Page 1

Table Top Miter Saw

Instruction Manual

Universal-Kapp- und Gehrungssäge

Betriebsanleitung

Piła ukośnica ze stołem

Instrukcja obsługi

Настольная торцовочная пила

Инструкция по эксплуатации

LH1040

LH1040F

Page 2

13

3

1

2

24

12

8

6

5

7

34

8

12

9

10

11

2

6

13

56

15

14

17

19

16

20

18

78

2

Page 3

11

11

21

17

910

23

24

22

11 12

11

13 14

10

6

26

7

28

27

15 16

12

25

2

6

29

3

Page 4

30

31

7

7

2

12

17 18

33

32

33

31

19 20

8

4-5 mm

38

39

2

2

34

31

2

31

35

36

37

21 22

38

2

40

23 24

4

45

43

41

44

42

Page 5

27

31

48

45

46

AB

45

C

D

47

25 26

45

49

43

46

44

27 28

46

51

51

45

50

46

8

31

50

31

45

29 30

55

52

52

53

54

31 32

53

54

5

Page 6

57

53

56

33 34

58

59

60

61

16

62

63

64

9

35 36

6362

37 38

66

65

64

3

67

63

68

39 40

6

68

Page 7

68

69

70

16

69

41 42

71

62

9

72

57

43 44

140mm

76

15mm

300mm

14mm

40mm

70mm

10mm

73

45 46

80

55mm

73

10

200mm

10mm

79

30mm

74

77

130mm

80mm

10mm

30mm

9mm

250mm

50mm

100mm

75

78

77

81

82

47 48

7

Page 8

25

49 50

2

51 52

59

11

84

53 54

85

83

16

83

19

31

14

11

59

1721

55 56

8

11

85

17

86

Page 9

87

57 58

89

88

9

Page 10

Symbols

The followings show the symbols used for the tool. Be sure that you understand their meaning before use.

Symbole

Die folgenden Symbole werden für die Maschine verwendet. Machen Sie sich vor der Benutzung unbedingt mit ihrer

Bedeutung vertraut.

Symbole

Poniższe symbole używane są do opisu urządzenia. Przed użyciem należy upewnić się, że rozumie się ich znaczenie.

Символы

Следующие объяснения показывают символы, используемые для инструмента. Убедитесь перед

использованием, что Вы понимаете их значение.

❏ Read instruction manual.

❏ Bitte Bedienungsanleitung lesen.

❏ Przeczytaj instrukcję obsługi.

❏ Прочитайте инструкцию по эксплуатации.

❏ DOUBLE INSULATION

❏ DOPPELT SCHUTZISOLIERT

❏ PODWÓJNA IZOLACJA

❏ ДВОЙНАЯ ИЗОЛЯЦИЯ

❏ To avoid injury from flying debris, keep holding the saw head down, after making cuts, until the

blade has come to a complete stop.

❏ Um Verletzungen durch herausgeschleuderte Teile zu vermeiden, halten Sie den Sägekopf nach

Ausführung von Schnitten abgesenkt, bis das Sägeblatt völlig zum Stillstand gekommen ist.

❏ Aby uniknąć zranienia odskakującymi odpadkami, po zakończeniu cięcia trzymaj głowicę piły w

dole, aż do całkowitego zatrzymania się brzeszczotu.

❏ Чтобы избежать травмы от летящих обрезков, удерживайте переднюю часть пилы,

обращенной вниз, после выполнения резки до тех пор, пока лезвие не остановится

полностью.

❏ When using the tool in the miter saw mode, secure the top table at the topmost blade never pro-

trudes from the top surface of the top table.

❏ Wenn Sie die Maschine im Gehrungssägenmodus verwenden, sichern Sie den oberen Tisch in

der Höchststellung, damit das Sägeblatt nicht über die Oberfläche des oberen Tisches hinausragt.

❏ W przypadku korzystania z urządzenia w trybie cięcia ukośnego, zamocuj stół górny tak, aby

brzeszczot nigdy nie wystawał poza górną powierzchnię stołu.

❏ При использовании инструмента в режиме торцовочной пилы закрепите верхний стол в

самом верхнем положении так, чтобы лезвие никогда не выступало на верхней

поверхности верхнего стола.

10

❏ For your safety, remove chips, small pieces, etc. from the table top before operation.

❏ Zur Sicherheit sollte die Tischplatte vor dem Betrieb von Spänen, Kleinteilen usw. gesäubert wer-

den.

❏ Dla bezpieczeństwa przed przystąpieniem do pracy usuń strużyny, małe odpady itp. z

powierzchni stołu.

❏ Для Вашей безопасности удалите стружки, маленькие куски и т.д. со стола перед

эксплуатацией.

❏ Do not place hand or fingers close to the blade.

❏ Halten Sie Hände oder Finger vom Sägeblatt fern

❏ Nie zbliżaj rąk i palców do brzeszczotu.

❏ Не помещайте руки или пальцы близко к лезвию.

Page 11

ENGLISH

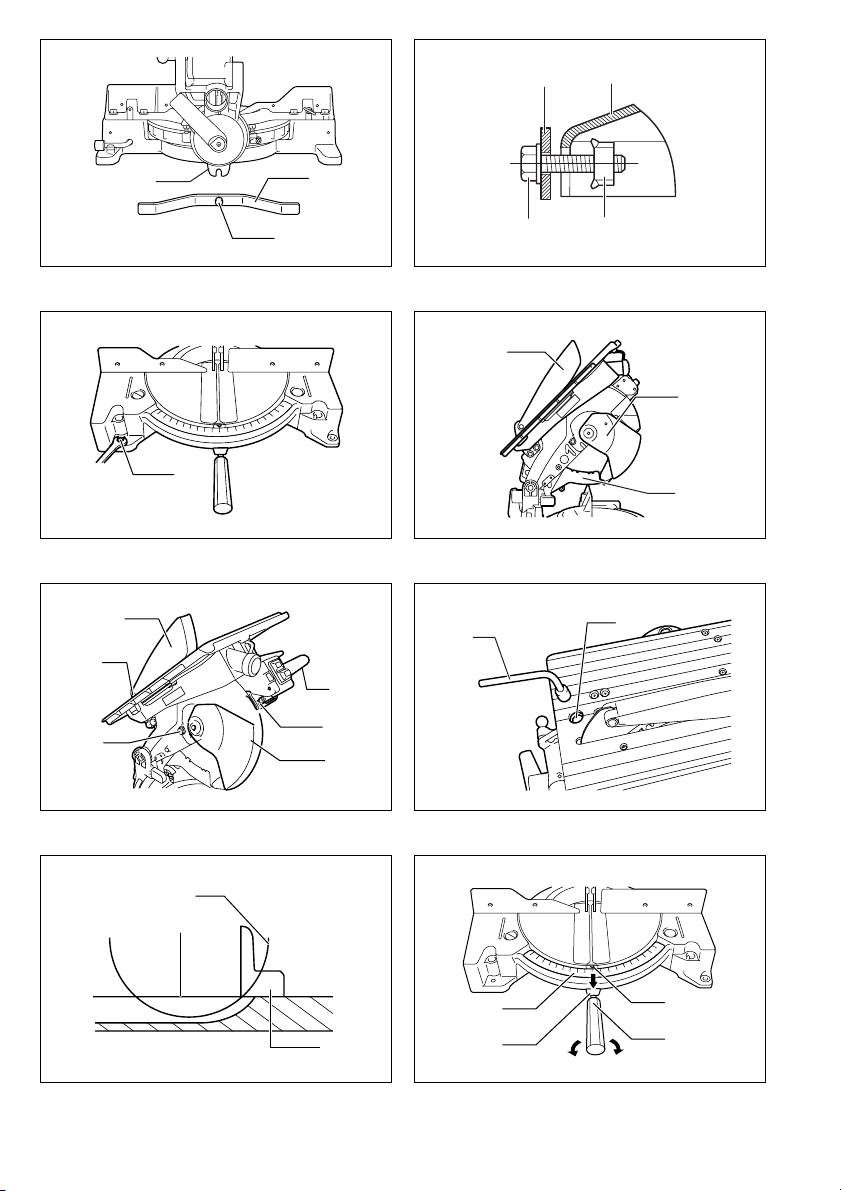

Explanation of general view

1 Auxiliary plate

2Hex bolt

3Base

4Nut

5Bolt

6 Lower blade guard A

7 Lower blade guard B

8 Top blade guard

9 Screw

10 Handle

11 Lever

12 Socket wrench

13 Adjusting bolt

14 Top surface of turn base

15 Periphery of blade

16 Guide fence

17 Pointer

18 Lock lever

19 Grip

20 Miter scale

21 Bevel scale

22 Switch

23 Lamp switch

24 Lamps

25 Stopper pin

26 Clamping screw

27 Top table

28 Motor housing

29 Center cover

30 Shaft lock

31 Saw blade

SPECIFICATIONS

Model LH1040/LH1040F

Blade diameter .................................................................................................................................. 255 mm – 260 mm

Hole diameter

For all countries other than European countries ........................................................................... 25.4 mm and 25 mm

For European countries ......................................................................................................................................30 mm

Max. Cutting capacities (H x W) with blade 260 mm in diameter in the miter saw mode

Bevel angle

0°

45° (left)

Max. Cutting capacities at 90° in the table saw (bench saw mode)....................................................................... 40 mm

No load speed (min

Table size (W x L) ............................................................................................................................... 260 mm x 405 mm

Dimensions (L x W x H) .....................................................................................................530 mm x 476 mm x 535 mm

Net weight .................................................................................................................................................. .......... 13.7 kg

Safety class ............................................................................................................................................................. /II

–1

) ............................................................................................................................................ 4,800

