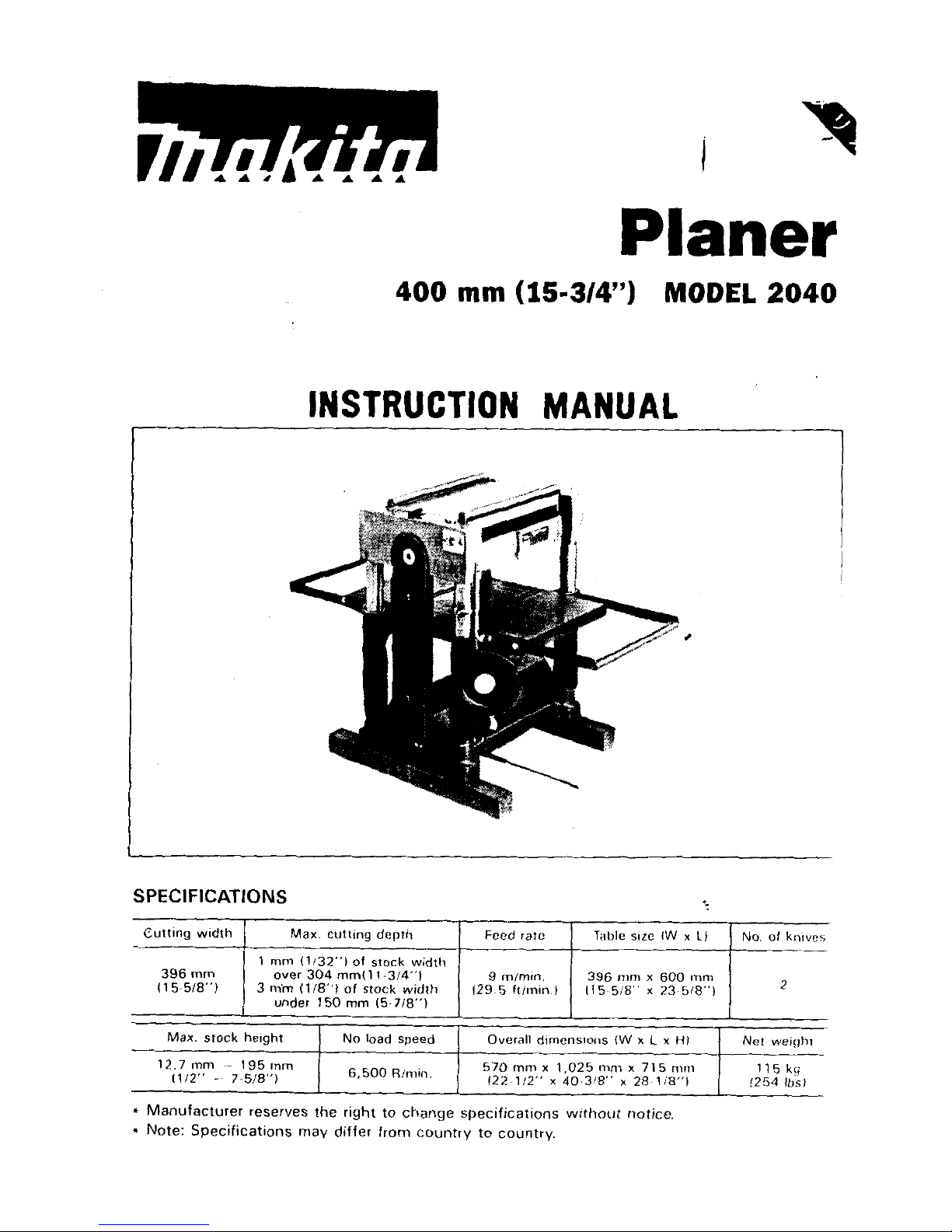

Makita PLANER 2040 Instruction Manual

Planer

1

mm

11/32")

of

stock

wtdth

over

304

mmll 1-314")

3

mm

1118"l

of

stock

width

under

150

mm

15-718")

Max.

