Page 1

648641 EN (02/02/2012)

MHT 7140 T-E3

MHT 10180 LT-E3

MHT 10225 LT-E3

YOUR DEALER

OPERATOR’S MANUAL

THIS OPERATOR’S MANUAL MUST BE KEPT IN THE LIFT TRUCK AND MUST BE READ AND UNDERSTOOD BY OPERATORS.

COSTRUZIONI INDUSTRIALI

Via Cristoforo Colombo, 2

Loc. CAVAZZONA

41013 Castelfranco Emilia (MO)

( Tel.059/959811 - Fax 059/959850)

Page 2

Page 3

THE TEXTS AND ILLUSTRATIONS IN THIS DOCUMENT MUST NOT BE REPRODUCED EITHER WHOLLY OR IN PART.

1 - OPERATING AND SAFETY INSTRUCTIONS

2 - DESCRIPTION

3 - MAINTENANCE

4 - ELECTRIC AND HYDRAULIC SYSTEMS

5 - ADAPTABLE ATTACHMENTS IN OPTION ON THE RANGE

6 - SPECIFIC AUSTRALIA

Operator manual supplement:

01/12/2011

02/02/2012

1ST DATE OF ISSUE

UPDATE( chapters-6 for load charts Specific Australia)

Page 4

MHT 7140 T-E3

Page 5

MHT 10180 LT-E3

Page 6

MHT 10225 LT-E3

Page 7

1-1

1 - OPERATING

AND SAFETY

INSTRUCTIONS

Page 8

1-2

Page 9

1-3

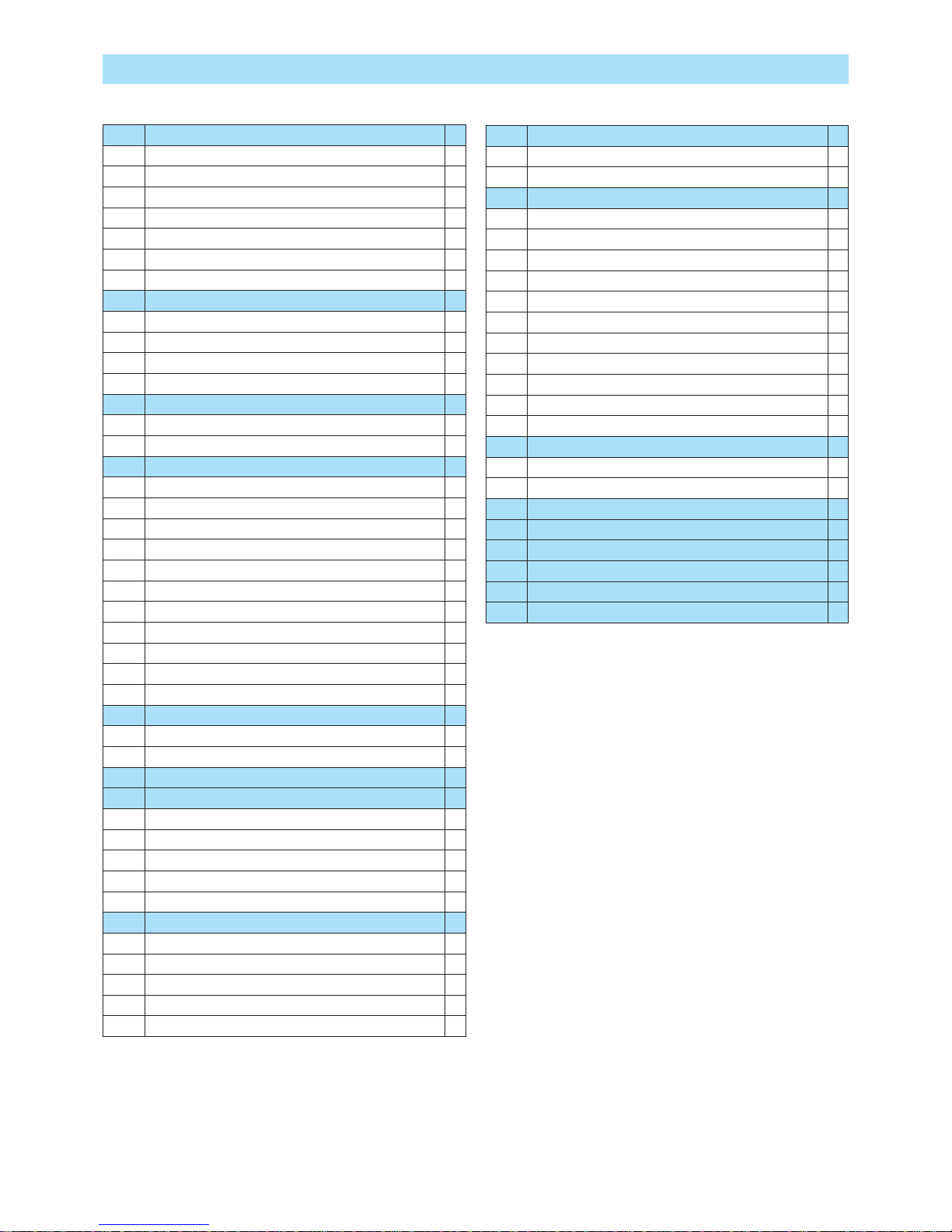

TABLE OF CONTENTS

INSTRUCTIONS TO THE COMPANY MANAGER

THE SITE

THE OPERATOR

THE LIFT TRUCK

A - THE LIFT TRUCK’S SUITABILITY FOR THE JOB

B - ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS

C - MODIFICATION OF THE LIFT TRUCK

D - FRENCH ROAD TRAFFIC RULES

(or see current legislation in other countries)

THE INSTRUCTIONS

THE MAINTENANCE

INSTRUCTIONS FOR THE OPERATOR

PREAMBULE

GENERAL INSTRUCTIONS

A - OPERATOR’S MANUAL

B - AUTHORIZATION FOR USE IN FRANCE

(or see current legislation in other countries)

C - MAINTENANCE

D - MODIFICATION OF THE LIFT TRUCK

E - LIFTING PEOPLE

OPERATING INSTRUCTIONS UNLADEN AND LADEN

A - BEFORE STARTING THE LIFT TRUCK

B - DRIVER’S OPERATING INSTRUCTIONS

C - ENVIRONMENT

D - VISIBILITY

E - STARTING THE LIFT TRUCK

F - DRIVING THE LIFT TRUCK

G - STOPPING THE LIFT TRUCK

H - DRIVING THE LIFT TRUCK ON THE PUBLIC HIGHWAY

(or see current legislation in other countries)

INSTRUCTIONS FOR HANDLING A LOAD

A - CHOICE OF ATTACHMENTS

B - MASS OF LOAD AND CENTRE OF GRAVITY

C - LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE

D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK

E - TAKING UP A LOAD ON THE GROUND

F - TAKING UP AND LAYING A HIGH LOAD ON TYRES

G - TAKING UP AND LAYING DOWN A SUSPENDED LOAD

H - TRAVELLING WITH A SUSPENDED LOAD

PLATFORM OPERATING INSTRUCTIONS

A - AUTHORISATION FOR USE

B - SUITABILITY OF THE PLATFORM FOR THE JOB

C - PRECAUTIONS WHEN USING THE PLATFORM

D - USING THE PLATFORM

E - ENVIRONMENT

F - MAINTENANCE

INSTRUCTIONS FOR USING THE RADIO-CONTROL

MAINTENANCE INSTRUCTIONS OF THE LIFT TRUCK

GENERAL INSTRUCTIONS

MAINTENANCE

LUBRICANT AND FUEL LEVELS

HYDRAULIC

ELECTRICITY

WELDING

WASHING THE LIFT TRUCK

IF THE LIFT TRUCK IS NOT TO BE USED FOR A LONG TIME

INTRODUCTION

PREPARING THE LIFT TRUCK

PROTECTING THE I.C. ENGINE

PROTECTING THE LIFT TRUCK

BRINGING THE LIFT TRUCK BACK INTO SERVICE

1 - 4

1 - 4

1 - 4

1 - 4

1 - 4

1 - 4

1 - 5

1 - 5

1 - 5

1 - 5

1 - 6

1 - 6

1 - 6

1 - 6

1 - 6

1 - 6

1 - 6

1 - 7

1 - 8

1 - 8

1 - 8

1 - 9

1 - 9

1 - 10

1 - 10

1 - 11

1 - 12

1 - 14

1 - 14

1 - 14

1 - 14

1 - 15

1 - 15

1 - 16

1 - 18

1 - 18

1 - 19

1 - 19

1 - 19

1 - 19

1 - 19

1 - 20

1 - 20

1 - 21

1 - 22

1 - 22

1 - 22

1 - 22

1 - 22

1 - 22

1 - 23

1 - 23

1 - 24

1 - 24

1 - 24

1 - 24

1 - 24

1 - 25

Page 10

1-4

INSTRUCTIONS TO THE COMPANY MANAGER

THE SITE

- Proper management of lift truck’s area of travel will reduce the risk of accidents:

. ground not unnecessarily uneven or obstructed,

. no excessive slopes,

. pedestrian traffic controlled, etc.

THE OPERATOR

- Only qualified, authorized personnel can use the lift truck. This authorization is given in writing by the appropriate person in the

establishment with respect to the use of lift trucks and must be carried permanently by the operator.

On the basis of experience, there are a number of possible situations in which operating the lift truck is contra-indicated. Such foreseeable abnormal uses,

the main ones being listed below, are strictly forbidden.

- The foreseeable abnormal behaviour resulting from ordinary neglect, but does not result from any wish to put the machinery to any improper use.

- The reflex reactions of a person in the event of a malfunction, incident, fault, etc. during operation of the lift truck.

- Behaviour resulting from application of the «principle of least action» when performing a task.

- For certain machines, the foreseeable behaviour of such persons as: apprentices, teenagers, handicapped persons, trainees tempted to drive a lift

truck, operator tempted to operate a truck to win a bet, in competition or for their own personal experience.

The person in charge of the equipment must take these criteria into account when assessing whether or not a person will makea suitable driver.

THE LIFT TRUCK

A - THE TRUCK’S SUITABILITY FOR THE JOB

- MANITOU has ensured that this lift truck is suitable for use under the standard operating conditions defined in this operator’s manual,

with a STATIC test coefficient OF 1.33 and a DYNAMIC test coefficient OF 1, as specified in harmonized norm EN 1459 for variable

range trucks.

- Before commissioning, the company manager must make sure that the lift truck is appropriate for the work to be done, and perform

certain tests (in accordance with current legislation).

B - ADAPTATION OF THE LIFT TRUCK TO STANDARD ENVIRONMENTAL CONDITIONS

- In addition to series equipment mount ed on your lift truck, many options are available, such as: road lighting, stop lights, flashing light,

reverse lights, reverse buzzer alarm, front light, rear light, light at the jib head, etc… (as model of lift truck).

- The operator must take into account the operating conditions to define the lift truck’s signalling and lighting equipment.

Contact your dealer.

- Take into account climatic and atmospheric conditions of the site of utilisation.

. Protection against frost (see: 3 - MAINTENANCE: LUBRICANTS AND FUEL).

. Adaptation of lubricants (ask your dealer for information).

. I.C. engine filtration (see: 3 - MAINTENANCE: FILTERS CARTRIDGES AND BELTS).

For operation under average climatic conditions, i.e.: between - 15 °C and + 35 °C, correct levels of lubricants in all the circuits are checked in production.

For operation under more severe climatic conditions, before starting up, it is necessary to drain all the circuits, then ensure correct levels of lubricants using

lubricants properly suited to the relevant ambient temperatures. It is the same for the cooling liquid.

- A lif t truck operating in an area without fire extinguishing equipment must be equipped with an individual extinguisher. There are

solutions, consult your dealer.

Your lift truck is designed for outdoor use under normal atmospheric conditions and indoor use in suitably aerated and ventilated premises. It is prohibited to

use the lift truck in areas where there is a risk of fire or which are potentially explosive (e.g. Refineries, fuel or gas depots, stores of inflammable products…).

For use in these areas, specific equipment is available (ask your dealer for information).

- Our trucks comply with Directiv e 2004/108/EC concerning electromagnetic compatibility (EMC), and with the corresponding har monized

norm EN 12895. Their proper operation is no longer guaranteed if they are used within areas in which the electromagnetic fields exceed

the limit specified by that norm (10 V/m).

- Directive 2002/44/EC requires company managers t o not e xpose their emplo y ees t o e xcessiv e vibration doses. There is no recog nized

code of measurement for comparing the machines of different manufacturers. The actual doses received can therefore be measured

only under actual operating conditions at the user's premises.

- The following are some tips for minimizing these vibration doses:

• Select the most suitable lift truck and attachment for the intended use.

• Adapt the seat adjustment to the operator's weight (according to lift truck model) and maintain it in good condition, as well

as the cab suspension. Inflate the tires in accordance with recommendations.

• Ensure that the operators adapt their operating speed to suit the conditions on site.

• As far as possible, arrange the site in such a way as to provide a flat running surface and remove obstacles and harmful

potholes.

Page 11

1-5

C - MODIFICATION OF THE LIFT TRUCK

- For your safety and that of others, you must not change the structure and settings of the various components used in your lift truck

(hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight, unapproved

attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

D - FRENCH ROAD TRAFFIC RULES

(or see current legislation in other countries)

- Only one certificate of conformity is issued. It must be kept in a safe place.

THE INSTRUCTIONS

- The operator’s manual must always be in good condition and kept in the place provided on the lift truck and in the language used by

the operator.

- The operator’s manual and any plates or stickers which are no longer legible or are damaged, must be replaced immediately.

THE MAINTENANCE

- Maintenance or repairs other than those detailed in part: 3 - MAINTENANCE must be carried out by qualified personnel (consult your

dealer) and under the necessary safety conditions to maintain the health of the operator and any third party.

Your lift truck must be inspected periodically to ensure that it remains in compliance. The frequency of this inspection is defined by current legislation in the

country in which the lift truck is used.

Page 12

1-6

INSTRUCTIONS FOR THE OPERATOR

PREAMBLE

WHENEVER YOU SEE THIS SYMBOL IT MEANS:

WARNING ! BE CAREFUL ! YOUR SAFETY OR THE SAFETY OF THE LIFT TRUCK IS AT RISK.

The risk of accident while using, servicing or repairing your lift truck can be restricted if you follow the safety instructions and safety measures detailed in

these instruction.

- Only the operations and manœuvres described in these operator’s manual must be performed. The manufacturer cannot predict

all possible risky situations. Consequently, the safety instructions given in the operator’s manual and on the lift truck itself are not

exhaustive.

- At any time, as an operator, you must envisage, within reason, the possible risk to yourself, to others or to the lift truck itself when you

use it.

Failure to respect the safety and operating instructions, or the instructions for repairing or servicing your lift truck may lead to serious, even fatal accident.

GENERAL INSTRUCTIONS

A - OPERATOR’S MANUAL

- Read the operator’s manual carefully.

- The operator’s manual must always be in good condition and in the place provided for it on the lift truck.

- You must report any plates and stickers which are no longer legible or which are damaged.

B - AUTHORISATION FOR USE IN FRANCE

(or see current legislation in other countries)

- Only qualified, authorized personnel can use the lift truck. This authorization is given in writing by the appropriate person in the

establishment with respect to the use of lift trucks and must be carried permanently by the operator.

- The operator is not competent to authorise the driving of the lift truck by another person.

C - MAINTENANCE

- The operator must immediately advise his superior if his lift truck is not in good working order or does not comply with the safety notice.

- The operator is prohibited from carrying out any repairs or adjustments himself, unless he has been trained for this purpose. He must keep

the lift truck properly cleaned if this is among his responsibilities.

- The operator must carry out daily maintenance (see: 3 - MAINTENANCE: A - DAILY OR EVERY 10 HOURS SERVICE).

- The operator must ensure tyres are adapted to the nature of the ground (see area of the contact surface of the tyres in the chapter:

2 - DESCRIPTION: FRONT AND REAR TYRES). There are optional solutions, consult your dealer.

. SAND tyres.

. LAND tyres.

. Snow chains.

Do not use the lift truck if the tyres are incorrectly inflated, damaged or excessively worn, because this could put your own safety or that of others at risk, or

cause damage to the lift truck itself. The fitting of foam inflated tyres is prohibited and is not guaranteed by the manufacturer, excepting prior authorisation.

D - MODIFICATION OF THE LIFT TRUCK

- For your safety and that of others, you must not change the structure and settings of the various components used in your lift truck

(hydraulic pressure, calibrating limiters, I.C. engine speed, addition of extra equipment, addition of counterweight, unapproved

attachments, alarm systems, etc.) yourself. In this event, the manufacturer cannot be held responsible.