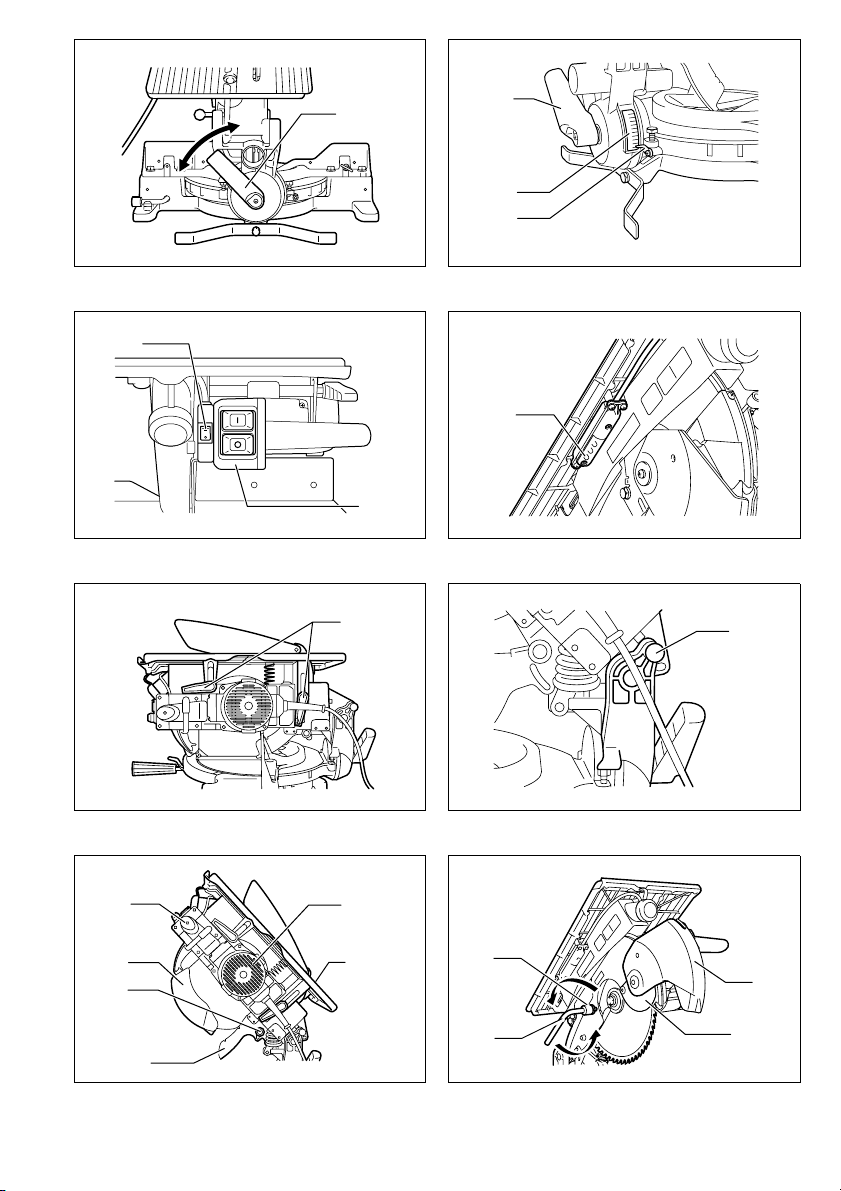

32 Blade case

33 Arrow

34 Outer flange

35 Inner flange

36 Spindle

37 Ring

38 Riving knife

39 Area to press in

40 Blade width

41 Rip fence holder

42 Guide rail on the top table

43 Clamping screw (A)

44 Clamping screw (B)

45 Rip fence

46 Rip fence holder

47 Workpiece

48 Line to be aligned with

49 Square nut

50 Scale

51 Two screws

52 Dust nozzle

53 Dust bag

54 Fastener

55 Cap

56 Vacuum cleaner

57 Blade cover

58 Support

59 Turn base

60 Vise arm

61 Vise rod

62 Holder

Miter angle

0° 45°

69 mm x 130mm

93 mm x 95 mm

35 mm x 130mm

53 mm x 95 mm

right 69 mm x 85 mm, 93 mm x 67 mm

left 69 mm x 85 mm, 93 mm x 67 mm

right 35mm x 91mm, 49 mm x 67 mm

left 35 mm x 65 mm, 49 mm x 42 mm

63 Holder assembly

64 Vise knob

65 Projection

66 Vise shaft

67 Rod 12

68 Vise (optional accessory)

69 Spacer block

70 Aluminum extrusion

71 Set plate

72 Small boss

73 Face/edge parallel

74 Wood screw

75 Glue together

76 Hole (7 mm in diameter)

77 Washer

78 Nut

79 Bolt M6

80 Push stick

81 Auxiliary fence

82 Push block

83 Triangular rule

84 0° adjusting bolt

85 Arm

86 45° bevel angle adjusting bolt

87 Limit mark

88 Screwdriver

89 Brush holder cap

• Due to our continuing program of research and development, the specifications herein are subject to change without

notice.

• Note: Specifications may differ from country to country.

11

Page 12

Intended use

The tool is intended for accurate straight cutting and

(only when used as a miter saw on the lower table) miter

cutting in wood.

Power supply

The tool should be connected only to a power supply of

the same voltage as indicated on the nameplate, and can

only be operated on single-phase AC supply. They are

double-insulated in accordance with European Standard

and can, therefore, also be used from sockets without

earth wire.

SAFETY INSTRUCTIONS

Warning! When using electric tools, basic safety precautions should always be followed to reduce the

risk of fire, electric shock and personal injury, including the following. Read all these instructions before

attempting to operate this product and save these

instructions.

For safe operation:

1. Keep work area clean

Cluttered areas and benches invite injuries.

2. Consider work area environment

Don’t expose power tools to rain. Don’t use power

tools in damp or wet locations. Keep work area well

lit. Don’t use power tools in presence of flammable

liquids or gases.

3. Guard against electric shock

Prevent body contact with grounded surfaces (e.g.

pipes, radiators, ranges, refrigerators).

4. Keep children away

Do not let visitors contact tool or extension cord. All

visitors should be kept away from work area.

5. Store idle tools

When not in use, tools should be stored in dry, high,

or locked-up place, out of the reach of children.

6. Don’t force tool

It will do the job better and safer at the rate for which

it was intended.

7. Use right tool

Don’t force small tools or attachments to do the job

of a heavy duty tool. Don’t use tools for purposes not

intended; for example, don’t use circular saw for cutting tree limbs or logs.

8. Dress properly

Do not wear loose clothing or jewelry. They can be

caught in moving parts. Rubber gloves and non-skid

footwear are recommended when working outdoors.

Wear protective hair covering to contain long hair.

9. Use safety glasses and hearing protection

Also use face or dust mask if cutting operation is

dusty.

10. Connect dust extraction equipment

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

11. Don’t abuse cord

Never carry tool by cord or yank it to disconnect it

from receptacle. Keep cord from heat, oil and sharp

edges.

12. Secure work

Use clamps or a vise to hold work. It’s safer than

using your hand and it frees both hands to operate

tool.

13. Don’t overreach

Keep proper footing and balance at all times.

14. Maintain tools with care

Keep tools sharp and clean for better and safer performance. Follow instructions for lubricating and

changing accessories. Inspect tool cords periodically and, if damaged, have repaired by authorized

service facility. Inspect extension cords periodically

and replace if damaged. Keep handles dry, clean

and free from oil and grease.

15. Disconnect tools

When not in use, before servicing, and when changing accessories such as blades, bits and cutters.

16. Remove adjusting keys and wrenches

Form the habit of checking to see that keys and

adjusting wrenches are removed from tool before

turning it on.

17. Avoid unintentional starting

Don’t carry plugged-in tool with finger on switch. Be

sure switch is off when plugging in.

18. Outdoor use extension cords

When tool is used outdoors, use only extension

cords intended for use outdoors and so marked.

19. Stay alert

Watch what you are doing. Use common sense. Do

not operate tool when you are tired.

20. Check damaged parts

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

determine that it will operate properly and perform

its intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced by an authorized service center unless otherwise indicated elsewhere in this instruction manual. Have defective

switches replaced by an authorized service center.

Do not use tool if switch does not turn it on and off.

21. Warning

The use of any other accessory or attachment other

than recommended in this operating instruction or

the catalog may present a risk of personal injury.

22. Have your tool repaired by an expert

This electric appliance is in accordance with the relevant safety rules. Repairing of electric appliances

may be carried out only by experts otherwise it may

cause considerable danger for the user.

ADDITIONAL SAFETY RULES FOR TOOL

For both miter saw mode and table saw (bench

saw) mode:

1. Wear eye and hearing protection. Other suitable

personal protective equipment should be worn.

2. NEVER wear gloves during operation except for

replacing saw blades or handling rough material

before operation.

3. Keep the floor area around the tool level well

maintained and free of loose materials e.g. chips

and cut-offs.

12

Page 13

4. Do not operate saw without guards and riving

knife in place. Check blade guards for proper

closing before each use. Do not operate saw if

blade guards do not move freely and close

instantly. Never clamp or tie the blade guards

into the open position. Any irregular operation of

the blade guards should be corrected immediately.

5. Clean and be careful not to damage the spindle,

flanges (especially the installing surface) and

hex bolt before or when installing the blade.

Damage to these parts could result in blade

breakage. Poor installation may cause vibration/

wobbling or slippage of the blade. Use only

flanges specified for this tool.

6. Check the blade carefully for cracks or damage

before operation. Do not use saw blade which

are damaged or deformed.

7. Use only saw blades recommended by the manufacturer and which conform to EN847-1, and

observe that the riving knife must not be thicker

than the width of the cut by the saw blade and

not thinner than the body of the blade.

8. Always use accessories recommended in this

manual. Use of improper accessories such as

abrasive cut-off wheels may cause an injury.

9. Select the correct saw blade for the material to

be cut.

10. Do not use saw blades manufactured from high

speed steel.

11. To reduce the emitted noise, always be sure that

the blade is sharp and clean.

12. Use correctly sharpened saw blades. Observe

the maximum speed marked on the saw blade.

13. Do not cut metals such as nails and screws.

Inspect for and remove all nails, screws and

other foreign matter from the workpiece before

operation.

14. Knock out any loose knots from workpiece

BEFORE beginning to cut.

15. Don’t use the tool in the presence of flammable

liquids or gases.

16. For your safety, remove the chips, small pieces,

etc. from the work area and table top before

plugging the tool and starting operation.

17. The operator is adequately trained in the use,

adjustment and operation of the tool.

18. Keep hands and make your bystander and yourself position out of path of and not in line with

saw blade. Avoid contact with any coasting

blade. It can still cause severe injury and never

reach around saw blade.

19. Be alert at all times, especially during repetitive,

monotonous operations. Don’t be lulled into a

false sense of security. Blades are extremely

unforgiving.

20. Make sure the shaft lock is released before the

switch is turned on.

21. Before using the tool on an actual workpiece, let

it run for a while. Watch for vibration or wobbling

that could indicate poor installation or a poorly

balanced blade.

22. Wait until the blade attains full speed before cutting.

23. The tool should not be used for slotting, rabbetting or grooving.

24. Refrain from removing any cut-offs or other

parts of the workpiece from the cutting area

whilst the tool is running and the saw head is not

in the rest position.

25. Stop operation immediately if you notice anything abnormal.

26. Turn off tool and wait for saw blade to stop

before moving workpiece or changing settings.

27. Unplug tool before changing blade, servicing or

not in use.

28. Some dust created from operation contains

chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of

these chemicals are:

- lead from lead-based-painted material and,

- arsenic and chromium from chemically-treated

lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work

in a well ventilated area and work with approved

safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

29. Connect the tool to a dust collecting device

when sawing.

When using in miter saw mode:

30. Do not use the saw to cut other than wood, aluminum or similar materials.

31. Do not perform operation freehand when cutting

workpiece in an area close to saw blade. The

workpiece must be secured firmly against the

turn base and guide fence during all operations.

32. Make sure that the turn base is properly secured

so it will not move during operation.

33. Make sure that the arm is securely fixed when

beveling. Tighten the lever clockwise to fix the

arm.

34. Make sure the blade does not contact the turn

base in the lowest position and is not contacting

the workpiece before the switch is turned on.

35. Hold the handle firmly. Be aware that the saw

moves up or down slightly during start-up and

stopping.

36. Replace the kerf board when worn.

When using in the table saw (bench saw) mode:

37. Do not perform any operation freehand. Freehand means using your hands to support or

guide the workpiece, in lieu of a rip fence.

38. Make sure that the arm is securely fixed in the

working position. Tighten the lever clockwise to

fix the arm.

39. Use a push stick or a push block to avoid working with the hands and fingers close to the saw

blade.

40. Make sure that the bench saw table is securely

fixed at the chosen height.

41. Make sure the blade is not contacting the riving

knife or workpiece before the switch is turned

on.

42. Always store the push-stick when it is not in use.

13

Page 14

43. Pay particular attention to instructions for reducing risk of KICKBACK. KICKBACK is a sudden

reaction to a pinched, bound or misaligned saw

blade. KICKBACK causes the ejection of the

workpiece from the tool back towards the operator. KICKBACKS CAN LEAD TO SERIOUS PERSONAL INJURY. Avoid KICKBACKS by keeping

the blade sharp, by keeping the rip fence parallel

to the blade, by keeping the riving knife and

blade guard in place and operating properly, by

not releasing the workpiece until you have

pushed it all the way past the blade, and by not

ripping a workpiece that is twisted or warped or

does not have a straight edge to guide along the

fence.

44. Avoid abrupt, fast feeding. Feed as slowly as

possible when cutting hard workpieces. Do not

bend or twist workpiece while feeding. If you

stall or jam the blade in the workpiece, turn the

tool off immediately. Unplug the tool. Then clear

the jam.

SAVE THESE INSTRUCTIONS.

INSTALLATION

CAUTION:

• Keep the floor area around the tool level well main-

tained and free of loose materials such as chips and

cut-offs.