srock

height

No

load

speed

12.7

mm

-

195mm

6,500

,,,,

In,

1112"

-

7-518")

400

mm

(15-3/4")

MODEL

2040

2

9

m/mm

129

5

ftimin.1

396

mm

x

600

nim

115 5/8"

x

23

5/8"1

Overall

dimenslons

(W

x

L

x

HI

570

mm

x

1,025

111111

x

715

rnnl

Net

weight

115

kg

(254

Ibsl

122

112"

x

40.318''

x

28

118"l

INSTRUCTION

MANUAL

SPEC

IF I CAT

IONS

396

mm

I1

5~518")

For Your Own Safety Read Instruction

Manual Before Operating Planer

GENERAL SAFETY PRECAUTIONS

(For

All

Tools)

1.

KNOW YOUR POWER TOOL. Read the owner's manual carefully. Learn the

tools applications and limitations, as well as the specific potential hazards

peculiar to

it.

2.

KEEP GUARDS IN PLACE and

in

working order.

3.

REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to

see that keys and adjusting wrenches are removed from tool before turning

it

on.

4.

KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

5. DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools

in

damp

or

wet locations, or expose them to rain. Keep work area well lighted.

6.

KEEP CHILDREN AWAY. All visitors should be kept safe distance from work

area.

7.

MAKE WORKSHOP KID

PROOF

with padlocks, master switches, or by

removing starter keys.

8.

DON'T FORCE TOOL.

It

will do the job better and safer at the rate for which

it

was designed.

9.

USE RIGHT TOOL. Don't force tool or attachment to do a job for which

it

was not designed.

10.

WEAR PROPER APPAREL. Wear no

loose

clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get caught

in

moving parts. Nonslip

footwear is recommended. Wear protective hair covering to contain long hair.

11.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask

if

cutting operation is dusty. Everyday eyeglasses only have impact resistant lenses, they

are NOT safety glasses.

12.

SECURE WORK. Use clamps or a vise to hold work when practical. It's safer

than using your hand and

it

frees both hands to operate tool.

13.

DON'T OVERREACH. Keep proper footing and balance at all times.

14.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and

safest performance. Follow instructions for lubricating and changing accessories.

15. DISCONNECT TOOLS before servicing; when changing accessories such as

blades, bits, cutters, and the like.

