Page 1

T

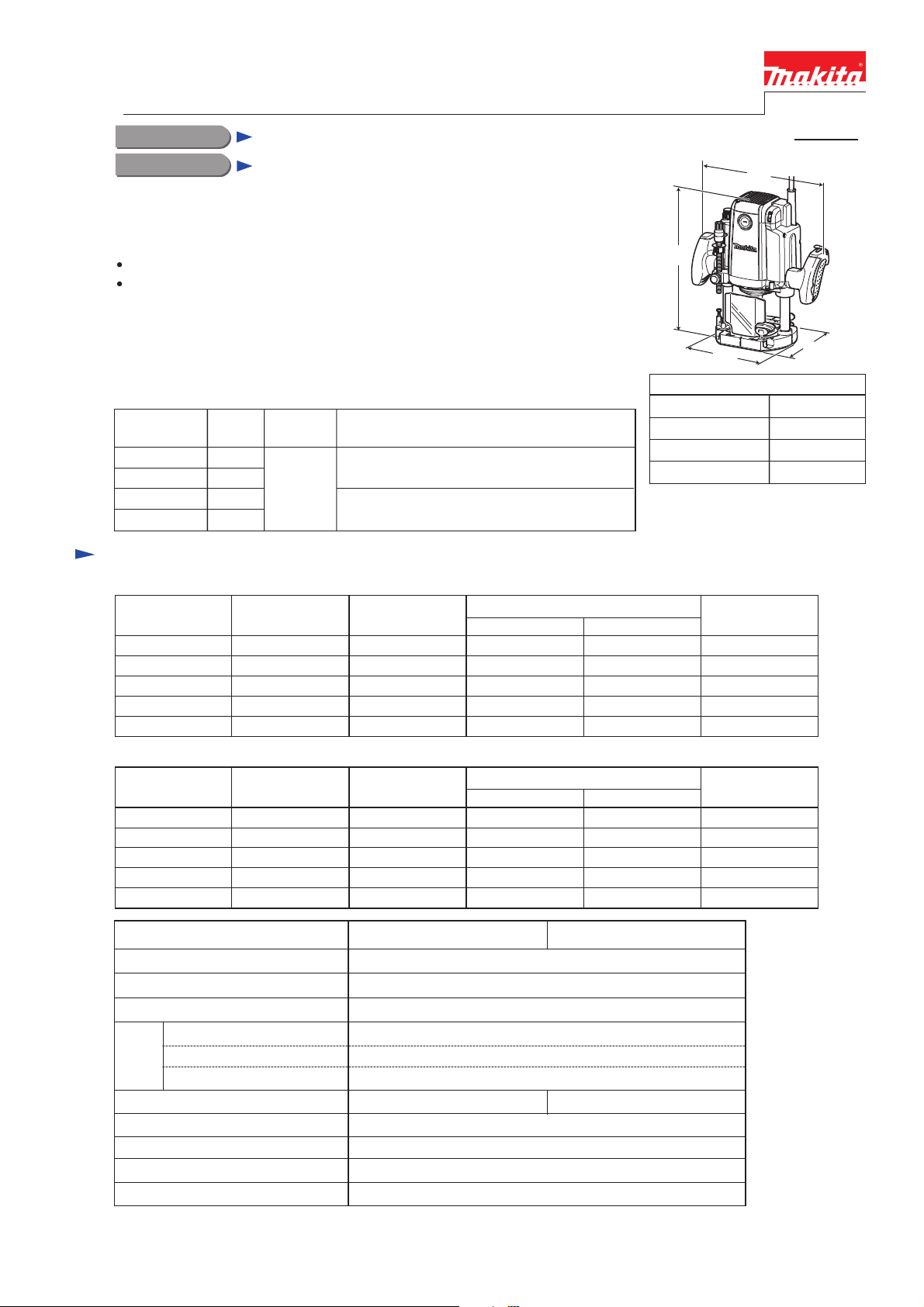

ECHNICAL INFORMATION

Model No.

Description

RP2300FC, RP2301FC

Router

CONCEPT AND MAIN APPLICATIONS

Models RP2300FC and RP2301FC are upgraded sister tools of our current

plunge-type electronic router Model 3612C. Their main benefits are:

Linear ball bearing for super-smooth plunge action

Ergonomically contoured knob style handles

Powerful cutting with the continuous rating input higher than Model 3612C;

RP2300FC: 2,300W, RP2301FC: 2,100W

RP2301FC additionally feature electric brake.

PRODUCT

P 1/ 27

W1

H

L

W2

These products are available in the following variations.

No

Yes

No

Yes

Twin LED

job lights

Yes

(Straight guide + Guide holder assembly)

High-precision type with fine adjustment function

(Fine adjusting straight guide)

Model No.

RP2300FC

RP2301FC

RP2300FCX

RP2301FCX

Electric

brake

Specification

RP2300FC

Voltage (V) Cycle (Hz)

110

120

220

230

240

RP2301FC

Voltage (V) Cycle (Hz)

110

120

220

230

240

Current (A)

15 1,650

15 650 2,60050/60

11 2,300 1,200 3,40050/60

11 2,300 1,200 3,40050/60

11 2,300 1,200 3,40050/60

Current (A)

15 1,650

15 650 2,60050/60

10 2,100 1,000 3,40050/60

10 2,100 1,000 3,40050/60

10 2,100 1,000 3,40050/60

Straight guide

Standard type

Continuous Rating (W)

Input Output

Continuous Rating (W)

Input Output

---

---

Dimensions: mm (")

Length (L) 155 (6-1/8)

Width (W1)

Height (H)

Width of base (W2) 170 (6-11/16)

Max. Output (W)

650 2,60050/60

Max. Output (W)

650 2,60050/60

294 (11-5/8)

312 (12-1/4)

Model No.

No load speed: min-1=rpm

Collet capacity: mm (")

Plunge capacity: mm (")

Constant speed control

Soft start

control

Variable speed control by dial

Electronic

Electric brake

LED job light

Double insulation

Power supply cord: m (ft)

Net weight*2: kg (lbs)

*1: Twin LED job lights with afterglow function

*2 Weight according to EPTA-Procedure 01/2003, including Dust nozzle

(See next page for Standard equipment and Optional accessories.)

Europe: 4.0 (13.1), Brazil: 2.0 (6.6), Other countries: 2.5 (8.2)

No Yes

9,000 - 22,000

12.0 or 12.7 (1/2)

0 - 70 (0 - 2-3/4)

Yes

Yes

Yes

Yes*1

Yes

6.1 (13.4)

RP2301FCRP2300FC

Page 2

Standard equipment

For all countries:

Straight guide (Standard type or High-precision type) .................. 1 pc

+ Pan head screw M6x135 (for adjusting cutting depth) .............. 1 pc

The standard equipment for the tool shown below may vary by country:

