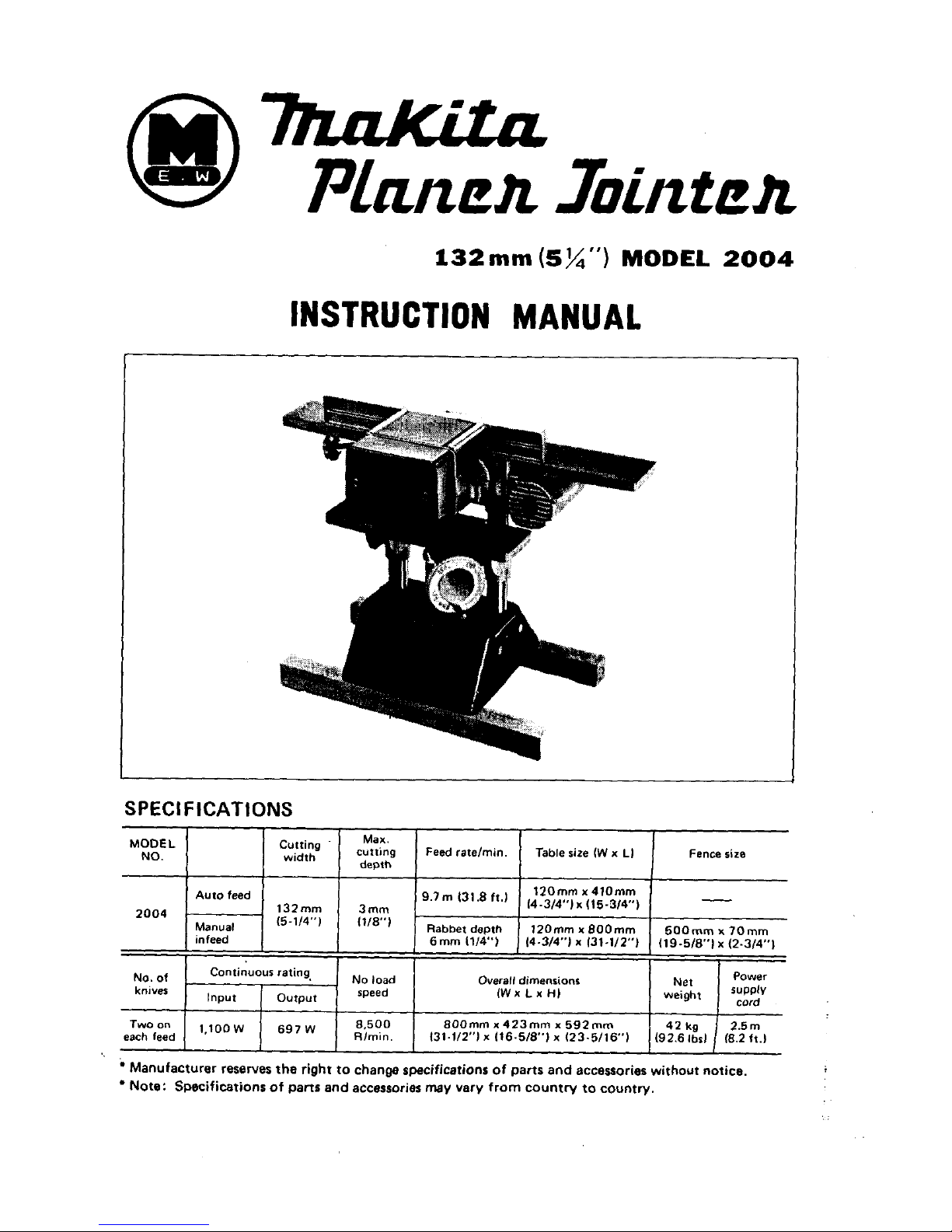

Makita PLANER JOINTER 2004, 2004 Instruction Manual

132

mm

(5%")

MODEL

2004

NO.

MODEL

2004

No,

of

knives

Two

on

each feed

INSTRUCTION

MANUAL

width

-

czkg Feed ratelmin. Table size fW

x

L)

Fence size

depth

-

120"

x

410"

Auto feed

9.7m

131'8ft') (4.3/4")~(15.3/4")

132" 3mm

~

Manual f5-1/4")

f118")

Rabbet depth l2Omm

x

8OOmm

500" x 70"

infeed

6mm

1114"l

1444")

x

131-1/2"1

119-5/8") x (2-3/4")

No

load Overall dimensions Power

Continuour rating,

Input

Output

speed fWx

Lx

HI

ws"$),

SUPPk

cord

8.500 800mm

x

423" x 592"

42

kg

2.5m

'''0°

697

R/min. 131.1/2") X (16-5/8") x 123.5/16') (92.6

lbsl

18.2

ft.)

