Page 1

EN

Cordless Angle Grinder INSTRUCTION MANUAL 6

FR

DE

IT

NL

ES

PT

DA

EL

TR

Meuleuse d’Angle sans Fil MANUEL D’INSTRUCTIONS 16

Akku-Winkelschleifer BETRIEBSANLEITUNG 27

Smerigliatrice angolare a

batteria

Haakse accuslijpmachine GEBRUIKSAANWIJZING 49

Esmeriladora Angular

Inalámbrica

Esmerilhadeira Angular a

Bateria

Ledningsfri vinkelsliber BRUGSANVISNING 82

Φορητός γωνιακός

λειαντήρας

Akülü Avuç Taşlama Makinesi KULLANMA KILAVUZU 104

DGA408

ISTRUZIONI PER L’USO 38

MANUAL DE

INSTRUCCIONES

MANUAL DE INSTRUÇÕES 71

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ 92

60

DGA458

DGA508

Page 2

2

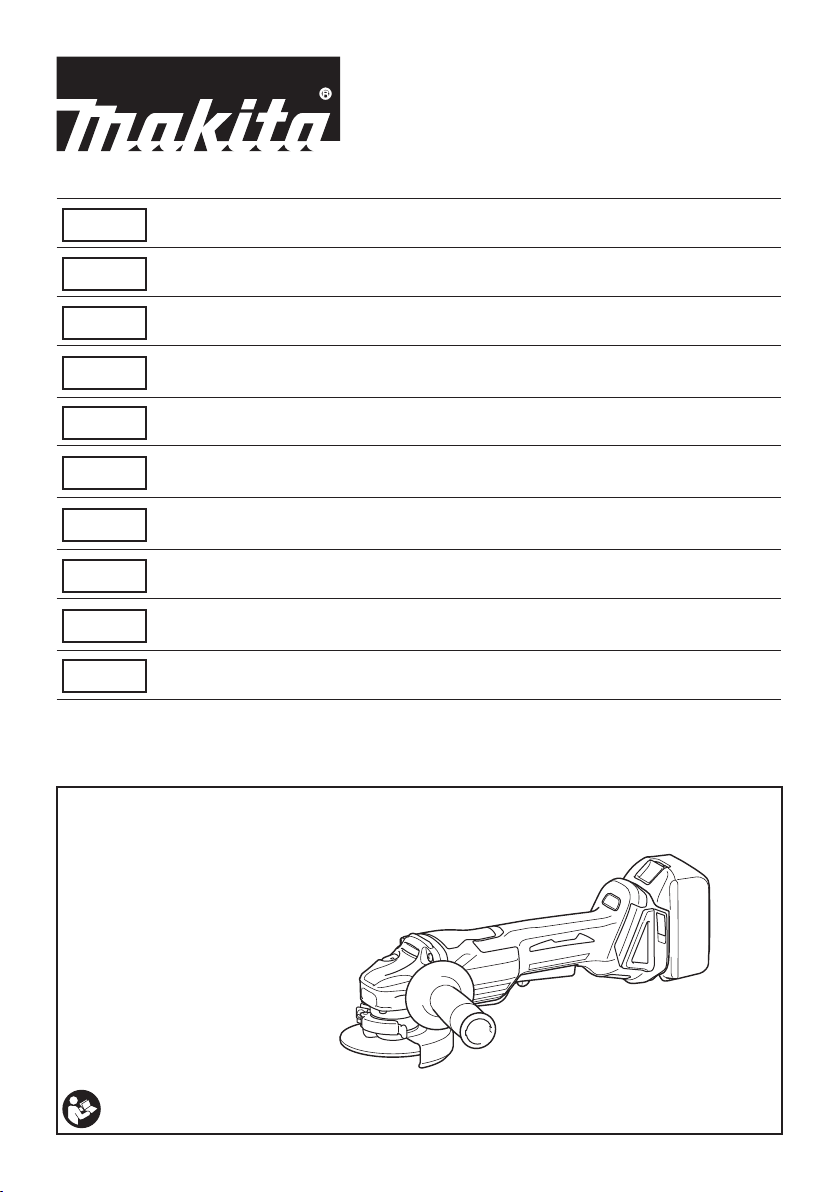

1

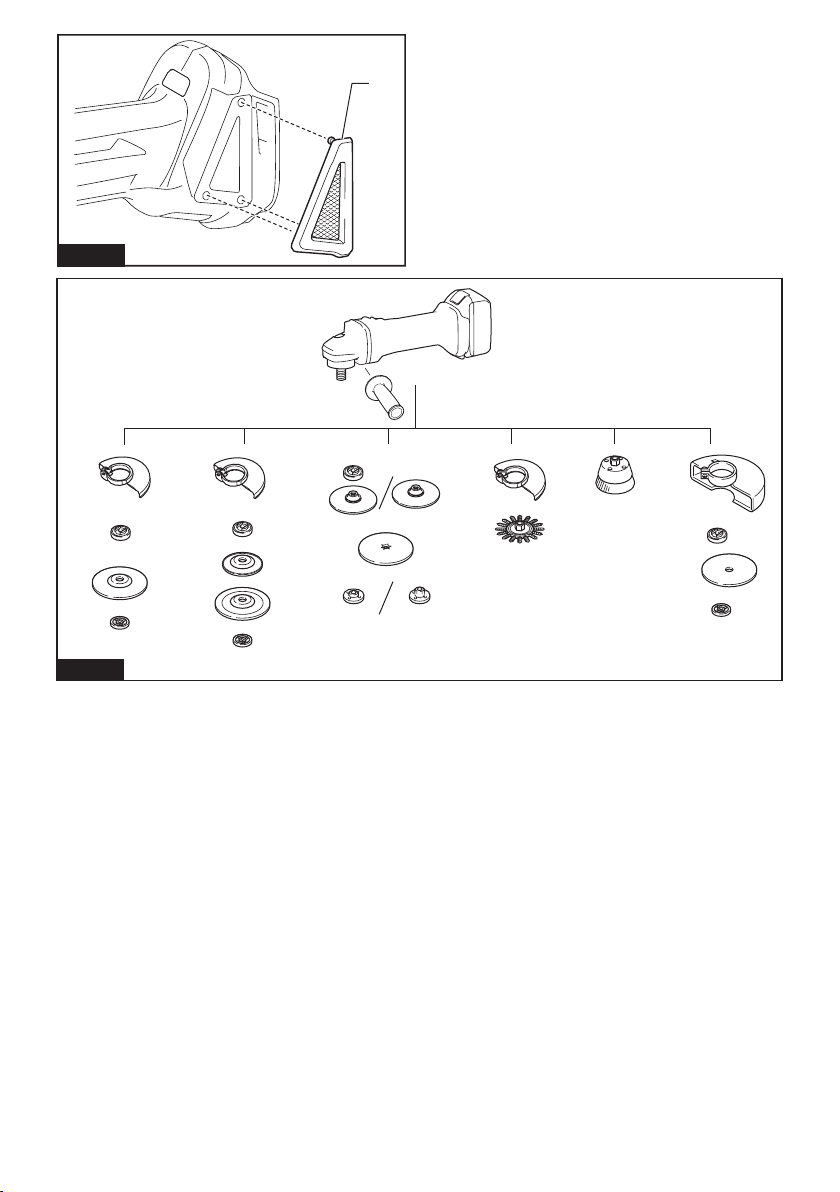

