Page 1

MAINTENANCE INSTRUCTIONS

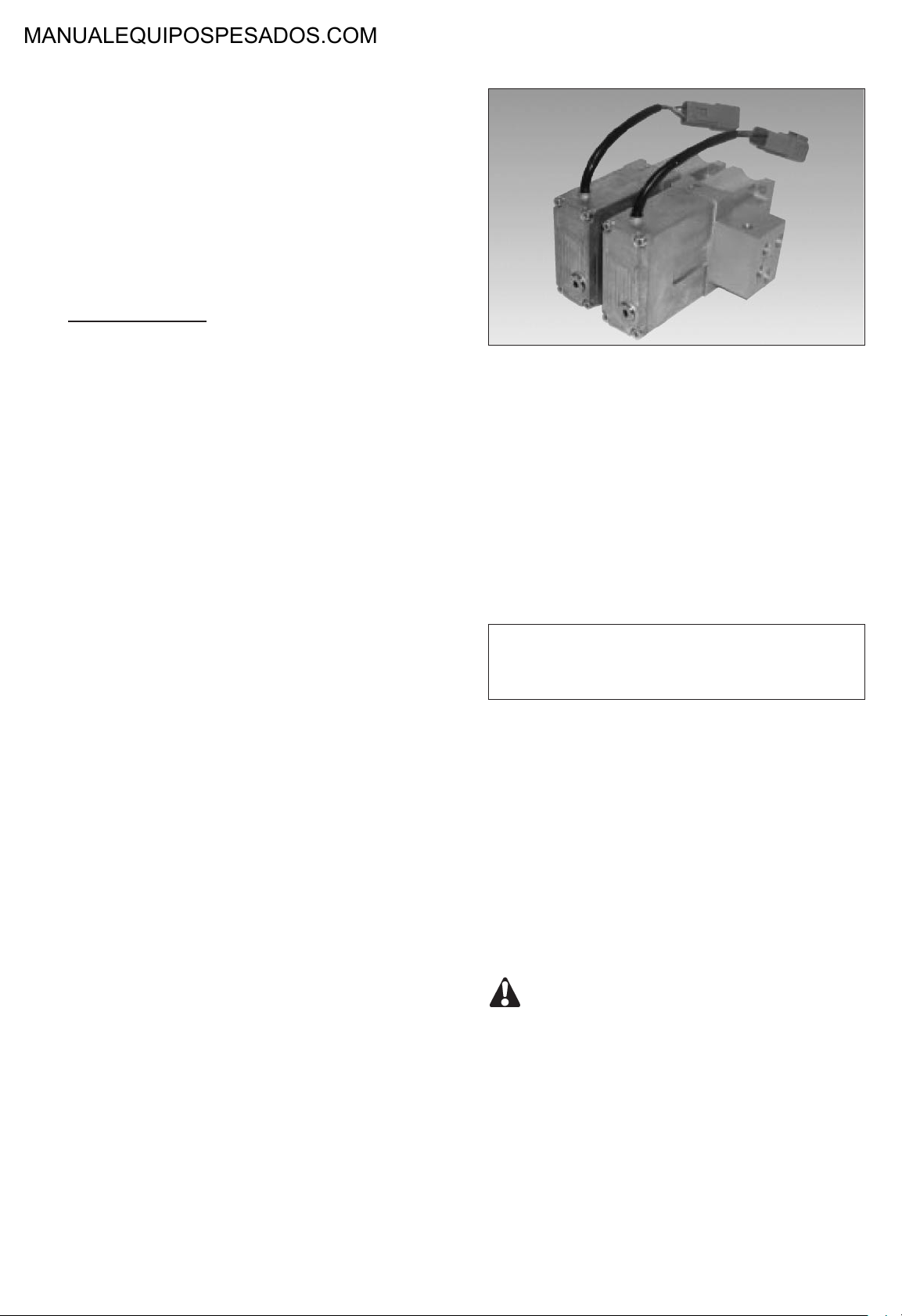

ELECTROHYDRAULIC ACTUATION

MODULE

TYPE EMS

MAINTENANCE

Type : electrohydraulic actuation module EMST = EMSP

SUMMARY

1. Introduction

1.1 Foreword

1.2 Safety instructions

2. Troubleshooting

3. Fondamental rules

3.1 General information concerning electrohydraulic actuation module connection

4. Removal / installation of electrohydraulic

actuation module

4.1 General recommendations

4.2 Removal of a single electrohydraulic actuation module

4.3 Removal of one of several electrohydraulic

actuation modules assembled together

4.4 Electrohydraulic actuation module assembly

4.5 Removal / disassembly of the electrohydraulic transformation stage

5. Removal / assembly of connecting flange and

filter

5.1 Connecting flange removal / assembly

5.2 Filter replacement

6. Neutral position adjustement

1. INTRODUCTION

1.1 - Foreword

It is recommended that only qualified personnel perform

the installation, connection and maintenance of this device, and that all operations be carried out in compliance

with the technical standards in force and the cleanliness

regulations specific to this type of installation.

To ensure maximum performance and safety during

maintenance operations we advise you to

READ THIS MANUAL THOROUGHLY

All informations, illustrations, instructions and characteristics contained in this document are based on the

latest product information available at the time of publication. In its attempts to maintain a high-quality product,

MANITOU reserves the right to make design or technical

modifications at any time and without prior notification.

1.2 - Safety instructions

Please pay a particular attention to the signals of the

safety alertsand special instructions in this manual. They

are indicated in the following manner :

Indicates informations or instructions which

must be followed to guarantee your safety

during operations.

CAUTION : WARNING AGAINST POSSIBLE

EQUIPMENT DAMAGE.

7. Start-up procedures

NOTE : Useful information.

14

Page 2

MAINTENANCE INSTRUCTIONS - Troubleshooting

Observed problems Probable cause

Absence of movement on all

the proportional functions.

Absence or defect of

movement on a proportional

function.

1. Supply voltage insufficient. Check minimum supply

2. Pilot pressure insufficient. Verify the supply pressure of

3. Sealing of the protection

filter of the proportional

controls.

1. Absence of signal of the

proportional control of the

distributor.

2. Signal defect of the proportional control of the distributor.

Additional verifications Solutions

voltage 9V of the proportional

control unit.

the pilot circuit of the

proportional control units

minimum 15 bar.

Clean the filter. Remove filter of the hydraulic

supply unit

(page 22).

Check the signal of the manipulator towards the proportional control units.

Value = 2.5 volts if manipulator knob is at neutral.

Ensure that the signal voltage

comprises of between 1 and

4 volts while using the control

knob of the manipulator.

Verify the connections and

clusters between proportional

control unit and manipulator.

If OK, change the manipulator.

If value outside of limits,

change the manipulator.

Untimely movement with proportional control of the manipulator in neutral.

Sudden or irregular movement on all the proportional

functions.

Sudden or irregular movement on a single proportional

function.

Sudden or irregular movement in a single direction on

a proportional function.

3. Insufficient voltage of the

proportional control units of

the distributor.

Signal defect of the proportional controls of the manipulator.

Protection filter partially sealed.

Looking or jamming of the

position sensor of the proportional control unit.

Looking or jamming of the

pilot drawer of the proportional control unit.

Verify control voltage 5 volts

provided by the proportional

control units to the manipulator.

Check the signal of the manipulator towards the proportional control units.

Value = 2.5 volts if manipulator knob is at neutral.

Clean the filter. Remove filters of hydraulic

If voltage nil or insufficient,

replace the proportional

control unit

(pages 17, 18, 19).

Verify the connections and

clusters between proportional

control unit and manipulator.

If OK, change the manipulator.

supply unit

(page 22).

Replace the proportional

control unit (pages 17, 18,

19).

Replace the proportional

control unit (pages 17, 18,

19).

15

Page 3

MAINTENANCE INSTRUCTIONS - Troubleshooting

Observed problems Probable cause

Symmetry defect of the

control of a proportional function.

Oil leak between two proportional control units.

Oil leak between electrohydraulic and mechanical

interface of the proportional

control units.

Shift of the neutral position of

the position sensor.

Imperviousness defect of the

piping of the pilot circuit between the units.

1. Packing damaged.

2. Pilot pressure too high. Verify that the supply pressu-

Additional verifications Solutions

Adjust the neutral position of

the position sensor

(page 24).

Change the packing

(pages 17, 18, 19).

Change the packing

(page 20).

re of the pilot circuit does not

exceed 35 bar.

3. FONDAMENTAL RULES

3.1 - General information concerning electrohydraulic actuation module connection

Hydraulic

When removing the electrohydraulic actuation module, all openings must be plugged immediately to prevent any contamination of the hydrailic system.

Check the hydraulic installation’s oil quality and filtration capacity during all servicing / maintenance operations.

When replacing the electrohydraulic actuation module, remove the plastic plugs from the openings and lines just before

making the connections.

Do not tighten connectors to a torque greater than that specified in the assembly instructions.

The use of Teflon tape, hemp and joint filler is prohibited.

Hydraulic lines and connections must not be under any strain whatsoever.

Electric

All along the operations, pay attention not to damage the cables and electrical connections.

Check that there is no residual voltage across the cables and electrical connections.

16

Page 4

MAINTENANCE INSTRUCTIONS

4. REMOVAL / INSTALLATION OF THE ELECTROHYDRAULIC ACTUATION MODULE

4.1 - General recommendations

CAUTION : BEFORE REMOVING THE CONTROL BACK FROM THE MACHINE, THE BLOCK AND ITS SURROUN-

DINGS MUST BE THOROUGHLY CLEANED (NOTE: DO NOT DIRECT THE JET OF A PRESSURE WASHING UNIT

DIRECTLY AT THE UNIT).

NO IMPURITIES MUST ENTER THE HYDRAULIC SYSTEM. PLASTIC PLUGS ARE TO BE FITTED ON LINES AND

ORIFICES IMMEDIATELY FOLLOWING THEIR REMOVAL.

Wear protective clothing and use suitable equipment to prevent accidents, particularly concerning the hydraulic fluid.

Use the lifting eyes and suitable handling equipment.

Set all actuators connected to the machine in neutral position (on the ground, at lower limit...) to avoid accidents which

could result from uncontrolled movements of the equipment when the hydraulic system is deconnected.

With the machine off, release the pressure remaining in the system by manipulating all of the distribution spools. This

can be performed by moving the handle in all directions.