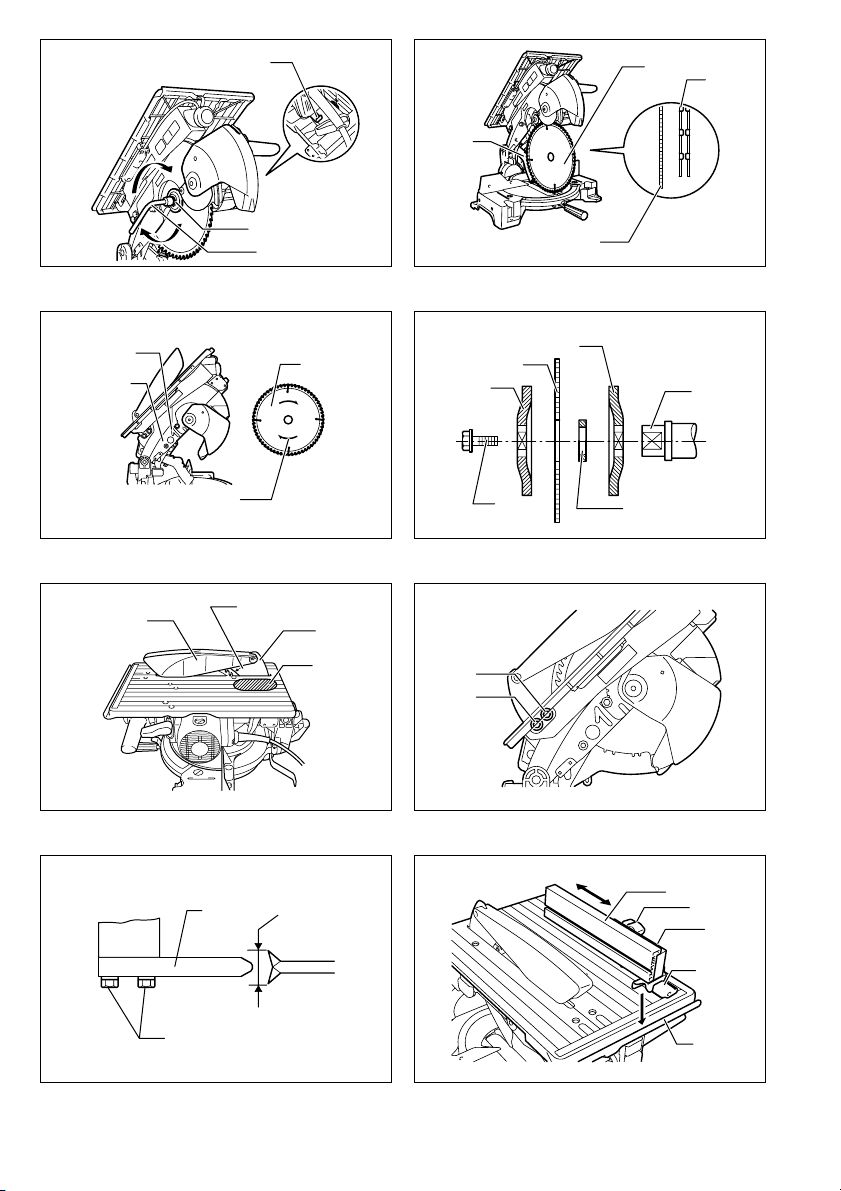

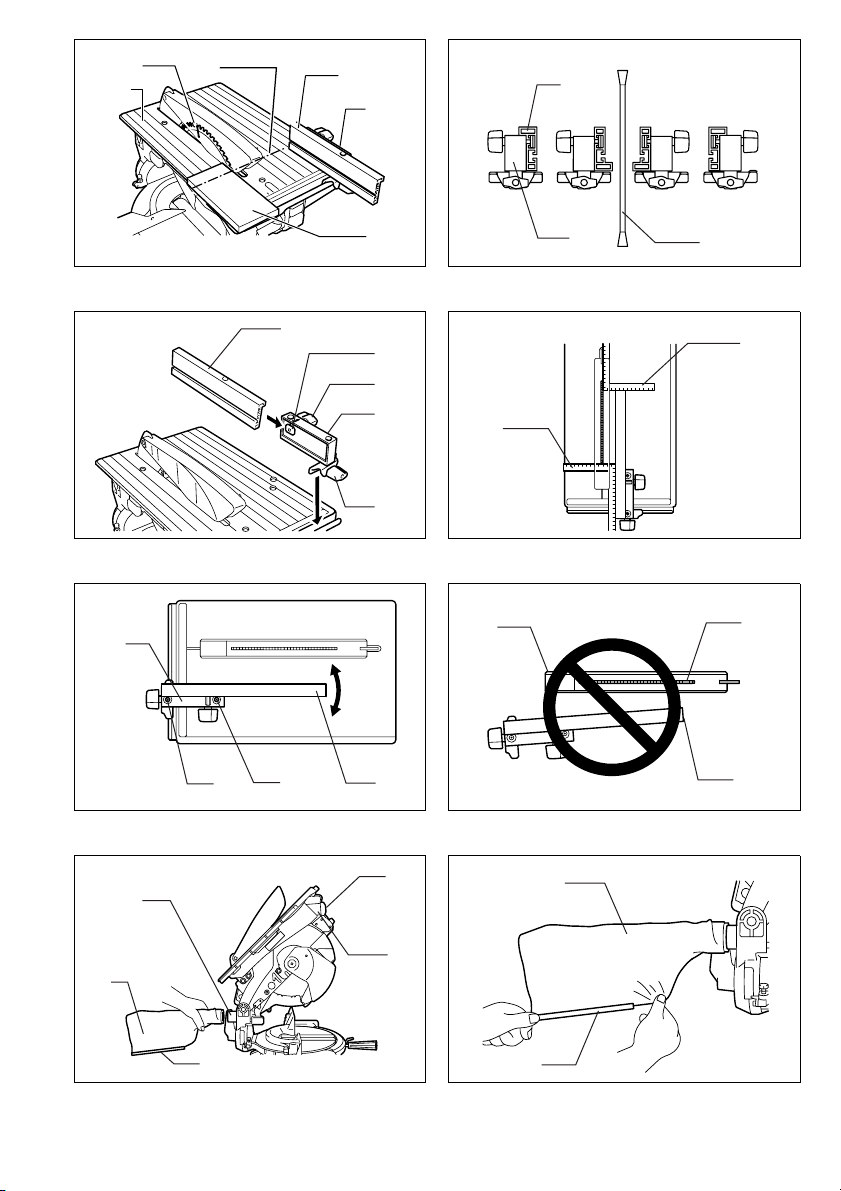

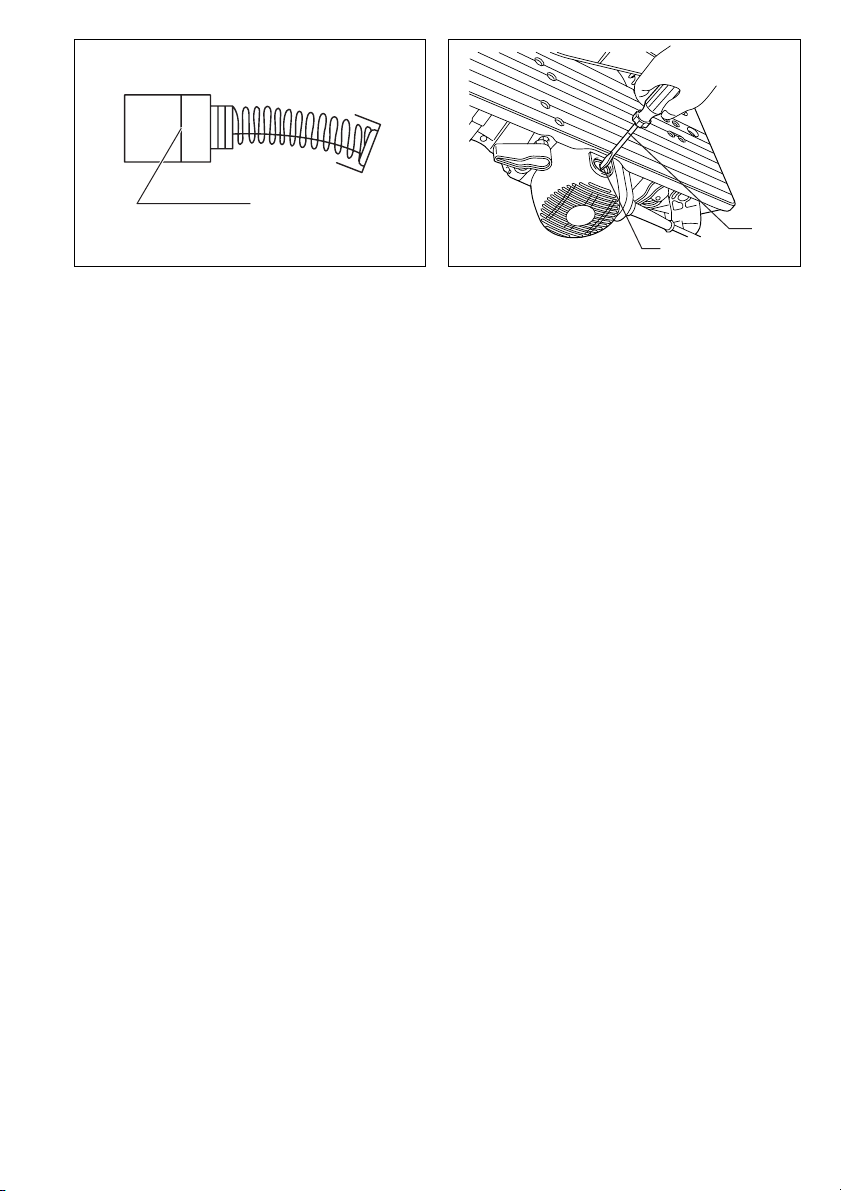

Installing auxiliary plate (Fig. 1 & 2)

Install the auxiliary plate using the notch in the tool’s

base and secure it by tightening the hex bolt.

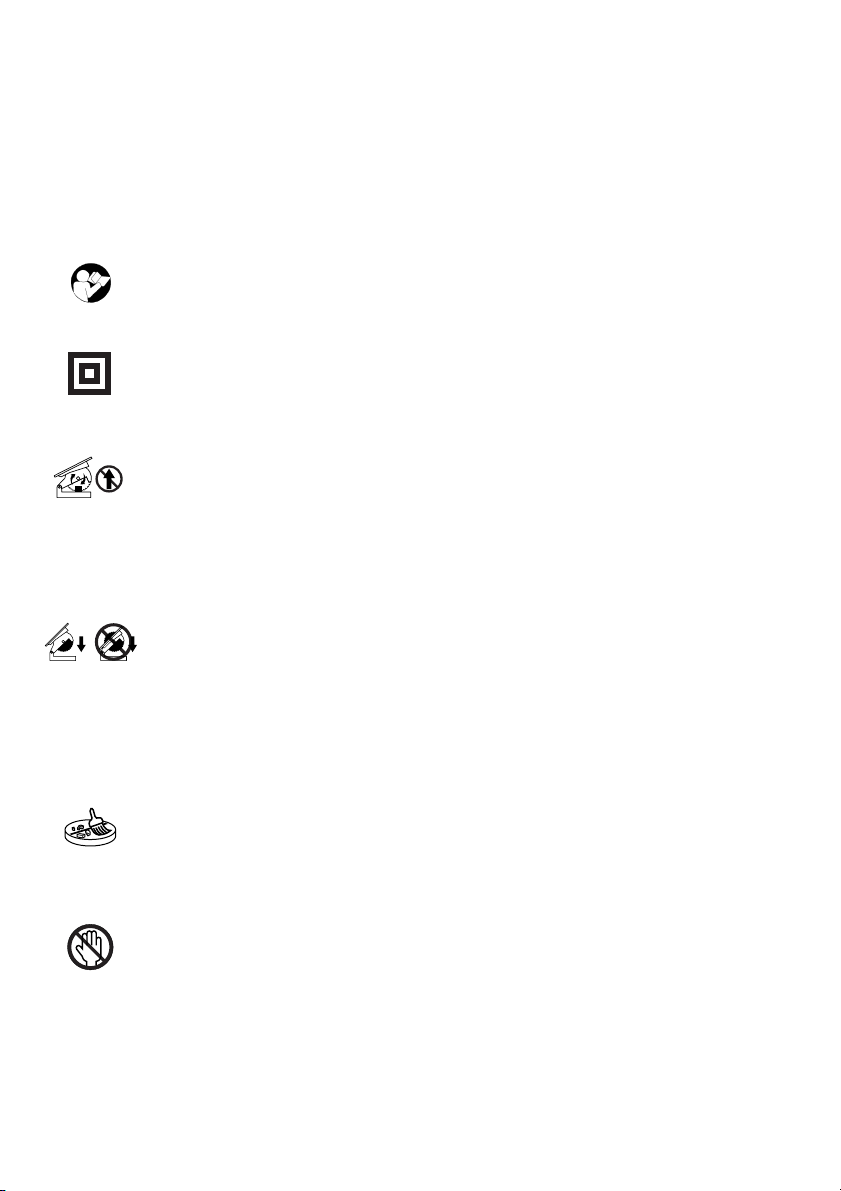

Bench mounting (Fig. 3)

This tool should be bolted with two bolts to a level and

stable surface using the bolt holes provided in the tool’s

base. This will help prevent tipping and possible injury.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and

unplugged before adjusting or checking function on the

tool.

Blade guard (Fig. 4 & 5)

CAUTION:

• Make sure that the handle cannot be lowered without

pushing the lever nearby the handle to the left.

• Make sure that the lower blade guards A and B dose

not open unless the lever near the handle is pushed at

the topmost position of the handle.

When lowering the handle while pushing the lever to the

left, the lower blade guard A rises automatically. The

lower blade guard B rises as it contacts a workpiece. The

lower blade guards are spring loaded so it returns to its

original position when the cut is completed and the handle is raised. The top blade guard falls flat on the top surface after workpiece has passed under it. NEVER

DEFEAT OR REMOVE THE LOWER BLADE GUARDS,

THE SPRING WHICH ATTACHES TO THE LOWER

BLADE GUARD, OR THE TOP BLADE GUARD.