Dust nozzle assembly ........... 1 pc

Knob 55 complete ................ 1 pc

Trimmer guide assembly ...... 1 pc

Templet guide 16 .................. 1 pc

Collet sleeve 6mm ............. 1 pc

Collet sleeve 8mm ............. 1 pc

Collet sleeve 1/4" ............... 1 pc

Collet sleeve 3/8" ............... 1 pc

Optional accessories

P 2/ 27

Collet cone 12mm or 1/2" ...... 1 pc

Wrench 24 .............................. 1 pc

Collet sleeve (for inch chuck) 10mm ..... 1 pc

Fine adjusting straight guide

Guide rail adapter set

Trimmer guide assembly

Templet guides

Templet guide 25

Templet guide adapter 30

Nut M30

Dust nozzle assembly

Collet sleeves

Router bits

Page 3

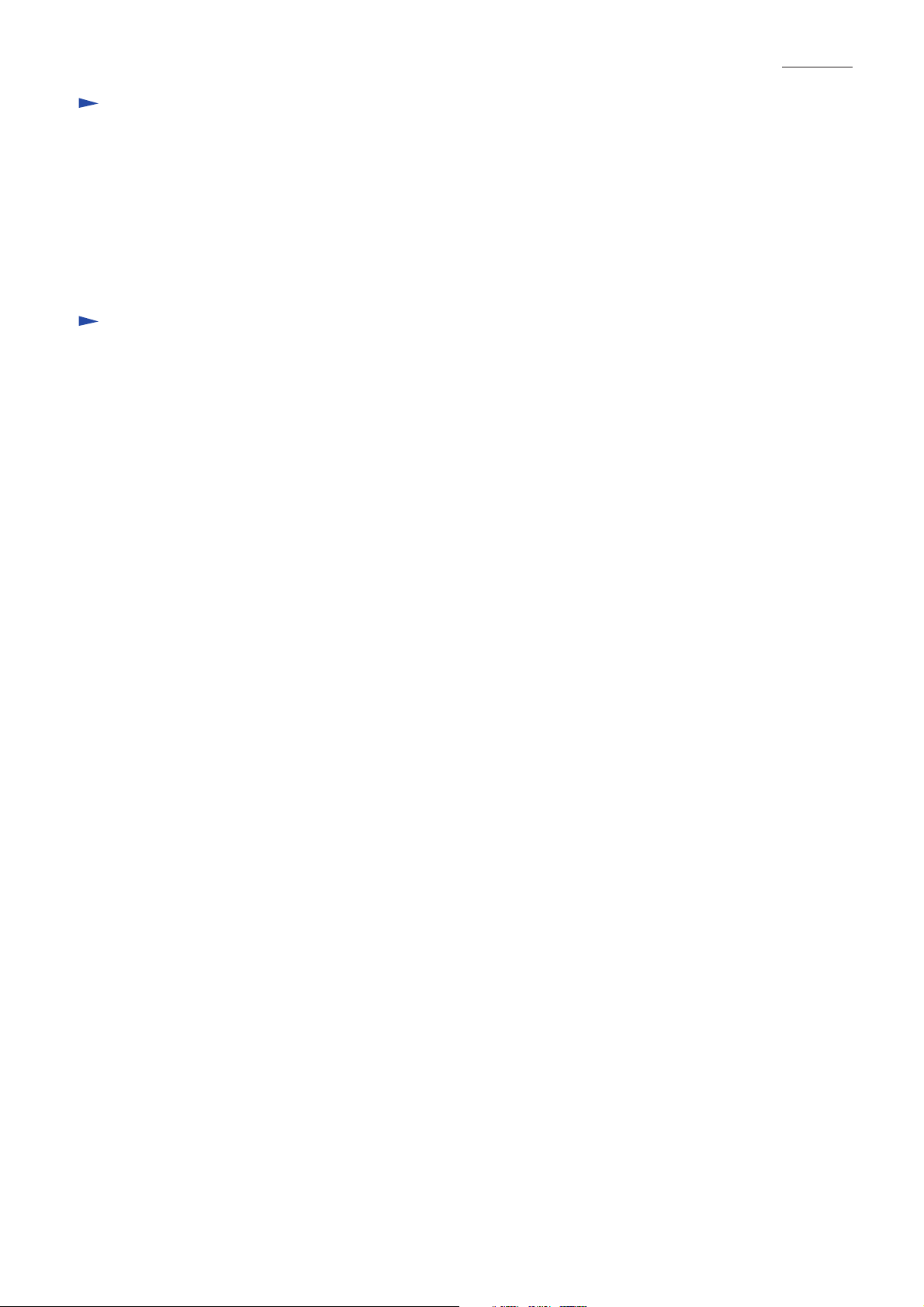

Repair

CAUTION: Remove the bit from the machine for safety before repair/ maintenance

in accordance with the instruction manual!

[1] NECESSARY REPAIRING TOOLS

[2] LUBRICATIONS

[3] DISASSEMBLY/ASSEMBLY

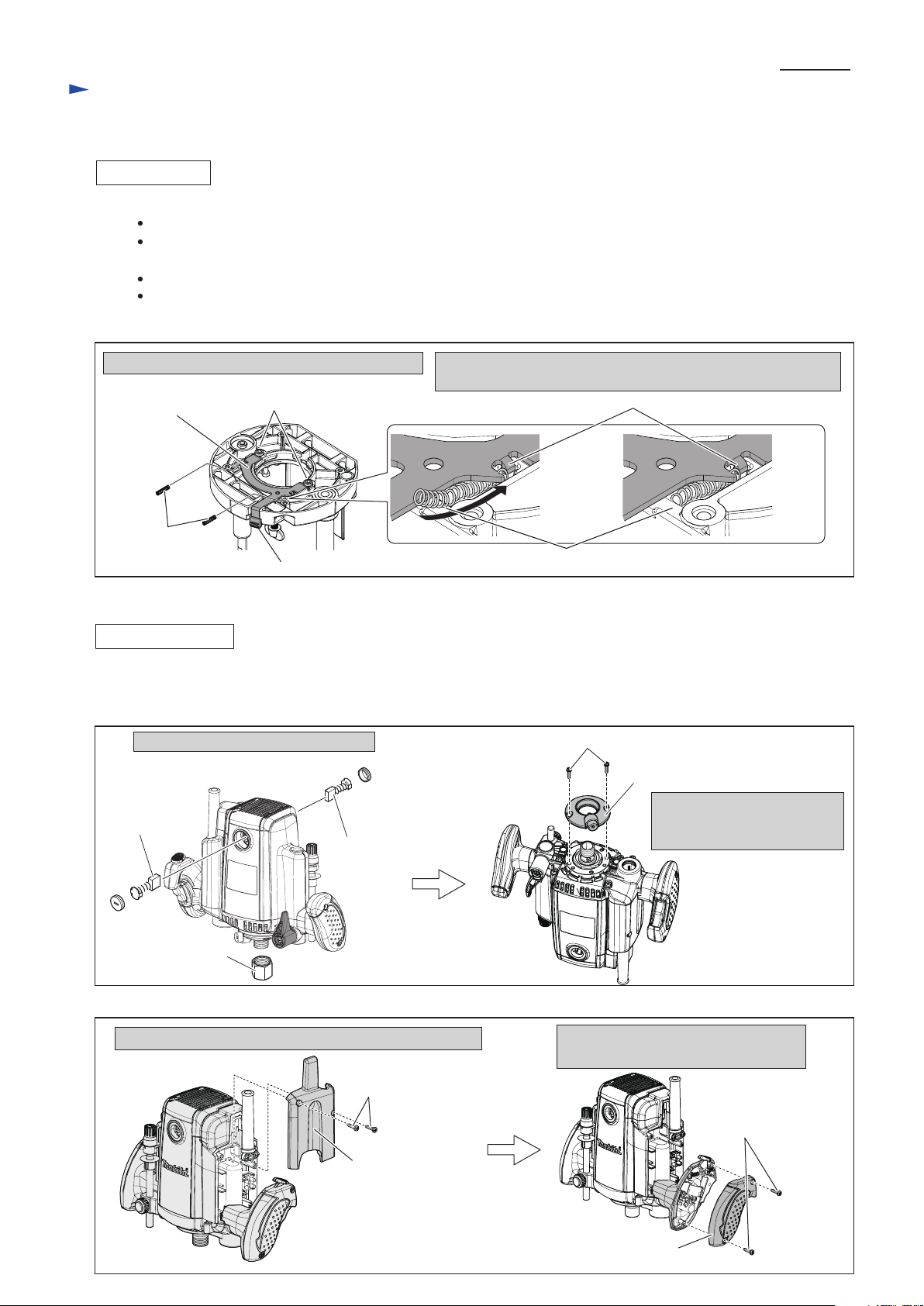

[3]-1. Base complete

Fig. 1

Fig. 2

Code No. Description Use for

1R030 Bearing setting pipe 25-17.2 Supporting Pin 6 when assembling shaft lock mechanism

1R268 Spring pin extractor 3 Removing Pin 6 of shaft lock mechanism

1R269 Bearing extractor Removing Ball bearing 629DDW

Item No.