17

Page 5

MAINTENANCE INSTRUCTIONS

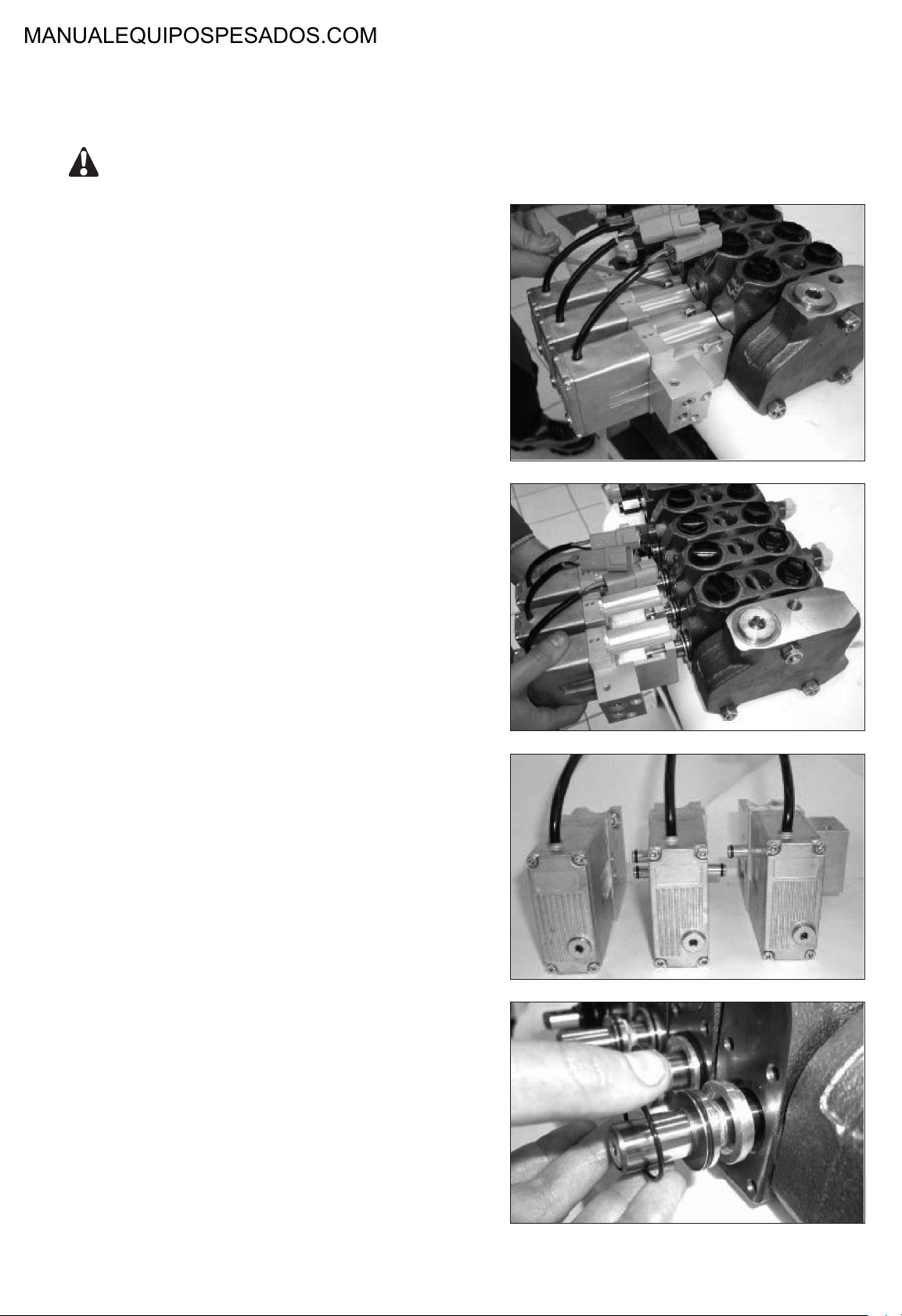

4.2 - Removal of a single electrohydraulic actuation

module

Machine off :

- place all of the machine’s actuators connected

to the control block in neutral position,

- release stored pressure by operating all the

spools (move the handler in all directions).

NOTE : Install a vacuum pump on the tank of the machi-

ne to limit oil leakage when connections are

removed.

After disconnecting the lines from the electrohydraulic actuation module, immediately fit the

sealing plugs. Make sure to collect any possible

oil leakage in a suitable receptacle.

Unscrew the mounting screw using an allen wrench M5.

Reassembly : torque : 15 ± 1 N.m.

Pull the electrohydraulic actuation module backward

parallely to the spool axis in order to release the operation piston.

Remove the cover of spring return system on the opposite side of the spool (see SX14 Maintenance instructions § 6.3).

Unscrew the positionning piston from the distributing

spool using a 19mm wrench on piston side and a M5

Allen wrench on spring side.

Reassembly : Apply 2 drops of loctite 242 onto the pis-

ton thread.

torque : 10 ± 1 N.m.

18

Page 6

MAINTENANCE INSTRUCTIONS

Remove and replace the tightness seal lying between

the actuator and the control valve.

Remove the centering plater.

NOTE : Do not remove the spool from the control valve.

Reassemble in reverse order.

Adjust the neutral position (see § 6).

19

Page 7

MAINTENANCE INSTRUCTIONS

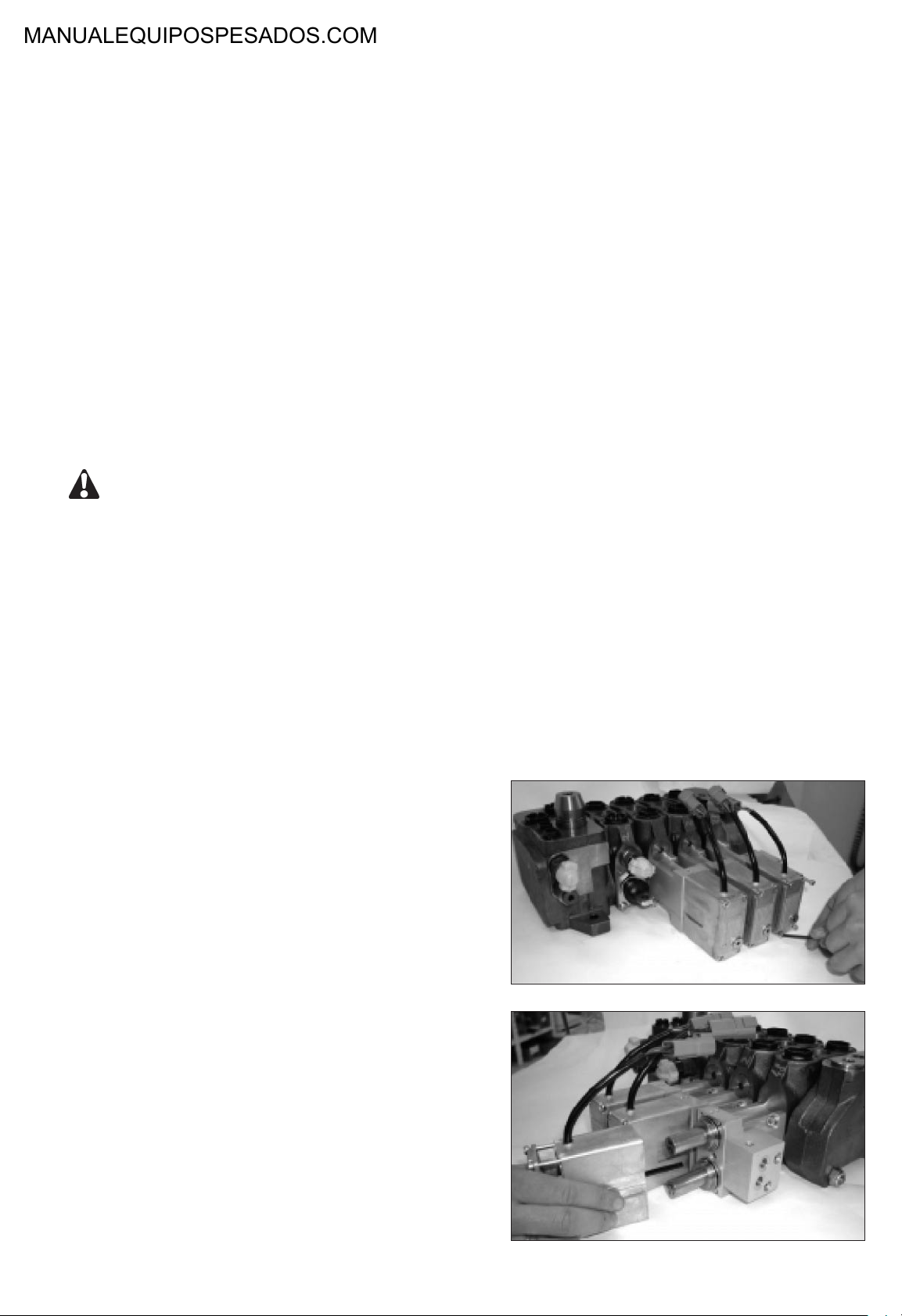

4.3 - Removal of one of several electrohydraulic

actuation modules assembled together

Machine off :

- Place all of the machine’s actuators connected

to the control block in neutral position.

- Release stored pressure by operating all the

spools (move the handler in all directions).

NOTE : Install a vacuum pump on the tank of the machi-

ne to limit oil leakage when connections are

removed.

After disconnecting the lines from the electrohydraulic actuation module, immediately fit the

sealing plugs. Make sure to collect any possible

oil leakage in a suitable receptacle.

To remove an intermediary or terminal electrohydraulic

actuation module, it is required to remove the complete

module assembly.

Unscrew all the mounting screws of each electrohydraulic actuation modules using an Allen wrench M5 (see §

4.2).

Reassembly : torque : 15 ± 1 N.m.

Pull the module assembly backward parallely to the

spool axis in order to release the opertion piston.

Place the modules on a clean and clear surface in order

to pull them apart.

Reassembly :

- Remove and replace the carry-over pipes of the faulty

module.

- Replace the faulty electrohydraulic actuation module.

- Replace all the tighteness seals lying between the

actuators ans their control valve.

- Reassemble in reverse order.

- Adjust the neutral position (see § 6).

20

Page 8

MAINTENANCE INSTRUCTIONS

4.4 - Electrohydraulique actuation module assembly

Check the cleanliness of the contact faces prior to reassemble.

Replace the carry-over pipes that have been removed.

Replace the O-ring between the electrohydraulic actuation module and the control valve element.

Reassemble the module in the reverse order of operations described in § 4.2 and 4.3.

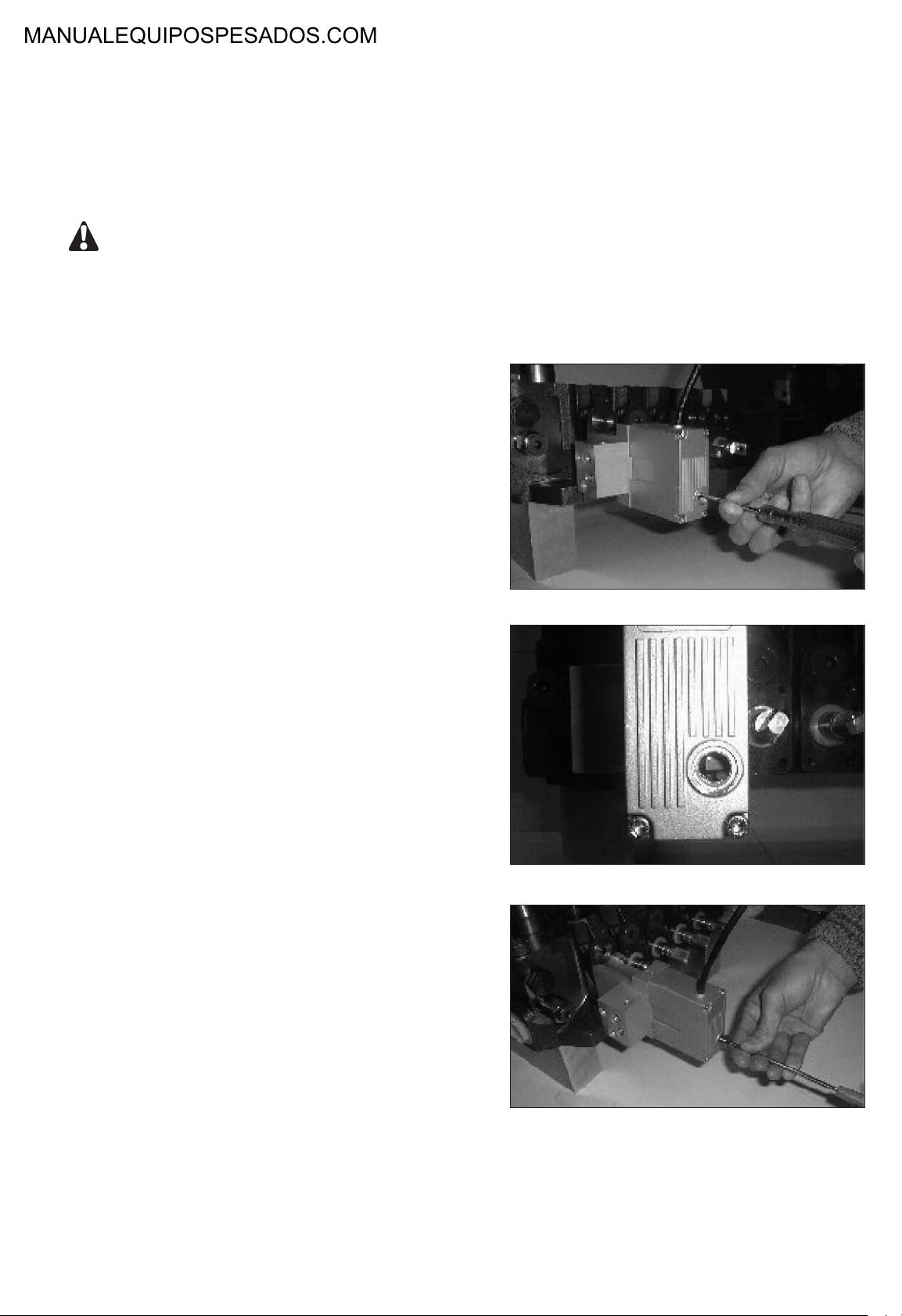

4.5 - Removal / disassembly of the electrohydraulic

transformation stage

NOTE : The electrohydraulic actuation module does not

need to be removed to perform this operation.