In the interest of your personal safety, always maintain

each blade guard in good condition. Any irregular operation of the guards should be corrected immediately.

Check to assure spring loaded return action of the lower

blade guards. NEVER USE THE TOOL IF THE LOWER

BLADE GUARD, SPRING OR THE TOP BLADE GUARD

ARE DAMAGED, FAULTY OR REMOVED. DOING SO IS

HIGHLY DANGEROUS AND CAN CAUSE SERIOUS

PERSONAL INJURY.

If any of these see-through blade guards becomes dirty,

or sawdust adheres to it in such a way that the blade is

no longer easily visible, unplug the saw and clean the

guards carefully with a damp cloth. Do not use solvents

or any petroleum-based cleaners on the plastic guard.

If the lower blade guard A is especially dirty and vision

through the guard is impaired, proceed as follows. Fix the

top table at the fully elevated position, raise the handle

fully, push in fully the stopper pin with the handle fully

raised, and use the supplied socket wrench to loosen the

hex bolt holding the center cover. Loosen the hex bolt by

turning it counterclockwise and raise the lower blade

guard A and center cover while pushing the lever to the

left. With the lower blade guard A so positioned, cleaning

can be more completely and efficiently accomplished.

When cleaning is complete, reverse procedure above

and secure bolt.

In the same case for the top blade guard as above

stated, loosen the screw holding it with a screwdriver and

remove the top blade guard. After cleaning, always reinstall it securely by tightening the screw to the extent that

the top blade guard moves smoothly up or down.

If any of these blade guards becomes discolored through

age or UV light exposure, contact a Makita service center

for a new guard. DO NOT DEFEAT OR REMOVE

GUARDS.

Maintaining maximum cutting capacity

(Fig. 6 & 7)

This tool is factory adjusted to provide the maximum cutting capacity for a 260 mm saw blade.

When installing a new blade, always check the lower limit

position of the blade and if necessary, adjust it as follows:

CAUTION:

• When making this adjustment, position the top table at

the lowest position after unplugging the tool.

First, unplug the tool. Position the top table at the lowest

position. Lower the handle completely. Use the socket

wrench to turn the adjusting bolt that you can find below

in the biggest hole in the top table, until the periphery of

the blade extends slightly below the top surface of the

turn base at the point where the front face of the guide

fence meets the top surface of the turn base.

With the tool unplugged, rotate the blade by hand while

holding the handle all the way down to be sure that the

blade does not contact any part of the lower base. Readjust slightly, if necessary.

CAUTION:

• After installing a new blade, always be sure that the

blade does not contact any part of the lower base when

the handle is lowered completely. Always do this with

the tool unplugged.

14

Page 15

Adjusting the miter angle (Fig. 8)

Loosen the grip by turning counterclockwise. Turn the

turn base while pressing down the lock lever. When you

have moved the grip to the position where the pointer

points to the desired angle on the miter scale, securely

tighten the grip clockwise.

CAUTION:

• When turning the turn base, be sure to raise the handle

fully.

• After changing the miter angle, always secure the turn

base by tightening the grip firmly.

Adjusting the bevel angle (Fig. 9 & 10)

To adjust the bevel angle, loosen the lever at the rear of

the tool counterclockwise.

Push the handle to the left to tilt the saw blade until the

pointer points to the desired angle on the bevel scale.

Then tighten the lever clockwise firmly to secure the arm.

CAUTION:

• When tilting the saw blade, be sure to raise the handle

fully.

• After changing the bevel angle, always secure the arm

by tightening the lever clockwise.

Switch action (Fig. 11)

CAUTION:

• Before operation, make sure that the tool is turned on

and off.

To start the tool, press the ON ( I ) button. To stop it,

press the OFF ( O ) button.

Lighting up the lamps (Fig. 11 & 12)

For Model LH1040F only

Push the upper position of the switch for turning on the

light and the lower position for off.

CAUTION:

• Do not look in the light or see the source of light

directly.

NOTE:

• Use a dry cloth to wipe the dirt off the lens of lamp. Be

careful not to scratch the lens of light, or it may lower

the illumination.

Adjusting the level of top table (Fig. 13)

To adjust the level of top table, loosen two levers by turning counterclockwise and then raise or lower the top

table. Tighten these levers firmly after the adjustment.

WARNING:

• Position the top table at the topmost position when

using the tool in the miter saw mode and at the desired

position when using in the table saw mode (bench

mode).

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and

unplugged before carrying out any work on the tool.

Installing or removing saw blade

CAUTION:

• Always be sure that the tool is switched off and

unplugged before installing or removing the blade.

• Use only the Makita socket wrench provided to install

or remove the blade. Failure to do so may result in

overtightening or insufficient tightening of the hex bolt.

This could cause an injury.

Secure the top table at the topmost position.

Lock the handle in the raised position by pushing in the

stopper pin. (Fig. 14)

To remove the blade, first loosen the clamping screw so

that the lower blade guard B is lowered as shown in the

figure. (Fig. 15)

Then use the socket wrench to loosen the hex bolt holding the center cover by turning it counterclockwise. Raise

the lower blade guard A and center cover while pushing

the lever nearby the handle to the left. (Fig. 16)

Press the shaft lock to lock the spindle and use the

socket wrench to loosen the hex bolt clockwise. Then

remove the hex bolt, outer flange and blade. (Fig. 17)

To install the blade, mount it carefully onto the spindle,

making sure that the direction of the arrow on the surface

of the blade matches the direction of the arrow on the

blade case. Install the outer flange and hex bolt, and then

use the socket wrench to tighten the hex bolt (lefthanded) securely counterclockwise while pressing the

shaft lock. (Fig. 18 & 19)

NOTE:

• When installing a saw blade, be sure to insert it from

the outside of the blade guard B at first and then raise it

so that the blade is finally placed in the blade guard B.

For all countries other than European countries

CAUTION:

• The silver ring 25.4 mm in outer diameter is factoryinstalled onto the spindle. The black ring 25 mm in

outer diameter is included as standard equipment.

Before mounting the blade onto the spindle, always be

sure that the correct ring for the arbor hole of the blade

you intend to use is installed onto the spindle. (Fig. 20)

For European countries

CAUTION:

• The ring 30 mm in outer diameter is factory-installed

between the inner and outer flanges. (Fig. 20)

Return the lower blade guard A and center cover to its

original position. Then tighten the hex bolt clockwise to

secure the center cover. Raise the blade guard B as far

as it will go and tighten the clamping screw firmly while

holding it in the raised position. Lower the handle to

make sure that the lower blade guards move properly.

Make sure shaft lock has released spindle before making

cut.

15

Page 16

Adjusting riving knife

Before adjusting the riving knife, loosen the two levers by

turning counterclockwise and press the top table on the

right side nearby the riving knife to its lowered position.

Then secure the top table by firmly re-tightening the two

levers as shown in the figure. (Fig. 21)

There must be a clearance of about 4 – 5 mm between

the riving knife and the blade teeth. Adjust the riving knife

accordingly by loosening two hex bolts counterclockwise

with the hex socket wrench and measuring the distance.

Tighten the hex bolts securely, and then check to see that

the top blade guard works smoothly before cutting.

(Fig. 22)

The riving knife has been installed before shipment from

the factory so that the blade and riving knife are in a

straight line. (Fig. 23)

CAUTION:

• If the blade and riving knife are not aligned properly, a

dangerous pinching condition may result during operation. Make sure they are properly aligned. You could

suffer serious personal injury while using the tool without a properly aligned riving knife. If they are not

aligned for any reasons, always have Makita authorized

service center repair it.

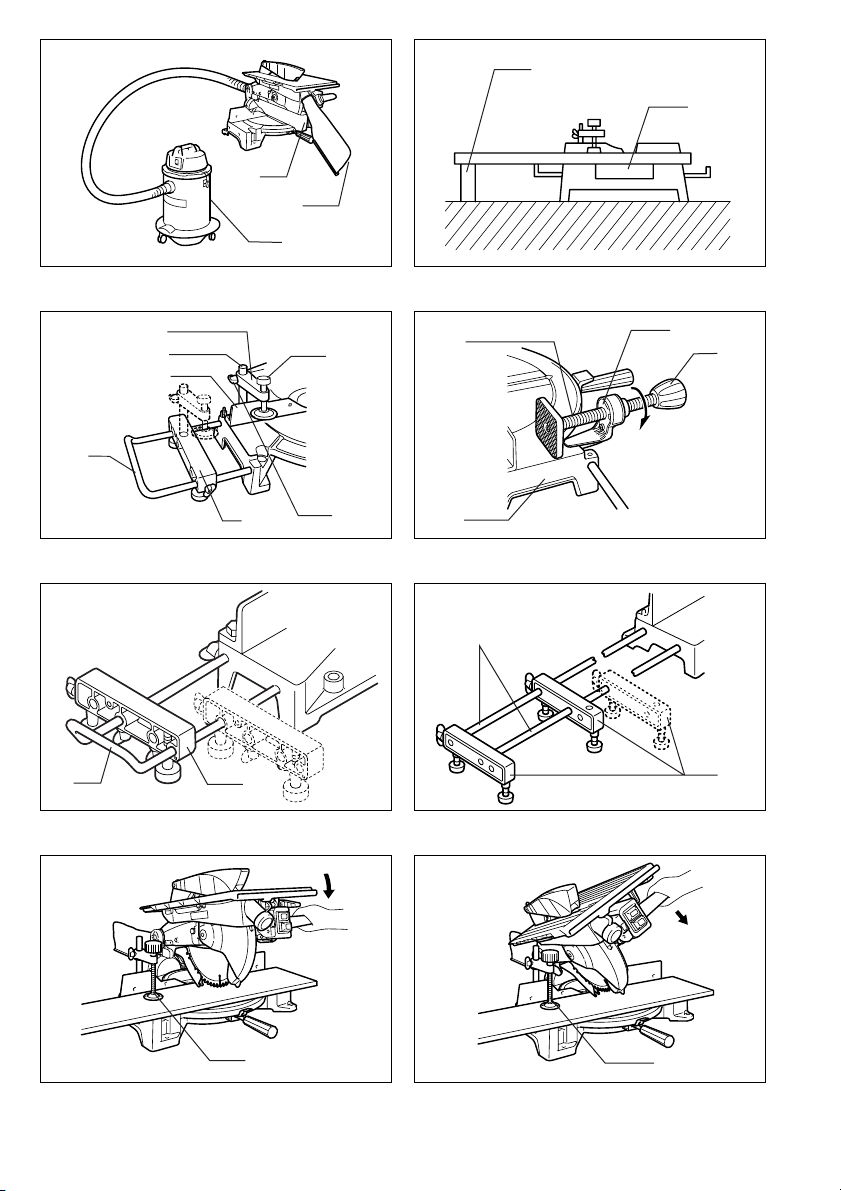

Installing and adjusting rip fence

1. Install the rip fence on the table so that the rip fence

holder engages with the guide rail. Tighten the

clamping screw (B) of the rip fence firmly clockwise.

2. Loosen the clamping screw (A).

3. Slide the rip fence and secure it so that the far end

from you of the rip fence is aligned with the point at

which the front edge of saw blade just appears from

top surface of the workpiece. The purpose of this

adjustment is to reduce risk of kick-back toward

operator that cut piece from the workpiece is

pinched between the saw blade and rip fence and

finally pushed out toward operator. The line 3 varies

by thickness of workpiece or the table level. Adjust

the position of the rip fence according to the thickness of the workpiece.

After adjusting the rip fence, tighten the clamping

screw (A) firmly. (Fig. 24 & 25)

NOTE:

• There are four patterns to position the rip fence as

shown in the figure. (Fig. 26) Rip fence has two slits on

its sides, one slit with an elevated fringe nearby on the

same side and the other without it. Use the surface of

rip fence with this fringe facing the workpiece only

when cutting off into a piece of a thin workpiece.

• To change the rip fence pattern, remove the rip fence

from the rip fence holder by loosening the clamping

screw (A) and change the facing of the rip fence to the

rip fence holder so that the rip fence faces the rip fence

holder according to your work as shown in the figure.

Insert the square nut on the rip fence holder into the

back end of either slit of the rip fence so that they fit as

shown in the figure.

To change from the pattern A or B to the pattern C or D,

or in adverse case, remove the square nut, washer and

clamping screw (A) from the rip fence holder, then position the clamping screw (A), washer and square nut on

the opposite position of the rip fence holder compared to

the original position. Tighten the clamping screw (A)

securely after inserting the square nut of the rip fence

holder into the rip fence slit. Insert the square nut on the

rip fence holder into the back end of either slit of the rip

fence so that they fit as shown in the figure. (Fig. 27)

The rip fence is factory adjusted so that it is parallel to

the blade surface. Make sure that it is parallel. To check

to be sure that the rip fence is parallel with the blade.

