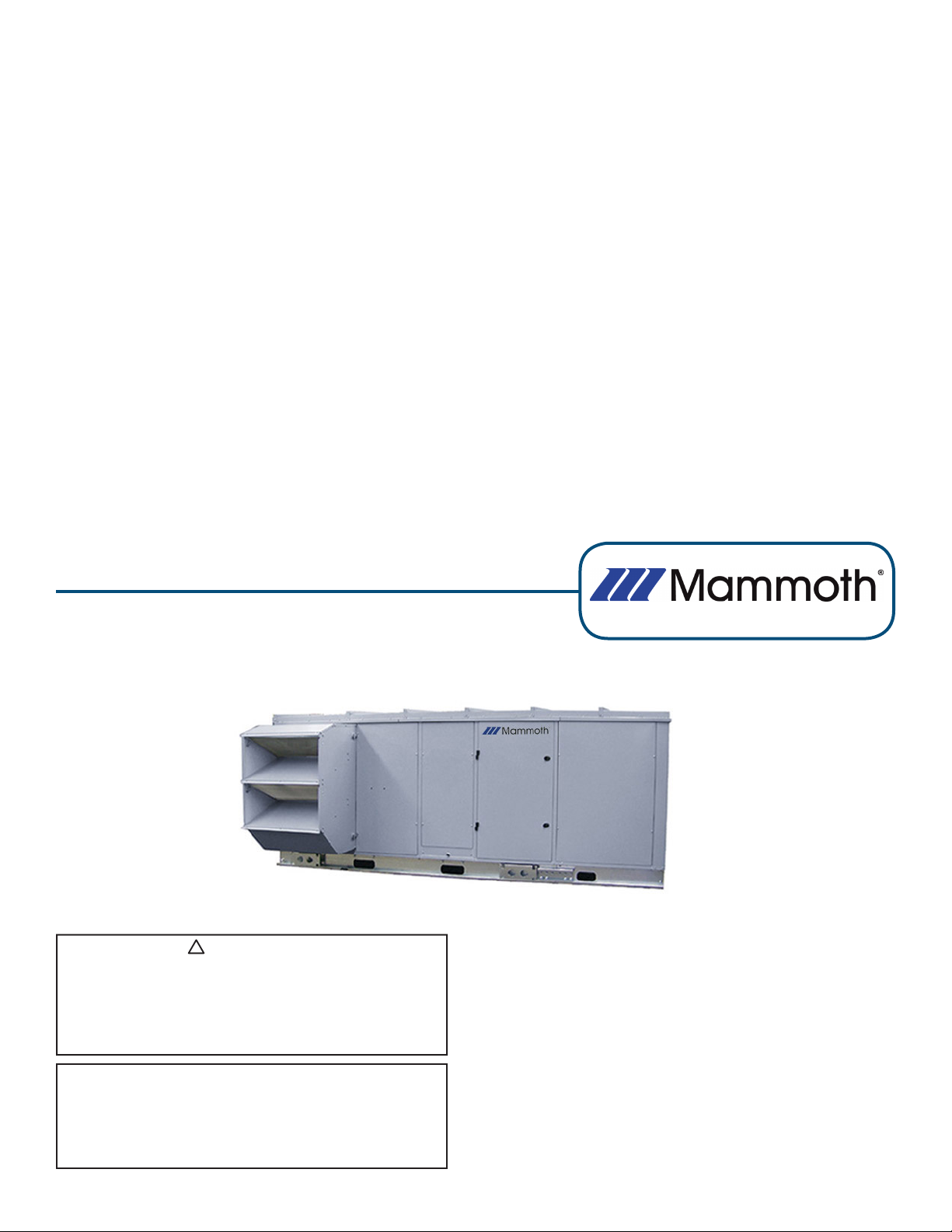

Mammoth 800, 5500 CFM User Manual

VHC

!

Energy Recovery Ventilators with Enthalpy Wheels and

Integrated Heating and Cooling

Installation, Operation and Maintenance

Capacity: 800 to 5,500 cfm

Model: VHC-36, VHC-42, VHC-50

WARNING

Improper installation, adjustment, alteration, service or

maintenance can cause injury or death. Read the installation, operation and maintenance instructions in this

appendix thoroughly before installing or servicing this

equipment.

IMPORTANT

The use of this appendix is specically intended for a

qualied installation and service agency. A qualied installation and service agency must perform all installation and

service of these appliances.

MAMM-VHC-IOM-1A (January 2013)

Table of Contents

Table of Contents .................................................................................................................................................................2

Nomenclature .......................................................................................................................................................................3

Safety Considerations ..........................................................................................................................................................4

General Information ..............................................................................................................................................................4

Unit Application Limitations ............................................................................................................................................4

Installation ............................................................................................................................................................................4

Unit Location Requirements ...........................................................................................................................................4

Roofcurbs Supplied by Mammoth (External Applications Only) ..................................................................................... 5

Roofcurbs Supplied by Others .......................................................................................................................................6

Rigging and Placing the Unit ..........................................................................................................................................6

Field Fabricated Ductwork ..............................................................................................................................................6

Hood Installation .............................................................................................................................................................7

Access Panels ................................................................................................................................................................ 7

Internal Packaging ..........................................................................................................................................................7

Electrical Connections .................................................................................................................................................... 8

Water Source Heat Pump (WSHP) Water Piping and Connections .............................................................................10

Condensate Drain Trap ................................................................................................................................................10

Start-up ...............................................................................................................................................................................11

Pre Start-up Procedure ................................................................................................................................................11

Start-up Procedure .......................................................................................................................................................11

Optional Controls and Accessory Sequence and Interlocks ........................................................................................12

Frost Control .................................................................................................................................................................13

Airow Balancing .......................................................................................................................................................... 14

Service................................................................................................................................................................................15

Quarterly Maintenance .................................................................................................................................................15

Annual Maintenance .....................................................................................................................................................15

Coils .............................................................................................................................................................................15

Testing and Replacement of the Damper Actuator ......................................................................................................16

Motor and Blower Removal – Down, Side and End Supply/Exhaust ...........................................................................16

Motor and Blower Service – Down, Side and End Supply/Exhaust .............................................................................16

Belt Tension Adjustment ..............................................................................................................................................17

Plenum Fan and Motor Removal ..................................................................................................................................17

Plenum Fan and Motor Service .................................................................................................................................... 18

Cassette Removal ........................................................................................................................................................18

Cassette Service ..........................................................................................................................................................19

Appendix A: Service Clearance Dimensions ...................................................................................................................... 20

Appendix B: Hood Installation ............................................................................................................................................21

Appendix C: Rigging Drawing.............................................................................................................................................22

Appendix D: Equipment Data .............................................................................................................................................23

Appendix E: Electrical Data ................................................................................................................................................ 24

Appendix F: Terminal Control Diagrams ............................................................................................................................27

Appendix G: Standard Field Wiring (FW) Terminals ..........................................................................................................30

Appendix H: VHC-36, 42 and 50 Start-up Report and Checklist ........................................................................................ 31

Appendix I: Troubleshooting ...............................................................................................................................................35

Appendix J: Electric Heating Coil and Controls Information ............................................................................................... 37

Appendix K: Water Line Field Mounted Options and Accessories .....................................................................................39

Appendix L: Enthalpy Wheel Pressure Drop vs. Flow Formulae and Curves ...................................................................47

Manufacturer reserves the right to discontinue or change specications or designs without notice or obligation.

MAMM-VHC-IOM-1A (JANUARY 2013)

2

Nomenclature

VHC-XX

Ventilator

with heating

and cooling

Nominal wheel

diameter

– 36

– 42

– 50

©Mammoth Inc. 2012. All rights reserved throughout the world.

Illustrations cover the general appearance of Mammoth products at the time of publication and Mammoth reserves the

right to make changes in design and construction at any time without notice.

™® The following are trademarks or registered trademarks of their respective companies: Tefzel from DuPont.

MAMM-VHC-IOM-1A (JANUARY 2013)

3

Safety Considerations

!

