Page 1

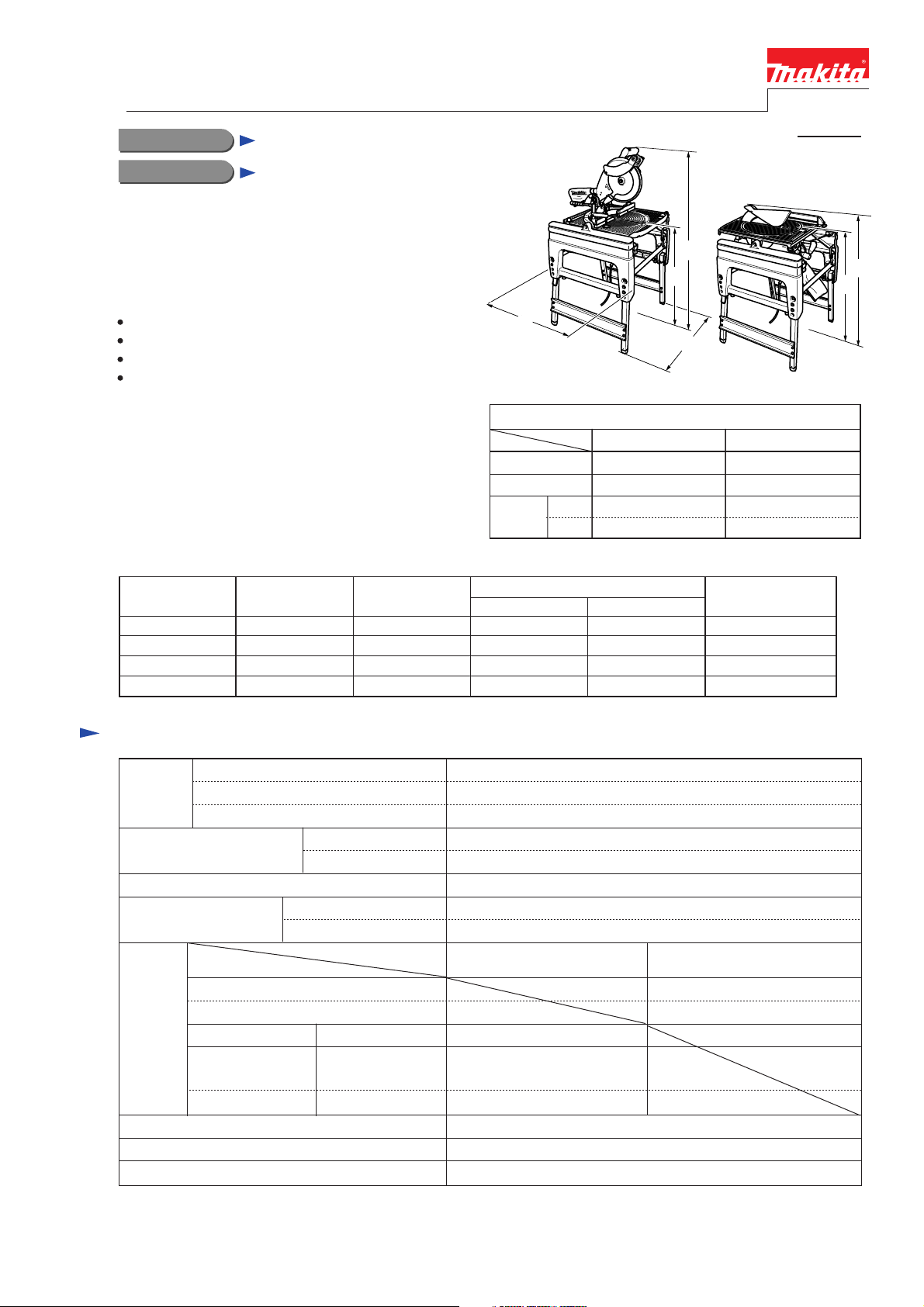

T

Model No.

ECHNICAL INFORMATION

LF1000

NEW TOOL

P 1 / 30

Description

Flip Over Saw 260mm (10-1/4")

CONCEPT AND MAIN APPLICATIONS

Model LF1000 is the first flip over saw from Makita.

Miter saw and Table saw are combined for great versatility.

Its main advantages are;

Weighs only 32kg (70lbs) for easy transport to job sites.

Quick miter saw/table saw conversion

Electronic with constant speed control and soft start

Rigid cast aluminum table

Voltage (V) Cycle (Hz)

110

220

230

240

Current (A)

15

8.5

8.4

8.3

50/ 60

50/ 60

50/ 60

50/ 60

H1

H2

L

W

[in Miter Saw mode] [in Table Saw mode]

Dimensions: mm (")

in Miter Saw mode in Table Saw mode

Length (L)

Width (W)

Height

H1: to the table top, H2: to the tool head

(H1)

(H2)

Continuous Rating (W)

Input Output

1,650

1,650

1,650

1,650

660 (26) 660 (26)

650 (25-1/2) 650 (25-1/2)

1,220 (48) 1,060 (41-3/4)

800 (31-1/2) 845 (33-1/4)

Max. Output (W)

900

900

900

900

H1

H2

2,200

2,200

2,200

2,200

Specification

Type

Saw blade

Continuous rating input: W

No load speed: min-1= rpm

Electronic feature

Cutting capacity*

Protection against electric shock

Power supply cord: m (ft)

Net weight: kg (lbs)

Diameter: mm (")

Hole diameter: mm (")

Cutting angle

45

0

degree

[Table saw: height only]

(height x width): mm (")

45

degrees

High voltage

Low voltage

Soft start

Constant speed control

Mode Miter saw Table saw

0

degree

degrees bevel

Miter angleBevel angle

0

degree

0

degree

TCT Saw blade

260 (10-1/4)

30 (1-3/16)

1,650 (230V)

1,650 (110V)

2,700

Yes

Yes

70 (2-3/4)

48 (1-7/8)

20 x 210 (13/16 x 8-1/4)

68 x 155 (2-11/16 x 6-1/8)

50 x 150 (2 x5-7/8)

Double insulation

2.5 (8.2)

32 (70)

*When cutting with 260mm diameter blade

Page 2

Standard equipment

P 2 / 30

TCT saw blade ......... 1 pc

Vise ass'y ................. 1 pc

Dust bag ass'y .......... 1 pc

Ruler ass'y ................ 1 pc

Note: The standard equipment for the tool shown above may differ by country.

Angle rule ass'y ....... 1 pc

Top cover ass'y ....... 1 pc

Dust cover ass'y ...... 1 pc

Elbow ..................... 1 pc

Box wrench 13-3 ...... 1 pc

Push stick ................. 1 pc

Fix plate ................... 3 pcs

Hex bolt M6x16 ....... 3 pcs

Optional accessories

Assorted TCT saw blades

Triangular rule ........ 1 pc

Page 3

P 3 / 30

Repair

CAUTION: Remove the saw blade from the machine for safety before repair/ maintenance !

[1] NECESSARY REPAIRING TOOLS

Code No.

Square

No.3 Philips driver bit

1R003 Retaining ring S Pliers ST-2N Removing Retaining ring from Safety cover

1R207 45 degree Set square Setting the miter/bevel angle of saw blade to 45 degrees

1R208 90 degree Set square Setting the miter/bevel angle of saw blade to 90 degrees

1R269 Bearing extractor Removing Ball bearings

1R288 Screwdriver magnetizer Removing Steel balls, etc.

1R230 1/4" Hex shank bit for M6 Disassembling Table

1R231 1/4" Hex shank bit for M8 Disassembling Frame

1R291 Retaining ring S and R pliers Removing Retaining ring S-15 from Spindle

1R340 Wrench for bearing retainer Removing/tightening Bearing retainer 25-36

Description

Use for

Assembling the legs of table

Removing/tightening of M6x60 Pan head screws that secure

Motor housing to Blade case.

