Single Circuit Horizontal and Vertical

Water Source Heat Pumps With R-410A

Installation, Operation and Maintenance Manual

Sizes: 009 to 072 — Horizontal

012 to 072 — Vertical

Model: U Vintage

MAMM-WSHP-IOM-1UB (September 2011)

P/N 71144909

Table of Contents

Model Nomenclature ·················································································································· 3

Transportation and Storage ········································································································ 3

Installation ·································································································································· 4

Discharge Conversion—Horizontal Units ··················································································· 4

Unit Location and Clearances ···································································································· 5

Unit Mounting ····························································································································· 6

Ductwork and Attenuation ·········································································································· 7

Ventilation Air ····························································································································· 7

Piping ········································································································································· 8

Cleaning and Flushing ················································································································ 9

Start-up····································································································································· 10

Operating Limits ······················································································································· 11

Controls ···································································································································· 12

I/O 560 ····································································································································· 12

I/O 583 ····································································································································· 14

I/O 6126···································································································································· 16

General Maintenance ··············································································································· 19

Troubleshooting ························································································································ 20

Performance Troubleshooting ································································································· 21

Unit check-out sheet ················································································································ 22

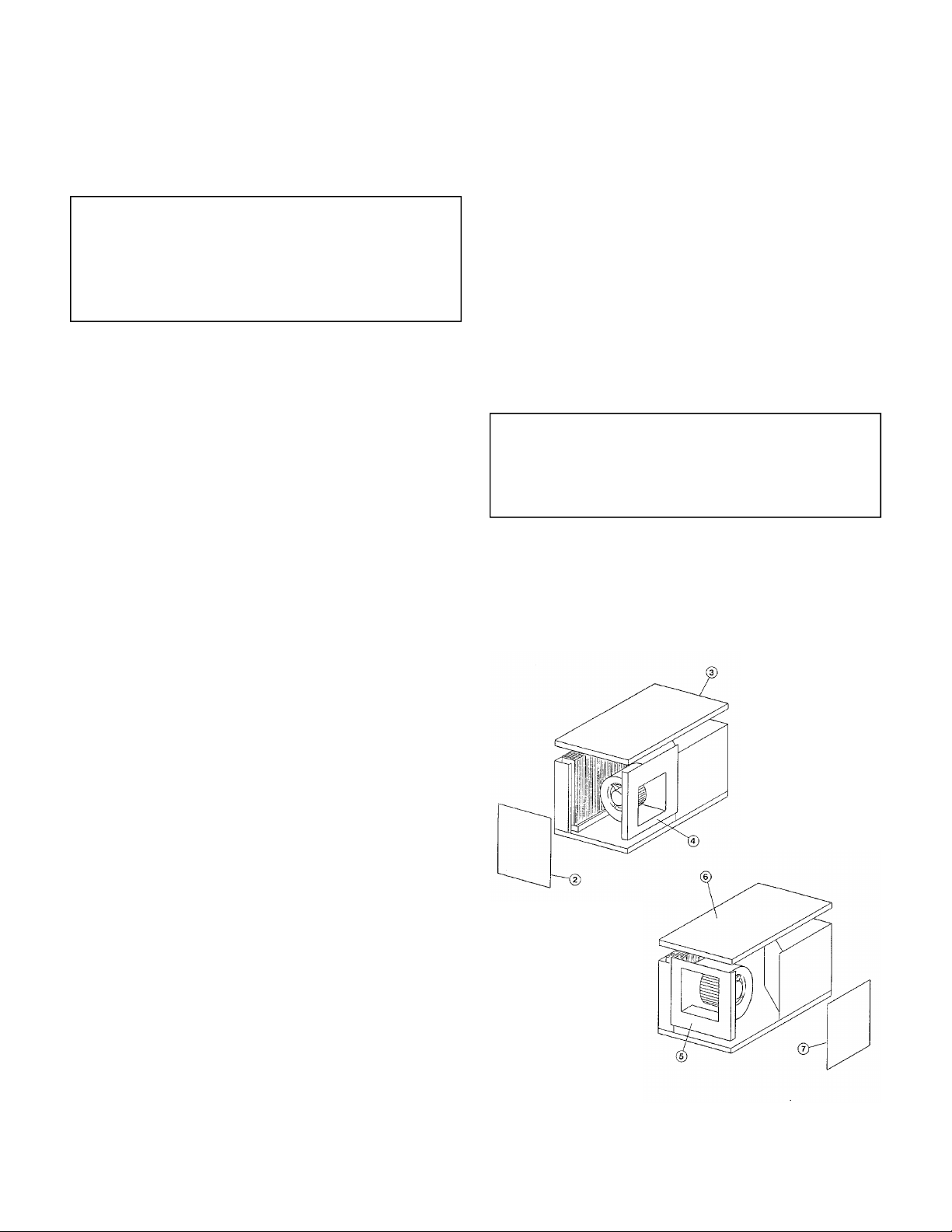

U Vintage Vertical

Size 012 to 072

MAMM-WSHP-IOM-1UB (September 2011)