!

!

Warning, Caution and Important notes appear throughout

this manual in specic and appropriate locations to alert Installing Contractors and maintenance or service personnel

of potential safety hazards, possible equipment damage or

to alert personnel of special procedures or instructions that

must be followed as outlined below.

WARNING

Identies an instruction which, if not followed, might cause

serious personal injuries including possibility of death.

CAUTION

Identies an instruction which, if not followed, might severely damage the unit, its components, the assembly or

nal installation.

General Information

These ventilators can provide 100% outdoor air ventilation or, depending on options selected, varying amounts of

recirculation between the exhaust and supply airstreams.

The VHCs use an enthalpy wheel for total energy recovery which provides superior efciency in hot and humid

climates. These models are also effective in cold climates

and use various types of frost control or defrost to ensure

IMPORTANT

Indicates supplementary information needed to fully complete an instruction or installation.

Hazards may exist within this equipment because it contains electrical and numerous moving components. Only

qualied service personnel should install or service this

equipment. Untrained personnel may perform basic maintenance such as maintaining lters. Observe precautions

marked in literature and on labels attached to the unit. Follow all safety codes.

WARNING

Disconnect the main power switch to the unit before performing service or maintenance. Electric shock can cause

personal injury or death.

proper operation when the outside temperatures are extremely low. Units intended for rooftop installations must

be installed on a factory or eld supplied roofcurb. This

manual contains information on optional components that

may or may not be included with this unit. Refer to the submittals for options that pertain to this unit.

Unit Application Limitations

WARNING

Mammoth equipment is not designed to be used for temporary heating, cooling and/or ventilation during construction.

Using Mammoth units for temporary ventilation during

construction constitutes a violation of Mammoth warranty

terms which indicate that the unit warranty would be void

“…if equipment is misapplied or if any alterations are made

to the basic design or operating requirements as listed

on the original order and shipped from the factory unless

Installation

Unit Location Requirements

Consult local building codes and electrical codes for special installation requirements and note additional requirements listed in this manual. In choosing the installation

location of the unit, consider the following factors:

approval is received in writing from Mammoth” Fine dust,

larger particulate matter, solvents, varnishes and other

chemicals may cause lter clogging and elevated cabinet

pressures, higher power consumption and possible irreparable damage to the desiccant material of the enthalpy

wheel, which could reduce energy recovery performance of

the wheel and also reduce the heat transfer effectiveness

of other components. Potential damages include, but are

not limited to, these examples.

• The unit should be installed to allow easy access for

maintenance and for systems operation. See the service clearance dimensions in Appendix A.

• When possible, mount the unit over an unused area

such as a hallway. Although fans and motors are

mounted on vibration isolators or are dynamically

MAMM-VHC-IOM-1A (JANUARY 2013)

4

balanced, the unit will be even less perceptible if positioned away from busy ofces.

• Locate the unit in an area requiring the least amount

of ductwork and direction changes to allow optimum

performance, to reduce pressure loss and to use less

electricity to achieve proper ventilation. Ductwork

must be in accordance with ducting mechanical rules

to prevent sound issues and system effects.

• The fresh air intake hood must be positioned away

from sources of contamination such as hot chimneys

or kitchen exhaust vents.

• Fresh air intake must also be positioned in a direction

opposite to that of prevailing winds to reduce entry of

snow or rain.

• The unit should be mounted on a level foundation to

allow condensation to ow into internal drains. The

foundation must provide adequate continuous support

to minimize deection of the unit base frame to not

more than 1/16” [1.6 mm] over entire length. In addition to these recommendations, a Structural Engineer

Roofcurbs Supplied by Mammoth (External Applications Only)

must be involved to properly size supporting structural

elements.

• When mounting the unit indoors, if drain connections

are required, mount the unit on a housekeeping pad

of sufcient height to allow for drain trap height and

condensate lines to slope toward the building drain.

• When mounting the unit on a roofcurb check the

height from the nished roof to the bottom of the

intake hood. Consult with Local Authorities or your

building code for minimal intake hood height for the

water-tight height from and above the nished roof

and in snow prone areas, the buildup of snow, to determine the height of the roofcurb. Mammoth optional

roofcurbs measure 18” [457 mm] in height. If additional height is required from the nished roof to the

top of the roofcurb, to the bottom of the intake hood

or if other than level, custom height roofcurbs must be

ordered.

Roofcurbs supplied by Mammoth should be mounted as

follows:

• The roofcurb is shipped knocked-down with assembly

hardware and instructions provided. The roofcurb

must be eld erected, assembled and set in place by

the Installing Contractor.

• Roofcurb dimensions are submitted with the unit mechanical drawings which can also be found in the unit

control panel pocket or by calling Technical Support

personnel from the Mammoth factory.

• After the roofcurb has been assembled, ensure that

the roofcurb dimensions suit the unit for which it is

designated.

• The cross members must be positioned as per the

roofcurb drawing to properly support the ductwork

plenums for bottom vertical return and supply connections and for stability.

• Ensure that the assembled roofcurb is square, plumb

and level to within 1/16” [1.6 mm] over the entire

length. The building structure must provide continuous structural support to the full perimeter of the

roofcurb and all cross members requiring support.

The roofcurb may be shimmed as required to provide

continuous support.

• The roofcurb must be fastened to the building structure.

• The Installing Contractor is responsible for making the roofcurb water-tight by caulking all roofcurb

joints.

IMPORTANT

The following items must be completed prior to setting the

unit on the roofcurb:

• The roofcurb roong must be completed including

insulation, cant strip, ashing and counter-ashing.

• Vertical ductwork must be attached to the roofcurb

cross members and building structure, not to the

unit. See the mechanical drawings for information on

roofcurb installation, recommended ductwork attachment and dimensions.

• If there is no building roof access underneath the

unit and drain or piping connections must be made

(in the roong), it is recommended to do so before

unit installation using the appropriate materials provided by the Installing Contractor.

• Remove the length of 3/8” x 1½” [9.5 mm x 38 mm]

polyvinyl gasket strip with adhesive backing supplied

with the unit and apply a continuous strip to the top

perimeter of the roofcurb and duct opening connections for an air and water-tight seal.

IMPORTANT

The gasket between the unit and the roofcurb is critical for

an air and water-tight seal. An improperly applied gasket

can result in air and water leakage and poor unit performance. Position the unit with equal spacing all around between the roofcurb and inside unit base rail using ½” [13

mm] wood shims as it is being lowered.

MAMM-VHC-IOM-1A (JANUARY 2013)

5

Roofcurbs Supplied by Others

Roofcurbs supplied by others must be designed with the

same dimensions and cross member arrangement as per

Mammoth roofcurb drawings and must be designed to

evenly withstand perimeter and cross section static loads.

Rigging and Placing the Unit

Inspect the equipment exterior and interior for damage

and for shipped loose parts. Ensure there is no damage to

internal components such as fans, motors, dampers, enthalpy wheel, insulation and structures. File a claim with the

shipping company if the unit is damaged. Check the packing slip against all items received. If any items are missing,

sign the carrier’s bill of lading with the notation “Shipment

Received Less Item #___.”

IMPORTANT

The hoods for these units are not installed from the factory and must be installed on site. They should be installed after the unit is installed. Hoods are shipped on top

of the unit. When rigging the unit, make sure the hoods

are secured and are not damaged by the spreader bars.

See Appendix B for hood installation.

IMPORTANT

Mammoth is not liable for any damages, costs or other issues arising from roofcurbs supplied by others.

Spreader bars are required to prevent damage to the roof

ange. Rollers may be used to move the unit across the

roof. Lifting holes are provided in the base rails as shown in

Appendix C. Refer to submittal documents for overall unit

dimensions and Appendix D for unit weights.

CAUTION

All panels must be in place when rigging.

Field Fabricated Ductwork

On vertical discharge units, secure all ducts to the roofcurb

and building structure. Do not secure ductwork to the unit.

For unit and duct opening sizes see submittal drawings.