Page 13

1-7

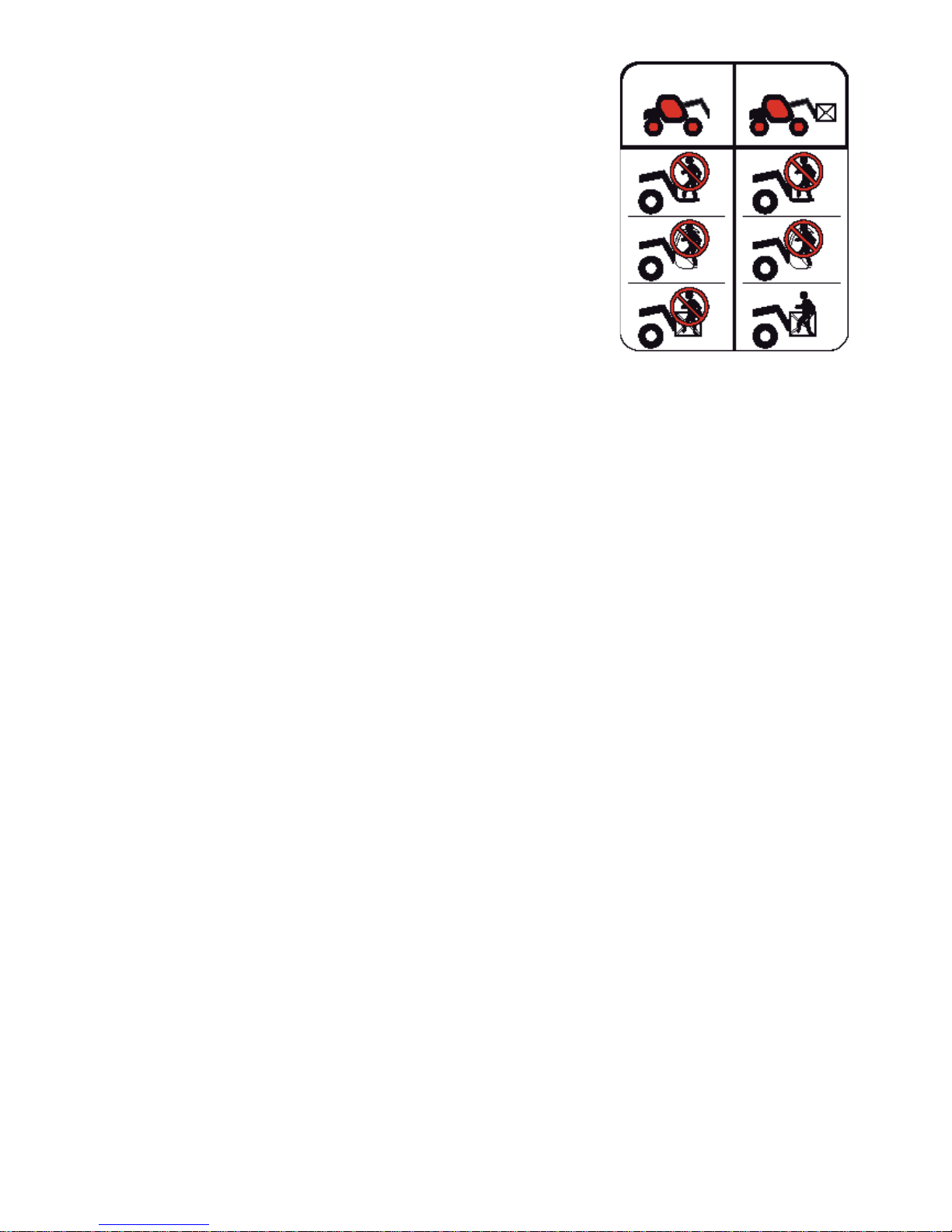

E - LIFTING PEOPLE

- The use of working equipment and load lifting attachments to lift people is:

• either forbidden

• or authorized e xceptionally and under certain conditions (see current regulations in

the country in which the lift truck is used).

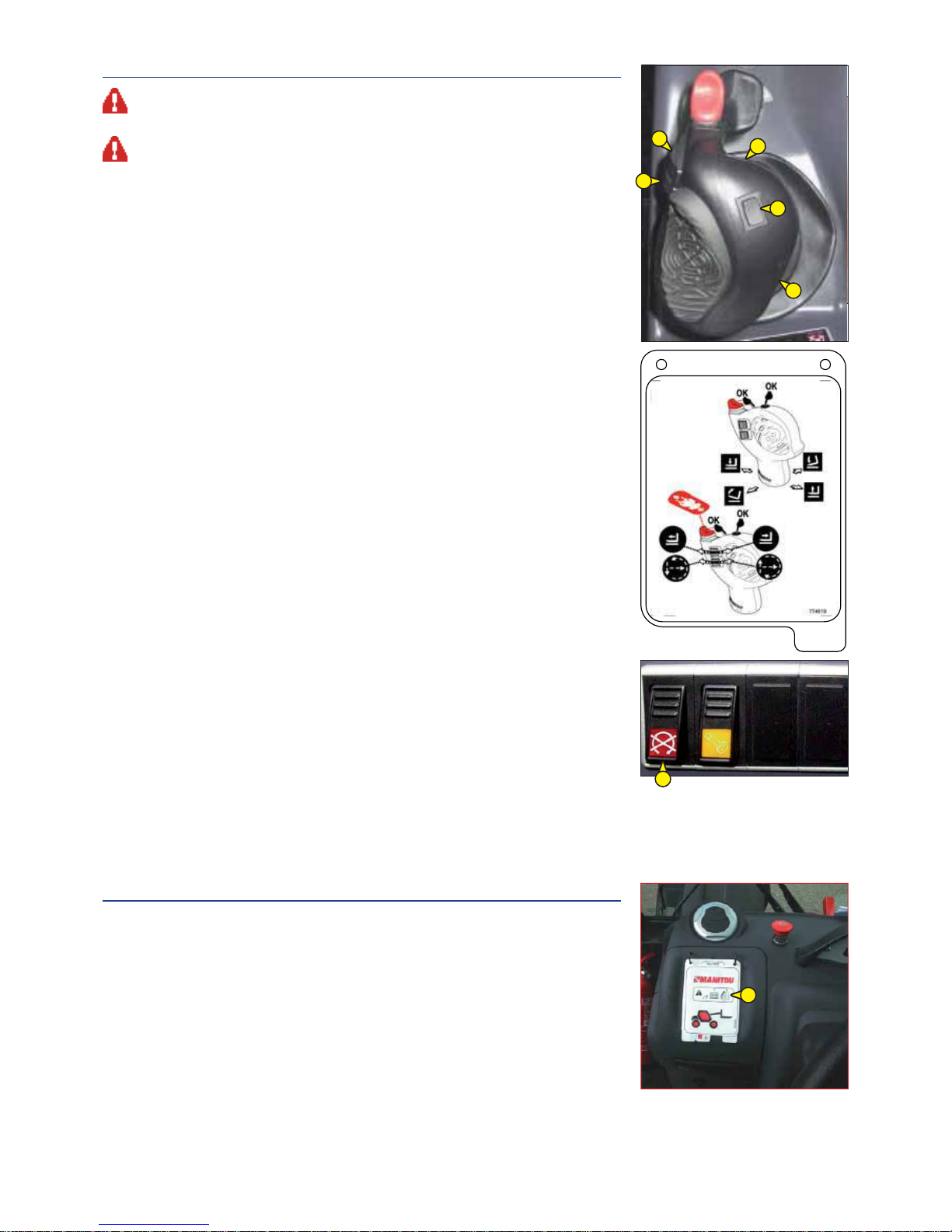

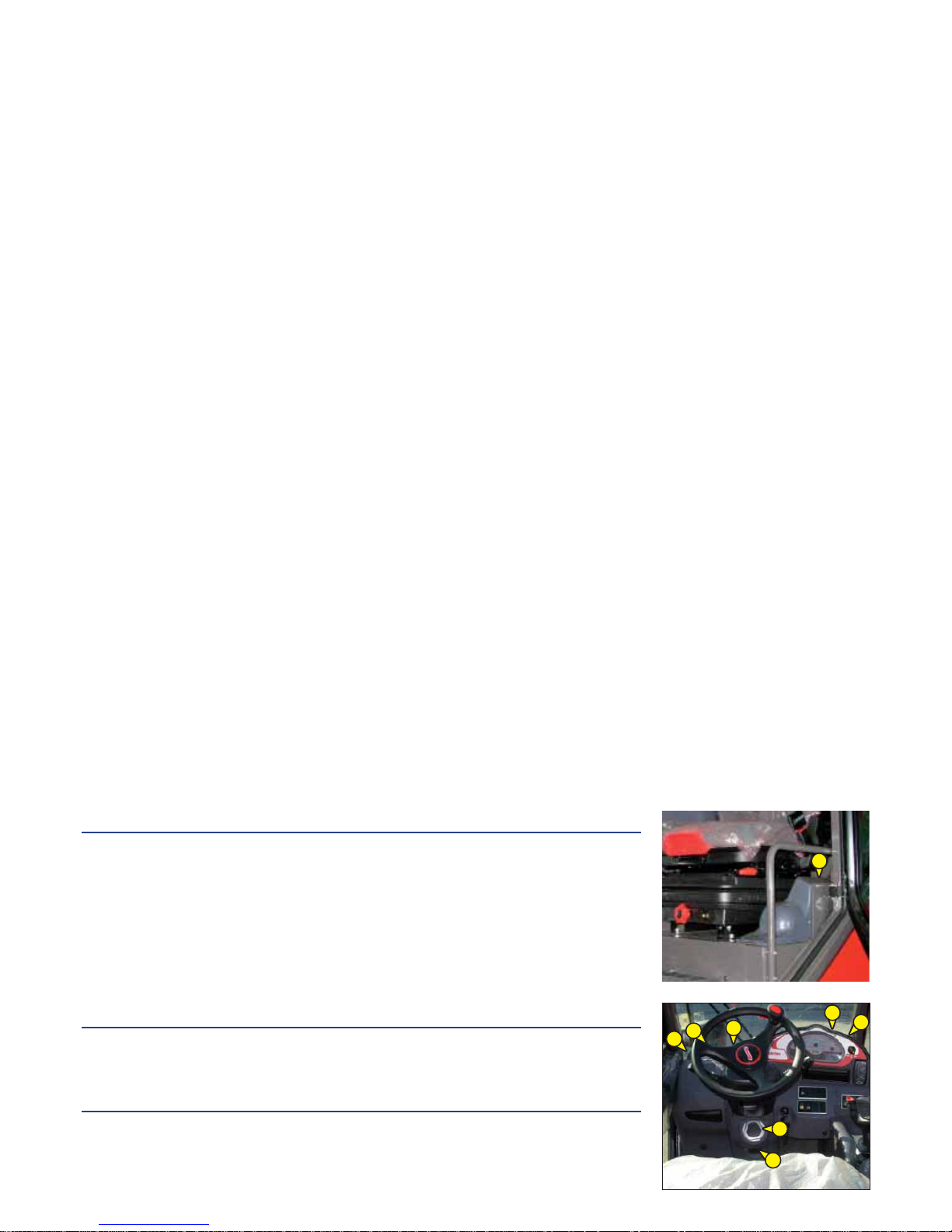

- The pictogram posted at the operator station reminds you that:

• Left-hand column

- It is forbidden to lift people, with any kind of attachment, using a non PLATFORM-

fitted lift truck.

• Right-hand column

- With a PLATFORM-fitted lift truck, people can only be lifted using platforms

designed by MANITOU for the purpose.

- MANITOU sells equipment specifically designed for lifting people (OPTION PLATFORM lift

truck, contact your dealer).

Page 14

1-8

OPERATING INSTRUCTIONS UNLADEN AND LADEN

A - BEFORE STARTING THE LIFT TRUCK

- Carry out daily maintenance (see: 3 - MAINTENANCE: A - DAILY OR EVERY 10 HOURS SERVICE).

- Make sure the lights, indicators and windscreen wipers are working properly.

- Make sure the rear view mirrors are in good condition, clean and properly adjusted.

- Make sure the horn works.

B - DRIVER’S OPERATING INSTRUCTIONS

- Whate ver his experience, the operator is advised t o familiarize himself with the position and operation of all the controls and instruments

before operating the lift truck.

- Wear clothes suited for driving the lift truck, avoid loose clothes.

- Make sure you have the appropriate protective equipment for the job to be done.

- Prolonged exposure to high noise lev els may cause hearing pr oblems. It is recommended to w ear ear muffs to prot ect against e xcessive

noise.

- Always face the lift truck when getting into and leaving the driving seat and use the handle(s) provided for this purpose. Do not jump

out of the seat to get down.

- Always pay attention when using the lift truck. Do not listen to the radio or music using headphones or earphones.

- Never operate the lift truck when hands or feet are wet or soiled with greasy substances.

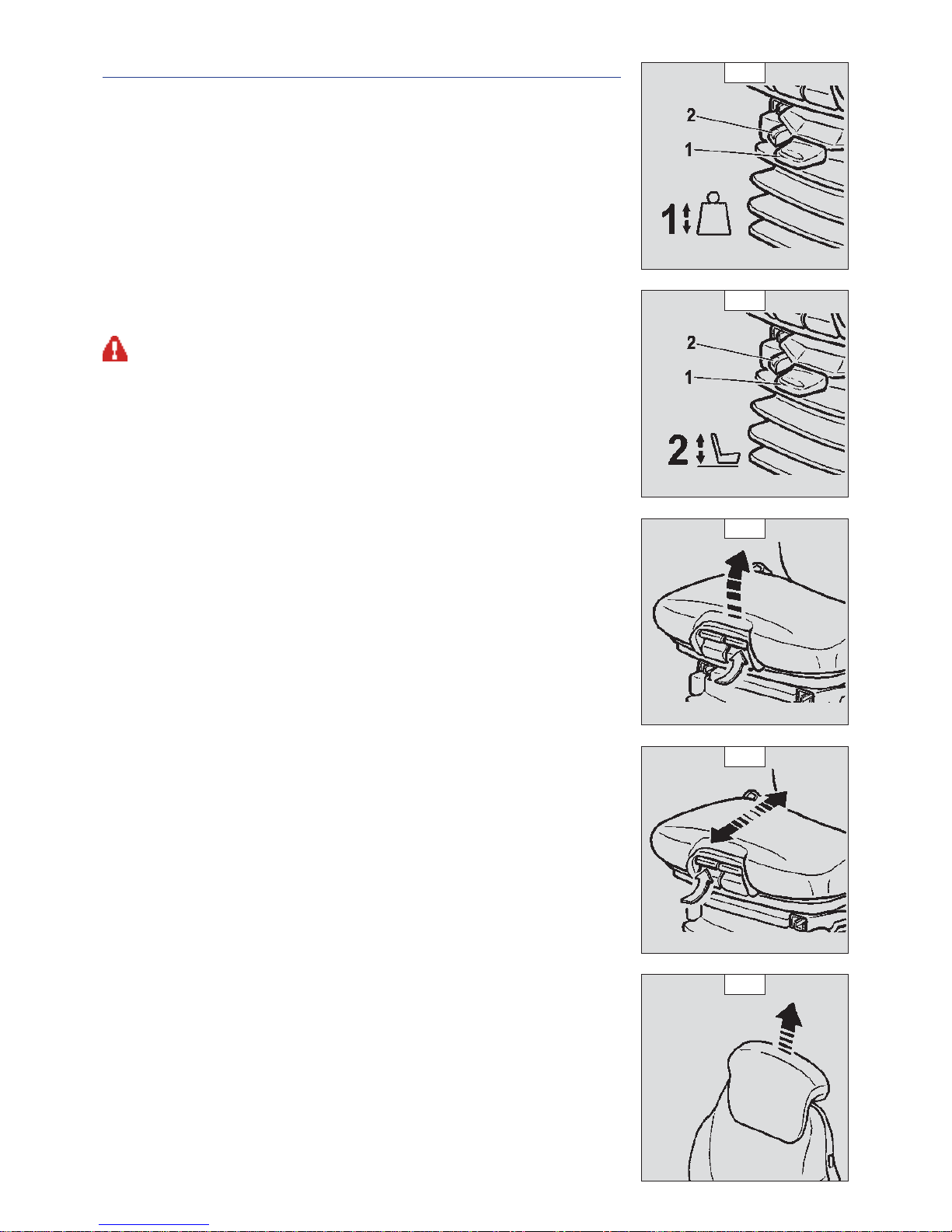

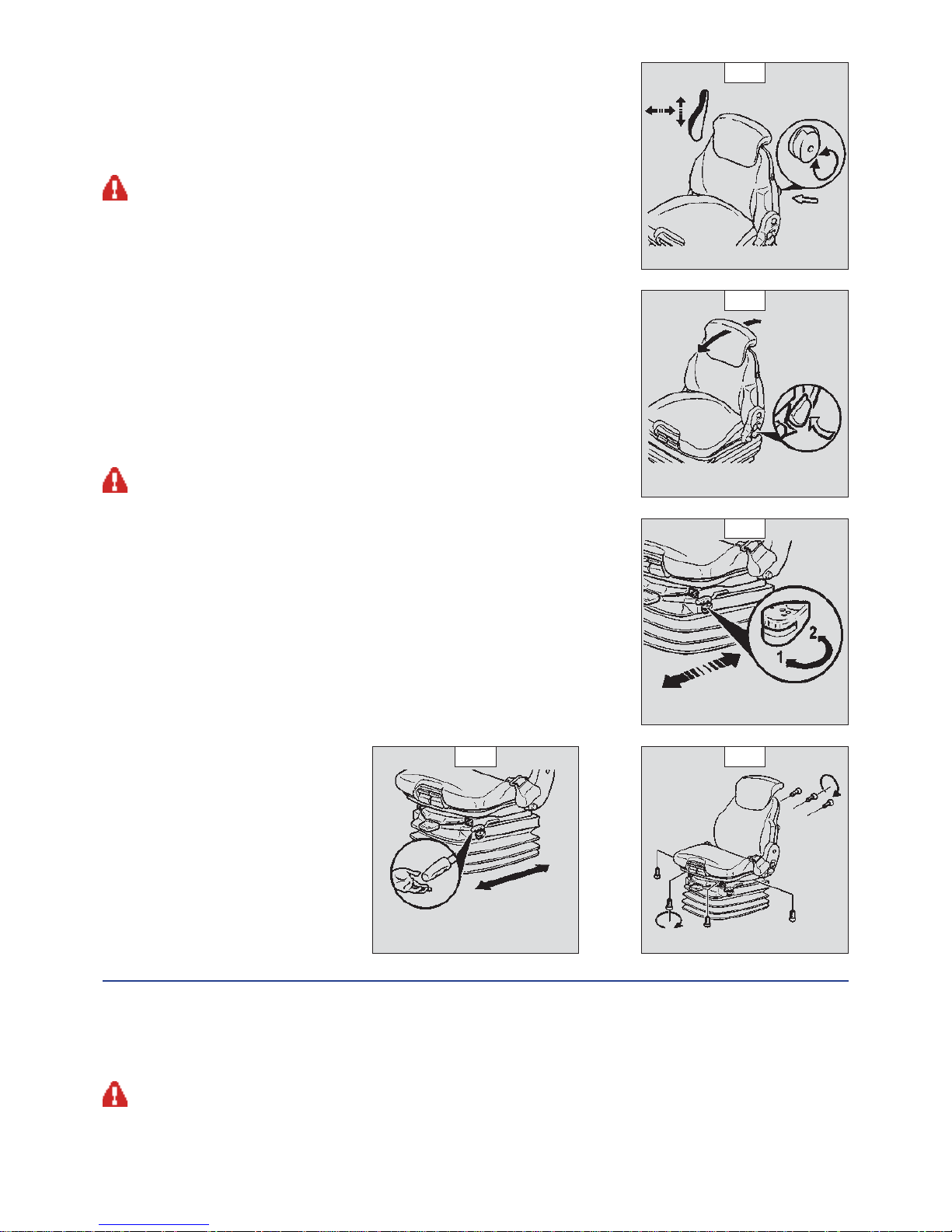

- For increased comfort, adjust the seat to your requirements and adopt the correct position in the driver’s cab.