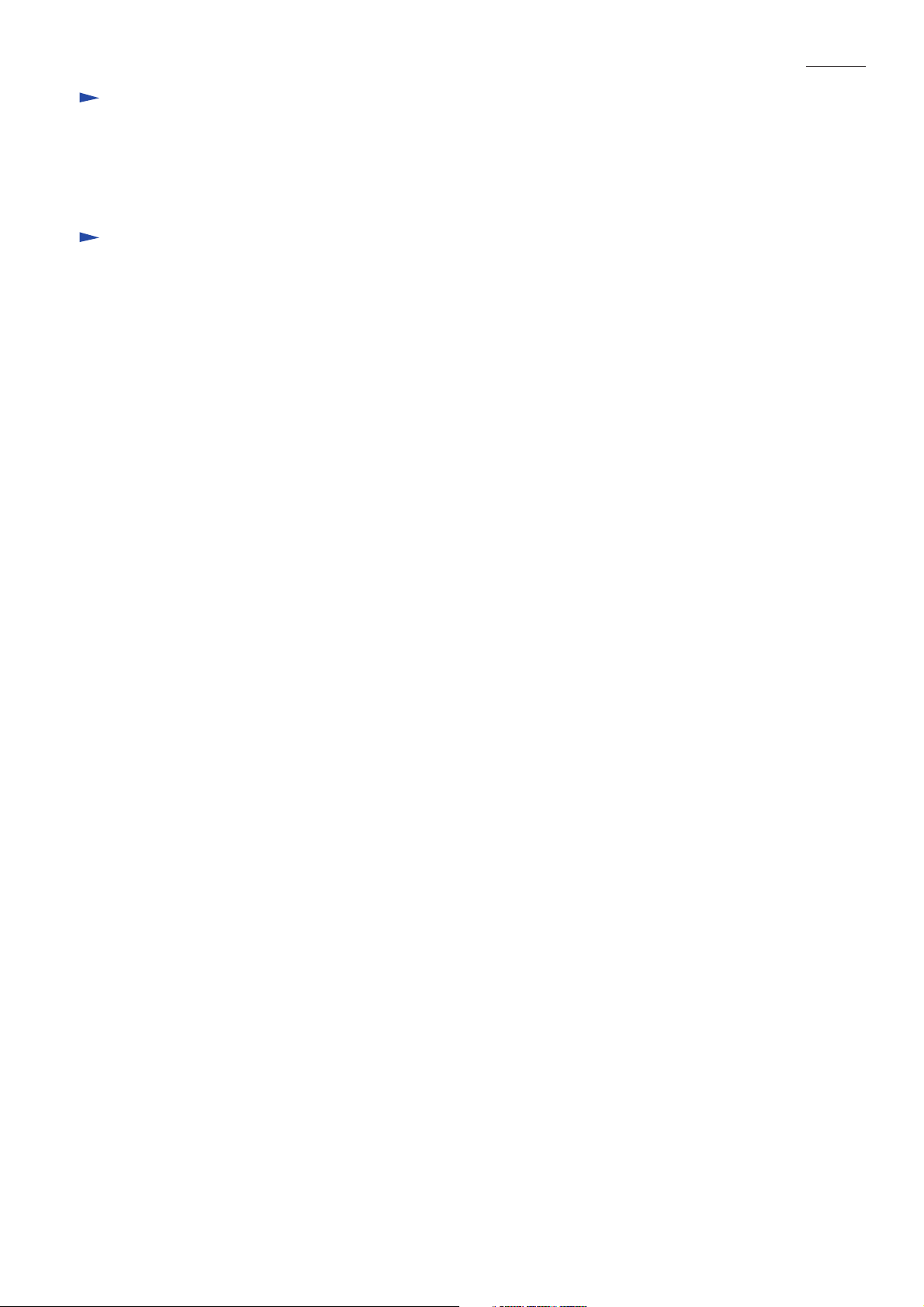

[2] LUBRICATION

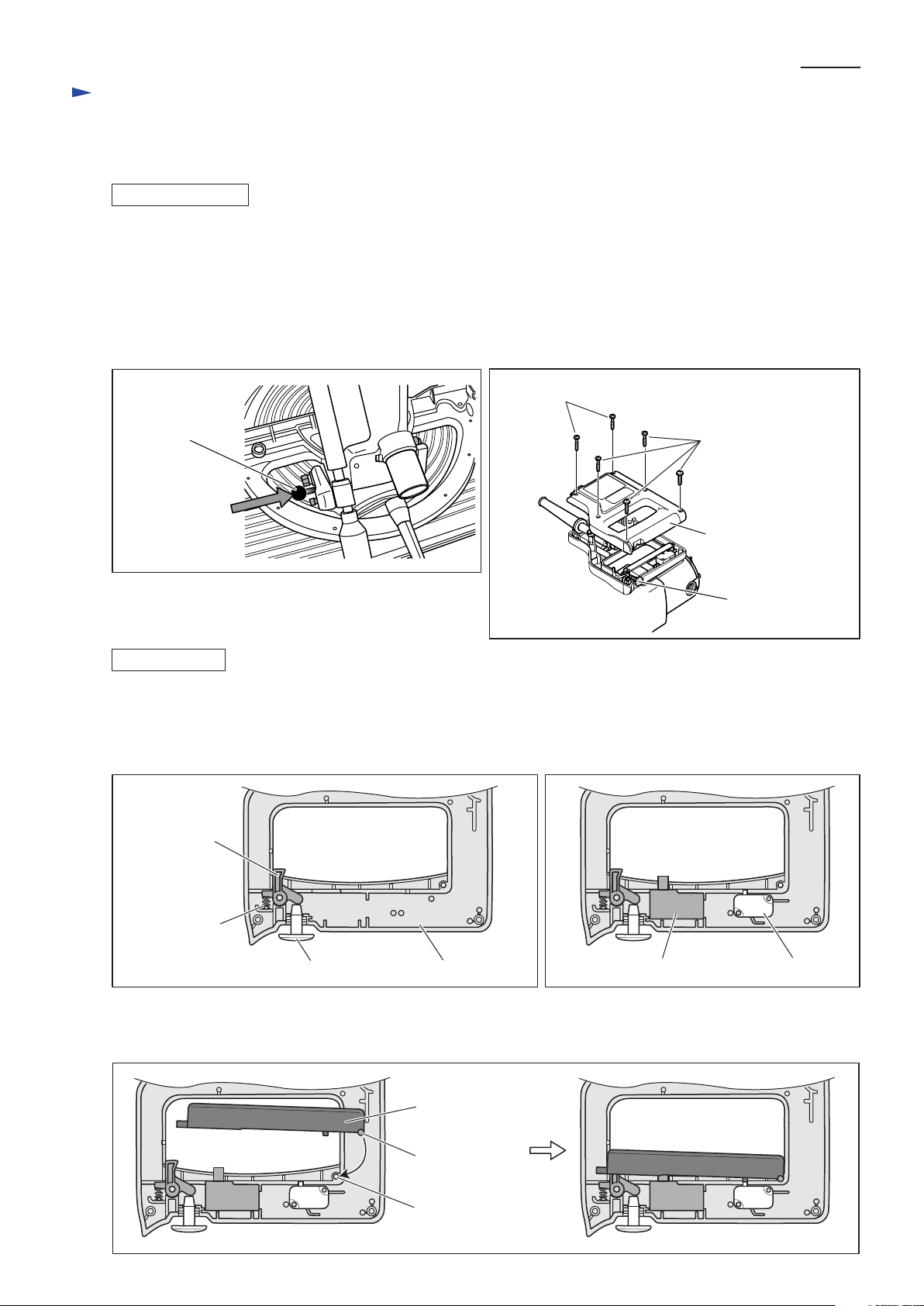

[2] -1. Saw Head Section

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion. See Fig. 1.

Item No. Description Portion to lubricate

50 Hex bolt M10

61

71

85

121

Knob 40

Steel ball 6

Sleeve 6 The surface that contacts Connecting rod64

Sleeve 10 The surface that contacts Adjust nut

Flat washer 10 The surface that contacts Connecting rod

Sub arm

Blade case

The surface that contacts Arm complete

The threaded portion

Whole surface62

Three surfaces that contacts Arm complete91

The gear room (Put approx. 7g.)