Insulate and weatherproof all external ductwork, joints and

roof openings with counter-ashing and mastic in accordance with applicable codes. Ductwork running through

roof decks must comply with local re codes. Ducts passing through unconditioned spaces must be insulated and

covered with a vapor barrier. Flexible connectors should

be installed close to the unit in the duct leading to occupied

spaces to minimize noise transmission.

Duct Design Considerations

The discharge ductwork immediately downstream from the

fan is critical for successful applications. Poorly designed

ductwork can degrade fan performance and contributes to

excessive pressure drop and noise.

When designing ductwork in the eld, it is important to

use a straight discharge duct of the correct dimensions to

obtain maximum fan performance. The straight section of

ductwork helps the airow to develop a uniform velocity

prole as it exits the fan and allows the velocity pressure to

recover into static pressure. See Figure 1.

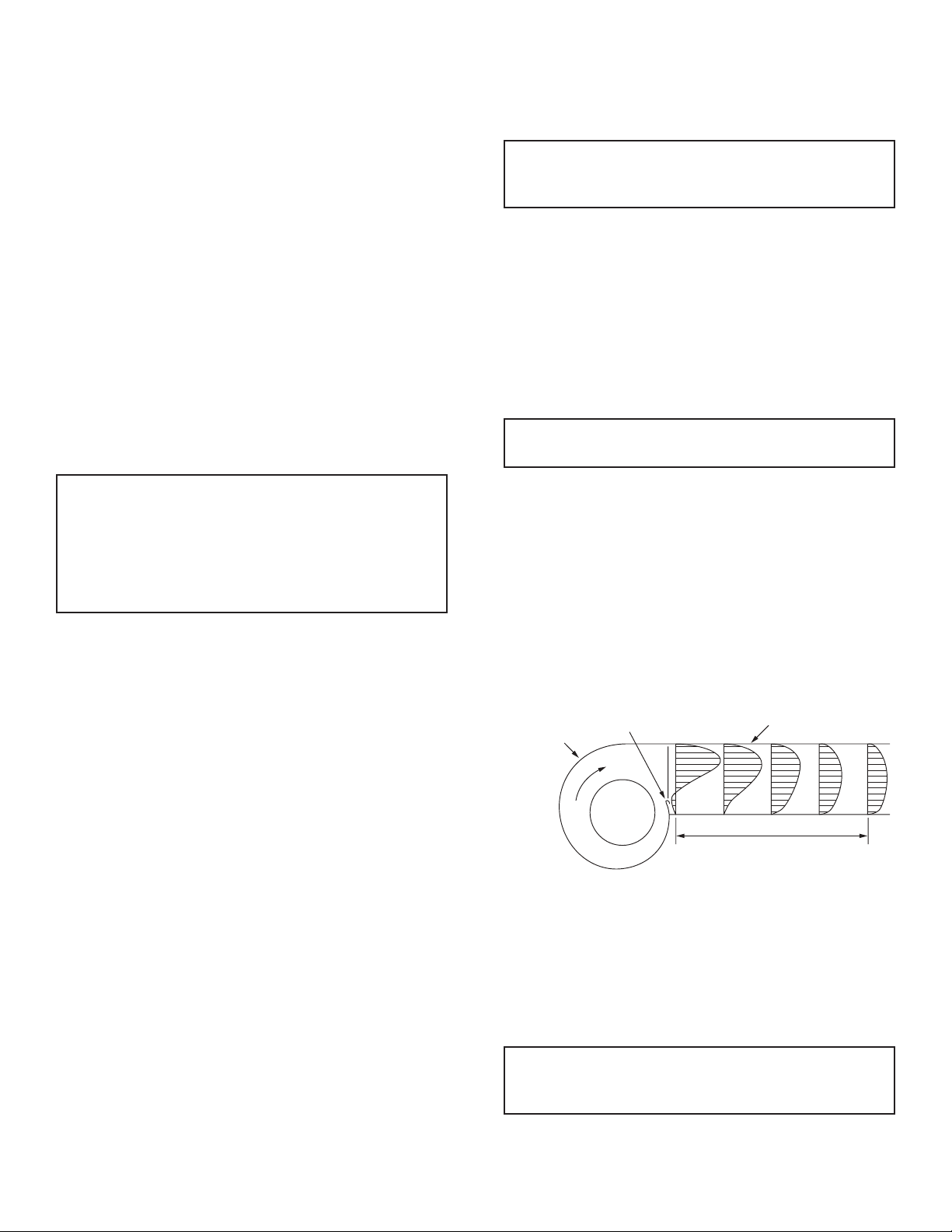

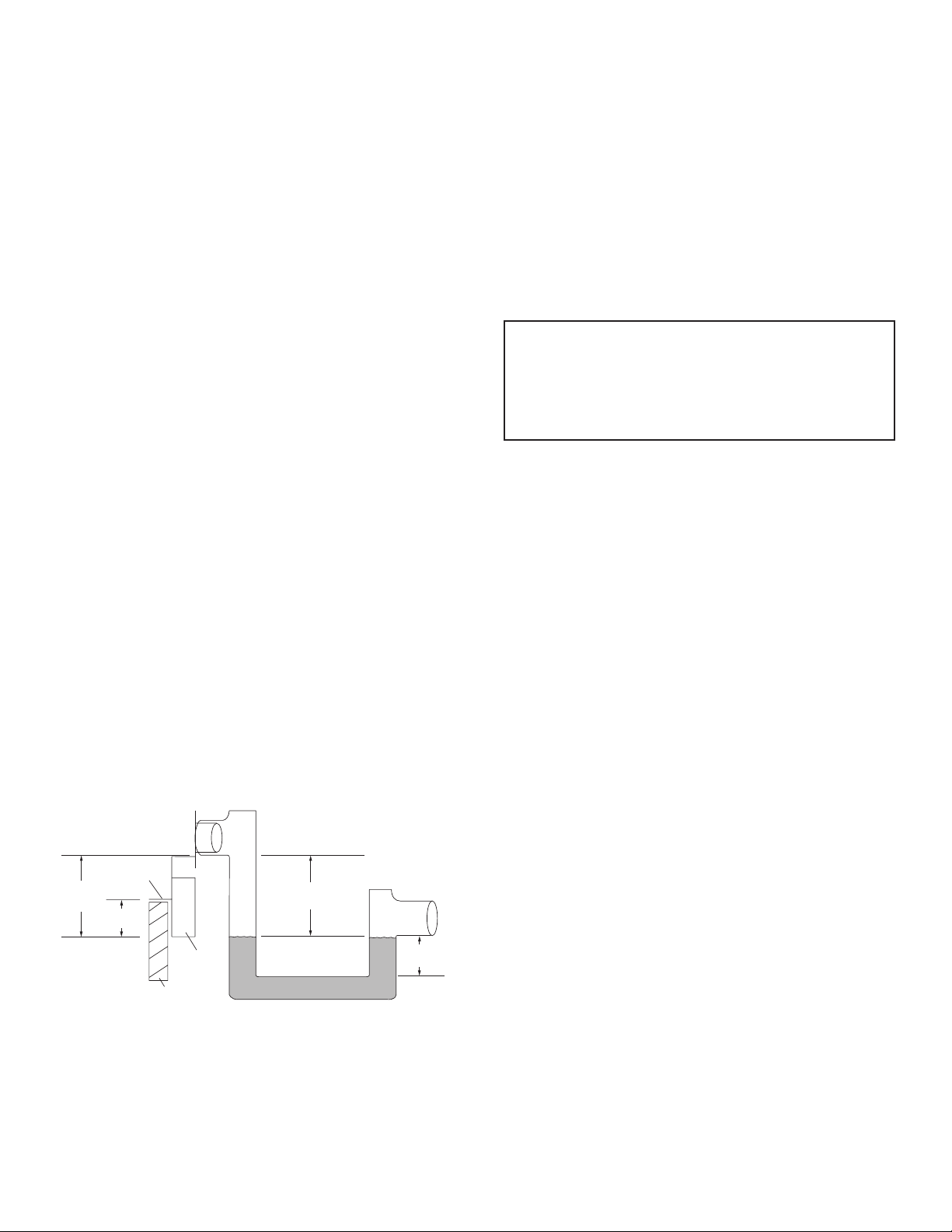

Centrifugal fan

Figure 1: Duct design

For 100% recovery of velocity pressure into static pressure, the straight portion of the discharge duct must be at

least 2.5 times the discharge diameter to the length of the

straight portion of ductwork.