Under no circumstances must the seat be adjusted while the lift truck is moving.

- The operator must always be in his normal position in the driver’s cab. It is prohibited to have arms or legs, or generally any part of the

body, protruding from the driver’s cab of the lift truck.

- The safety belt must be worn and adjusted to the operator’s size.

- The control units must never in any event be used for any other than their intended purposes (e.g. climbing onto or down from the lift

truck, portmanteau, etc.).

- If the control components are fitted with a forced operation (lever lock) device, it is forbidden t o lea ve the cab without f irst putting these

controls in neutral.

- It is prohibited to carry passengers either on the lift truck or in the cab.

Page 15

1-9

C - ENVIRONMENT

- Comply with site safety regulations.

- If you have to use the lift truck in a dark area or at night, make sure it is equipped with working lights.

- During handling operations, make sure that no one is in the way of the lift truck and its load.

- Do not allow anybody to come near the working area of the lift truck or pass beneath an elevated load.

- When using the lift truck on a transverse slope, before lifting the jib, follow the instructions given in the paragraph: INSTRUCTIONS FOR

HANDLING A LOAD: D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK.

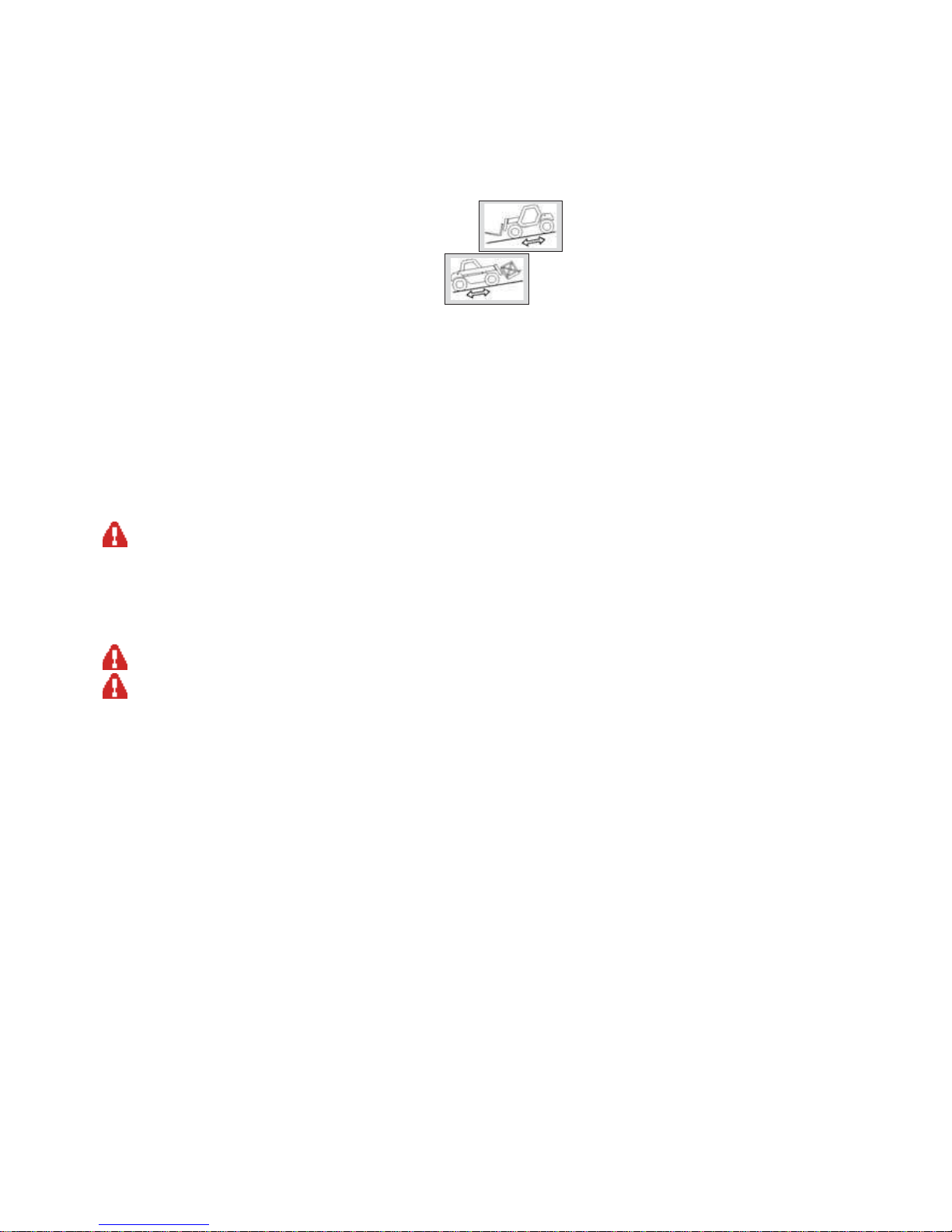

- Travelling on a longitudinal slope:

• Drive and brake gently.

• Moving without load: Forks or attachment facing downhill.

• Moving with load: Forks or attachment facing uphill.

- Take into account the lift truck’s dimensions and its load before trying to negotiate a narrow or low passageway.

- Never move onto a loading platform without having first checked:

• That it is suitably positioned and made fast.

• That the unit to which it is connected (wagon, lorry, etc.) will not shift.

• That this platform is prescribed for the total weight of the lift truck to be loaded.

• That this platform is prescribed for the size of the lift truck.

- Never move onto a foot bridge, floor or freight lift, without being certain that they are prescribed for the weight and size of the lift truck

to be loaded and without having checked that they are in sound working order.

- Be careful in the area of loading bays, trenches, scaffolding, soft land and manholes.

- Make sure the ground is stable and firm under the wheels and/or stabilizers before lifting or removing the load. If necessary, add

sufficient wedging under the stabilizers.

- Make sure that the scaffolding, loading platform, pilings or ground is capable of bearing the load.

- Never stack loads on uneven ground, they may tip over.

If the load or the attachment must remain above a structure for a long time, there is the risk that it will rest on the structure because of the jib descending

owing to the oil in the cylinders cooling down.

To eliminate this risk:

- Regularly check the distance between the load or the attachment and the structure and readjust this if necessary.

- If possible use the lift truck at an oil temperature as close as possible to ambient temperature.

- In the case of work near aerial lines, ensure that the safety distance is sufficient between the working area of the lift truck and the

aerial line.

You must consult your local electrical agency. You could be electrocuted or seriously injured if you operate or park the lift truck too close to power cables.

In the event of high winds, do not carr y out handling work that jeopardizes the stability of the lift truck and its load, particularly if the load catches the wind

badly.

D - VISIBILITY

- The safety of people within the lift truck’s working area, as well as that of the lift truck itself and the operator are depend on good

operator visibility of the lift truck’s immediate vicinity in all situations and at all times.

- This lift truck has been designed to allow good operator visibility (direct or indirect by means of rear-view mirrors) of the immediate

vicinity of the lift truck while traveling with no load and with the jib in the transport position.

- Special precautions must be taken if the size of the load restricts visibility towards the front:

- moving in reverse,

- site layout,

- assisted by a person directing the maneuver (while standing outside the truck’s area of travel), making sure to keep this person

clearly in view at all times.

- in any case, avoid reversing over long distances.

- Certain special accessories may require the truck to travel with the jib in the raised position. In such cases, visibility on the right hand

side is restricted, and special precautions must be taken:

- site layout,

- assisted by a person directing the maneuver (while standing outside the truck’s area of travel).

- If visibility of your road is inadequate, ask someone to assist by directing the maneuver (while standing outside the truck’s area of

travel), making sure to keep this person clearly in view at all times.

- Keep all components affecting visibility in a clean, properly adjusted state and in good working order (e.g. windscreens, windows,

windscreen wipers, windscreen washers, driving and work lights, rear-view mirrors).

Page 16

1-10

E - STARTING THE LIFT TRUCK

SAFETY INSTRUCTIONS

The lift truck must only be started up or maneuvered when the operator is sitting in the driver’s cab, with his seat belt adjusted and fastened.

- Never try to start the lif t truck by pushing or towing it. Such operation may cause severe damage to the transmission. If necessary, to

tow the lift truck in an emergency, the transmission must be placed in the neutral position (see: 3 - MAINTENANCE: G - OCCASIONAL

MAINTENANCE).

- If using an emergency battery for start-up, use a battery with the same characteristics and respect battery polarity when connecting it.

Connect at first the positive terminals before the negative terminals.

Failure to respect polarity between batteries can cause serious damage to the electrical circuit. The electrolyte in the battery may produce an explosive gas.

Avoid flames and generation of sparks close to the batteries. Never disconnect a battery while it is charging.

INSTRUCTIONS

- Check the closing and locking of the hood(s).

- Check that the cab door is closed.

- Check that the forward/reverse selector is in neutral.

- Turn the ignition key to the position I to activate the electrical system and the preheat.

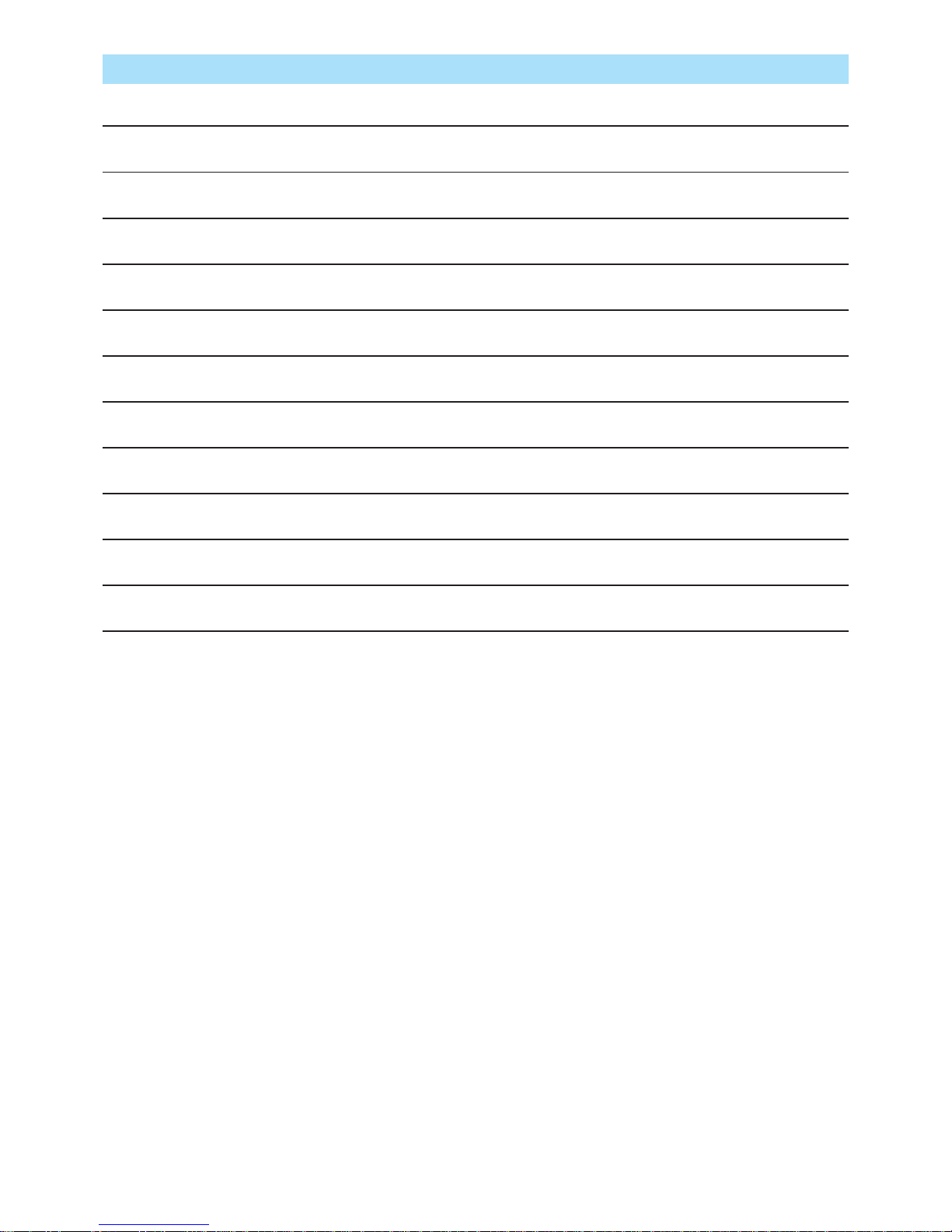

- Whenever you switch on the lift truck, perform the automatic check on the longitudinal stability limiter and warning device system (see:

2 - DESCRIPTION: INSTRUMENTS AND CONTROLS). Do not use the lift truck if it does not conform to the regulations.

- Check the fuel level on the indicator.

- Turn the ignition key fully: the I.C. engine should then start. Release the ignition key and let the I.C. engine run at idle.

- Do not engage the starter motor for more than 15 seconds and carry out the preheating between unsuccessful attempts.

- Make sure all the signal lights on the control instrument panel are off.

- Check all control instruments when the I.C. engine is warm and at regular intervals during use, so as to quickly detect any f aults and t o

be able to correct them without any delay.

- If an instrument does not show the correct display, stop the I.C. engine and immediately carry out the necessary operations.

F - DRIVING THE LIFT TRUCK

SAFETY INSTRUCTIONS

Operators’ attention is drawn to the risks involved in using the lift truck, in particular:

- Risk of losing control.

- Risk of losing lateral and frontal stability of the lift truck.

The operator must remain in control of the lift truck.

In the event of the lift truck overturning, do not try to leave the cabin during the incident. YOUR BEST PROTECTION IS TO STAY FASTENED IN THE CABIN.

- Observe the company’s traffic regulations or, by default, the public highway code.

- Do not carry out operations which exceed the capacities of your lift truck or attachments.

- Always drive the lift truck with the forks or attachment to the transport position, i.e. at 300 mm from the ground, the jib retracted and

the carriage sloping backwards.

- Only carry loads which are balanced and properly anchored to avoid any risk of a load falling off.

- Ensure that palettes, cases, etc, are in good order and suitable for the load to be lifted.

- Familiarise yourself with the lift truck on the terrain where it will be used.

- Ensure that the service brakes are working properly.

- The loaded lift truck must not travel at speeds in excess of 12 km/h.

- Drive smoothly at an appropriate speed for the operating conditions (land configuration, load on the lift truck).

- Do not use the hydraulic jib controls when the lift truck is moving.

- Never change the steering mode whilst driving.

- Do not manoeuvre the lif t truck with the jib in the raised position unless under exceptional circumstances and then with extreme

caution, at very low speed and using gentle braking. Ensure that visibility is adequate.

- Take bends slowly.

- In all circumstances make sure you are in control of your speed.

- On damp, slippery or uneven terrain, drive slowly.

- Brake gently, never abruptly.

- Only use the lift truck’s forward/reverse selector from a stationary position and never do so abruptly.

- Do not drive with your foot on the brake pedal.

- Always remember that hydrostatic type steering is extremely sensitive t o movement of the st eering wheel, so turn it gently and not jerkily .

- Never leave the I.C. engine on when the lift truck is unattended.

- Do not leave the cab when the lift truck has a raised load.

- Look where you are going and always make sure you have good visibility along the route.

Page 17

1-11

- Use the rear-view mirrors frequently.

- Drive round obstacles.

- Never drive on the edge of a ditch or steep slope.

- It is dangerous to use two lift trucks simultaneously to handle heavy or voluminous loads, since this operation requires particular

precautions to be taken. It must only be used exceptionally and after risk analysis.

- The ignition switch has an emergency stop mechanism in case of an operating anomaly occurring in the case of lift trucks not fitted with

a punch-operated cut-out.

INSTRUCTIONS

- Always drive the lift truck with the forks or attachment to the transport position, i.e. at 300 mm from the ground, the jib retracted and

the carriage sloping backwards.

- For lift trucks with gearboxes, use the recommended gear (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS).

- Select the steering mode appropriate for its use and/or working conditions (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS) (as

model of lift truck).

- Release the parking brake.

- Shift the forward/reverse selector to the selected direction of travel and accelerate gradually until the lift truck moves off.

G - STOPPING THE LIFT TRUCK

SAFETY INSTRUCTIONS

- Never leave the ignition key in the lift truck during the operator’s absence.

- When the lift truck is stationary, or if the operator has t o leave his cab (e ven f or a moment), place the forks or attachmen t on the ground,

apply the parking brake and place the forward/reverse selector in neutral.