Apply lubricant “VG100” to the following portions designated with the gray triangle to protect parts

and product from unusual abrasion.

Description

Armature

Portion to lubricate

DISASSEMBLING

(1) Separate Base section from Motor section as illustrated in Figs. 2 and 3.

3. Remove M10 Thumb nut

and M10 Nylon nut

24

Motor bracket complete

Collet nut

Motor housing

85

24

85 Base complete

Threaded portion for removing Collet nut smoothly

Pipe 20 for making plunging action smooth

M10 Thumb nut

M10 Nylon nut

1R041 Vise plate Protecting Armature when holding in vise

1. Set Motor section to

the upper position.

2. Lock Motor section

by turning Lock lever.

P 3/ 27

Page 4

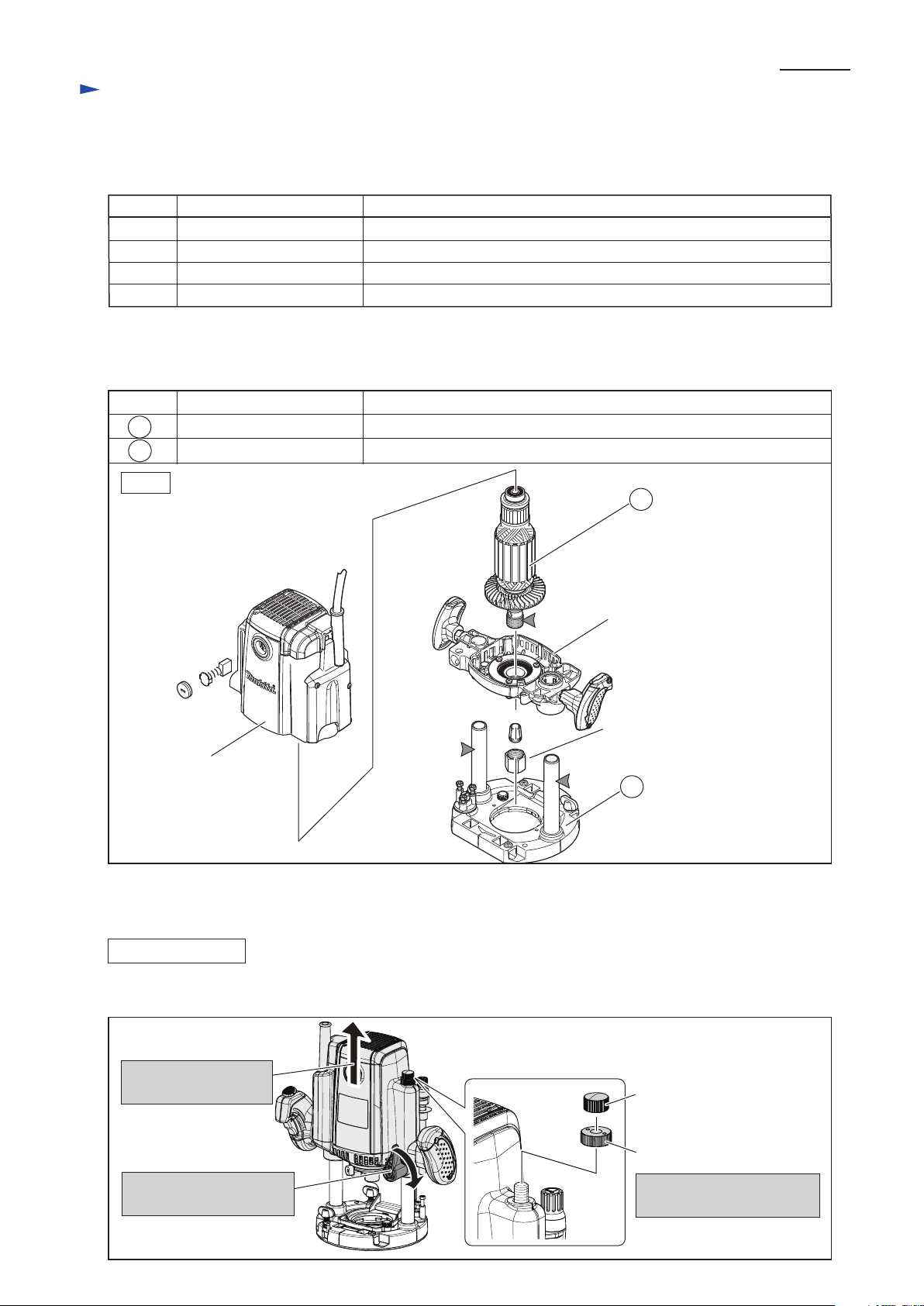

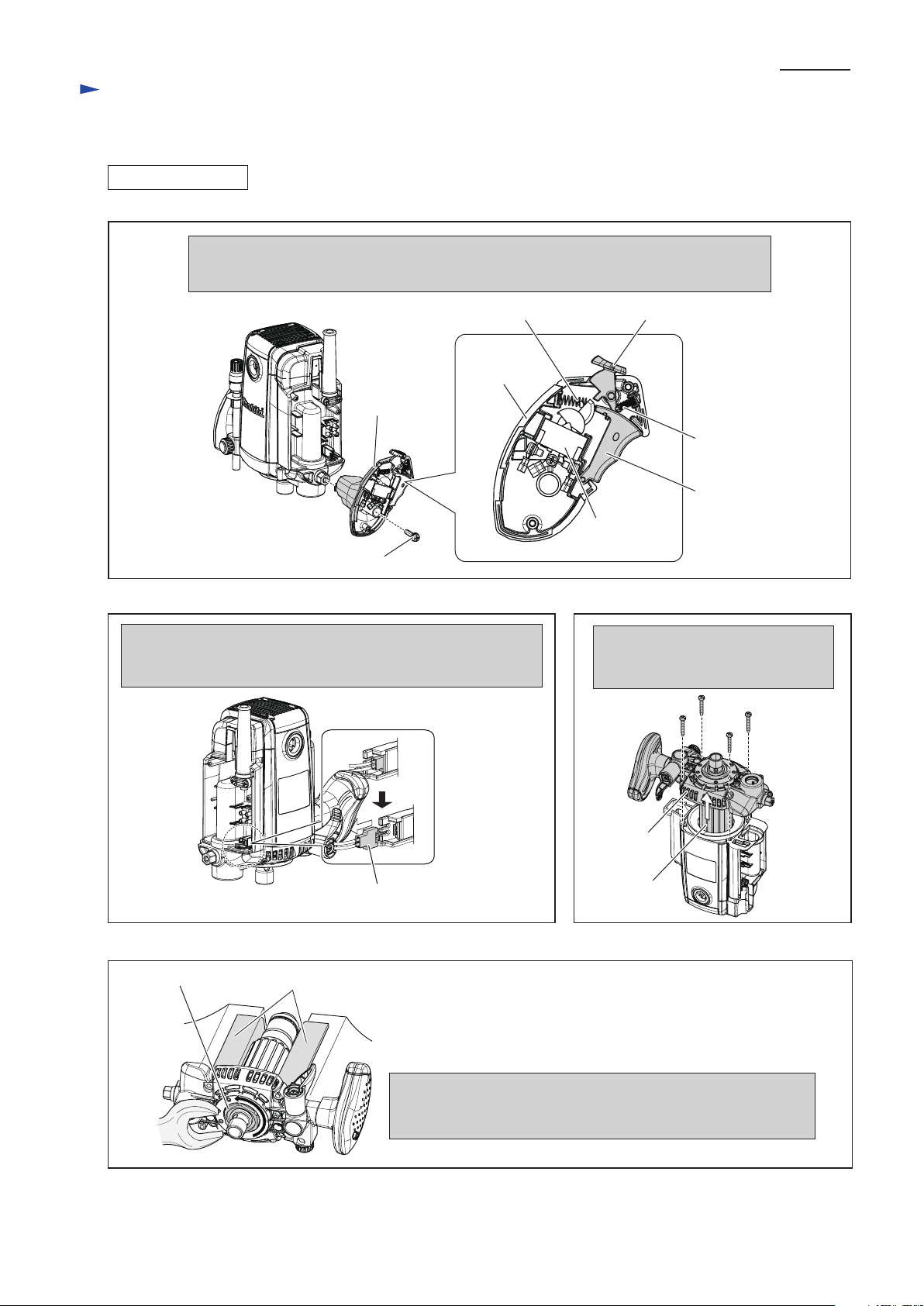

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Base complete (cont.)

DISASSEMBLING

4. Loosen Lock lever.

Base can be separated

from Motor section.

5. Remove Pole, Silent pole, Compression spring 13

and Compression spring 11.

6. Remove Base plate by unscrewing

M4x10 Countersunk head screw (4pcs.)

7. Remove Lock plate by unscrewing M5x10 Set bolt (2pcs.)

Separate Compression spring 4 (2pcs.) from Lock plate.

M4x10

Countersunk

head screw

(4pcs.)

Base plate

The other parts can be removed from Base

complete as illustrated below.

Lock plate

Compression

spring 4 (2pcs.)

M5x10 Set bolt (2pcs.)

Motor section

M6 Hex nut

M10 Screw

Remove M6 Hex nut, Flat washer 6

and M10 Screw.

Stopper

Compression spring 5

Compression spring 7

Compression

spring 7

Steel ball 7.1

M4x19 Thumb screw

M5x14 Thumb screw

M5x14

Thumb screw

O ring 3

M6 Flat head screw O ring 8

Flat washer 6

Fig. 3

Fig. 4

Fig. 5

(2) Remove Base plate, Lock plate, Compression spring 4 and other component parts.

Refer to Figs. 4 and 5.