As an example of how to size the straight portion of duct,

assume the fan has a 13.5”x 9.5” discharge outlet = 0.89

Cutoff

100% effective duct length

2½ diameters at 2,500 FPM

Discharge duct

IMPORTANT

This information is referenced from AMCA Fans and Systems Publication 201.

ft2.

MAMM-VHC-IOM-1A (JANUARY 2013)

6

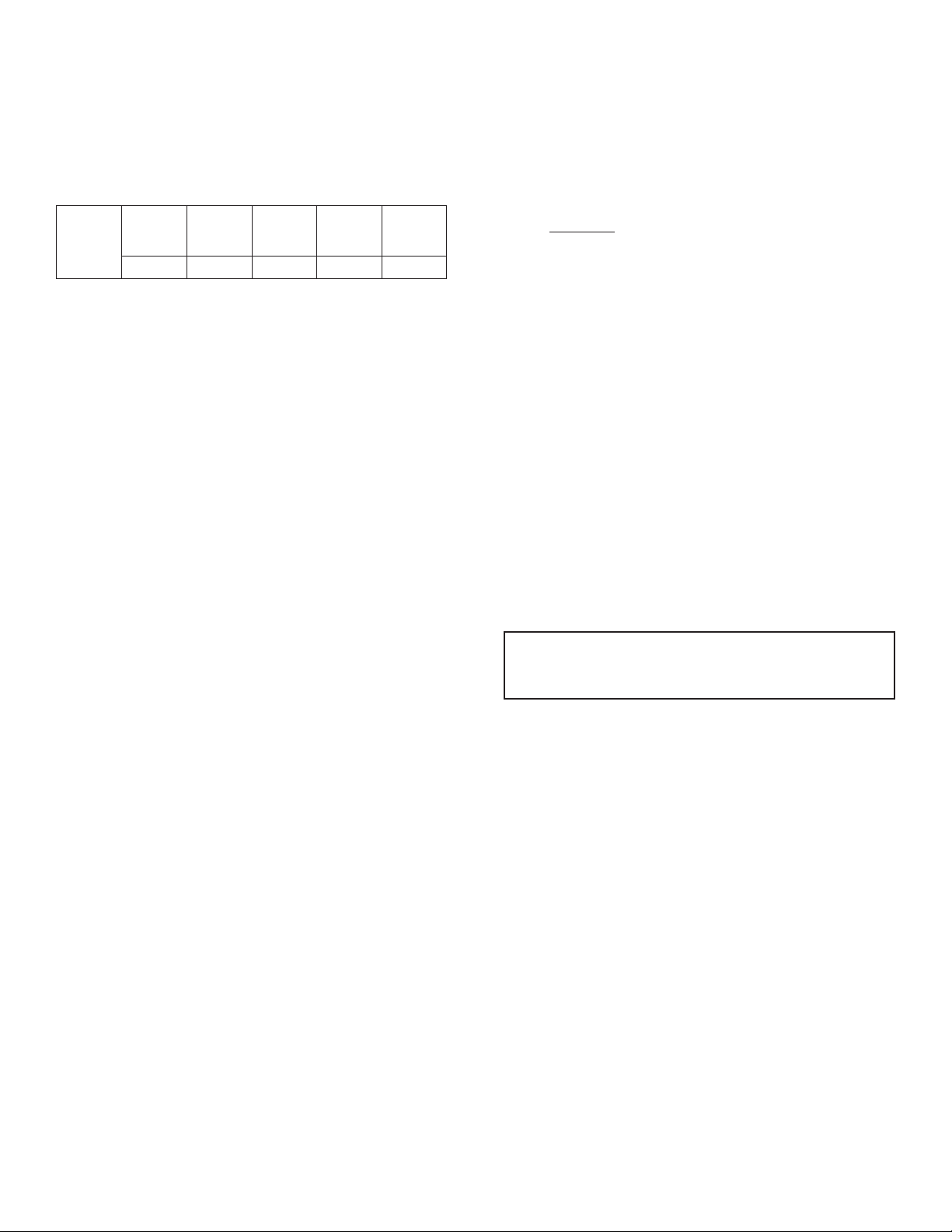

Refer to Table 1 for the effect of undersized equivalent duct

diameter.

Table 1: Effect of Undersized Equivalent Duct Diameter

Pressure

recovery

12%

No Duct

Effective

Duct

0% 50% 80% 90% 100%

25%

Effective

Duct

50%

Effective

Duct

100%

Effective

Duct

Hood Installation

Calculate Equivalent Duct Diameter

The equivalent duct diameter of the fan outlet.

= (4ab + n)

= (4 x 13.5 x 9.5)

n

= 12.75

= ~13

So the straight duct length required would be:

= 2.5 x 13

= 32.5” long [2.7 feet]

0.5

0.5

Intake and exhaust hoods for these models are shipped

separately from the unit. To install hoods see Appendix B.

A quick connect for the damper motors is provided to con-

Access Panels

Handles for lift off exterior access panels with screw door

fasteners are provided but must be installed on site. Handles and fasteners are secured inside the unit.

Internal Packaging

Open access doors or panels and remove all packaging

from the unit. Note that there is packaging for wheel support during shipping. Removal of all packaging is critical.

nect to the main body of the unit. Make sure that all screws

are secured to maintain proper support and keep seals

water-tight.

IMPORTANT

Securing door fasteners too tightly has negative effects on

the door gasket and should be avoided.

MAMM-VHC-IOM-1A (JANUARY 2013)

7

Electrical Connections

!

WARNING

When installed, the appliance must be electrically

grounded in accordance with local codes or, in the absence of local codes, with the National Electrical Code,

ANSI/NFPA70, and/or the Canadian Electrical Code CSA

C22.1. Unit cabinet must have an uninterrupted, unbroken

electrical ground to minimize the possibility of personal

injury if an electrical fault should occur. Failure to follow

this warning could result in the Installer being liable for

personal injury of others.

Power Supply

Units are available in all voltages and phases. Please see

Appendix E for electrical data. These units may or may not

have a factory installed disconnect switch. If disconnect is

eld supplied, provide a disconnect as per local electrical

codes and NEC. Use copper conductors only.

All eld wiring must comply with NEC and local requirements. In Canada, electrical connections must be in accordance with CSA C22.1 Canadian Electrical Code Part One.

Units equipped with electric preheaters and/or post heaters

have either single-point or two-point power connections.

See Appendix E, submittal data and/or nameplate to de-

termine which. All units equipped with two-point electric

heaters require two-point power connection—one to the

unit control panel and one to the electric heater fed from a

single eld supplied disconnect.

Field Connection

A high voltage connection hole is located on the outside of

the unit with knock-out; see submittal drawings for location.

A eld installed disconnect switch must use a liquid-tight

connector between the disconnect switch and the outside

panel of the unit eliminating any water penetration into the

control box. A wiring diagram is located within the control

panel area of the unit.