- Make sure that the lift truck is not stopped in any position that will interfere with the traffic flow and at less than one meter from the

track of a railway.

- In the event of prolonged parking on a site, protect the lift truck from bad weather, particularly from frost (check the level of antifreeze),

close and lock all the lift truck accesses (doors, windows, cowls…).

INSTRUCTIONS

- Park the lift truck on flat ground or on an incline lower than 15 %.

- Set the forward/reverse selector to neutral.

- Apply the parking brake.

- For lift trucks with gearboxes, place the gear lever in neutral.

- Retract entirely the jib.

- Lower the forks or attachment to rest on the ground.

- When using an attachment with a grab or jaws, or a bucket with hydraulic opening, close the attachment fully.

- Before stopping the lift truck after a long working period, leave the I.C. engine idling for a few moments, to allow the coolant liquid and

oil to lower the temperature of the I.C. engine and transmission. Do not forget this precaution, in the event of frequent stops or warm

stalling of the I.C. engine, or else the temperature of certain parts will rise significantly due to the stopping of the cooling system, with

the risk of badly damaging such parts.

- Stop the I.C. engine with the ignition switch.

- Remove the ignition key.

- Lock all the accesses to the lift truck (doors, windows, cowls…).

Page 18

1-12

H - DRIVING THE LIFT TRUCK ON THE PUBLIC HIGHWAY

(or see current legislation in other countries)

SAFETY INSTRUCTIONS

- Operators driving on the public highway must comply with current highway code legislation.

- The lift truck must comply with current road legislation. If necessary, there are optional solutions. Contact your dealer.

INSTRUCTIONS

- Make sure the revolving light is in place, switch it on and verify its operation.

- Make sure the lights, indicators and windscreen wipers are working properly.

- Switch off the working headlights if the lift truck is fitted with them.

- Select the steering mode “HIGHWAY TRAFFIC” (as model of lift truck) (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS).

- Retract entirely the jib and put the attachment at 300 mm from the ground.

- Place the slope correctors in the central position, i.e. the transverse shaft of the axles parallel to the chassis (as model of lift truck).

- Lift up the stabilizers to the maximum and turn the blocks inwards (as model of lift truck).

Never move in neutral (forward/reverse selector or gear lever in neutral or transmission cut-off button pressed) to preserve the lift truck engine brake. Failure

to respect this instruction on a slope will lead to excessive speed which may make the lift truck uncontrollable (steering, brakes) and cause serious mechanical

damage.

Page 19

1-13

DRIVING THE LIFT TRUCK WITH A FRONT-MOUNTED ATTACHMENT

- You must comply with current regulations in your country, co vering the possibility of driving on the public highway with a front-mounted

attachment on your lift truck.

- If road legislation in your country authorizes circulation with a front-mounted attachment, you must at least:

• Protect and report any sharp and/or dangerous edges on the attachment (see: 4 - ADAPTABLE ATTACHMENTS IN OPTION ON

THE RANGE: ATTACHMENT SHIELDS).

• The attachment must not be loaded.

• Make sure that the attachment does not mask the lighting range of the forward lights.

• Make sure that current legislation in your country does not require other obligations.

OPERATING THE LIFT TRUCK WITH A TRAILER

- For using a trailer, observe the regulations in force in your country (maximum travel speed, braking, maximum weight of trailer, etc.).

- Do not forget to connect the trailer’s electrical equipment to that of the lift truck.

- The trailer’s braking system must comply with current legislation.

- If pulling a trailer with assisted braking, the tractor lift truck must be equipped with a trailer braking mechanism. In this case, do not

forget to connect the trailer braking equipment to the lift truck.

- The vertical force on the towing hook must not exceed the maximum authorised by the manufacturer (consult the manufacturer’s plat e

on your lift truck).

- The authorised gross vehicle weight must not exceed the maximum weight authorised by the manufacturer (see: 2 - DESCRIPTION:

CHARACTERISTICS).

IF NECESSARY, CONSULT YOUR DEALER.

Page 20

1-14

INSTRUCTIONS FOR HANDLING A LOAD

A - CHOICE OF ATTACHMENTS

- Only attachments approved by MANITOU can be used on its lift trucks.

- Make sure the attachment is appropriate for the work to be done (see: 4 - ADAPTABLE ATTACHMENTS IN OPTION ON THE RANGE).

- If the lift truck is equipped with the Single side-shif t carriage OPTION (TSDL), use only the authorised attachments (see: 4 - ADAPTABLE

ATTACHMENTS IN OPTION ON THE RANGE).

- Make sure the attachment is correctly installed and locked onto the lift truck carriage.

- Make sure that your lift truck attachments work properly.

- Comply with the load chart limits for the lift truck for the attachment used.

- Do not exceed the rated capacity of the attachment.

- Never lift a load in a sling without the attachment provided for the purpose, as the sling risks to slip (see: INSTR UCTIONS FOR HANDLING

A LOAD: H - TAKING UP AND LAYING DOWN A SUSPENDED LOAD).

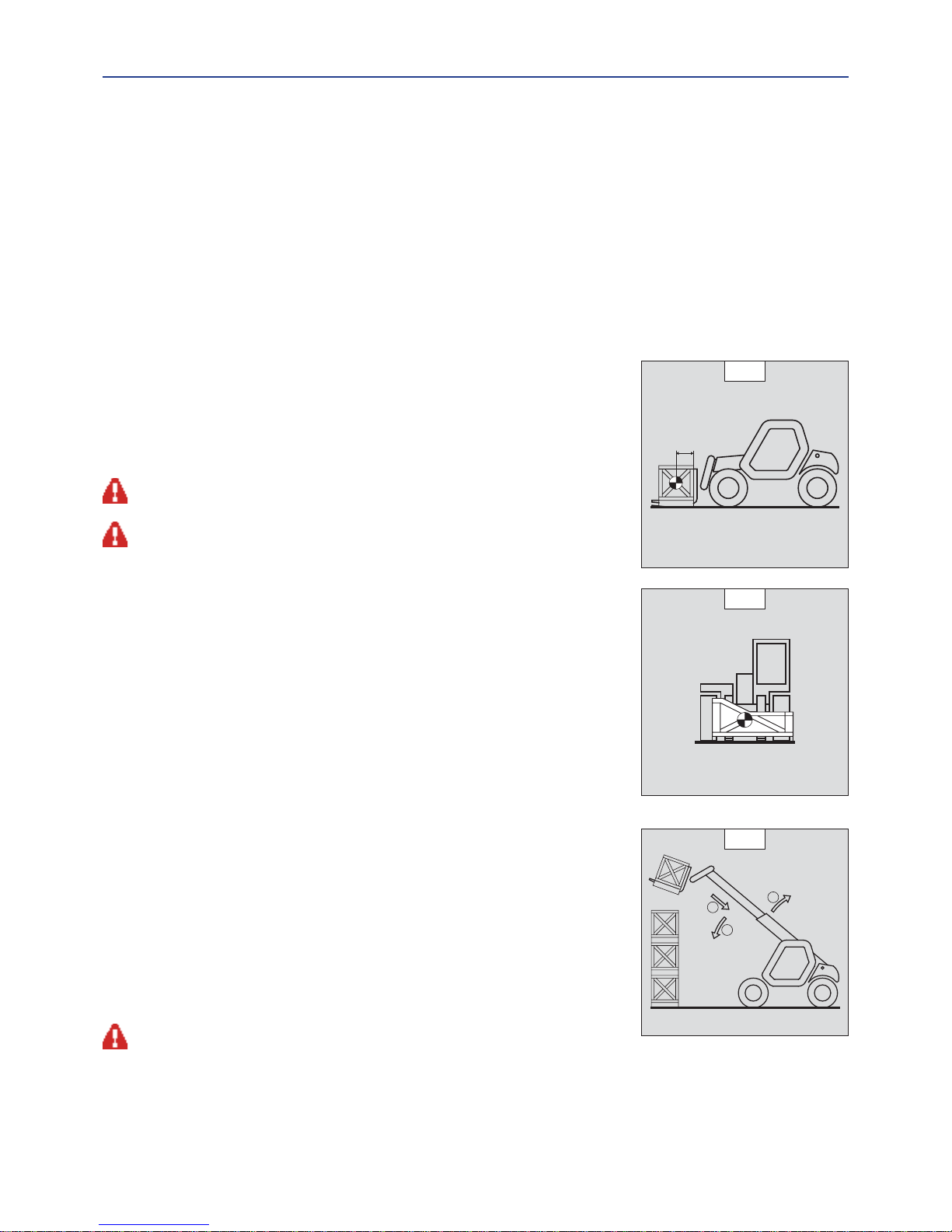

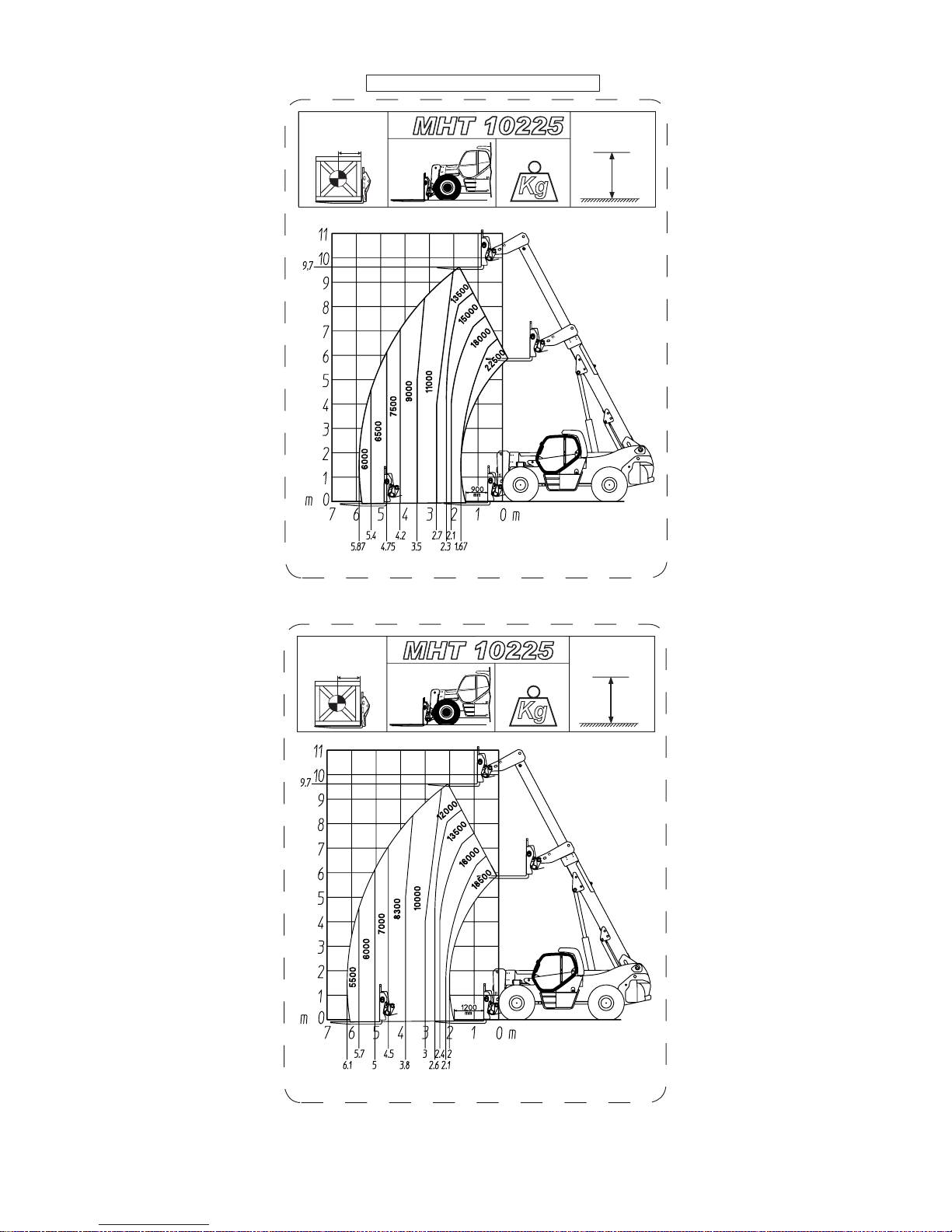

B - MASS OF LOAD AND CENTRE OF GRAVITY

- Before taking up a load, you must know its mass and its centre of gravity.

- The load chart for your lift truck is valid for a load in which the longitudinal position of the

centre of gravity is 500 mm from the base of the forks (fig. B1). For a higher centre of gravity,

contact your dealer.

- For irregular loads, determine the transverse centre of gravity before any movement (fig. B2)

and set it in the longitudinal axis of the lift truck.

It is forbidden to move a load heavier than the effective capacity defined on the lift truck load chart.

For loads with a moving centre of gravity (e.g. liquids), take account of the variations in the centre of gravity

in order to determine the load to be handled and be vigilant and take extra care to limit these variations as

far as possible.

C - LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE

This device gives an indication of the longitudinal stability of the lift truck, and limits hydraulic

movements in order to ensure this stability, at least under the following operating conditions:

• when the lift truck is at a standstill,

• when the lift truck is on firm, stable and consolidated ground,

• when the lift truck is performing handling and placing operations.

- Move the jib very carefully when approaching the authorized load limit (see: 2 - DESCRIPTION:

INSTRUMENTS AND CONTROLS).

- Always watch this device during handling operations.

- In the event that "AGGRA VA TING" hydraulic mov ements are cut-off, only perform de-aggravating

hydraulic movements in the follo wing order (fig. C): if necessary, raise the jib (1), retract the jib

as far as possible (2) and lower the jib (3) to set down the load.

The instrument reading may be erroneous when the steering is at its maximum limit or the rear axle

oscillated to its limit. Before lifting a load, make sure that the lift truck is not in either of these situations.

500 mm

B1

B2

1

2

3

C

Page 21

1-15

D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK

Depending on the model of lift truck

The transverse attitude is the transverse slope of the chassis with respect to the horizontal.

Raising the jib reduces the lift truck’s lateral stability. The transverse attitude must be set with

the jib in down position as follows:

1 - LIFT TRUCK WITHOUT SLOPE CORRECTOR USED ON TYRES

- Position the lift truck so that the bubble in the level is between the two lines (see: 2 -

DESCRIPTION: INSTRUMENTS AND CONTROLS).

2 - LIFT TRUCK WITH SLOPE CORRECTOR USED ON TYRES

- Correct the slope using the hydraulic control and verify the horizontality via the level. The

bubble in the level must be between the two lines (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS).

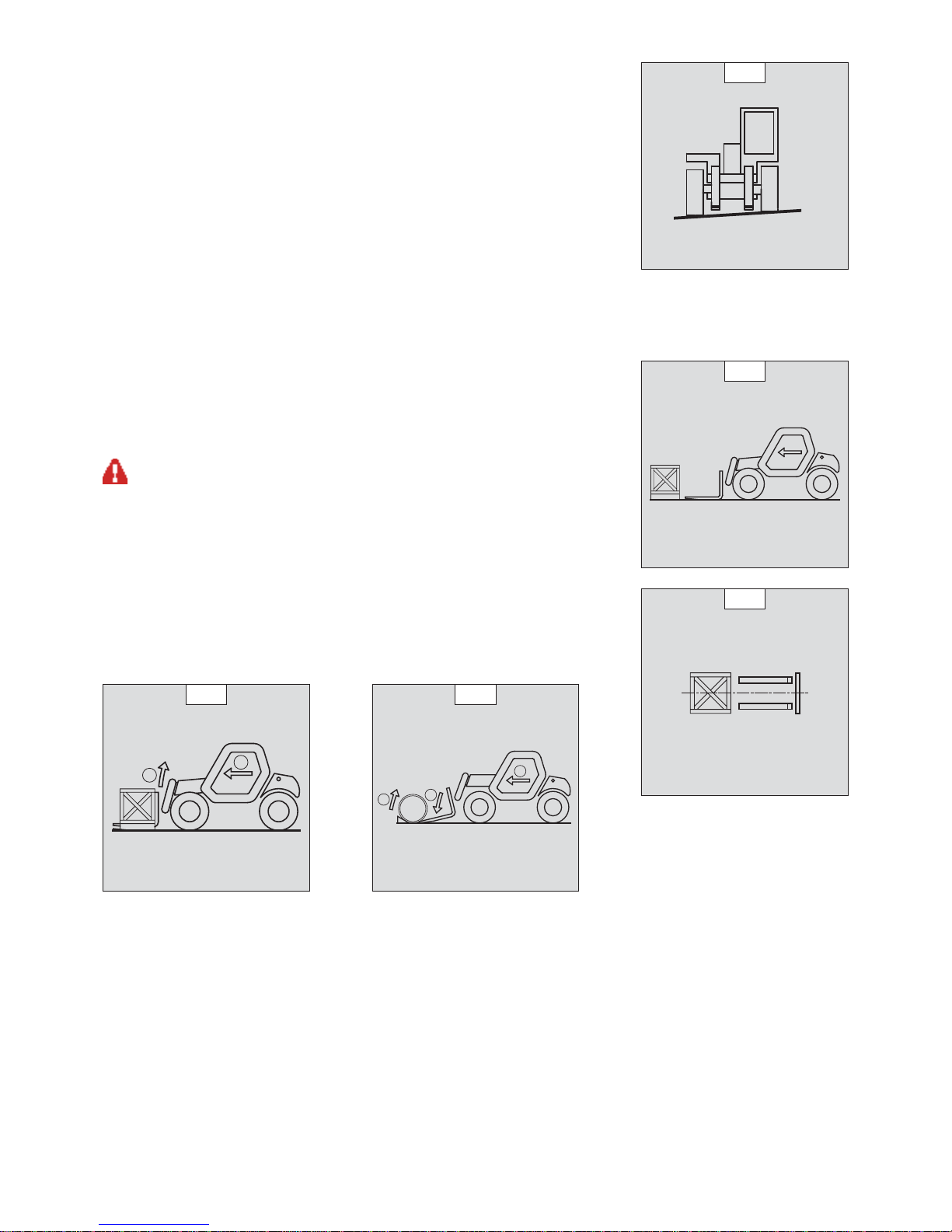

E - TAKING UP A LOAD ON THE GROUND

- Approach the lift truck perpendicular to the load, with the jib retracted and the forks in a

horizontal position (fig. E1).

