hilfsmittel ebenfalls

über ein Pulsarmband mit Widerstand mit auf

diesem Potential.

Alle IC’s en vele andere halfgeleiders zijn gevoelig

voor elektrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan de

levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een polsband

met weerstand verbonden bent met apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono sensibili

alle scariche statiche (ESD).

La loro longevita potrebbe essere fortemente ridatta

in caso di non osservazione della piu grande

cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto a

resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo potenziale.

LASER SAFETY

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDS

Æ

TTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL Å PNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYONNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE

OF PROCEDURE OTHER THAN THOSE SPECIFIED HEREIN

MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

AVOID DIRECT EXPOSURE TO BEAM

WARNING

The use of optical instruments with this product will

increase eye hazard.

Repair handling should take place as much as possible with

a disc loaded inside the player

WARNING LOCATION: INSIDE ON LASER COVERSHIELD

This unit employs a laser. Only a qualified service person should

remove the cover or attempt to service this device, due to

possible eye injury.

100301DM

8

TECHNICAL SPECIFICATIONS

nAudio section

• CD player

Playback frequency response:

Wow & flutter:

Sampling frequency:

• Audio amplifier

Rated output:

Dynamic power:

Output terminals:

Input sensitivity/impedance:

THD+N (1 kHz, 5 W, 6 Ω/ohms):

S/N ratio (10 W, 6 Ω/ohms, IHF-A):

Tone control:

Frequency response:

Below measurable limits (± 0.001%)

2-channel driving

50 W + 50 W (6 Ω/ohms, 1 kHz, THD+N 0.7 %)

60 W + 60 W (6 Ω/ohms, 1 kHz, THD+N 10 %)

Speaker 6 – 8 Ω/ohms

Suited for headphones/stereo headphones

Dynamic Bass Boost : 100 Hz + 8 dB

BASS : 100 Hz ± 10 dB

TREBLE : 10 kHz ± 10 dB

nTuner section (U only)

Receiving Range:

Usable Sensitivity:

Channel separation:

S/N ratio:

THD+N:

nTuner section (N Only)

Receiving Range:

Usable Sensitivity:

Channel separation:

S/N ratio:

THD+N (1 kHz):

87.50 MHz – 108.00 MHz

1.2 μV / 75 Ω/ohms

Monaural : 74 dB / Stereo : 70 dB

Monaural : 0.3 % / Stereo : 0.4 %

10 Hz – 20 kHz

44.1 kHz

Analog In 1/2 : 200 mV/22 kΩ/kohms

Analog In 1/2 : 0.1 %

Analog In 1/2 : 86 dB

Analog In 1/2 : 5 Hz – 22 kHz (± 3dB)

FM 87.5 MHz – 107.9 MHz

AM 520 kHz – 1710 kHz

FM 1.2 μV / 75 Ω/ohms

AM 20 μV

30 dB (1 kHz)

MONO 74 dB

STEREO 70 dB

MONO 0.3 % (1 kHz)

STEREO 0.4 % (1 kHz)

30 dB (1 kHz)

nDAB tuner section (N Only)

Frequency Range:

Sensitivity:

S/N ratio:

THD+N (1 kHz):

Channel separation:

174.928 (5A) – 239.200 (13F) MHz (BAND III)

–85 dBm

95 dB

0.03 %

80 dB (1 kHz)

nWireless LAN

Network type

(wireless LAN

standards):

Transfer rate:

Security:

Used frequency

range:

No. of channels:

Wi-Fi® conformity indicates tested and proven interoperability by the “Wi-

z

Fi Alliance”, a group certifying interoperability among wireless LAN devices.

Conforming to IEEE 802.11b

Conforming to IEEE 802.11g

(Conforming to Wi-Fi®)z

DS-SS: 11 / 5.5 / 1 Mbps (Automatic switching)

OFDM: 54 / 48 / 36 / 24 / 18 / 12 / 9 / 6 Mbps

(Automatic switching)

SSID (Network name)

WEP key (network key) (64/128 bits)

WPA-PSK (TKIP/AES)

WPA2-PSK (TKIP/AES)

2.412 GHz – 2.462 GHz

onforming to IEEE 802.11b : 11ch (DS-SS) (Of which 1

channel used)

Conforming to IEEE 802.11g : 11ch (OFDM) (Of which

1 channel used)

nClock/Alarm

Clock type:

Alarm:

Power line frequency synchronized method (Within ±60

seconds per month)

Everyday alarm / Once alarm : One system each

Sleep timer : Max. 90 minutes

nGeneral

Power supply:

Power consumption:

Power consumption in standby mode:

Power consumption in “Network Control” – “On” mode:

AC 120 V, 60 Hz

AC 230 V, 50/60 Hz

55 W

0.3 W

3 W

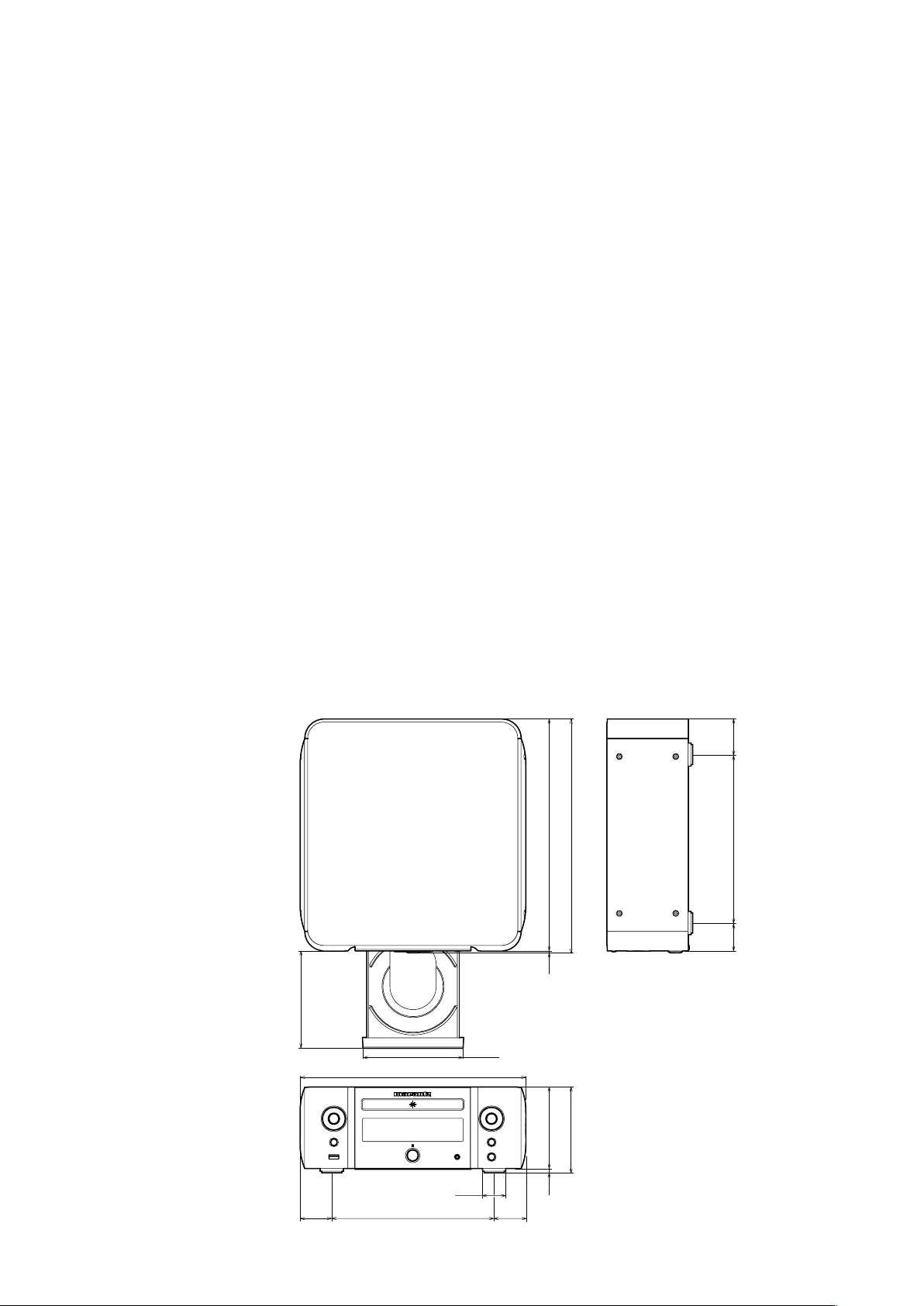

DIMENSION

Unit : in. (mm)

Weight : 7 lbs 8 oz (3.4 kg)

4 51/64 (122)

11 1/2 (292)

5 1/8 (130)

11 13/16 (300)

(3)

1/8

11 59/64 (303)

(46)

1 13/16

8 37/64 (218)

(36)

1 37/64

1 39/64

(41)

8 17/64 (210)

1 3/16

(30)

4 11/64 (106)

4 13/32 (112)

(6)

15/64

1 39/64

(41)

9

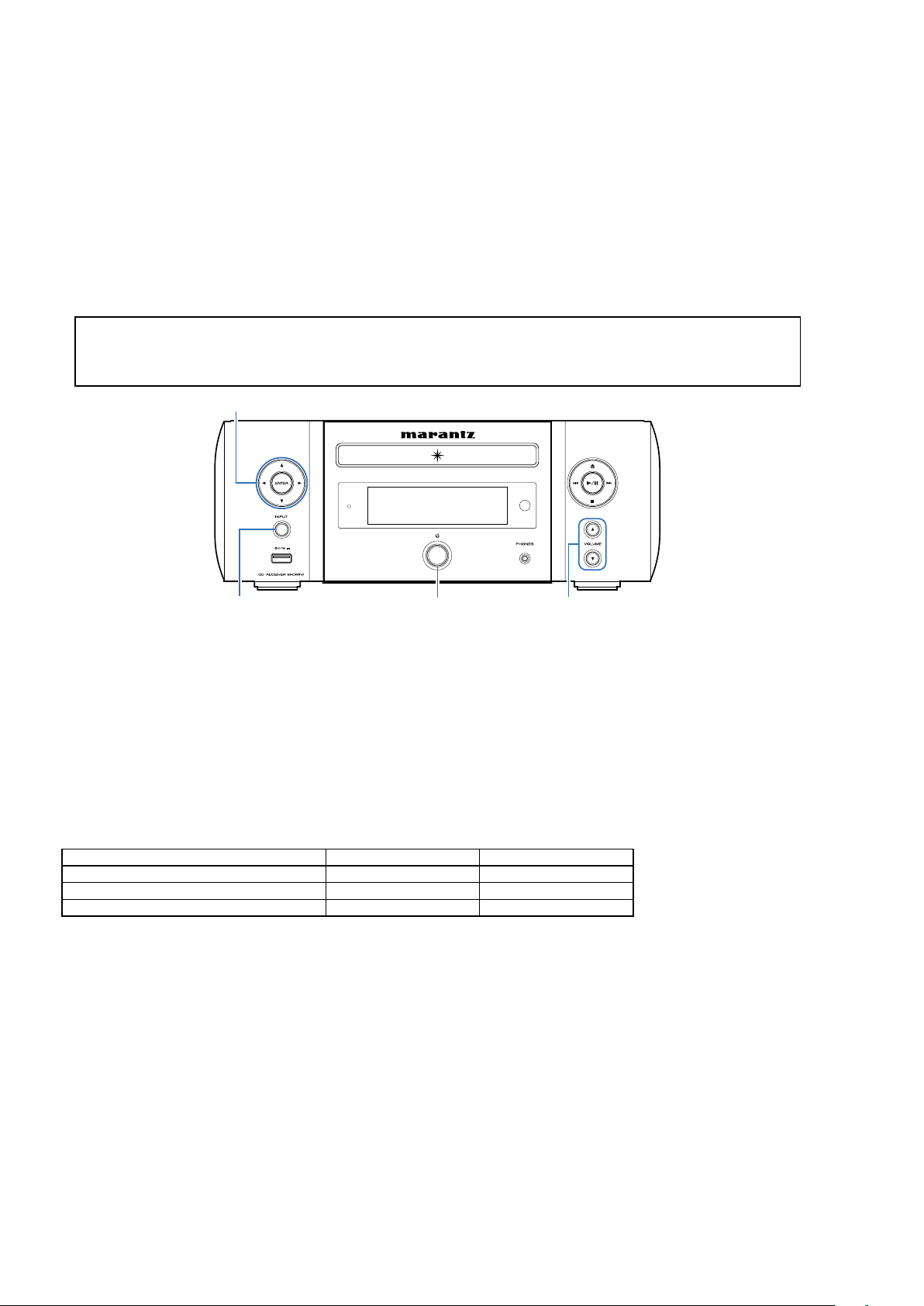

CAUTION IN SERVICING

InitializingNETWORKCDRECEIVER

NETWORK CD RECEIVER initialization should be performed when the μ-COM, peripheral parts of μ-COM, and Digital

PWB were replaced.

