Page 1

Page 2

Hayes Performance Systems

5800 W. Donges Bay Rd.

Mequon, WI 53092

Tel: 888.686.3472

Email: techsupport@hayesbicycle.com

Web: www.hayescomponents.com

Hayes Components Europe

Dirnismaning 20 a

85748 Garching (b. Munich)

Germany

ph: +49 (0)89 203237450

Email: techsupportEU@hayesbicycle.com

Web: www.hayescomponents.com

2

CIRCUS EXPERT SERVICE MANUAL

Page 3

INTRODUCTION

This manual is intended to guide the user through the steps necessary to fully service and maintain

the Circus Expert suspension fork.

We highly recommend that service to this fork be performed by a certied

bicycle mechanic. Failure to follow instructions presented in this manual could lead to serious

injury or death. Any questions about the servicing of this fork or the manual itself should be

directed to Manitou Customer Support at:

Phone: 888-686-3472

Email: techsupport@hayesbicycle.com

Suspension forks by design can contain preloaded springs, gases and uids under

extreme pressures. Warnings contained in this manual must be observed to avoid damage to fork,

serious injury or even death.

CIRCUS EXPERT SERVICE MANUAL

3

Page 4

TABLE OF CONTENTS

SECTI ON PAGE N UMBER

REQUIRED TOOLS 5

EXPLODED DIAGRAM 6–8

CASTING REMOVAL & SERVICE 10–12

AIR SPRING SERVICE 13–17

TRAVEL CHANGE (OPTIONAL) 14-15

DAMPER SERVICE 18–19

CASTING INSTALLATION 20–22

COMPRESSION DAMPER INSTALL 23–26

4

CIRCUS EXPERT SERVICE MANUAL

Page 5

REQUIRED TOOLS

Below is a list of tools necessary for servicing the Circus Expert fork.