Lower the table to the lowest position so that the blade

appears at the topmost position from the table. Mark one

of the blade teeth with a crayon. Measure the distance

(A) and (B) between the rip fence and blade. Take both

measurements using the tooth marked with the crayon.

(Fig. 28) These two measurements should be identical. If

the rip fence is not parallel with the blade, proceed as follows: (Fig. 29)

1. Turn two adjusting screws counterclockwise.

2. Shift the back edge of the rip fence slightly to right or

left until it becomes parallel with the blade.

3. Tighten the two screws on the rip fence firmly.

CAUTION:

• Be sure to adjust the rip fence so that it is parallel with

the blade, or a dangerous kickback condition may

occur.

• Be sure to adjust the rip fence so that it does not con-

tact the top blade guard or saw blade. (Fig. 30)

Dust bag

The use of the dust bag makes cutting operations clean

and dust collection easy. To attach the dust bag, fit it onto

the dust nozzle. (Fig. 31)

NOTE:

• In miter saw mode, always insert the dust bag to the

back nozzle only.

When the dust bag is about half full, remove the dust bag

from the tool and pull the fastener out. Empty the dust

bag of its contents, tapping it lightly so as to remove particles adhering to the insides which might hamper further

collection. (Fig. 32)

If you connect a vacuum cleaner to your saw, more efficient and cleaner operations can be performed.

To install the blade cover when using in the table saw

mode (bench mode), turn the turn base to 0° miter angle

(see the section titled “Adjusting miter angle”) and place

the blade cover on the turn table so that the blade cover

is centered over the slit for the blade entrance in the turn

table and then lock the handle in the lowest position by

fully pushing in the stopper pin as shown in the figure.

(Fig. 33)

NOTE:

• To attach the dust bag to the front dust nozzle in the

table saw mode (bench mode), first remove the cap

from the front dust nozzle and then attach the dust bag

to the dust nozzle.

• When not in use of dust bag, always replace the cap to

the front dust nozzle. Failure to do so result in dust

scattering from the nozzle.

• When using the tool in the table saw mode (bench

mode), make sure that the blade cover is installed on

the turn table.

16

Page 17

Securing workpiece

Whenever possible, secure the workpiece with the

optional vise. If you must use your hand to hold the workpiece, then it must be done firmly and securely so as not

to lose control of the workpiece. Your hand and arm must

be kept well away from the blade area (100 mm minimum). Squeeze the workpiece firmly against the guide

fence with your fingers held over the top of the guide

fence. The workpiece must also rest steadily on the turn

base.

WARNING:

• Never use your hand to hold the workpiece that

requires your hand to be any closer than 100 mm from

the blade area. In this case, always use the optional

vise to secure the workpiece. After any cutting operation, raise the blade gently. Never raise the blade until it

has come to a complete stop. Serious injury may result.

CAUTION:

• When cutting long workpieces, use supports that are

as high as the top surface level of the turn base. Do not

rely solely on the vertical vise and/or horizontal vise

(both optional) to secure the workpiece. (Fig. 34)

Thin material tends to sag. Support workpiece over its

entire length to avoid blade pinch and possible KICKBACK.

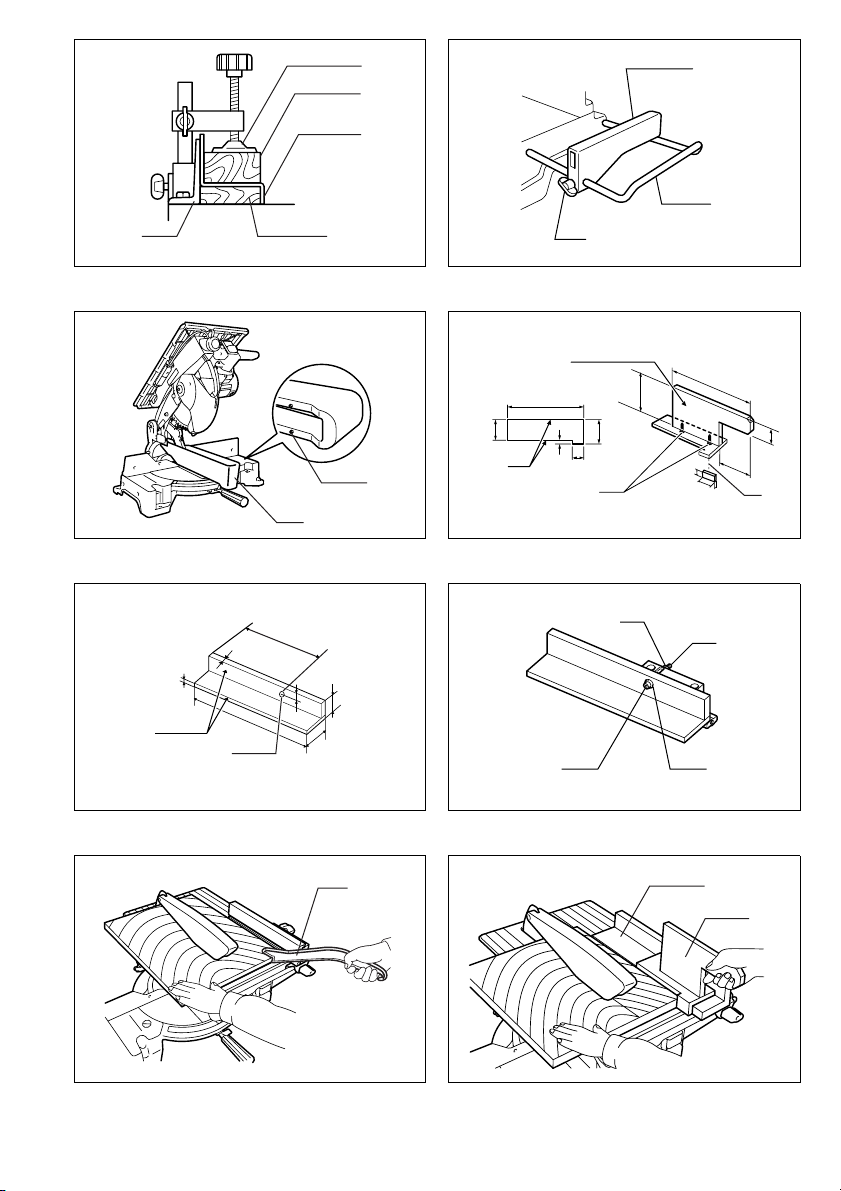

Vertical vise (optional accessory) (Fig. 35)

The vertical vise can be installed in two positions on

either the left or right side of the guide fence or the holder

assembly (optional accessory). Insert the vise rod into

the hole in the guide fence or the holder assembly and

tighten the screw to secure the vise rod.

Position the vise arm according to the thickness and

shape of the workpiece and secure the vise arm by tightening the screw. If the screw to secure the vise arm contacts the guide fence, install the screw on the opposite

side of vise arm. Make sure that no part of the tool contacts the vise when lowering the handle all the way. If

some part contacts the vise, re-position the vise.

Press the workpiece flat against the guide fence and the

turn base. Position the workpiece at the desired cutting

position and secure it firmly by tightening the vise knob.

CAUTION:

• The workpiece must be secured firmly against the turn

base and guide fence.

Horizontal vise (optional accessory) (Fig. 36)

The horizontal vise can be installed on either the left or

right side of the base. When performing 15° or greater

miter cuts, install the horizontal vise on the side opposite

the direction in which the turn base is to be turned. By

turning the vise knob counterclockwise, the screw is

released and the vise shaft can be moved rapidly in and

out. By turning the vise knob clockwise, the screw

remains secured. To grip the workpiece, turn the vise

knob gently clockwise until the projection reaches its topmost position, then fasten securely. If the vise knob is

forced in or pulled out while being turned clockwise, the

projection may stop at an angle. In this case, turn the

vise knob back counterclockwise until the screw is

released, before turning again gently clockwise.

The maximum width of the workpiece which can be

secured by the horizontal vise is 130 mm.

Holders and holder assembly

(optional accessories)

The holders and the holder assembly can be installed on

either side as a convenient means of supporting workpieces horizontally. Install them as shown in the figure.

Then tighten the screws firmly to secure the holders and

the holder assembly. (Fig. 37)

When cutting long workpieces, use the holder-rod

assembly (optional accessory). It consists of two holder

assemblies and two rods 12. (Fig. 38)

CAUTION:

• Always support long workpieces level with the top surface of the turn base for accurate cuts and to prevent

dangerous loss of control of the tool.

OPERATION

CAUTION:

• Before use, be sure to release the handle from the lowered position by pulling the stopper pin.

• Make sure the blade is not contacting the workpiece,

etc. before the switch is turned on.

CUTTING AS MITER SAW

WARNING:

• When using the tool in the miter saw mode, secure the

top table at the topmost position so that the saw blade

never protrudes from the top surface of the top table.

CAUTION:

• Do not apply excessive pressure on the handle when

cutting. Too much force may result in overload of the

motor and/or decreased cutting efficiency. Push down

handle with only as much force as is necessary for

smooth cutting and without significant decrease in

blade speed.

• Gently press down the handle to perform the cut. If the

handle is pressed down with force or if lateral force is

applied, the blade will vibrate and leave a mark (saw

mark) in the workpiece and the precision of the cut will

be impaired.

1. Press cutting (Fig. 39)

Secure the workpiece against guide fence and turn table.

Switch on the tool without the blade making any contact

and wait until the blade attains full speed before lowering.

Then gently lower the handle to the fully lowered position

to cut the workpiece. When the cut is completed, switch

off the tool and WAIT UNTIL THE BLADE HAS COME

TO A COMPLETE STOP before returning the blade to its

fully elevated position.

2. Miter cutting

Refer to the previously covered “Adjusting the miter

angle”.

3. Bevel cut (Fig. 40)

Loosen the lever and tilt the saw blade to set the bevel

angle (Refer to the previously covered “Adjusting the

bevel angle”). Be sure to retighten the lever firmly to

secure the selected bevel angle safely. Secure the workpiece against guide fence and turn table. Make sure the

carriage is pulled all the way back toward the operator.

Switch on the tool without the blade making any contact

and wait until the blade attains full speed. Then gently

lower the handle to the fully lowered position while applying pressure in parallel with the blade. When the cut is

completed, switch off the tool and WAIT UNTIL THE

BLADE HAS COME TO A COMPLETE STOP before

returning the blade to its fully elevated position.

17

Page 18

CAUTION:

• Always be sure that the blade will move down to bevel

direction during a bevel cut. Keep hands out of path of

saw blade.

• During a bevel cut, it may create a condition whereby

the piece cut off will come to rest against the side of the

blade. If the blade is raised while the blade is still rotating, this piece may be caught by the blade, causing

fragments to be scattered which is dangerous. The

blade should be raised ONLY after the blade has come

to a complete stop.

• When pressing the handle down, apply pressure parallel to the blade. If the pressure is not parallel to the

blade during a cut, the angle of the blade might be

shifted and the precision of the cut will be impaired.

6. Wood facing

Use of wood facing helps to assure splinter-free cuts in workpieces. Attach a wood facing to the guide fence using the

holes in the guide fence.

See the figure concerning the dimensions for a suggested wood facing.

Over 460 mmOver 10 mm

4. Compound cutting

Compound cutting is the process in which a bevel angle

is made at the same time in which a miter angle is being

cut on a workpiece. Compound cutting can be performed

at angle shown in the table.

Bevel angle Miter angle

45° Left and Right 0° – 45°

When performing compound cutting, refer to “Press cutting”, “Miter cutting” and “Bevel cut” explanations.

5. Cutting aluminum extrusion (Fig. 41)

When securing aluminum extrusions, use spacer blocks

or pieces of scrap as shown in the figure to prevent deformation of the aluminum. Use a cutting lubricant when

cutting the aluminum extrusion to prevent buildup of the

aluminum material on the blade.

CAUTION:

• Never attempt to cut thick or round aluminum extrusions. Thick aluminum extrusions may come loose during operation and round aluminum extrusions cannot

be secured firmly with this tool.

• Never cut aluminum in the table saw mode (bench

mode).

25 mm

Hole

CAUTION:

• Use straight wood of even thickness as the wood facing.

• Use screws to attach the wood facing to the guide fence. The screws should be installed so that the screw heads are

below the surface of the wood facing.

• When the wood facing is attached, do not turn the turn base with the handle lowered. The blade and/or the wood facing will be damaged.