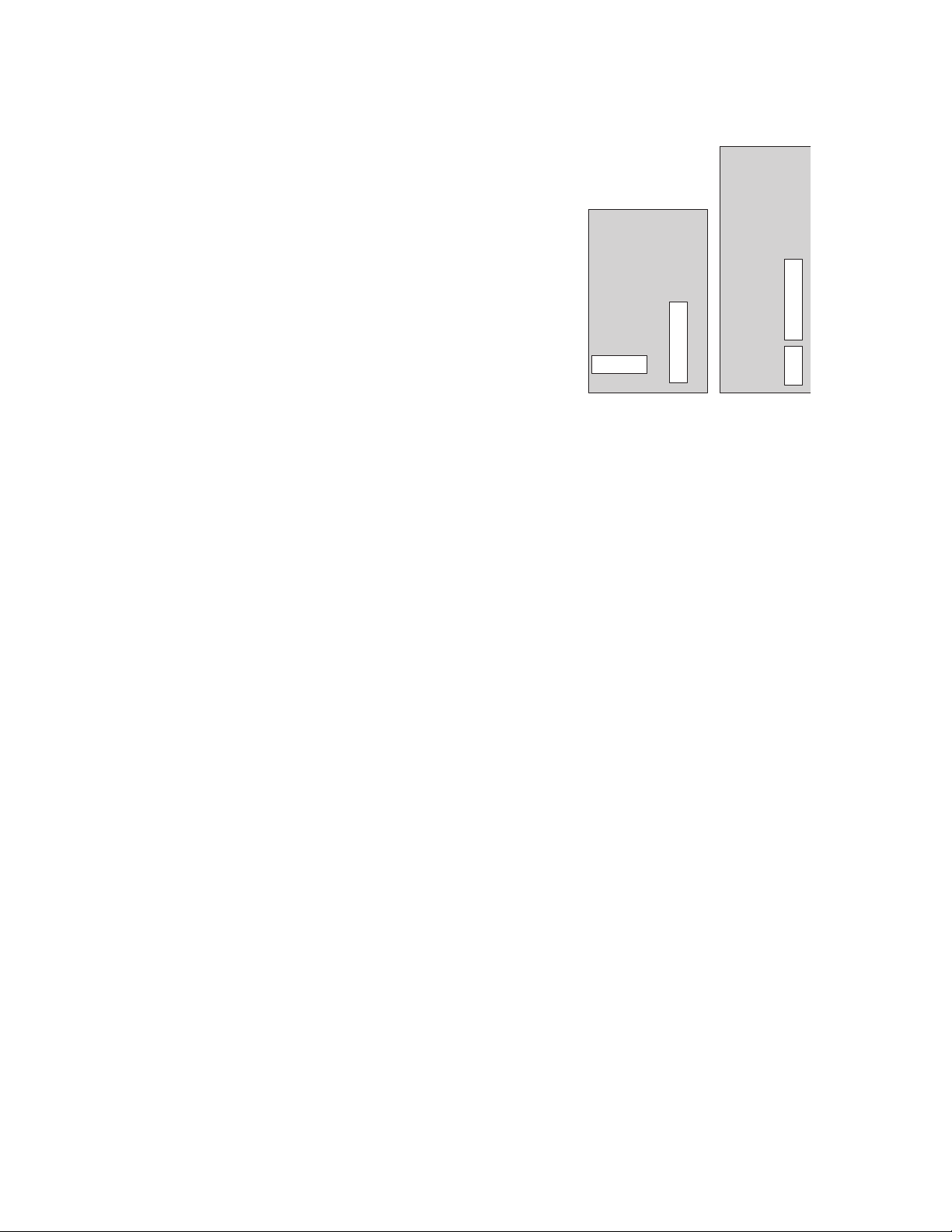

A low voltage Field Wiring (FW) interface is provided near

the control Panel (PNL) terminals for shipped loose or eld

supplied controls, sensors or interlock connections. The

location of the eld wiring and panel terminals may vary

depending upon options selected as illustrated in Figure 2.

The low voltage eld wiring entry is made through the side

of the unit below the input power supply connection (see

Appendix G) which runs through the outside casing and

requires a liquid-tight connector or conduit to avoid water

penetration.

Installer must provide wiring for controls that are supplied

optionally and shipped loose or eld supplied. All eld supplied low voltage wiring must be Class 2. Mark the Field

Wiring terminals schematic (Appendix G) with the connections completed and leave with the unit for start-up and

service.

Units will require a start contact interlock from a remote

time clock, light sensor, occupancy sensor, manual selector switch or remotely through BACnet from a Building

Management System (BMS) depending on ventilation

control scheduling mode required. Select required interlock and ventilation control scheduling mode from description below.

See Appendix F and Appendix G for wiring terminal con-

trol diagram examples and standard Field Wiring (FW) terminal and interlock connections available.

Units Supplied with DDC Control Package

The DDC control package enables stand alone operation of the VHC unit and includes a factory installed, programmed and run tested stand alone microprocessor

based controller, all necessary sensors and interfaces to

provide control of optional post conditioning functions. See

the VHC-36, 42 and 50 DDC Control Package Manual

(VCES-DDC-IOM-1 (500020459)) for overview, installation

and start-up.

An intelligent programmable interface device (BacStat II)

with built in room sensor is included for communication,

display, setpoint control and to allow for servicing and is

shipped loose for eld wiring and installation at the unit or

remotely. Determine required location for installation and

connect using two twisted pair cables, the rst for power

connection. The LinkNet cable needs to be balanced 100

to 120 ohm nominal impedance twisted shielded pair cable,

nominal capacitance of 16 PF/FT or lower.

Units Supplied with an Electro-mechanical

Controls (EMC) Package

The EMC controls package or dry contact control option

include: all relays, motor starters, motor overloads, damper

actuators, heating and cooling initiate contacts and selected option pickup points. All necessary connections are

wired to a terminal strip in the control panel for eld wiring

connections to a Building Management System (BMS), for

eld supplied DDC or standard controls and thermostats.

See the Control Contractor’s ow and wiring schematics

for connection details.

Ventilation Control Scheduling Modes

Occupied Ventilation (Ov)

If the occupancy contact closes or a jumper is placed

across terminals FW 304–305 this will enable the unit to

run in 100% fresh air mode. Free cooling and defrost will

initiate based on the setpoint.

Unoccupied Recirculation (Ur)

If the unoccupied recirculation contact closes or a jumper

is placed across terminals FW 305–306 the unit will turn off

unless there is a call for heating/cooling or dehumidication

across the heating/cooling or dehumidication contacts.

MAMM-VHC-IOM-1A (JANUARY 2013)

8

This must come from an optional thermostat or humidistat.

The unit will run in recirc mode upon a call.

Occupied Recirculation (Or) (DDC Control Package

only)

If the occupied recirculation contact closes or a jumper is

placed across terminals, heat wheel starts (not in free cooling), defrost recirculation damper closes (if equipped), outside and exhaust air dampers (if equipped) begin to open;

after outside air damper opens fully the supply blower

starts; after exhaust air damper opens fully the exhaust

blower starts, the occupied recirculation damper opens and

outside and exhaust dampers modulate to the minimum

setpoints.

Unoccupied (Un)

If the contact opens or jumper removed on any of the terminals 304, 305, 306, 307 or 308 the unit will turn off.

PNL

PNL

FW

FW

Figure 2: Possible terminal strip locations in electrical panel

MAMM-VHC-IOM-1A (JANUARY 2013)

9

Water Source Heat Pump (WSHP) Water Piping and Connections

[76 mm]

Before connecting piping to the unit, the water supply line

and return line must be ushed to eliminate the foreign

material. In low temperature applications, the water supply

line and return line should be insulated to prevent condensate and antifreeze solution should be used to protect

water-to-refrigerant heat exchanger from freezing damage.

See submittal drawings for water piping connection location. The concentration of water/glycol solution depends

on the eld application. On open loop systems, a water

strainer (16–20 mesh minimum, 20–40 mesh best) is recommended to be installed in the water inlet line to the unit

to eliminate contaminants and it must be used for units

having water-to-refrigerant brazed plate heat exchanger.

A water ow switch is recommended to be installed in line

to prevent possible freeze-up due to loss of water ow.

