MANITOU 160 ATJ EURO 3, 180 ATJ 2 EURO 3 Service Manual

MANUALEQUIPOSPESADOS.COM

647123EN (09/06/2016)

160 ATJ EURO 3

180 ATJ 2 EURO 3

REPAIR MANUAL

MANUALEQUIPOSPESADOS.COM

2 647123EN

DATE OF ISSUE |

OBSERVATION |

19 / 09 / 2012 |

1st PUBLICATION DATE |

19 / 03 / 2013 |

UPDATE (ADDITION OF THE 180 ATJ 2 EURO 3) |

02 / 05 / 2013 |

UPDATE (ref. CP-NI 547>647, addition ref MR DANA axle som30, modification of |

|

hydraulic diagram 70-02, addition of machine selection 80-04, modification speed |

|

settings 80-04) |

19 / 11 / 2013 |

UPDATE (10-04 ENGINE VALUES, 20-04 HYDRAULIC VALUES, 20-06 HYDROSTATIC |

|

ENGINE REMOVAL, 70-02 HYDRAULIC DIAGRAM, 70-04 HYDRAULIC VALUES, 80- |

|

01 LOCATION AND BUNDLES, 80-02 ELECTRIC DIAGRAM, 80-04 NEW UPC |

23 / 12 / 2015 |

UPDATE : Update electric localisation et electric diagrams |

31 / 05 / 2016 |

UPDATE : separation of V2 and V3 electrical diagrams |

09 / 06 / 2016 |

UPDATE : ELECTRICAL CONTROL AND ADJUSTMENT (ASSIST) |

MANITOU BF S.A Limited liability company with a Board of Directors. Head office: 430, Rue de l’Aubinière - 44150 Ancenis - FRANCE

Share capital: 39,548,949 euros 857 802 508 RCS Nantes

Tel: +33 (0)2 40 09 10 11 www.manitou.com

This manual is for information purposes only. Any reproduction, copy, representation, recording, transfer, distribution, or other, in part or in whole, in any format is prohibited. The plans, designs, views, commentaries and instructions, even the document organization that are found in this document, are the intellectual property of MANITOU BF. Any violation of the aforementioned may lead to civil and criminal prosecution. The logos as well as the visual identity of the company are the property of MANITOU BF and may not be used without express and formal authorization. All rights are reserved.

MANUALEQUIPOSPESADOS.COM

647123EN 3

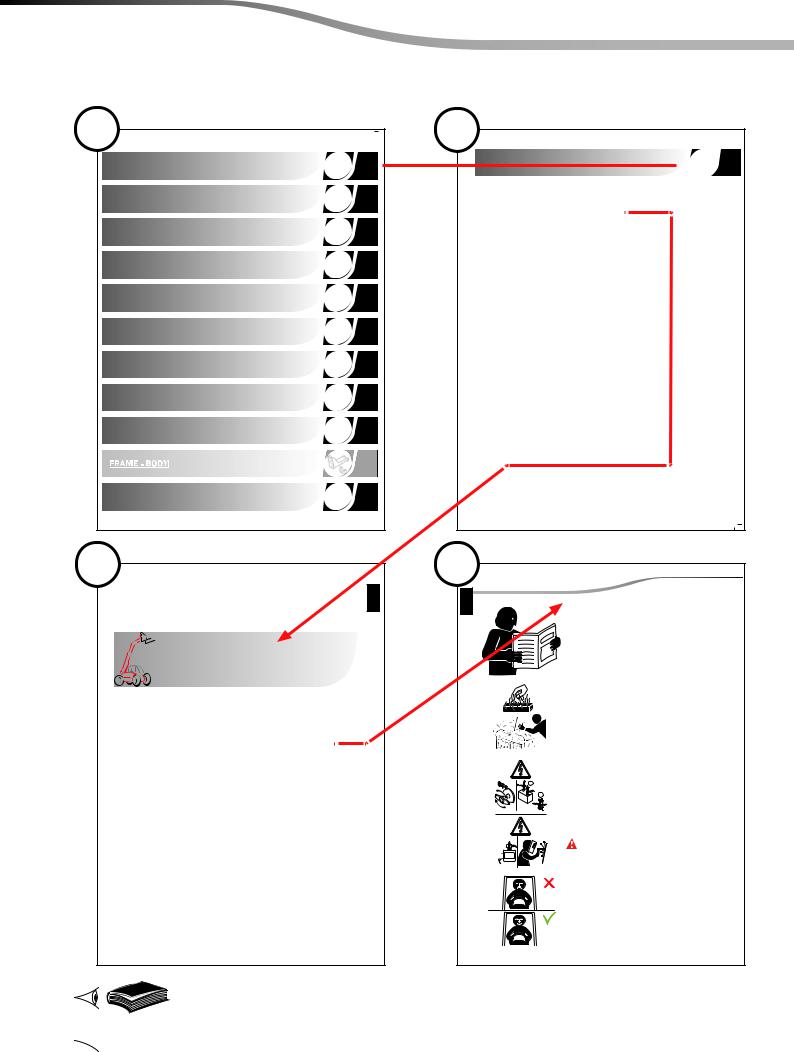

HOW TO USE THIS REPAIR MANUAL ?