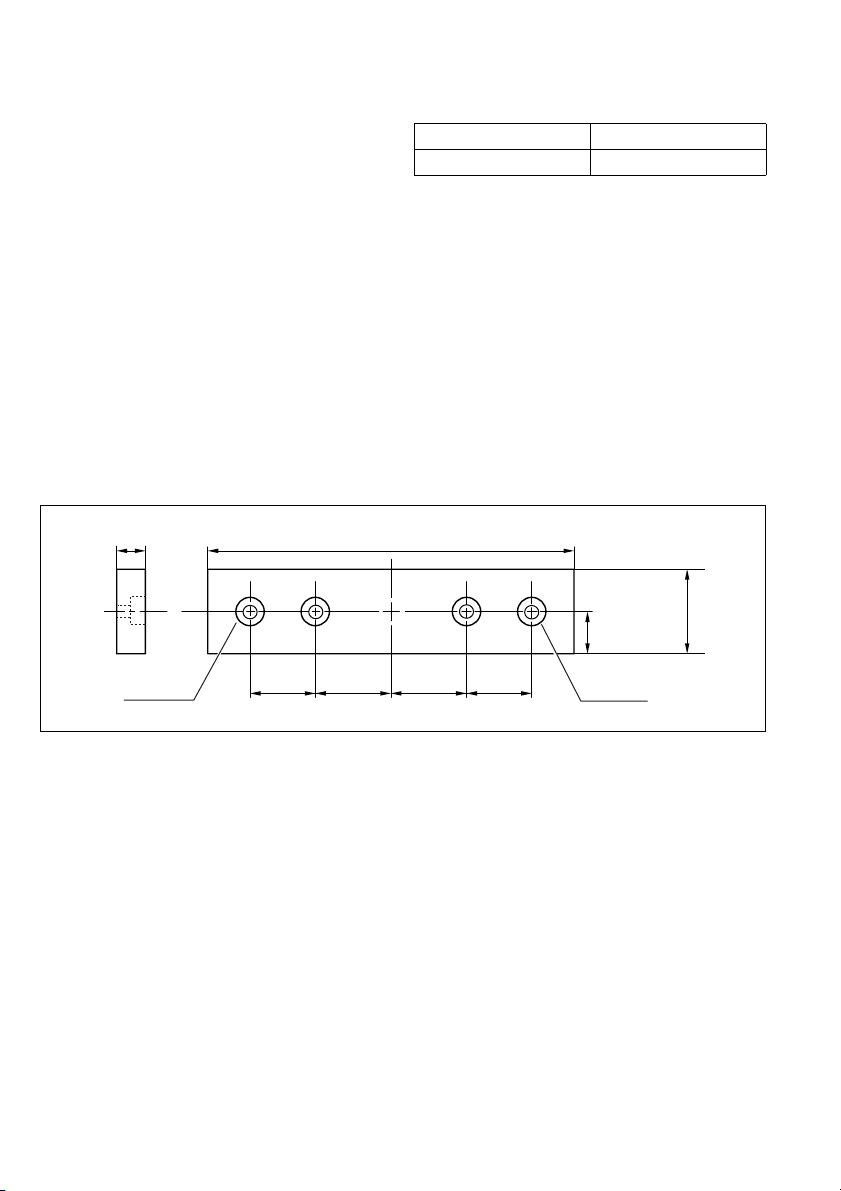

7. Cutting repetitive lengths (Fig. 42)

When cutting several pieces of stock to the same length,

ranging from 240 mm to 400 mm, use of the set plate will

facilitate more efficient operation. Install the set plate on

the holder as shown in the figure.

Align the cutting line on your workpiece with either the

left or right side of the groove in the kerf board, and while

holding the workpiece from moving, move the set plate

flush against the end of the workpiece. Then secure the

set plate with the screw. When the set plate is not used,

loosen the screw and turn the set plate out of the way.

NOTE:

• Use of the holder-rod assembly (optional accessory)

allows cutting repetitive lengths up to 2,200 mm

approximately.

90 mm 107 mm 107 mm 90 mm

90 mm

Hole

18

Page 19

CUTTING AS TABLE SAW (BENCH MODE)

CAUTION:

• When using the tool in the table saw mode (bench

mode), place the blade cover on the turn table so that

the blade cover is centered over the slit for the blade

entrance in the turn table and two small bosses on the

underside of the blade cover fit into the semi-circular

slit in the periphery of the turn table as shown in the figure and then lock the handle in the lowest position by

fully pushing in the stopper pin. (Fig. 43)

• Always use “work helpers” such as push sticks and

push blocks when there is a danger that your hands or

fingers will come close to the blade.

• NEVER withdraw the workpiece while the blade is running. If you must withdraw the workpiece before completing a cut, first switch the tool off while holding the

workpiece firmly. Wait until the blade has come to a

complete stop before withdrawing the workpiece. Failure to do so may cause dangerous kickbacks.

• NEVER remove cut-off material while the blade is running.

• NEVER place your hands or fingers in the path of the

saw blade.

• Always secure the rip fence firmly, or dangerous kickbacks may occur.

Work helpers

Push sticks, push blocks or auxiliary fence are types of

“work helpers”. Use them to make safe, sure cuts without

the need for the operator to contact the blade with any

part of the body.

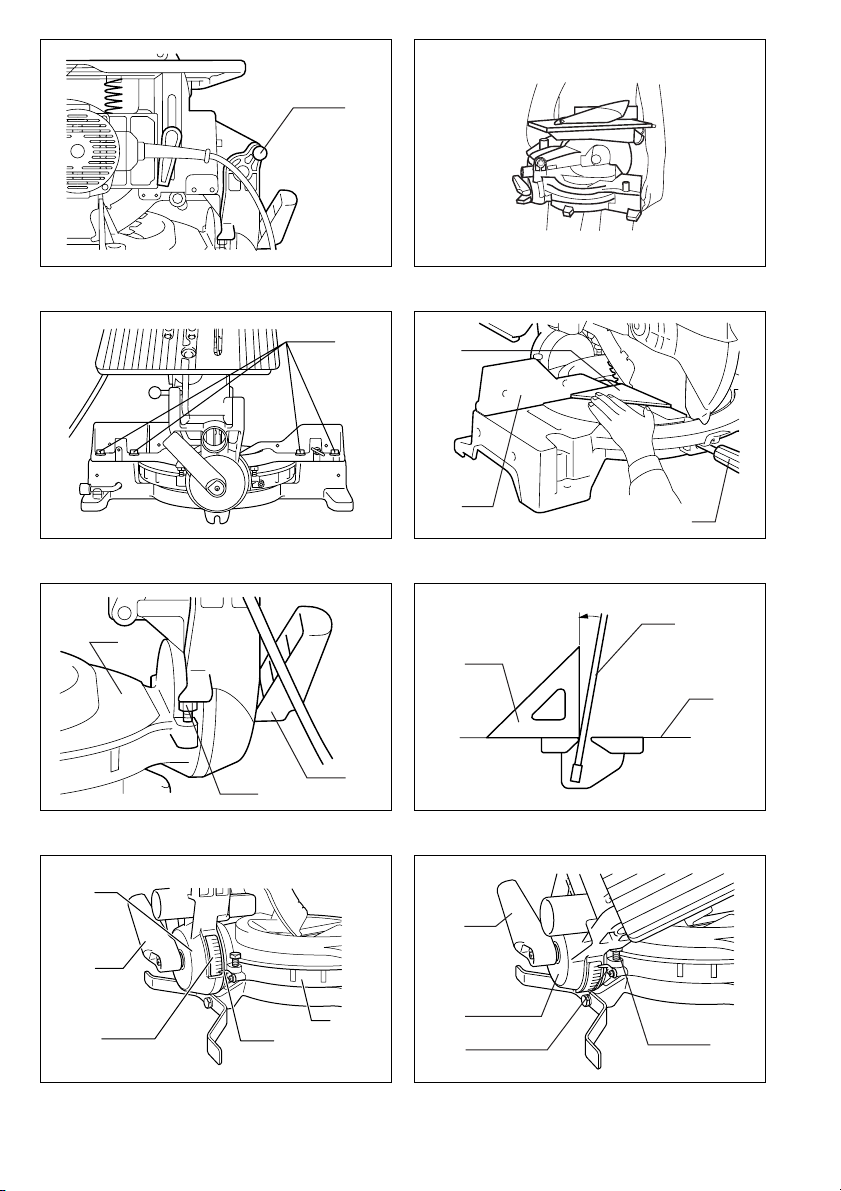

Push block (Fig. 44)

Use a 15 mm piece of plywood.

Handle should be in center of plywood piece. Fasten with

glue and wood screws as shown. Small piece 10 mm x

9 mm x 30 mm of wood must always be glued to plywood

to keep the blade from dulling if the operator cuts into

push block by mistake. (Never use nails in push block.)

Auxiliary fence (Fig. 45 & 46)

Make auxiliary fence from 10 mm and 15 mm plywood

pieces.

Remove the rip fence, clamping screw (A), flat washer

and square nut from the rip fence holder and then attach

and secure the auxiliary fence to the rip fence holder by

using a bolt M6 longer than M6 x 50, washers and nut.

Ripping

CAUTION:

• When cutting long or large workpieces, always provide

adequate support behind the table. DO NOT allow a

long board to move or shift on the table. This will cause

the blade to bind and increase the possibility of kickback and personal injury. The support should be at the

same height as the table.

1. Adjust the depth of cut a bit higher than the thick-

ness of the workpiece. To make this adjustment,

loosen two levers and lower or raise the top table.

2. Position the rip fence to the desired width of rip and

secure in place by tightening the clamping screw

(A). Before ripping, make sure the two screws of the

rip fence holder are secured. If it is not secured

enough, retighten it.

3. Turn the tool on and gently feed the workpiece into

the blade along with the rip fence.

(1) When the width of rip is 40 mm or wider, use a

push stick. (Fig. 47)

(2) When the width of rip is narrower than 40 mm,

the push stick cannot be used because the

push stick will strike the top blade guard. Use

the auxiliary fence and push block.

Install securely the auxiliary fence which is

secured to the rip fence holder on the table.

Feed the workpiece by hand until the end is

about 25 mm from the front edge of the top

table. Continue to feed using the push block on

the top of the auxiliary fence until the cut is

complete. (Fig. 48)

Carrying tool

Make sure that the tool is unplugged. Secure the blade at

0° bevel angle and the turn base at left miter angle fully.

Lower the handle fully and lock it in the lowered position

by fully pushing in the stopper pin. (Fig. 49)

Carry the tool by holding both sides of the tool base as

shown in the figure. If you remove the holders, dust bag,

etc., you can carry the tool more easily. (Fig. 50)

CAUTION:

• Always secure all moving portions before carrying the

tool.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and

unplugged before attempting to perform inspection or

maintenance.

WARNING:

• Always be sure that the blade is sharp and clean for the

best and safest performance.

Adjusting the cutting angle

This tool is carefully adjusted and aligned at the factory,

but rough handling may have affected the alignment. If

your tool is not aligned properly, perform the following:

1. Miter angle

Loosen the grip which secures the turn base. Turn the

turn base so that the pointer points to 0° on the miter

scale. Tighten the grip and loosen the hex bolts securing

the guide fence using the socket wrench. (Fig. 51)

Lower the handle fully and lock it in the lowered position

by pushing in the stopper pin. Square the side of the

blade with the face of the guide fence using a triangular

rule, try-square, etc. Then securely tighten the hex bolts

on the guide fence in the order from the right side.

(Fig. 52)

2. Bevel angle

(1) 0° bevel angle

Lower the handle fully and lock it in the lowered position by pushing in the stopper pin. Loosen the lever

at the rear of the tool. Turn the 0° bevel angle adjusting bolt on the right side of the turn base two or three

revolutions clockwise to tilt the blade to the right.

(Fig. 53)

Carefully square the side of the blade with the top

surface of the turn base using the triangular rule, trysquare, etc. by turning the 0° bevel angle adjusting

bolt counterclockwise. (Fig. 54)

Make sure that the pointer on the turn base point to

0° on the bevel scale on the arm. If it does not point

to 0°, loosen the screw which secures the pointer

and adjust the pointer so that it will point to 0°.

(Fig. 55)

19

Page 20

(2) 45° bevel angle

Adjust the 45° bevel angle only after performing 0°

bevel angle adjustment. To adjust left 45° bevel

angle, loosen the lever and tilt the blade to the left

fully. Make sure that the pointer on the arm points to

45° on the bevel scale on the arm. If the pointer

does not point to 45°, turn the 45° bevel angle

adjusting bolt on the left side of the arm until the

pointer points to 45°. (Fig. 56)

Replacing carbon brushes (Fig. 57 & 58)

Remove and check the carbon brushes regularly.