BEFORE CONNECTING YOUR TOOL

TO

A

POWER SOURCE

Be

sure

you

have

read

all

GENERAL POWER TOOL SAFETY RULES

GENERAL SAFETY PRECAUTIONS

1.

KEEP GUARDS IN PLACE and

in

working order.

2.

REMOVE ADJUSTING KEYS AND WRENCHES.

Form habit of checking to

see

that keys and adjusting wrenches are removed from tool before turning

it

on.

3.

KEEP WORK AREA CLEAN. Cluttered areas

and

benches invite accidents.

4.

AVOID DANGEROUS ENVIRONMENT. Don't

use

power tools in damp or wet

locations. Keep work

area

well

lit.

5.

KEEP CHILDREN AWAY. All visitors should

be

kept

safe

distance from work area.

6.

MAKE WORKSHOP KID PROOF

-With

padlocks, master switch-, or by remov-

7.

DON'T FORCE TOOL.

It

will do

the

job

better and safer

at

the rate for which

it

8.

USE

RIGHT

TOOL. Don't force tool or attachment to do a job

it

was not designed

9.

WEAR PROPER APPAREL. No loose clothing or jewelry to get caught

in

moving

10.

USE SAFETY GLASSES. Also

use

face or dust mask

if

cutting operation

is

dusty.

11.

SECURE WORK. Use clamps or a vise to hold work when practical.

It's

safer than

12.

DON'T OVERREACH. Keep proper footing and balance

at

all

times.

13.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest

performance. Follow instructions for lubricating and changing accessories.

14.

DISCONNECT TOOLS before servicing; when changing accessories such

as

cutter

blades.

15.

AVOID ACCIDENTAL STARTING. Make sure switch

is

in

off

position before

plugging in.

16.

USE RECOMMENDED ACCESSORIES. Consult the owner's manual for recommended accessories. The use

of

improper accessories may cause hazards.

17.

NEVER STAND ON TOOL. Serious injury could occur

if

the

tool

is

tipped or

if

the cutting tool

is

accidentally contacted.

18.

CHECK DAMAGED PARTS.

Before further use of

the

tool, a guard or other part

that

is

damaged should be carefully checked to ensure that

is

will operate properly

and perform

its

intended function - check for alignment

of

moving

parts,

binding

of moving parts, breakage of

parts,

mounting, and any other conditions that

may

affect

its

operation. A guard or other part that

is

damaged should

be

properly

re-

paired or replaced.

19.

PROPER GROUNDING. These tools should be grounded while in

use

to protect

the

operator from electric shock.

ing starter keys.

was designed.

for.

parts. Rubberjoled footwear

is

recommended for best footing.

using your hand and

it

frees both hands to operate

tool.