• Safety Glasses

• Nitrile Gloves

• Lint-Free Rags

• Torque Wrench

• Slickoleum Grease

• Semi-bath Oil, 5/40w Synthetic - Manitou part number 85-0022

• 5wt Maxima Fork oil - Manitou part number 85-0023

• 8mm Hex Socket

• 2mm Hex Wrench

• 20mm Socket

• 24mm Socket

• 22mm Box end Wrench

• 12mm Box End Wrench

• 12mm Socket

• Ratchet

• 22mm Crow’s Foot

• Fork/Shock Pump

• Pick

• Adjustable Wrench

• Downhill tire lever or at blade screwdriver

CIRCUS EXPERT SERVICE MANUAL

5

Page 6

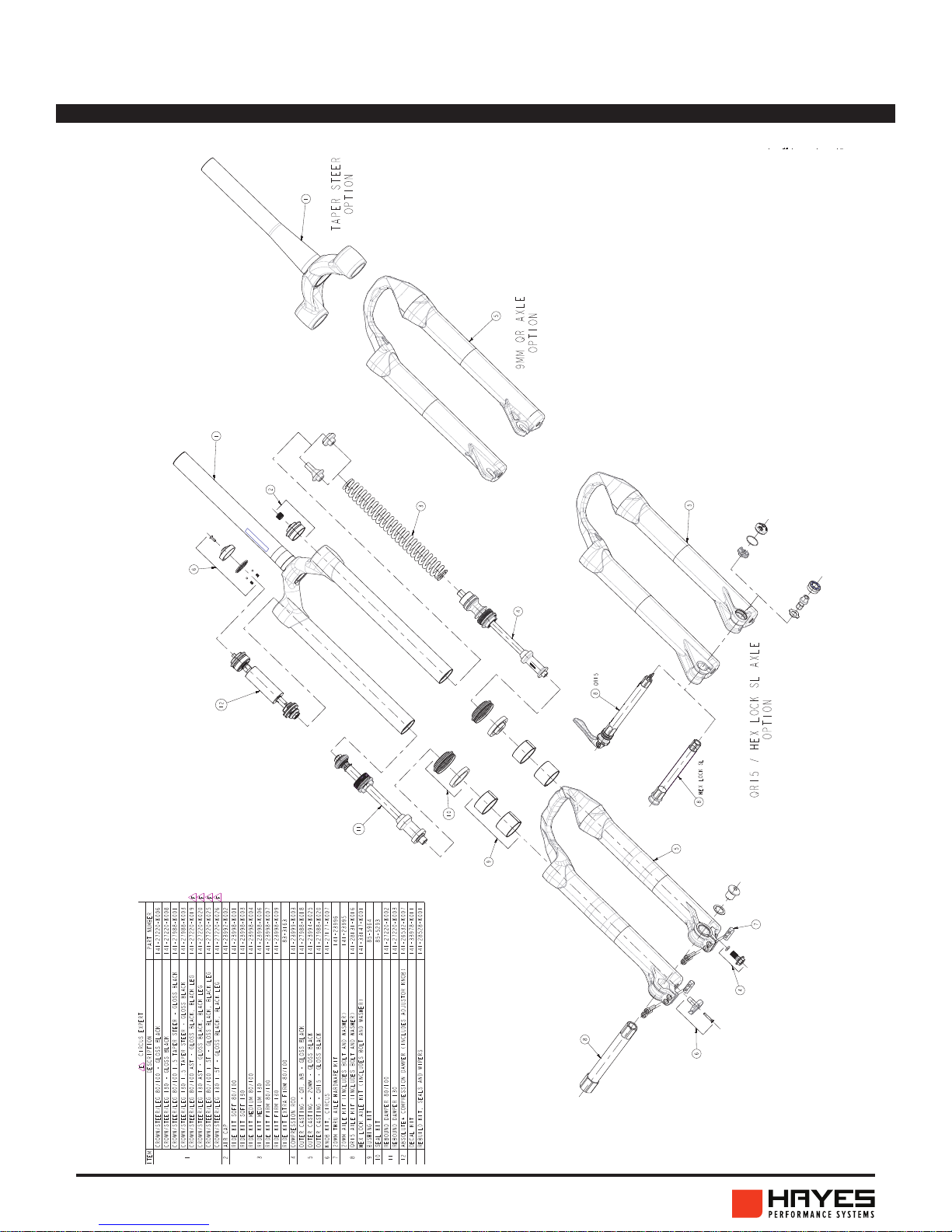

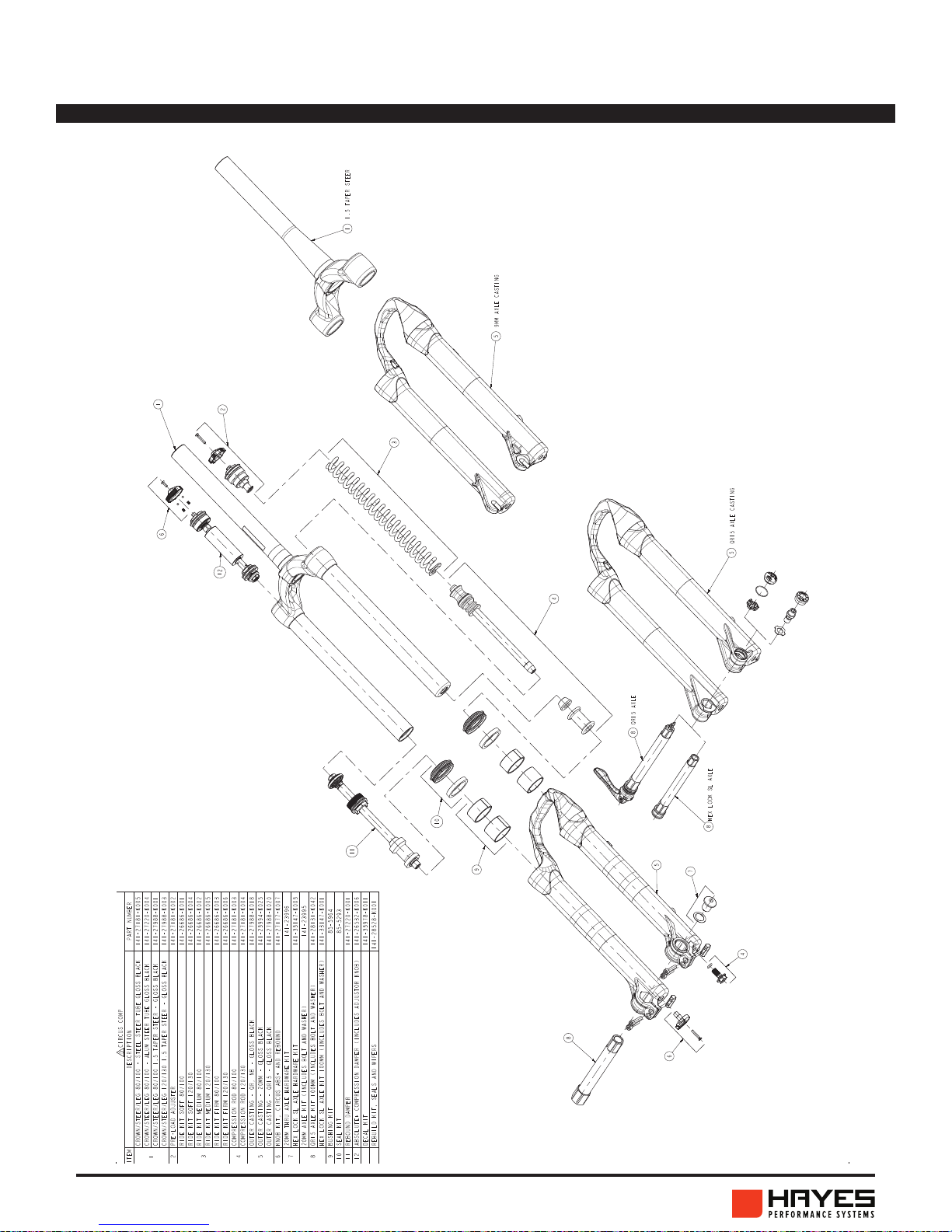

CIRCUS EXPERT Exploded view

6

CIRCUS EXPERT SERVICE MANUAL

Page 7

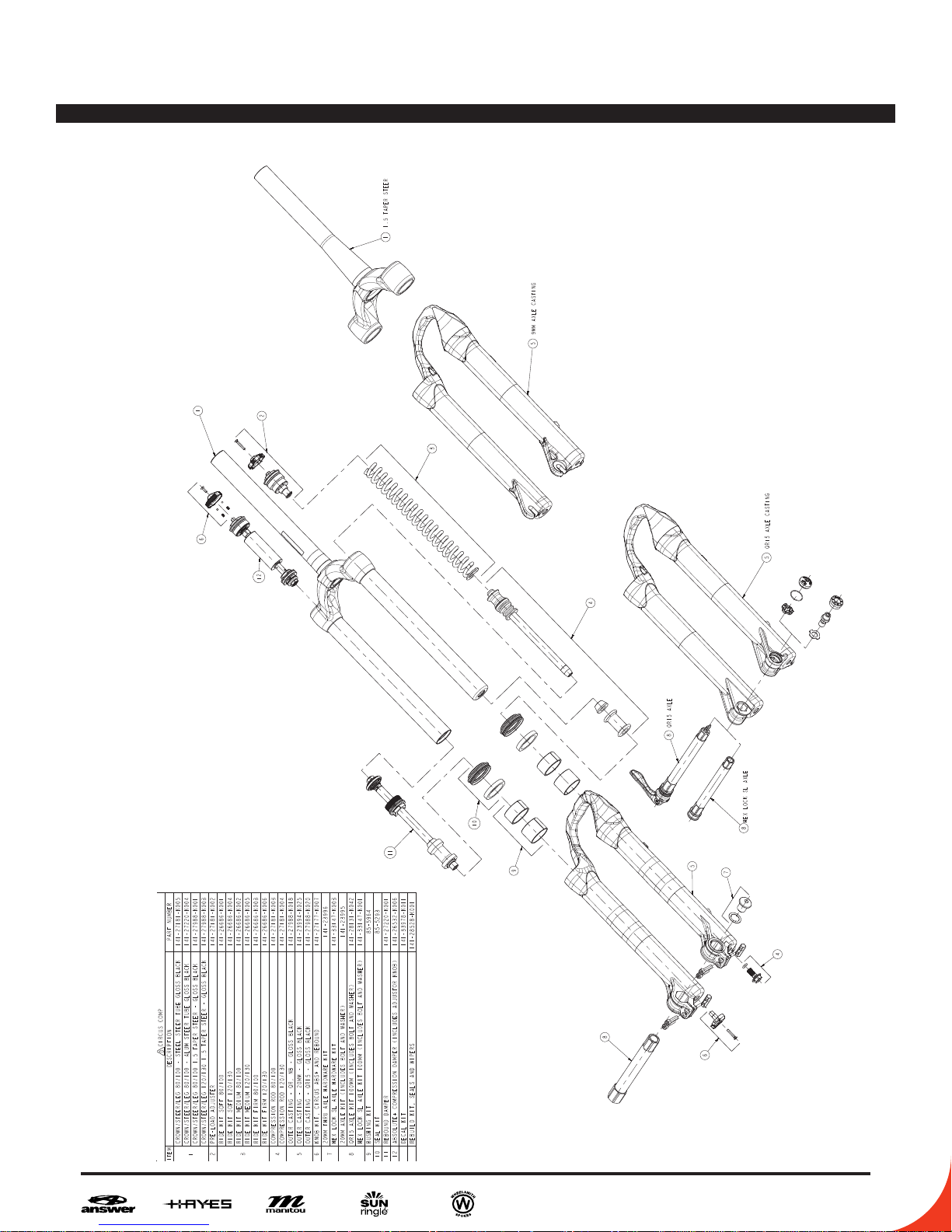

CIRCUS comp Exploded view

CIRCUS EXPERT SERVICE MANUAL

7

Page 8

CIRCUS sport Exploded view

8

CIRCUS EXPERT SERVICE MANUAL

Page 9

HAYES PERFORMANCE SYSTEMS WARRANTY

Limited Warranty:

HAYES warrants its products to be free from defects in materials or workmanship under

normal intended use for a period of one year (two years in European Union countries)

from the date of purchase, subject to normal wear and tear. Unless otherwise prohibited

by law, any such defective products will be repaired or replaced at the option of HAYES

when received with proof of purchase, freight prepaid. This warranty does not cover

breakage, bending, or damage that may result from crashes or falls. This warranty