Machine off :

- Place all of the machine’s actuators connected to the control block in neutral position.

- Release stored pressure by operting all the

spools.

Once correctly installed, the unit can be placed into

operation :

- Check the condition of line connector seals.

- Check the condition of electric wires.

- Connect the lines to the block as per the connecting

diagram and tighten to the torque specification

(refer to the table in the Data sheat).

- Ensure that hoses are not twisted nor rub.

NOTE : Install a vacuum pump on the tank of the machi-

ne to limit oil leakage when connections are

removed.

After disconnecting the lines from the electrohydraulic actuation module, immediately fit the

sealing plugs. Make sure to collect any possible

oil leakage in a suitable receptacle.

Unscrew the 4 mounting screws using an allen wrench

M3.

Reassembly : torque : 3 to 3,5 N.m.

Remove the electrohydraulic transformation stage by

gently pulling it backward parallely to the spool axis until

the rod of the position sensor is completly extracted.

NOTE : The removal of the 4 mounting screws of the

electrohydraulic transformation stage releases

the PCB tightened protecting cover. Avoid all

risk of pollution, humidification or impacts on

electronics and hydraulics parts during the

operations.

21

Page 9

MAINTENANCE INSTRUCTIONS

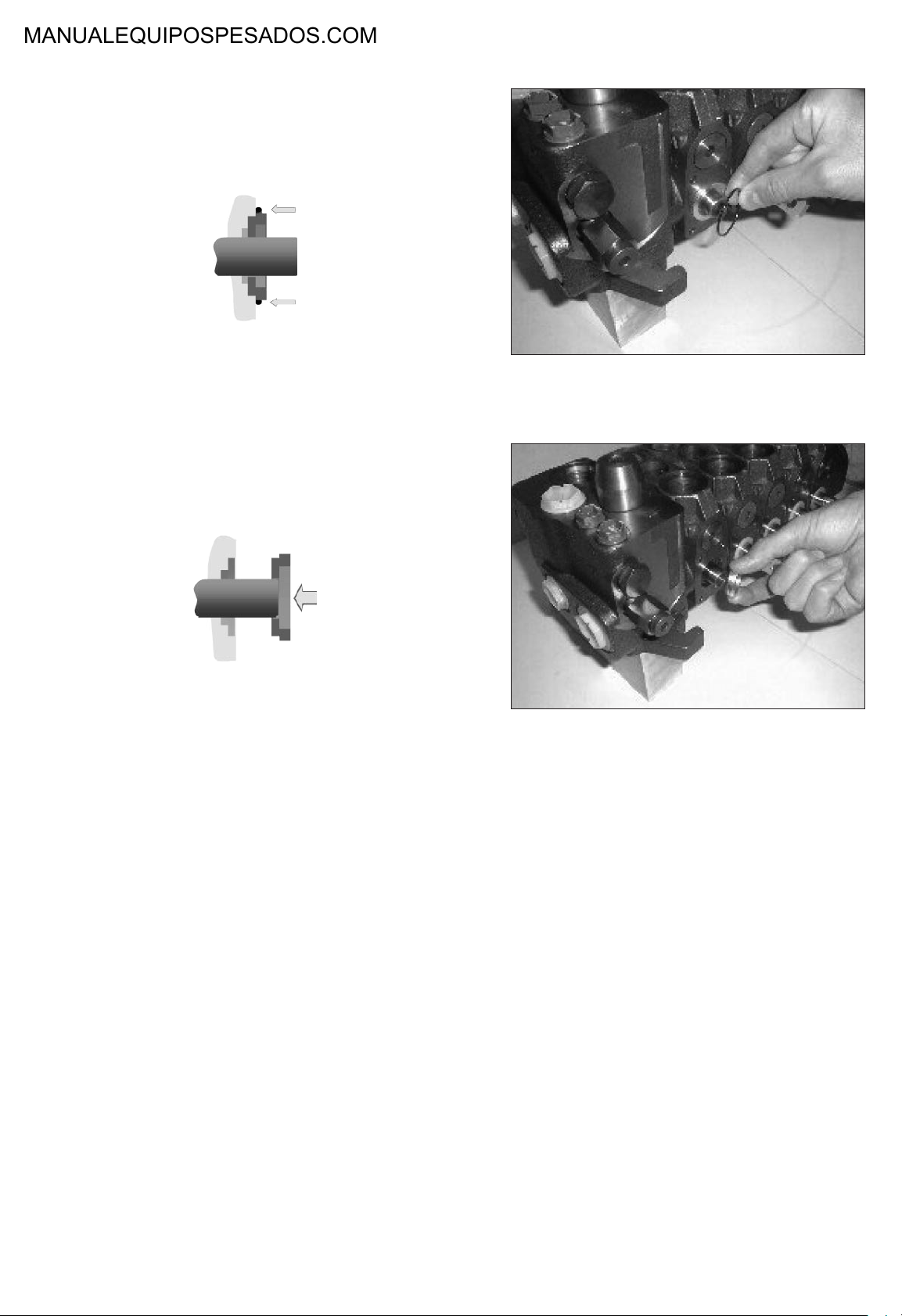

Remove one or both electrohydraulic valve(s).

NOTE : This operation is to be performed only in the

case of an external leakage noticed around the

tightness seal between the valve and the housing.

Reassembly :

- replace the external tightness seals on the valves

- fit the valve(s) into its (their) housing(s).

Replace the external tightness seal of the rod (or sensor

O-ring).

NOTE : Place the sensor O-ring in its groove on the

mechanical interface side prior to assembly.

Reassemble the electrohydraulic transformation stage in

reverse order.

Joints d'étanchéité

22

Page 10

MAINTENANCE INSTRUCTIONS

5. REMOVAL / ASSEMBLY OF CONNECTING

FLANGE AND FILTER

Machine off :

- Place all of the machine’s actuators connected to the control block in neutral position.

- Release stored pressure by operating all the

spools.

NOTE : Install a vacuum pump on the tank of the machi-

ne to limit oil leakage when connections are

moved.

After disconnecting the lines from the electrohydraulic actuation module, immediately fit the

sealing plugs. Make sure to collect any possible

oil leakage in a suitable receptacle.

5.1 - Connecting flange removal / assembly

Unscrew the 2 mounting screws using an allen wrench

M5.

Reassembly : torque : 11 ± 1 N.m.

Remove the connecting flange. Pull the connecting flange backward parallely to the screw axis in order to release the carry-over pipes.

Reassemly :

- Replace carry-over pipes.

- Reassemble parts in reverse order.

5.2 - Filter replacement

Unscrew the filter in the port P using a flat screw driver.

Reassembly : hand tight the filter in port P.

23

Page 11

MAINTENANCE INSTRUCTIONS

6. NEUTRAL POSITION ADJUSTMENT

NOTE : To perform this operation, the control block does

not need to be removed from the machine, nor

the electrohydrauic actuator module from the

control valve.

Machine off :

- Place all of the machine’s actuators connected

to the control block in neutral position.

- Release stored pressure by operating all the

spools (move the handler in all directions).

Locate and remove the inspection plug on the lower side

of the actuation module rear cover.

Switch on the electrical power (12VDC or 24VDC) only

(no hydraulic power).

The assistance pressure of 35 bar must absolutely be

decompressed.

Locate the adjusting trimmer inside and the green LED

underneath. The green LED will turn on by the time the

”mechanical zero” of the spool matches the ”electrical

zero” of the electronic setup.

Using a flat and thin screwdriver, turn the trimmer clockwise or counterclockwise until the green LED turns on.

24

Page 12

MAINTENANCE INSTRUCTIONS

7. START UP PROCEDURES

Machine off :

- Place all of the machine’s actuators connected to the control block in neutral position.

- Release stored pressure by operating all the spools. Make sure that the remote control is switched off

while starting up the engine and before the hydraulic pump is engaged.

Start up the engine and engage the oil pump. Turn on the remote control system.

CAUTION

THE ELECTROHYDRAULIC PROPORTIONAL SYSTEM IS DESIGNED AND QUALIFIED FOR LOW TEMPERATURE

OPERATION UP TO -40°C. FOR OIL TEMPERATURE LESS THAN -15°C, ACTUATORS MOVEMENTS MAY INITIALLY RESULT SLOW AND JERKY. IT IS STRONGLY RECOMMANDED THAT COLD WEATHER START-UP ARE FOLLOWED BY PROPER OIL HEATING PROCEDURES.

Engage the remote control device and slowly vary the control signal making sure that no external obstacle can be hit in

case of unadverted movements.

In response to a variable signal generated by the remote control device, the selected machine’s function must smoothly

accelerate / decelerate, showing good stability and repeatability.

When one remote control function at a time is engaged, only the corresponding machine function must respond, while all

the other machine functions remain at rest.