1 |

|

GENERAL, CHARACTERISTICS AND SAFETY |

00 |

|

|

ENGINE |

10 |

|

|

TRANSMISSION |

20 |

|

|

AXLE |

30 |

|

|

BRAKE |

40 |

BOOM |

50 |

HYDRAULIC |

70 |

ELECTRIC |

80 |

DRIVER’S CAB |

85 |

|

90 |

OPTIONS - ATTACHMENTS |

110 |

|

|

3 |

|

|

00 |

GENERAL INSTRUCTIONS AND SAFETY NOTICE

pages

PREAMBLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

MAINTENANCE POSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

RULES FOR MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2 |

GENERAL, CHARACTERISTICS AND SAFETY

- GENERAL INSTRUCTIONS AND SAFETY NOTICE

00

00

4 |

General instructions and safety |

|

|

|

notice |

00 |

RULES FOR MAINTENANCE |

|

Do not carry out any work on the machine unless you have followed |

|

a suitable training course and have the knowledge required for it. |

|

Make sure you have taken into consideration all the indicator plates |

|

on the machine and in the instruction manual. |

|

Be careful not to burn yourself when touching hot liquids or parts |

|

when operations have to be done before the machine has had |

|

time to cool down. |

1 |

Before carrying out any operation on an electrically powered |

|

component, activate the battery cut-off. |

||

|

||

2 |

If the telehandler does not have a battery isolation device, disconnect |

|

|

the battery connecters then re-assemble them. |

Before carrying out any welding operations, think about

disconnecting computers.

ECU

ECU

A machine operating in a contaminated environment should be specifically equipped. Moreover, local safety notices deal with maintenance and repair work on such machines.

00-M173EN |

(29/09/2011) |

(29/09/2011) |

00-M173EN |

M R

547982 : See the repair manual N° 547982.

70 - HYDRAULIC : See the group N° 70 called «Hydraulic».

70 - HYDRAULIC : See the group N° 70 called «Hydraulic».

MANUALEQUIPOSPESADOS.COM

MANUALEQUIPOSPESADOS.COM

GENERAL

ENGINE SPECIFICATION

TRANSMISSION

AXLE

BRAKE

JIB - ACCESS PLATFORM

HYDRAULICS

ELECTRICITY

DRIVER'S CAB

FRAME - BODY

OPTIONS - ATTACHMENTS

110 90 85 80 70 55 40 30 20 10 00

110 90 85 80 70 55 40 30 20 10 00

MANUALEQUIPOSPESADOS.COM

MANUALEQUIPOSPESADOS.COM

GENERAL

-GENERAL INSTRUCTIONS AND SAFETY NOTICE

-GENERAL CONTROL AND ADJUSTMENT

00

00

MANUALEQUIPOSPESADOS.COM

MANUALEQUIPOSPESADOS.COM

00

GENERAL INSTRUCTIONS AND SAFETY NOTICE

pages

GENERAL INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPARE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

TECHNICAL DOCUMENTATION . . . . . . . . . . . . . . . . . . . . . . . . . . 4

REPAIR PROCEDURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

HYDRAULICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

SERVICING AND REPAIR EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . 8

(02/05/2013) |

00-00-M193EN |

MANUALEQUIPOSPESADOS.COM

2 GENERAL INSTRUCTIONS AND SAFETY NOTICE

00

GENERAL INSTRUCTIONS

This chapter sets out the safety instructions to be followed when carrying out repairs on an access platform.

Maintenance or repairs other than those detailed in part: 3 - MAINTENANCE OF THE OPERATOR’S MANUAL for the platform, are to be carried out by qualified personnel (consult your dealer) and under optimum safety conditions to maintain the health of the operator and of others, as well as to avoid damage to the platform.

Insofar that the platform manufacturer does not directly control maintenance or repair operations, the operator and the manager in charge of the establishment shall be responsible for the safety of these processes.

bbBEWARE OF LEAKS - Diesel fuel or hydraulic fluid escaping under high pressure may pierce the skin and cause serious injury. In the event of injury due to a pressurised liquid jet, immediately consult a doctor.

FRONT and rear are indicated in the figures for ease of understanding.

For information:

PLATFORM TYPE |

FRONT |

REAR |

ARTICULATED |

Counterweight |

Basket |

SCISSOR |

Steering axle |

Steps |

VERTICAL MAST |

Counterweight |

Basket |

TRUCK-MOUNTED PLATFORM |

Driver's cab |

Basket |

TELESCOPIC |

Basket extension |

Steps |

|

|

|

As our policy is one of constant improvement of our products, our range of access platforms may undergo certain modifications, without obligation for us to advise our customers.

00-00-M193EN |

(02/05/2013) |

Loading...

Loading...