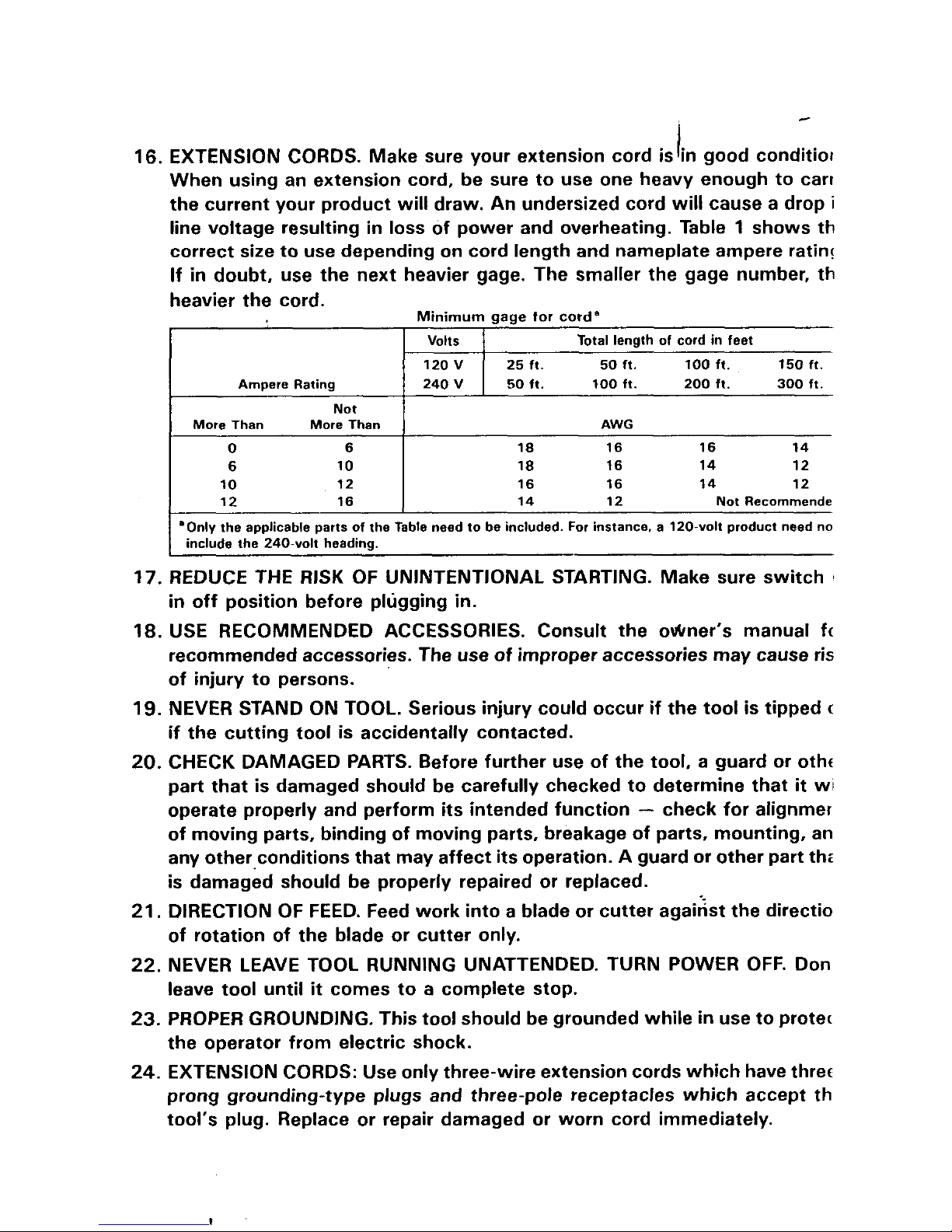

"

Ampere Rating

Not

More Than More Than

0

6

6 10

10 12

12 16

Volts

12OV 25ft. 50ft. 100ft. 150

ft.

240V 5011. 100 ft. 200 ft.

300

ft.

Total length of cord in feet

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommende

'Only the applicable parts of the Table need to be included. For instance. a 120-volt product need no

I

include the 240-volt headina.

17. REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure switch

in

off position before plugging

in.

18.

USE RECOMMENDED ACCESSORIES. Consult the owner's manual fc

recommended accessories. The use of improper accessories may cause ris

of injury to persons.

19.

NEVER STAND ON TOOL. Serious injury could occur

if

the tool is tipped

c

if

the cutting tool is accidentally contacted.

20.

CHECK DAMAGED PARTS. Before further use of the tool, a guard or otht

part that is damaged should be carefully checked to determine that

it

wi

operate properly and perform its intended function

-

check for alignmer

of moving parts, binding of moving parts, breakage of parts, mounting, an

any other.conditions that may affect its operation. A guard or other part

thc

is damaged should be properly repaired or replaced.

21.

DIRECTION OF FEED. Feed work into a blade or cutter against the directio

of rotation of the blade or cutter only.

22.

NEVER LEAVE TOOL RUNNING UNATTENDED. TURN POWER OFF. Don

leave tool

until

it

comes to a complete stop.

23.

PROPER GROUNDING. This tool should be grounded while

in

use to protec

the operator from electric shock.

24.

EXTENSION CORDS: Use only three-wire extension cords which have threr

prong grounding-type plugs and three-pole receptacles which accept th

tool's plug. Replace or repair damaged or worn cord immediately.

I

3LTAGE WARNING: Before connecting the tool to a power source (receptacle,

Itlet, etc.) be sure the voltage supplied is the same as that specified on the

meplate of the tool. A power source

)r the tool can result

le tool. If

in

doubt, DO NOT PLUG IN THE TOOL. Using a power source

in

SERIOUS INJURY to the user - as well as damage to

with

voltage greater than that specified

with

oltage less than the nameplate rating is harmful to the motor.