An air vent must be installed on the high side of the water

line to discharge the non-condensable air in order to avoid

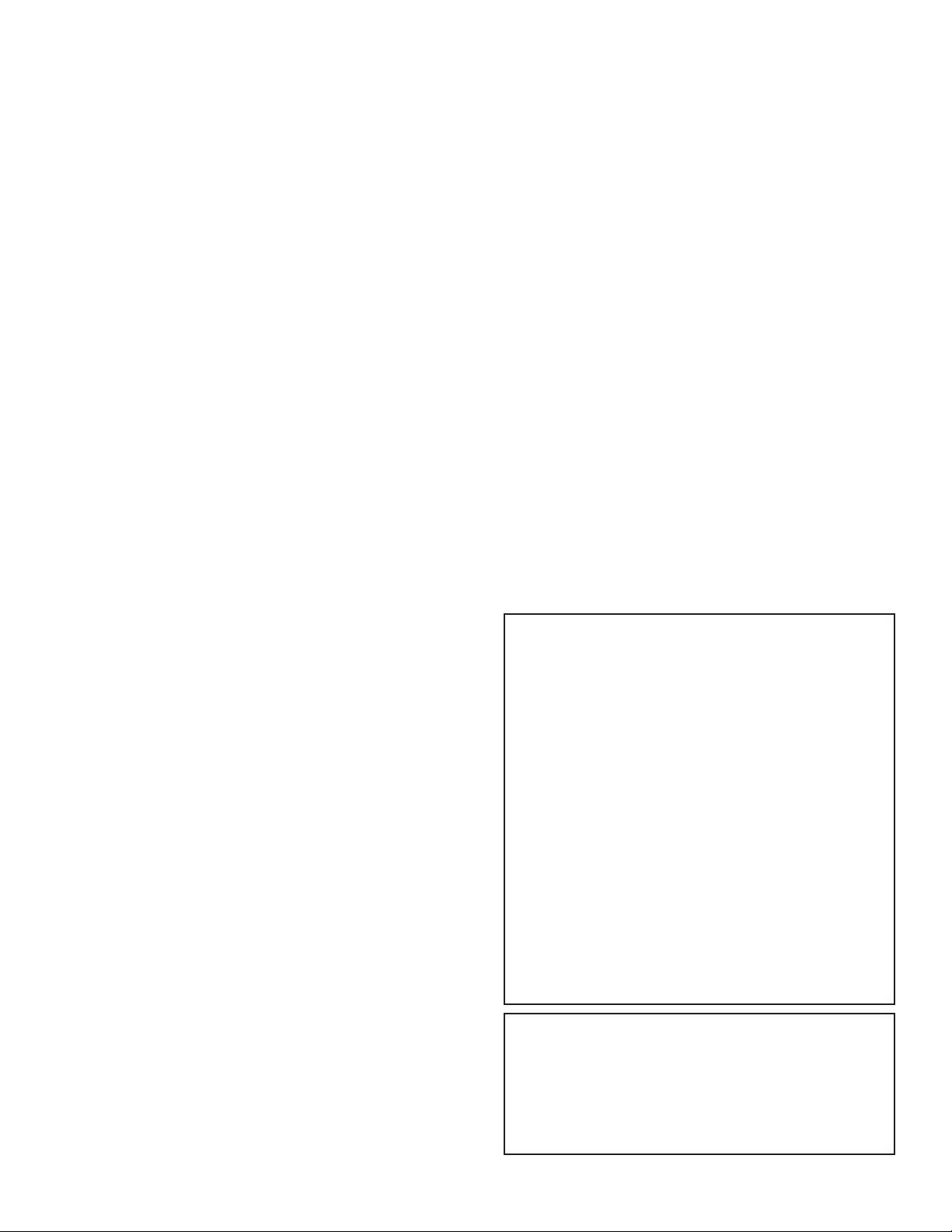

Condensate Drain Trap

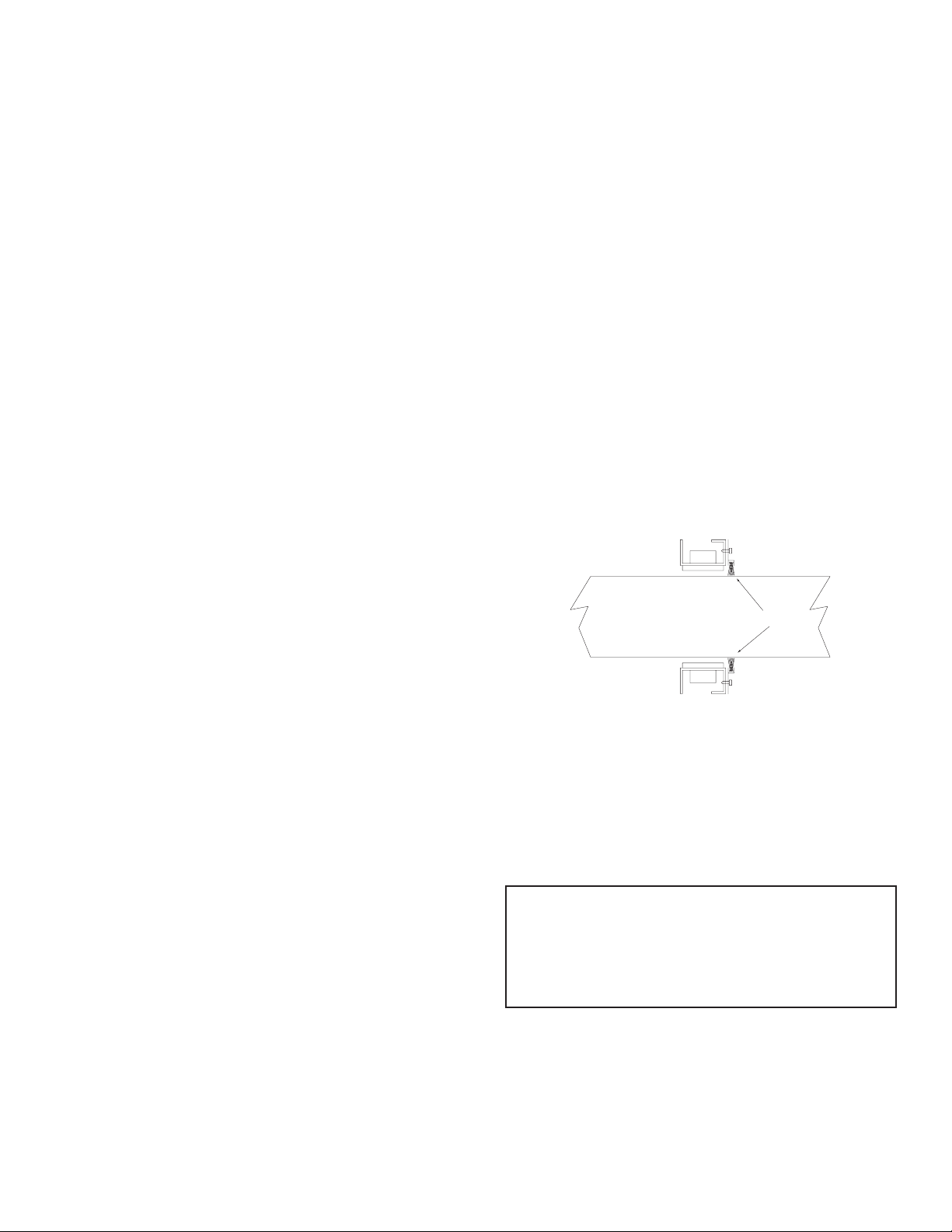

Cooling coil drain pan is provided with a 1¼” MPT drain

connection. A drain trap and condensate line of equal size

must be eld provided on the drain connection to prevent

air or sewer gases from being pulled into the unit caused

by the negative (suction) pressure and forcing water out of

the pan into the unit.

A label with recommended trap height is provided on the

unit as per Figure 3.

Condensate drain must be trapped as shown.

Refer to IOM for further instructions and maintenance.

Le drain de condensation doit être fabriqué et intallé tel que

le croquis ci-bas. Voir le manuel d’installation,

opération et maintenance pour instructions.

Curb

6.578”

[167.08 mm]

support

3.375”

[85.73 mm]

6.0” [191 mm]

minimum

unexpected high head pressure and poor cooling/heating

performance. Manual shut-off valves are recommended to

be installed for the convenience of future service.