1. Turn off the power using "ON/STANDBY" button, unplug the power cord.

2. Plug the power cord into a power outlet while pressing "INPUT" and "CURSOR i" button simultaneously.

(Factory Reset)

3. Turn off the power using "ON/STANDBY" button, unplug the power cord.

4. Plug the power cord into a power outlet while pressing "VOLUME d" and "f" button simultaneously.

(Initialized)

Note: • All user settings will be lost and this factory setting will be recovered when this initialization mode. So

make sure to memorize your setting for restoring after the initialization.

CURSOR

i

INPUT

ON/STANDBY

VOLUME d/

f

Service tools

Measuring Disc: CD/TCD-784

CD-R/TCD-R082W

CD-RW/TCD-W082W

Refer to "MEASURING METHOD AND WAVEFORMS".

z

ABOUT REPLACE THE WLAN MODULE WITH A NEW ONE

When replaced of the WLAN MODULE(CX870-3D-D60), conrm contents of the following.

(1) Part numbers differ depending on the destination country of the WLAN MODULE. Be sure to follow the table below

when replacing the parts.

MODULE Name Remarks Part No.

CX870-3D-D60 ROM ASSY MCR610 N(EU) 943189100611S

CX870-3D-D60 ROM ASSY MCR610 U(NA) 943189100610S

CX870-3D-D60 ROM ASSY MCR610 F(JP) 943189100612S

(2) The rmware is updated by DPMS or USB Memory. Refer to [ VERSION UPGRADE PROCEDURE OF FIRMWARE

"1. How to update by DPMS" or "2. How to update by USB Memory"] (36 page) for the details of the Version up.

(3) MAC Address Label pasted to Bottom is pasted to Mac Address Label (GEN8341; MAC ADDRESS SUB ASSY) of

exchanged WLAN MODULE and it substitutes it.

10

Measurement of Board Test Points for Servicing

When measuring the board test points during servicing, the measurements can be performed easily by turning over the

MAIN board with the back panel still attached by screws, as shown in the gure below.

Disassembly Procedure (See "DISASSEMBLY" for details on the disassembly procedure)

1. Remove all of the screws from the MAIN PWB, SMPS PWB, CD Mecha, CD Foot, NET PWB, USB PWB and chassis (CD

Mecha and CD Foot are for the M-CR610 only).

2. Remove the SMPS PWB, CD Mecha and CD Foot (CD Mecha and CD Foot are for the M-CR610 only).

3. Remove the wire and FFC connected to the FRONT PWB.

4. Remove the molded parts from the back panel.

5. Raise the MAIN board, slide the entire back panel to the rear, and remove everything from the back panel to PWB as a

set.

11

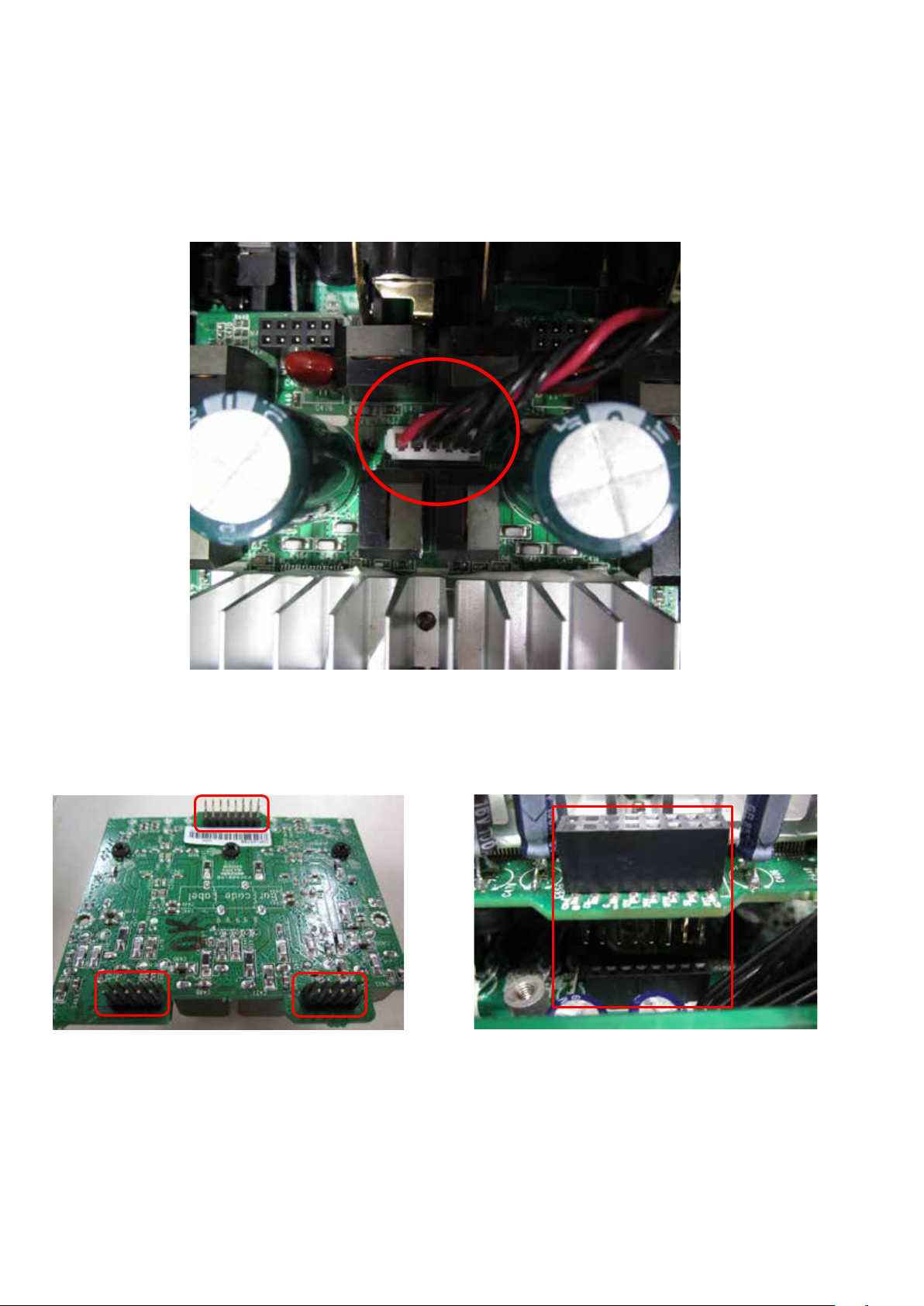

Removing the AMP PWB from the MAIN PWB

Pay close attention to the following two points when removing/attaching the AMP PWB to the MAIN PWB during servicing.

1. Wait for approximately 5 minutes after turning the power off before removing the wire connector that connects the SMPS

PWB and AMP PWB.

When connected to the SMPS PWB wire connector, a surge current may occur due to the charge stored in the AMP

PWB causing damage to the D-AMP IC41 and IC42 (IC41 only for the M-CR510).

2. When attaching the AMP PWB to the MAIN PWB connector, insert the connector pins into the AMP PWB beforehand,

and securely connect while checking that the position is correct.

If the MAIN PWB and AMP PWB terminals are connected incorrectly (if the connection pins are misaligned), the PWM

Processor IC56, D-AMP IC41 and IC42 (IC41 only for the M-CR510) may be damaged by the charge stored in the

condenser.

12

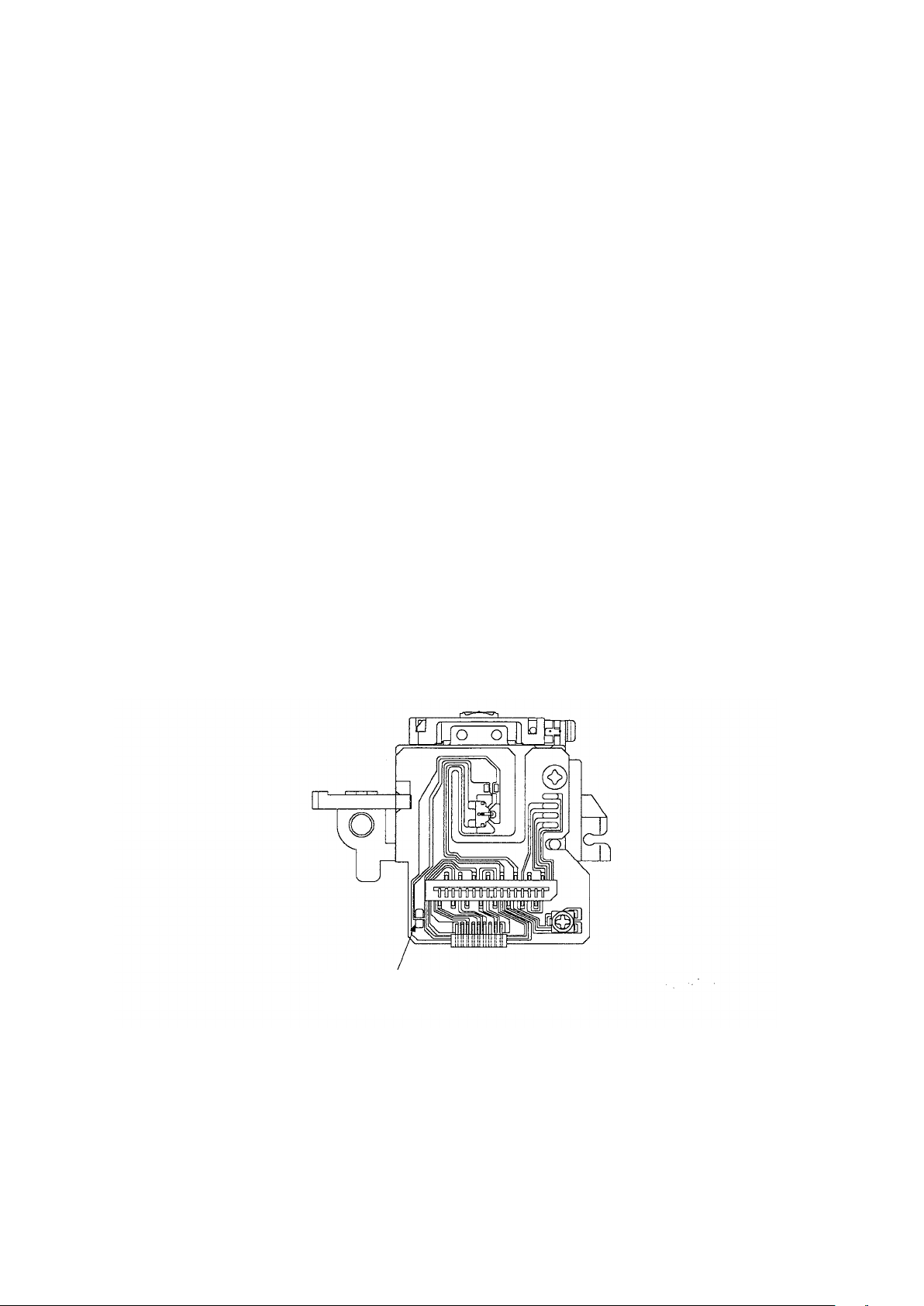

NOTE HANDLING AND REPLACEMENT OF THE LASER PICK-UP

1. Protection of the LD

Short a part of the LD circuit by soldering. After connection to a circuit, remove the short solder.

2. Precautions when handling the laser CD mechanism

• Handle the laser pick-up so that it is not exposed to dust.

• Do not leave the laser pick-up bare. Be sure to cover it.

• If dust adheres on lens of the pick-up, blow it off with a blower brush.

• Do not shock the laser pick-up.

• Do not watch the light of the laser pick-up.

3. Cautions on assembling and adjustment

• Be sure that to the bench, jig, head of soldering iron (with ceramic) and measuring instruments are well grounded.

• Workers who handle the laser pick-up must be grounded.

• The nished mechanism (prior to anchoring in the set) should be protected against static electricity and dust.

The mechanism must be stored that damaging outside forces are not received.

• When carrying the nished mechanism, hold it by the chassis body

• For proper operation, storage and operating environment should not contain corrosive gases. For example H2S, SO2,

NO2, CI2 etc. In addition storage environment should not have materials that emit corrosive gases especially from

silicic, cyanic, formalin and phenol group. I the mechanism or the set, existence of corrosive gases may cause no

rotation in motor.

4. Determining whether the laser pick-up is defective

• Check the Iop(Laser drive current). Check lop in "SPECIAL MODE". (Refer to 21 page.)

• If the present Iop (current) value becomes more than 50mA, replace the Traverse unit with a new one.

• No mechanical adjustment is necessary after the replacement.

Protective soldering place for laser diode.