- Adjust the fork spread and centering in connection with the load (fig. E2) (optional solutions

exist, consult your dealer).

- Never lift a load with a single fork.

Beware of the risks of trapping or squashing limbs when manually adjusting the forks.

- Move the lift truck forward slowly (1) and bring the forks to stop in front of the load (fig. E3), if

necessary, slightly lift the jib (2) while taking up the load.

- Bring the load into the transport position.

- Tilt the load far enough backwards to ensure stability (loss of load on braking or going downhill).

FOR A NON-PALLETIZED LOAD

- Tilt the carriage (1) forwards and move the lift truck slowly forwards (2), to insert the fork

under the load (fig. E4) (block the load if necessary).

- Continue to move the lift truck forwards (2) tilting the carriage (3) (fig. E4) backwards to

position the load on the forks and check the load’s longitudinal and lateral stability.

D1

E1

E2

1

2

E3

1

2

3

E4

Page 22

1-16

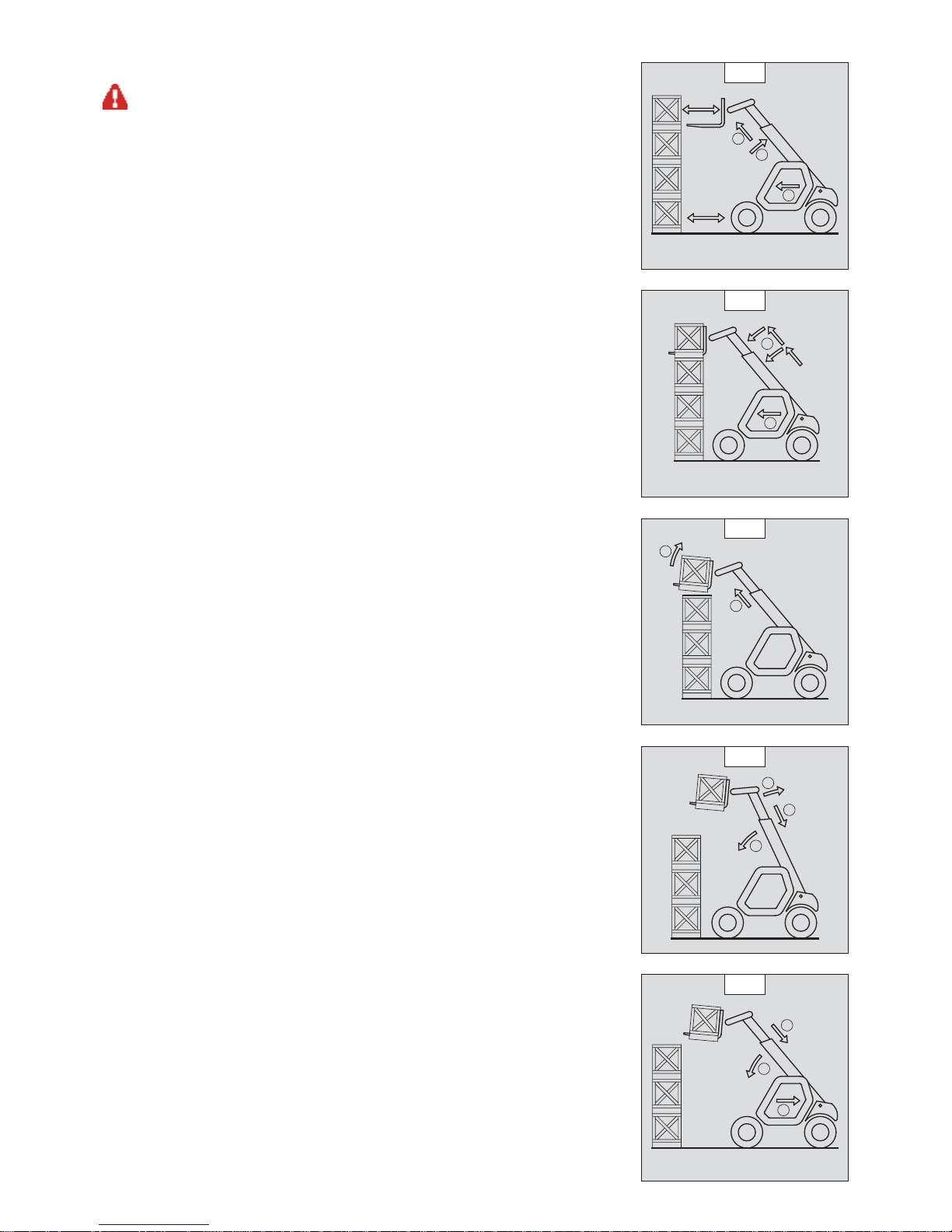

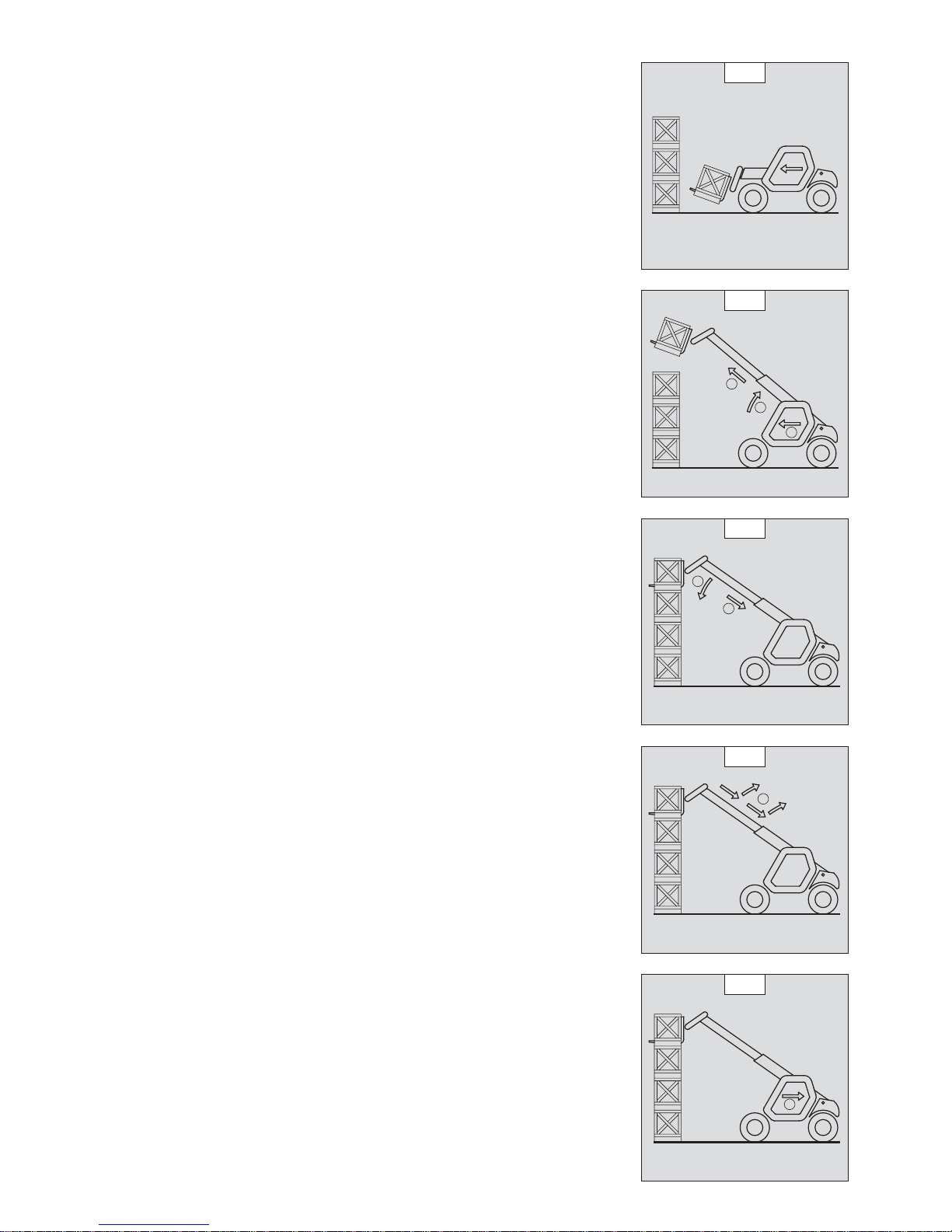

F - TAKING UP AND LAYING A HIGH LOAD ON TYRES

Y ou must not raise the jib if you have not checked the transverse attitude of the lift truck (see: INSTRUCTIONS

FOR HANDLING A LOAD: D - TRANSVERSE ATTITUDE OF THE LIFT TRUCK).

REMINDER: Make sure that the following operations can be performed with good visibility (see:

OPERATIONS INSTRUCTIONS UNLADEN AND LADEN: D - VISIBILITY).

TAKING UP A HIGH LOAD ON TYRES

- Ensure that the forks will easily pass under the load.

- Lift and extend the jib (1) (2) until the forks are level with the load, moving the lift truck (3)

forward if necessary (fig. F1), moving very slowly and carefully.

- Always think about keeping the distance necessary to fit the forks under the load, between the

pile and the lift truck (fig. F1) and use the shortest possible length of jib.

- Stop the forks in front of the load by alternately extending and retracting the jib (1) or, if

necessary, moving the lift truck forward (2) (fig. F2). Put the handbrake on and set the

forward/reverse selector to neutral.

- Slightly lift the load (1) and incline the carriage (2) backwards to stabilize the load (fig. F3).

- Tilt the load sufficiently backwards to ensure its stability.

- W atch the longitudinal stability limiter and warning device (see: INS TRUCTIONS FOR HANDLING

A LOAD: C - LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE). If it is overloaded,

replace the load in the place from which it was taken.

- If possible lower the load without shifting the lift truck. Lift the jib (1) to release the load,

retract (2) and lower the jib (3) to bring the load into the transport position (fig. F4).

- If this is not possible, back up the lift truck (1), manoeuvring very gently and carefully to release

the load. Retract (2) and lower the jib (3) to bring the load into the transport position (fig. F5).

1

2

3

F1

1

2

F2

1

2

F3

1

3

2

F4

1

2

3

F5

Page 23

1-17

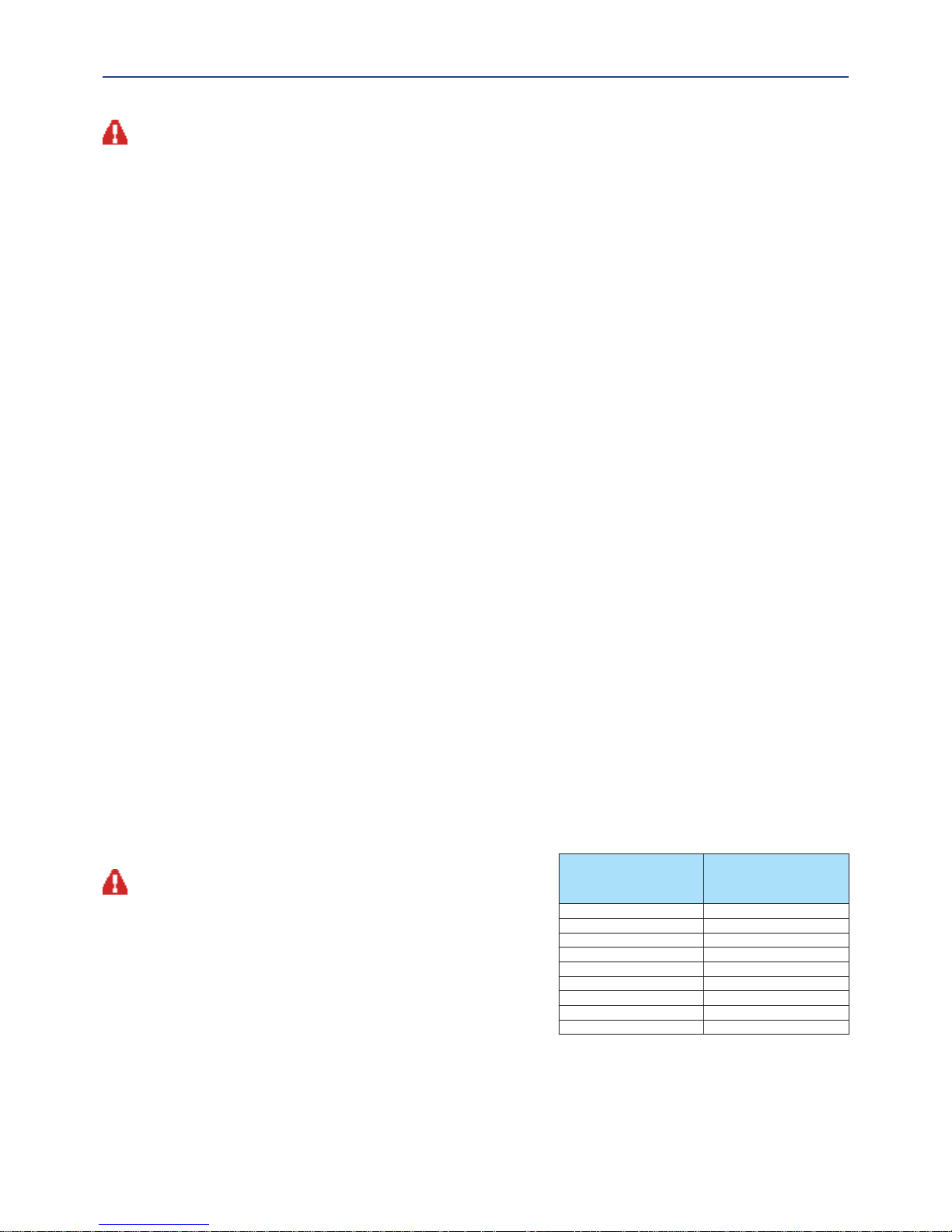

LAYING A HIGH LOAD ON TYRES

- Approach the load in the transport position in front of the pile (fig. F6).

- Put the handbrake on and set the forward/reverse selector to neutral.

- Lift and extend the jib (1) (2) until the load is above the pile, while keeping an eye on the

longitudinal stability limiter and warning device (see: INSTRUCTIONS FOR HANDLING A LOAD:

C - LONGITUDINAL STABILITY LIMITER AND WARNING DEVICE). If necessary, move the lift

truck (3) forward (fig. F7), driving very slowly and carefully.

- Place the load in a horizontal position and lay it down on the pile by lowering and retracting

the jib (1) (2) in order to position the load correctly (fig. F8).

- If possible, release the fork by alternately retracting and raising the jib (1) (fig. F9). Then set the

forks into transport position.

- If this is not possible, reverse the lift truck (1) very slowly and carefully to release the forks (fig.

F10). Then set them into transport position.

F6

1

2

3

F7

1

2

F8

1

F9

1

F10

Page 24

1-18

G - TAKING UP AND LAYING DOWN A SUSPENDED LOAD

WARNING: Failure to follow the above instructions may lead the lift truck to loose stability and overturn.

MUST be used with a lift truck equipped with an operational hydraulic movement cut-out device.

CONDITIONS OF USE

- The length of the sling or the chain shall be as short as possible to limit swinging of the load.

- Lift the load vertically along its axis, never by pulling sideways or lengthways.

HANDLING WITHOUT MOVING THE LIFT TRUCK

- Whether on stabilisers or on tyres, the lateral attitude must not exceed 1 % and the longitudinal attitude must not exceed 5%, the

bubble of the level must be held at “0”.

- Ensure that the wind speed is not higher than 10 m/s.

- Ensure that there is no one between the load and the lift truck.

H - TRAVELLING WITH A SUSPENDED LOAD

- Before moving, inspect the terrain in order to avoid excessive slopes and cross-falls, bumps and potholes, or soft ground.

- Ensure that the wind speed is not higher than 10 m/s.

- The lift truck must not travel at more than 0.4 m/s (1.5 km/h, i.e., one quarter walking speed).

- Drive and stop the lift truck gently and smoothly to minimise swinging of the load.

- Carry the load a few centimetres above the ground (max. 30 cm) the shortest possible jib length. Do not exceed the offset indicated on

the load chart. If the load begins to swing excessively, do not hesitate to stop and lower the jib to set down the load.

- Before moving the lift truck, check the longitudinal stability limiter and warning device (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS), only the green LEDs and possibly the yellow LEDs should be lit.

- During transpor t, the lif t truck operator must be assisted by a person on the ground (standing a minimum of 3 m from the load), who

will limit swinging of the load using a bar or a rope. Ensure that this person is always clearly in view.

- The lateral attitude must not exceed 5%, the bubble in the level must be kept between the two “MAX.” marks

- The longitudinal attitude must not exceed 15%, with the load facing uphill, and 10%, with the load facing downhill.

- The jib angle must not exceed 45°.

- If the first red LED of the longitudinal stability limiter and warning device (see: 2 - DESCRIPTION: INSTRUMENTS AND CONTROLS) comes

on while travelling, gently bring the lift truck to a stop and stabilise the load. Retract the telescope to reduce the offset of the load.

Page 25

1-19

PLATFORM OPERATING INSTRUCTIONS

For PLATFORM-fitted lift trucks

Installation of the platform on the lift truck is only possible if the shields “operating the platform” of the lift truck and the platform are identical (see: 2 -

DESCRIPTION: OPERATING THE PLATFORM).