U Vintage Horizontal

Size 009 to 072

2

Model Nomenclature

F -024- H- H- U

Voltage

BTU/hr Cooling

Unit Type Temperature Range Vintage

D = 208-230/1/60

E = 265/1/60

F = 208-230/3/60

G = 460/3/60

J = 380/3/50

K = 575/3/60

L = 220-240/1/50

S = 380/3/60

043 = 43,000

052 = 52,000

062 = 62,000

072 = 72,000

Illustrations cover the general appearance of Mammoth products at the time of publication and Mammoth, Inc. reserves the right to make changes

in design and construction at anytime without notice.

009 = 9,000 V = Vertical H = Standard Range

012 = 12,000 H= Horizontal L = Low Temp Operation

013 = 13,000

016 = 16,000

019 = 19,000

024 = 24,000

030 = 30,000

036 = 36,000

“Mammoth” is a registered trademark of Mammoth, Inc.

©Mammoth, Inc. 2011. All rights reserved throughout the world.

Transportation and Storage

Upon receipt of the equipment, check for visible damage. Make a notation on the shipper’s delivery ticket

before signing. If there is any evidence of rough handling, immediately check for concealed damage. If any

damage is found, notify the carrier within 48 hours to

establish your claim and request their inspection and a

report. Then contact the Mammoth Service department

at (952) 358-6618 or info@mammoth-inc.com

for a warranty claim number.

MAMM-WSHP-IOM-1UB (September 2011)

Do not stand or transport the unit on end. In the event

that elevator transfer makes up-ended positioning unavoidable, absolutely ensure that the unit is in the normal upright position for at least 24 hours before operating.

Temporary storage at the job site must be indoors,

completely sheltered from rain, snow, etc. High or low

temperatures naturally associated with weather patterns will not harm units. Excessively high temperatures, 140°F (60°C) and higher, may deteriorate certain

plastic materials and cause permanent damage.

3

Installation

General

IMPORTANT:

Mammoth water source heat pumps should be installed only by qualified personnel, experienced in the

installation of this equipment and related systems.

Read these instructions carefully before unpacking,

installing and operating this unit

1. To prevent damage, this equipment should not be

operated for supplementary heating and cooling

during the construction period.

2. Inspect the unit for any specific tagging numbers

indicated by the factory per a request from the installing contractor.

3. Check the unit nameplate for the size and voltage

rating and confirm against the plans that the unit is

being installed in the correct location.

4. Verify the installation location with the piping, sheet

metal and electrical contractors prior to installation

Discharge Conversion—Horizontal Units

5. Verify all clearances are available for the unit prior

to installation.

6. Note the location and routing of water piping, condensate drain piping, and electrical wiring. The locations of these items are clearly marked on submittal drawings.

7. Mammoth recommends the unit be covered during

construction to protect components from dust and

other harmful material. This is critical while spraying fireproofing material on bar joists, sandblasting,

spray painting and plastering.

NOTE:

Check the unit name plate for correct voltage with the

plans before installing the equipment. Make sure all

electrical ground connections are made in accordance

with local code.

All horizontal units from size 009 to 062 can be field

converted from straight discharge to side discharge.

1. Set the unit on a level surface.

2. Remove the blower access panel.

3. Remove the top panel.

4. Remove the screws that secure the panel where

blower is mounted.

5. Re-install the blower panel assembly for side discharge configuration (assembly will be flipped 180

degrees). See unit specification sheet for dimensional information.

6. Re-install the top of the unit.

7. Re-install the blower access panel where the

blower panel assembly was for straight-through

discharge.