A circuit balancing valve with pressure and temperature

gauge connections is recommended to be installed in the

water line for balancing and service.

See Appendix K for water line eld mounted options and

accessories.

CAUTION

In areas where scaling can become serious, a periodic

cleaning for the water-to-refrigerant heat exchanger is

recommended. Standard water coil cleaning procedure

should be followed which must be done by a qualied service mechanic.

The trap height allows for the maximum suction pressure

after the cooling coil with intake damper, dirty pre and nal

high efciency lters, high efciency heat wheel plus 1” w.c.

per ASHRAE guidelines for outdoor units with intake hood

or indoor unit with up to 0.5” w.c. external static intake duct.

Slope the drain lines downward in direction of ow 1/8 inch

per foot referring to local codes for proper drainage requirements. Installing a plug for cleaning of the trap is recommended. Prime the trap by lling with water before start-up.

Winterize the drain line before freezing on outdoor units.

Check and clear drains annually at start of cooling season. Drainage problems can occur should drains be inactive and dry out, or due to reduced water ow caused

by buildup of algae. Regular maintenance will prevent

these from occurring.

Unit baserail

Curb

Figure 3: Condensate drain trap label

MAMM-VHC-IOM-1A (JANUARY 2013)

3.0”

minimum

PN 500005436

10

Start-up

Pre Start-up Procedure

Before requesting start-up, check that the installation is

complete and unit is ready. Complete the pre start-up

check list below and in the Appendix H for each unit as

items are checked.

1. Set the electrical disconnect to the ‘Off’ position.

2. Check the unit for obstructive packaging, objects near

or in blowers, dampers, heat wheel, etc. Remove all

red tie down bolts on fan assemblies and heat wheel if

so equipped.

3. Check that the fans and heat wheel are rotating

freely.

4. Check blower wheels and drive set screws. Tighten if

required.

5. Check belt alignment and tension.

6. Check that the air lters are installed and clean. Replace if necessary.

7. Check coils (if equipped) if ns have been damaged

in transit or construction and are clean. Straighten ns

with n comb and clean coil if required.

8. Check the refrigerant components and piping that they

are in good condition and have no damage or leaks

from shipping or installation.

9. Check that the water strainer has been installed for a

WSHP with a brazed heat exchanger.

10. Check that ductwork is connected and complete.

11. Check that condensate drain connections have been

trapped, installed correctly and lled.

12. Check that all shipped loose or eld supplied components have been correctly installed and wired and that

start interlocks have been completed for the ventilation

control desired.

13. Check that the standard eld wiring (FW) terminal

diagram has been marked up accordingly and left with

the unit.

14. Check that all power supplies and control wiring have

been inspected and approved by the Local Authorities

having jurisdiction.

15. Check all factory and eld wiring connections for tightness. Tighten if necessary.

16. Check that all fuses are properly installed in holders.

17. Check the voltage at the disconnect switch against the

nameplate and against phase-to-phase readings on

three-phase. If the voltage is not within 10% of rated

or 2% of phase-to-phase, have the condition corrected

before continuing start-up.

18. Check that all eld piping and venting installation and

connections for the heating and cooling options have

been completed and test.

19. Set the heating and cooling enable switches to the

‘Off’ position.

Start-up Procedure

To ensure proper operation of each unit, qualied personnel should perform the start-up and complete the checklist

below and the start-up report in Appendix H for permanent

record. A completed checklist will provide valuable information for personnel performing future maintenance.

IMPORTANT

A completed copy must be sent back to the factory for

warranty validation and for factory assistance.

All units are factory run tested. Blowers, heat wheel and

compressors (if equipped) are set up to run correct when

power is connected. If any one blower is running backwards or compressor is making loud noises disconnect

power and switch two leads (on three-phase power) to ensure proper rotation and avoid damage.

If units are equipped with compressors power must be

turned on for 24 hours prior to a call for cooling, for the

compressor crank case heaters to be energizing to prevent

possible damage.

The BacStat II interface module (if equipped with DDC control package and mounted remotely) may be temporarily

connected at the unit for checkout. Ensure it is connected

to the Net 2 contacts otherwise it will not give readings.

1. Before proceeding complete the pre start-up checklist.

2. Check that all access panels or doors are closed.

3. Turn the main disconnect to the ‘On’ position.

4. Set the timer, selector switch or BMS contact to the

ventilation control scheduling mode selected and

check operation according to sequence. Only one of

the following modes selected can have their contacts

closed or jumped.

a. Occupied ventilation (Ov): With the occupancy

contact closed or a jumper placed across terminals, heat wheel starts (not in free cooling), defrost recirculation damper closes (if equipped),

outside and exhaust air dampers open fully,

the supply blower starts and after exhaust air

damper opens fully, the exhaust blower starts.

b. Unoccupied recirculation (Ur): With the unoc-

cupied recirculation contact closed or a jumper

MAMM-VHC-IOM-1A (JANUARY 2013)

11

placed across terminals, heat wheel stops,

defrost recirculation damper opens, outside

and exhaust air dampers (if equipped) begin to

close and supply blower starts.

c. Occupied recirculation (Or) (DDC control pack-

age only): With the occupied recirculation

contact closed or a jumper placed across terminals, heat wheel starts (not in free cooling), defrost recirculation damper closes (if equipped),

outside air damper (if equipped) opens. After

outside air damper opens supply blower starts,

exhaust air damper (if equipped) opens; after

exhaust air damper opens, exhaust blower

starts, occupied recirculation damper opens,

outside and exhaust air dampers modulate to

the damper minimum setpoints.

5. Check that dampers are operating properly.

6. Check that blowers and heat wheel are rotating in the

correct direction.

7. For occupied recirculation scheduling mode the outside air and exhaust air dampers must be adjusted

during start-up to achieve the required outside and exhaust air volumes. See Airow Balancing for further

information.

8. Re-check the voltage at the disconnect switch against

the nameplate and against phase-to-phase readings on three-phase with all blowers operating. If the

voltage is not within 10% of rated or 2% of phase-tophase have the condition corrected before continuing

start-up.

9. Check amperage draw to each motor on each

phase against motor nameplate FLA. If signicantly

different, check ductwork static and/or take corrective action.

10. Before activating the compressor on WSHP units, are

water shut-off valves open and is water circulating

through the water-to-refrigerant heat exchanger.

11. Enable cooling and check if the sound of the compressor is normal or if there is excessive vibration.

12. Check all eld and factory refrigerant and water piping

connections for leaks and correct.

13. Enable heating options, see start-up and check out instructions in Appendix J for electric coil and complete.

14. Check the operation of the control options provided

on the unit. A functional description is provided below

and in the VHC-36, 42 and 50 DDC Control Package

Manual.

15. Check the setpoints on the DDC Points Reference,

adjust and record changes as required.

16. When unit has achieved steady state take measurements and complete the readings section of the start-

up report in Appendix H and send copy of the start-up

report to Mammoth to validate warranty. Maintain a

copy of the report at the unit for future reference.

Optional Controls and Accessory Sequence and Interlocks

Free Cooling

Power connected, unit ventilating, free cooling call. Wheel

stops rotating.

Variable Speed Setpoint Free Cooling

Power connected, unit ventilating. Wheel modulates to

keep discharge temperature air at setpoint.

Unit Fault

An external unit fault can be initiated by removing the

dry contact jumper to the eld wire terminal in the control

panel. This contact is normally closed and requires an

open contact to initiate a fault and shut down the unit.

Dirty Filter Sensor

The VHCs can be equipped with dirty lter sensors which

monitor the pressure across the lters and close the contacts when the lters become restricted with dirt. Field

wired connections can be made to the terminal interface

MAMM-VHC-IOM-1A (JANUARY 2013)

for both the supply and exhaust lter sensors (electro-mechanical controls [EMC] units only).

Remote Fan Control

Remote fan control can be achieved by connecting dry

contacts to the terminal interface (during occupied or unoccupied recirculation). These controls could also be the

following: SPDT switch, dehumidistat, CO2 sensor, light sensor, heat sensor, timer, Building Management System, etc.