25

Page 13

50

Transmission control and adjustment

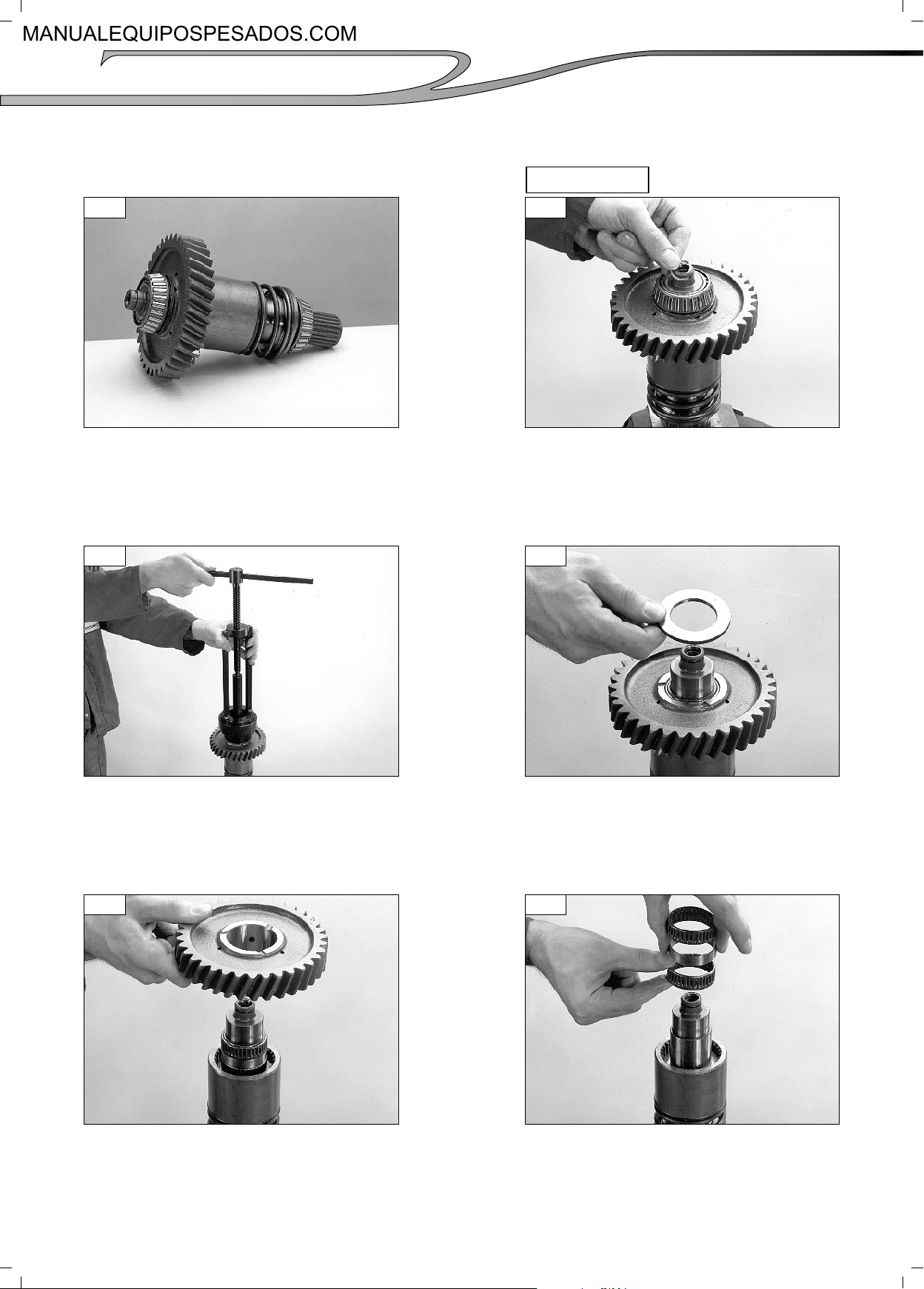

6 - SPRUNG-ON 4 WHEEL DRIVE DIS-ASSEMBLY AND RE-ASSEMBLY

DIS-ASSEMBLY

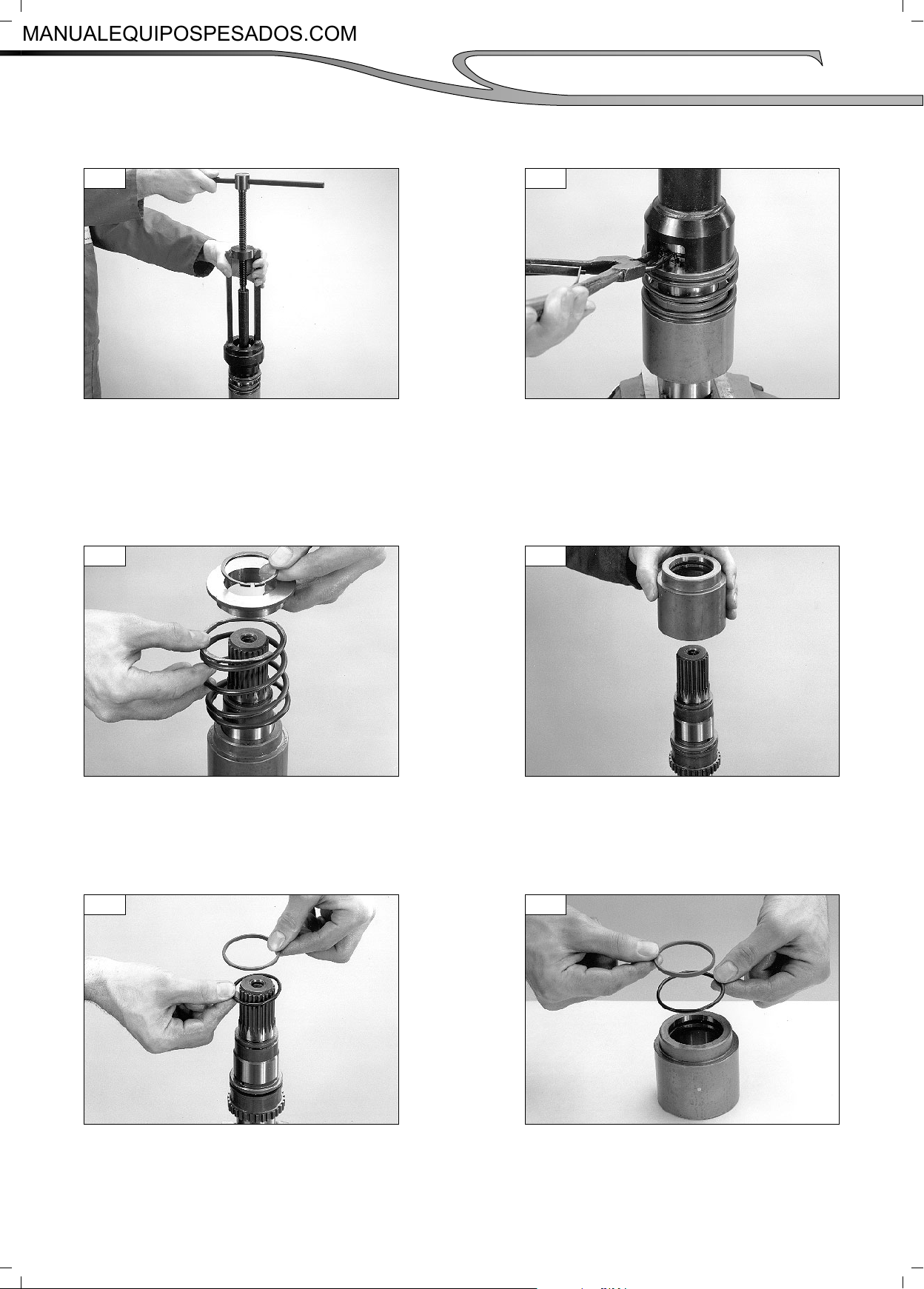

6-1

The sprung on 4 wheel drive assembly.

6-2

Position the shaft in a soft jawed vice

and remove the sealing ring.

6-3

Using the appropriate bearing puller

remove the rear bearing.

6-5

6-4

Remove the thrust washer.

6-6

Remove the 4 wheel drive gear.

Remove the two needle bearings and

spacer.

(01/07/2008)

Page 14

6-7

Invert the shaft and using the appropriate

bearing puller remove the front bearing.

Transmission control and adjustment

6-8

Using the appropriate tool compress the

spring and release the circlip.

51

6-9

Remove the circlip, retainer, and spring.

6-11

6-10

Remove the piston drum assembly.

6-12

Remove the piston seal and «O»ring from

the shaft and discard.

(01/07/2008)

Remove and discard the piston seal and

«O»ring from the piston drum.

Page 15

52

Transmission control and adjustment

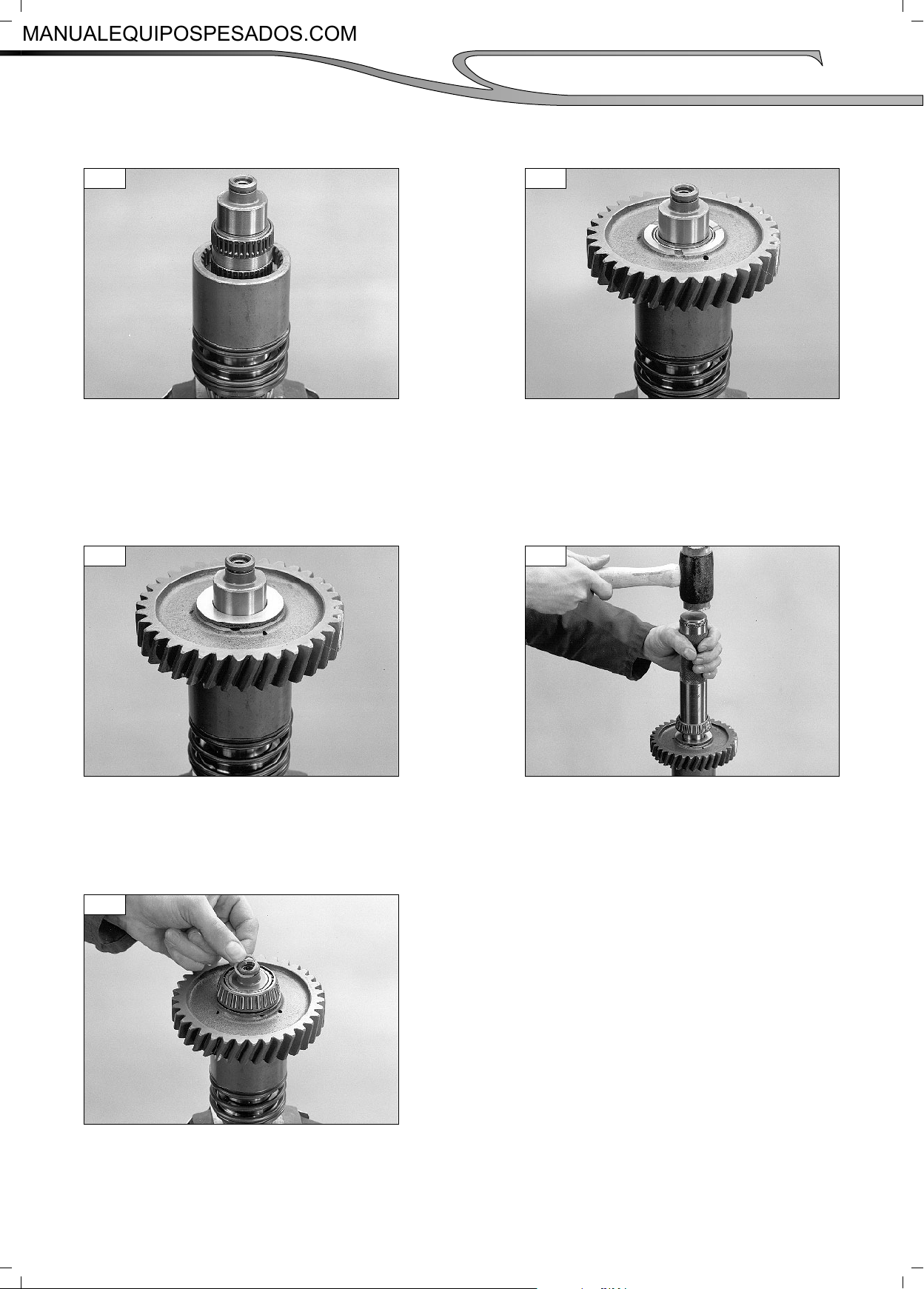

RE-ASSEMBLY

6-13

Fit a new «O»ring and sealing ring to the

shaft.

See (fi g. 6-11).

6-14

Fit a new «O»ring and sealing ring into the

piston. Bend the sealing ring into a heart

shape as shown to assist assembly.

6-15

Lubricate the seals with a light grease

and refi t the piston to the shaft.

6-17

6-16

Replace the piston spring and retainer.

6-18

Using the appropriate tool compress the

spring and retainer and refi t the circlip.

Using an appropriately sized tube refi t

the front bearing.

(01/07/2008)

Page 16

6-19

Invert the shaft and refi t the two needle

bearings and spacer as shown.

Transmission control and adjustment

6-20

Replace the 4 wheel drive gear.

53

6-21

Replace the thrust washer.

6-23

6-22

Using an appropriately sized tube replace

the rear bearing.

Fit a new sealing ring.

(01/07/2008)