A - AUTHORISATION FOR USE

- Operation of the platform requires further authorisation in addition to that of the lift truck.

B - SUITABILITY OF THE TRUCK FOR USE

- MANITOU has ensured that this lift truck is suitable for use under the standard operating conditions defined in this operator’s manual,

with a STA TIC test coefficient of 1.25 and a DYNAMIC test coefficient of 1.1, as specified in harmonised standard EN 280 for “mobile

elevating work platforms”.

- Before commissioning, the company manager must make sure that the platform is appropriate for the work to be done, and perform

certain tests (in accordance with current legislation).

C - PRECAUTIONS WHEN USING THE PLATFORM

- Wear clothes suited for operating the platform, avoid loose clothes.

- Never operate the platform when hands or feet are wet or soiled with greasy substances.

- Always pay attention when using the platform. Do not listen to the radio or music using headphones or earphones.

- For increased comfort, adopt the correct position at the platform’s operator station.

- The platform’s guard rail exempts the operator from wearing a safety harness under normal operating conditions. As a result, you are

responsible deciding whether to wear a safety harness.

- The controls must not be used for any other than their intended purpose (e.g. getting in and out of the lift truck, coat hanger etc.).

- Safety helmets must be worn.

- The operator must always be in the normal operator’s position. It is prohibited to have arms or legs, or generally any part of the body,

protruding from the basket.

- Ensure that any materials loaded onto the platform (pipes, cables, containers, etc.) cannot fall out. Do not pile these materials to the

point where it is necessary to step over them.

D - USING THE PLATFORM

- However experienced the y ma y be, operators must acquaint themselv es with the emplacement and operation of all contr ol instruments

prior to operating the platform.

- Check before operating that the platform has been correctly assembled and locked onto the lift truck.

- Check before operating the platform that the access gate has been properly locked.

- The platform should be operated in an area free of any obstructions or danger when it is lowered to the ground.

- The operator using the platform must be aided on the ground by a person with adequate training.

- You should stay within the limits set out in the platform load chart.

- The lateral stresses are limited pressure (see: 2 - DESCRIPTION: CHARACTERISTICS).

- It is strictly forbidden to hand a load from the platform or the lift truck jib without a specially designed attachment (see: INSTRUCTIONS FOR

HANDLING A LOAD: H - TAKING UP AND LAYING DOWN A SUSPENDED LOAD).

- The platform cannot be used as a crane or a lift for permanently transporting people or materials, nor as jacks or supports.

- The lift truck must not be moved with one (or more) person(s) in the platform.

- It is forbidden to transport people on the platform using the hydraulic controls in the lift truck’s driver’s cab (except in case of rescue).

- The operator must not get in or out of the platform when it is not on ground level (jib retracted and in the down position).

- The platform must not be fitted with attachments that increase the unit’s wind load.

- Do not use ladders or improvised structures in the platform to gain extra height.

- Do not climb onto the sides of the platform to gain extra height.

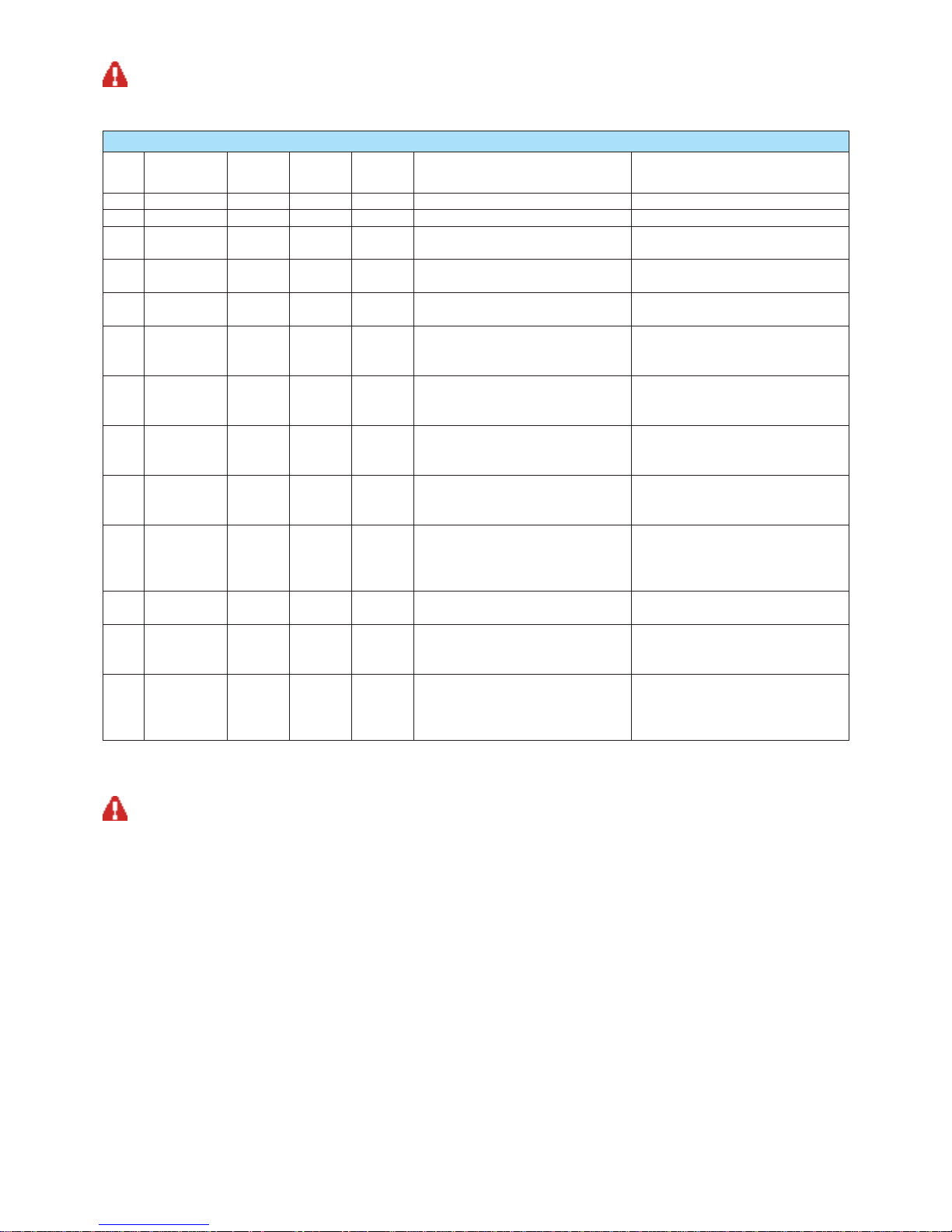

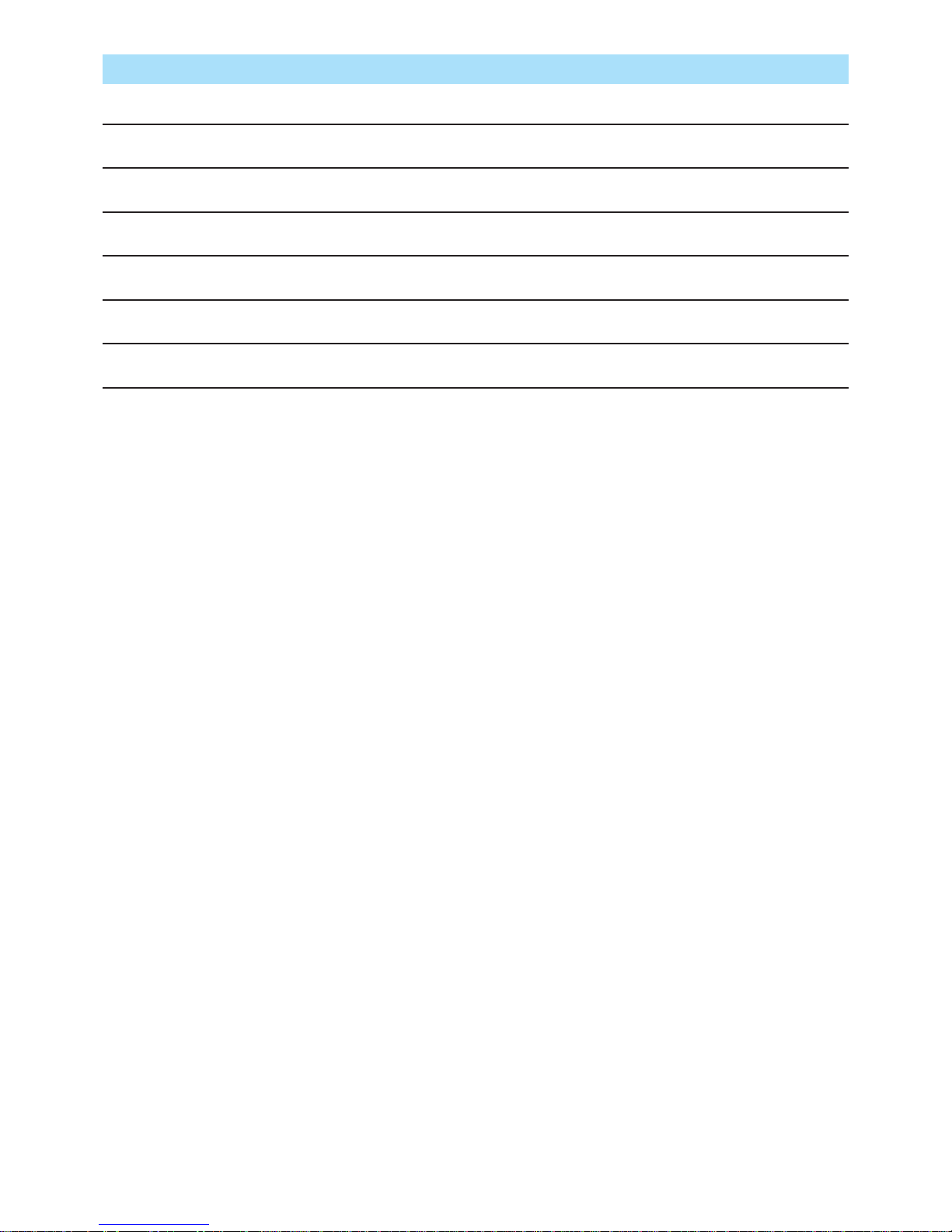

E - ENVIRONMENT

Operating the platform close to electricity cables is forbidden. Maintain the specified

safe distances.

NOMINAL VOLTAGE

DISTANCE ABOVE THE

GROUND OR THE FLOOR

IN METRES

50 < U < 1000 2,30 M

1000 < U < 30000 2,50 M

30000 < U < 45000 2,60 M

45000 < U < 63000 2,80 M

63000 < U < 90000 3,00 M

90000 < U < 150000 3,40 M

150000 < U < 225000 4,00 M

225000 < U < 400000 5,30 M

400000 < U < 750000 7,90 M

Page 26

1-20

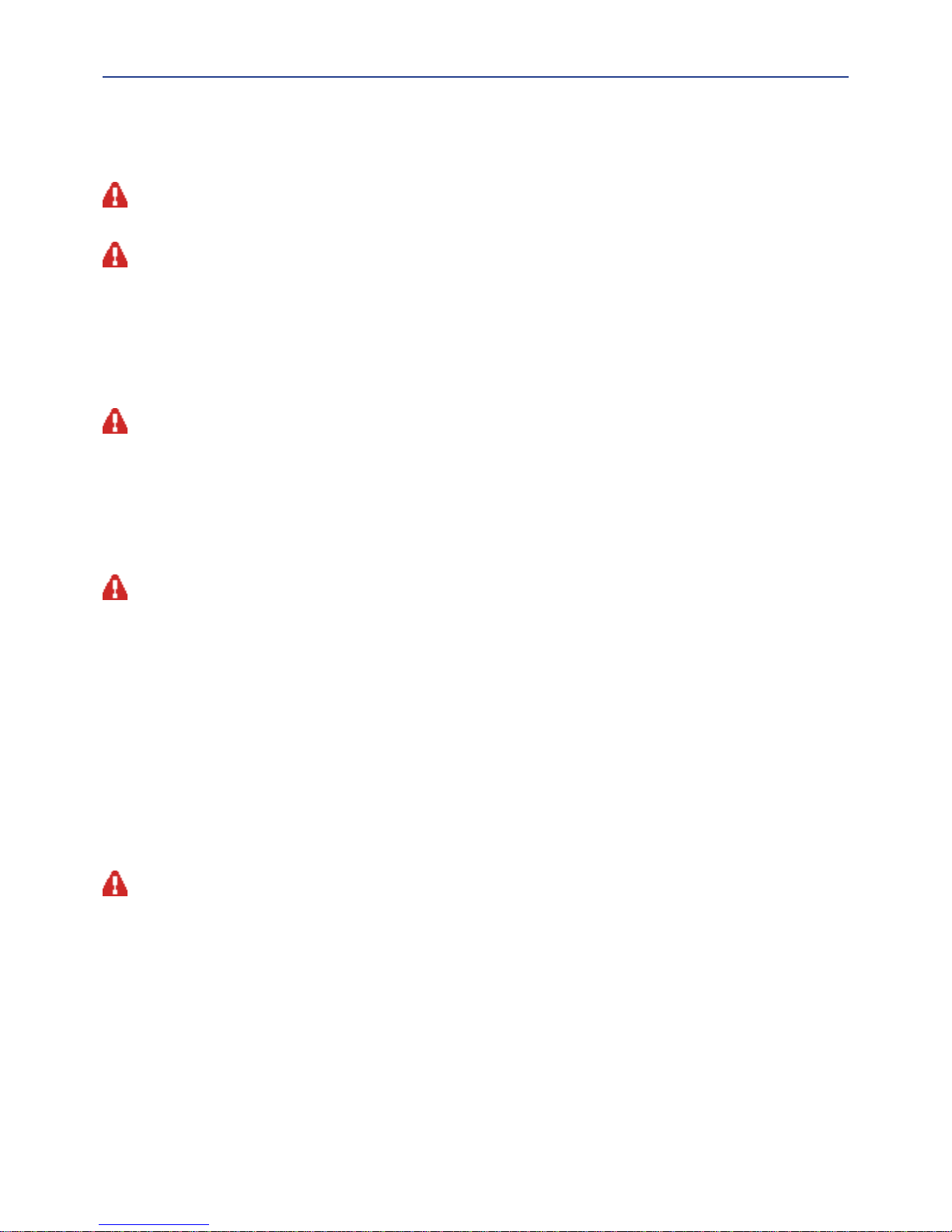

Operation of the platform is strictly forbidden in the event of wind speeds of over 45 km/h.

- The following scale is given for an empiric evaluation of the wind speed:

BEAUFORT scale (wind speed at a height of 10 m from flat ground)

Force Type of wind

Speed

(knots)

Speed

(kph)

Speed

(m/s)

Effects on Land Sea condition

0

Calm

0 - 1 0 - 1 < 0,3

Smoke rises vertically. Sea like a mirror.

1

Light air

1 - 3 1 - 5 0,3 - 1,5

The wind bends the smoke. Ripples but without foam crests.

2

Light breeze

4 - 6 6 - 11 1,6 - 3,3

The wind can be felt on the face,

shakes the leaves.

Small but evident wavelets.

3

Gentle

breeze

7 - 10 12 - 19 3,4 - 5,4

The wind continuously shakes the

leaves and twigs.

Large wavelets Perhaps scattered

white horses.

4

Moderate

breeze

11 - 16 20 - 28 5,5 - 7,9

The wind raises dust and scraps of

paper, shakes the twigs.

Small waves. Fairly frequent white

horses.

5

Fresh breeze

17 - 21 29 - 38 8 - 10,7

Leafy shrubs sway.

Small waves form on inland waters.

Moderate waves, many white horses.

6

Strong

breeze

22 - 27 39 - 49 10,8 - 13,8

Shakes thick branches, metal wires

hum, it becomes difficult to keep an

umbrella open.

Large waves begin to f orm, white f oam

crests, probably spray.

7

Near gale

28 - 33 50 - 61 13,9 - 17,1

Whole trees sway, it is difficult to walk

against the wind.

Sea heaps up and white foam blown

in streaks along the direction of the

wind.

8

Gale

34 - 40 62 - 74 17,2 - 20,7

Breaks the branches of trees, it is

almost impossible to walk against the

wind.

Moderately high waves, crests begin

to break into spindrift.

9

Strong gale

41 - 47 75 - 88 20,8 - 24,4

Causes slight damage to buildings

(stacks, tiles, etc..).

High waves. Dense foam along the

direction of the wind. Crests of waves

begin to roll over. Spray may affect

visibility.

10

Storm

48 - 55 89 - 102 24,5 - 28,4

Rare inland, uproots trees, causes

considerable damage to buildings.

Very high waves with long ov erhanging

crests. Visibility affected.

11

Violent storm

56 - 63 103 - 117 28,5 - 32,6

Very rare, causes extensive

devastation.

Exceptionally high waves that may

hide medium sized ships. Visibility

affected.

12

Hurricane

64 + 118 + 32,7 +

Causes very serious catastrophes.

The air is filled with foam and spray.

Sea completely white with driving

spray. Visibility very seriously affected.

F - MAINTENANCE

Your platform must be periodically inspected to ensure its continued compliance. The inspection frequency is defined by the current legislation in the country

in which the platform is used.

Page 27

1-21

INSTRUCTIONS FOR USING THE RADIO-CONTROL

For lift trucks with RC radio control

HOW TO USE THE RADIO-CONTROL

SAFETY INSTRUCTIONS

- This radio-contr ol consists of electronic and mechanical safety elements. It cannot receiv e commands from another transmitte r because

the internal encoding is unique to each radio-control.

If it is used improperly or incorrectly, there is a risk of danger to:

- The physical and mental health of the user or others.

- The lift truck and other neighbouring items.

Everyone working with this radio-control:

- Must be qualified in line with current regulations and therefore appropriately trained.