Two surfaces that contact Arm complete

Fig. 1

Arm complete

50

Connecting rod

85

64

61

62

Sleeve 13

Adjust nut

71

91

121

Page 4

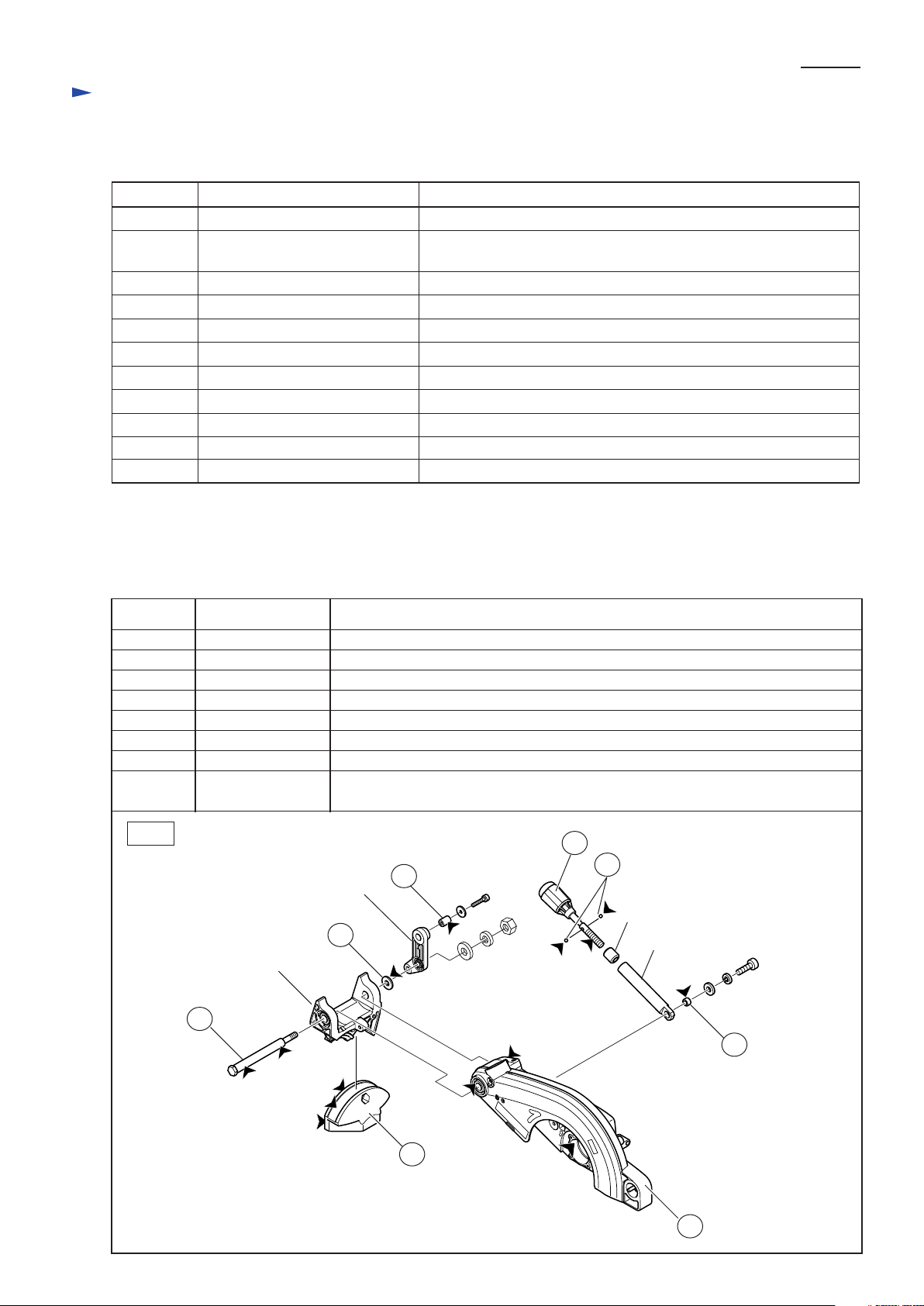

Repair

[2] LUBRICATION (cont.)

[2] -2. Table Section

Apply Makita grease N. No.1 to the following portions designated with the black triangle to protect

parts and product from unusual abrasion. See Fig.2.

Item No. Description Portion to lubricate

P 4 / 30

153 Guide fence

228

260

Fig. 2

Table complete

Sleeve 8

The both ends which contact Frame set.

The surfaces that contact Slide plates and Turn table

The surface that contacts Frame set

Slide plate R

Slide plate L

228

Turn table

228

260

260

153

Frame set

Page 5

Repair

[3] DISASSEMBLY/ASSEMBLY

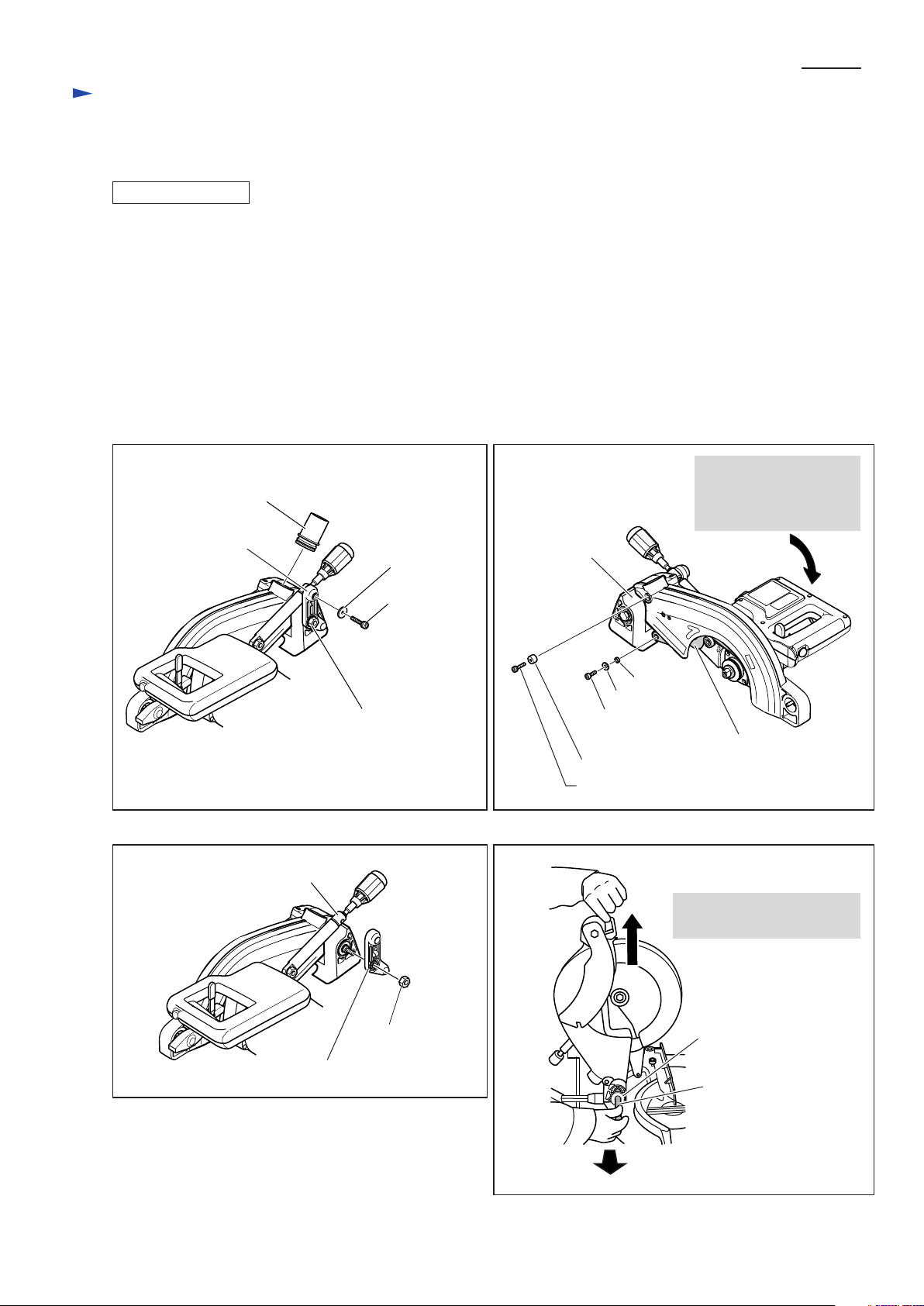

[3] -1. Handle Section

DISASSEMBLING

The Handle section can be disassembled without separating Motor housing from Blade case.

Take the following steps:

1) Set the machine in the mode of miter saw. And lock the saw head unit at the lowest position by pushing Knob 20

as illustrated in Fig. 3.

2) Remove Handle cover by unscrewing two 4x25 Tapping screws and four 4x18 Tapping screws. (Fig. 4)

Now the inner parts of the Handle section can be replaced.

Note: Be careful not to lose Switch button (Lock off button) when removing Handle cover.

Fig. 3

Fig. 4

Tapping screw 4x25

P 5 / 30

Knob 20

Push to lock the

saw head unit at

the lowest position.

ASSEMBLING

1) Assemble Now lock-off mechanism to Handle by mounting first Compression spring 4, then Lock-off lever and

Switch button as illustrated in Fig. 5.

Note: Put Compression spring 4 securely in place. If not, the lock-off mechanism will not work properly.