Page 17

54

Transmission control and adjustment

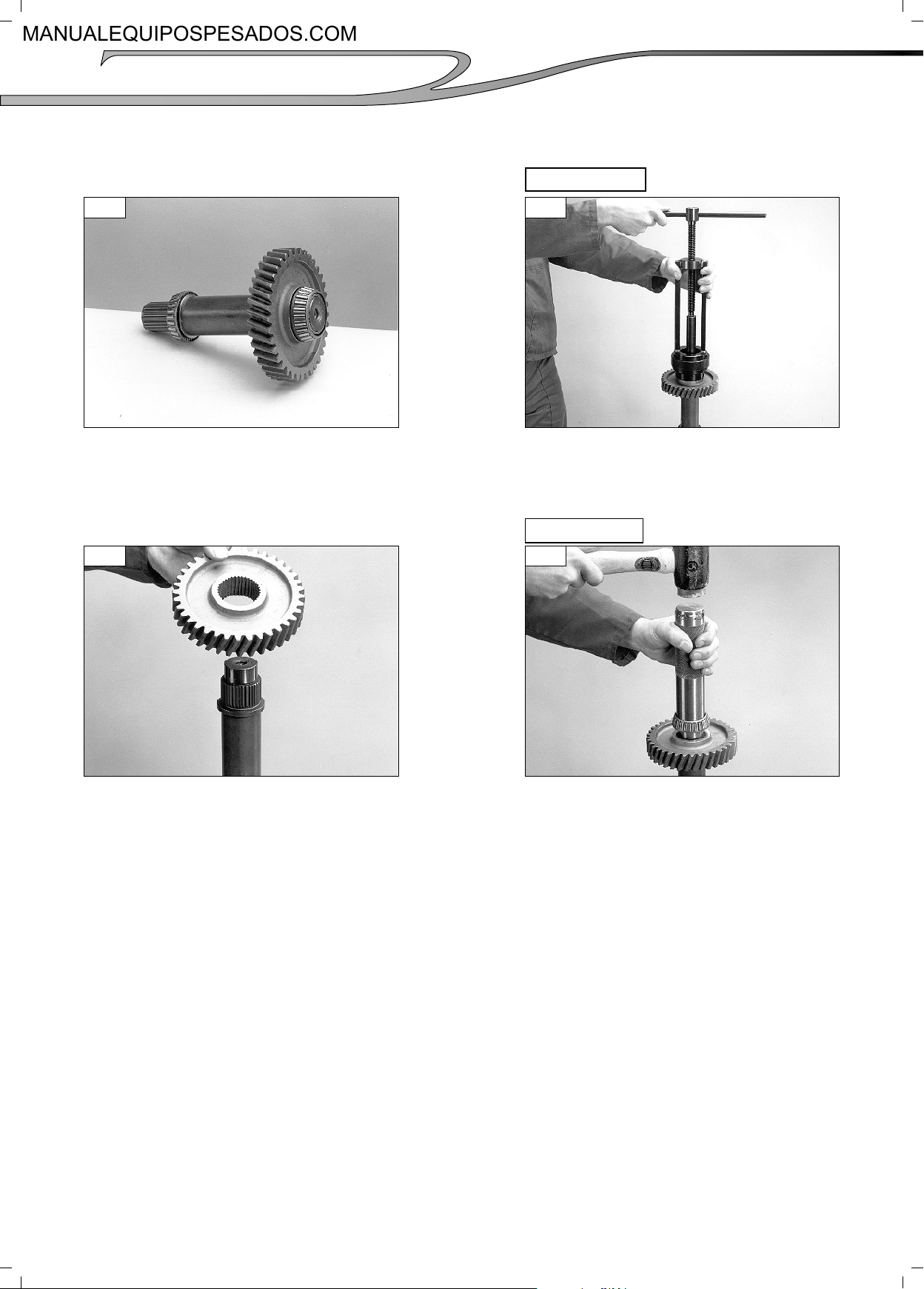

7 - PERMANENT 4 WHEEL SHAFT DIS-ASSEMBLY AND RE-ASSEMBLY

DIS-ASSEMBLY

7-1

The permanent 4 wheel drive shaft.

7-2

Using the appropriate bearing puller

remove the front and rear bearings.

7-3

Remove the 4 wheel drive gear.

RE-ASSEMBLY

7-4

Replace the 4 wheel drive gear using

stop threaded product (P / N° 548110),

on the shaft splines . Then using a

suitably sized tube re-fi t the front and

rear bearings.

(01/07/2008)

Page 18

Transmission control and adjustment

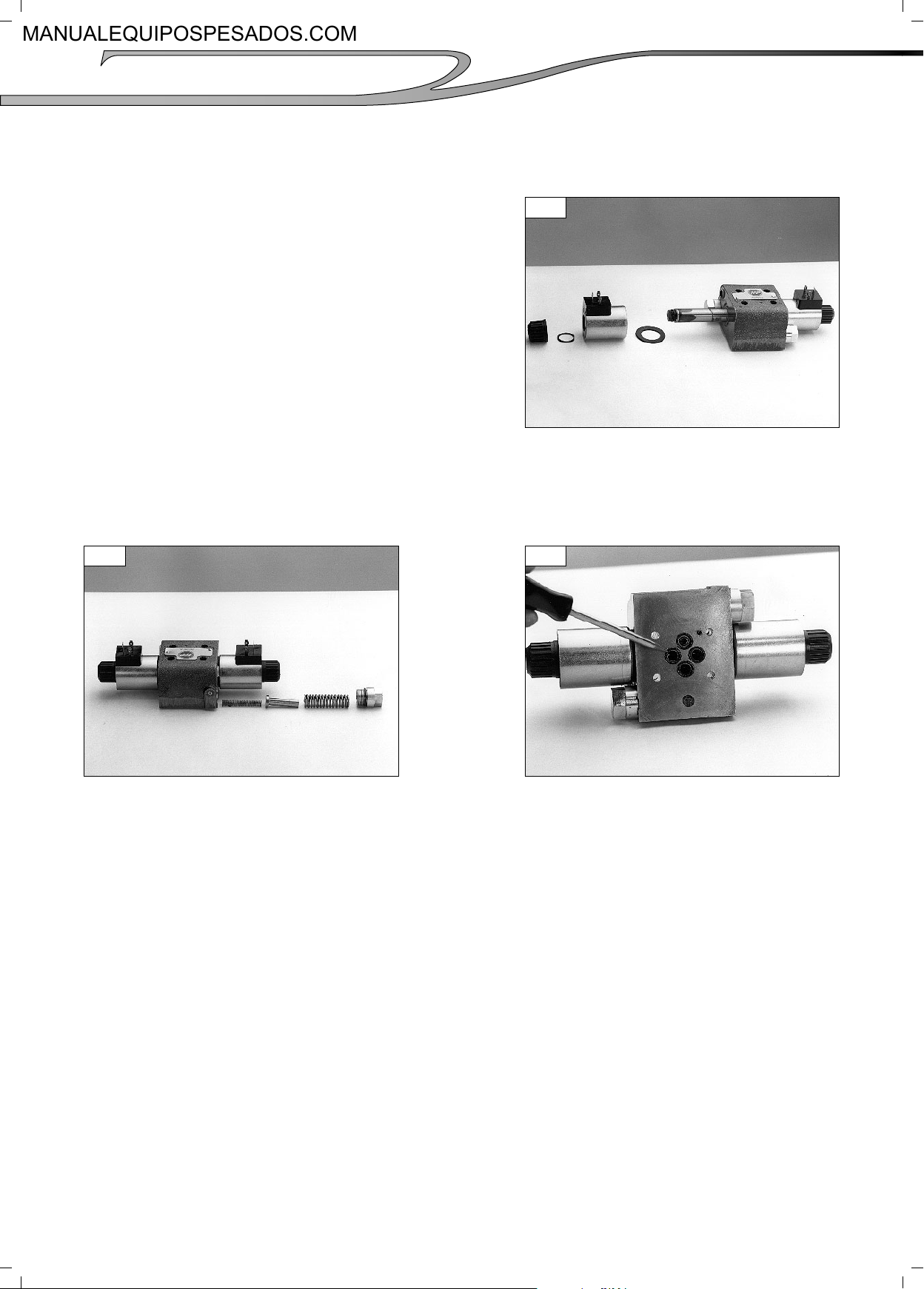

8 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE OIL PUMP

Note : Individual components of the oil

pump are non serviceable. The pump

may, however, be stripped for cleaning

and examination purposes.

8-1

View showing a dismantled pump

assembly.

55

8-2

The pump oil seal may be replaced using

an approprietely sized tube.

(01/07/2008)

Page 19

56

Transmission control and adjustment

9 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE VALVE

Nota : Dis-assembly of the control valve

is not generally recommended

as, with the exception of the

solenoids, individual parts are

non serviveable. It may however

be dismantled for cleaning and

examination.

9-1

The retaining nut, coil and washers

removed.

9-2

The modulation components removed.

9-3

There are 4 «O»rings fi tted to the

underside of the valve which may be renewed if necessary.

(01/07/2008)

Page 20

Transmission control and adjustment

10 - GEAR LEVER HOUSING DIS-ASSEMBLY AND RE-ASSEMBLY

10-1

Remove the plastic ties from the rubber

gaiter and pull the assembly apart as

shown.

Nota : Before re-assembly remove all

traces of old sealant from the

joint faces.

57

10-2 10-3

Apply a airtightness product (P / N°

562228) to the sealing face as shown.

Lubricate the ball seating with a light

grease and push the two halves of the

assembly together. Secure the rubber

gaiter with two new plastic ties.

(01/07/2008)

Page 21

58

Transmission control and adjustment

11 - TRANSMISSION RE-ASSEMBLY

Note : All shafts and bearing should be

lubricated with transmission fl uid prior

to assembly.

To prevent possible contamination of

hydraulic parts lint or cotton rags

should not be used.

11-1

4WD VERSION : Position the front case

as shown and using a suitably sized

tube fi t a new 4 wheel drive output shaft

oil seal to a depth of 6mm below the

housing face. Fill the seal lip with light

grease.

11-2

Re-fi t the oil pump assembly and sealing

ring. Tighten 4 bolts to a torque of 1323 Ib / ft. New copper washers must be

fi tted under the bolt heads.

11-4

11-3

If previously removed, replace the two

plug and «O»ring assemblies as shown

and tighten to a torque of 30 to 40 Ibs

/ft.

11-5

Invert the case and then re-fi t the bearing

cups if previously removed.

Using a suitable tool push the inner

detent spring and ball into the case and

secure in place with a dummy plug as

shown. (ø 18 mm, lg. 25 mm).

(01/07/2008)

Page 22

11-6

Dummy plug in place

11-8

Transmission control and adjustment

11-7

Replace the countershaft and reverse

idler shaft assemblies.

11-9

59

Slide the 1st / 2nd fork onto the 3rd /

4th rail then refi t the 3rd / 4th shift fork

and tighten the screw to a torque of 13

to 18 Ibs / ft. Hold the forks and rail

in place on the output shaft then re-fi t

the complete assembly into the case.

The shift rail should displace the dummy

plug as it enters the bore.

Note : Check that the inner detent spring

and ball have not become displaced and

remove the loose dummy plug from the

case sump.

11-10

Push the interlock ball into the detent

bore.

11-11

Re-fi t the 1st / 2nd shift rail and tighten

the shift fork screw to a torque of 13 to

18 Ibs / ft. Check that the interlock ball

is correctly positioned in between the

two rails.

(01/07/2008)

Replace the outer detent ball and spring.

Tighten the plug to a torque of 30 to 40

Ibs /ft.

Page 23

60

Transmission control and adjustment

11-12

4WD VERSION : Replace the 4 wheel

drive shaft assembly. Lubricate the rear

seal with a light grease.

11-14

11-13

Lubricate the input shaft front and rear

seals a light grease and re-fi t the shaft

assembly into the case.

11-15

Rear case with all shaft assemblies

fi tted.

11-16

Invert the case and replace the shim

packs and bearing cups. The 2mm thick

spacer shim should be fi tted into the

case fi rst, then fi t the remaining shims

followed by the bearing cup. A light

grease may be used to help hold the

cups in the case.

Position the rear case as shown and

using a suitably sized tube fi t a new

output shaft oil seal to a depth of 6mm

below the housing face. Fill the seal lip

with a light grease.

11-17

Re-fi t the rear case, (without sealant at

this stage), and secure with at least 6

equally spaced bolts. When fi tting the

rear case be careful to avoid damaging

the input shaft sealing rings.

(01/07/2008)

Page 24

11-18

Position a D.T.I. on the end of the input

shaft as shown, and using a suitable

pry bar through the side access hole,

measure and note the shaft end fl oat.

11-20

Transmission control and adjustment

11-19

Attach a suitable shimming tool, (with a

12mm thread), to the end of the reverse

idler shaft. Position a D.T.I. as shown,

and using a pry bar lift the shaft, then

measure and note the end fl oat.

11-21

61

Attach a suitable shimming tool, (with

a 12mm thread), to the end of the

countershaft. Position a D.T.I. as shown,

and using a pry bar lift the shaft, then

measure and note the end fl oat .

11-22

4WD VERSION : Attach a suitable

shimming tool, (with a 12mm thread),

to the end of the 4 wheel drive shaft.

Position a D.T.I. as shown, and using a

pry bar lift the shaft, then measure and

note the end fl oat.

(01/07/2008)

Attach a suitable shimming tool, (with

a 12 mm thread), to the end of the

output shaft. Position a D.T.I. as shown,

and using a pry bar lift the shaft, then

measure and note the end fl oat.

Remove the rear case and add or remove

shims as necessary to give .001» to

.003» end fl oat on all shafts.

Repeat steps 11.17 to 11.22 until all

shaft end fl oats are correct.

Page 25

62

Transmission control and adjustment

11-23

Replace the 4 «O»rings in the front case.

(There are only 3 fi tted on the 2 wheel

drive model).

11-24

Re-fi t the rear case using an approved

liquid gasket Taking care not to damage

the input shaft sealing rings. Tighten the

17 bolts to a torque of 33 to 47 Ibs /

ft.