8. After first operation, check all fasteners for tightness.

MAMM-WSHP-IOM-1UB (September 2011)

4

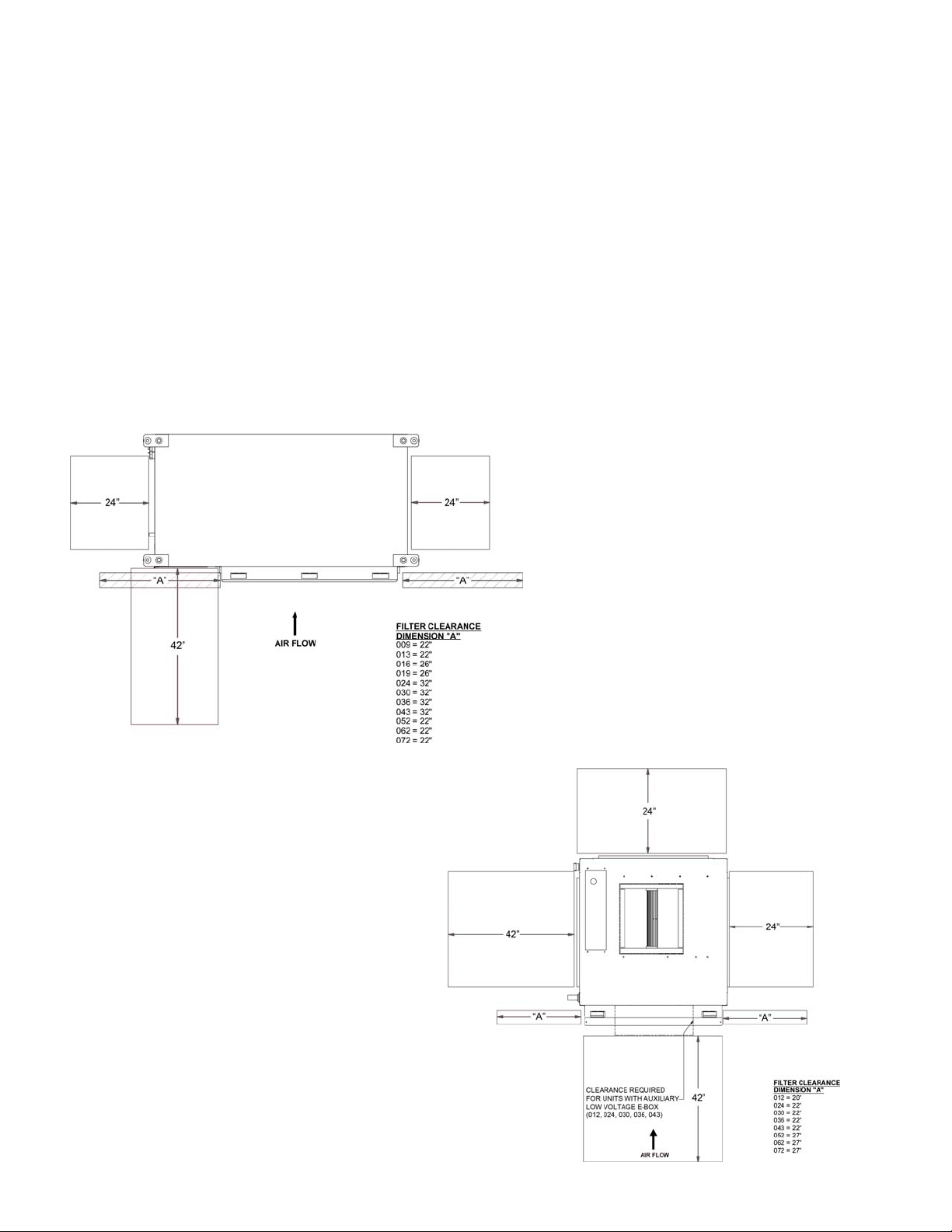

Unit Location and Clearances

The diagrams below show minimum suggested clearances. Any additional clearances would be beneficial,

but not always necessary. The requirements on any

specific unit may increase or be reduced depending on

several factors such as maintenance requirements and

mechanical or electrical installation codes. If return air

is not ducted, enough clearance will be required to provide for adequate airflow.

Horizontal unit clearances

Horizontal units have three access panels; one panel

for the blower, one for the electrical panel and one for

the compressor compartment. Horizontal unit filters are

removed from the right or left side with an option for

bottom removal.

Vertical units need to be accessed on three sides; two

panels for the compressor and blower, one for the electrical panel and compressor compartment. Vertical unit

filters are removed from the right or left side.