Fig.1

Fig.2

Fig.3

3

Fig.5

2

1

1

1

2

Fig.6

1

Fig.7

Fig.4

1

1

2

Fig.8

2

3

Page 3

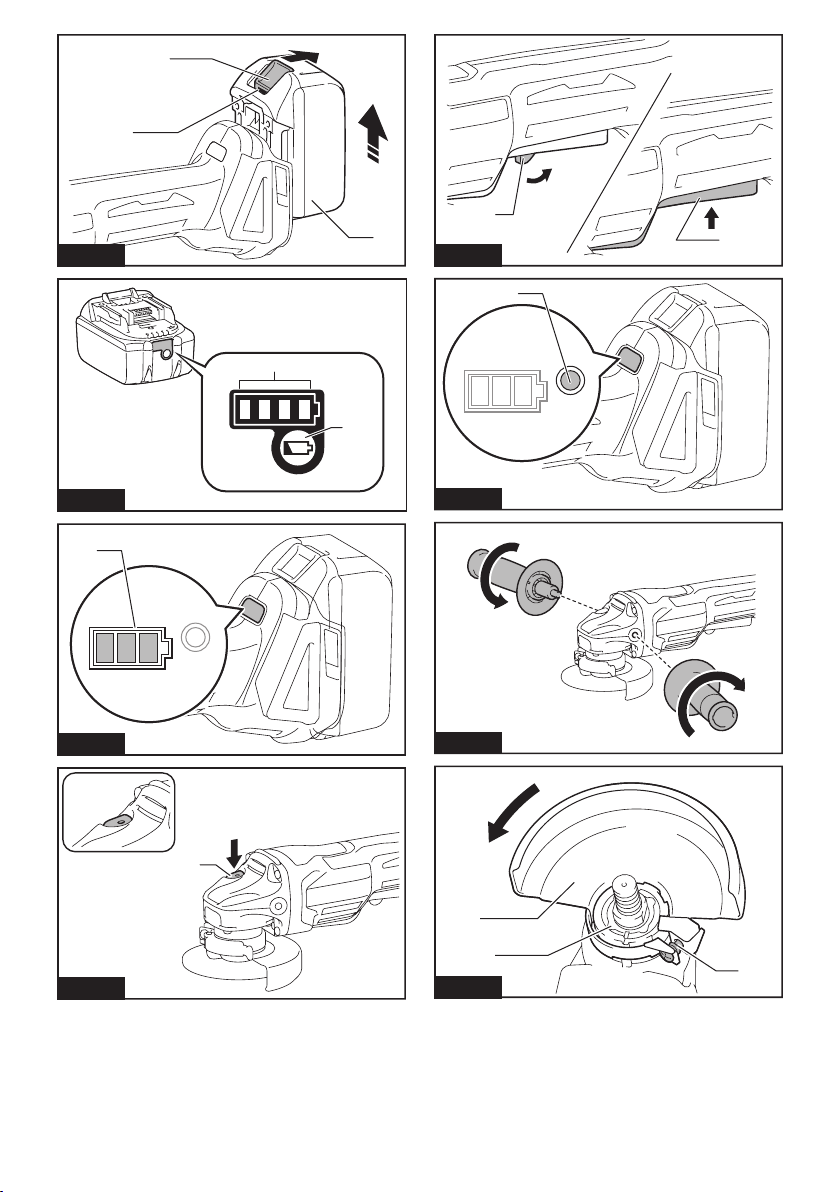

1

1

Fig.9

Fig.10

2

3

3

4

2

4

2

1

Fig.13

1

2

3

4

Fig.14

1

1

2

3

4

2

3

Fig.11

Fig.12

Fig.15

1

2

Fig.16

3

Page 4

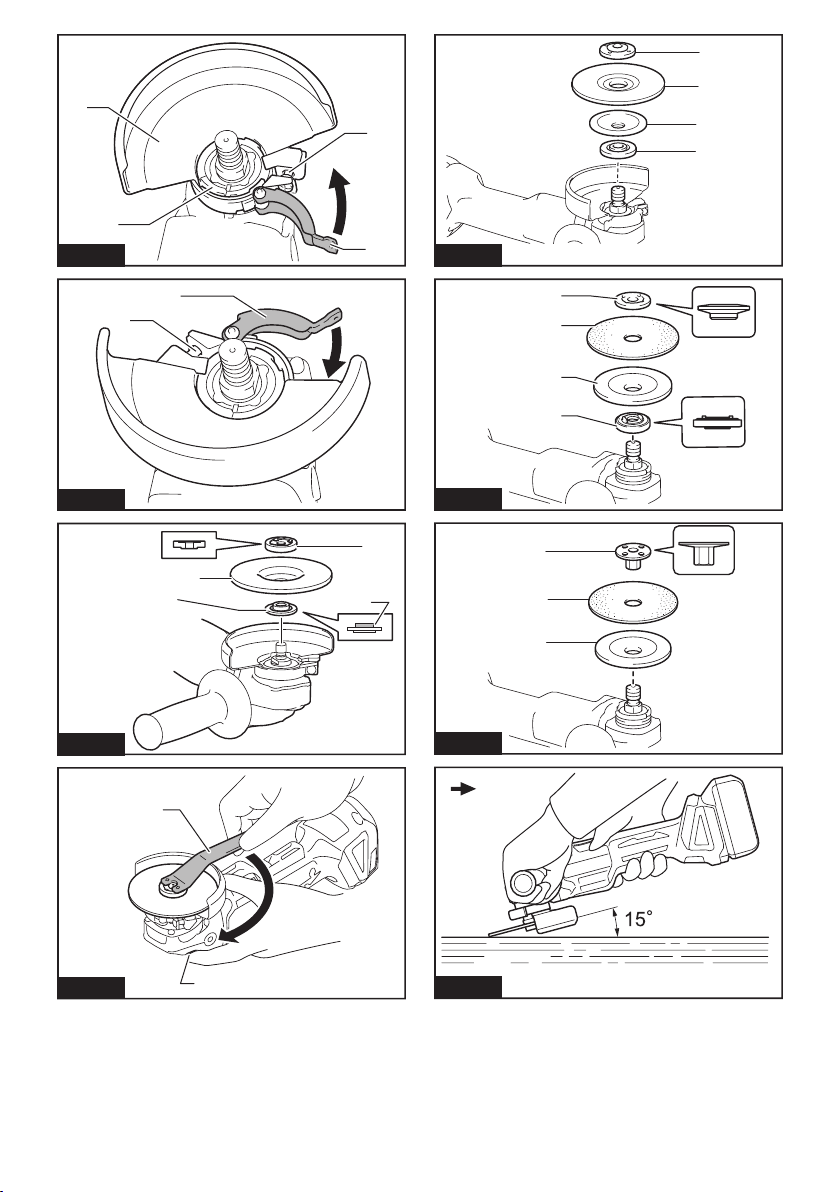

1

2