11-25

Replace the shaft end plug and «O»ring

assemblies. Note the special breather

plug es fi tted in the reverse idler position.

Tighten to a torque of 30 to 40 Ibs / ft.

11-27

11-26

Fit a new expansion plug to the shimming

access hole using an approved

sealant. Stop threaded product (P / N°

562227).

11-28

Replace the output yoke, «O»ring, washer

and bolt. Then tighten to a torque of 50

to 65 Ibs / ft.

4WD VERSION : Replace the spacer,

4WD yoke, «O»ring, washer and bolt.

Then tighten to a torque of 50 to 65 Ibs

/ ft.

(01/07/2008)

Page 26

11-29

Re-fi t the cold start ball, spring and

housing. Then tighten to a torque of 34

to 44 Ibs / ft.

11-31

Transmission control and adjustment

11-30

Lubricate the seals with transmission

fl uid then re-fi t the pressure regulator

valve and tighten to a torque of 34 to 44

Ibs / ft.

11-32

63

Lubricate the seals with transmission

fl uid then re-fi t the converter regulator

valve and tighten to a torque of 17 to 22

Ibs / ft.

11-33

Ensure the 4 «O»ring are in place then refi t the control valve assembly and tighten

the 4 caps crews to a torque of 5.0 to

6.3 Ibs / ft. The valve can only be fi tted

one way round as it is located by a small

dowel pin.

Re-fi t the temperature sender and tighten

to a torque of 15 to 20 Ibs / ft.

11-34

Re-fi t the strainer, spacer, «O»ring and

cover plate. Then tighten the two screws

to a torque of 13 to 23 Ibs / ft.

(01/07/2008)

Page 27

64

Transmission control and adjustment

11-35

Re-fi t the drain plug and «O»ring assembly.

Tighten to a torque of 25 to 40 Ibs / ft.

11-36

Re-fi t the 4th gear lock out screw, (when

this feature is not required a shorter

blanking screw is fi tted). On some

applications an additionnal sealing plug

may be fi tted.

11-37

Apply a bead of RTV joint compound (P /

N° 562228) to the gear case as shown.

11-39

11-38

Re-fi t the gear lever assembly and tighten

the three bolts to a torque of 12 to 18

Ibs / ft.

11-40

Re-fi t the fi lter housing and gasket.

Tighten the two bolts to a torque of 33

to 47 Ibs / ft.

Lubricate the seals with a light grease

and screw on a new oil fi lter.

(01/07/2008)

Page 28

11-41

4WD VERSION : Lubricate the seals with

a light grease and re-fi t the 4 wheel drive

solenoid spool. Tighten to a torque of 15

to 20 Ibs / ft.

11-43

Transmission control and adjustment

11-42

4WD VERSION : Re-fi t the 4 wheel drive

solenoid coil and nut. Tighten to a torque

of 4 Ibs / ft maximum.

65

4WD VERSION : If previously removed

re-fi t the 4 wheel drive clutch supply

pipe, apply air tightness product (P / N°

62175) to threads and thighten nuts to

a torque of 5 to 7.5 Ibs / ft.

(01/07/2008)

Page 29

66

Transmission control and adjustment

INSTALLATION AND ADJUSTEMENT OF SPEED PROBE

Align a gear tooth directly in the centre of the threaded sensor opening. screw in by hand. The

speed sensor (A) until it makes contact with the tooth (C). Unscrew the speed sensor by one half

to three quarters of a turn (in an anti-clockwise direction).

This will set the gap (B) between the speed probe and the gear tooth to between 0,71 & 1,06 mm.

Tighten the lock nuts to a torque of between 2,5 to 5 Nm after adjustment is completed

(01/07/2008)

Page 30

TEST PROCEDURE

Transmission control and adjustment

67

(01/07/2008)

Page 31

OPERATING AND SETTING OF THE LONGITUDINAL STABILITY ALARM

OPERATOR

Switch the machine

on

Engine turning over

To position "0", machine :

- Stable (no movement)

- With no attachments

- Jib raised to max., telescope

retracted

- On wheels (stabilizers raised)

- Wheels aligned

- On machines fitted withtilting

corrector.

- Frame an horizontal position.

Press for 2 s the adjust button

located at the back of the unit

(see diagram 2)

Press the "STOP

BUZZER" button

To position "MAX":

Jib on horizontal position.

Take the machine's rated load,

position it at max. startup as

indicate on load chart minus

100mm.

UNIT VISUAL DISPLAY AUDIO SIGNAL

All the LEDS are on

Start of setting

2 yellow LEDS and 2

Enter set mode

"O" setting saved

green LEDS in the

middle flash alternately

2 green LEDS at the bottom

remain on

2 red LEDS at the top remain

on

2 yellow LEDS and 2

green LEDS in the

middle flash alternately

5 beeps indicate that the setting

has been saved

Press the "TEST"

button

Check the setting against the load

chart : put the rated load at max.

startup

setting

conforms

to load

chart

YES

NO

"MAX" setting saved

setting

conforms

consistency

"MAX" and "0"

YES

The unit automatically leaves the set

position the LEDS stop coming on

End of setting

Operator starts setting over

again

NO

The unit returns to the

"locked" position

All the LEDS are on, with

no buzzer ignition on

The LEDS come on up to

the first red LED

5 beeps indicate that the setting

has been saved

Operator starts setting over

again

A continuous 2s beep

indicates to the operator that

the settings have been taken

into account and that the unit

is passing automatically into

the normal operation position

Stick on the other part of the

"SESALY" sticker to seal the setting

(see diagram 2)

The operator can put the truck in the

desired position

3

Page 32

1 - This setting must be made with the rear axle assembly at a stable temperature.

Do not carry out after braking tests as the temperature difference between the

axle assembly and the gauge would disturb the setting.

2 - Before setting the unit, it is important to operate the machine for placing the strain

gauge (for example, when testing the machine, in which case make sure to

comply with point N° 1).

3 - Last checking of setting must be done before forwarding the machine

WARNING

2 red LEDS

2 yellow LEDS

4 green LEDS

DIAGRAM 1

1 red LED

DIAGRAM 2

Place the sticker after setting and

conformity checks

(To change at each setting)

Set button clearance hole

(tool Ø 2, min. length 40)

4

Page 33

2 red LEDS

SAFETY SYSTEM

Test switch

Sound alarm signal light off

2 yellow LEDS

4 green LEDS

Sound alarm

off switch

Power supply connector +

aggravating movements cut-off

signal output

Connection to the strain

gauge

adjustment microswitch (accessible with a 6 mm

male hexagonal wrench)

5

Page 34

INSPECTION PROCEDURE FOR THE LONGITUDINAL STABILITY ALARM STRAIN GAUGE

Connector engineering :

+ power supply red wire / contact N° 1

- power supply and PT 100 brown wire / contact N° 2

+ measurement yellow wire / contact N° 3

- measurement green wire / contact N° 4

PT 100 blue wire / contact N° 5

Shielding white / contact N° 6

Description of the connectors of strain gauge.

Shielding 6

PT 100 5

Measurement - 4

+ power supply 1

- power supply 2

Measurement + 3

Prior to any electrical inspection, carry out a visual check on the state of the gauge and its

connections.

6

Page 35

Electrical Inspection

Disconnect the gauge from the electrical circuit.

Use a multimeter to take the following

measurements :

(Fig.A)

- Measure the impedance between A+ and A- =

Z power (power supply impedance)

Values : 300Ω≤Z power ≤ 400Ω

(Fig.B)

- Measure the impedance between M+ and M- =

Z meas. (measuring system impedance)

Values : 300Ω≤Z power ≤ 400Ω

(Fig.C)

- Measure the impedance between A- and PT

100 = Z PT100

Values : 101Ω + 0.39xT

T corresponds to the gauge temperature.

Example : T=20°C then

Z PT 100 = 101Ω + 7.8Ω = 109Ω

Fig.A

Fig.B

Between A+ and A-

350 Ω

off 500Ω

5 KΩ

Between M+ and M-

350 Ω

off 500Ω

5 KΩ

(Fig.D)

-

Measure the impedance between A+ and

shielding : Zbl

Zbl > 30 MΩ (infinite resistance or open

circuit)

(Fig.E)

- Measure the impedance between A+ and the

machine frame : Z frame

Z frame > 30 MΩ (infinite resistance or

open circuit)

Fig.D

Betwen A+ and shielding

l

off 500Ω

5 KΩ

Fig.C

Fig.E

Between A- and PT100

109 Ω

off 500Ω

5 KΩ

Between A+ and Frame

l

off 500Ω

5 KΩ

7

Page 36

8

Page 37

1- MANITOU S.A. AIR CONDITIONING UNIT OPERATING

PRINCIPLE

1.1- GENERAL INFORMATION ON THE MANITOU AIR-CONDITIONING FUNCTION

1 Compressor

2 Condenser

3 Dehydrating

filter

4 Expansion valve

5 Evaporator

6 Blower system

The MANITOU air-conditioning unit is based on the coolant's ability to absorb heat in considerable

quantities when it is subjected to physical changes on being transformed from a liquid state to a gas.

Operating cycle (see diagram) :

The gas coolant, at low temperature and pressure, is sucked in by the compressor which is driven by the

vehicle engine.

The compressor expulses the coolant, still as a gas, at high pressure and temperature, and it goes into the

condenser in this state.

Inside the condenser, the fluid undergoes a physical transformation from a gas to a liquid state, giving off

heat in the process. The warm air which passes through the condenser is evacuated by a dynamic effect

produced by the engine cooling fans. The liquid coolant leaving the condenser crosses the dehumidifying

filter which removes the humidity and solid impurities, then goes on to the expansion valve.

When the liquid is vaporized in the expansion valve, the pressure falls and lowers the temperature in the

evaporator. During its travel through the evaporator, the coolant is physically transformed from a liquid to

a gaseous state and then sent to the compressor. The air which flows over the cold surfaces of the

evaporator is cooled in turn, lowering the temperature in the cab.

This air, which is circulated by an electric blower system is dehumidified because the vapour in the air, is

condensed following contact with the cold walls of the evaporator. This condensation water is collected in

a drainage trap and evacuated outside the machine.

3 / 32

Page 38

Electric skeleton diagram

TC Control panel

BP Bouton poussoir

L Tongue

S Blower

T Thermostat

P1 Low pressure gauge

P2 High pressure gauge

R Relay

EC Compressor clutch

F1 7.5 A fuse

F2 30 A fuse

CONNECTORS

C1 5-way, black AMP MIC IV-TV - Ref. 144 518-2

C2 6.35 x 0.8 mm female connector

C3 90" 6.35 x 0.8 mm female connector

C4 Deutsch Ref. HD10-6-12P

C5 1-way RKG female connector Ref. 920 510

C6 Deutsch Ref. HD16-6-12S-B010

C7 2-way female DT - Ref. 552 459

C8 2-way male DT - Ref. 552 457

C9 2-way male DT - Ref. 552 457

C10 2-way female DT - Ref. 552 459

4 / 32

Page 39

1.2- THE COMPRESSOR

The compressor's job is to pump the coolant leaving the evaporator, in gas phase, at low temperature and

pressure, and compress it into the condensor at high pressure and temperature.

The compressor mechanisms are lubricated with a special oil which is included in the compressor during

manufacture. Part of this lubricant is circulated through the installation by the coolant.

The compressor is driven by the engine via a belt and activated by engaging an electromagnetic clutch.

10 cm3 extra oil PAG SP20 is added to the original quantity to compensate for the length of

the hoses.

A fluorotracer additive, miscible in the oil lubricant, is used to detect leaks in the system

during after sales service operations and this is in the compressor casing.

5 / 32

Page 40

1.3- THE CONDENSER

The condenser is a heat exchanger which condenses the coolant. This arrives in the form of a gas at high

pressure and temperature, and the condenser liquefies it through the fall in temperature caused by the air

passing throught it. The condenser is fitted with easily identified input and output connections. The fluid

arriving as a gas goes in through the large connection and leaves by the small one in liquid form. The

condenser must be supplied with air by the radiator cooling fan which pulses air through it to condense

the fluid.