MAMM-WSHP-IOM-1UB (September 2011)

Vertical unit clearances

5

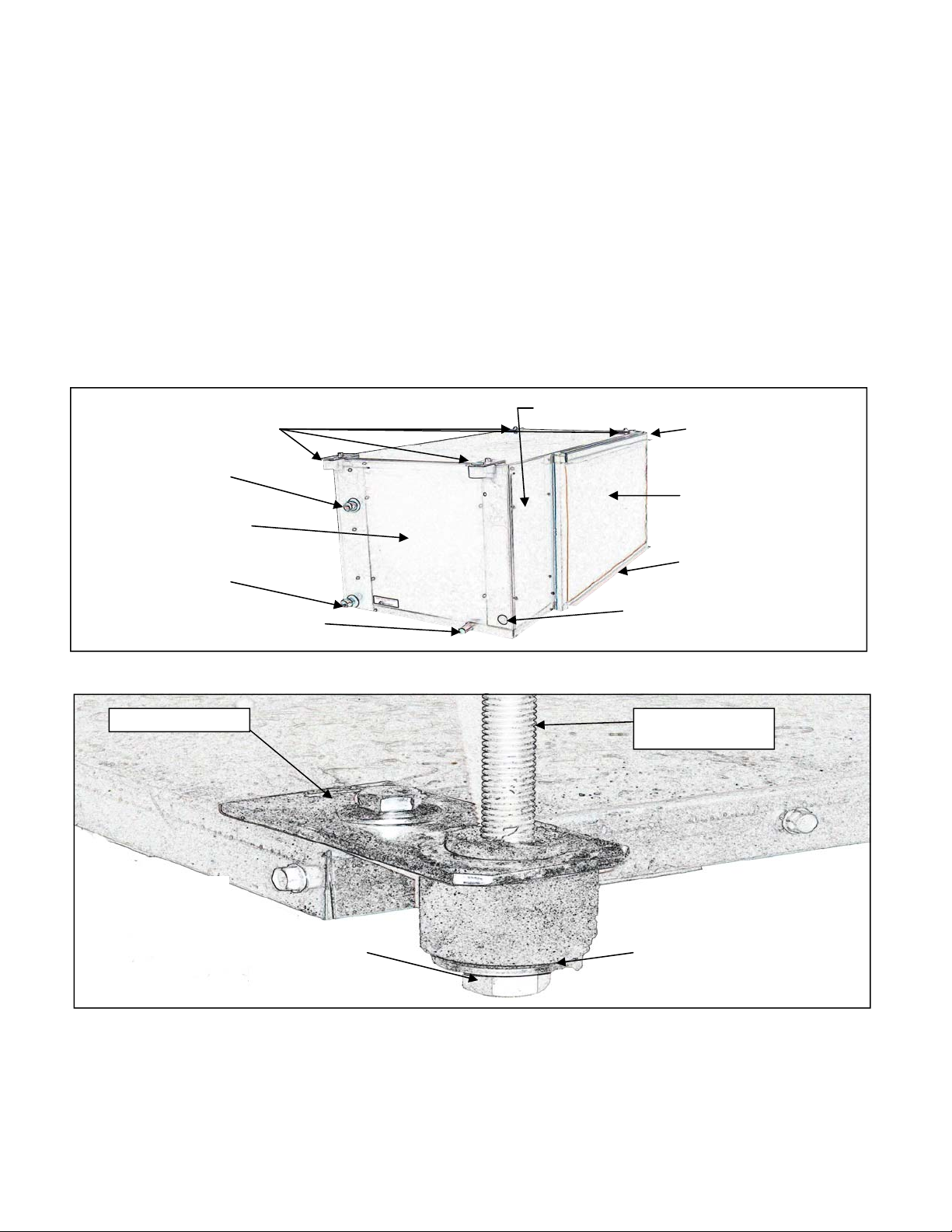

Mounting

Vertical units can be mounted on the floor or a concrete

pad, typically in a mechanical closet or other area enclosed from the space to promote a quieter occupied

environment..

Horizontal units must be hung from the ceiling. Mounting brackets, rubber grommets, bolts and washers are

shipped in place on the unit. The mounting brackets

are designed to accept up to a 3/8-inch threaded rod

(by others). A flat washer and two nuts (both by others)

should be used to mount the unit on the ceiling attached threaded rods. When installed, the unit should

be slightly pitched toward the condensate drain connection.