;ROUNDING INSTRUCTIONS

\LL GROUNDED, CORD-CONNECTED

TOOLS:

In

the event of a malfunction or

Breakdown, giounding provides a path of least resistance for electric current to

educe the risk of electric shock. This tool is equipped with an electric cord having

an

equipment-grounding conductor and a grounding plug. The

ilugged into a matching outlet that is properly installed and grounded

plug

must be

in

ac-

zordance with all local codes and ordinances.

Do

not modify the

plug

provided-if

it

will

not fit the outlet, have the proper

outlet installed by a qualified electrician.

in

Improper connection of the equipment-grounding conductor can result

of electric shock. The conductor

is

green with or without yellow stripes is the equipment-grounding conductor.

If

repair or replacement of

the

with

insulation having an outer surface that

electric cord or plug is necessary, do not connect

a risk

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or serviceman if the grounding instructions

are not completely understood, or if

in

doubt as to whether the tool is properly

grounded.

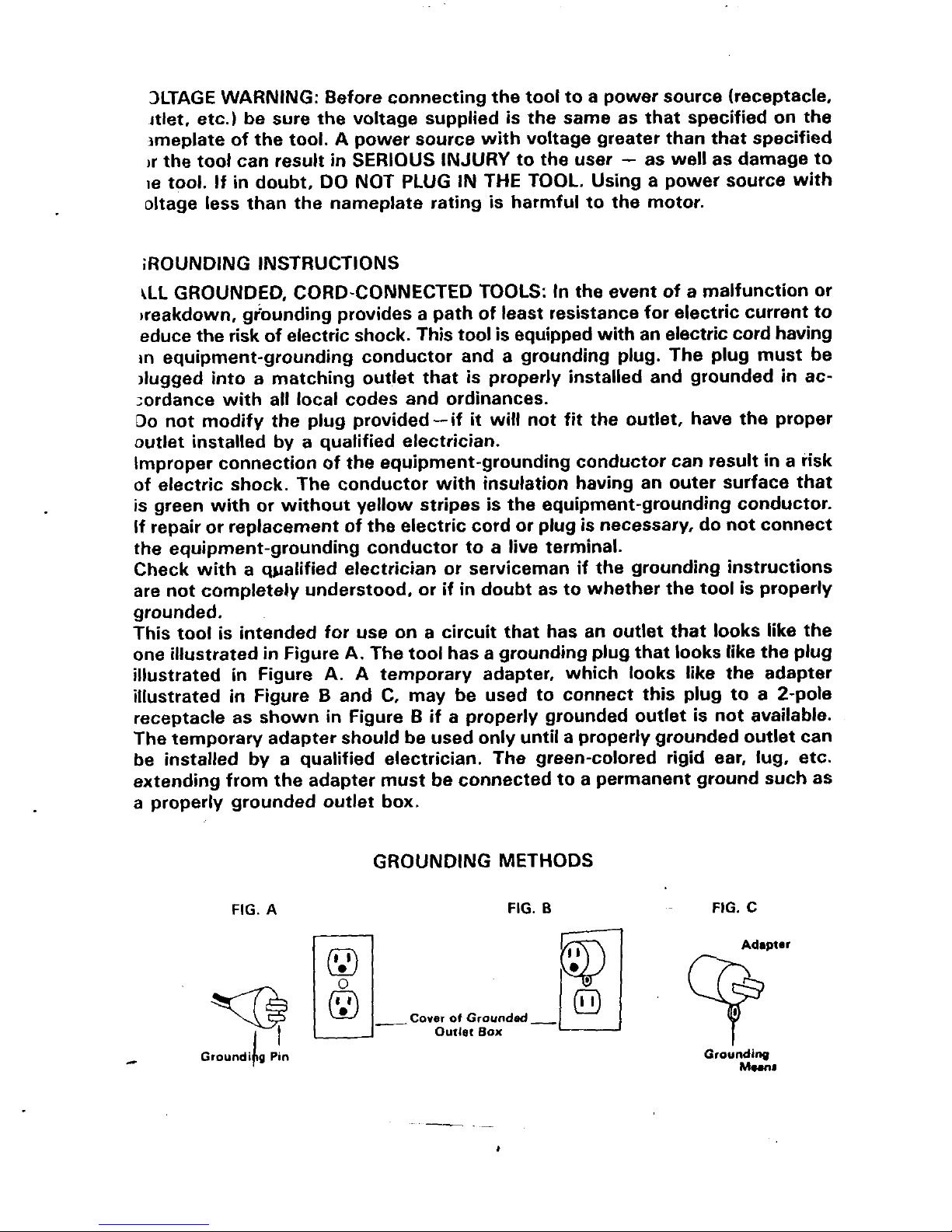

This tool is intended for use on a circuit that has an outlet that looks like the

one illustrated

illustrated

illustrated

receptacle as shown

The temporary adapter should be used only

be installed by a qualified electrician. The green-colored rigid ear,

in

Figure A. The tool has a grounding

in

Figure A.

in

Figure B and C, may be used

A

temporary adapter, which looks like the adapter

in

Figure B if a properly grounded outlet is not available.

plug

that looks like the

to

connect this

until

a properly grounded outlet can

plug

to a 2-pole

lug,

plug

etc.

extending from the adapter must be connected to a permanent ground such as

a properly grounded outlet box.

FIG.

A

Groundibg

Pin

GROUNDING METHODS

FIG.

B

--

I

~

FIG.

C

Grounding

Munl

ADDITIONAL

SAFETY

RULES

1.