6 / 32

Page 41

17

INNER TELESCOPING CYLINDER

MT 932 Série B

OUTER TELESCOPING CYLINDER

MT 932 Série B

2

3

5

6

17

POCHETTE DE JOINTS

DICHTUNGSATZ

JUEGO DE JUNTAS

SEAL KIT

SERIE GUARNIZIONE

236 813

7

12 x 2

13

16 x 2

1

1er MONTAGE

1ste MONTAGE

1ro MONTAJE

1st MOUNTING

1mo MONTAGGIO

12

11

19

18

15

14

14

11

10

15

13

12

2ème MONTAGE

2te MONTAGE

2do MONTAJE

2nd MOUNTING

2do MONTAGGIO

2

4

5

6

7

16

16

3

2

3

5

6

17

7

POCHETTE DE JOINTS

DICHTUNGSATZ

JUEGO DE JUNTAS

SEAL KIT

SERIE GUARNIZIONE

236 812

12 x 2

13

16 x 2

1

9

8

1er MONTAGE

1ste MONTAGE

1ro MONTAJE

1st MOUNTING

1mo MONTAGGIO

2ème MONTAGE

2te MONTAGE

2do MONTAJE

2nd MOUNTING

2do MONTAGGIO

12

11

19

18

15

14

14

11

15

16

3

16

4

5

6

7

13

12

10

2

8

9

Page 42

18

TILTING CYLINDER

MLT 630 / 634 Série B

TILTING CYLINDER

MLT 731 Série B

11

12 x 2

13

14

22

15

POCHETTE DE JOINTS

DICHTUNGSATZ

JUEGO DE JUNTAS

SEAL KIT

SERIE GUARNIZIONE

16

18 x 2

19

20

1

224 074

5

3

4

2

5

16

20

18

19

17

21

18

11

12

13

12

10

14

15

7

6

9

8

7

11

12 x 2

13

14

22

POCHETTE DE JOINTS

DICHTUNGSATZ

JUEGO DE JUNTAS

SEAL KIT

SERIE GUARNIZIONE

15

16

18 x 2

19

20

1

20

238 842

2

13

5

3

4

5

15

16

10

14

12

17

21

18

11

12

18

19

7

6

9

8

7

Page 43

FUNCTIONAL DESCRIPTION, SECTION

5143128

12 11

7

64109 13

EMS HYDRAULIC OUTLINE ADAPTED TO THE MACHINE

Electronic card

Analogic

microcontroller

5

PWM Driver

Input signal

Hall effect sensor

7

TP

VPB

3

8

6

Tp

12 11

Pp

3

SP

VPA

10

9

RPM

SX14

13

Hydraulic

machine

Pressure reducer

6

Page 44

FUNCTIONAL DESCRIPTION, SECTION

The electrohydraulic actuation module consists of an electronic box (1), a stage for electrohydraulic transformation

(2) and a mechanical interface (4).

The analog electronic card (5) modulates the current sent to the proportional electrohydraulic valves (3) so that the

position of the positioning piston (6) measured by the linear transducer (7) complies with the command value, the

sensor (7) is adjustable owing to a screw + LED (14), refer to page : 11. Each electrohydraulic valve (3) is connected to one of the positioning piston chamber (8). The amount of oil sent by the valve shifts the positioning piston of

the value required by the closed loop control. The pressure generated by the fluid inside chambre (8) of the positioning piston depends on the external force that acts against the movement of the positioning piston (6).

The mechanical interface (4) matches the actuation module to the side face of the hydraulic control block. The

module is held in central position by the ring (9) and fixed by two screws. The cross chanel (11) provides oil to the

electrohydraulic valves, chanel (12) drains the modules. Through a flange on the side face of the first module, all

modules connected to each other can be connected to the external source of reduced pressure. Screw (10)

connects the positioning piston (6) and the directional control block spool.

The positioning piston + control spool unit is brought back to the neutral position by the return spring (13).

HYDRAULIC TECHNICAL DATA

Oil consumption :

at stroke end : 3,6 cc at 46 cst

Maximum supply pressure : 35 bar

Maximum return pressure : 1,5 bar

Fluid temperature range : - 20 to + 80 °C

2

Viscosity range : 10 to 380 mm

Maximum permissible fluid cleanless : class 9 to NAS1638

Fluid type : Manitou hydraulic ISO 46

/sec

7

Page 45

13

BA Power unit + Accumulator

CA Suction strainer

CR(O) Towing hook (Option)

CSP Piloted safety valve

D Valve bank 4 or 5 sections

EA Attachment section

EA(O) Attachment section (Option)

EE Inlet section

EI Tilting section

EL Lifting section

ES Outlet section

ET Telescope section

D3 Driving valve bank 3 positions

Position 1 : Braquage court

Position 2 : Braquage roues avant

Position 3 : Position crab

EVHAR(O) Rear hydraulic electrovalve (Option)

EVTF(O) Jib head electrovalve (Option)

FDAV Front disk brake

FDAR Rear disk brake

FR Return filter

M I. C. Engine

MA Joystick

G Retracting/Extending telescope

B Attachment

MC Master cylinder

N Level

P Hydraulic pump

PAAV Front attachment fitting

PAAV(O) Front attachment fitting (Option)

PAAR(O) Rear attachment fitting (Option)

PD Steering pump

PFR(O) Trailer braking fitting (Option)

PP Pressure point

PRF(O) Drain-back fitting (Option)

R Hydraulic tank

RLF Braking oil tank

SC Circuit selector

SCFR(O) Trailer braking circuit selector (Option)

SCHAR(O)Rear hydraulic circuit selector (Option)

S2F Selector 2 functions

1 Telescoping

2 Attachment

S3F Sélecteur 3 fonctions

1 Telescoping

2 Attachment

3 Attachment (Option)

VACM(O) Movements cut-off valve (Option)

VACR Idling checking valve

VAI Insulation valve

VAFR(O) Trailer braking valve (Option)

VC Compensation cylinder DE 100x50 C310

VDAR Rear steering cylinder DE 90x45 C80x2

VDAV Front steering cylinder DE 90x45 C80x2

VI Tilting cylinder DE 120x60 C445 (MLT 6)

DE 130x65 C380 (MLT 7)

VL Lifting cylinder DE 130x70 C720 (MLT 6)

DE 140x70 C720 (MLT 7)

VT Telescoping cylinder DE 70x50 C2100 (MLT 6)

DE 70x50 C2750 (MLT 7)

VVT(O) Locking carriage cylinder DE 60x45 C183 (Option)

NOTE

:1 - The main relief valve's pressure, on inlet sections are given at engine's maximum rating.

2 - The secundary valve's pressure, are given at 1000 rpm of the engine.

3 - Pressure relief valve's control must be done at an oil temperature of 50°C.

Page 46

14

HYDRAULIC DIAGRAM MLT 634 / 731 Turbo LSU Série B-E2 (3/3)

bar

22,5

A5

B5

EF

EA(O)EL

a

A4

B4

bb

A3

B3

b

b

B2

bar

280

B

T

a

EI

T

A

280

bar

bar

B

190

T

a

bar

200

B

T

a

ET

A1B1 A2

D

LS

M

b

DLS

a

P

LS

T

270

EA

ps

bar

EE

T

VACM

MA

MA

T

P

EVHAR(O)

D

G

342

1

2

4

3

1

Page 47

80

Disassembly and Assembly Section

End By:

a. Install the cover for the fuel injectors. Refer to this

Disassembly and Assembly Manual, “Fuel Injector

Cover - Remove

and Install”.

b. If equipped, ensure that the heat shields are clean

andfreefromd

ust, oil, and paint. Install the heat

shields.

Rocker Shaft and Push rod -

i01947657

Remove

Removal Procedure

Table 20

Required Tools

Part

Number

27610227

Start By:

a. Remove the valve mechanism cover. Refer to

this Disassembly and Assembly Manual, “Valve

Mechanism Cover - Remove and Install”.

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The removal procedure is identical for the

three cylinder and the four cylinder engines. The

lustrations show the four cylinder engine.

il

Part Description Qty

Rocker Asse

mbly Tool

NOTICE

4

Illustration 173

Illustration 174

Typical example

g01013998

g01015730

1. If the rocker shaft will not be disassembled, install

the rocker assembly tools (6) between each pair

of rocker arms (2). The rocker arms (2) must be

held away from the machined face of the cylinder

head (3) during reassembly.

2. Start from the ends of the rocker shaft assembly

(1) and work toward the center of the rocker shaft

assembly in order to remove the torx screws (5).

Evenly loosen the torx screws (5) in order to

remove the rocker shaft assembly (1).

Illustration 172

Typical examp le

3. Remove the rocker shaft assembly (1) from the

cylinder head (3).

4. Place an identification mark on the pushrods (4)

for installation. Remove the pushrods (5) from the

cylinder head (3).

g01014000

Page 48

81

Disassembly and Assembly Section

i01947658

Rocker S h aft - Disassemb le

Disassembly Pr

Table 21

Part Description Qty

Suitable Pliers for External Circlips 1

Start By:

a. Remove the rocker shaft assembly. Refer to this

Disassembly and Assembly Manual, “Rocker

ft and Pushrod - Remove”.

Sha

rsonal injury can result from being struck by

Pe

parts propelled by a released spring force.

ke sure to wear all necessary protective equip-

Ma

ment.

llow the recommended procedure and use all

Fo

recommended tooling to release the spring force.

te: The disassembly procedure is identical for the

No

three cylinder and the four cylinder engines. The

illustration shows the four cylinder engine.

ocedure

Required Tools

2. Place an identification mark on each of the

components for

installation. Ensure that you note

the component’s relationship to the machined flat

(7).

3. Remove the rocker arm assembly (3) for the inlet

valve from the rocker shaft (6). Remove the rocker

arm assembly

(4) for the exhaust valve from the

rocker shaft (6).

4. Remove the sp

ring (5) from the rocker shaft (6).

5. Repeat Step 3 and Step 4 in order to completely

disassemble

the rocker shaft assembly.

i01947659

Rocker Shaft - Assemble

Assembly Procedure

Table 22

Required Tools

Part Description

Suitable Pl

iers for External Circlips

Note: The assembly procedure is identical for the

three cylinder and the four cylinder engines. The

illustration shows the four cylinder engine.

Qty

1

Illustration 175

Typical examp le

g01014249

1. Remove the circlip (1) and remove the washer (2)

from both ends of the rocker shaft assembly.

Note: The rocker shaft (6) is not symmetrical as there

is a machined flat (7) toward one end of the shaft.

Illustration 176

Typical example

g01014249

1. Clean all of the components and inspect all of

the components. Inspect the grooves for the

circlips (1) and ensure that all of the oil holes

in the rocker shaft (6) and in the rocker arms

(3 and 4) are not plugged before you begin the

assembly procedure. If necessary, replace any

worn components and any damaged components.

Page 49

54

Index Section

M

Main Bearings - Inspect ......................................... 44

P

Piston Height

Piston Ring Groove - Inspect................................. 43

Inspect the Clearance of the Piston Ring........... 43

Inspect the Pis

Inspect the Piston Ring End Gap....................... 43

S

Systems Operat

T

Table of Contents..................................................... 3

Testing and Ad

V

V-Belt - Test ........................................................... 52

Val ve Depth - I

Valve Guide - Inspect ............................................ 33

W

- Inspect .......................................... 45

ton and the Piston Rings ............ 43

ion Section ..................................... 4

justing Section ............................... 22

nspect ............................................ 33

Wastegate - Tes

Water Temperature Regulator - Test ..................... 42

t.................................................... 29

Page 50

Repair manual

547983EN (24/04/2012)

AXLE ASSEMBLY

TYPE 212

Repair manual

MANITOU BF

B.P 10249 - 44158 ANCENIS Cedex Tél. 33 (0) 2 40 09 10 11

Fax commercial France : 02 40 09 10 96 // Export : 33 2 40 09 10 97

www.manitou.com

Page 51

10

ASSEMBLY

B

B

7

FIGURE 15: Fit the pin screws (10) making sure that they are

all of the same color.

White: 1 mm gap

Yellow: 0.75 mm gap

Blue: 0.5 mm gap

Apply Loctite 270 to the thread.

Torque wrench setting: 5 - 7 N·m.

8

9

8

FIGURE 16: Fit the reversal springs (8) on the piston (9).