Horizontal mounting detail (See unit submittal drawing for specific component locations on your unit)

Hanger

Brackets (4)

Water Outlet FPT

Connection

Access to Compressor

Water Coil, Reversing Valve

Water Inlet FPT

3/4” OD Copper Condensate Drain

Electrical

Flange on Filter Guide

Filter, Left or Tight Side

Removal. Lift and Pull on

Flange on Filter Guide

7/8” or 1-3/32” Hole for line

voltage conduit connection

Grommet detail

Hanger Bracket

Note: Rotate Brackets

90° And Tighten

Retaining nut

(by others)

Threaded Rod

(By Others)

Washer (by others) must cover

entire bottom of grommet

MAMM-WSHP-IOM-1UB (September 2011)

6

Ductwork and Attenuation

Discharge ductwork is normally used with U-vintage

horizontal and vertical single circuit units. Return air

ductwork may also be required.

All ductwork should conform to industry standards

of good practice as described in the ASHRAE Systems

Guide.

The discharge duct system will normally consist of

a flexible connector at the unit connection, a transition

piece to the full duct size, a short run of duct,

and elbow with vanes, and a trunk duct teeing into

a branch duct with discharge diffuses. The transition

piece must not have angles totaling more than

30° or severe reduction in airflow performance can

result.

Do not connect the full duct size to the unit. Use a

transition piece sized according to the discharge collar

on the unit to get to the full duct size. With metal duct

material, the sides of only the elbow and entire branch

duct should be internally lined with acoustic fibrous

insulation for sound attenuation. Glass fiber duct board

material is more absorbing and may permit omission of

the canvas connector.

The ductwork should be laid out so that there is no

line of sight between the unit discharge and

the distribution diffusers.

Do not use sheet metal screws directly into the unit

cabinet for connection of supply or return air ductwork,

especially return ductwork which can hit the drain pan

or the air coil.