13

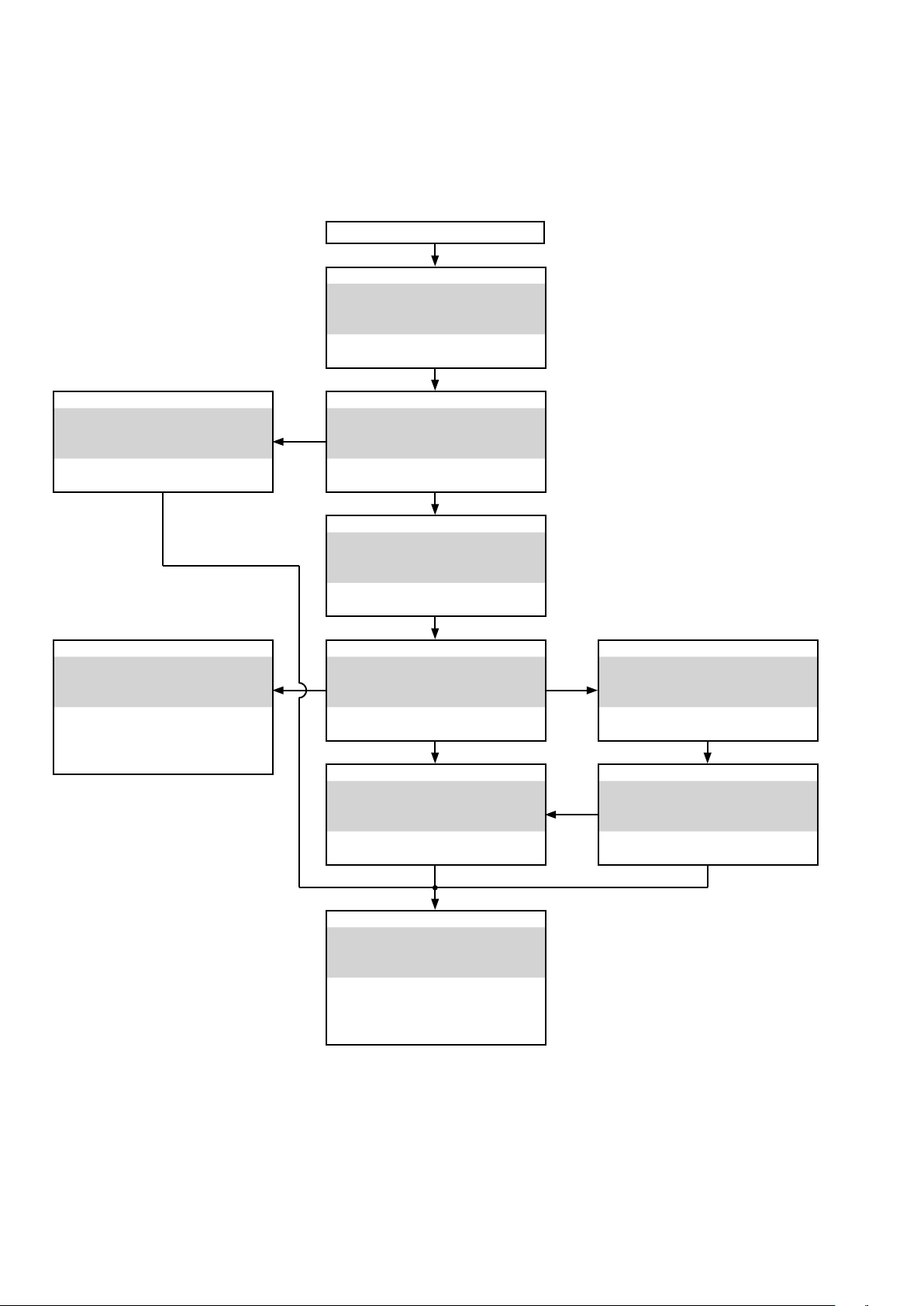

DISASSEMBLY

• Disassemble in order of the arrow in the following gure.

• In the case of the re-assembling, assemble it in order of the reverse of the following ow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

SIDE PANEL

TOP COVER ASSY

Refer to "DISASSEMBLY

2. TOP COVER ASSY"

and "EXPLODED VIEW"

TOP COVER ASSY

(Ref. No. of EXPLODED VIEW : 17)

CD PWB ASSY

Refer to "DISASSEMBLY

4. CD PWB ASSY"

and "EXPLODED VIEW"

PWB CD

(Ref. No. of EXPLODED VIEW : P8)

SMPS PWB ASSY

Refer to "DISASSEMBLY

8. SMPS PWB ASSY"

and "EXPLODED VIEW"

PWB INLET

(Ref. No. of EXPLODED VIEW : P3c)

PWB SMPS

(Ref. No. of EXPLODED VIEW : P4)

CD MECHA ASSY

Refer to "DISASSEMBLY

3. CD MECHA ASSY"

and "EXPLODED VIEW"

CD MECHA ASSY

(Ref. No. of EXPLODED VIEW : P1)

TUNER UNIT

Refer to "DISASSEMBLY

5. TUNER UNIT"

and "EXPLODED VIEW"

PWB TUNER

(Ref. No. of EXPLODED VIEW : P9)

SHIELD CASE

Refer to "DISASSEMBLY

6. SHIELD CASE"

and "EXPLODED VIEW"

SHIELD CASE

(Ref. No. of EXPLODED VIEW : 29)

INPUT PWB ASSY

Refer to "DISASSEMBLY

9. INPUT PWB ASSY"

and "EXPLODED VIEW"

PWB INPUT

(Ref. No. of EXPLODED VIEW : P1b)

FRONT PANEL ASSY

Refer to "DISASSEMBLY

7. FRONT PANEL ASSY"

and "EXPLODED VIEW"

PWB FRONT

(Ref. No. of EXPLODED VIEW : P1a)

ETHETNET PWB ASSY

Refer to "DISASSEMBLY

10. ETHETNET PWB ASSY"

and "EXPLODED VIEW"

PWB ETHETNET

(Ref. No. of EXPLODED VIEW : P3b)

MAIN PWB ASSY

Refer to "DISASSEMBLY

11. MAIN PWB ASSY"

and "EXPLODED VIEW"

PWB AMP

(Ref. No. of EXPLODED VIEW : P5)

PWB MAIN

(Ref. No. of EXPLODED VIEW : P3a)

14

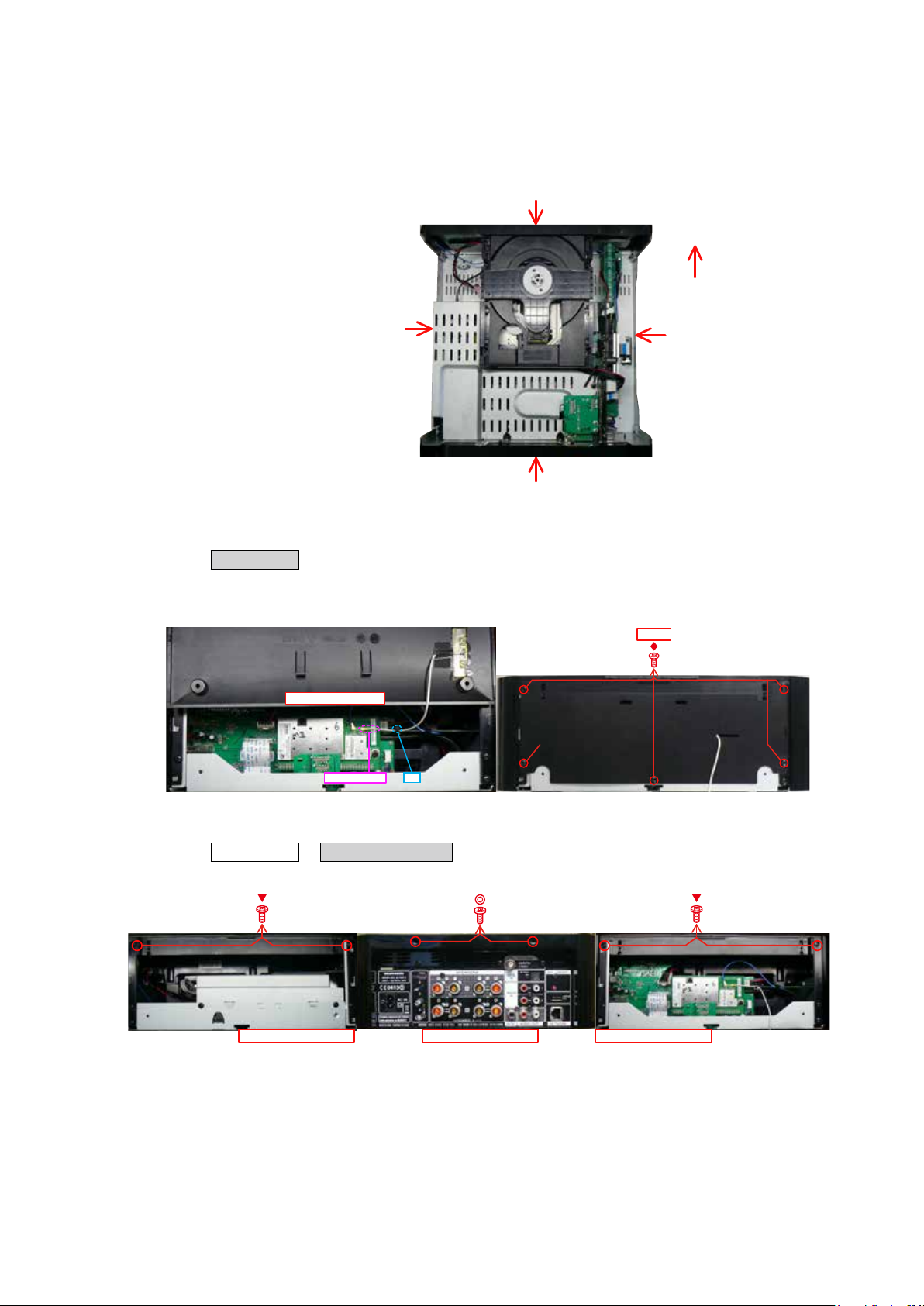

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

Shooting direction: B

(Shooting direction X)

[View from the top]

Shooting

direction: C

Shooting direction: A

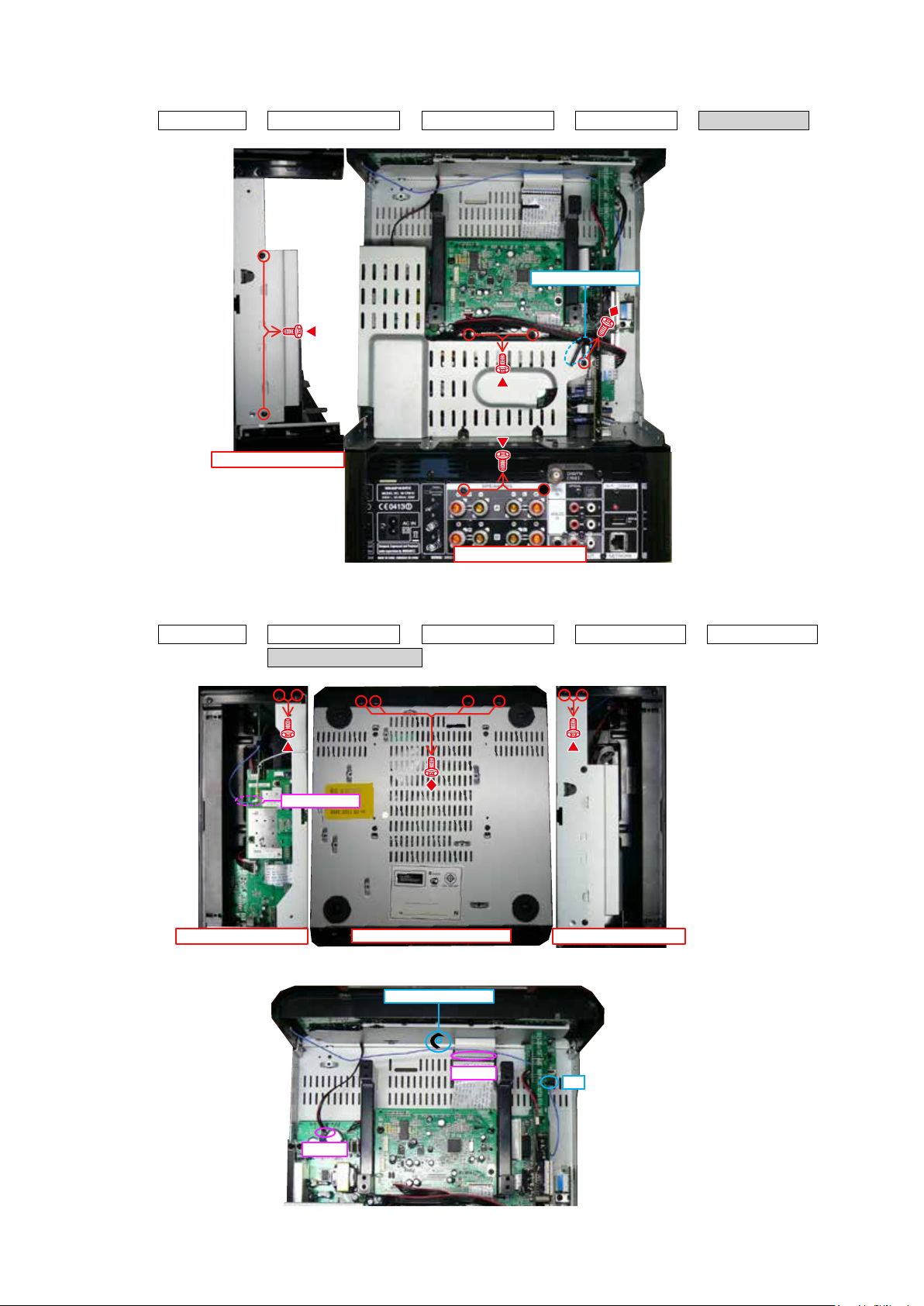

1. SIDE PANEL

Proceeding : SIDE PANEL

(1) Remove the screws.