CAUTION

FIGURE 17:

in the arm following the correct sequence; orient them so that the

oil circulation holes and the marks "B" are perfectly lined up.

NOTE:

When installing the steel discs, the slot corresponding to

the oil level cap should always be kept free.

Slightly lubricate the braking disks (7) and fit them

16

FIGURE 18: Check that the positioning of the sealing ring (16)

on the arm is intact; install the complete arm.

Lock it into position using two screws (4) and washers (5).

Pay attention not to deform the connect ions of th e springs.

T2

T2

FIGURE 19: Check the flatness of the arms using tool T2 (See

drawing T2 p. 24) and finally lock the arms with the screws (4)

and the washer (5) using the criss-cross method.

Torque wrench setting: 298 N·m

23Dana Holding CorporationASM-0025E - 212 Axle Service Manual

Page 52

32

32

32

32

10

4.5

25

45 °

110

160

25

1

4.3

45 °

8

1

SPECIAL TOOLS

SPECIAL TOOLS

T1

P/N: 2313

T2

P/N: 2305

200

0.1

±

120

20

=

=

90

=

=

50

0.1

±

120

840

930

24

Dana Holding Corporation ASM-0025E - 212 Axle Service Manual

Page 53

2

4

6

8

10

1

3

5

9

12

13

10

14

15

16

17

18

COMPLETE STEERING CASE

EXPLODED VIEW

25Dana Holding CorporationASM-0025E - 212 Axle Service Manual

Page 54

DISASSEMBLY

DISASSEMBLY

4

8

15

FIGURE 1: Loosen and remove the capscrews (15)(8) from

the articulation pin (19)(4).

4

19

9

3

3

4

1

FIGURE 4: Remove the complete st eering case (1).

19

FIGURE 2: Using two levers, remove the top articulation pin

(4) complete with front seal (9) and shims (3).

CAUTION

Pay attention not to damage t he surfaces.

10

19

FIGURE 3: Remove the bottom ar ticulatio n (19) pi n complete

with front sealing ring (10).

26

Dana Holding Corporation ASM-0025E - 212 Axle Service Manual

Page 55

DISASSEMBLY

CAUTION

31

FIGURE 12: 3-FUNCTION VERSION ONLY

Loosen and remove the pin-type screws (31).

NOTE:

Loosen screws (31) in an alternate and criss-cross method.

32

33

Hold piston (33) as it may be rapidly ejected and damaged.

39

FIGURE 15: 2-FUNCTION VERSION ONLY

Remove the spacer (39).

38

8

FIGURE 13: 3-FUNCTION VERSION ONLY

Remove springs (32) of piston (33) backward movement.

33

FIGURE 16: Remove sealing ring (38) from cover (8).

NOTE:

Take note of direction of assembly of ring (38) and replace

ring every time the unit is disassembled.

14

13 14

FIGURE 14: 3-FUNCTION VERSION ONLY

Slowly introduce compressed air through the connection

point of the service brake to ext ract the piston (33).

114

Dana Holding Corporation ASM-0025E - 212 Axle Service Manual

15 16

FIGURE 17: Remove sealing rings (13) and (15) and anti-extrusion rings (14) and (16) from the piston (12).

12

13

15

16

Page 56

NOTE:

Sealing rings (13) and (15) and anti-extrusion rings (14)

and (16) must be replaced each time the unit is disassembled.

34

35

36

DISASSEMBLY

37

33

34 35

FIGURE 18: 3-FUNCTION VERSION ONLY

Remove sealing rings (34) and (36) and anti-extrusion rings

(35) and (37) from piston (33).

NOTE:

Sealing rings (34), (36) and anti-extrusion rings (35), (37)

must be replaced each time the unit is disassembled.

26

A

A min. =1,36 mm

36 37

25

FIGURE 20: BRAKING DISCS PA CK C ON TENTS

The braking discs pack is comprised of: 11 braking discs and

12 steel counterdiscs.

10

9

FIGURE 21: If the braking discs unit is replaced, shims (9) which determine the preloading of Belleville washers (11) must to be restored.

11

FIGURE 19: Always check the thickness of braking discs (26),

even if the braking unit is being disassembled for other reasons than this.

If thickness "A" of one of the discs (26) is close to the minimum admissible size of 1.36 mm, replace the whole pack.

42

41

FIGURE 22: ONLY WHEN REPLACEMENT IS NECESSARY

Remove the union pieces (41) and (42) connecting the lubrication tube (2).

NOTE:

During the assembly stage, union pieces (41) and (42)

must be coated with Loctite 577 and tightened to a torque

wrench setting of 35 - 50 N·m.

115Dana Holding CorporationASM-0025E - 212 Axle Service Manual

Page 57

2

GEAR BOX COMPACT PLUS

ISSUE

01 / 07 / 2008 - 1st ISSUE

1st date of issue :

01 / 07 / 2008

THE TEXTS AND PICTURES IN THIS DOCUMENT CANNOT BE REPRODUCED EITHER TOTALLY OR PARTLY.

(01/07/2008)MR647020EN

Page 58

TRANSMISSION CONTROL AND ADJUSTMENT

GAER BOX COMPACT PLUS

pages

GEAR BOX AND CONVERTER(DETAILS 4WD VERSION) . . . . . . . . . . . . . . . . . . . . . . .5

GEAR BOX AND CONVERTER (WITH BRAKE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

GEAR BOX AND CONVERTER(WITHOUT BRAKE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

GEAR BOX (ELECTRICAL CONTROL VALVE DETAILS) . . . . . . . . . . . . . . . . . . . . . . . .22

TRANSMISSION HYDRAULIC CIRCUIT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

TRANSMISSION HYDRAULIC PRINCIPLE CIRCUIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

TRANSMISSION MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

PRESSURE CHECKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

PRESSURE READING ON GEAR BOX -TURNER COMPACT PLUS- . . . . . . . . . . . . . . . .30

SPECIAL TOOLS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

SHAFT AND GEAR END FLOAT TOLERANCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

DIS-ASSEMBLY / RE-ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

–

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

–

1 - TRANSMISSION DIS-ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

–

2 - INPUT SHAFT DIS-ASSEMBLY AND RE-ASSEMBLY . . . . . . . . . . . . . . . . . . . 40

–

3 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE COUNTERSHAFT . . . . . . . . . . . 45

–

4 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE REVERSE IDLER SHAFT . . . . . .45

(01/07/2008)

–

5 - OUTPUT SHAFT DIS-ASSEMBLY AND RE-ASSEMBLY . . . . . . . . . . . . . . . . . .46

–

6 - SPRUNG-ON 4 WHEEL DRIVE DIS-ASSEMBLY AND RE-ASSEMBLY . . . . . . . . 50

–

7 - PERMANENT 4 WHEEL SHAFT DIS-ASSEMBLY AND RE-ASSEMBLY . . . . . . .54

–

8 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE OIL PUMP . . . . . . . . . . . . . . . . 55

–

9 - DIS-ASSEMBLY AND RE-ASSEMBLY OF THE VALVE. . . . . . . . . . . . . . . . . . . 56

–

10 - GEAR LEVER HOUSING DIS-ASSEMBLY AND RE-ASSEMBLY . . . . . . . . . . .57

–

11 - TRANSMISSION RE-ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

INSTALLATION AND ADJUSTEMENT OF SPEED PROBE . . . . . . . . . . . . . . . . . . . . . . . 66

TEST PROCEDURE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Page 59

4

Transmission control and adjustment

(01/07/2008)

Page 60

GEAR BOX AND CONVERTER

(DETAILS 4WD VERSION)

Transmission control and adjustment

5

(01/07/2008)

Page 61

8

GEAR BOX

(mecanism details - gears)

22 23

27

30

31

32

39

40

35

41

33

25

37

43

42

28

66

67

48

57

56

61

4756

59

77

84

70

83

54

55

58

92

98

97

99

100

102

107

106

90

86

92

92

65

1

12

13

14

17

19

20

6

6386

12

13

14

17

19

20

16

8

10

9

21

18

2

9

10

15

11

6

38

26

24

10

3

9

16

8

21 36

41

36

26

7

7

5

4

11

9

29

52

60

64

51

63

44

46

45

48

49

50

72

74

75

69 91

91 76

80

77

78

94

89

85

93

105

104

103

101

99

88

79

68

79

88

78

81

82

81

83

71 73

96 95

80

85

84

87

58

75

62

53

89

90

61

34

T9

T7

T6

T4

T10

T8

Page 62

9

1 – Input shaft

2 – Gear (24 teeth)

3 – Gear (32 teeth)

4 – Bearing

5 – Thrustwasher

6 – "O" ring

7 – Roller bearing

8 – Snap ring

9 – Bearing

10 – Washer

11 – Circlips

T7: Clutch forward gear low speed (FL)

T9: Clutch forward gear high speed (FH)

12 – Seal

13 – Piston

14 – "O" ring

15 – Bearing

16 – Plate

17 – Spring retainer

18 – Spacer

19 – Clutch disc

20 – Friction disc

21 – Roller bearing

22 – Shim

23 – Spacer

24 – Countershaft

25 – Gear (24 teeth)

26 – Bearing

27 – Piston

T8: Clutch reverse gear

28 – Seal

29 – "O" ring

30 – Spring retainer

31 – Clutch disc

32 – Friction disc

33 – Spacer

34 – Circlips

35 – Washer

36 – Bearing

37 – Thrustwasher

38 – Seal

39 – Plate

40 – Snap ring

41 – Roller bearing

42 – Spacer

43 – Shim

44 – Countershaft

45 – Gear (44 teeth)

46 – Gear (38 teeth)

47 – Gear 1st and 2nd gear

48 – Bearing

49 – Washer

50 – Screw

51 – Seal

52 – Clutch disc

53 – Friction disc

54 – Snap ring

55 – Plate

56 – Bearing

57 – Washer

58 – Seal

59 – Washer

60 – Circlips

61 – Roller bearing

62 – Spring retainer

63 – "O" ring

64 – Piston

T6: Clutch N°1

65 – Spacer

66 – Spacer

67 – Shim

68 – Out put shaft

69 – Gear 4th gear (26 teeth)

70 – Gear 3rd gear (38 teeth)

71 – Gear (48 teeth)

72 – Bearing

73 – Bearing

74 – Washer

75 – Bearing

76 – Washer

77 – Clutch disc

78 – Friction disc

79 – Piston

T4: Clutch N°3

T10: Clutch N°2

80 – Plate

81 – Roller bearing

82 – Spacer

83 – Bearing

84 – Stop washer

85 – Snap ring

86 – Circlips

87 – Spring plate

88 – Spring

89 – "O" ring

90 – Seal

91 – Roller bearing

92 – Seal

93 – Spring plate

94 – Circlips

95 – Spacer

96 – Shim

97 – Out put shaft

98 – Gear

99 – Bearing

100 – Spacer

101 – Seal

102 – End yoke

103 – "O" ring

104 – Washer

105 – Screw

106 – Spacer

107 – Shim

GEAR BOX

(mecanism details - gears)

Page 63

24

Angle gear box

- 65 -

- To aid assembly it may be helpful to highlight

the teeth markes ”X” with a suitable dye.

CHECK ADJUSTMENT OF THE PACK

- 66 -

- Using a dial gauge and a bolt and nut fitted ti

the input flange.

- Install a comparator and check the backlash of

the bevel gears.

Note : The output shaft should be stationary

during this measurement.

- The backlash when measured by this method

should be 0.12 - 0.18 mm.

If necessary adjut both the shim packs equally

to achieve the correct blacklash.

- Once the correct backlash has been achieved

remove and refit the input and output shaft

assemblies using golden hermatite or an

equivalent sealant between the housings, shim

packs and case.

(20/11/2008)

Page 64

Angle gear box

- 67 -

- Refit the drive plate.

Torque the bolt to 39 - 58 Nm.

25

- 68 -

- Photo showing breather, dipstick and filter plug.

- 69 -

Photo showing drain plug.

Note : - Oil seal lips should be lubricated with a light grease on assembly.

- Bearings should be lubricated with an appropriate oil on assembly.

- Drain, filler, and oil level plugs should be torqued to 20 - 30 Nm.

(20/11/2008)

Page 65

26

Angle gear box

(20/11/2008)

Loading...

Loading...