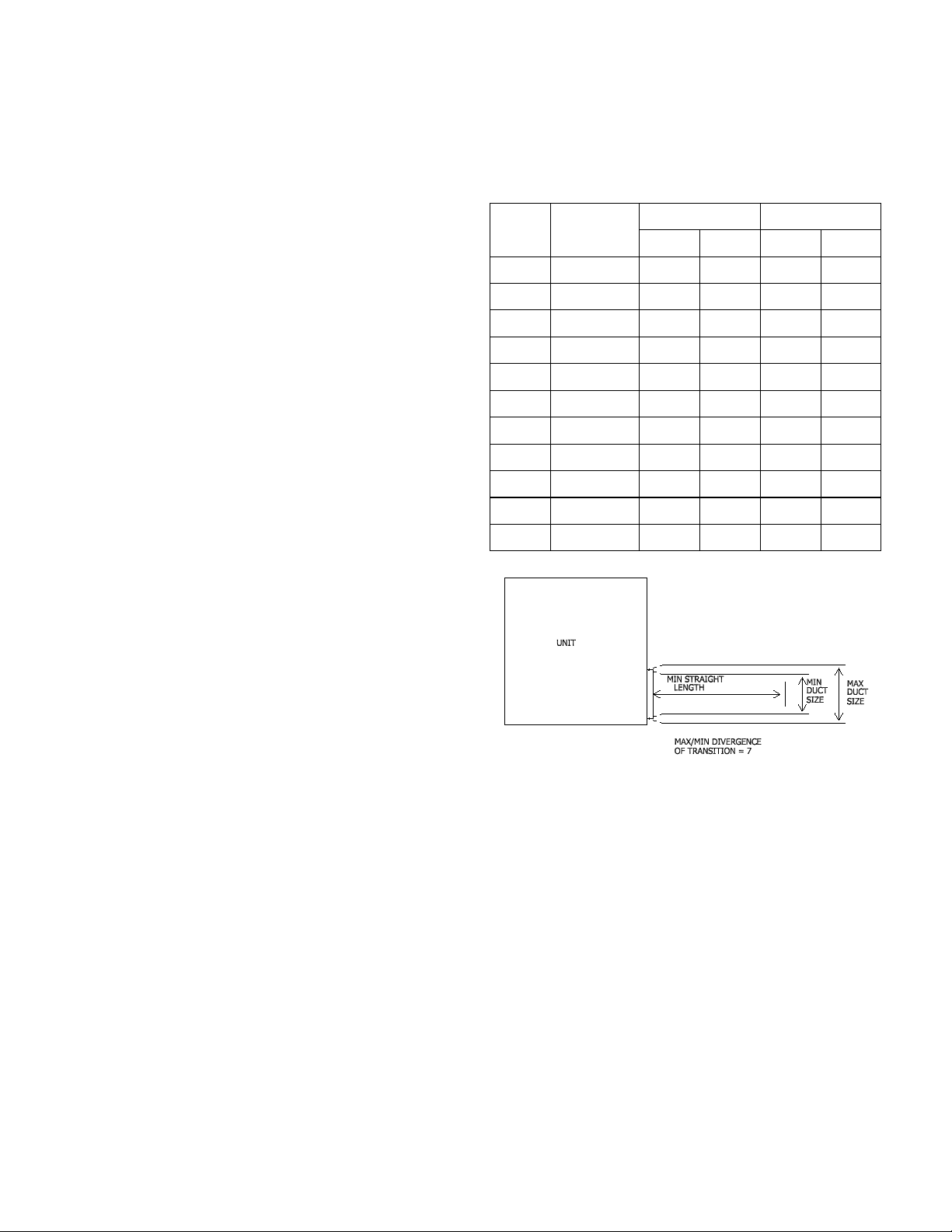

Minimum/maximum duct connections

MODEL

009 23.21 9 11.25 6 9.0

013 23.21 9 11.25 6 9.0

016 26.0 9 11.25 6 9.0

019 26.0 11.3 12.4 9.2 10.0

024 26.82 11.3 12.4 9.2 10.0

030 26.82 11.3 12.4 9.2 10.0

036 29.76 12.5 13.25 10.5 11.25

043 29.76 12.5 13.25 10.5 11.25

052 29.76 13 13.5 11 11.5

062 29.76 13 13.5 11 11.5

072 33.51 14.5 13.5 12.5 11.5

MIN. STRAIGHT

DISCH. LENGTH

MAX. DUCT MIN. DUCT

WIDTH HEIGHT WIDTH HEIGHT

Legend

Outside air may be required for ventilation. The

temperature of the ventilation air must be controlled so

that the mixture of outside air and return air entering

the unit is within application limits. It is typical to close

off the ventilation air system during unoccupied periods

(i.e. night setback).

MAMM-WSHP-IOM-1UB (September 2011)

V entilation Air

The ventilation air system is typically a separate

building subsystem with distribution ductwork. Simple

introduction of the outside air into each return air

plenum chamber reasonably close to the unit air inlet is

recommended. Do not duct outside air directly to the

unit inlet. Provide sufficient distance for the thorough

mixing of outside and return air.

.

7

Supply Piping

1. All heat pumps should be connected to supply and

return piping in a two-pipe reverse return

configuration. A reverse return system is inherently

self-balancing and requires only trim balancing

where multiple quantities of heat pumps with

different flow and pressure drop characteristics

exist in the same loop. Check for proper water

balance by measuring differential temperature

reading across the water connections. To insure

proper water flow, the differential temperature

should be between 10°F to 14°F for heat pumps in

the cooling mode.

2. The piping may be steel, copper, or PVC. Avoid

dissimilar metal fittings as they may corrode. If the

use of dissimilar metals is unavoidable, use

dielectric isolation at that connection point.

3. Supply and return run-outs usually join the heat

pump via short lengths of high pressure flexible

hose which are sound attenuators for both heat

pump operating noise and hydraulic pumping

noise. One end of the hose should have a swivel

fitting to facilitate removal for service. Hard piping

can also be brought directly to the heat pump. This

option is not recommended since no vibration or

noise attenuation can be accomplished. The hard

piping must have a union to facilitate heat pump

removal.

4. Make sure that threaded fittings are sealed. Teflon

tape can be used to provide a tight seal.

5. Supply and return shutoff valves are required at

each heat pump. The return valve is used for

balancing and should have a “memory stop” so that

it can always be closed off but can only be

reopened to the proper position for the flow

required.

6. No heat pump should be connected to the supply

and return piping until the water system has been

cleaned and flushed completely. After the cleaning

and flushing has taken place, the initial connection

should have all valves wide open in preparation for

the water system flushing.

Condensate Piping

1. Condensate piping can be steel, copper, or PVC.

Each unit includes a condensate connection.

2. The condensate disposal piping must be trapped.

Vertical units are internally trapped and horizontal

units must be externally trapped. The piping must

be pitched away from the heat pump not less than

¼” per foot. The unit is supplied with a 1-1/4” male

pipe fitting to accommodate the condensate drain

connection.

3. Do not locate any point in the drain system above

the drain connection of any unit.

4. The condensate piping system must be vented at

its highest point.

MAMM-WSHP-IOM-1UB (September 2011)

8

Loading...

Loading...