2) Mount the inner parts (Switch, Brake switch, Line filter, etc). (Fig. 6)

Fig. 5

Lock-off lever

Fig. 6

Tapping screw 4x18

Handle cover complete

Switch button

(Lock off button)

Compression

spring 4

Switch button

3) Install Switch lever on Handle by fitting the fulcrum boss on Switch lever securely in the switch lever installation hole

of Handle. (Fig. 7) And then do the reverse of disassembling steps.

Fig. 7

Handle

Switch lever

fulcrum boss

Switch lever

installation hole

Switch Brake switch

Page 6

Repair

[3] DISASSEMBLY/ASSEMBLY

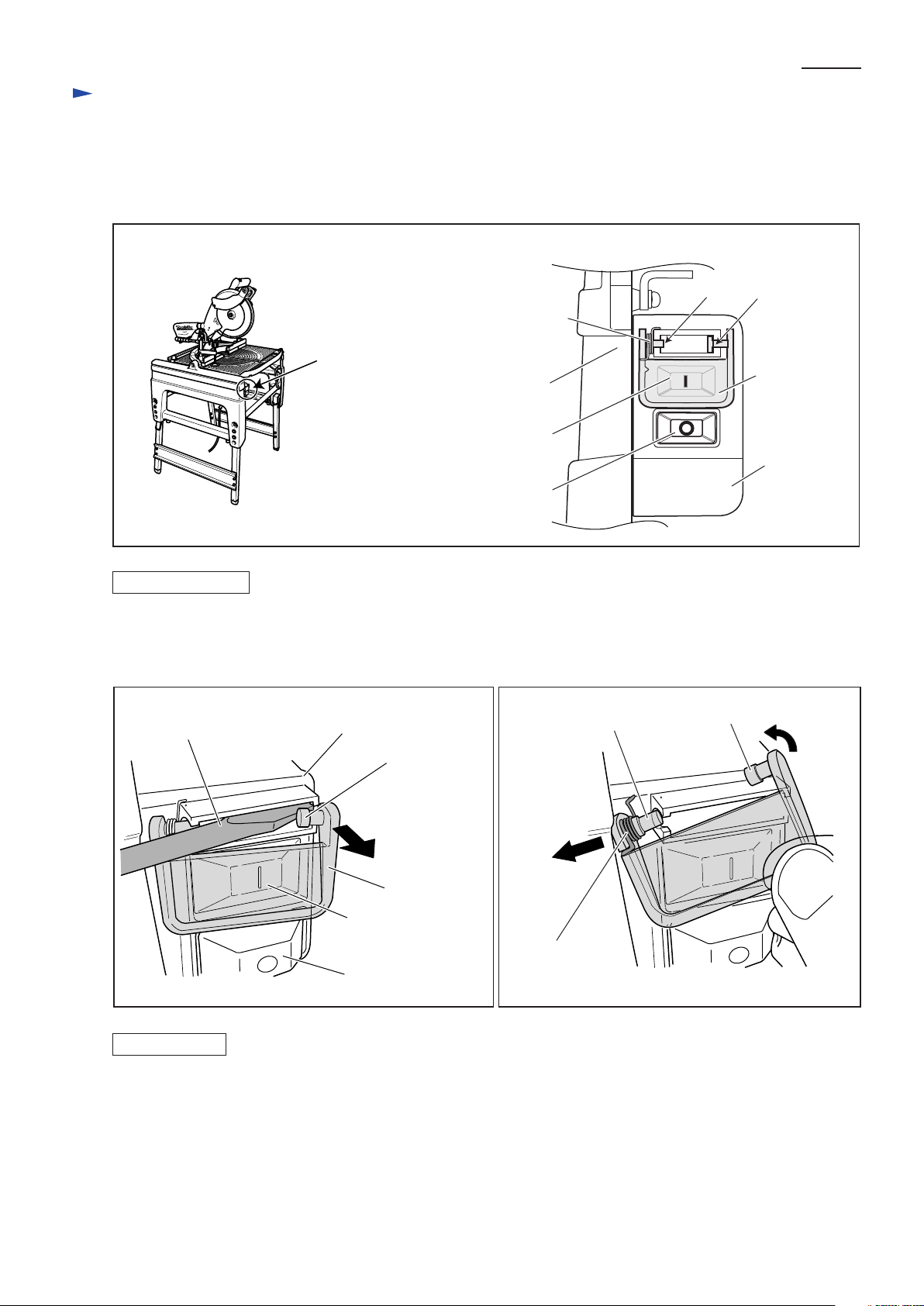

[3] -2. Switch Box (On/Off Switch Section)

Switch box is located below Table on Frame complete. (Fig. 8)

Fig. 8

P 6 / 30

[Large view]

left hinge

Torsion spring 5

Switch box

Frame complete

Switch button "ON"

Switch button "OFF"

DISASSEMBLING

1) First, disconnect the right hinge of Switch cover from Switch box using slotted screwdriver. (Fig. 9)

2) Then, while lifting up the right hinge, pull off the left hinge from Switch cover. (Fig. 10)

3) Remove Torsion spring 5 from the left hinge.

Fig. 9

Slotted screwdriver

Switch box

Fig. 10

Left hinge

Right hinge

right hinge

Switch cover

Switch box

Switch button "ON"

Switch button "OFF"

ASSEMBLING

Do the reverse of the disassembling steps.

Right hinge

Switch cover

Torsion spring 5

Page 7

P 7 / 30

Repair

[3] DISASSEMBLY/ASSEMBLY

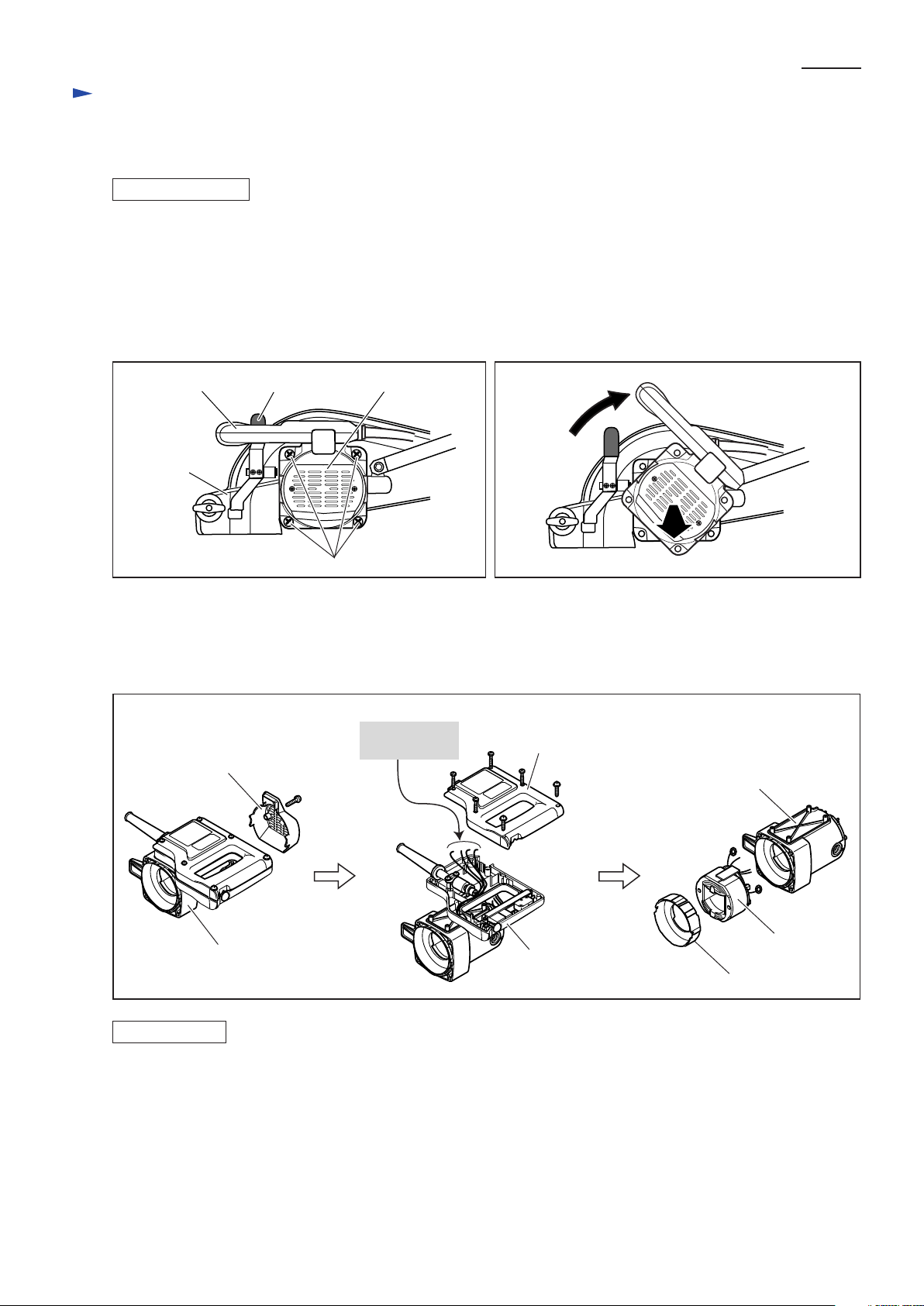

[3] -3. Motor Housing

DISASSEMBLING

1) Remove Brush holder caps and Carbon brushes from Motor housing.