Silent pole

Pole

Compression

spring 11

Compression

spring 13

Repair

P 4/ 27

Page 5

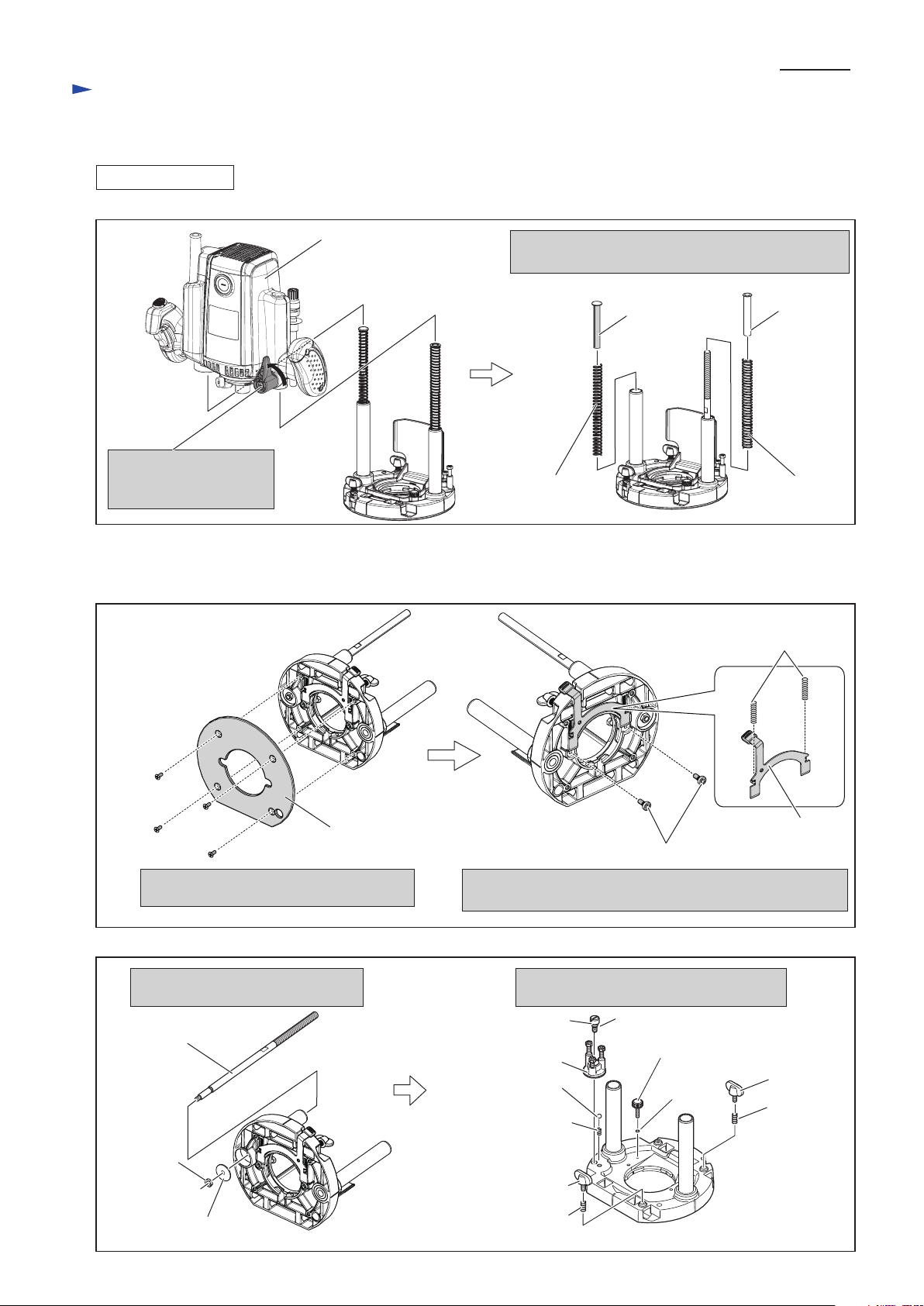

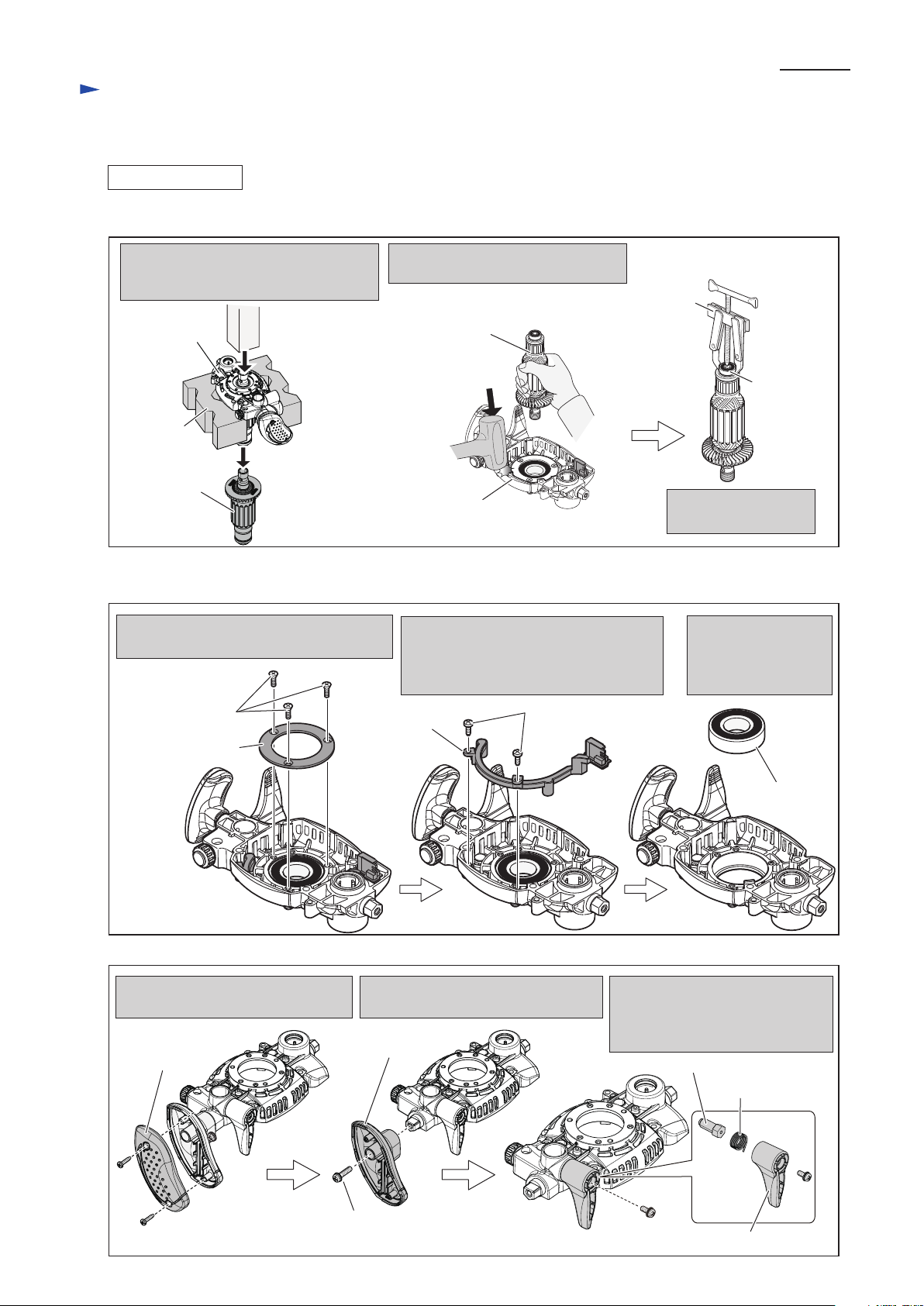

[3] DISASSEMBLY/ASSEMBLY

[3]-1. Base complete

DISASSEMBLING

ASSEMBLING

Fig. 6

Fig. 7

Fig. 8

Lock plate

Lever portion of Lock plate

Hook of Lock plate

1. Screw M5x10 Set bolt (2pcs.) to Base complete 2. Set Compression spring 4 in place between the groove end of

Base complete and the hook of Lock plate.

Groove end of Base complete

M5x10 Set bolt (2pcs.)

Compression

spring 4

Take the disassembling step in reverse.

[3]-2. Armature, Motor bracket complete

(1) Separate Base section from Motor section as illustrated in Figs. 2 and 3.

(2) Disassemble Armature as illustrated in Figs. 7, 8, 9, 10, 11, 12 and 13.

Collet nut

Carbon brush

Carbon brush

Cover

Remove carbon brush and Collet nut.

Remove Retainer cover by

unscrewing M4x18 Pan head

screw (2pcs.)

Remove Cover by unscrewing 4x18 Tapping screw (2pcs.)

Note: It is impossible to

disassemble Grip R

without removing

Cover.

M4x18 Pan head screw (2pcs.)

4x18 Tapping screw

(2pcs.)

4x18 Tapping

screw (2pcs.)

Retainer cover

Grip cover (R)

Remove Grip cover (R) by unscrewing

4x18 Tapping screw (2pcs.)

Repair

Note: Set Compression spring 4 (2pcs.) in the groove on Base complete as illustrated in Fig. 6