Wear eye protection.

2. Never perform planing operation with drive guard removed.

3.

Do not perform planing operations on material shorter than (a dimension

equal to the cutter head length plus 2 inches), narrower than

314

inch, or

wider than (the cutter capacity

in

inches) or thinner than

1/2

inch.

4.

Don't use the tool

in

presence of flammable liquids or gases.

5.

Handle the blades very carefully.

6. Check the blades carefully for cracks or damage before operation. Replace

7.

Be sure the planer blade installation bolts are securely tightened before

8.

Sharpen both blades evenly, or replace both blades or both cutterhead covers

9.

Remove nails and clean the workpiece before cutting. Nail, sand or other

10.

Make sure

the

blade is not contacting workpiece before

the

switch is turned

11.

Wait

until

the blades attain full speed before cutting.

12.

Keep hands away from rotating parts.

13. Don't back the workpiece toward the infeed table.

14.

Two or more pieces of narrow but similar thickness stock can be passed

through the auto-planer side by side.

However, allow some spacing between the stock to permit the feed rollers

to grip the thinnest piece.

Otherwise, a slightly thinner piece could be kicked back by the cutterhead.

15. Stop operation immediately if you notice anything abnormal.

16. Always switch off and wait for blades to come to a complete stop before

17.

Never stick your finger into

the

chip chute. Chute may jam when cutting

18. Don't touch blades right after operation, they may be extremely hot and could

19.

Don't abuse cord. Never yank cord to disconnect from receptacle. Keep cord

cracked

or

damaged blades immediately.

operating.

at the same time.

matter can cause blade damage.

on.

adjusting any parts, cleaning out chips or approaching the blade.

damp wood. Turn off the planer and then clean out chips with a stick.

burn your skin.

from heat,

oil

and sharp edges.

SAVE THESE INSTRUCTIONS.