2) Remove four M6x60 Pan head screws using No.3 Phillips screwdriver. (Fig. 11)

Note: Motor housing can not be separated from Blade case in this step because Handle is interfered by Lock lever.

3) Turn Motor housing until handle is released from Lock lever. Then separate Motor housing from Blade case

by pulling off. (Fig. 12) Now Armature can be replaced.

Note: Pull off Motor housing carefully so as to prevent Compression spring 9 of the shaft lock mechanism from

popping out of place.

Fig. 11

Fig. 12

Lock leverHandle

Blade case

Pan head screw M6x60

4) When replacing Field, separate Motor housing first as described above.

5) Then remove Rear cover from Motor housing. Remove Handle cover complete from handle, and disconnect lead

wires from Field. Now Motor housing can be separated from Handle. (Fig. 13)

6) After removing Baffle plate, remove Field by tapping the edge of Motor housing with plastic hammer. (Fig. 13)

Fig. 13

Rear cover

Motor housing

Disconnect

the lead wires.

Handle cover

complete

Motor housing

Motor housing

ASSEMBLING

Do the reverse of the disassembling steps.

Field

Handle

Baffle plate

Page 8

P 8 / 30

Repair

[3] DISASSEMBLY/ASSEMBLY

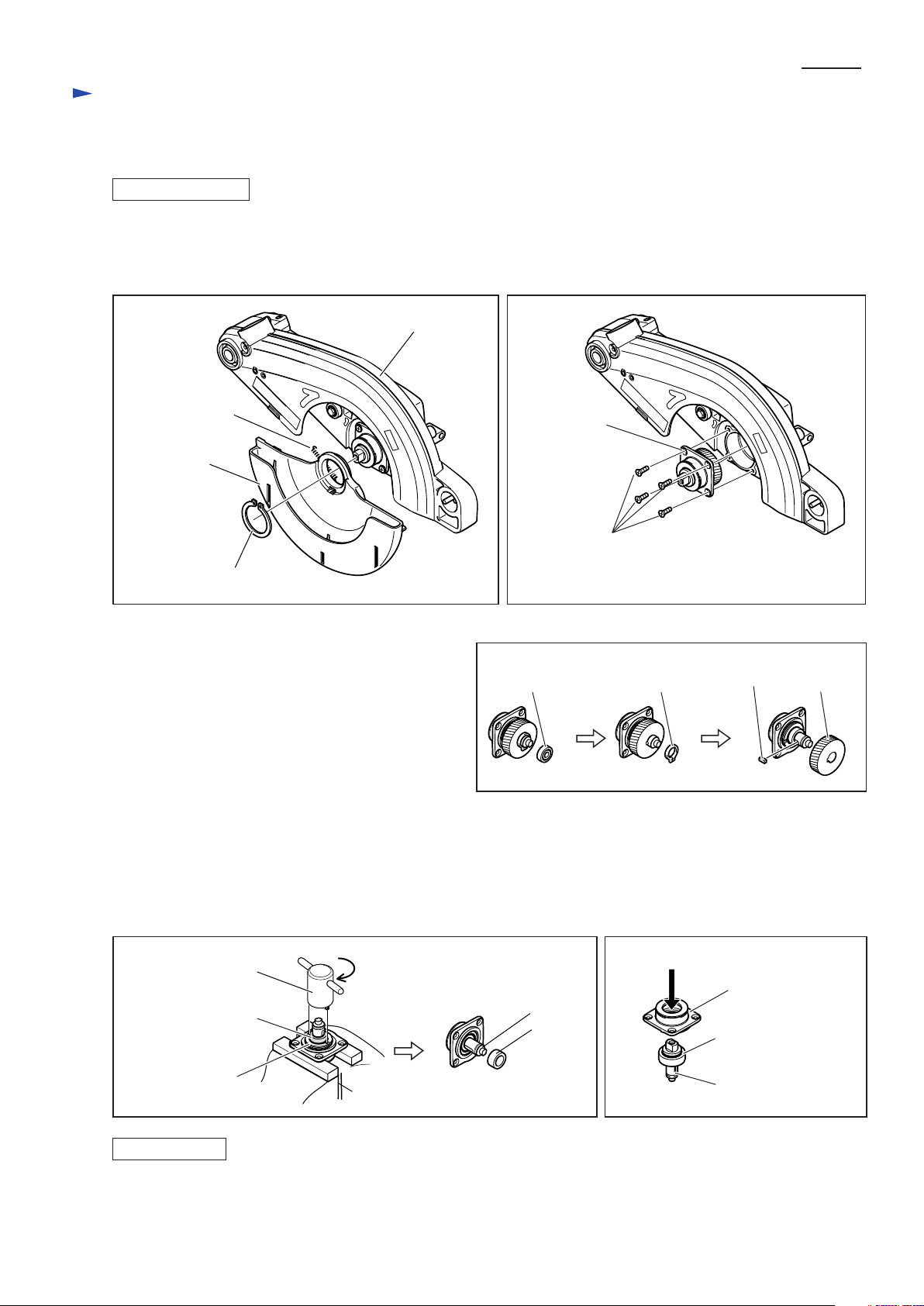

[3] -4. Gear Section

DISASSEMBLING

1) Disconnect Tension spring 4 from Blade case. By removing Retaining ring S-42 with Retaining pliers ST-2N

(No.1R003), Safety cover can be separated from Blade case. (Fig. 14)

2) By unscrewing four M5x16 Countersunk head screws, the Gear section can be separated from Blade case. (Fig. 15)

Fig. 14

Blade case

Tension spring 4

Safety cover

Retaining ring S-42

3) Remove Ball bearing 608LLB from Spindle with

Bearing extractor (No.1R269), then Retaining ring

S-15 with Retaining Ring S and R Pliers (No.1R291).

Now Helical gear 46 can be removed by hand.

(Fig. 16)

Fig. 15

Fig. 16

Ball bearing

608LLB

Gear section

Countersunk

head screw M5x16

Retaining

ring S-15

Key 4

Helical

gear 46

4) Fix Bearing box in vise.

Note: It is not necessary to remove Ring 15 in this step because it can be used as a guide for Wrench for Bearing

Retainer (No.1R340) when removing Bearing retainer 25-36.

Set No.1R340 on Bearing retainer 25-36, and turn clockwise to remove Bearing retainer 25-36 from Bearing box.

Then remove Ring 15 from Spindle. (Fig. 17)

5) When removing Spindle from Bearing box, press from the Flange installation side. (Fig. 18)

Fig. 17

No.1R340

Ring 15

(guide for No.1R340)

Bearing retainer

25-36

ASSEMBLING

Do the reverse of the disassembling steps.

Spindle

Ring 15

Fig. 18

Bearing box

Ball bearing 6202LLB

Spindle

Page 9

P 9 / 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Blade Case Section

DISASSEMBLING

1) Remove Safety cover as illustrated in Fig. 14.

2) Remove Dust nozzle. Then remove Hex socket head bolt M6x30 and Flat washer 6 for disconnecting the cutting

depth adjusting mechanism and Connecting rod. (Fig. 19)

3) Loosen Hex nut M10 on Connecting rod. But do not remove from Connecting rod in this step. (Fig. 19)

4) Remove Hex socket head bolt M6x20, Flat washer 6 and Ring 6 for disconnecting the linkage of Link plate and

Arm complete. (Fig. 20)

5) Remove Hex socket head bolt M5x20 and Sleeve 5 from Blade case with 1/4" Hex shank bit for M6 (No.1R230)

while pressing down Blade case so that it is not raised by the force of Torsion spring 34. (Fig. 20)

6) Disconnect Connecting rod from Arm complete by removing Hex nut M10. (Fig. 21)

7) While holding Blade case as illustrated in Fig. 22, remove Hex bolt M10 and Flat washer 16 from Arm complete.