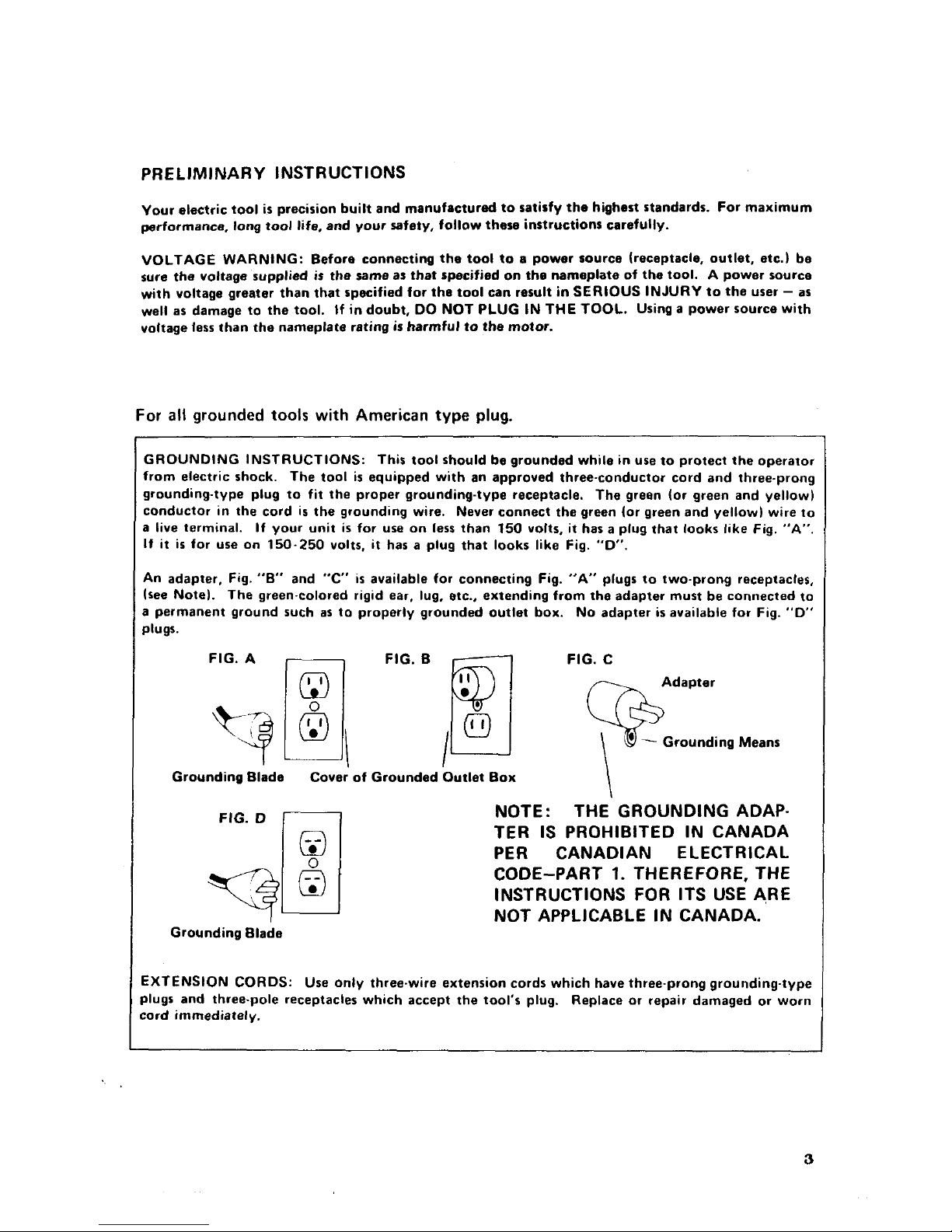

PRE

LlMl NAR

Y I NSTR UCTl ONS

Your electric tool

is

precision built and manufactured

to

satisfy the highest standards. For maximum

performance,

long

tool life, and your safety, follow these instructions carefully.

VOLTAGE WARNING: Before connecting the tool to

a

power source (receptacle, outlet, etc.) be

sure the voltage supplied

is

the same as that specified

on

the nameplate of the tool.

A power source

with voltage greater than that specified for

the

tool can result

in

SERIOUS INJURY to the user - as

well as damage to the tool. If

in

doubt,

DO

NOT PLUG

IN

THE TOOL. Using a power source with

voltage

less

than the nameplate rating

is

harmful

to

the motor.

For

all

grounded

tools

with

American type plug.

GROUNDING INSTRUCTIONS: This tool should be grounded while

in

use to protect

the

operator

from electric shock. The tool

is

equipped with an approved three-conductor cord and threeprong

grounding-type plug to fit the proper grounding-type receptacle. The green (or green and yellow)

conductor

in

the

cord

is

the grounding wire. Never connect the green (or green and yellow) wire to

a live terminal. If your unit

is

for use

on

less than

150

volts,

it

has a plug that looks like Fig.

"A".

It

it

is

for ure on

150-250

volts, it has a plug that

looks

like Fig.

"D".

An adapter, Fig. "B" and

"C'

is

available for connecting Fig.

"A'

plugs to two-prong receptacles,

(see Note). The green-colored rigid ear, lug, etc., extending from the adapter must be connected to

a permanent ground such as to properly grounded outlet box.

No adapter

is

available for Fig.

"D"

plugs.

\

Grounding Blade

Cover' of Grounded Outlet Box

FIG.

D

NOTE: THE GROUNDING ADAP-

TER

IS

PROHIBITED IN CANADA

PER

CANADIAN ELECTRICAL

INSTRUCTIONS FOR ITS USE ARE

NOT APPLICABLE IN CANADA.

CODE-PART

1.

THEREFORE, THE

Grounding Blade

EXTENSION

CORDS:

Use

only three-wire extension cords which have three-prong grounding-type

plugs and three-pole receptacles which accept the tool's plug.

Replace or repair damaged or worn

:ord immediately.