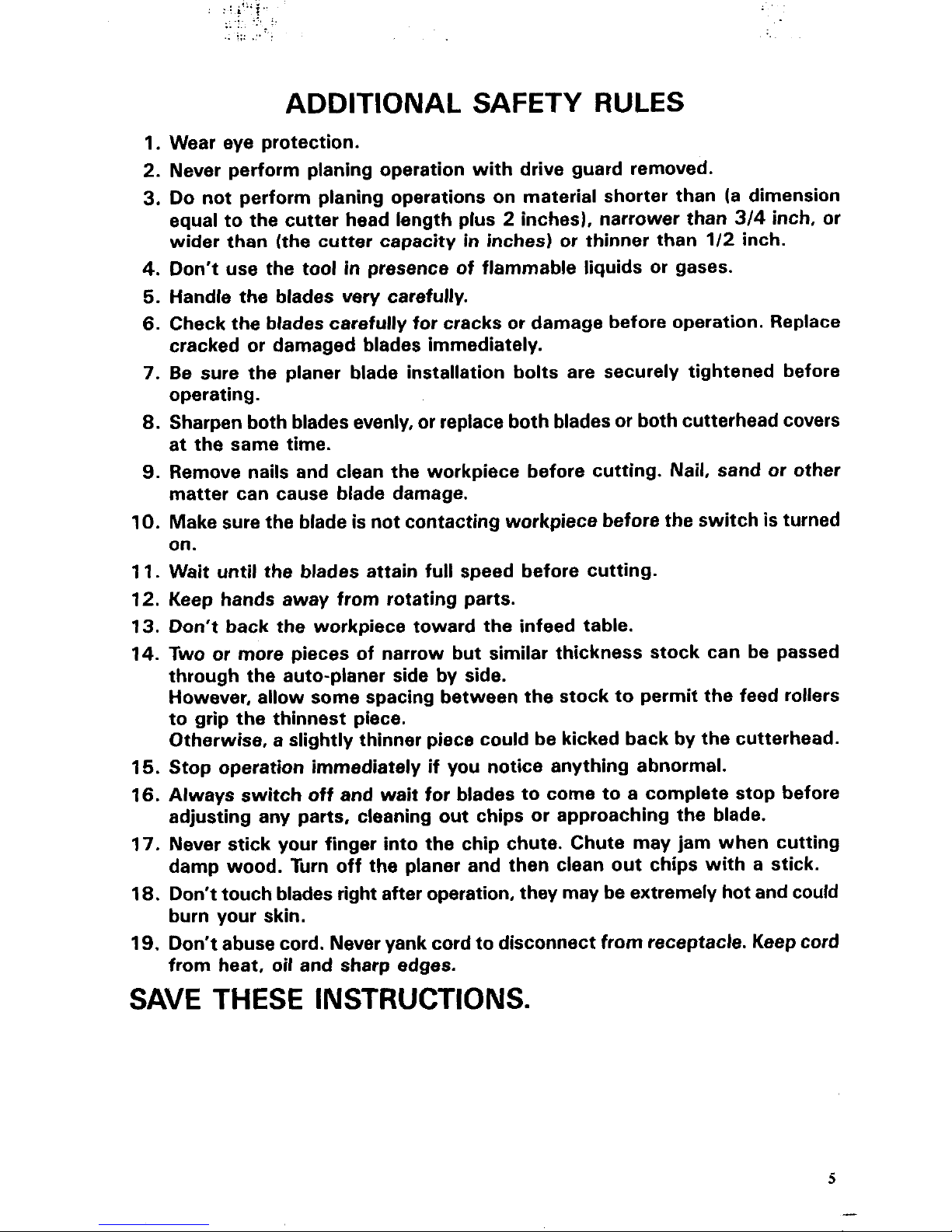

the scale bar graduation for the desired

finished dimension

is

reached. Algin your

workpiece with the top of the table. (One

handle revolution makes for

3

mm

(1/8")

ascent or descent.)