M6 - Flat head screw is thread-locker type. When removing it, be sure to apply adhesive (ThreeBond 1321/ 1342

or Loctite 242) to the thread before reusing.

Assemble Compression spring 11, Compression spring 13, Pole and Silent pole as illustrated in Fig. 3.

Check that two Compression springs 4 work properly by pulling the lever portion of Lock plate after assembling

Base plate to Base. Refer to Figs. 6 and 4.

P 5/ 27

Page 6

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Armature, Motor bracket complete (cont.)

DISASSEMBLING

Compression

spring 4

Switch

lever

Compression spring 5

Lock off button

Grip R

Switch

Grip R

Connector of Controller

In case of Models RP1800F, RP1801F, RP2300FC and RP2301FC,

disconnect Connector of Controller from LED circuit prior to

the step described in Fig. 11.

Disassemble Switch lever, Lock off button, Compression spring 5, Compression spring 4

from Grip R. And remove Grip R from the machine by unscrewing M5x25 Pan head screw.

In case of Models RP1800 and RP1801, refer to Fig. 11.

M5x25 Pan Head screw

Fig. 9

Fig. 10 Fig. 11

Fig. 12

Armature

Motor

bracket

Remove Motor bracket together with

Armature from Motor housing by

removing 5x35 Tapping screw (4pcs.)

5x35 Tapping

screw (4pcs.)

1R041

Retainer

Remove Retainer from Armature shaft by:

1) holding Armature using 1R041 and vise

2) turning counterclockwise with Wrench 41 or Hex socket 41-80.