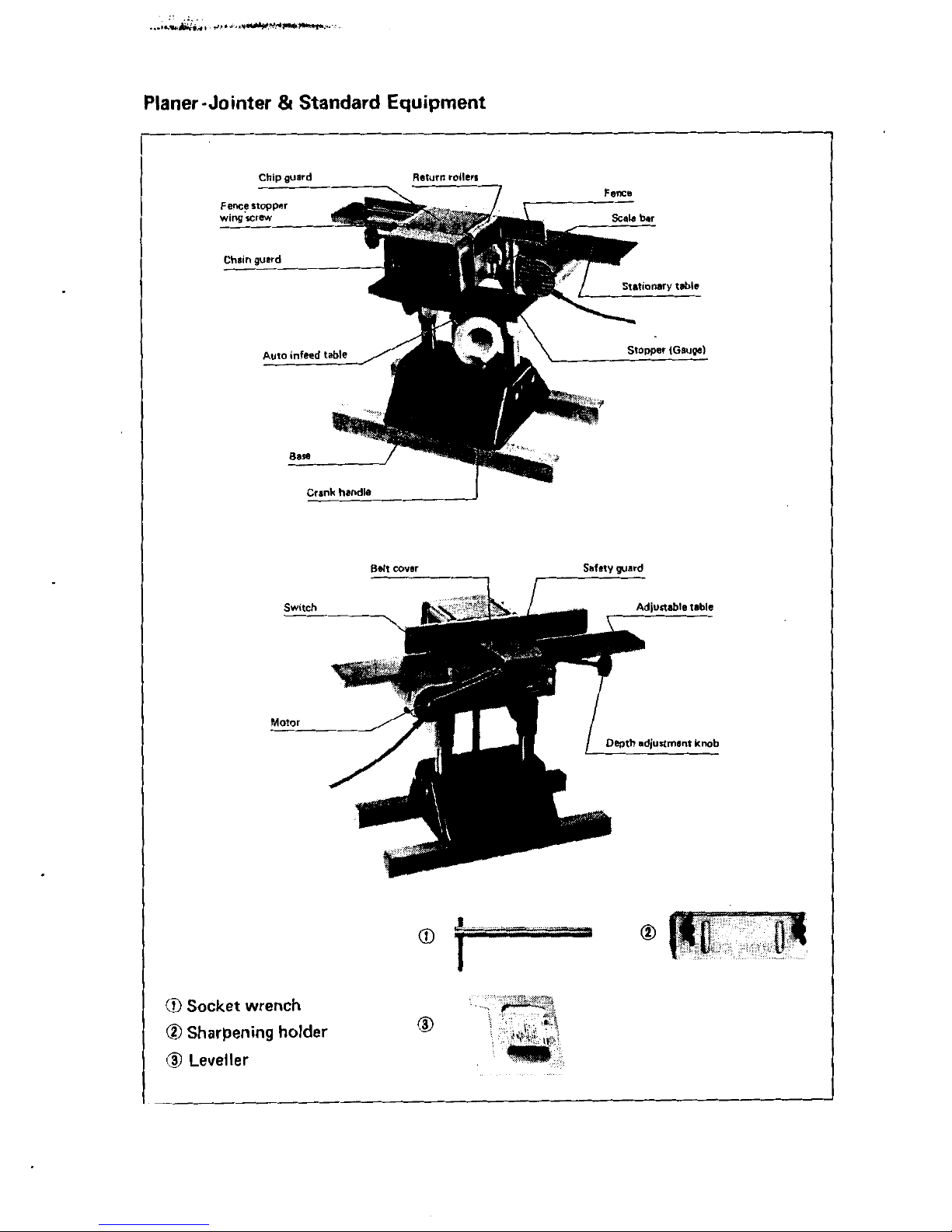

3

Crank

handle

I

safety

guard

Belt

cover

------lI

0

Socket wrench

0

Sharpening holder

@

Leveller

0

I

Special Precautions with Planer- Jointer

a.

Jointing Operations

Do

not perform jointing operations on material shorter than

4-3/8

inches

(110

mm),

narrower than

314

inch

(19

mm), or

less

than

1/4

inch

(6.4

mm) thick.

Do

not perform planing operations on material shorter than

4-3/8

inches

(110

mm),

narrower than

3/4

inch

(19

mm), wider than

5-1/4

inches

(132

mm)

in auto feed and

5-1/4

inches

(132

mm) in manual infeed or thinner than

1/2

inch

(12.7

mm).

c.

Maintain the proper relationships of infeed and outfeed table surfaces and cutter head

b.

Planing Operations

knife path.

d. Support the workpiece adequately

at

all

times during operation; maintain control of

the work

at

all

times.

e.