- Must follow this instruction manual as closely as possible.

- The system is used to control the lift truck remotely via radio waves. Commands are also transmitted if the lift truck is out of sight

(behind an obstacle or a building for example), this is why:

• After stopping the truck and removing the key button (only possible when it is stationary), always place the transmitter in a

safe, dry place.

• Before performing any installation, servicing or repair work, always switch off power sources (in particular, electric welding

devices and electric head units on hydraulic distributors must be disconnected at each section).

• Never remove or alter the safety devices (such as the hand-guard frame, key, emergency stop button, etc.).

Never drive the lift truck if it is not continuously and perfectly within view of the operator!

- Before leaving the transmitter, the operator must mak e sure that it cannot be used b y an unauthorized thir d person: either b y remo ving

the key button from the transmitter or locking it in an inaccessible place.

- The user must ensure that the instruction manual is accessible at all times and that operators have read and understood it.

INSTRUCTIONS

- Take up position in a stable place with no risk of slipping.

- Before using the transmitter, make sure there is nobody within the working area.

- Only use the transmitter with its carrying device or installed correctly on the platform.

When you remove the transmitter, remove the accumulator and key button so that it cannot be used accidentally or deliberately by anyone else.

PROTECTIVE DEVICES

- The lift truck will be immobilised within 450 milliseconds (approx. 0.5 second) at most:

• If the transmitter emergency stop button (50 milliseconds), or the one on the lift is pressed.

• If the transmission distance of the radio waves is exceeded.

• If the transmitter is faulty.

• If an interfering radio signal is received from elsewhere.

• If the accumulator is removed from its housing in the transmitter.

• If the accumulator reaches the end of its autonomy.

• If the transmitter is switched off by turning the key button to stop.

- These protective devices are provided for the safety of personnel and property and must never be altered, removed or bypassed in any

way whatsoever!

- The hand-guard frame prevents external action on a manipulator (if the transmitter falls, for example, or if the operator leans on a

guard-rail).

- An electronic safety device prevents radio transmission from being initiat ed if the manipulat ors are not mechanically and electrically at

rest and if the internal combustion engine speed selector is not set to idle.

In an emergency, press the transmitter emergency stop button immediately ; then follow the manual’s instructions (see: 2 - DESCRIPTION: INSTRUMENTS AND

CONTROLS).

Page 28

1-22

MAINTENANCE INSTRUCTIONS OF THE LIFT TRUCK

GENERAL INSTRUCTIONS

- Ensure the area is sufficiently ventilated before starting the lift truck.

- Wear clothes suitable for the maintenance of the lift truck, avoid wearing jewellery and loose clothes. Tie and protect your hair, if

necessary.

- Stop the I.C. engine and remove the ignition key, when an intervention is necessary.

- Read the operator’s manual carefully.

- Carry out all repairs immediately, even if the repairs concerned are minor.

- Repair all leaks immediately, even if the leak concerned is minor.

- Make sure that the disposal of process materials and of spare parts is carried out in total safety and in a ecological way.

- Be careful of the risk of burning and splashing (exhaust, radiator, I.C. engine, etc.).

MAINTENANCE

- Perform the periodic service (see: 3 - MAINTENANCE) to keep your lift truck in good working conditions. Failure to perform the periodic

service may cancel the contractual guarantee.

MAINTENANCE LOGBOOK

- The maintenance operations carried out in accordance with the recommendations given in part: 3 - MAINTENANCE and the other

inspection, servicing or repair operations or modifications performed on the lift truck or its attachments shall be recorded in a

maintenance logbook. The entry for each operation shall include details of the date of the works, the names of the individuals or

companies having performed them, the type of operation and its frequency, if applicable. The part numbers of any lift truck items

replaced shall also be indicated.

LUBRICANT AND FUEL LEVELS

- Use the recommended lubricants (never use contaminated lubricants).

- Do not fill the fuel tank when the I.C. engine is running.

- Only fill up the fuel tank in areas specified for this purpose.

- Do not fill the fuel tank to the maximum level.

- Do not smoke or approach the lift truck with a flame, when the fuel tank is open or is being filled.

HYDRAULIC

- Any work on the load handling hydraulic circuit is forbidden except for the operations described in part: 3 - MAINTENANCE.

- Do not attempt to loosen unions, hoses or any hydraulic component with the circuit under pressure.

BALANCING VALVE: It is dangerous to change the setting and remove the balancing valv es or safety valves which may be fitted to your lift truck cylinders. These

operations must only be performed by approved personnel (consult your dealer).

The HYDRAULIC ACCUMULATORS that may be fitted on your lift truck are pressurized units. Removing these accumulators and their pipework is a dangerous

operation and must only be performed by approved personnel (consult your dealer).

ELECTRICITY

- Do not short-circuit the starter relay to start the IC engine. If the forward/reverse selector is not in neutral and the parking brake is not

engaged, the lift truck may suddenly start to move.

- Do not drop metallic items on the battery.

- Disconnect the battery before working on the electrical circuit.

Page 29

1-23

WELDING

- Disconnect the battery before any welding operations on the lift truck.

- When carrying out electric welding work on the lift truck, connect the negative cable from the equipment directly to the part being

welded, so as to avoid high tension current passing through the alternator.

- Never carry out welding or work which gives off heat on an assembled tyre. The heat would increase the pressure which could cause

the tyre to explode.

- If the lift truck is equipped with an electronic control unit, disconnect this before starting to weld, to av oid the risk of causing irreparable

damage to electronic components.

WASHING THE LIFT TRUCK

- Clean the lift truck or at least the area concerned before any intervention.

- Remember to close and lock all accesses to the lift truck (doors, windows, cowls…).

- During washing, avoid the articulations and electrical components and connections.

- If necessary, protect against penetration of water, steam or cleaning agents, components susceptible of being damaged, particularly

electrical components and connections and the injection pump.

- Clean the lift truck of any fuel, oil or grease trace.

FOR ANY INTERVENTION OTHER THAN REGULAR MAINTENANCE, CONSULT YOUR DEALER.

Page 30

1-24

IF THE LIFT TRUCK IS NOT TO BE USED FOR A LONG TIME

INTRODUCTION

The following recommendations are intended to prevent the lift truck from being damaged when it is withdrawn from service for an

extended period.

For these operations, we recommend the use of a MANITOU protective product, reference 603726.

Instructions for using the product are given on the packaging.

Procedures to follow if the lift truck is not to be used for a long time and for starting it up again afterwards must be performed by your dealership.

PREPARING THE LIFT TRUCK

- Clean the lift truck thoroughly.

- Check and repair any leakage of fuel, oil, water or air.

- Replace or repair any worn or damaged parts.

- Wash the painted surfaces of the lift truck in clear and cold water and wipe them.

- Touch up the paintwork if necessary.

- Shut down the lift truck (see: OPERATING INSTRUCTIONS UNLADEN AND LADEN).

- Make sure the jib cylinder rods are all in retracted position.

- Release the pressure in the hydraulic circuits.

PROTECTING THE I.C. ENGINE

- Fill the tank with fuel (see: 3 - MAINTENANCE: A - DAILY OR EVERY 10 HOURS SERVICE).

- Empty and replace the cooling liquid (see: 3 - MAINTENANCE: F - EVERY 2000 HOURS SERVICE).

- Leave the I.C. engine running at idling speed for a few minutes, then switch off.

- Replace the I.C. engine oil and oil filter (see: 3 - MAINTENANCE: D - EVERY 500 HOURS SERVICE).

- Add the protective product to the engine oil.

- Run the I.C. engine for a short time so that the oil and cooling liquid circulate inside.

- Disconnect the battery and store it in a safe place away from the cold, after charging it to a maximum.

- Remove the injectors and spray the protective product into each cylinder for two seconds with the piston in low neutral position.

- Turn the crankshaft once slowly and refit the injectors (see I.C. engine REPAIR MANUAL).

- Remove the intake hose from the manifold or turbocharger and spray the protective product into the manifold or turbocharger.

- Cap the intake manifold or turbocharger hole with waterproof adhesive tape.

- Remove the exhaust pipe and spray the protective product into the exhaust manifold or turbocharger.

- Refit the exhaust pipe and block the outlet with waterproof adhesive tape.

NOTE: The spray time is noted on the product packaging and must be increased by 50 % for turbo engines.

- Open the filler plug, spray the protective product around the rocker arm shaft and refit the filler plug.

- Cap the fuel tank using waterproof adhesive tape.

- Remove the drive belts and store them in a safe place.

- Disconnect the engine cut-off solenoid on the injection pump and carefully insulate the connection.

PROTECTING THE LIFT TRUCK

- Set the lift truck on axle stands so that the tyres are not in contact with the ground and release the handbrake.

- Protect cylinder rods which will not be retracted, from corrosion.

- Wrap the tyres.

NOTE: If the lift truck is to be stored outdoors, cover it with a waterproof tarpaulin.

Page 31

1-25

BRINGING THE LIFT TRUCK BACK INTO SERVICE

- Remove the waterproof adhesive tape from all the holes.

- Refit the intake hose.

- Refit and reconnect the battery.

- Remove the protection from the cylinder rods.

- Perform the daily service (see: 3 - MAINTENANCE: A - DAILY OR EVERY 10 HOURS SERVICE).

- Put the handbrake on and remove the axle stands.

- Empty and replace the fuel and replace the fuel filter (see: 3 - MAINTENANCE: D - EVERY 500 HOURS SERVICE).

- Refit and set the tension in the drive belts (see: 3 - MAINTENANCE: C - EVERY 250 HOURS SERVICE).

- Turn the I.C. engine using the starter, to allow the oil pressure to rise.

- Reconnect the engine cut-off solenoid.

- Lubricate the lift truck completely (see: 3 - MAINTENANCE: SERVICING SCHEDULE).

Make sure the area is adequately ventilated before starting up the lift truck.

- Start up the lift truck, following the safety instructions and regulations (see: OPERATING INSTRUCTIONS UNLADEN AND LADEN).

- Run all the jib’s hydraulic movements, concentrating on the ends of travel for each cylinder.

Page 32

1-26

Page 33

2-1

2 - DESCRIPTION

Page 34

2-2

Page 35

2-3

TABLE OF CONTENTS

« EC» DECLARATION OF CONFORMITY

2-4

IDENTIFICATION OF THE LIFT TRUCK

2-6

CHARACTERISTICS

2-7

DIMENSIONS AND LOAD CHART

2-21

INSTRUMENTS AND CONTROLS

2-23

TOWING PIN AND HOOK

2-72

DESCRIPTION AND USE OF THE OPTIONS

2-76

Page 36

2-4

« EC» DECLARATION OF CONFORMITY

1) DECLARATION "CE" DE CONFORMITE (originale)

"

EECC""DDEECCLLAARRAATTIIOONNOOFFCCOONNFFOORRMMIITTY

Y

((oorriiggiinnaall)

)

2) La société, The company : MANITOU C.I.

3) Adresse, Address : Via Cristoforo Colombo 2, 41013 Cavazzona in Castelfranco Emilia –ITALIE

4)Dossier technique,Technical fi le : Manitou C.I., Via Cristoforo Colombo 2, 41013 Cavazzona in

Castelfranco Emilia (MO) , Italie

5) Constructeur de la machine décrite ci-après, Manufacturer of the machine described below :

CHARIOT ELEVATEUR MHT ... T N° 3

PFB p.n............ + FOURCHES ...... KG p.n.........

6) Déclare que cette machine, Declares that this machine :

7)- Est conforme aux directives suivantes et à leurs transpositions en droit national, Complies

with the following directives and their transpositions into national law

:

8) - Pour les machines annexe IV , For annex IV machines :

9) - Numéro d’attestation, Certifi cate number: /

10) - Organisme notifi é, Notifi ed body : /

11) -Procédure appliquée, Applied procedure : Annexe VI – 2000 / 14 / CE proc.I

10) - Organisme notifi é, Notifi ed body : ECO s.p.a. EUROPEAN CERTIFYNG .........................

ORGANIZATION,

Via Mengolina 33 48018 Faenza- Ravenna - Italia –

Organismo notifi cato n° 0714

12) - Niveau de puissance acoustique, Sound power level :

13) Mesuré, Measured : 106 dB (A)

14) Garanti,

Guaranteed : 108 dB (A)

15)-Normes harmonisées utilisées, Harmonised standards used : EN 12895

16)-Normes ou dispositions techniques utilisées, Standards or technical provisions used :

EN 1459 : 1999 + A1 : 2007

17) - Fait à, Done at : CASTELFRANCO EMILIA 18) - Date, Date : / /

19) - Nom du signataire, Name of signatory : FELICANI DANIELE

20) - Fonction, Function : DIRECTEUR TECHNIQUE

21) - Signature, Signature :

Page 37

2-5

bg : 1) удостоверение за « СЕ » съответствие (oригинална), 2) Фирмата, 3) Адрес, 4) Техническо досие, 5) Фабрикант на описаната по-долу машина, 6) Обявява, че

тази машина, 7) Отговаря на следните директиви и на тяхното съответствие национално право, 8) За машините към допълнение IV, 9)Номер на удостоверението, 10)

Наименувана фирма, 15) хармонизирани стандарти използвани, 16) стандарти или технически правила, използвани, 17) Изработено в, 18) Дата, 19) Име на разписалия

се, 20) Функция, 21) Функция.

cs : 1)

ES prohlášení o shodě (původní), 2) Název společnosti, 3) Adresa, 4) Technická dokumentace, 5) Výrobce níže uvedeného stroje, 6) Prohlašuje, že tento stroj,

7) Je v souladu s následujícími směrnicemi a směrnicemi transponovanými do vnitrostátního práva, 8) Pro stroje v příloze IV, 9) Číslo certifikátu, 10) Notifikační orgán,

15) harmonizované normy použity, 16) Norem a technických pravidel používaných, 17) Místo vydání, 18) Datum vydání, 19) Jméno podepsaného, 20) Funkce, 21) Podpis.

da : 1)

EF Overensstemmelseserklæring (original), 2) Firmaet, 3) Adresse, 4) tekniske dossier, 5) Konstruktør af nedenfor beskrevne maskine, 6) Erklærer, at denne maskine,

7) Overholder nedennævnte direktiver og disses gennemførelse til national ret, 8) For maskiner under bilag IV, 9) Certifikat nummer, 10) Bemyndigede organ, 15) harmoniserede

standarder, der anvendes, 16) standarder eller tekniske regler, 17) Udfærdiget i, 18) Dato, 19) Underskrivers navn, 20) Funktion, 21) Underskrift.

de : 1) EG-Konformitätserklärung (original), 2) Die Firma, 3) Adresse, 4) Technischen Unterlagen, 5) Hersteller der nachfolgend beschriebenen Maschine, 6) Erklärt, dass diese

Maschine, 7) den folgenden Richtlinien und deren Umsetzung in die nationale Gesetzgebung entspricht, 8) Für die Maschinen laut Anhang IV, 9) Bescheinigungsnummer,

10) Benannte Stelle, 15) angewandten harmonisierten Normen, 16) angewandten sonstigen technischen Normen und Spezifikationen, 17) Ausgestellt in, 18) Datum,

19) Name des Unterzeichners, 20) Funktion, 21) Unterschrift.

el : 1) Δήλωση συμμόρφωσης CE (πρωτότυπο), 2) Η εταιρεία, 3) Διεύθυνση, 4) τεχνικό φάκελο, 5) Κατασκευάστρια του εξής περιγραφόμενου μηχανήματος,

6) Δηλώνει ότι αυτό το μηχάνημα, 7) Είναι σύμφωνο με τις εξής οδηγίες και τις προσαρμογές τους στο εθνικό δίκαιο, 8) Για τα μηχανήματα παραρτήματος IV,

9) Αριθμός δήλωσης, 10) Κοινοποιημένος φορέας, 15) εναρμονισμένα πρότυπα που χρησιμοποιούνται, 16) Πρότυπα ή τεχνικούς κανόνες που χρησιμοποιούνται,

16) Είναι σύμφωνο με τα εξής πρότυπα και τεχνικές διατάξεις, 17) Εν, 18) Ημερομηνία, 19) Όνομα του υπογράφοντος, 20) Θέση, 21) Υπογραφή.

es : 1)Declaración DE de conformidad (original), 2) La sociedad, 3) Dirección, 4) expediente técnico, 5) Constructor de la máquina descrita a continuación, 6) Declara que esta

máquina, 7) Está conforme a las siguientes directivas y a sus transposiciones en derecho nacional, 8) Para las máquinas anexo IV, 9) Número de certificación, 10) Organismo

notificado, 15) normas armonizadas utilizadas, 16) Otras normas o especificaciones técnicas utilizadas, 17) Hecho en, 18) Fecha, 19) Nombre del signatario, 20) Función, 21) Firma.

et : 1) EÜ vastavusdeklaratsioon (algupärane), 2) Äriühing, 3) Aadress, 4) Tehniline dokumentatsioon, 5) Seadme tootja, 6) Kinnitab, et see toode, 7) On vastavuses järgmiste

direktiivide ja nende riigisisesesse õigusesse ülevõtmiseks vastuvõetud õigusaktidega, 8) IV lisas loetletud seadmete puhul, 9) Tunnistuse number, 10) Sertifitseerimisasutus,

15) kasutatud ühtlustatud standarditele, 16) Muud standardites või spetsifikatsioonides kasutatakse, 17) Väljaandmise koht, 18) Väljaandmise aeg, 19) Allkirjastaja nimi,

20) Amet, 21) Allkiri.

fi : 1) EY-vaatimustenmukaisuusvakuutus (alkuperäiset), 2) Yritys, 3) Osoite, 4) teknisen eritelmän, 5) Jäljessä kuvatun koneen valmistaja, 6) Vakuuttaa, että tämä kone,