Repair

P 6/ 27

Page 7

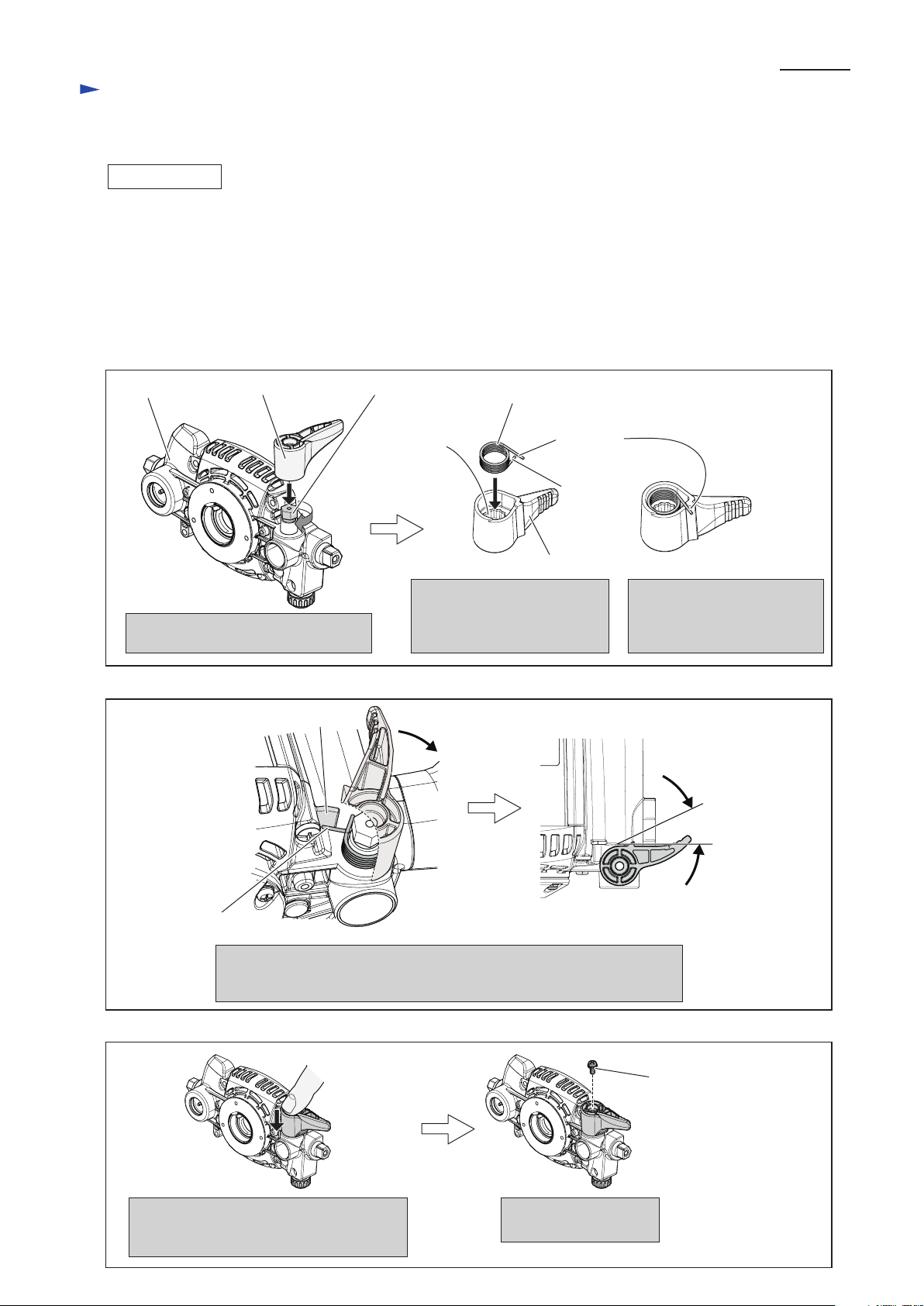

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Armature, Motor bracket complete (cont.)

DISASSEMBLING

Fig. 13

Fig. 14

Fig. 15

(3) Armature can be removed in the manner A or B shown in Fig. 13. Remove Ball bearing 629DDW from Armature.

(4) Disassemble the Motor bracket as illustrated in Figs. 14 and 15.

Motor bracket

Remove Ball bearing

629DDW with 1R269.

Remove Bearing retainer 60 by unscrewing

M4x14 Countersunk head screw.

In case of Models RP1800F, RP1801F,

RP2300FC and RP2301F, remove LED

Circuit by removing Bind CT4x12

Tapping screw (2pcs.)

A: Supporting Motor bracket with 2 pcs.

of 1R258, remove Armature with

Arbor press.

1R258

Armature

Bearing retainer 60

Ball bearing

6205DDW

Remove Ball bearing

6205DDW by striking

Motor bracket with

Plastic hammer.

Bind CT4x12

Tapping screw (2pcs.)

4x12 Tapping

screw (2pcs.)

M4x14 Countersunk

head screw (3pcs.)

LED circuit

Grip cover L

Remove Grip cover L by unscrewing

4x12 Tapping screw (2pcs.)

Grip L can be removed by unscrewing

M6x25 Pan head screw.

Grip L

M5x12 Pan

head screw Lock lever

Remove Lock lever by unscrewing

M5x12 Pan head screw.

Separate M10 Set bolt and Torsion

spring 15 from Lock lever.

Torsion spring 15

M10 Set bolt

M6x25 Pan head screw

Motor bracket

Ball bearing

629DDW

Armature

1R269

Repair

B: Strike Motor bracket with Plastic

hammer while gripping Armature.

P 7/ 27

Page 8

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Armature, Motor bracket complete

ASSEMBLING

(1) Assemble Ball bearing 6205DDW to Motor bracket. Refer to the right illustration in Fig. 14.

(2) In case of RP1800F, RP1801F, RP2300FC and RP2301FC, secure LED circuit with 4x12 Tapping screw (2pcs.).

Refer to the center illustration in Fig. 14.

(3) Tighten Bearing retainer 60 with M4x14 Countersunk head screw (3pcs.) to secure Ball bearing 6205DDW.

Refer to the left illustration in Fig. 14.

Note: Apply adhesive ThreeBond 1321 / 1342 or Loctite 242 to the threaded portion of M4x14 Countersunk head

screw (3pcs.)

(4) Assemble Lock lever to Motor bracket as illustrated in Figs. 16, 17 and 18.

Hooking the long tail of Torsion spring 15 on the wall of Motor bracket,

turn Lock lever without engaging the spline hole with the hex screw head

of M10 Set bolt until it comes to the position illustrated right.

M10 Set boltLock lever

Screw M10 Set bolt to Motor bracket

with Lock Lever.

Put Torsion spring 15 into

Lock lever so that the short tail

of Torsion spring 15 faces

Lock lever.

Putting the long tail of

Torsion spring 15 on

the edge of Lock lever,

set Torsion spring 15 in place.

Motor bracket

Short tail

Long tail

Spline hole

Long tail of

Torsion spring 15

Wall

Torsion spring 15

Lock lever

30 degrees

Engaging the spline hole of the Lock lever

with the hex screw head of M10 Set bolt,

push Lock lever as illustrated above.

Secure Lock lever with

M5x12 Pan head screw.

M5x12 Pan head

screw

Fig. 16

Fig. 17

Fig. 18

Repair

P 8/ 27

Page 9

[3] DISASSEMBLY/ASSEMBLY

[3]-2. Armature, Motor bracket complete (cont.)

DISASSEMBLING

ASSEMBLING

(5) Assemble Grip L to Motor bracket on Lock lever side and secure it with M6x25 Pan head screw. Refer to Fig. 15.

Assemble Grip cover L to Grip L by screwing two 4x12 Tapping screws. Refer to Fig. 15.

(6) Assemble Armature to Motor bracket. Refer to Fig. 13

(7) Assemble Retainer to Armature shaft by turning with Wrench 41 or Hex socket 41-80 clockwise. Refer to Fig. 12.

(8) Assemble Motor bracket to Motor housing. Refer to Fig. 11.

(8) In case of Models RP1800F, RP1801F, RP2300F, RP2301FC, connect LED circuit. Refer to Fig. 10.

(9) Assemble Grip R section to Motor bracket. Refer to Fig. 9.

(10) Secure Grip cover (R) with two 4x18 Tapping screws to the Grip R. Refer to right illustration in Fig. 8.

And assemble Cover to Motor housing. Refer to left illustration in Fig. 8.

(11) Mount Retainer cover to Motor bracket. Refer to right illustration in Fig. 7. And assemble Carbon brushes and

Collet nut. Refer to left illustration in Fig. 7.

[3]-3. Shaft Lock

(1) Separate Base section from Motor section as illustrated in Figs. 2, 3.

(2) Remove Retainer cover by unscrewing two M4x18 Pan head screws as the right illustration in Fig. 7.