Do

not back the work toward the infeed table.

f.

Do

not attempt to perform an abnormal or little-used operation without study and the

use

of

adequate holddown/push blocks, jigs, fixtures, stops, etc.

HOW

TO

USE

I

Forthe Planer

1

1.

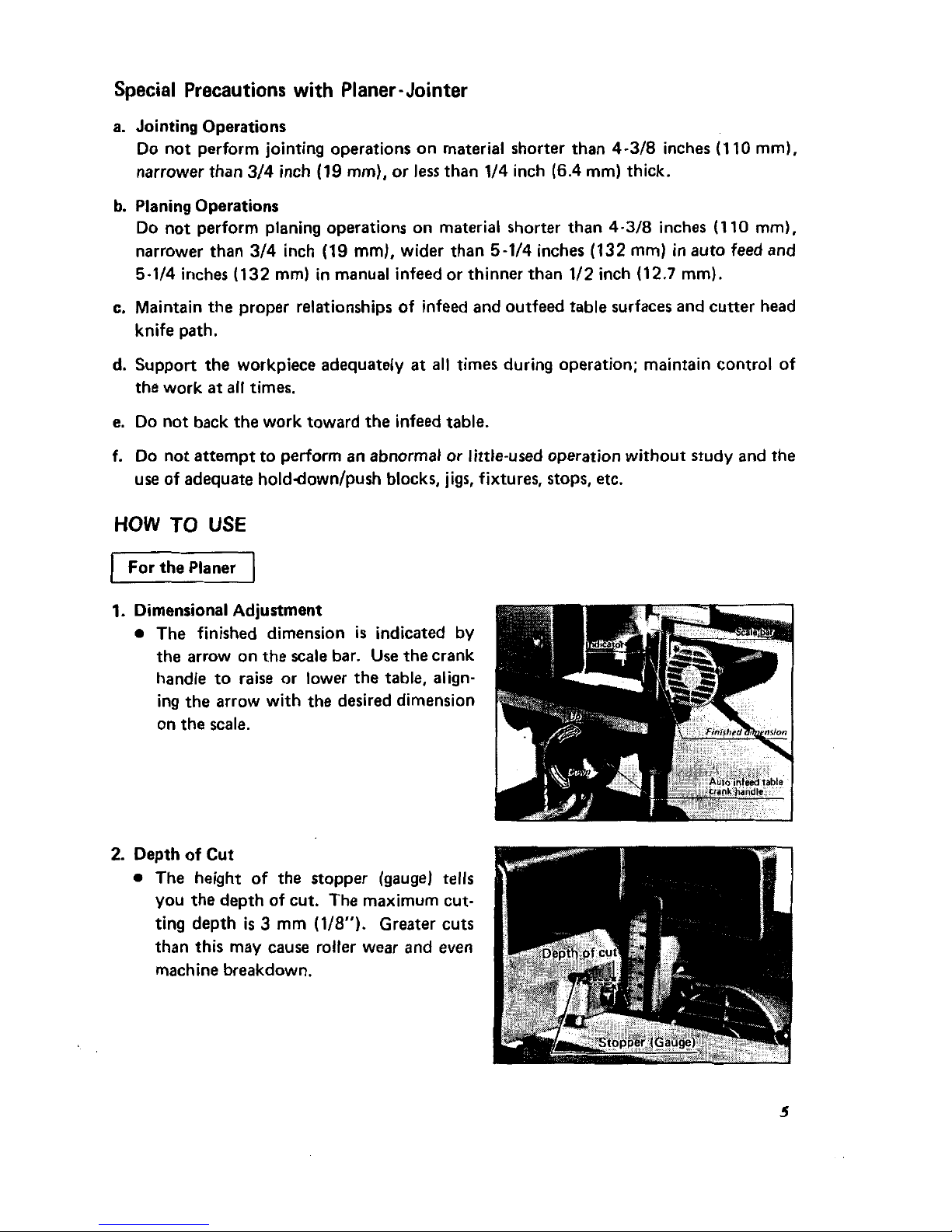

Dimensional Adjustment

0

The finished dimension

is

indicated by

the arrow on the scale bar.

Use

the crank

handle to raise or lower the table, aligning the arrow with the desired dimension

on the scale.

2.

Depth

of

Cut

0

The height

of

the stopper (gaugej

tells

you the depth of cut. The maximum cutting depth

is

3

mm

(1/8").

Greater cuts

than this may cause roller wear and even

machine breakdown.

5

Loading...

Loading...