(2) Cut the wire clamp bands, then disconnect the connector wires.

Front side

Shooting

direction: D

U only

Shooting direction: D

CON1(WHT)

cut

2. TOP COVER ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

(1) Remove the screws.

Shooting direction: AShooting direction: C Shooting direction: D

15

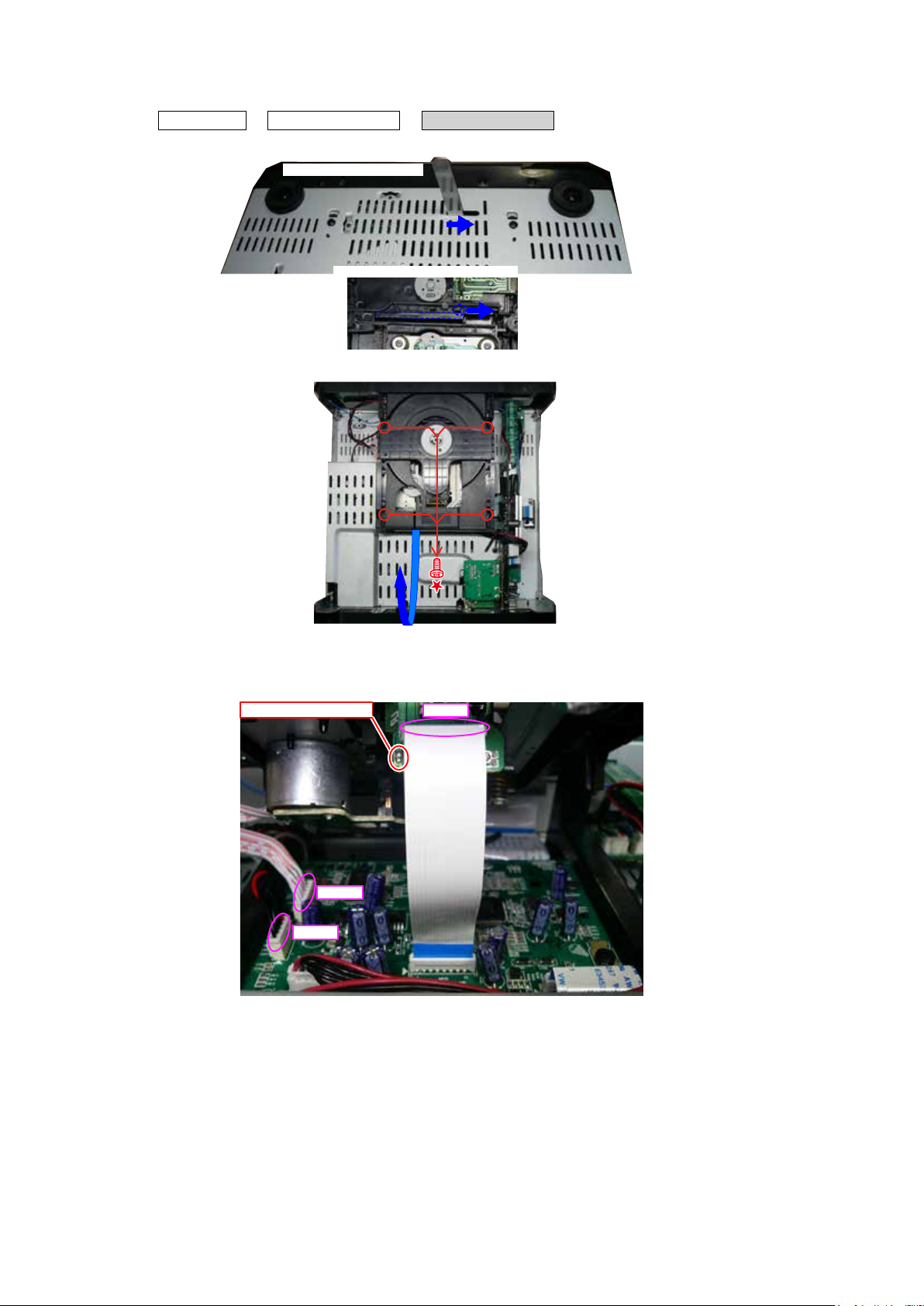

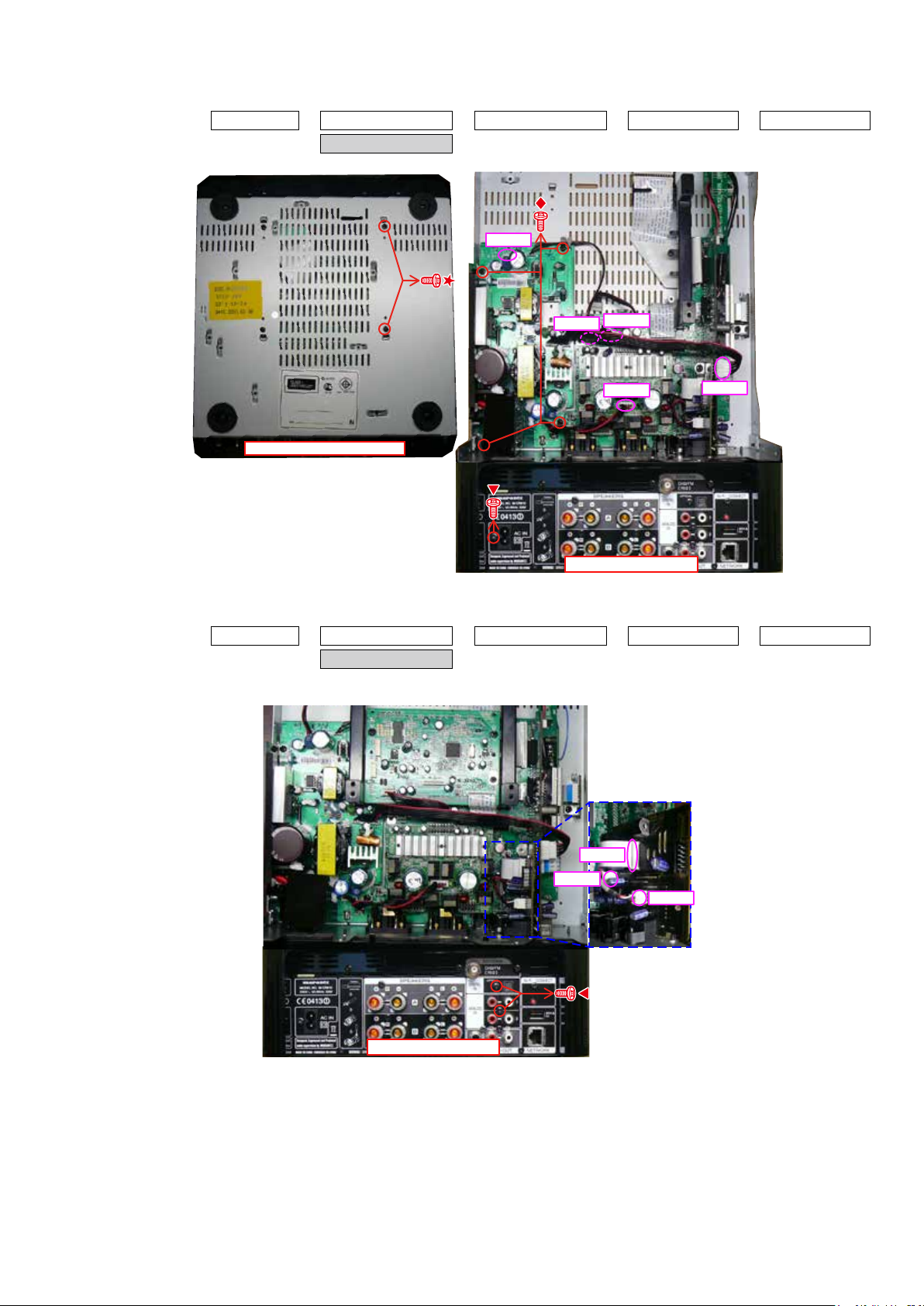

3. CD MECHA ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

(1) Tray is opened and CD DOOR is removed.

View from the bottom

View from the CD MECHA bottom

(2) Remove the screws.

CD MECHA ASSY

→

(3) Laser short-circuit in Pick-up of CD MECHANISM ASS'Y, then disconnect the connector wires and FFC cable.

Be sure to wear a grounding band.

Disconnect the connector wire.

Soldering place

CN70

CN71

FFC

16

4. CD PWB ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

(1) Remove the screw. Disconnect the connector wire.

CD MECHA ASSY

→

FFCBN27

5. TUNER UNIT

Proceeding : SIDE PANEL→TOP COVER ASSY

(1) Remove the screw and NUT. Disconnect the connector board.