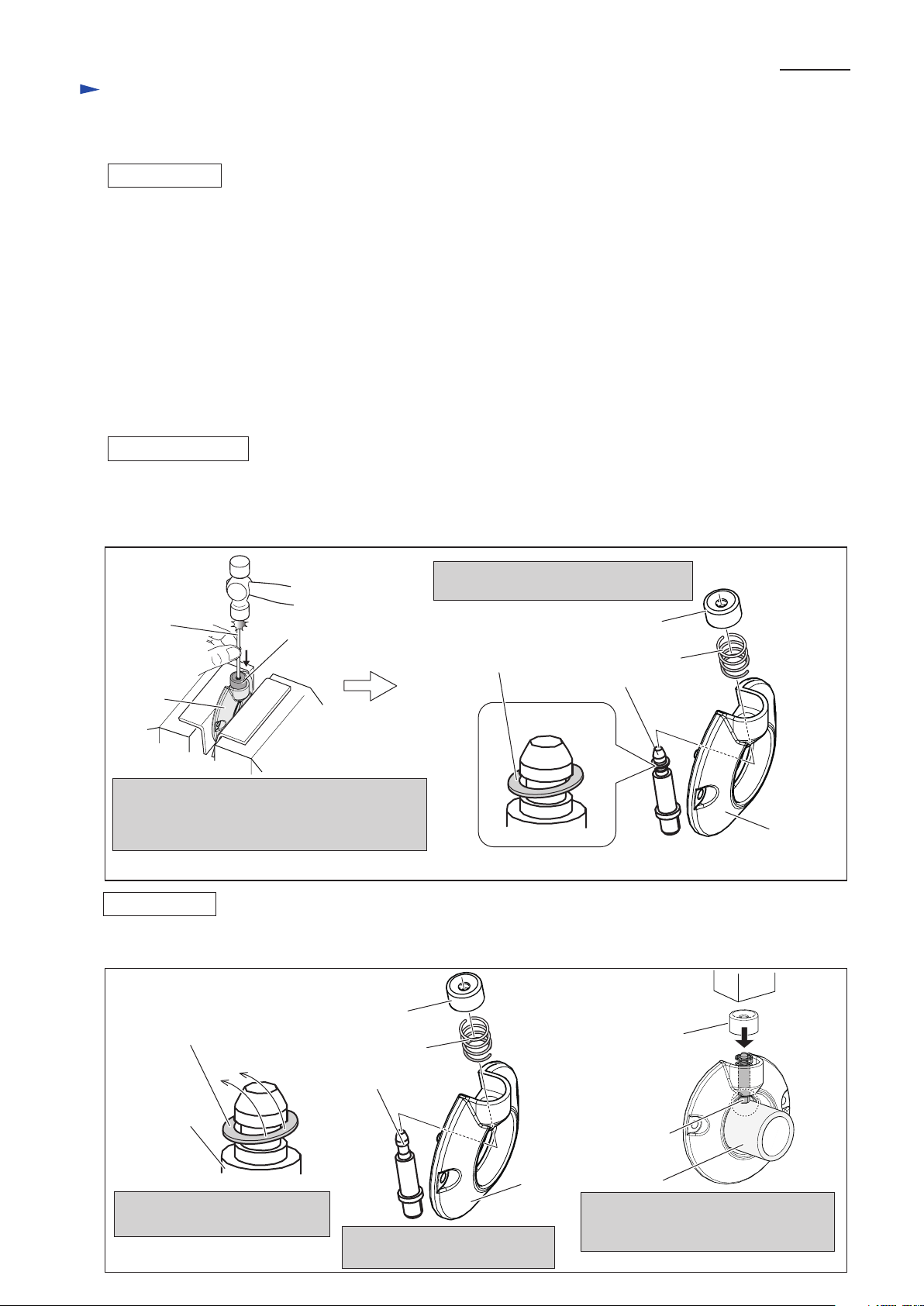

(3) Shaft lock mechanism can be disassembled as illustrated in Fig. 19.

Fig. 19

1R268

Retainer

cover

Applying 1R268 to the pin hole of Push button,

strike Collared pin 6 through the pin hole of

Push button.

Collared pin 6 can be removed from Push button.

Collared pin 6 and Compression spring 8

are removed from Push button.

Push button

Push button

Collared pin 6

Splinter of

Push button

Push button

Compression spring 8

Retainer

cover

Note: The removed Push button has to be replaced with new Push button.

Repair

ASSEMBLING

Shaft lock section can be assembled as illustrated in Fig. 20.

Splinter of

Push button

Fig. 20

Push Button

Note: Use new Push button.

Collared pin 6

Collared pin 6

1R030

Collared pin 6

Compression spring 8

Retainer

cover

Remove Splinter of Push button

from Collared pin 6.

Set the parts to Retainer cover

as illustrated above.

Supporting Collared pin 6 with 1R030,

assemble Push button by pressing with

Arbor press.

P 9/ 27

Page 10

Circuit diagram

RP2301FC with electric Brake, LED Job Light, Electronic Control

White

Orange

Purple

Color index of lead wires' sheath

* Support unit without Choke coil is used for some countries.

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Controller

Power

supply

cord

LED

Circuit

*Support Unit

Chokecoil

Switch

Connector

of Controller

Connector

of LED

Yellow

Red

Fig. D-1A

This Lead wire

may be blue for

some countries.

Brown Lead wire

is used for some

countries.

Blue Lead wire

is used for

some countries.

P 10/ 27

Page 11

Wiring diagram

RP2301FC with electric Brake, LED Job Light, Electronic Control

Grip R

Lead Wire

Holder

When putting Lead wires for

connecting to Terminal block,

into this Lead wire holder,

Controller’s thin Lead wire (purple)

has to be put under the following

Lead wires.

* Controller’s thick Lead wire (red)

* Thick Connecting lead wire (purple)

for connecting Switch to Terminal

block

Switch lever

Connector

of Controller

The extra portion of Controller’s

thin Lead wires (black, red) to be

connected to LED has to be put

in this position.

Connector of Controller’s lead wires

has to be connected to LED circuit

that facies Lead wire (Red) to Red

marking side.

And put the Lead wires into Lead

wire holder.

Terminal block

Red marking

Controller’s Lead wire (red)

Lead wire holder

Wiring in Motor housing

on Grip R side (Switch side)

Connecting Lead Wires

(yellow, orange purple) to

be connected to Switch in

Grip R

Fig. D-2A

P 11/ 27

Page 12

Wiring diagram

RP2301FC with electric Brake, LED Job Light, Electronic Control

Fig. D-3A

Lead wire holder

Wiring in Motor housing

on top side (Rear cover side)

Wiring in Grip (R)

Support unit

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wires (orange, yellow)

into Lead wire holder of inside

Controller

Support unit’s Lead wire (orange)

Support unit’s Lead wire (black)

Insulated connector

Connect Insulated connector to

Switch terminal 2 while keeping

it away from Boss.

Support unit’s Lead wire (yellow)

Put Controller into

the above illustrated

position.

Switch terminal 2

RP2301FC with electric Brake, LED Job Light, Electronic Control

Boss

P 12/ 27

Page 13

Circuit diagram

RP2300FC with LED Job Light, Electronic Control

White

Orange

Purple

Color index of lead wires' sheath

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Controller

Power

supply

cord

LED

Circuit

Support unit

Blue Lead wire

is used for

some countries.

Brown Lead wire

is used for some

countries.

Switch

Connector

of Conroller

Connector

of LED

Red

Fig. D-1B

Blue Lead wire

is used for

some countries.

P 13/ 27

Page 14

Wiring diagram

RP2300FC with LED Job Light, Electronic Control

Grip R

Lead Wire

Holder

When putting Lead wires for

connecting to Terminal block,

into this Lead wire holder,

Controller’s thin Lead wire (purple)

has to be put under the following

Lead wires.

* Controller’s thick Lead wire (red)

* Thick Connecting lead wire (purple)

for connecting Switch to Terminal

block

Switch lever

Connector

of Controller

The extra portion of Controller’s

thin Lead wires (black, red) to be

connected to LED has to be put

in this position.

Connector of Controller’s lead wires

has to be connected to LED circuit,

facing Lead wire (Red) to Red

marking side.

And put the Lead wires into Lead

wire holder.

Terminal block

Wiring in Motor housing

on Grip R side (Switch side)

Connecting lead wires

(orange purple) to be

connected to Switch in

Grip R

Fig. D-2B

Lead wire holder

Controller’s lead wire (red)

Red marking

P 14/ 27

Page 15

Wiring diagram

RP2300FC with LED Job Light, Electronic Control

Fig. D-3B

Lead wire holder

Wiring in Motor housing

on top side (Rear cover side)

Wiring in Grip R

Support unit

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wire (orange)

into Lead wire holder of inside

Controller

Support unit’s Lead wire (orange) Support unit’s Lead wire (black)

Put Controller into

the above illustrated

position.