Now Blade case section with Torsion spring 34 and Sleeve 17 (2pcs) can be separated from Arm complete.

Fig. 19 Fig. 20

While pressing down

Dust nozzle

Connecting rod

Arm complete

Flat washer 6

Blade case, remove Hex

socket head bolt M5x20

and Sleeve 5.

Hex socket

head bolt

M6x30

Hex nut M10

Fig. 21 Fig. 22

Sleeve 13

Hex nut M10

Ring 6

Flat washer 6

Hex socket head

bolt M6x20

Sleeve 5

Hex socket head bolt M5x20

While lifting up Blade case,

pull off hex bolt M10.

Link plate

Flat washer 16

Connecting rod

Hex bolt M10

Page 10

P 10/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -5. Blade Case Section (cont.)

ASSEMBLING

Do the reverse step of disassembling steps. Remember the following notes.

1. When installing Sleeve 13 and Connecting rod on Knob 40;

Slide Sleeve 13 as far as possible toward Steel ball 6. At this time, the distance between Sleeve 13 and the neck of

Knob 40 will be about 7mm. While keeping the distance, secure Connecting rod to Sleeve 13 with Hex socket head bolt

M6x30. (Fig. 23)

Fig. 23

7mm

Knob 40

Sleeve 13

Steel ball 6

on Knob 40

Adjust nut

2. When installing Link plate and Safety cover on Blade case;

As illustrated in Fig. 24, put Link plate on Ball bearing 608LLB that is mounted to the inside wall of Blade case for

smooth action of Link plate. Then secure Link plate to Arm complete with Hex socket head bolt M6x20. (Fig. 20)

On the back of Safety cover, there is a rib that acts as a guide rail for the Ball bearing on Link plate.

Mount Safety cover to Bearing box so that the Ball bearing of Link plate fits on the rib. (Fig. 25)

And secure Safety cover with Retaining ring S-42. (Fig. 14)

Fig. 24 Fig. 25

Blade case

Connecting rod

Hex socket head

bolt M6x30

Flat washer 6

Sleeve 6

Link plate

Ball bearing

608LLB

Ball bearing

(integral part of Link plate)

Tension spring 4

Safety cover

Rib

Safety cover and Link plate correctly set in place,

viewed from the Motor housing side

Blade case

Link plate

Ball bearing

of Link plate

Rib

Tension spring 4

Safety cover

Page 11

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -6. Riving Knife

DISASSEMBLING

1) First, fix riving knife as illustrated in Fig. 26.

2) Remove Stop ring E-4, then loosen Wing bolt M8. Now Riving knife can be removed. (Fig. 27)

Fig. 26

P 11/ 30

1) Loosen Wing nut M8.

Riving knife

2) Pull Riving knife a little

in the direction of arrow.

Fig. 27

Stop ring E-4

3) Turn Riving knife

90 degrees.

Flat washer 8

Spring washer 8

Hex bolt M8x86

5) Secure Riving knife

with Wing nut M8.

4) Slightly push Riving knife

in the direction of arrow.

Wing nut M8

Flat washer 8

Knife support

ASSEMBLING

Do the reverse of the disassembling steps.

Riving knife

Page 12

P 12/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Table Section

DISASSEMBLING

When disassembling the Table section, Arm complete has to be separated from Sub arm. However, it is not necessary

to separate the Blade case section from Arm complete.

1) Remove Power supply cord from Strain relieves on Frame. However, it is not necessary to remove from the Strain

relief on Connecting rod.

2) Remove Pan head screw M4x10 and Lever 100. After unscrewing Hex nut M10-17, remove Spacer and Thrust

needle gauge 1022. (Fig. 28)

3) Unscrew Hex lock nut M10-17. Then remove Indication plate from Sub arm by unscrewing Pan head screw M4x10.

(Fig. 29)

4) By removing Hex bolt M10, Arm complete can be separated from Sub arm. (Fig. 30)

Fig. 28

Blade case

Thrust needle gauge 1022

Arm complete

Spacer

Hex nut M10-17

Lever 100

Pan head screw M4x10

Fig. 29 Fig. 30

Indication plate

Hex lock nut

M10-17

Pan head screw

M4x10

5) Remove Screw M6x25 and Pin 5. And remove Hex socket head set screw M10x12, Compression spring 6 and

Steel ball 7.9. Then turn over the Table section in the direction of arrow. (Fig. 31)

Fig. 31

Sub arm

Hex socket head set screw M10x12

* Compression spring 6

* Steel ball 7.9

Sub arm

Turn table complete

Hex bolt M10

Screw M6x25

* Pin 5

The small parts designated

with an asterisk can be

removed using a bar or

screwdriver magnetized

with No.1R288.

Guide fence

Turn table complete

Table complete

Page 13

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Table Section (cont.)

DISASSEMBLING

6) Now the Table section can be removed from Guide fence

by unscrewing nine M6x20 Hex socket head bolts from

the back side of Table complete. (Fig. 32)

P 13/ 30

Fig. 32

[Table section turned over]

7) Remove Hex socket head bolt M8x50 and Flat washer 8

from each end of Guide fence. (Fig. 33)

8) Insert a slotted screwdriver into the hole of Sleeve 8

on each end of guide fence, and lever it out from the hole

of Frame as illustrated to left in Fig. 34.

Note:

Hold Guide fence by hand to prevent from falling down.

Now Guide fence can be separated from Frame

as illustrated to right in Fig. 34.

Fig. 33

Guide fence

Flat washer 8

Hex socket head bolt M8x50

Table complete

Frame

Fig. 34

Slotted screwdriver

Guide fence

Sleeve 8

Page 14

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -7. Table Section (cont.)

DISASSEMBLING

9) Lever (Lock lever) is fastened to Frame with each two pieces of

Hex socket button head bolt M6 and Flat washer 7.

When removing Lever, follow the instruction described in Fig. 35.

Fig. 35

If this bolt is removed first, the force of Torsion spring

will cause the Bolt and Flat washer 7 to pop off.

P 14/ 30

Lever

Lever

Flat washer 7

Hex socket

button head

bolt M6

Be sure to remove this bolt first

for easy removal of Lever.

ASSEMBLING

Do the reverse of the disassembling steps 1) - 9).

Note:

When installing Torsion spring 17 on Frame, insert the spring

straight over the boss till it touches the inside wall of Frame.

Be careful not to tilt the spring. (Fig. 36)

Frame

Torsion spring 17

Fig. 36

Torsion spring 17

Boss for Torsion spring installation

Frame

Boss for Torsion

spring installation

Page 15

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Frame Section

DISASSEMBLING

1) After removing Switch box, place the Frame section as illustrated in Fig. 37, and remove four Square pipes by

unscrewing eight M8x20 Hex socket head bolts.

2) Place the Frame section as illustrated in Fig. 38. Then, by removing four M10 Hex nuts from Pipe 32 complete

(with Makita mark label) and Pipe 32 (without Makita mark label), separate right Frame from left Frame.

Fig. 37

Hex socket head bolt M8x20 (8 pcs)

Square pipe

(4 pcs)

Fig. 38

Pipe 32

P 15/ 30

Pipe 32 complete

Flat washer 10

Spring washer 10

Hex nut M10

3) From each of *right and *left Frames, remove Pipe 32 complete (Pipe 32) and Screw M10. (Fig. 39)

4) Caps can be removed from Frame by tapping the joint of Cap and Frame with slotted screwdriver. (Fig. 40)

Note: Do not reuse Caps removed from Frame because it is deformed or damaged when removed.

Fig. 39

Frame, right

(See Note below.)

Pipe 32

Screw M10

Fig. 40

(4 pcs each)

Cap

Frame, left

(See Note below.)

Note:

This end of Screw M10 is screwed in the threaded hole

of Frame. Therefore, unscrew when removing from Frame.

Pipe 32 complete

Cap

*Right Frame and Left Frame;

Are exactly the same in size and shape.

However, some different parts such as Switch box

or Lock lever are assembled to them.

For convenience, therefore, we call the one on

operator's right hand "Right Frame" and the other

"Left Frame".

Page 16

P 16/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -8. Frame Section (cont.)