does not cover any defects or damage caused by alterations or modications of HAYES

products or by normal wear, accidents, improper maintenance, damages caused by the

use of HAYES products with parts of dierent manufacturers, improper use or abuse

of the product, application or uses other than those set forth in the HAYES instruction

manual or failure to follow the instructions contained in the applicable HAYES instruction

manual. Instruction manuals can be found on-line at www.hayescomponents.com. Any

modications made by the BUYER or any subsequent user will render the warranty null

and void. This warranty does not apply when the serial number or production code has

been deliberately altered, defaced or removed from the product. The cost of normal

maintenance or replacement of service items, which are not defective, shall be the

BUYER’s responsibility. If permitted by local law, this warranty is expressly in lieu of all

other warranties (except as to title), express or implied, and in particular and without

limitation HAYES disclaims the implied warranties of merchantability or tness for

purpose If for any reason warranty work is necessary, return the component to the place

of purchase or contact your dealer or local HAYES distributor. In the USA, contact HAYES

for a return authorization number (RA#) at (888) 686-3472. At that time, instructions

for repair, return, or replacement shall be given. Customers in countries other than the

USA should contact their dealer or local HAYES distributor.

Limitation of Liability.

Unless required by mandatory law, HAYES shall not be liable for any incidental, indirect,

special or consequential damages.

This warranty does not apply to normal wear and tear. Wear and tear parts are subject to

damage through normal use, failure to service according to recommendations or riding in

conditions other than recommended. The cost of normal maintenance or replacement of service

items, which are not defective, shall be paid for by the original purchaser. Wear and tear parts

that will not be replaced under warranty include but are not limited to the following:

- Bushings

- Rear Shock

Mount Hardware

- Handlebar grips

- Tubeless Valves

- Dust Seals

- Fork and Shock air

Seals and/or O-rings

- Bearings

- Upper Stanchion Tubes

- Stripped or worn bolts

- Remote Lockout Cable

- Gloves

- Lower Stanchion

Tubes(Dorado)

CIRCUS EXPERT SERVICE MANUAL

9

Page 10

CASTING REMOVAL & SERVICE

Remove rebound knob using a

1

2

2mm hex wrench.

Insert an 8mm hex wrench into the

end of the rebound damper rod and

turn the rod clockwise until it is

disengaged from the casting and

can be pushed into the casting.

3

10

Use a 12mm wrench to remove the

compression rod bolt.

CIRCUS EXPERT SERVICE MANUAL

Page 11

CASTING REMOVAL & SERVICE

Remove casting from fork. It is

4

5

recommended this be done over

a drain pan as the lower casting

contains semi-bath oil. Allow oil

in casting to drain out before

continuing to next step.

Using a downhill tire lever or similar

tool, gently pry the dust seals out

of the casting.

Remove old foam wiper rings. Apply

6

semi-bath uid to the new foam

wiper rings and install into fork

casting.

CIRCUS EXPERT SERVICE MANUAL

11

Page 12

CASTING REMOVAL & SERVICE

Remove springs from lip of dust seals.

7

Using the Manitou 32mm Seal Press

(Manitou part number 172-31122) or

large socket press in the dust seals.

Reinstall springs onto seals.

12

CIRCUS EXPERT SERVICE MANUAL

Page 13

AIR SPRING SERVICE

Release air from the fork. Depress

1

2

Schrader valve a few times to ensure all

air is released.

Remove air cap using a 20mm socket.

Remove the compression spring.

3

CIRCUS EXPERT SERVICE MANUAL

13

Page 14

AIR SPRING SERVICE/TRAVEL CHANGE

Invert the fork and use a 22mm box end

4

5

wrench to unthread the compression rod

assembly from the stanchion.

Remove compression rod assembly from

the stanchion. Clean the assembly and

re-grease.

6

With the compression rod assembly

removed you can adjust the travel on the

aftermarket Circus Expert by adjusting

the spacer as shown.

14

CIRCUS EXPERT SERVICE MANUAL

Travel c hang e (optio nal)

Page 15

AIR SPRING SERVICE/TRAVEL CHANGE

Travel c hang e (optio nal)

Liberally grease the piston seal and

7

outer surface with Slickoleum™ grease

Install air spring assembly into

8

stanchion. Using a 22mm crow’s foot,

tighten assembly end cap to 80-100 in

lbs [9.0-11.3 NM].

CIRCUS EXPERT SERVICE MANUAL

15

Page 16

AIR SPRING SERVICE

Liberally grease the compression spring

9

10

outer surface with Slickoleum™ grease

Insert the compression spring and install

air cap onto stanchion. Tighten to 60-80

in lbs. [6.8-9.0 NM].

16

CIRCUS EXPERT SERVICE MANUAL

Page 17

DAMPER SERVICE

Remove ABS+ knob using a 2mm hex

1

wrench. Remove knob carefully as there

are two detent ball bearings on springs

below the knob.

(ABS+ knob detent ball and springs.)

Unthread ABS+ compression damper

2

assembly from the stanchion using a

24mm socket and ratchet.

CIRCUS EXPERT SERVICE MANUAL

17

Page 18

DAMPER SERVICE

Remove ABS+ compression damper

3

4

assembly from the stanchion.

Pour damper oil into a catch pan.

Using a 22mm box end wrench, unthread

5

18

the rebound damper assembly from the

fork stanchion.

CIRCUS EXPERT SERVICE MANUAL

Page 19

DAMPER SERVICE

Remove rebound damper assembly

6

7

from the fork. Once the damper

assembly is removed, clean the inside of

the stanchion with isopropyl alcohol and

a lint free towel. Inspect the inside and

outside of the stanchion for scratches

and other damage. Inspect rebound

damper for damage as well. Replace if

necessary.

Install rebound damper into stanchion.

Using a 22mm crow’s foot and torque

wrench, tighten the rebound damper

assembly end cap to 80-100 in lbs [9.0-

11.3 NM].

CIRCUS EXPERT SERVICE MANUAL

19

Page 20

CASTING INSTALL

Before lling the fork with fork oil and

1

2

installing the ABS+ compression damper,

the casting must rst be installed. This

ensures correct oil level. First apply a

generous amount of grease to the oil

seal/dust seal area of the casting.

Spread grease evenly along entire seal

inner diameter.

Fill the air chamber with a small amount

3

20

of air (30-50PSI). This will extend the

air spring assembly and make casting

installation easier.