CD MECHA ASSY

→

CD PWB ASSY

→

TUNER UNIT

→

Shooting direction: A

17

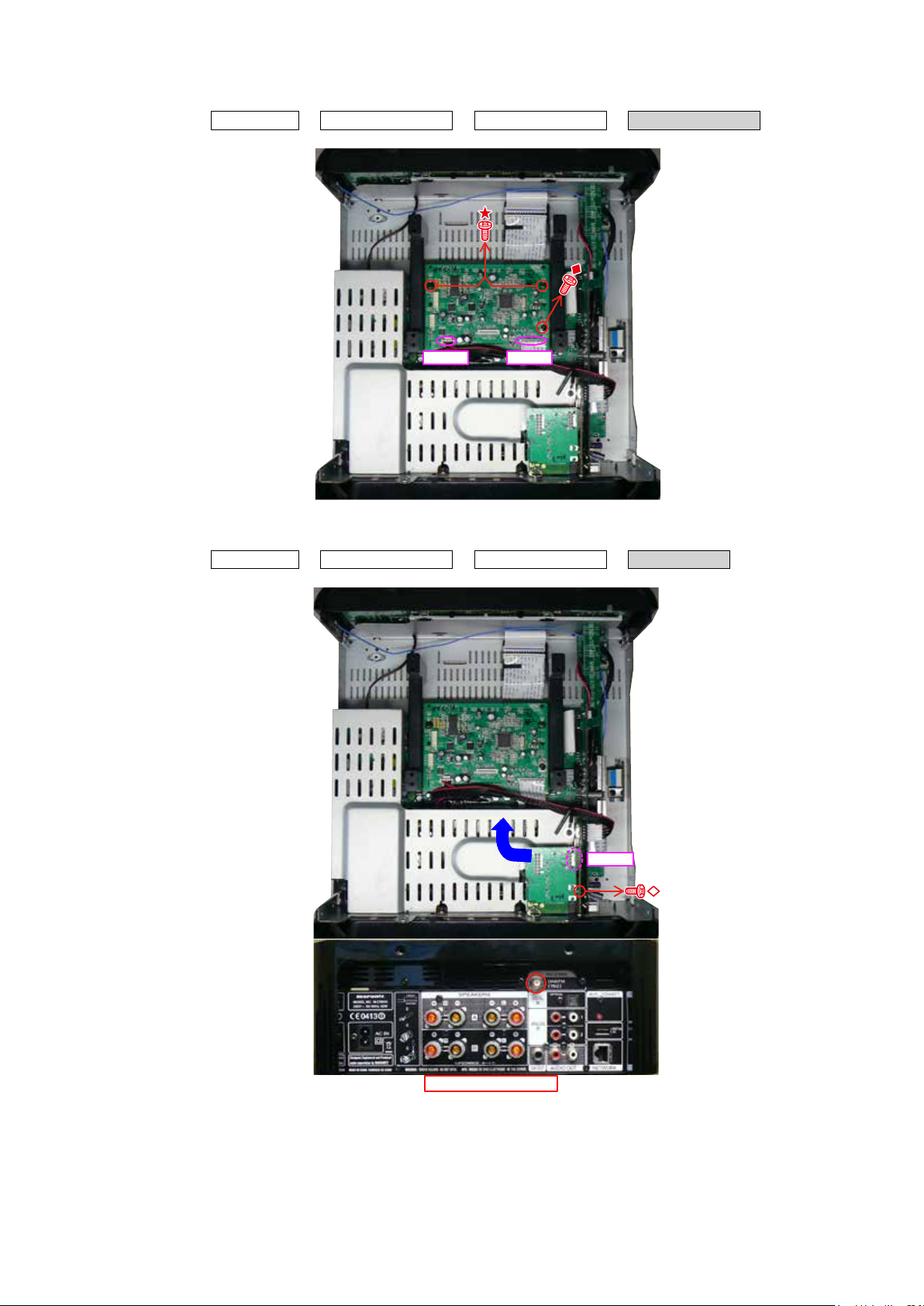

PM61

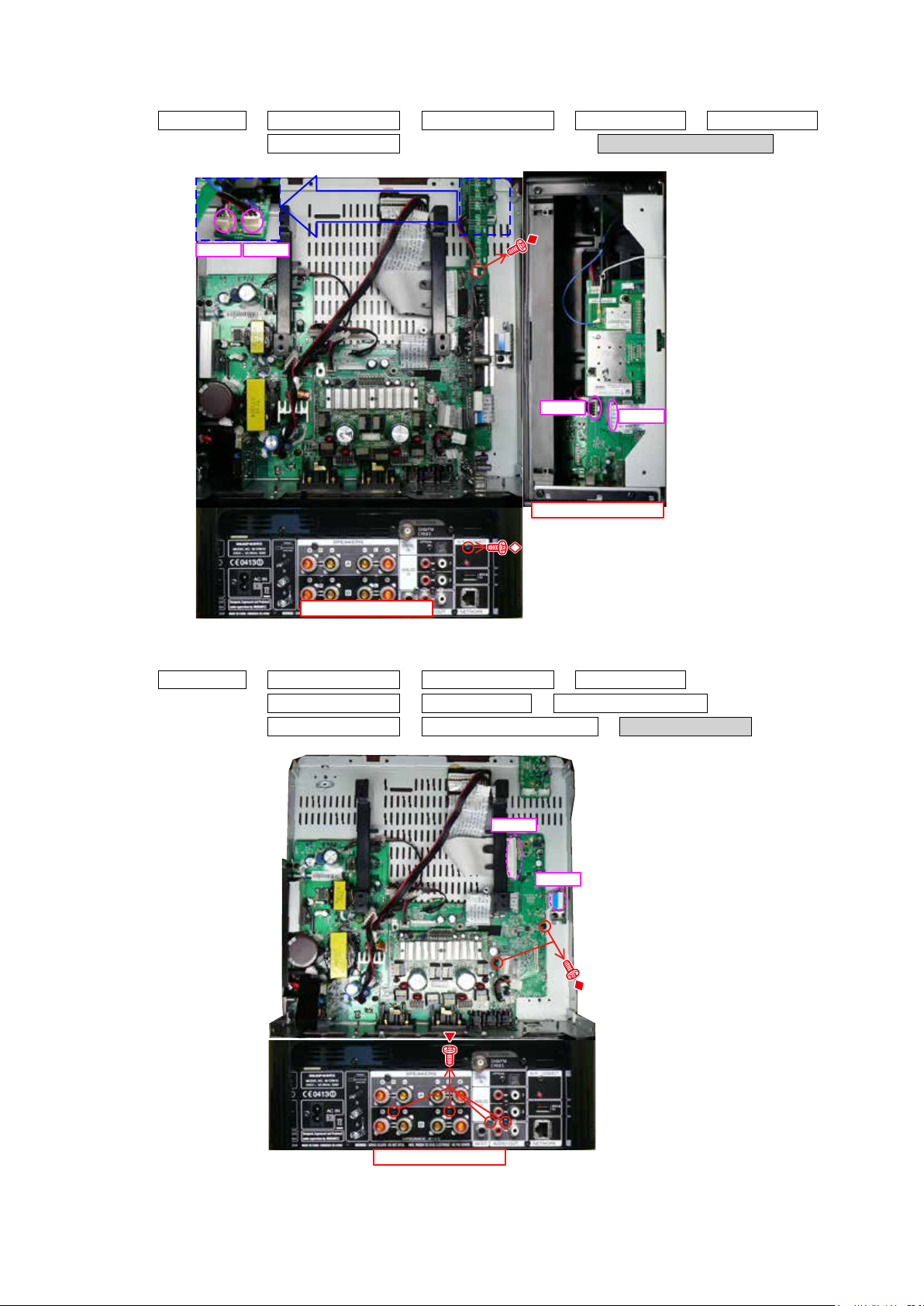

6. SHIELD CASE

Proceeding : SIDE PANEL→TOP COVER ASSY

(1) Remove the screw. Disconnect the CORD HOLDER.

Shooting direction: C

→

CD MECHA ASSY

Shooting direction: A

TUNER UNIT

→

CORD HOLDER

SHIELD CASE

→

7. FRONT PANEL ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

FRONT PANEL ASSY

→

(1) Remove the screw. Disconnect the connector wire.

CON2(BLU)

View from the bottom

(2) Cut the wire clamp band, then disconnect the connector wires and CORD HOLDER.

CD MECHA ASSY

→

CORD HOLDER

TUNER UNIT

→

Shooting direction: CShooting direction: D

SHIELD CASE

→

CN94

18

FFC

cut

8. SMPS PWB ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

SMPS PWB ASSY

→

(1) Remove the screw. Disconnect the connector wires.

View from the bottom

→

CD MECHA ASSY

CN94

CN24

Shooting direction: A

TUNER UNIT

→

CN28

CN92

CN81

SHIELD CASE

→

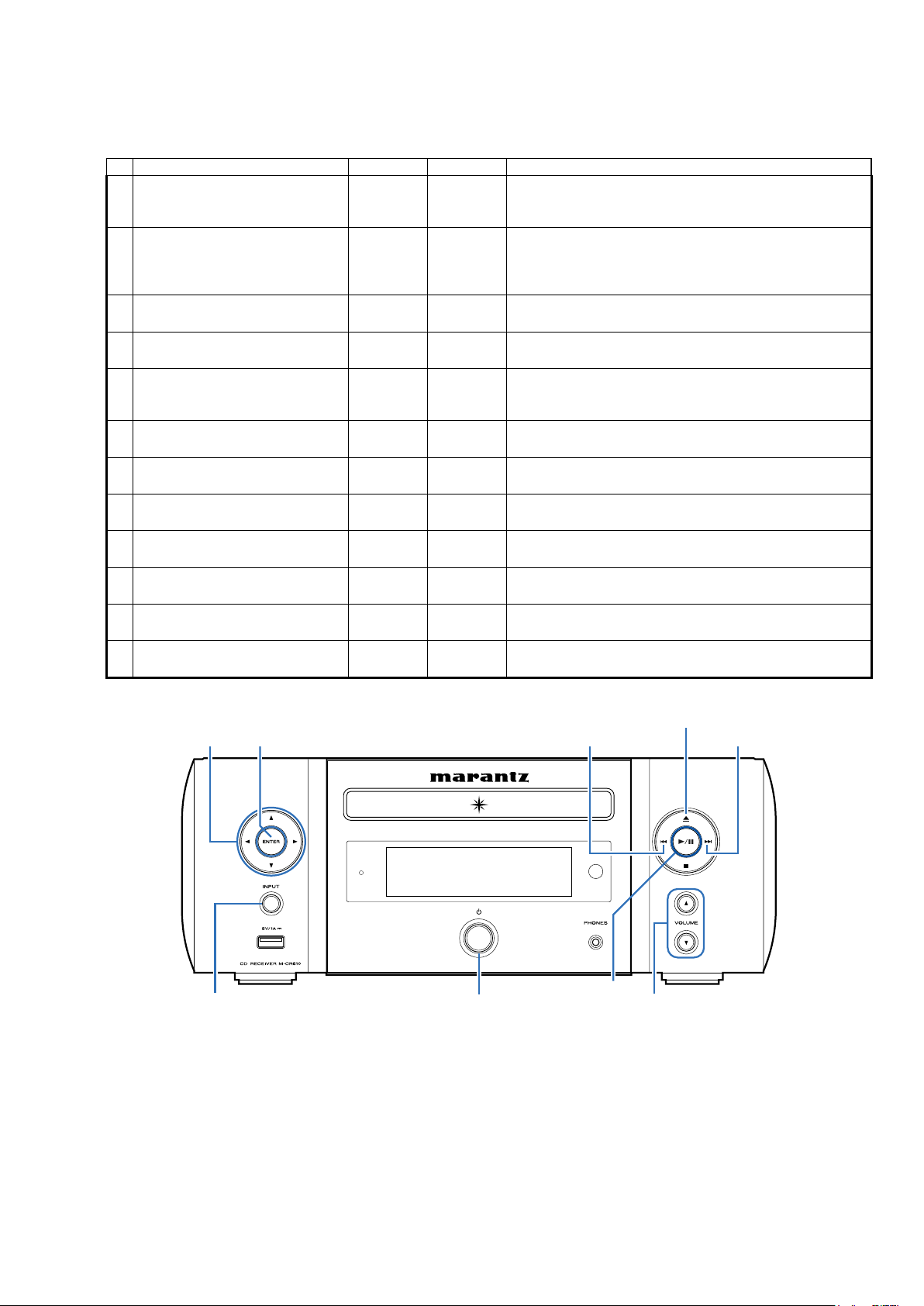

9. INPUT PWB ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

INPUT PWB ASSY

→

(1) Remove the screw. Disconnect the connector wires and FFC.

Shooting direction: A

CD MECHA ASSY

→

CN61

WF29

TUNER UNIT

→

CN62

SHIELD CASE

→

19

10. ETHETNET PWB ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

INPUT PWB ASSY

→

(1) Remove the screw. Disconnect the connector wires and FFC.

CN16 CN15

CD MECHA ASSY

→

FRONT PANEL ASSY

→

TUNER UNIT

→

ETHETNET PWB ASSY

→

CN81

Shooting direction: D

WF35

SHIELD CASE

→

Shooting direction: A

11. MAIN PWB ASSY

Proceeding : SIDE PANEL→TOP COVER ASSY

TUNER UNIT

→

INPUT PWB ASSY

→

(1) Remove the screw. Disconnect the connector wires and FFC.

CD MECHA ASSY

→

SHIELD CASE

→

ETHETNET PWB ASSY

→

CN30

CD PWB ASSY

→

FRONT PANEL ASSY

→

MAIN PWB ASSY

→

WF63

Shooting direction: A

20

SPECIAL MODE

Special mode setting button

Plug AC cord into power outlet while pressing buttons A and B.

Each button continue to press until the lit of "ON/STANDBY".

No. Mode Button A Button B Contents

Initializing. Factory Reset

Defaults to the setting value

Can't erase the Recently Played list

b

Initializing. (Contents User's Guide is published)

Except that it does not clear the version up information and the

history of protection is the same as the factory initialization.

Can erase the Recently Played list

b

- Version Display

Servo adjustment, Leaser current, ON time

Heat run

Factory use.

Factory use.

To view a history of only one of the most recent protection.

- Development/Factory use. The details cannot be disclosed.

DPMS UP date Mode

1 Initialization mode (Factory Reset) INPUT

2 Initialization mode ( User Reset)

3 Version display

4 CD test mode

5 Heat Run mode

6 Product mode 1 INPUT

7 Product mode 2 INPUT

8 Protection history mode

9 USB UPDATE

10 DPMS forced up date mode

11 MAC Address rewrite mode

12 Access to development server mode

VOLUME UPVOLUME

CURSOR

UP

VOLUME

UP

VOLUME

DOWN

VOLUME

DOWN

CURSOR

DOWN

PLAY/

PAUSE

CURSOR

DOWN

CURSOR

DOWN

CURSOR

DOWN

DOWN

PLAY/

PAUSE

DISC TRAY

OPEN/

CLOSE

CURSOR

RIGHT

CURSOR

LEFT

PLAY/

PAUSE

FORWARD-

DKIP

ENTER Development/Factory use. The details cannot be disclosed.

ENTER Development/Factory use. The details cannot be disclosed.