RP2300FC with LED Job Light, Electronic Control

Insulated connector

Connect Insulated connector to

Switch terminal 2 while keeping

it away from Boss.

Switch terminal 2

Boss

P 15/ 27

Page 16

Circuit diagram

RP1801F with electric Brake, LED Job Light

White

Orange

Purple

Color index of lead wires' sheath

* Support unit without Choke coil is used for some countries.

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Power supply circuit

Power

supply

cord

LED

Circuit

*Support unit

Choke coil

Switch

Connector

of Conroller

Connector

of LED

Yellow

Red

Fig. D-1C

Brown Lead wire

is used for

some countries.

Blue Lead wire

is used for

some countries.

Blue Lead wire

is used for

some countries.

P 16/ 27

Page 17

Wiring diagram

P 17/ 27

R1801F with electric Brake, LED Job Light

Grip R

Lead wire

holder

When putting Lead wires for connecting

to Terminal block, into this Lead wire holder,

thin Lead wire (purple) of Power supply circuit

has to be put under the following Lead wires.

* Thick Lead wire (red) of Power supply circuit

* Thick Connecting lead wire (purple) for

connecting Switch to Terminal block

Switch lever

The extra portion of Controller’s

thin Lead wires (black, red) to be

connected to LED has to be put

in this position.

Connector of Controller’s lead wires

has to be connected to LED circuit,

facing Lead wire (Red) to Red

marking side.

And put the Lead wires into Lead

wire holder.

Terminal block

Lead wire holder

Connector of

controller

Red marking

Controller’s Lead wire (red)

Wiring in Motor housing

on Grip R side (Switch side)

Connecting lead wires

(yellow, orange purple) to

be connected to Switch in

Grip R

Fig. D-2C

Page 18

Wiring diagram

RP1801F with electric Brake, LED Job Light

RP1801F with electric Brake, LED Job Light

Fig. D-3C

Lead wire holder

Wiring in Motor housing

on top side (Rear cover side)

Support unit

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wires (orange, yellow)

into Lead wire holder of inside

Power supply circuit

Support unit’s Lead wire (orange)

Support unit’s Lead wire (black)

Insulated connector

Wiring in Grip R

Connect Insulated connector to

Switch terminal 2 while keeping it

away from Boss.

Support unit’s Lead wire (yellow)

Put Power supply

circuit into the above

illustrated position.

Switch terminal 2

Boss

P 18/ 27

Page 19

Circuit diagram

RP1801 with electric Brake

White

Orange

Purple

Color index of lead wires' sheath

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Power

supply

cord

*Support unit

Choke coil

Switch

Yellow

Fig. D-1D

Blue Lead wire

be used for

some countries.

Brown Lead wire

be for some

countries.

Noise

Suppressor

* Noise suppressor is not used for some countries.

P 19/ 27

Page 20

Wiring diagram

RP1801 with electric Brake

Grip R

Lead Wire

Holder

When putting Lead wires for

connecting to Terminal block,

into this Lead wire holder,

Noise suppressor’s thin Lead wire

(white) has to be put under the

following Lead wires.

* Support unit’s lead wire (black)

* Thick Connecting lead wire (purple)

for connecting Switch to Terminal

block

Switch lever

Terminal block

Connecting lad wires

(yellow, orange purple) to

be connected to Switch in

Grip R

Fig. D-2D

Noise

suppressor

Wiring in Motor housing

on Grip R side (Switch side)

P 20/ 27

Page 21

Wiring diagram

RP1801 with electric Brake

RP1801 with electric Brake

Fig. D-3D

Lead wire holder

Support unit

Wiring in Motor housing

on top side (Rear cover side)

Wiring in Grip (R)

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wires (orange, yellow)

into Lead wire holder of inside

Support unit’s Lead wire (orange)

Support unit’s Lead wire (black)

Insulated connector

Connect Insulated connector to

Switch terminal 2 while keeping it

away from Boss.

Support unit’s Lead wire (yellow)

Switch terminal 2

Boss

P 21/ 27

Page 22

Circuit diagram

RP1800F with LED Job Light

White

Orange

Purple

Color index of lead wires' sheath

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Power supply circuit

Power

supply

cord

LED

circuit

Support unit

Blue Lead wire

is used for

some countries.

Blue Lead wire

is used for

some countries.

Brown Lead wire

is used for some

countries.

Switch

Connector

of Conroller

Connector

of LED

Red

Fig. D-1E

P 22/ 27

Page 23

Wiring diagram

RP1800F with LED Job Light

Grip R

Lead Wire

Holder

Switch lever

Connector

of Controller

The extra portion of Controller’s

thin Lead wires (black, red) to be

connected to LED has to be put

in this position.

Connector of Controller’s lead wires

has to be connected to LED circuit,

facing Lead wire (Red) to Red

marking side.

And put the Lead wires into Lead

wire holder.

Lead wire holder

Terminal block

Red marking

Controller’s Lead wire (red)

Wiring in Motor housing

on Grip R side (Switch side)

Connecting lead wires

(orange purple) to be

connected to Switch in

Grip R

Fig. D-2E

When putting Lead wires for connecting

to Terminal block, into this Lead wire holder,

thin Lead wire (purple) of Power supply circuit

has to be put under the following Lead wires.

* Thick Lead wire (red) of Power supply circuit

* Thick Connecting lead wire (purple) for

connecting Switch to Terminal block

P 23/ 27

Page 24

Wiring diagram

Wiring in Motor housing

on top side (Rear cover side)

RP1800F with LED Job Light

Fig. D-3E

Lead wire holder

Support Unit

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wire (orange)

into Lead wire holder of inside

Power supply

circuit

Support unit’s Lead wire (orange) Support unit’s Lead wire (black)

Put Power supply

circuit into the above

illustrated position.

Wiring in Grip (R)

RP1800F with LED Job Light

Insulated connector

Connect Insulated connector to

Switch terminal 2, keeping it

away from the Boss.

Switch terminal 2

Boss

P 24/ 27

Page 25

Circuit diagram

RP1800

White

Orange

Purple

Color index of lead wires' sheath

* Noise suppressor is not used for some countries.

Black

Makita

logo side

Name

plate side

Motor housing

Grip R

Power

supply

cord

Support unit

Switch

Fig. D-1F

Blue Lead wire

is used for

some countries.

Brown Lead wire

is used for some

countries.

Noise

suppressor

P 25/ 27

Page 26

Wiring diagram

RP1800

Grip R

Lead Wire

Holder

When putting Lead wires for

connecting to Terminal block,

into this Lead wire holder,

Noise suppressor’s thin Lead wire

(white) has to be put under the

following Lead wires.

* Support unit’s lead wire (black)

* Thick Connecting lead wire (purple)

for connecting Switch to Terminal

block

Switch lever

Terminal block

Wiring in Motor housing

on Grip R side (Switch side)

Connecting lead wires (orange, purple)

to be connected to Switch in Grip R

Fig. D-2F

Noise

suppressor

P 26/ 27

Page 27

Wiring diagram

Wiring in Motor housing

on top side (Rear cover side)

RP1800

Fig. D-3F

Lead wire holder

Support unit

When putting Support unit’s Lead wires

into Lead wire holders, put them as follows.

* Support unit’s Lead wire (black)

into Lead wire holder of outside

* Support unit’s Lead wire (orange)

into Lead wire holder of inside

Support unit’s lead wire (orange) Support unit’s lead wire (black)

Wiring in Grip (R)

RP1800

Insulated connector

Connect Insulated connector to

Switch terminal 2 while keeping

it away from Boss.

Switch terminal 2

Boss

P 27/ 27

Loading...

Loading...