Replace when they wear down to the limit mark. Keep

the carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time. Use only identical carbon brushes.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes, insert the new ones and

secure the brush holder caps.

After use

• After use, wipe off chips and dust adhering to the tool

with a cloth or the like. Keep the blade guard clean

according to the directions in the previously covered

section titled “Blade guard”. Lubricate the sliding portions with tool oil to prevent rust.

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be performed by Makita Authorized Service Centers, always

using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita service center.

• Steel & Carbide-tipped saw blades

• Auxiliary plate

• Vise assembly (Horizontal vise)

• Vertical vise

• Socket wrench 13

• Holder set

• Holder assembly

• Holder rod assembly

• Set plate

• Dust bag

• Triangular rule

• Blade cover (Blade guard C)

• Push stick

• Ruler assembly (Rip fence)

Noise and Vibration

The typical A-weighted noise levels are

sound pressure level: 92 dB (A)

sound power level: 105 dB (A)

ENG005-1

– Wear ear protection. –

The typical weighted root mean square acceleration

value is not more than 2.5 m/s

EC-DECLARATION OF CONFORMITY

We declare under our sole responsibility that this product is

2

.

ENH003-1

in compliance with the following standards of standardized

documents,

EN61029, EN55014, EN61000

in accordance with Council Directives, 73/23/EEC,

89/336/EEC and 98/37/EC.

Certificate of adequacy of the technical file with respect

to 98/37/EC having been obtained from the following

notified body:

Intertek SEMKO AB, Torshamnsgatan 43, Box 1103,

SE-164 22 Kista, Sweden

Yasuhiko Kanzaki

CE2004

Director

MAKITA INTERNATIONAL EUROPE LTD.

Michigan Drive, Tongwell, Milton Keynes,

Bucks MK15 8JD, ENGLAND

20

Page 21

DEUTSCH

Übersicht

1 Kippsicherung

2 Sechskantschraube

3 Grundplatte

4 Mutter

5 Schraube

6 Untere Schutzhaube A

7 Untere Schutzhaube B

8 Obere Schutzhaube

9 Schraube

10 Handgriff

11 Hebel

12 Steckschlüssel

13 Einstellschraube

14 Drehteller-Oberfläche

15 Sägeblattumfang

16 Gehrungsanschlag

17 Zeiger

18 Verriegelungshebel

19 Griff

20 Gehrungswinkelskala

21 Neigungswinkelskala

22 Schalter

23 Lampenschalter

24 Lampen

25 Anschlagstift

26 Klemmschraube

27 Oberer Tisch

28 Motorgehäuse

29 Mittenabdeckung

30 Spindelarretierung

31 Sägeblatt

TECHNISCHE DATEN

Modell LH1040/LH1040F

Sägeblattdurchmesser ....................................................................................................................... 255 mm – 260 mm

Bohrungsdurchmesser

Für alle Länder außerhalb Europas .............................................................................................. 25,4 mm und 25 mm

Für europäische Länder ..................................................................................................................................... 30 mm

Max. Schnitttiefen (H × B) mit Sägeblatt von 260 mm Durchmesser im Gehrungssägenmodus

Neigungswinkel

0°

45° (links)

Max. Schnitttiefen bei 90° im Tischsägenmodus (Banksägenmodus)................................................................... 40 mm

Leerlaufdrehzahl (min

Tischgröße (B x L) .............................................................................................................................. 260 mm x 405 mm

Abmessungen (L x B x H)...................................................................................................530 mm x 476 mm x 535 mm

Nettogewicht......................................................................................................................................................... 13,7 kg

Sicherheitsklasse..................................................................................................................................................... /II

–1

) ......................................................................................................................................... 4 800

32 Sägeblattgehäuse

33 Pfeil

34 Außenflansch

35 Innenflansch

36 Spindel

37 Ring

38 Spaltkeil

39 Andrückbereich

40 Sägeblattbreite

41 Parallelanschlaghalter

42 Führungsschiene auf dem

oberen Tisch

43 Klemmschraube (A)

44 Klemmschraube (B)

45 Parallelanschlag

46 Parallelanschlaghalter

47 Werkstück

48 Ausrichtungslinie

49 Vierkantmutter

50 Maßstab

51 Zwei Schrauben

52 Absaugstutzen

53 Staubsack

54 Verschluss

55 Kappe

56 Staubsauger

57 Sägeblattabdeckung

58 Stütze

59 Drehteller

60 Schraubstockarm

61 Schraubstockstange

Gehrungswinkel

0° 45°

69 mm x 130mm

93 mm x 95 mm

35 mm x 130mm

53 mm x 95 mm

rechts 69 mm x 85 mm, 93 mm x 67 mm

links 69 mm x 85 mm, 93 mm x 67 mm

rechts 35 mmx 91mm, 49 mm x 67 mm

links 35 mm x 65 mm, 49 mm x 42 mm

62 Auflagebügel

63 Auflageplatte

64 Schraubstockknopf

65 Vorsprung

66 Schraubstockspindel

67 Stange 12

68 Schraubstock (Sonderzubehör)

69 Distanzblock

70 Aluminium-Werkstoff

71 Halteplatte

72 Kleiner Vorsprung

73 Seitenfläche/Kante parallel

74 Holzschraube

75 Zusammenleimen

76 Loch (7 mm Durchmesser)

77 Unterlegscheibe

78 Mutter

79 Schraube M6

80 Schiebestock

81 Hilfsanschlag

82 Schiebeklotz

83 Einstelldreieck

84 0°-Einstellschraube

85 Arm

86 45°-Neigungswinkel-Einstell-

schraube

87 Verschleißgrenze

88 Schraubendreher

89 Bürstenhalterkappe

• Wir behalten uns vor, Änderungen im Zuge der Entwicklung und des technischen Fortschritts ohne vorherige Ankün-

digung vorzunehmen.

• Hinweis: Die technischen Daten können von Land zu Land abweichen.

21

Page 22

Vorgesehene Verwendung

Die Maschine ist für präzise Geradschnitte und (nur bei

Einsatz als Gehrungssäge auf dem unteren Tisch) Gehrungsschnitte in Holz vorgesehen.

Stromversorgung

Die Maschine darf nur an die auf dem Typenschild angegebene Spannung angeschlossen werden und arbeitet

nur mit Einphasen-Wechselspannung. Sie ist entsprechend den Europäischen Richtlinien doppelt schutzisoliert und kann daher auch an Steckdosen ohne

Erdungskabel angeschlossen werden.

SICHERHEITSHINWEISE

Achtung! Beim Gebrauch von Elektrowerkzeugen

sind zum Schutz gegen elektrischen Schlag. Verletzungsund Brandgefahr folgende grundsätzlichen Sicherheitsmaßnahmen zu geachten.

Lesen und beachten Sie diese Hinweise, bevor

Sie das Gerät benutzen.

1. Halten Sie Ihren Arbeitsbereich in Ordnung

Unordnung im Arbeitsbereich ergibt Unfallgefahr.

2. Berücksichtigen Sie Umgebungseinflüsse

Setzen sie Elektrowerkzeuge nicht dem Regen aus.

Benützen Sie Elektrowerkzeuge nicht in feuchter

oder nasser Umgebung. Sorgen Sie für gute

Beleuchtung. Benützen Sie Elektrowerkzeuge nicht

in Nähe von brennbaren Flüssigkeiten oder Gasen.

3. Schützen Sie sich vor elektrischem Schlag

Vermeiden Sie Körperberührung mit geerdeten Teilen, zum Beispiel Rohren, Heizkörpern, Herden,

kühlschränken.

4. Halten Sie Kinder fern!

Lassen Sie andere Personen nicht das Werkzeug

oder Kabel berühren, halten Sie sie von Ihrem

Arbeitsbereich fern.

5. Bewahren Sie Ihre Werkzeuge sicher auf

Unbenutzte Werkzeuge sollten in trockenem, verschlossenem Raum und für Kinder nicht erreichbar

aufbewahrt werden.

6. Überlasten Sie Ihr Werkzeug nicht

Sie arbeiten besser und sicherer im angegebenen

Leistungsbereich.

7. Benützen Sie das richtige Werkzeug

Verwenden Sie keine zu schwachen Werkzeuge

oder Vorsatzgeräte für schwere Arbeiten.

Benützen Sie Werkzeuge nicht für Zwecke und

Arbeiten, Wofür sie nicht bestimmt sind; zum Beispiel benützen Sie keine Handkreissäge, um Bäume

zu flällen oder Äste zu schneiden.

8. Tragen Sie geeignete Arbeitskleidung

Tragen Sie keine weite Kleidung oder Schmuck. Sie

können von beweglichen Teilen erfaßt werden. Bei

Arbeiten im Freien sind Gummihandschuhe und

rutschfestes Schuhwerk empfehlenswert. Tragen

Sie bei langen Haaren ein Haarnetz.

9. Schutzbrille und Gehörschutz tragen

Verwenden Sie eine Atemmaske bei stauberzeugenden Arbeiten.

10. Schlleßen Sie eine Staubabsaugvorrichtung an

Wenn Geräte für den Anschluß von Staubabsaugund-sammelvorrichtungen ausgelegt sind, sorgen

Sie dafür, daß Jiese angeschlossen und korrekt

benutzi werden.

11. Zweckentfremden Sie nicht das Kabel

Tragen Sie das Werkzeug nicht am Kabel, und

benützen Sie es nicht, um den Stecker aus der

Steckdose zu ziehen. Schützen Sie das Kabel vor

Hitze, Öl und scharfen Kanten.

12. Sichern Sie das Werkstück

Benützen Sie Spannvorrichtungen oder einen

Schraubstock, um das Werkstück festzuhalten. Es

ist damit sicherer gehalten als mit Ihrer Hand und

ermöglicht die Bedienung der Maschine mit beiden

Händen.

13. Überdehnen Sie nicht Ihren Standbereich

Vermeiden Sie abnormale Körperhaltung. Sorgen

Sie für sicheren Stand, und halten Sie jederzeit das

Gleichgewicht.

14. Pflegen Sie Ihre Werkzeuge mit Sorgtalt

Halten Sie Ihre Werkzeuge scharf und sauber, um

gut und sicher zu arbeiten. Befolgen Sie die Wartungsvorschriften und die Hinweise für Werkzeugwechsel. Kontrollieren Sie regelmäßig den Stecker

und das Kabel, und lassen Sie diese bei Beschädi-

gung von einem anerkannten Fachmann erneuern.

Kontrollieren Sie Verlängerungskabel regelmäßig

und ersetzen Sie beschädigte. Halten Sie Handgriffe

trocken und frei von Öl und Fett.

15. Ziehen Sie den Netzstecker

Bei Nichtgebrauch, vor der Wartung und beim Werkzeugwechsel, wie zum Beispiel Sägeblatt, Bohrer

und Maschinenwerkzeugen aller Art.

16. Lassen Sie keine Werkzeugschlüssel stecken

Überprüfen Sie vor dem Einschalten, daß die

Schlüssel und Einstellwerkzeuge entfernt sind.

17. Vermeiden Sie unbeabsichtigten Anlauf

Tragen Sie keine an das Stromnetz angeschlossene

Werkzeuge mit dem Finger am Schalter. Vergewissern Sie sich, daß der Schalter beim Anschluß an

das Stromnetz ausgeschaltet ist.

18. Verlängerungskabel im Freien

Verwenden Sie im Freien nur dafür zugelassene

und entsprechend gekennzeichnete Varlängerungs-

kabel.

19. Seien Sie stets aufmerksam

Beobachten Sie Ihre Arbeit. Gehen Sie vernünftig

vor. Verwenden Sie das Werkzeug nicht, wenn Sie

unkonzentriert sind.

20. Kontrollieren Sie Ihr Gerät auf Beschädigungen

Vor weiterem Gebrauch des Werkzeugs die Schutzeinrichtungen oder leicht beschädigte Teile sorgfäl-

tig auf ihre einwandfreie und bestimmungsgemäße

Funktion überprüfen. Überprüfen Sie, ob die Funktion beweglicher Teile in Ordnung ist, ob sie nicht

klemmen onder ob Teile beschädigt sind. Sämtliche

Teile müssen richtig montiert sein und alle Bedingungen erfüllen, um den einwandfreien Betrieb des

Gerätes zu gewährleisten.

Beschädigte Schutzvorrichtungen und Teile sollen

sachgemäß durch eine Kundendienstwerkstatt repariert oder ausgewechselt werden, soweit nichts

anderes in den Betriebsanleitungen angegeben ist.

Beschädigte Schalter müssen bei einer Kundendienstwerkstatt ersetzt werden. Benutzen Sie keine

Werkzeuge, bei denen sich der Schalter nicht ein

und ausschalten läßt.