CURSOR ENTER

INPUT

DISC TRAY OPEN/CLOSE

PLAY/PAUSE

VOLUMEON/STANDBY

FORWARD-SKIPREVERSE-SKIP

21

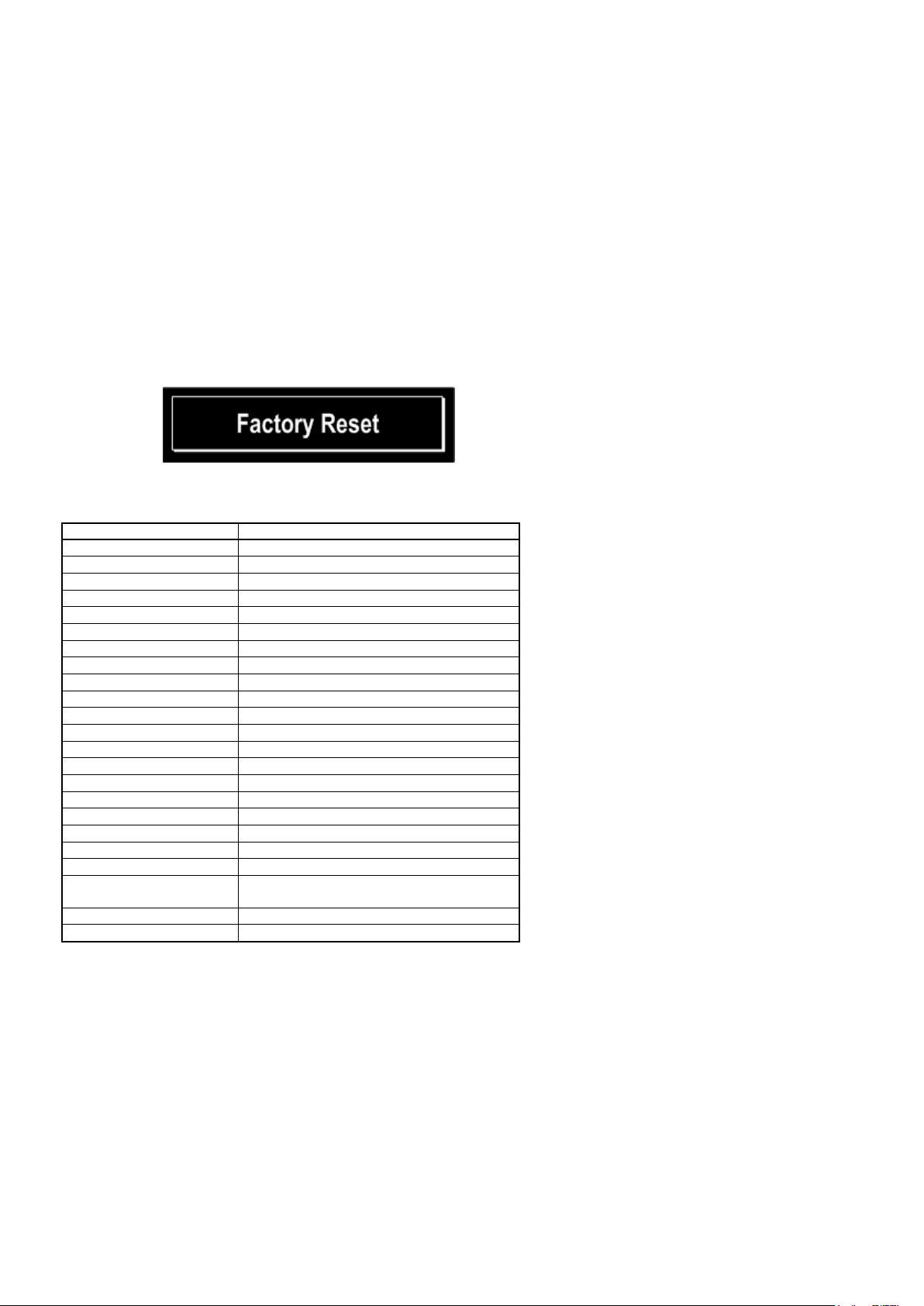

1. Initializationmode(FactoryReset)

Backup data initialization is carried out. Refer to Initialization Items (Default setting).

After initialization, move on to normal mode.

CAUTION

Version information (such as rewriting failed log) Clear.

Clear the history of protection. "Initial value of laser current" and "The accumulated laser on time" not cleared.

Power failure ag is not cleared.

Can't erase the Recently Played list.

Startup display

Lighting of the standby indicator LED(Green).

↓

Full lighting of all dots(2 seconds) & Lighting of the standby indicator LED(Orange) (2 seconds).

↓

"Factory Reset" displayed for 5 seconds.

InitializationItems(Defaultsetting)

Default

source Internet Radio

TUNER(band) FM

DBB OFF

BASS 0 dB

TREBLE 0 dB

BALANCE CENTER

DIMMER 100%

VOLUME 5

TUNER Preset (Favorite list) Clear all

Favorite list Clear all

Clock 00:00 (ExceptNA) 12:00AM (NA)

TIMER (EVERYDAY/ONCE) Timer function CD

ON TIME 0:00 (ExceptNA) 12:00AM (NA)

OFF TIME 0:00

Speaker Response Flat

Volume Offset 0dB

Bi-Amp Disable

iPod mode Remote mode

Auto-Standby ON (EU), OFF (ExceptEU)

Protection history NO PROTECT

Auto Adjust Time Zone:+1h (EU),+9h (JP)

Summer Time:Off (0h)

Network setting DHCP (On)

Network Control OFF

22

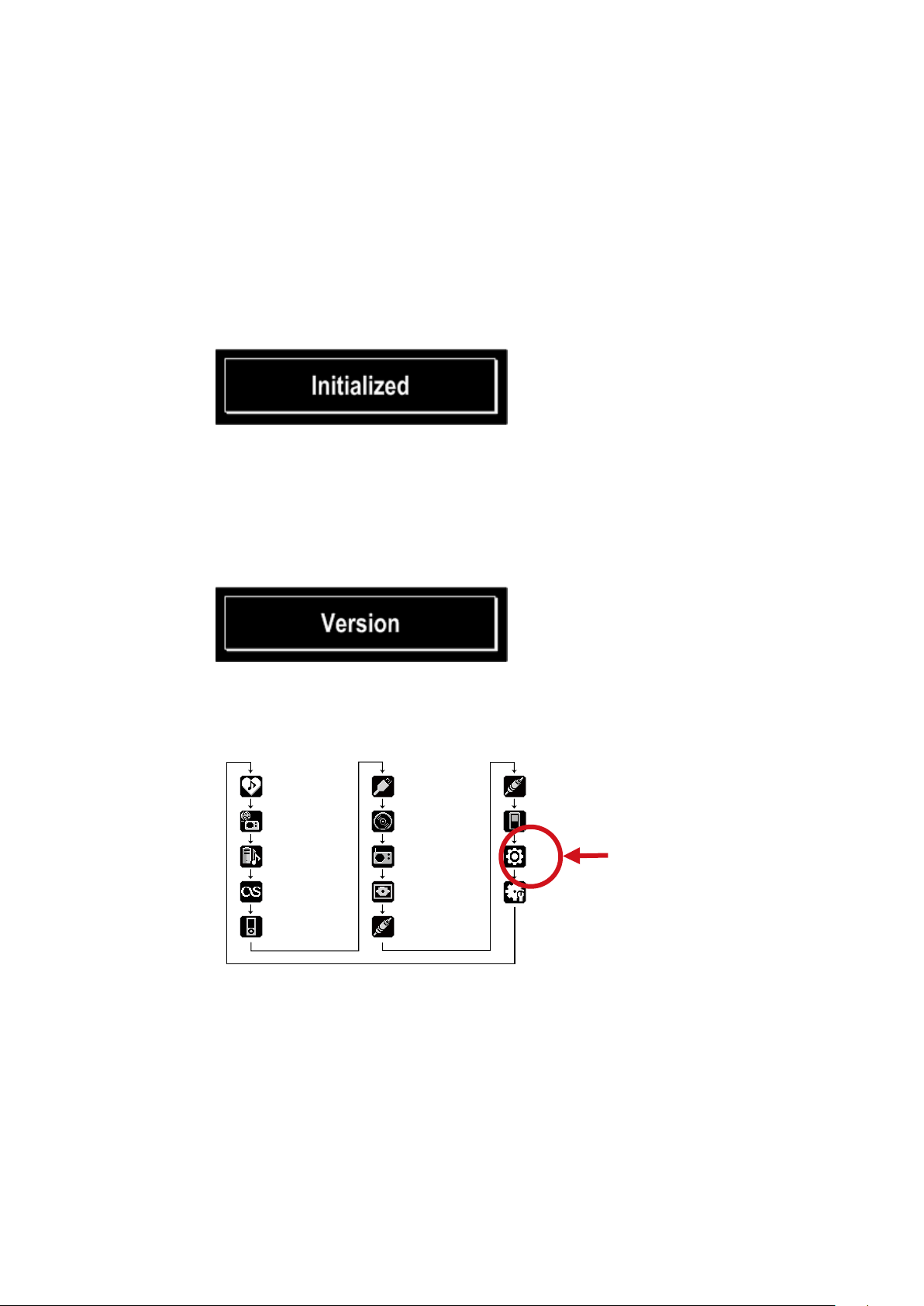

2. Initializationmode(UserReset)

Backup data initialization is carried out. Refer to Initialization Items (Default setting).

After initialization, move on to normal mode.

CAUTION

The difference is the following three points.

•Version information (such as rewriting failed log) not cleared.

•History of protection not cleared.

•Can erase the Recently Played list.

Startup display

Lighting of the standby indicator LED(Green).

↓

"Initialized" displayed for 5 seconds.

3. Version display

Menu items appear in the Add Version. Otherwise, normal operation.

To exit this mode, unplug the power cord.

Startup display

"Version" displayed for 5 seconds.

How to Display Version

Press "SOURCE" and "Cursor p" , "Cursor o" to select the Setup.

Press "ENTER" button.

Favorite

Internet Radio

Music Server

Last.fm

iPod

USB

CD

FM

Digital In

Analog In 1

Analog In 2

Portable In

Setup

Menu

z

23

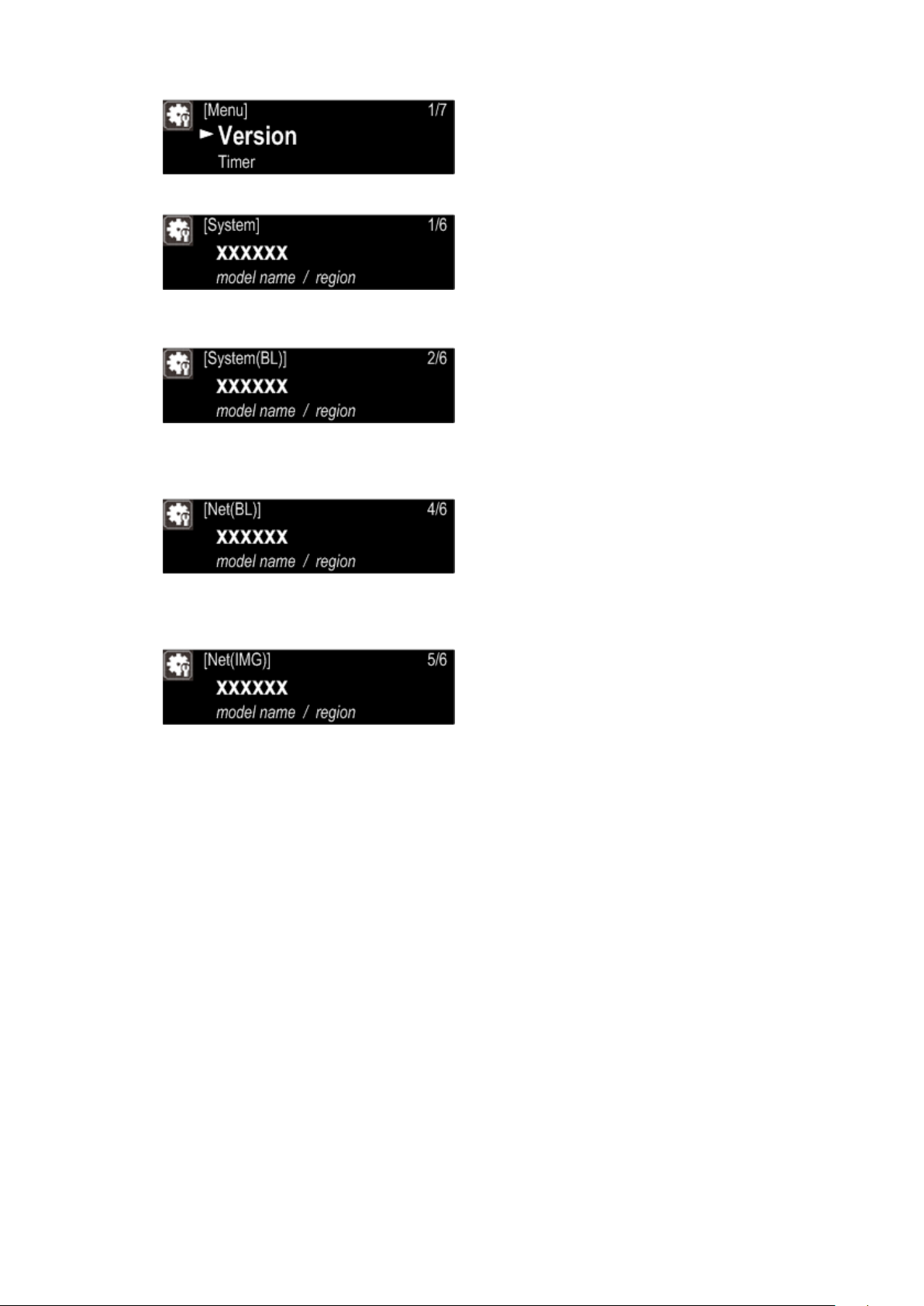

Select the "Version" in the "Setup".

Press "ENTER" button

The version of the System u-com.

Press "Cursor i"

The version of the boot loader System u-com.

Press "Cursor i"

The version of the boot loader Network u-com.

Press "Cursor i"

The version of the image Network u-com.