ASSEMBLING

1) Fasten Screw M10 to left Frame/ right Frame so that Pipe 32 complete/ Pipe 32 covers 2 pitches of the thread portion

on the opposite side of the screw when the pipe is set in place over the screw. (Fig. 41)

Fig. 41

Frame, right

Cross section of [A]

Pipe 32

Screw M10

Pipe 32 complete (Pipe 32)

Screw M10

[A]

2 pitches

Pipe 32 complete

Frame, left

2) Tighten Frames with four M10 Hex nuts. (Fig. 38)

3) Assemble Lever to the right Frame. (Fig. 35 and 42)

4) Assemble Switch box to the left Frame. (Fig. 42)

5) Install each three Cushions to the right and left Frames.

Then to the right frame, fasten Leaf spring with Pan head screw M4x10, and fasten two M6 screws. (Fig. 43)

Fig. 42 Fig. 43

Frame, left

Switch box

Lever

Frame, right

Operator's position

Switch box

Frame, left

Cushion

Pan head screw M4x10

Leaf spring

Lever

Frame, right

Screw M6

Page 17

P 17/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -9. Assembling Feet Section

LEFT FEET SECTION

1) For smooth folding action of the Feet section, follow the steps described below to assemble Support bracket to

Square pipes precisely at an angle of 90 degrees:

i) Put Support bracket on Square pipe 32-510, while keeping about 238 mm distance from the top of Support bracket

to the top end of Square pipe. You don't need to tighten hex bolt M6x45 securely in this step.

Then while applying angle ruler to Square pipe and Support bracket, adjust the angle to 90 degrees. (Fig. 44)

ii) While keeping the 90 degrees obtained in the previous step, tighten the bolt securely to fasten Support bracket to

Square pipe 32-510.

iii) Fasten Support bracket to Square pipe 32-475 as the same way you have done in the steps i) and ii).

The distance between Square pipe 32-510 and Square pipe 32-475 will be about 529mm if Support bracket is

assembled correct to the two pipes. (Fig. 45)

Fig. 44 Fig. 45

Square pipe

32-510

approx.

283mm

Hex bolt M6x45

Flat washer 6

Framing square

Support bracket

2) See Fig. 46. Mount Bracket on Square pipe 32-510 from the Support bracket installation side.

Put Pin 8 (long) through Flat washer 8, elliptic holes of Bracket and the first holes from the top of Square pipe 32-510.

And secure the Pin 8 with another Flat washer 8 and Stop ring E-6. Then assemble another Pin 8 (long) in the second

hole from the top of the Square pipe as illustrated below.

3) See Fig. 47. Assemble Bracket to the first hole from the top of Square pipe 32-475 as the same way you have done

in the step 2). Then assemble Pin 8 (long) in the second hole from the top, and Pin 8 (short) in the third hole from

the top as illustrated below.

Fig. 46 Fig. 47

Hex nut M6

Flat washer 8

Square pipe

32-510

approx.

529mm

Framing square

approx. 283mm

Hex bolt M6x45

Square pipe

32-475

Hex nut M6

Flat washer 8

Flat washer 6

Installing Bracket on Square pipe 32-510 Installing Bracket on Square pipe 32-475

Bracket

Bracket

Support bracket

Support bracket

Pin 8 (long) Pin 8 (short)Flat washer 8 Sleeve 8 Stop ring E-6

Page 18

P 18/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -9. Assembling Feet Section (cont.)

LEFT FEET SECTION

4) To Square pipe 32-510, assemble Hook and Foot. And to Square pipe 32-475, assemble Stopper hook and Foot nut.

(Fig. 48)

Fig. 48

Hook

Square pipe 32-510

Hex nut M6

Foot

Foot

Support bracket

Foot nut

RIGHT FEET SECTION

Note: Different from the Left feet section, two 32-475 Square pipes are used for the right Feet section.

1) The same way as you did in assembling the left feet section;

Assemble Support bracket to Square pipes precisely at an angle of 90 degrees. (Fig. 45, 46)

Then assemble Bracket and Pin 8 to each Square pipe. (Fig. 47, 48)

2) Assemble Stopper hook to the Square pipe 32-475 on the side of operator's position. (Fig. 49)

3) Mount Foot to each Square pipe. (Fig. 49)

Fig. 49

Stopper hook

Square pipe 32-475

Foot bolt

Compression spring 13

Foot nut

Hex nut M6

Pin 8 (long)

Foot

Bracket

Support bracket

Stopper hook

Pin 8 (long)

Pin 8 (short)

Foot

Page 19

P 19/ 30

Repair

[3] DISASSEMBLY/ASSEMBLY

[3] -10. Assembling Feet Section to Frame Section

With eight M8x20 Hex socket bolts, fasten the left Feet section to Frame, left; and the right Feet section to Frame, right.

Important:

a) Before assembling, be sure that the following parts are in the correct position as illustrated in Fig. 50.

b) Fasten with the bolts as illustrated in Fig. 51.

If not assembled as illustrated below, it will be impossible to fold the feet section or obtain a flat table surface.

Fig. 50

[Feet section, right]

Stopper hook

Foot nut

[Frame, right]

Switch box

Feet section

[Feet section, left]

Hook

Lever

Frame section

[Frame, left]

Fig. 51

Fastening the left Feet section to Frame, left Fastening the right Feet section to Frame, right

Tighten the bolts through the second and third holes

from the bottom of the Frame.

Tighten the bolts through the first and second holes

from the bottom of the Frame.

Page 20

P 20/ 30

Repair

[4] ADJUSTMENT

[4] -1. Adjusting Bevel Angle

0 Degree Bevel

1) Lock the saw head unit in the full down position, and loosen Lever 100. Then rotate the 90 degree adjusting screw

two or three turns counterclockwise using Hex wrench 3, and tilt the blade to the right. (Fig. 52)

2) Put 90 degree set square (No.1R208) on the top surface of Turn table and beside the blade. Turn the 0 degree

adjusting screw carefully clockwise until No.1R208 closely contacts the blade without gap between their surfaces

and between the surfaces of No.208 and Turn table. Then tighten Lever 100. (Fig. 53)

3) After performing this adjustment, make sure that the pointer of Indication plate is indicating 0 degree on Bevel scale.

If not, loosen the screw that fastens Indication plate and adjust the pointer to 0 degree.

Fig. 52 Fig. 53

[Bottom of Table viewed from the Lever 100 installation side] [Table and Blade viewed from

the Lever 100 installation side]

Lever 100

Saw blade

[right][left]

No.1R208

[right][left]

0 degree adjusting screw 45 degree adjusting screw

Turn table

45 Degree Bevel

Important: Before performing 45 degree bevel angle adjustment, be sure to do 0 degree bevel angle adjustment.

1) Tilt the saw head unit fully to the right. (Fig. 54)

2) Put 45 degree set square (No.1R207) on the top surface of Turn table and beside the blade. Turn the 45 degree

adjusting screw carefully clockwise until No.1R207 closely contacts the blade without gap between their surfaces

and between the surfaces of No.207 and Turn table. Then tighten Lever 100. (Fig. 55)

3) After performing this adjustment, make sure that the pointer of Indication plate is indicating 45 degrees on Bevel

scale. If not, loosen the screw that fastens Indication plate and adjust the pointer to 45 degrees.

Fig. 54 Fig. 55

[Bottom of Table viewed from the Lever 100 installation side]

Saw head unit

[Table and Blade viewed from

the Lever 100 installation side]

[right][left]

0 degree adjusting screw 45 degree adjusting screw

Saw blade

No.1R207

[right][left]

Turn table

Page 21

P 21/ 30

Repair

[4] ADJUSTMENT

[4] -2. Adjusting Miter Angle

In case of LF1000, it is impossible to adjust miter angle by moving Guide fence because the Guide fence is designed

also as the axis on which Table is flipped over.

Therefore, adjust miter angle by moving the saw head unit carefully as follows:

1) Lock the saw head unit in the full down position.

2) Slightly loosen four M6x20 hex socket head bolts that fasten the Arm section to Turn table. (Fig. 56)

3) Lightly tighten one of the four bolts. Then, applying 90 degree set square (No.1R208) to the side of saw blade and

Guide fence, pivot the Arm section slightly on the tightened bolt until No.1R208 closely contacts the side of the saw

blade and Guide fence without gap between the surfaces. While keeping the 90 degree angle between the blade and

Guide fence, tighten four M6x20 hex socket head bolts securely. (Fig. 57)

4) After performing this adjustment, make sure that Pointer on Table complete is indicating 0 degree on Miter scale.

If not, loosen the screw that fastens Pointer to Table complete and adjust it to 0 degree.