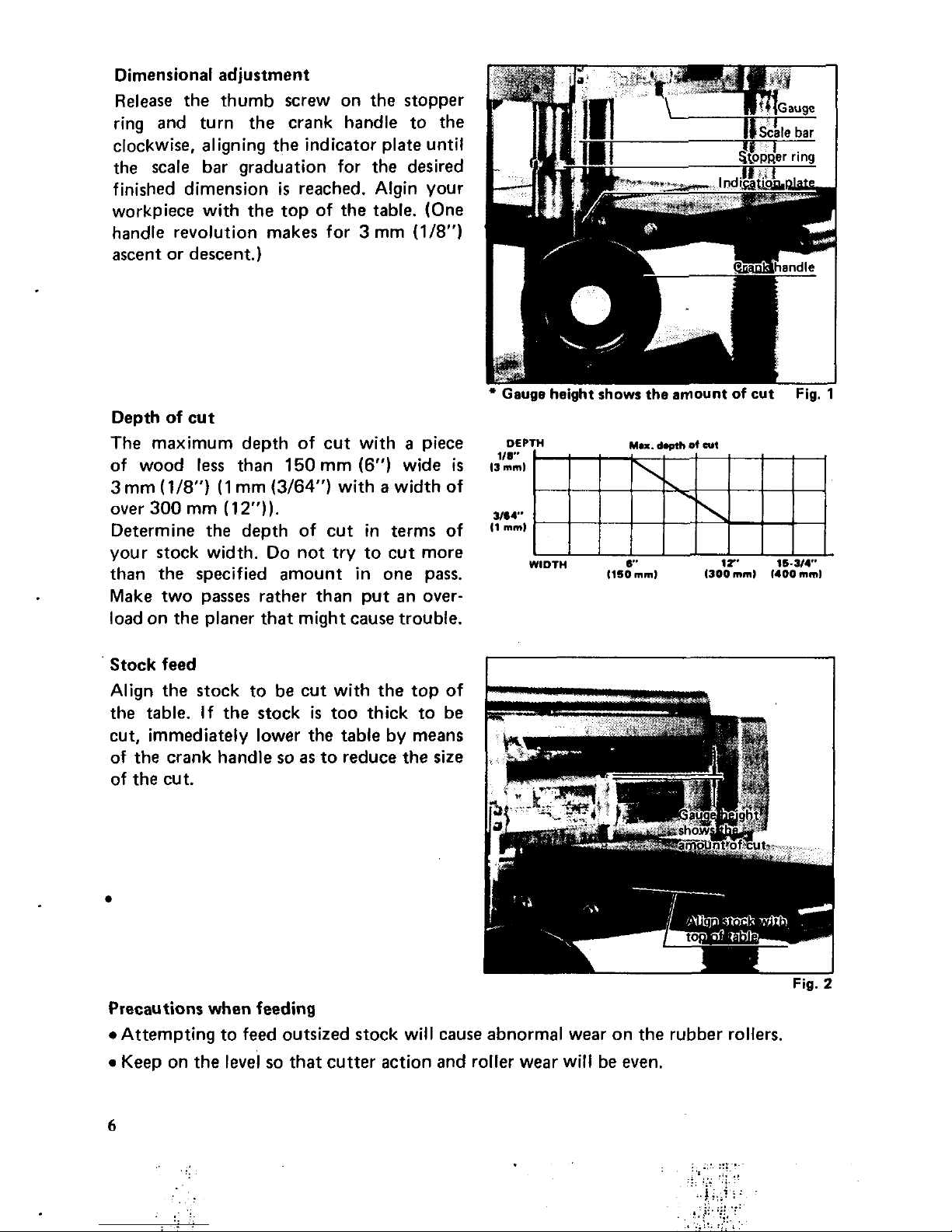

Depth of cut

The maximum depth of cut with

a

piece

of wood

less

than

150

mm

(6")

wide

is

3

mm

(1/8") (1

mm

(3/64")

with a width of

over

300

mm

(1

2")).

Determine the depth of cut in terms of

your stock width.

Do

not try to

cut

more

than the specified amount in one pass.

Make two passes rather than put an overload on the planer that might cause trouble.

Gauge height shows the amount

of

cut Fig.

1

OEP

118-

I3

mml

3m4"

11

mml

c'

1I'

16-314"

1150

mml

1300

mml

1400mml

WIDTH

Stock feed

Align the stock to be cut with the top

of

the table. If the stock

is

too thick to be

cut, immediately lower the table by means

of

the

crank handle

so

as

to reduce

the

size

of the cut.

Fig.

:

Precautions when feeding

*Attempting to feed outsized stock will cause abnormal wear on the rubber rollers.

Keep on the

level

so

that cutter action and roller wear will be even.

6

Loading...

Loading...