CO2 Ventilation Control

VHCs can be directly controlled by a CO2 controller (accessory or eld supplied) that can be connected to the supply

and exhaust high speed contact terminals (VFD units only).

As the CO2 levels exceed acceptable limits, dry contacts

close raising high speed fan ventilation. See Appendix F,

CO2 Ventilation Control. Alternatively a eld supplied CO2

controller output can be connected to the BMS which can

then be connected to the supply and exhaust fan modulating signal input terminals (VFD units only). As the CO2

12

levels rise and fall the BMS must modulate the signal to

the supply and exhaust fans to change the ventilation rate

proportionally. See Appendix G. The minimum VFD speed

is factory default set to 40 Hertz.

Smoke Detector

VHCs can be equipped with a duct mount smoke detector

which will monitor the air when passing through the duct

system into the unit. When sufcient smoke is detected, an

alarm condition is activated. By connecting the occupied

terminals to the NC alarm auxiliary contacts on the duct

sensor, an alarm condition will open the auxiliary contact

and stop operation of the VHC. Locate in a normally occupied area of premises. Recommended for compliance to

NFPA-90A and IMC code 606.

Cooling Override (DDC Controls Units Only)

These terminals are available for a room or return air summer thermostat. All thermostats are eld installed and wired.

Dehumidication (DDC Controls Units Only)

IMPORTANT

Removal of dry contacts that close on high speed terminals is required for VFDs to modulate.

These terminals are available for a room or return air dehumidistat. All dehumidistats are eld installed and wired.

Heating Override (DDC Controls Units Only)

These terminals are available for a room or return air winter

thermostat. All thermostats are eld installed and wired.

For standard eld wiring terminals diagram, refer to Appen-

dix G.

Frost Control

During cold temperatures, defrost and frost prevention are

controlled by the unit’s integrated controls as follows.

Preheat will prevent frost formation on the enthalpy wheel

to maintain proper operation and provide continuous ventilation and make-up air. This prevention occurs when a preheater is energized to maintain an outdoor air temperature

higher or when the wheel speed is reduced to maintain an

exhaust air temperature higher than minimum required for

the enthalpy wheel to operate frost free.

The requirement for frost control is based upon the outdoor

air temperature and humidity content of the return air. In

areas where the winter outdoor air condition falls below 5°F

[−15°C] or the return air relative humidity is above 30%,

frost control is probably required.

Preheat Frost Prevention

Preheat frost prevention is an outdoor air temperature

controlled function that allows for continuous ventilation by

ensuring a minimum enthalpy wheel entering air temperature of 5° F [−15°C]. The temperature sensor is located between the open wire electric heating coil and the enthalpy

wheel. The electric heating coil is selectable in 1 kW increments and available in two-stage, four-stage or SCR control. With staged control, one stage cycles to maintain 5°

F [−15°C] temperature to the enthalpy wheel as the other

stages are continuously on as the outdoor air temperature

drops. If the selected kW is insufcient, based upon the

entered design conditions, selection software automatically

adjusts the minimum kW required to maintain the minimum

wheel entering air temperature.

Non-defrost

No frost control is required in areas where the winter outdoor air condition stays above 5°F [−15°C] and the return

air humidity level is below 30%.

MAMM-VHC-IOM-1A (JANUARY 2013)

13

!

Airow Balancing

IMPORTANT

On initial power up, the unit will perform a system check

and operate at high speed for ve seconds.

For proper performance the unit must operate and be

balanced at the design supply and exhaust airow rates.

Permanent or temporarily eld supplied and installed ow

measuring stations (FMS) can be used to measure airow

or by using other ASHRAE suggested methods. Where

space is limited in the outdoor air or exhaust air ducts

for measurements, pressure drop readings can be taken

across the enthalpy wheel rotor and airow extrapolated

from the curves in Appendix L for the wheel effectiveness

category or thickness. Heat recovery performance is tested

in accordance to AHRI Standard 1060 and is accurate to

within +/− 5% if there is no dirt buildup in the heat recovery

wheel rotor.

When FMS are used it is important to locate it in the “warm

side” ductwork to minimize the effects of differences in air

density especially during cold outside conditions. Air density variations can affect the FMS by more than 15%. The

FMS should be located downstream from straight sections

of duct and not immediately after fans or obstructions that

will cause turbulent ow.

coils or reheat to protect building systems must be eld

provided.

Setting Flow Rate

Units supplied with belt driven double width double inlet

fans have an adjustable motor sheave factory set at the

midpoint of travel at rpm for the ow rate and external static

specied. With optional VFD driven motors this factory setting is at 60 Hz. For 100% outdoor and exhaust, ow rate

should be balanced with motors operating at high speed

and at 60 Hz by adjusting the motor sheave pitch diameter.

The VFD can be used for ne tuning depending on sequence.

With the optional direct driven plenum supply fan the VFD

is used for speed setting and balancing at the required

Hertz.

With the optional internal bypass the airow rate may be

reduced. Consult the factory for setting the ow rate during

internal bypass.

WARNING

Disconnect the main power switch to the unit before performing service and maintenance procedures.

Imbalanced airow may cause supply air temperatures

to be below freezing. Adequate freeze protection such as

glycol or low limit temperature protection for downstream

MAMM-VHC-IOM-1A (JANUARY 2013)

14

Service

Quarterly Maintenance

Quarterly maintenance (every three months) should include:

Air Filters

The standard medium efciency lters and optional high efciency lters are disposable and should be replaced every

three months. More frequent replacement may be required

under extremely dirty operating conditions.

To replace the lters, open the lter access door, grasp the

lters and pull straight out. The lters will slide completely

Annual Maintenance

Annual maintenance should include:

Aluminum Enthalpy Wheel

No cleaning of the enthalpy wheel is required as it is

self-cleaning due to the opposing airows. If it is desired

to clean the enthalpy wheel, use low pressure air or a

vacuum. Wash the cassette panels with a soft cloth and

mild cleaning solution. Visually inspect the cassette brush

seals (shown in Figure 4), perimeter seal and drive belt

for proper operation.

out of the unit. Slide the new lters into the frame and close

the lter access door.

Cassette Panels and Interior of Unit

Remove the lters from the unit. Wipe the foil faced insulation, or the optional interior galvanized liner, surfaces

and cassette panels with a soft cloth and mild cleaning

solution.

System Operation Check

Verication of all control modes should be checked to ensure proper operation. Refer to Start-up section.

Rotor

Brush seal

Fans

Blower wheels and fan housing should be checked for dirt

buildup. If they are dirty, it will be necessary to remove the

blower assembly to clean the dust out through the fan mouth.

Dirt on the surface of the coil reduces its ability to transfer

heat which lowers the efciency of the unit, resulting in

poor air quality and expensive operating costs. Because

of the condensate on the coil, the dirt often becomes wet

and contributes to the growth of microbial organisms.

Negligence in maintenance may result in serious health

related indoor air quality problems.

The coil should be kept clean for maximum performance.

To achieve maximum efciency, clean the coil often during

periods of high demand or when dirty conditions prevail.

Mammoth recommends cleaning the coil a minimum of

once per year to prevent dirt buildup in the coil ns where

it may not be visible.

Coil ns can be cleaned by using steam with detergent, hot

water spray or a commercial chemical coil cleaner. After

cleaning the coil, be sure to rinse thoroughly.

Figure 4: System operation check

Coils

Cleaning Procedure

CAUTION

Do not use acidic chemical coil cleaners. Do not use alkaline chemical coil cleaners with a pH value greater than

8.5 or lower than 6 (after mixing) without using an alu-

minum corrosion inhibitor in the cleaning solution. Using

these types of cleaners may result in unit damage.

1. Shut down the unit by closing the main disconnect

at the power inlet.

2. Open panels or doors to gain access to both sides of

the coil section.

3. Remove soft debris from both sides of the coil with a

soft brush.

MAMM-VHC-IOM-1A (JANUARY 2013)

15

Loading...

Loading...