Fig. 56 Fig. 57

[Bottom of Table viewed from the Lever 100 installation side] [Saw blade and Guide fence viewed from top]

Saw head unit

Hex socket head bolt M6x20

Lever 100

Arm section

(Arm and

Sub arm)

Saw head unit

Guide fence

Saw blade

No.1R208

Arm section

Lever 100

Page 22

Circuit diagram

P 22/ 30

All European Countries Except UK-110V

Color index of lead wires' sheath

OrangeBlue

Brown Purple Yellow

Black

Cord from Switch box

A

B

Red

Handle

*Pick up coil is factory-assembled to Controller.

(See page 23 for UK-110V.)

White

Motor Housing

Handle

A B

Field

Noise suppressor

Brake switch

Switch

Choke

coil

Controller

Relay

Strain relief

Line filter

Band

A1313141

A2423242

Connecting cord between

Terminal

block

Strain relief on Frame complete

Switch box and Handle

Strain relief on Connecting rod

Noise suppressor

Switch Box

Power supply cord

Strain relief

When Connecting Wires to Relay;

Attach Receptacle sleeve (indicated by in

the diagram) to the Receptacle on the wires

to connect with the following terminals:

No.31, No.3, No.42, No.2, No.A2

Page 23

Circuit diagram

UK-110V

Color index of lead wires' sheath

OrangeBlue

Brown Purple Yellow

Black

Red

White

P 23/ 30

Cord from Switch box

A

Motor Housing

A B

Field

Choke

coil

Controller

B

Handle

*Pick up coil is factory-assembled to Controller.

Handle

Noise suppressor

Switch

Relay

Noise suppressor

Power supply cord

Switch Box

A153141

A264242

Terminal

block

Strain relief

Strain relief

Line filter

Band

Connecting code between

switch box and handle

Strain relief on Connecting rod

Strain relief on Frame complete

When Connecting Wires to Relay;

Attach Receptacle sleeve (indicated by in

the diagram) to the Receptacle on the wires

to connect with the following terminals:

No.5, No.42, No.4 No.A2

Page 24

Wiring diagram

P 24/ 30

All European Countries Except UK-110V

(See page 28 for UK-110V.)

[1] Wiring on the Rear End Surface of Motor Housing

Choke coil,

connected with Controller

Motor housing

Lead wire holder C

Lead wire holder B

Fix two wires of

Pick up coil with

the lead wire

holders B and C.

Lead wires of

Pick up coil

Controller

Field lead wire (orange)

Field lead wire (black)

Field lead wire (yellow)

Route three Field lead wires

(orange, black, yellow)

through the opening B.

Opening B

Lead wire holder A

Handle

Motor housing

Field lead wire (purple)

Field lead wire (white)

Opening A

Route two Field lead wires (purple, white) through the

opening A, and fix with the lead wire holders A, B and C.

Important: Be sure that the lead wires are tight between

the opening A and the lead wire holder C.

With the lead wire holder D on Handle,

Lead wire holder D

Choke coil

Controller

fix the following lead wire holders:

*five Field lead wires

(white, purple, orange, black, yellow)

*four lead wires from Controller

(orange, black, red, brown)

Important:

Be sure that the nine wires are tight

between Motor housing and the

lead wire D.

Choke-coil's lead wire

(orange), connected

with Controller

Controller's lead wire

(black)

Controller's lead wire

(red)

Controller's lead wire

(brown)

Page 25

Wiring diagram

P 25/ 30

All European Countries Except UK-110V

[2] Wiring in Handle

Put Line filter between Strain relief and Band.

Install Connecting cord and Band on Handle so that;

*the distance between the end of Connecting cord and the inside wall A is 10 - 20mm

*the distance between the end of Connecting cord and Band is 10 - 20mm.

Switch

Noise

suppressor

10 - 20mm

(See page 29 for UK-110V.)

10 - 20mm

Band

Be careful not to

route lead wires

over Strain relief.

Line filter

Strain relief

Connecting cord

from Switch box

Brake switch

Route the three lead wires to Switch and

the two lead wires to Brake switch between

the L-shaped rib and the inside wall A.

How to Connect lead wires to Brake switch

Connect lead wires to Brake switch as illustrated below.

Correct Wrong

Handle cover side

Brake switch

Handle cover side

L-shaped ribInside wall A

Lead wires from

Controller and Field

Bottom of Handle

Bottom of Handle

Page 26

Wiring diagram

P 26/ 30

All European Countries Except UK-110V

[3] Wiring in Switch Box

Do not route any lead wire in the shaded area

in order not to pinch between relay and the

inside wall or the boss of Switch box.

When mounting Grommet to Switch box,

be sure to place;

*the big end outside of Switch box

*the small end inside of Switch box.

Small end of Grommet

Big end of Grommet

Grommet

Connecting cord from Handle

(See page 30 for UK-110V.)

Do not route lead wires over Relay.

Do not place Noise suppressor on Relay.

Relay

Strain relief

Switch box

Noise suppressor

Strain relief Terminal block

Power supply cord

Page 27

Wiring diagram

All Countries

[4] Wiring at Connecting Rod

P 27/ 30

Handle

Blade case

Cord guard

Be sure that Connecting cord is tight

between Cord guard and Strain relief.

[5] Wiring Under Table

As illustrated below, fix Connecting cord

with the Strain relief at two points.

As illustrated to right, be sure to place the

Cord below Pan head screw M4x10 that

secures Strain relief to Connecting rod.

Connecting rod

Pan head screw M4x10

Strain relief

Connecting cord

(from Switch box)

Fix Connecting cord with the Strain relief.

Be sure to place the Cord below Pan head

screw M4x10 that secures Strain relief to

Connecting rod.

Pan head screw

M4x10

Strain relief

Switch box

Grommet

Frame complete

Be sure that Connecting cord is tight

between Grommet and Strain relief.

Connecting cord

Connecting cord from

Switch box to Handle

Be sure that Connecting cord is tight

between the two Strain relieves.

Page 28

Wiring diagram

UK-110V

[1] Wiring on the Rear End Surface of Motor Housing

P 28/ 30

Lead wire holder C

Lead wire holder B

Fix two wires of

Pick up coil with

the lead wire

holders B and C.

Lead wires of

Pick up coil

Lead wire holder A

Choke coil,

connected with Controller

Motor housing

Field lead wire (orange)

Field lead wire (black)

Field lead wire (yellow)

Route three Field lead wires

(orange, black, yellow)

through the opening B.

Opening B

Controller

Opening A

Handle

Motor housing

Field lead wire (white)

Field lead wire (white)

Route two Field lead wires (white, white) through the

opening A, and fix with the lead wire holders A, B and C.

Important: Be sure that the lead wires are tight between

the opening A and the lead wire holder C.

With the lead wire holder D on Handle,

Lead wire holder D

Choke coil

Controller

fix the following lead wire holders:

*five Field lead wires

(white, white, orange, black, yellow)

*four lead wires from Controller

(orange, black, red, white)

Important:

Be sure that the nine wires are tight

between Motor housing and the

lead wire D.

Choke-coil's lead wire

(orange), connected

with Controller

Controller's lead wire

(black)

Controller's lead wire

(red)

Controller's lead wire

(white)

Page 29

Wiring diagram

UK-110V

[2] Wiring in Handle

Put Line filter between Strain relief and Band.

Install Connecting cord and Band on Handle so that;

*the distance between the end of Connecting cord and the inside wall A is 10 - 20mm

*the distance between the end of Connecting cord and Band is 10 - 20mm.

Switch

10 - 20mm

Noise

suppressor

10 - 20mm

Band

P 29/ 30

Be careful not to

route lead wires

over Strain relief.

Line filter

Strain relief

Connecting cord

from Switch box

L-shaped ribInside wall A

Route the three lead wires to Switch between

the L-shaped rib and the inside wall A.

Lead wires from

Controller and Field

Page 30

Wiring diagram

UK-110V

[3] Wiring in Switch Box

Do not route any lead wire in the shaded area

in order not to pinch between relay and the

inside wall or the boss of Switch box.

When mounting Grommet to Switch box,

be sure to place;

*the big end outside of Switch box

*the small end inside of Switch box.

Small end of Grommet

Big end of Grommet

Grommet

P 30/ 30

Do not route lead wires over Relay.

Do not place Noise suppressor on Relay.

Relay

Connecting cord from Handle

Strain relief

Strain relief Terminal block

Power supply cord

[4] Wiring at Connecting Rod

Do the same way as "All European Countries Except UK-110V". (See page 27.)

[5] Wiring Under Table

Do the same way as "All European Countries Except UK-110V". (See page 27.)

Switch box

Noise suppressor

Loading...

Loading...