24

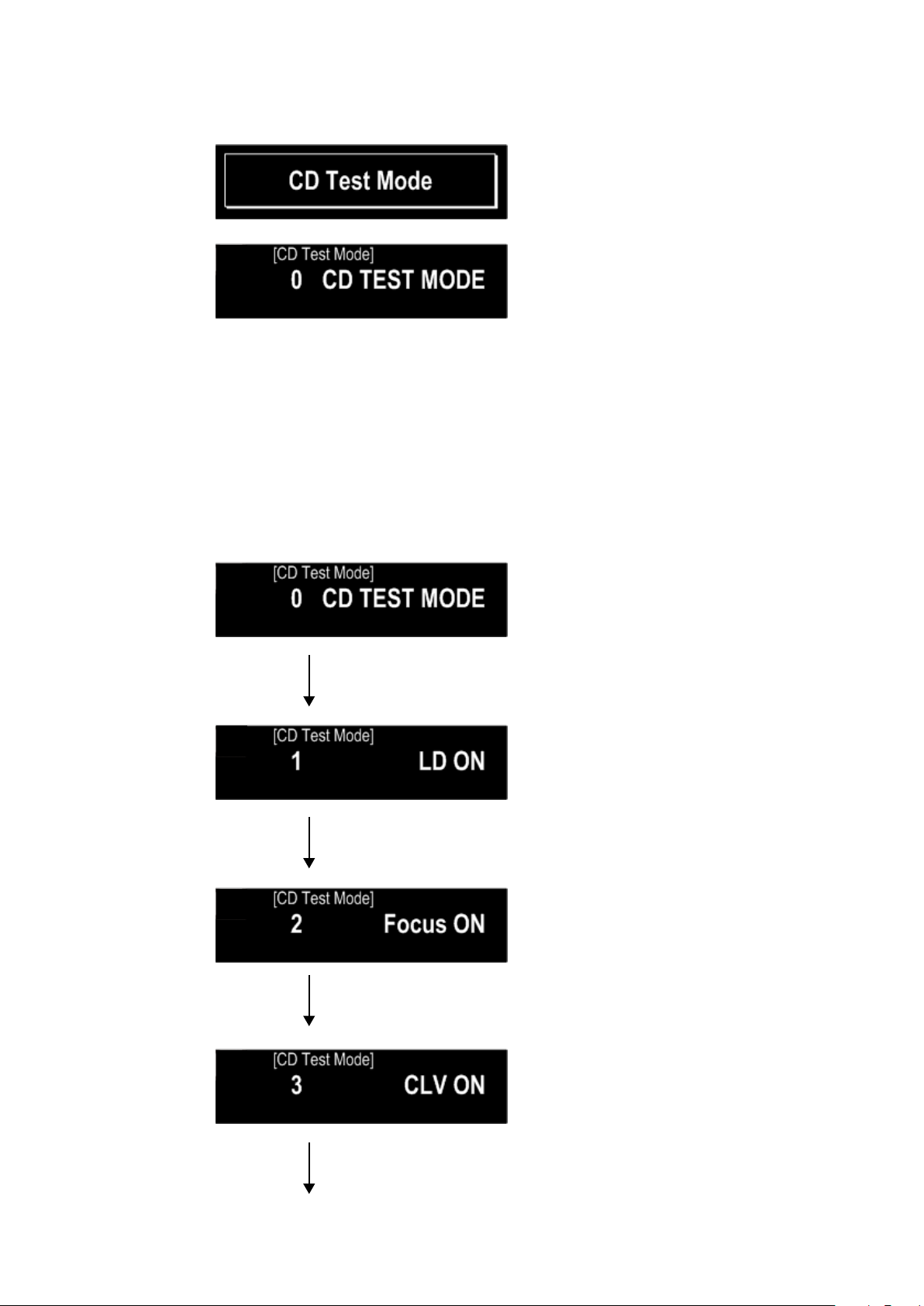

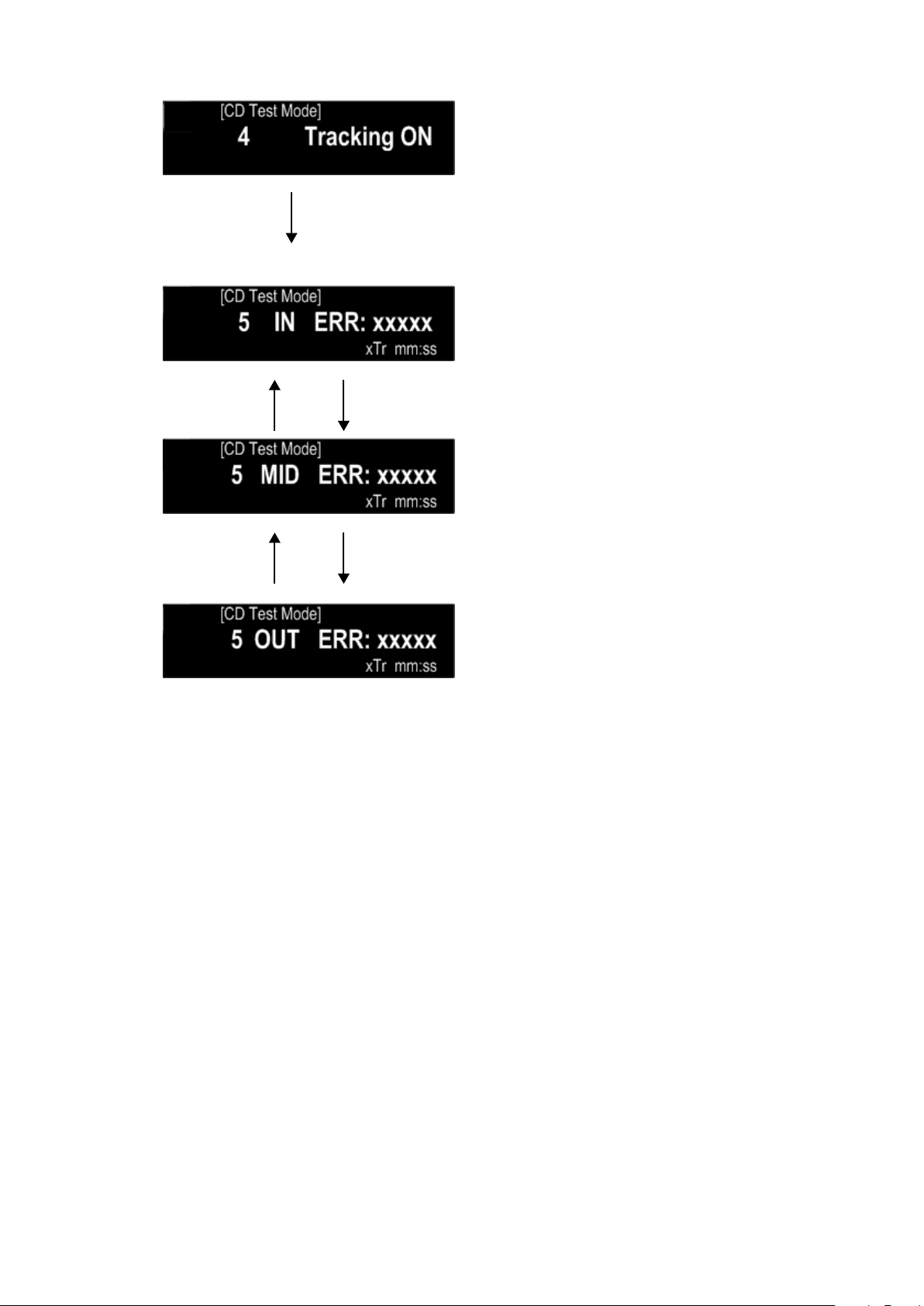

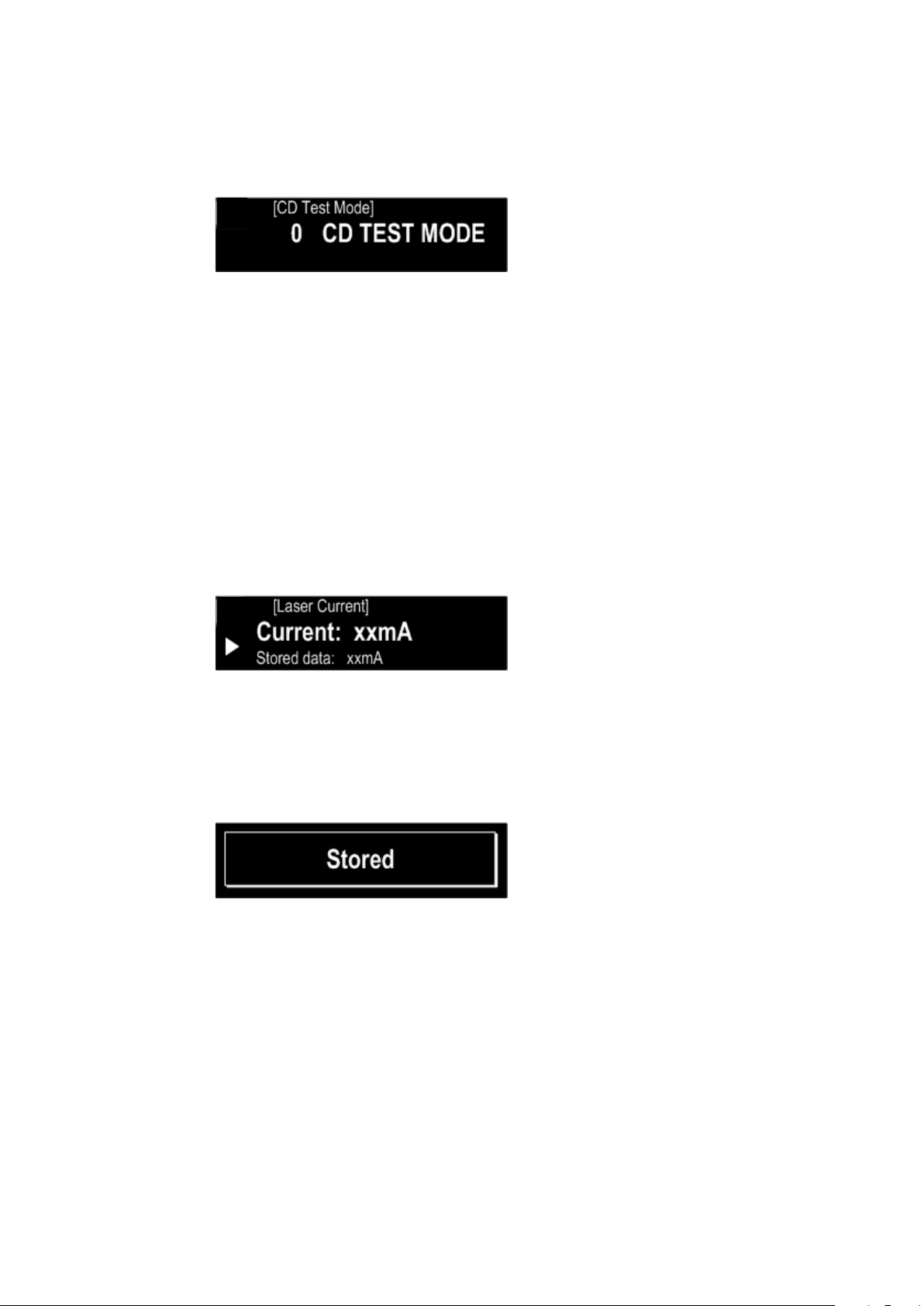

4. CD test mode

Startup display

"CD Test Mode" displayed for 5 seconds.

CD TEST MODE display

To exit this mode, unplug the power cord.

4.1. Before starting the test

Open the tray and set the disc.

Even if the disc is, the tray must let OPEN → CLOSE.

4.2. Servo check

Press "

"

z

1/3

button to return to "0 CD TEST MODE".

" button. Execute the following steps.

1/3

" button continuously for over 1 second to switch directly to SUB CODE readout in step t. Press the "INPUT"

LD ON

q

FOCUS ON

w

CLV ON

e

1/3

1/3

1/3

button

button

button

1/3

button

25

TRACKING ON

r

button

1/3

SUB CODE readout (playback sound output)

t

The BER (Block Error Rate) generated in 1second's time is displayed of the display.

Cursor p buttonCursor o button

Cursor o button

Cursor

button

p

Inner (IN), Ataru Amane (MID), outer (OUT) to play go to three places, make the error count.

4.3. Pickup movement

In the stop mode, pickup moves in FWD (outwards) or REV (inwards) direction when "Cursor p" or "Cursor

pressed.

Pickup movement stops when button released.(Pickup moves while button is pressed.)

When "Cursor

" button pressed, move to stop operation after detection that inner switch has turned on.

o

" button

o

26

4.4. All servo on and Auto Adjustment

When "Cursor u" button is pressed, all servos turn on, auto adjustment is performed and switch to playback operation.

(Playback sound output)

Stop (stop to the playback state after auto adjustment)

When "SOURCE" button is pressed, play operation and servo stop. The following will be displayed.

After stopping, conduct reading of auto adjust values.