7) Täyttää seuraavien direktiivien sekä niitä vastaavien kansallisten säännösten vaatimukset, 8) Liitteen IV koneiden osalta, 9) Todistuksen numero, 10) Ilmoitettu laitos,

15) yhdenmukaistettuja standardeja käytetään, 16) muita standardeja tai, 17) Paikka, 18) Aika, 19) Allekirjoittajan nimi, 20) Toimi, 21) Allekirjoitus.

ga : 1) « EC »dearbhú comhréireachta (bunaidh), 2) An comhlacht, 3) Seoladh, 4) comhad teicniúil, 5) Déantóir an innill a thuairiscítear thíos, 6) Dearbhaíonn sé go bhfuil an t-inneall,

7) Go gcloíonn sé le na treoracha seo a leanas agus a trasuímh isteach i ndlí náisiúnta, 8) Le haghaidh innill an aguisín IV, 9) Uimhir teastais, 10) Comhlacht a chuireadh i bhfios,

15) caighdeáin comhchuibhithe a úsáidtear, 16) caighdeáin eile nó sonraíochtaí teicniúla a úsáidtear, 17) Déanta ag, 18) Dáta, 19) Ainm an tsínitheora, 20) Feidhm, 21) Síniú.

hu : 1) CE megfelelőségi nyilatkozat (eredeti), 2) A vállalat, 3) Cím, 4) műszaki dokumentáció, 5) Az alábbi gép gyártója, 6) Kijelenti, hogy a gép, 7) Megfelel az alábbi

irányelveknek valamint azok honosított előírásainak, 8) A IV. melléklet gépeihez, 9) Bizonylati szám, 10) Értesített szervezet, 15) felhasznált harmonizált szabványok,

16) egyéb felhasznált műszaki szabványok és előírások hivatkozásai, 17) Kelt (hely), 18) Dátum, 19) Aláíró neve, 20) Funkció, 21) Aláírás.

is : 1) (Samræmisvottorð ESB (upprunalega), 2) Fyrirtækið, 3) Aðsetur, 4) Tæknilegar skrá, 5) Smiður tækisins sem lýst er hér á eftir, 6) Staðfestir að tækið, 7) Samræmist

eftirfarandi stöðlum og staðfærslu þeirra með hliðsjón af þjóðarrétti, 8) Fyrir tækin í aukakafla IV, 9) Staðfestingarnúmer, 10) Tilkynnt til, 15) samhæfða staðla sem notaðir,

16) önnur staðlar eða forskriftir notað, 17) Staður, 18) Dagsetning, 19) Nafn undirritaðs, 20) Staða, 21) Undirskrift.

it : 1) Dichiarazione CE di conformità (originale), 2) La società, 3) Indirizzo, 4) fascicolo tecnico, 5) Costruttore della macchina descritta di seguito, 6) Dichiara che questa

macchina, 7) È conforme alle direttive seguenti e alle relative trasposizioni nel diritto nazionale, 8) Per le macchine Allegato IV, 9) Numero di Attestazione, 10) Organismo

notificato, 15) norme armonizzate applicate, 16) altre norme e specifiche tecniche applicate, 17) Stabilita a, 18) Data, 19) Nome del firmatario, 20) Funzione, 21) Firma.

lt : 1) CE atitikties deklaracija (originalas), 2) Bendrovė, 3) Adresas, 4) Techninė byla, 5) Žemiau nurodytas įrenginio gamintojas, 6) Pareiškia, kad šis įrenginys, 7) Atitinka toliau

nurodytas direktyvas ir į nacionalinius teisės aktus perkeltas jų nuostatas, 8) IV priedas dėl mašinų, 9) Sertifikato Nr, 10) Paskelbtoji įstaiga, 15) suderintus standartus naudojamus,

16) Kiti standartai ir technines specifikacijas, 17) Pasirašyta, 18) Data, 19) Pasirašiusio asmens vardas ir pavardė, 20) Pareigos, 21) Parašas.

lv : 1) EK atbilstības deklarācija (oriģināls), 2) Uzņēmums, 3) Adrese, 4) tehniskās lietas, 5) Tālāk aprakstītās iekārtas ražotājs, 6) Apliecina, ka šī iekārta, 7) Ir atbilstoša tālāk

norādītajām direktīvām un to transpozīcijai nacionālajā likumdošanā, 8) Iekārtām IV pielikumā, 9) Apliecības numurs, 10) Reģistrētā organizācija, 15) lietotajiem saskaņotajiem

standartiem, 16) lietotajiem tehniskajiem standartiem un specifikācijām, 17) Sastādīts, 18) Datums, 19) Parakstītāja vārds, 20) Amats, 21) Paraksts.

mt : 1) Dikjarazzjoni ta’ Konformità KE (oriġinali), 2) Il-kumpanija, 3) Indirizz, 4) fajl tekniku, 5) Manifattriċi tal-magna deskritta hawn isfel, 6) Tiddikjara li din il-magna,

7) Hija konformi hija konformi mad-Direttivi segwenti u l-liġijiet li jimplimentawhom fil-liġi nazzjonali, 8) Għall-magni fl-Anness IV, 9) Numru taċ-ċertifikat, 10) Entità nnotifikata,

15) l-istandards armonizzati użati, 16) standards tekniċi u speċifikazzjonijiet oħra użati, 17) Magħmul f’, 18) Data, 19) Isem il-firmatarju, 20) Kariga, 21) Firma.

nl : 1) EG-verklaring van overeenstemming (oorspronkelijke), 2) Het bedrijf, 3) Adres, 4) technisch dossier, 5) Constructeur van de hierna genoemde machine, 6) Verklaart

dat deze machine, 7) In overeenstemming is met de volgende richtlijnen en hun omzettingen in het nationale recht, 8) Voor machines van bijlage IV, 9) Goedkeuringsnummer,

10) Aangezegde instelling, 15) gehanteerde geharmoniseerde normen, 16) andere gehanteerde technische normen en specificaties, 17) Opgemaakt te, 18) Datum,

19) Naam van ondergetekende, 20) Functie, 21) Handtekening.

no : 1) CE-samsvarserklæring (original), 2) Selskapet, 3) Adresse, 4) tekniske arkiv, 5) Fabrikant av følgende maskin, 6) Erklærer at denne maskinen, 7) Oppfyller kravene i

følgende direktiver, med nasjonale gjennomføringsbestemmelser, 8) For maskinene i tillegg IV, 9) Attestnummer, 10) Notifisert organ, 15) harmoniserte standarder som brukes,

16) Andre standarder og spesifikasjoner brukt, 17) Utstedt i, 18) Dato, 19) Underskriverens navn, 20) Stilling, 21) Underskrift.

pl : 1) Deklaracja zgodności CE (oryginalne), 2) Spółka, 3) Adres, 4) dokumentacji technicznej, 5) Wykonawca maszyny opisanej poniżej, 6) Oświadcza, że ta maszyna,

7) Jest zgodna z następującymi dyrektywami i odpowiadającymi przepisami prawa krajowego, 8) Dla maszyn załącznik IV, 9) Numer certyfikatu, 10) Jednostka certyfikująca,

15) zastosowanych norm zharmonizowanych, 16) innych zastosowanych norm technicznych i specyfikacji, 17) Sporządzono w, 18) Data, 19) Nazwisko podpisującego,

20) Stanowisko, 21) Podpis.

pt : 1) Declaração de conformidade CE (original), 2) A empresa, 3) Morada, 4) processo técnico, 5) Fabricante da máquina descrita abaixo, 6) Declara que esta máquina,

7) Está em conformidade às directivas seguintes e às suas transposições para o direito nacional, 8) Para as máquinas no anexo IV, 9) Número de certificado,

10) Entidade notificada, 15) normas harmonizadas utilizadas, 16) outras normas e especificações técnicas utilizadas, 17) Elaborado em, 18) Data, 19) Nome do signatário,

20) Cargo, 21) Assinatura.

ro : 1) Declaraţie de conformitate CE (originală), 2) Societatea, 3) Adresa, 4) cărtii tehnice, 5) Constructor al maşinii descrise mai jos, 6) Declară că prezenta maşină,

7) Este conformă cu directivele următoare şi cu transpunerea lor în dreptul naţional, 8) Pentru maşinile din anexa IV, 9) Număr de atestare, 10) Organism notificat, 15) standardele

armonizate utilizate, 16) alte standarde si specificatii tehnice utilizate, 17) Întocmit la, 18) Data, 19) Numele persoanei care semnează, 20) Funcţia, 21) Semnătura.

sk : 1) ES vyhlásenie o zhode (pôvodný), 2) Názov spoločnosti, 3) Adresa, 4) technickej dokumentácie, 5) Výrobca nižšie opísaného stroja, 6) Vyhlasuje, že tento stroj,

7) Je v súlade s nasledujúcimi smernicami a smernicami transponovanými do vnútroštátneho práva, 8) Pre stroje v prílohe IV, 9) Číslo certifikátu, 10) Notifikačný orgán,

15) použité harmonizované normy, 16) použité iné technické normy a predpisy, 17) Miesto vydania, 18) Dátum vydania, 19) Meno podpisujúceho, 20) Funkcia, 21) Podpis.

sl : 1) ES Izjava o ustreznosti (izvirna), 2) Družba. 3) Naslov. 4) tehnične dokumentacije, 5) Proizvajalac tukaj opisanega stroja, 6) Izjavlja, da je ta stroj, 7) Ustreza

naslednjim direktivam in njihovi transpoziciji v državno pravo, 8) Za stroje priloga IV, 9) Številka potrdila, 10) Obvestilo organu, 15) uporabljene harmonizirane standarde,

16) druge uporabljene tehnične standarde in zahteve, 17) V, 18) Datum, 19) Ime podpisnika, 20) Funkcija, 21) Podpis.

sv : 1)

CE-försäkran om överensstämmelse (original), 2) Företaget, 3) Adress, 4) tekniska dokumentationen, 5) Konstruktör av nedan beskrivna maskin, 6) Försäkrar att denna

maskin, 7) Överensstämmer med nedanstående direktiv och införlivandet av dem i nationell rätt, 8) För maskinerna i bilaga IV, 9) Nummer för godkännande, 10) Organism som

underrättats, 15) Harmoniserade standarder som använts, 16) andra tekniska standarder och specifikationer som använts, 17) Upprättat i, 18) Datum, 19) Namn på den som

undertecknat, 20) Befattning, 21) Namntecknin.

Page 38

2-6

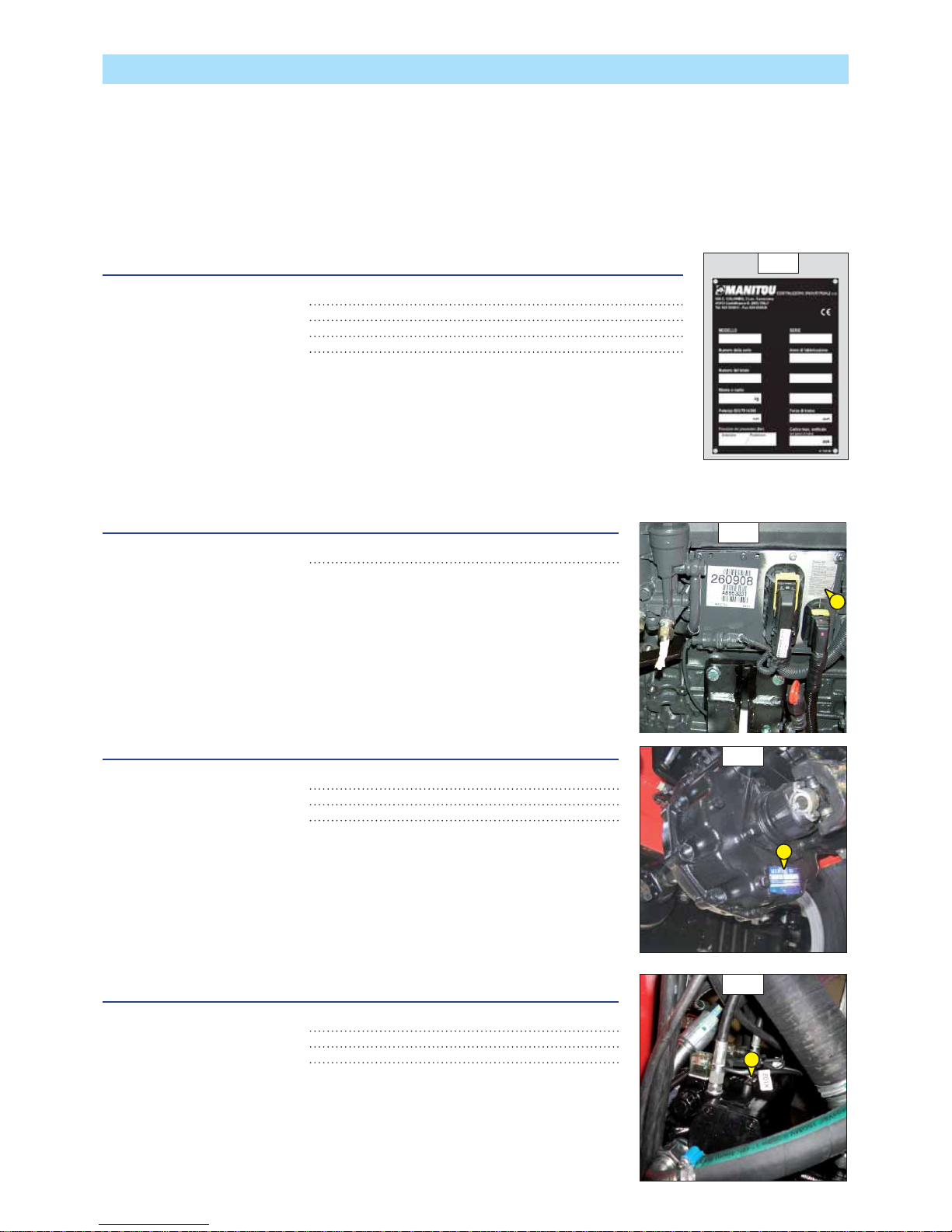

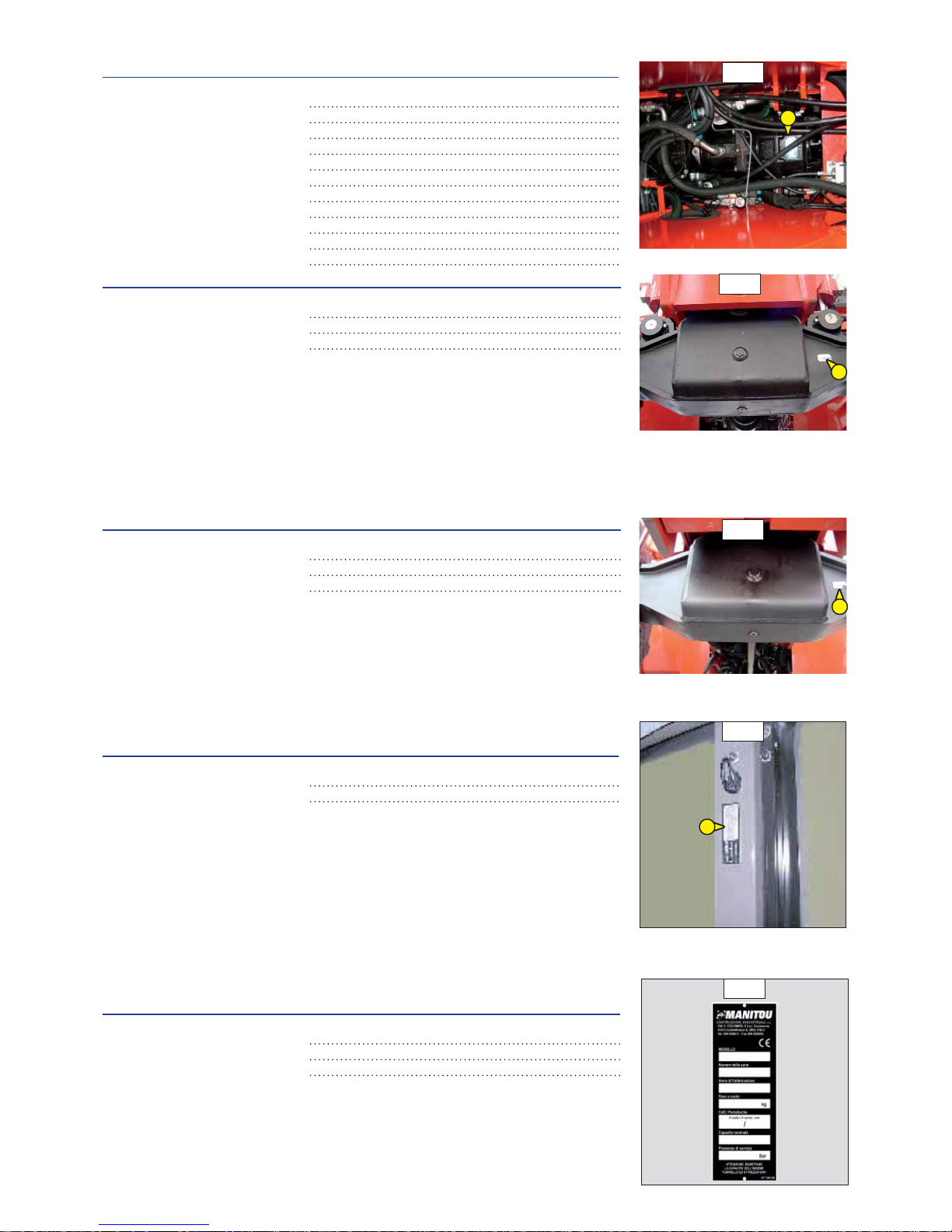

IDENTIFICATION OF THE LIFT TRUCK

As our policy is to promote a constant improvement of our products, our range of telescopic lift trucks may undergo certain modifications,

without obligation for us to advise our customers.

When you order parts, or when you require any technical information, always specify: