Mammoth 830, 840 User Manual

V-Cube Slim™ Split

Floor-by-Floor Cooling Systems

Installation, Operation & Maintenance Manual

Sizes: 830 and 840

Model: F-Series

MAMM-VCS-IOM-3FA (September 2013) PN 71144924

Contents

Nomenclature .......................................................................................................................3

Introduction ...........................................................................................................................4

Warnings, Cautions and Notices ..........................................................................................4

Receiving Inspection and Storage .......................................................................................5

Disassembly and Assembly..................................................................................................6

Installation ..........................................................................................................................11

Startup ................................................................................................................................15

General Maintenance .........................................................................................................18

Troubleshooting ..................................................................................................................19

Electrical Terminal Tightening Torques ...............................................................................21

Unit Checkout Sheet ..........................................................................................................24

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 2

Nomenclature

F 830 S H F

Voltage Size (BTUH Cooling) Unit Type Temperature Range Design Series

F = 208-230/3/60 830 = 732,000 S = Split H = Standard Range

G = 460/3/60 840 = 732,000 L = Low Temperature

J = 380/3/50

K = 575/3/60

“Mammoth” is a registered trademark of Mammoth, Inc.

©Mammoth, Inc. All rights reserved throughout the world.

Illustrations cover the general appearance of Mammoth products at the time of publication. Mammoth, Inc. reserves the right to make

changes in design and construction at any time without notice.

Introduction

This manual provides guidelines for installation, startup,

operation and maintenance of your Mammoth V-Cube

Slim unit. Also provided with your unit are submittal documents that contain detailed specifications for your unit,

including drawings and wiring schematics. If your system

is equipped with EPiC™ controls from Mammoth, full

documentation on their use is also provided.

Installation, startup and operation of this unit must follow

accepted industry practices as described in the ASHRAE

Handbook, the National Electric Code, and other applicable standards. Operate this equipment in accordance

with regulations of authorities having jurisdiction and

all applicable codes. Maintenance and service must be

performed by qualified personnel familiar with applicable

codes and regulations and experienced with this type of

equipment.

If you have additional questions about the operation or

maintenance of your Mammoth system, contact your

local Mammoth representative, or the Mammoth Service

department at (952) 358-6618 or info@mammoth-inc.

com. For assistance in locating your Mammoth representative, call 952-358-6600 or send an email to info@

mammoth-inc.com. Or, go to www.mammoth-inc.com and

click on the Find a Rep link.

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 3

Warnings, Cautions and Notices

Warnings, cautions and notices appear at appropriate

locations throughout this manual. Your personal safety

and the proper operation of this machine depend upon

the strict observance of these precautions. Read this

manual thoroughly before operating or servicing this unit.

WARNING! Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

CAUTION! Indicates a potentially hazardous

situation which, if not avoided, could result

in minor or moderate injury. It could also be

used to alert against unsafe practices.

Receiving Inspection and Storage

When receiving equipment, check the Bill of Lading to

verify that all crates and cartons have been received.

Compare shipped-loose items received against the

list provided. Check for visible damage. If there is any

evidence of rough handling, immediately check for concealed damage. If any damage is found, refuse delivery

of the damaged item. Then contact your Mammoth Representative to place an order for a new unit or the repair

and reshipment of the damaged unit. It is encouraged

that detailed photos be taken for documentation.

This vertical unit must remain in an upright position at

all times. If this unit must be positioned horizontally during transport or rigging, it must be returned to its normal

upright position for at least 24 hours before operating.

IMPORTANT! Operating a unit after it has

been stored or transported on its side can

result in serious compressor damage which

is not covered under the equipment warranty. Make sure the unit is first returned to its

normal upright position for at least 24 hours

before operating.

Temporary storage at the job site must be indoors, completely sheltered from rain, snow, etc. High or low temperatures naturally associated with weather patterns will not

harm units. Excessively high temperatures, 140°F (60°C)

and higher, may deteriorate certain plastic materials and

cause permanent damage.

General Warnings

WARNING! Electric shock and moving equip-

ment hazard. Can cause severe injury or

death. Lock and tag out all electric power

before servicing equipment. More than one

disconnect may be required to de-energize

the unit.

CAUTION! Installation and servicing of this

equipment should only be undertaken by a

trained professional with experience working

on commercial HVAC systems. Contact your

Mammoth representative or the Mammoth Service Department for help in scheduling service.

CAUTION: Sharp edges on sheet metal, coil

surfaces and fasteners can cause personal

injury. Avoid contact and wear protective

clothing and gloves.

IMPORTANT! This product was carefully

packed and thoroughly inspected before

leaving the factory. Responsibility for its safe

delivery was assumed by the carrier upon

acceptance of the shipment. Claims for loss

or damage sustained in transit must therefore

be made upon the carrier as follows:

Visible Loss or Damage

If there is any external evidence of loss or

damage, refuse delivery of the damaged item.

Refusal of items must be noted on the freight

bill or carrier’s receipt, and signed by the carrier’s agent. Failure to adequately describe

such external evidence of loss or damage

may result in the carrier’s refusal to honor a

damage claim. The form required to file such

a claim will be supplied by the carrier.

Concealed Loss or Damage

Concealed loss or damage means loss or

damage which does not become apparent

until the product has been unpacked. The

contents may be damaged in transit due to

rough handling even though the carton may

not show external damages. When the damage is discovered upon unpacking, make a

written request for inspection by the carrier’s

agent within fifteen (15) days of the delivery

date and file a claim with the carrier.

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 4

Disassembly and Assembly

General Guidelines

The Mammoth V Cube Slim Split is engineered to be

disassembled in the field and moved through 36” doors

into position then reassembled without breaking into the

refrigeration circuits. Only qualified personel experienced

in operation and maintenance of HVAC equipment should

perform these procedures.

WARNING! This equipment presents hazards

of electricity, rotating parts, sharp edges,

heat and weight. Failure to read and follow

these instructions can result in property damage, severe personal injury or death. This

equipment must be installed by experienced,

trained personnel only.

WARNING! A mechanical lift is required to

move or lift all sections of a V-Cube Slim™

unit. Do not attempt to move or lift sections

without a mechanical lift. Failure to do so can

result in equipment damage, severe personal

injury or death.

WARNING! Lifting the entire unit (blower

section, coil section, etc.) using lifting lugs,

eye bolts or straps attached to the top of the

unit can result in serious damage to the unit,

personal injury or death.Lifting the entire unit

should only be done using a forklift or a strapping spreader bar mechanism attached to the

base of the unit.

WARNING! All utilities (water, electric, and

communication cables) must be removed

prior to unit disassembly. Follow approved

lockout/tagout procedures before any disassembly of the unit. Failure to do so can result

in electric shock, equipment damage, severe

personal injury, or death.

IMPORTANT! All blower wiring is correctly

phased at the factory and must be re-wired

correctly upon re-assembly for correct compressor and blower operation. Mark all wires

and pull through knockouts using care not

to scrape the insulation of the wiring when

separating sections. If the wire insulation or

wire jacket is torn during the disassembly/

re-assembly procedure, replace the wire. Do

not use wire that is missing insulation. Control and sensor wiring uses Molex plugs for

proper polarity.

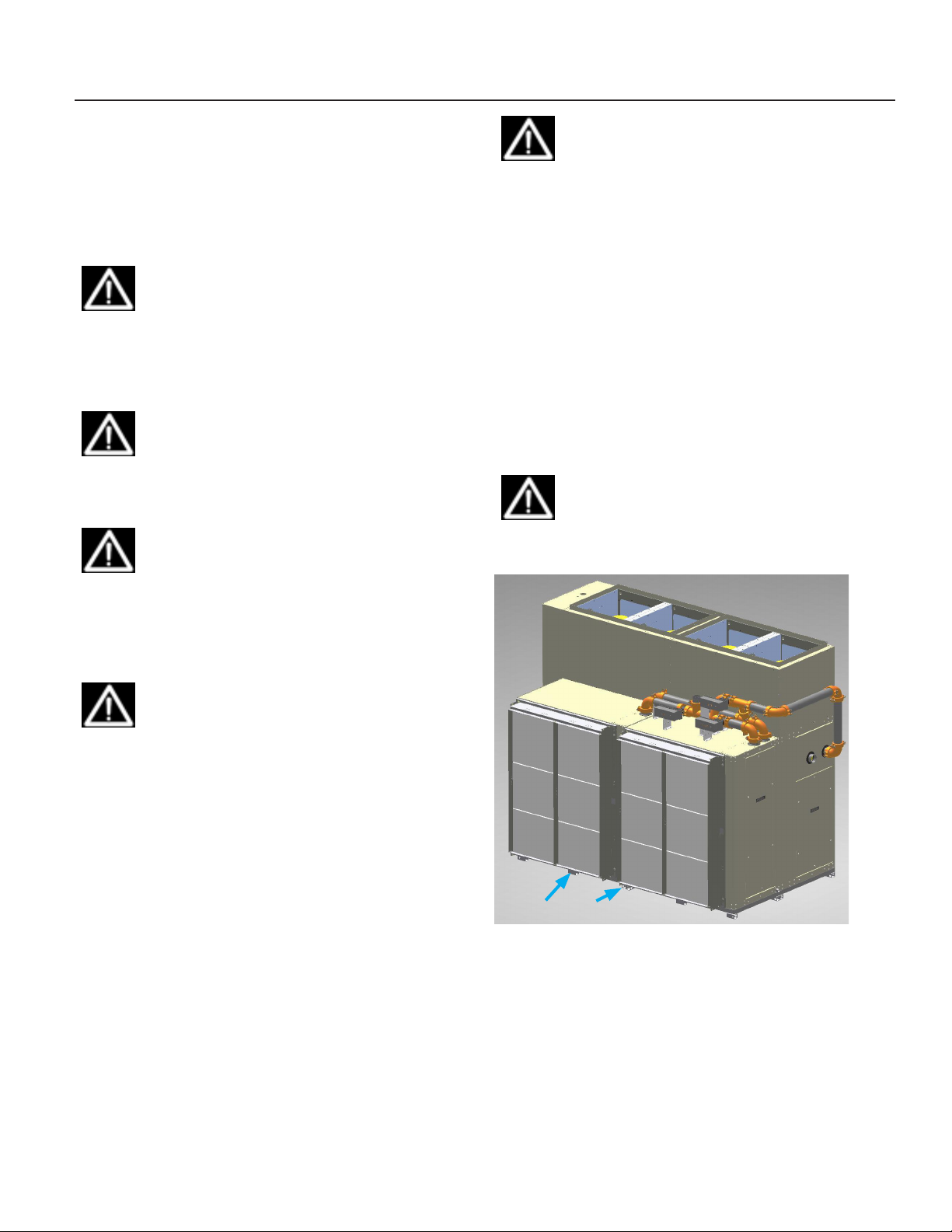

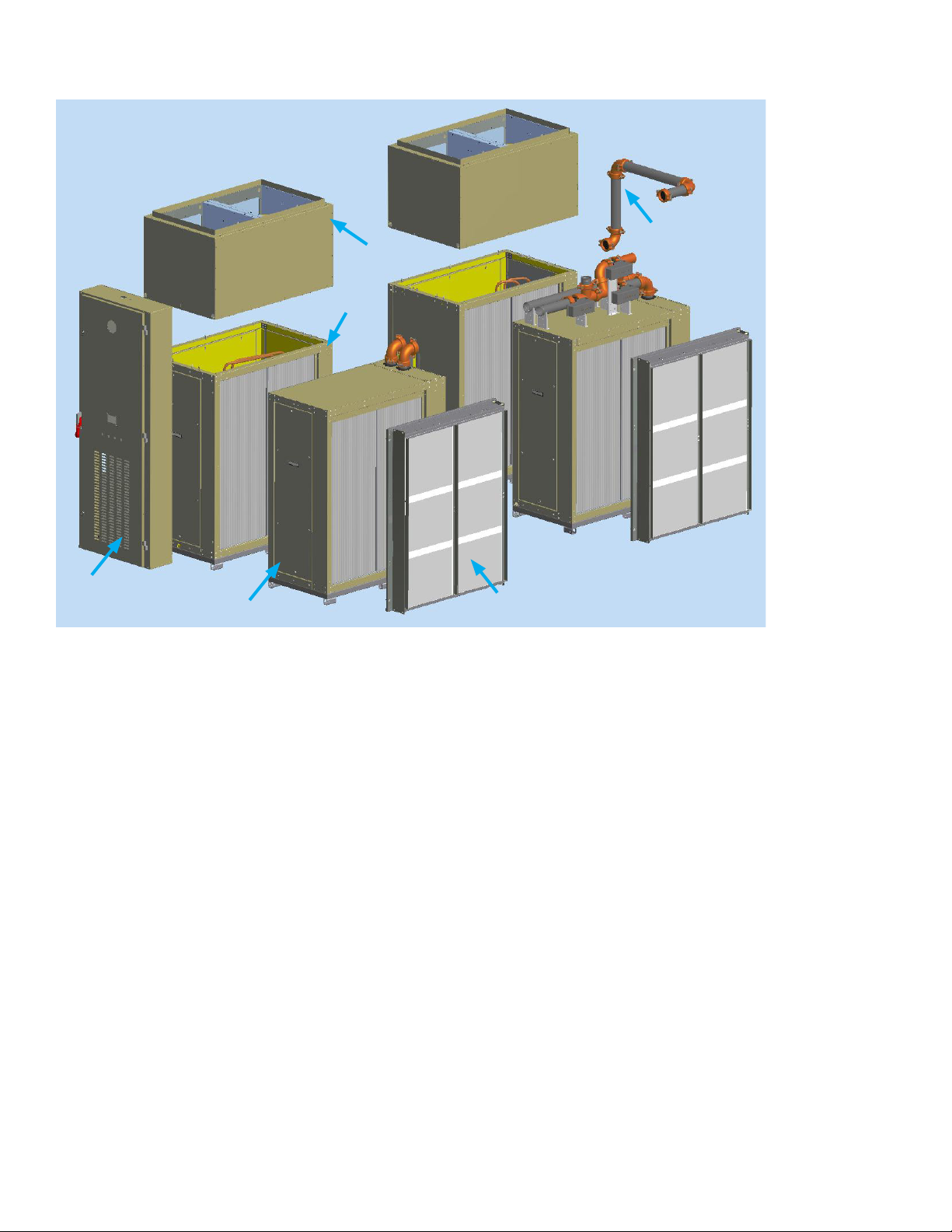

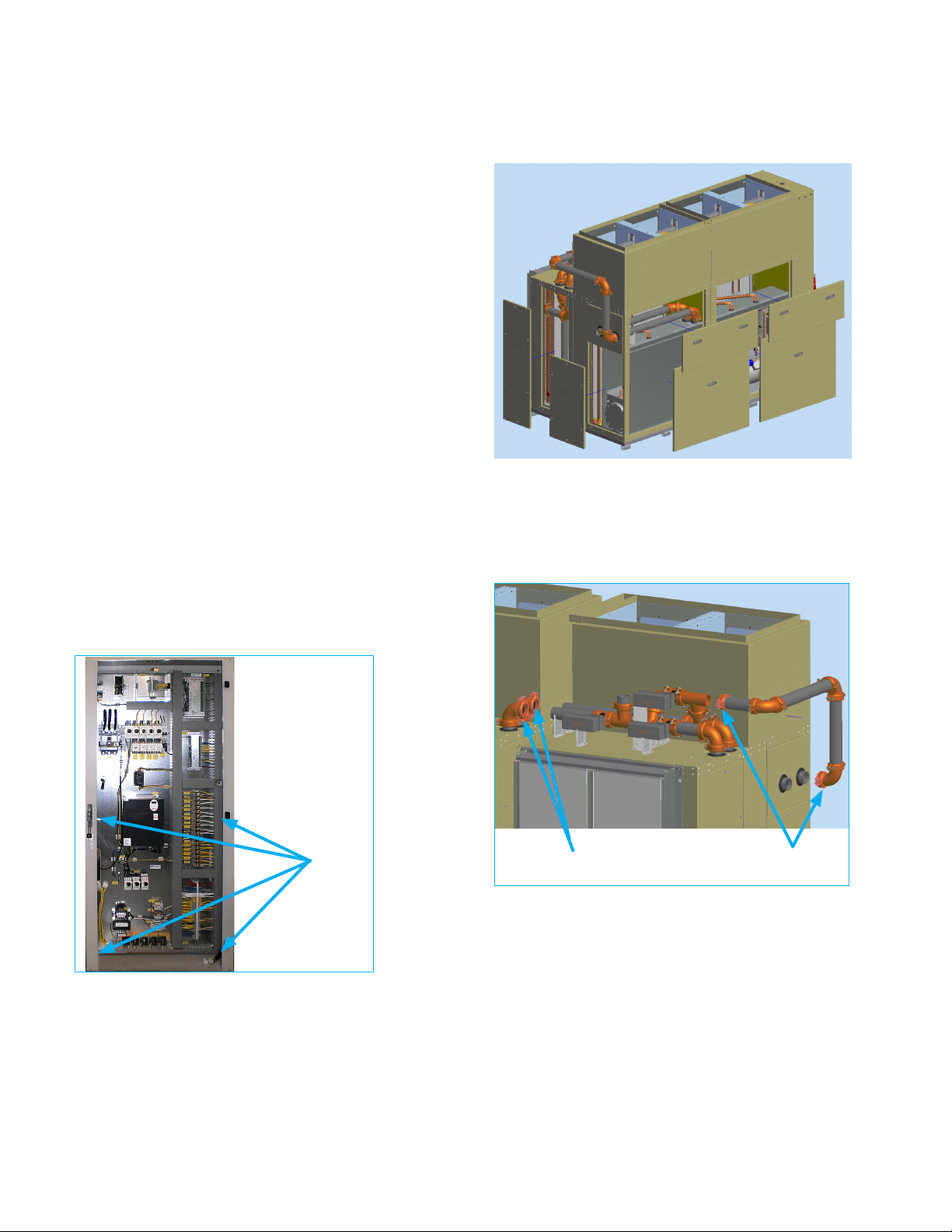

Figure 1 shows the unit as shipped from the factory. Figure 2 shows an exploded view of the unit, equipped with

coil cabinets and 2” x 4 “ filter racks. Note that the coil

cabinets and refrigeration sections are resting on welded

steel bases. These bases are an integral part of the subassemblies and must not be removed.

IMPORTANT! The welded steel bases are

integral to subassembly stability and mobility.

Do not detach!

Figure 1: Unit As Shipped

Welded steel base

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 5

Figure 2: Exploded View

FANWALL section

Main chassis

End piping

assembly

Main electrical panel

Coil cabinet

Mechanical lifting equipment is necessary to dismantle

and relocate the V Cube Slim Split. This unit will weigh

between 4000 and 5800 pounds depending on options

and features built into the unit at the factory.

Mechanical lifting equipment is also required to remove

the sub assemblies from the main chassis. Subassemblies weigh a minimum of 205 pounds and as much as

1500 pounds each.

Wiring

NEMA does not allow quick-connect plugs for power (high

voltage) wiring. For this reason, all power wires have raw

ends and are ‘hardwired’ to terminal blocks in the unit and

Filter Rack

require handtools for removal. These power wires must

be labeled prior to removal to avoid problems.

All low voltage wires are connected using quick-connect

plugs.

Piping

All water piping is iron with grooved (Victualic®) connections.

Refrigeration circuits are copper pipe and do not require

any disassembly and reassembly.

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 6

Main Electrical Panel Removal

The main electrical panel is removed as follows.

1. Unplug the wiring harness that connects the EPiC™

keypad, reset buttons and selector switches from the

panel door to the main electrical panel.

2. Remove the panel door by lifting it from its hinges.

Carefully set it away from the unit to help prevent

damage during the remaining disassembly process.

3. Unplug all control wiring harnesses that run from the

main electrical panel to the main cabinet section. All

wiring connecting the main electrical panel to the unit

passes through knockouts on the left inside corner.

These plugs are labeled for correct re-installation.

4. Disconnect all high voltage wiring to the fan motors.

5. Verify that all electrical connections to the unit from

the control panel have been disconnected.

6. Support the electrical panel from above or below to

prevent it from falling once the connecting bolts have

been removed.

7. Loosen and remove the section bolts that fasten the

main electrical panel to the main cabinet sections, as

shown in Figure 3.

8. Set the main electrical panel aside, away from the

unit to help prevent damage during the remaining disassembly process.

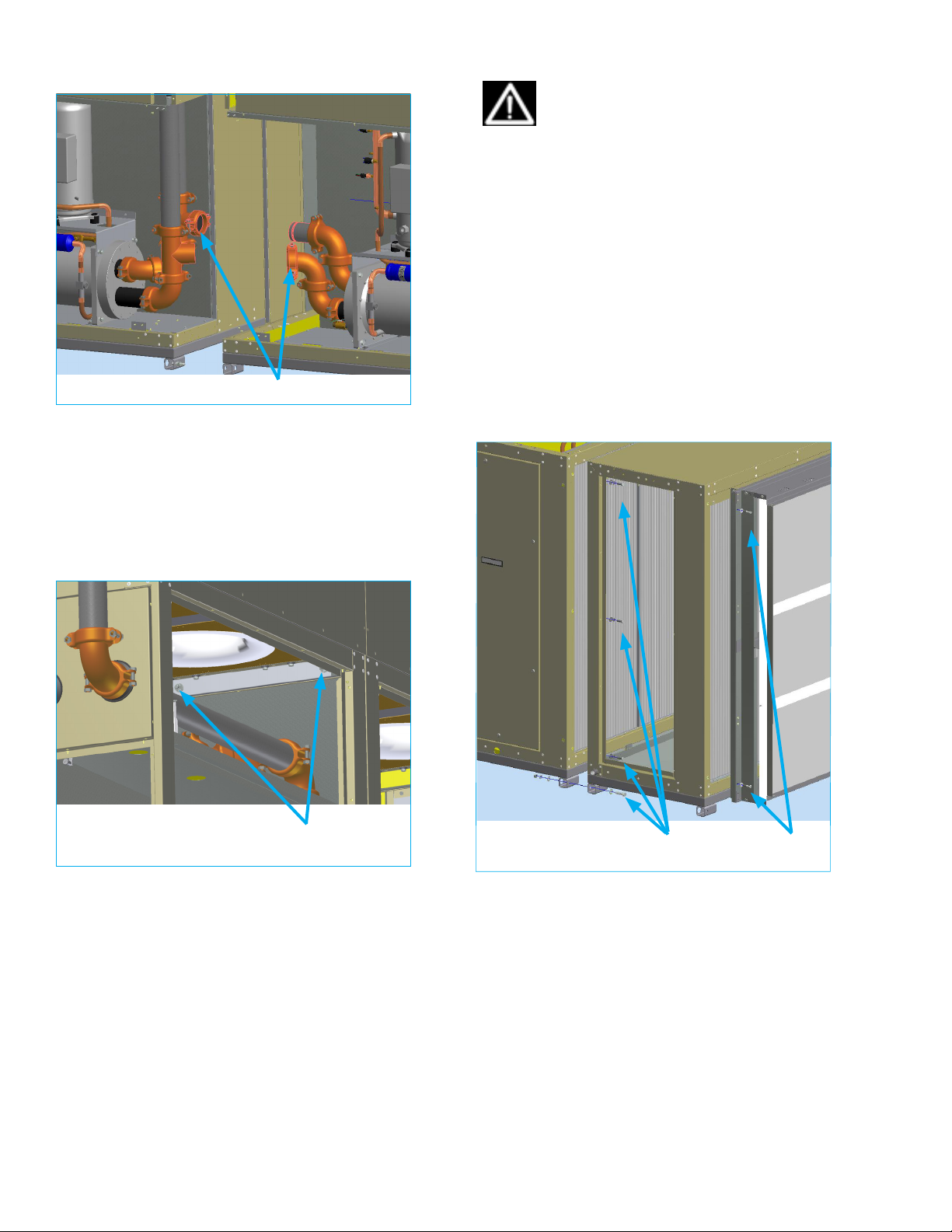

1. Remove all access panels and set them aside. See

Figure 4. Quarter turn, twist lock fasteners secure

most access panels.

Figure 4: Panel Removal

Unit Rear

Unit Front

2. Facing the rear side of the unit, loosen the top piping

connections between the two main sections as shown

in Figure 5. The pipes will separate as cabinet halves

are separated.

Figure 5: Rear Side Piping Disconnects

Figure 3: Main Electrical Panel Removal

Remove

mounting

bolts

Splitting Apart The Main Sections

To disassemble the unit’s two main sections into separate

halves, carry out the following procedures. To reassemble, follow these procedures in reverse.

Top piping

connections

End piping assembly

connections

3. Loosen the piping connections on either end of the

end piping assembly, as shown in Figure 5. Then

remove the end piping assembly and set it aside. (If

the end piping assembly is not already installed, it is

packed inside the unit for field assembly.)

4. Facing the front of the unit, loosen the piping connections between the two main sections as shown in Figure 6. The pipe connections will separate as cabinet

halves are separated.

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 7

Figure 6: Front Side Piping Disconnects

Piping connections

IMPORTANT! Filter rack mounting bolts are

a specific length so as to not contact the coil

behind the bulkhead. If any are lost, replacement bolts must be the same length.

2. If still in place, remove the coil cabinet inner access

panel from the side of the cabinet.

3. Remove the six fasteners (three on each side) connecting the sides of the coil cabinet to the main chassis.

4. Remove the nuts and bolts (two sets, one on each

end) connecting the coil cabinet to the main chassis

at the welded steel base.

5. The coil cabinet can now be separated from the main

chassis. Each coil cabinet will weigh at least 300

pounds.

5. Remove the nuts and bolts connecting the two main

sections at the welded steel base.

6. Remove the connecting bolts from the upper access

panel location as shown in Figure 7.

7. The unit should now come apart in two halves. Each

side will weigh at least 1000 pounds.

Figure 7: Upper Access Panel Conecting Bolts

Upper access

panel bolts

Figure 8: Filter Rack and Coil Cabinet Removal

Coil cabinet

fasteners

Filter rack

fasteners

Filter Rack and Coil Cabinet Removal

Once the unit has been split apart into separate halves,

the coil cabinet and filter rack can be removed from the

FANWALL Section Removal

The FANWALL cells come off in pairs; each pair weighing

roughly 600 pounds. They are removed as follows.

main chassis, as follows. See Figure 8 for fastener locations.

1. Loop lifting straps around both motor mount frames

as shown in Figure 9 and then to a spreader bar or to

1. Remove the filter rack from the coil cabinet by screwtwo forklift forks.

ing out the fasteners from the four corners of the

rack.

Mammoth V-Cube Slim Split IOM, MAMM-VCS-IOM-3FA (September 2013) 8

Loading...

Loading...