CIRCUS EXPERT SERVICE MANUAL

Page 21

CASTING INSTALL

Slide casting onto the stanchion

4

5

assembly. Only slide the casting down

about halfway at this point. Take care

that the seals do not get folded over on

installation.

Insert 15cc’s (15ml) of semi-bath into

each casting leg. Once the semi-bath is

in the legs slide the casting the rest of

the way onto the stanchion assembly.

Using an 8mm hex wrench tighten the

6

rebound damper rod and air spring

assembly to 35–40in lbs [3.95–4.5 Nm]

by turning them counter-clockwise. Do

not overtighten, doing so can damage

the end of the rods.

CIRCUS EXPERT SERVICE MANUAL

21

Page 22

CASTING INSTALL

Install the rebound knob using a 2mm

7

8

hex wrench. Add a small drop of blue

Loctite to the screw before installation

to prevent the screw from backing out

during riding.

Install compression rod bolt. It helps

to have at least 30-50PSI in the air

chamber when tightening down the bolt

to the proper torque. Use a 12mm socket

and torque wrench and tighten to 45 –55

in lb [5.1–6.2 N m].

22

CIRCUS EXPERT SERVICE MANUAL

Page 23

COMPRESSION DAMPER INSTALL

Pour 5wt Maxima fork oil into the

1

2

damper leg. Fill it up ¾ of the way.

Place a lint-free towel over the opening

in the damper leg and compress the fork

10-15 times.

Pour additional 5wt fork oil into the

3

damper leg until the oil height (space

from the top of the damper leg to the top

of the oil) is set at the proper level. See

following page for the correct oil height

depending on compression damper type

and fork travel. An oil height setting tool

used for motorcycle forks similar to the

one pictured makes this job easier.

CIRCUS EXPERT SERVICE MANUAL

23

Page 24

COMPRESSION DAMPER INSTALL

oil height chart 2017-2018

fork model oil height

Mastodon pro

mastodon comp

markhor (80/100mm)

markhor (120mm)

mattoc pro

mattoc comp

machete (abs+)

machete (kwik toggle, 90-120mm)

machete (kwik toggle, 130-140mm)

circus comp/expert

circus sport (ffd)

R7 PRO

75mm

87mm

92mm

97mm

75mm

87mm

87mm

87mm

91mm

87mm

83mm

83mm

oil

height

(refers to the air

space between the top

of the oil and top of

the fork leg)

dorado (see dorado service guide)

180-190mm

note

1. oil height is set with compression damper

removed.

2. oil height is set with fork fully extended

and casting installed.

24

CIRCUS EXPERT SERVICE MANUAL

Page 25

COMPRESSION DAMPER INSTALL

Insert the ABS+ compression damper

4

5

into the damper leg. Ensure the damper

is set in the unlocked position when

installing.

Install the ABS+ damper using a 24mm

socket and torque wrench, tighten the

damper to 60–80 in lbs [6.8–9.0 NM].

Install springs and ball bearings into

6

ABS+ top cap. A small dab of grease on

top of the spring can help hold the ball

bearings in place.

CIRCUS EXPERT SERVICE MANUAL

25

Page 26

COMPRESSION DAMPER INSTALL

Using a 2mm hex wrench, install the

7

8

ABS+ or Kwik Toggle knob.

Clean fork and use a shock pump to

set to desired pressure. Pressure chart

below for reference.

RIDER WEIGHT

LBS KGS

220 99.8 30-50 PSI [2.0-3.4 BAR]

200 90.7 20-35 PSI [1.4-2.4 BAR]

170 77.1 10-25 PSI [0.7-17 BAR]

140 63.5 5-15 PSI [0.3-1.0 BAR]

120 54.4 0-10 PSI [0-.07 BAR]

ACT AIR

MAX PRESSURE NOT TO EXCEED 50PSI (3.45 BAR)

MAX PRESSURE NOT TO EXCEED 50PSI (3.45 BAR)

SOFT SPRING FIRM SPRING

15 PSI [1.0 BAR]

10 PSI [0.7 BAR]

N/A

N/A

N/A

26

CIRCUS EXPERT SERVICE MANUAL

Page 27

WWW. MANITOUMTB.COM WWW.HAYESCOMPONENTS.COM

5800 W DONGES BAY ROAD MEQUON WI 53092

Loading...

Loading...