Adjustment value display (After All Servo on and Auto Adjustment)

Press the "SOURCE" button, after All servo on and Auto Adjustment.

When "Cursor u/i" button is pressed, the adjustment values are displayed in the following order.

FOCUS BALANCE

q

FOCUS GAIN

w

TRACKING BALANCE

e

TRACKING GAIN

r

FOCUS OFFSET

t

TRACKING OFFSET

y

RFRP

u

(Caution) If you have not completed the adjustment, the value is not correct.

4.5. All servo on and auto adjustment.

When "VOLUME d" button is pressed for over 1 second while the Unit is in the CD TEST MODE, the laser turns on and

the laser current is measured.

The laser drive current undergoes A/D conversion for calculation. The decimal point is omitted.

The current value is updated every 3 seconds.

Press the "SOURCE" button, CD TEST MODE display reappears.

Stored data is not cleared, even when the Unit is reset(Factory/User).

Overwriting the stored data

When the "1/3" button is pressed for over 5 seconds while the laser current is displayed, the current value is stored in

the EEPROM (overwriting the stored data).

Once rewriting is completed, the display in "Laser current display" reappears. Rewriting is performed upon shipment

from the factory and when the mechanism is replaced.

27

4.6. Accumulated laser on time display

When the "Volumef" button is pressed while this Unit is in the "CD TEST MODE "displayed, the accumulated laser on

time is displayed.

The laser drive times are added and the result is displayed.

One count corresponds to 10 minutes. The accumulated laser on time is displayed in hours. Displays up to 10922 hours.

Press the "SOURCE" button, CD TEST MODE display reappears.

The count values are not cleared, even when the set is reset (Factory/User).

Count value is reset

When the "1/3"

reset.

Count value is reset upon shipment from the factory and when the mechanism is replaced.

button is pressed for over 5 seconds while the accumulated laser on time is displayed, the count value is

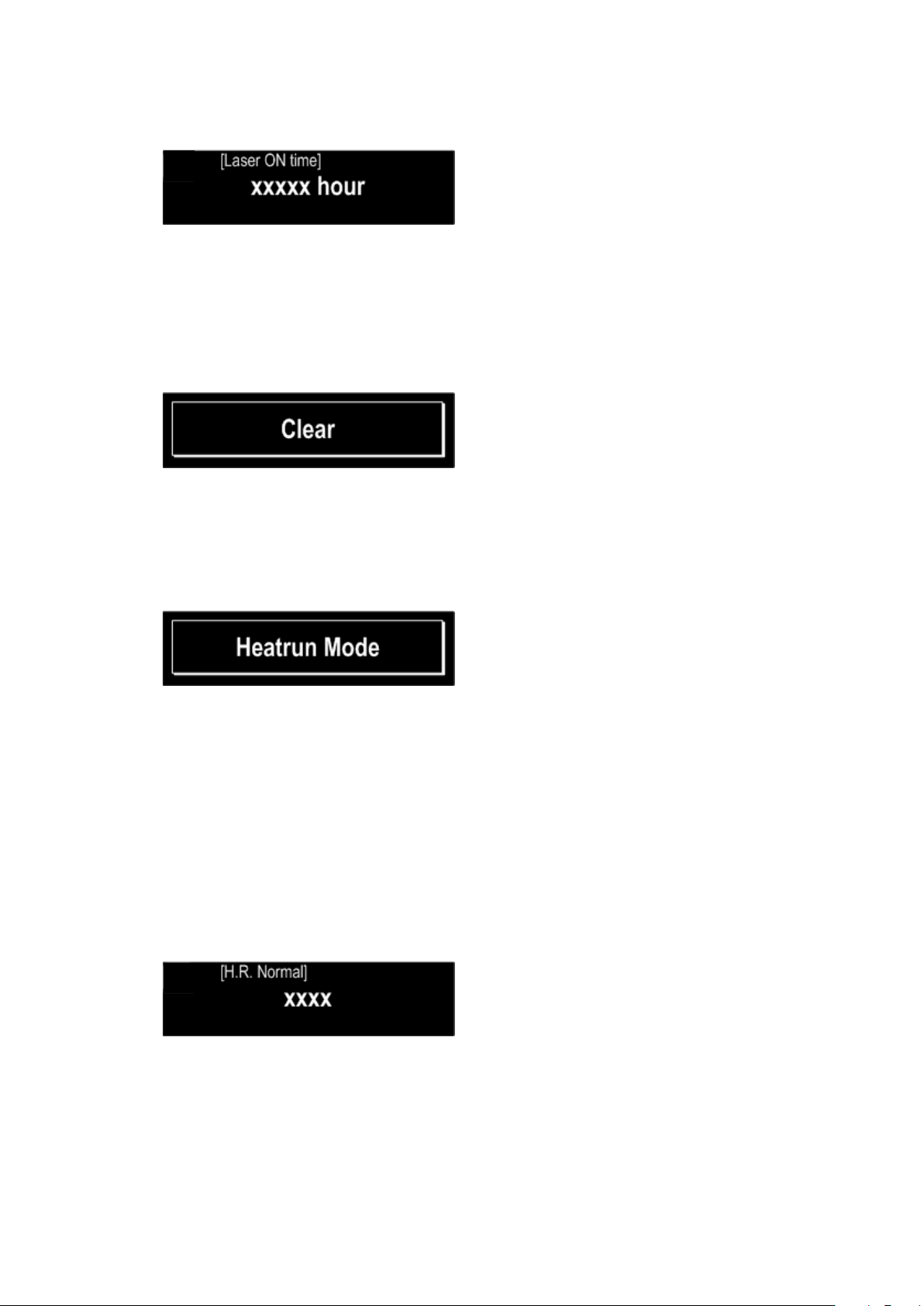

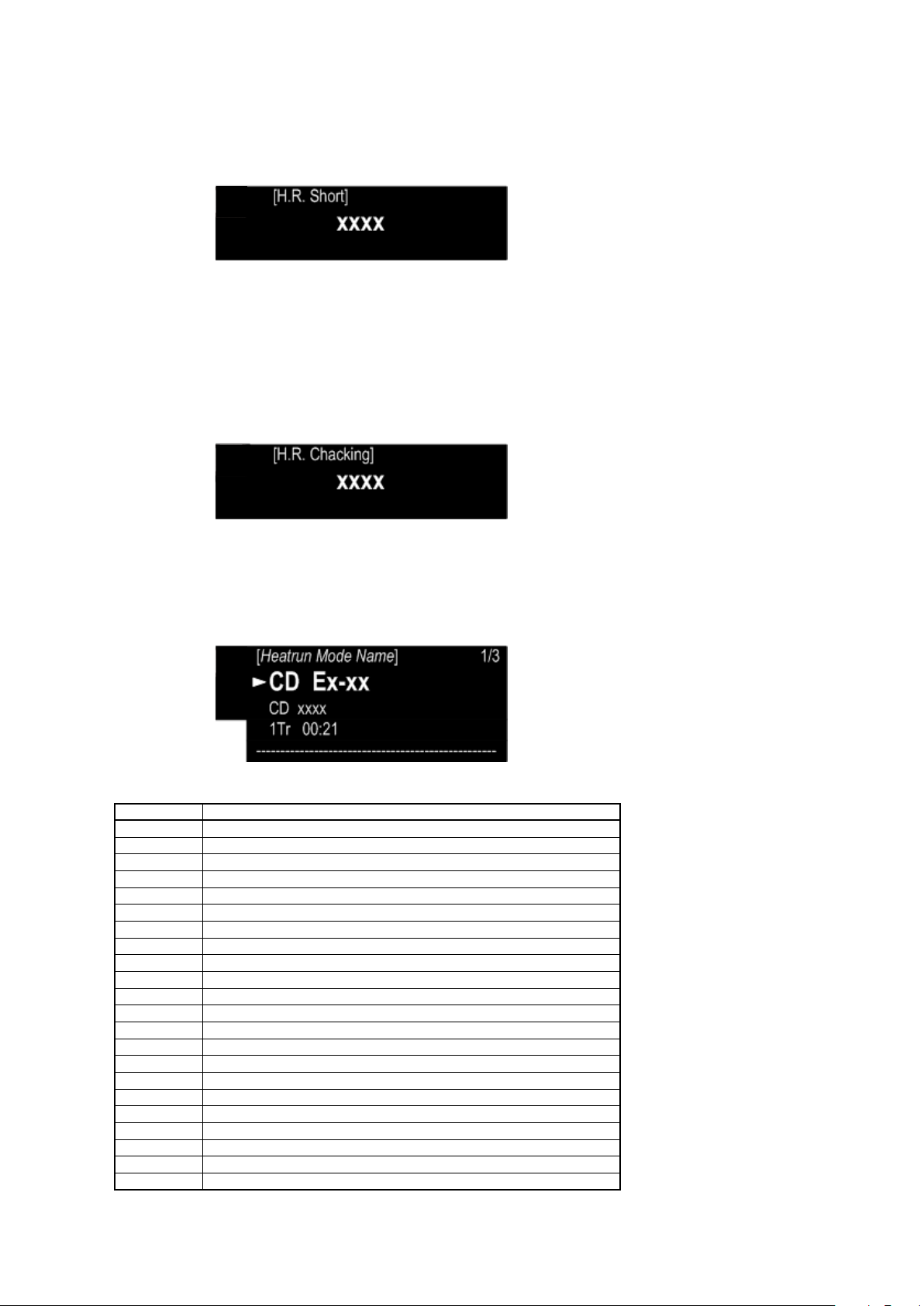

5. CD heat run mode

Heat run mode Startup display

"Heatrun Mode" displayed for 5 seconds.

Press the "Cursoru/i" button to switch the mode. (H.R. Normal, H.R. Short, H.R. Chacking)

After loading the disc, press "1/3"

While heat run, the operation of each button is not valid If an error occurs, display the error and stop operation at that

point. Refer to Heat run error code table.

To exit this mode, unplug the power cord.

5.1. Normal heat run mode

Playing from the rst track to last track on disc. After disc playback has nished, then tray open and close. And playback

again.

The heat run repetition no. is incremented (increased by 1) when the tray is opened.

Repeat this operation.

[H.R. Normal] displayed.

button.

Select "H.R.Normal", and press "1/3" button.

Press the "Cursoru" button to display the count.

28

5.2. Heat run Short mode

Playing last track on disc. After disc playback has nished, then tray open and close. And playback again.

The heat run repetition no. is incremented (increased by 1) when the tray is opened.

Repeat this operation.

[H.R. Short] displayed.

Select "H.R.Short", and press "1/3" button.

Press the "Cursor

" button to display the count.

u

5.3. Heat run chacking mode

TOC read the CD, the rst song disk search, open / closed later, and again read TOC.

The heat run repetition no. is incremented (increased by 1) when the tray is opened.

Repeat this operation.

[H.R. Chacking] displayed.

Select "H.R.Chacking", and press "1/3" button.

Press the "Cursoru" button to display the count.

5.4. Error display

Press the "Cursoru/i" to display the error information.

Heat run error code table

Error Code Details of Error code

E1-00 Disc cannot be detected

E1-01 Tracking offset adjustment not possible

E1-02 Focus offset adjustment not possible

E2-00 Focus servo dropped during playback.

E2-01 Focus servo dropped during searching.

E2-03 Focus servo dropped during TOC reading.

E2-05 Focus servo dropped during manual search.

E2-10 Subcode can no longer be read during playback

E2-11 Subcode can no longer be read during searching

E2-12 Subcode can no longer be read during TOC reading

E2-14 Subcode cannot be read during pause

E2-15 Subcode cannot be read during manual search

E3-00 TOC could not be read within specied time

E3-01 PVD/SVD analysis could not be completed within specied time

E4-04 Search time out (The search was not completed within the stipulated time)

E4-05 Decoder bus error (Error in communications with CD decoder)

E5-00 Inner switch not on

E6-00 Inner switch not off

E8-00 Tray is not opened by the specied time.

E8-01 Tray is not closed by the specied time.

E9-00 CD Microprocessor error

E9-01 Other error

29

6. Product Mode 1

Startup display

"Product Mode1" displayed for 5 seconds.

To exit this mode, unplug the power cord.

7. Product Mode 2

Startup display

"Product Mode2" displayed for 5 seconds.

Tested during production to perform the following settings automatically.

Sleep setting : 4 minutes

Auto Standby :4 minutes

Sleep setting and timer started.

Auto Standby to set up and will stand under the following conditions.

Auto Standby Conditions

CD : No Disc, Tray Open, Unsupported Disc or continue no operation and Stop state.

USB/iPod : No Connection or Unsupported Disc or continue no operation and Stop state.

Network : No Connection or Unsupported Disc or continue no operation and Stop state.

DIGITAL IN : No Input(unlock). And continue no operation.

ANALOG IN : Continue no operation.

To exit this mode, unplug the power cord.

8. Protection history display mode

Startup display

"Detect Protection" displayed for 5 seconds.

To exit this mode, unplug the power cord.

Protection history display mode

Thermal protection

30

Loading...

Loading...