22

Page 23

21. Achtung!

Zu Ihrer eigenen Sicherheit, benützen Sie nur Zubehör und Zusatzgeräte, die in der Bedienungsanleitung angegeben oder vom Werkzeug-Hersteller

empfohlen oder angegeben werden. Der Gebrauch

anderer als der in der Bedienungsanleitung oder im

Katalog empfohlenen Einsatzwerkzeuge oder Zubehöre kann eine persönliche Verletzungsgefahr für

Sie bedeuten.

22. Reparaturen nur vom Elektrofachmann.

Dieses Elektrowerkzeug entspricht den einschlägi-

gen Sicherheitsbestimmungen. Reparaturen dürfen

nur von einer Elektrofachkraft ausgeführt werden,

andernfalls können Unfälle für den Betreiber entstehen.

ZUSÄTZLICHE SICHERHEITSREGELN FÜR

DIE MASCHINE

Für Gehrungs- und Tischsägenmodus

(Banksägenmodus):

1. Tragen Sie Augen- und Gehörschutz. Das Tragen

anderer geeigneter Schutzausrüstung ist zu

empfehlen.

2. Tragen Sie NIEMALS Handschuhe während der

Arbeit, außer zum Auswechseln von Sägeblättern oder Handhaben von Rohmaterial vor der

Arbeit.

3. Halten Sie den Bodenbereich um die Maschinen-

ebene aufgeräumt und frei von losen Teilen, wie

z.B. Spänen und Sägeabfällen.

4. Betreiben Sie die Säge nicht ohne Schutzvor-

richtungen und Spaltkeil. Überprüfen Sie die

Schutzhauben vor jeder Benutzung auf einwandfreies Schließen. Betreiben Sie die Säge nicht,

wenn sich die Schutzhauben nicht ungehindert

bewegen und unverzüglich schließen. Die

Schutzhauben dürfen auf keinen Fall in der

geöffneten Stellung festgeklemmt oder festgebunden werden. Funktionsstörungen der

Schutzhauben müssen sofort behoben werden.

5. Reinigen Sie die Spindel, die Flansche (beson-

ders die Montagefläche) und die Sechskantschraube, bevor oder während Sie das Sägeblatt

montieren, und achten Sie darauf, dass diese

Teile nicht beschädigt werden. Eine Beschädigung dieser Teile kann zu einem Sägeblattbruch

führen. Schlechte Montage kann Vibrieren/Flattern oder Schlupf des Sägeblatts verursachen.

Verwenden Sie nur die für diese Maschine vorgeschriebenen Flansche.

6. Überprüfen Sie das Sägeblatt vor dem Betrieb

sorgfältig auf Risse oder Beschädigung. Verwenden Sie keine beschädigten oder verformten

Sägeblätter.

7. Verwenden Sie nur vom Hersteller empfohlene

Sägeblätter, die dem Standard EN847-1 entsprechen, und achten Sie darauf, dass der Spaltkeil

nicht dicker als die Breite des vom Sägeblatt

erzeugten Schnitts und nicht dünner als die

Sägeblattdicke ist.

8. Verwenden Sie immer die in dieser Anleitung

empfohlenen Zubehörteile. Der Gebrauch ungeeigneten Zubehörs, z.B. von Trennscheiben,

kann Verletzungen zur Folge haben.

9. Wählen Sie das korrekte Sägeblatt für das zu

schneidende Material aus.

10. Verwenden Sie keine Sägeblätter aus Schnellstahl.

11. Um den erzeugten Geräuschpegel zu reduzieren,

achten Sie stets darauf, dass das Sägeblatt

scharf und sauber ist.

12. Verwenden Sie korrekt geschärfte Sägeblätter.

Halten Sie die auf dem Sägeblatt angegebene

Maximaldrehzahl ein.

13. Schneiden Sie keine Metallgegenstände, wie z.B.

Nägel oder Schrauben. Untersuchen Sie das

Werkstück sorgfältig auf Nägel, Schrauben und

sonstige Fremdkörper, und entfernen Sie diese

vor der Bearbeitung.

14. Schlagen Sie etwaige lose Knorren aus dem

Werkstück heraus, BEVOR Sie mit dem Sägen

beginnen.

15. Benutzen Sie die Maschine nicht in Gegenwart

von brennbaren Flüssigkeiten oder Gasen.

16. Säubern Sie den Arbeitsbereich und die Tischplatte sicherheitshalber von Spänen, Kleinteilen

usw., bevor Sie die Maschine anschließen und

mit der Arbeit beginnen.

17. Die Bedienungsperson sollte in der Handhabung, Einstellung und Bedienung der Maschine

hinreichend geschult sein.

18. Halten Sie Ihre Hände vom Sägeblatt fern, und

achten Sie darauf, dass Umstehende und Sie

selbst ausreichenden Abstand vom Sägeblatt

haben und nicht in seiner Fluchtlinie stehen.

Vermeiden Sie jegliche Berührung mit dem auslaufenden Sägeblatt. Es kann auch in diesem

Zustand noch schwere Verletzungen verursachen. Fassen Sie auch niemals um das Sägeblatt.

19. Seien Sie stets wachsam, besonders bei sich

dauernd wiederholenden, eintönigen Arbeiten.

Lassen Sie sich nicht in ein trügerisches Sicherheitsgefühl wiegen. Sägeblätter kennen kein

Erbarmen.

20. Vergewissern Sie sich vor dem Einschalten der

Maschine, dass die Spindelarretierung freigegeben ist.

21. Lassen Sie die Maschine vor dem eigentlichen

Schneiden eines Werkstücks eine Weile laufen.

Achten Sie auf Vibrationen oder Taumelbewegungen, die Anzeichen für schlechte Montage

oder ein schlecht ausgewuchtetes Sägeblatt

sein können.

22. Warten Sie, bis das Sägeblatt die volle Drehzahl

erreicht hat, bevor Sie mit dem Schneiden beginnen.

23. Die Maschine darf nicht für Nutenfräsen, Falzfräsen oder Auskehlen verwendet werden.

24. Unterlassen Sie das Entfernen von Bruchstücken

oder anderen Teilen des Werkstücks vom

Schnittbereich, während die Maschine läuft und

das Sägeblatt sich nicht in der Ruhestellung

befindet.

25. Brechen Sie den Betrieb sofort ab, wenn Sie

irgendetwas Ungewöhnliches bemerken.

26. Schalten Sie die Maschine aus und lassen Sie

das Sägeblatt zum Stillstand kommen, bevor Sie

das Werkstück bewegen oder Einstellungen

ändern.

23

Page 24

27. Trennen Sie die Maschine vom Stromnetz, bevor

Sie das Sägeblatt wechseln und die Maschine

warten oder stillsetzen.

28. Bei manchen Werkstoffen kann der beim Sägen

erzeugte Staub Chemikalien enthalten, die erwiesenermaßen Krebs, Geburtsfehler oder Schäden an Fortpflanzungsorganen verursachen.

Beispiele dieser Chemikalien sind wie folgt:

- Blei in Lack mit Bleizusatz sowie

- Arsen und Chrom in chemisch behandeltem

Bauholz.

Ihre Gefährdung durch den Umgang mit solchen

Chemikalien hängt davon ab, wie oft Sie diese

Arbeiten verrichten. Um Ihre Aussetzung zu diesen Chemikalien zu reduzieren: Arbeiten Sie in

gut belüfteter Umgebung, und verwenden Sie

geprüfte Sicherheitsvorrichtungen, wie z.B.

Staubmasken, die mikroskopische Teilchen herausfiltern.

29. Schließen Sie die Maschine beim Betrieb an eine

Staubsammelvorrichtung an.

Beim Betrieb im Gehrungssägenmodus:

30. Verwenden Sie die Säge nur zum Schneiden von

Holz, Aluminium oder ähnlichen Materialien.

31. Halten Sie Werkstücke zum Schneiden nicht mit

den Händen in der Nähe des Sägeblatts. Das

Werkstück muss bei allen Operationen fest an

Drehteller und Gehrungsanschlag anliegend

gesichert werden.

32. Vergewissern Sie sich, dass der Drehteller einwandfrei gesichert ist, damit er sich während

des Betriebs nicht bewegt.

33. Vergewissern Sie sich, dass der Arm einwandfrei

gesichert ist, wenn Sie Neigungsschnitte ausführen. Ziehen Sie den Hebel zur Sicherung des

Arms im Uhrzeigersinn an.

34. Vergewissern Sie sich, dass das Sägeblatt in der

Tiefstellung nicht den Drehteller berührt und vor

dem Einschalten der Maschine nicht mit dem

Werkstück in Berührung ist.

35. Halten Sie den Handgriff sicher fest. Beachten

Sie, dass sich die Säge beim Anlaufen und

Abstellen geringfügig nach oben oder unten

bewegt.

36. Wechseln Sie die Schlitzplatte bei Verschleiß

aus.

Beim Betrieb im Tischsägenmodus

(Banksägenmodus):

37. Führen Sie keine freihändigen Arbeiten aus. Mit

freihändig ist die Verwendung nur der Hände

zum Halten oder Führen des Werkstücks anstelle

eines Parallelanschlags gemeint.

38. Vergewissern Sie sich, dass der Arm einwandfrei

in der Arbeitsstellung gesichert ist. Ziehen Sie

den Hebel zur Sicherung des Arms im Uhrzeigersinn an.

39. Verwenden Sie einen Schiebestock oder -klotz,

um zu vermeiden, dass Ihre Hände und Finger in

die Nähe des Sägeblatts kommen.

40. Vergewissern Sie sich, dass der Banksägentisch

einwandfrei in der gewünschten Höhe festgestellt ist.

41. Vergewissern Sie sich vor dem Einschalten der

Maschine, dass das Sägeblatt nicht den Spaltkeil

oder das Werkstück berührt.

42. Bewahren Sie den Schiebestock stets sicher auf,

wenn er nicht benutzt wird.

43. Beachten Sie besonders die Anweisungen zur

Verringerung der Gefahr von RÜCKSCHLAG.

RÜCKSCHLAG ist eine plötzliche Reaktion auf

ein klemmendes, schleifendes oder versetztes

Sägeblatt. RÜCKSCHLAG verursacht das Auswerfen des Werkstücks aus der Maschine nach

hinten in Richtung der Bedienungsperson.

RÜCKSCHLAG KANN ZU SCHWEREN VERLETZUNGEN FÜHREN. Vermeiden Sie RÜCKSCHLAG, indem Sie das Sägeblatt scharf halten,

den Parallelanschlag parallel zum Sägeblatt halten, den Spaltkeil und die Schutzhaube anbringen und in einwandfreiem Betriebszustand

halten, das Werkstück nicht eher loslassen, bis

es vollkommen am Sägeblatt vorbeigeschoben

ist und Werkstücke, die verdreht oder verzogen

sind oder keine gerade Kante zur Führung entlang dem Parallelanschlag haben, nicht längssägen.

44. Vermeiden Sie ruckartiges oder zu schnelles

Vorschieben. Schieben Sie harte Werkstücke

möglichst langsam vor. Unterlassen Sie Biegen

oder Verdrehen des Werkstücks während des

Vorschubs. Falls das Sägeblatt im Werkstück

hängen bleibt oder sich verklemmt, schalten Sie

die Maschine sofort aus. Trennen Sie die

Maschine vom Stromnetz. Befreien Sie dann das

Sägeblatt.

BEWAHREN SIE DIESE HINWEISE

SORGFÄLTIG AUF.

INSTALLATION

VORSICHT:

• Halten Sie den Bodenbereich um die Maschinenebene

aufgeräumt und frei von losen Teilen, wie z.B. Spänen

und Sägeabfällen.

Installieren der Kippsicherung (Abb. 1 und 2)

Montieren Sie die Kippsicherung in der Aussparung am

Maschinenfuß, und sichern Sie sie durch Anziehen der

Sechskantschraube.

Werkbankmontage (Abb. 3)

Diese Maschine sollte unter Verwendung der Schraubenbohrungen in der Grundplatte mit zwei Schrauben auf

einer ebenen und stabilen Oberfläche befestigt werden.

Dadurch werden Umkippen und mögliche Verletzungen

vermieden.

24

Page 25

FUNKTIONSBESCHREIBUNG

VORSICHT:

• Vergewissern Sie sich vor jeder Einstellung oder Funktionsprüfung der Maschine stets, dass sie ausgeschaltet und vom Stromnetz getrennt ist.

Schutzhaube (Abb. 4 und 5)

VORSICHT:

• Vergewissern Sie sich, dass der Handgriff nicht abgesenkt werden kann, ohne den Hebel in seiner Nähe

nach links zu drücken.