1

1

2

3

3

4

4

4

Fig.17

16 mm (5/8″)

Fig.18

Fig.19

11

23

4

4

11

23

4

4

1

1

2

3

Fig.21

1

16 mm (5/8″)

Fig.22

1

Fig.23

1

Fig.20

4

4

Fig.24

4

2

Page 5

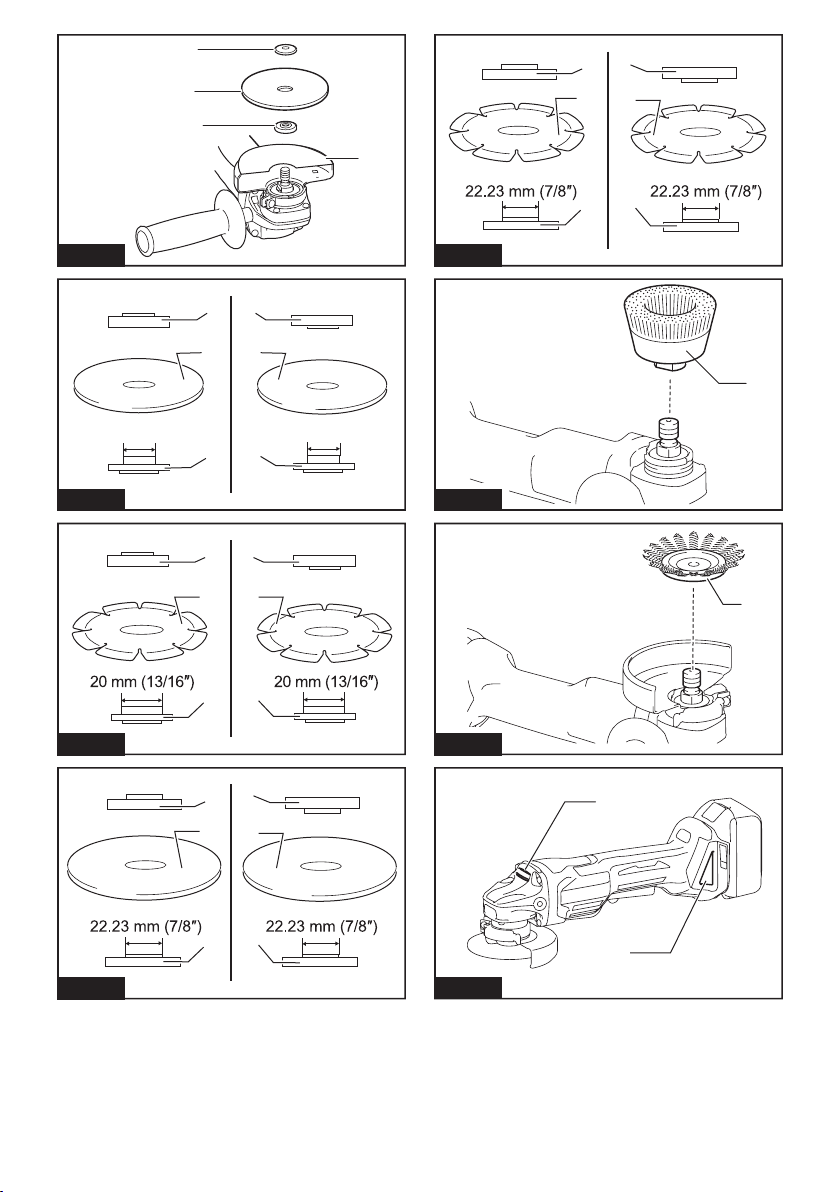

Fig.25

1

1

2

3

4

5

Fig.26

22

3

6

7

8

11

9

10

12

13

3

14

5

5

5

Page 6

ENGLISH (Original instructions)

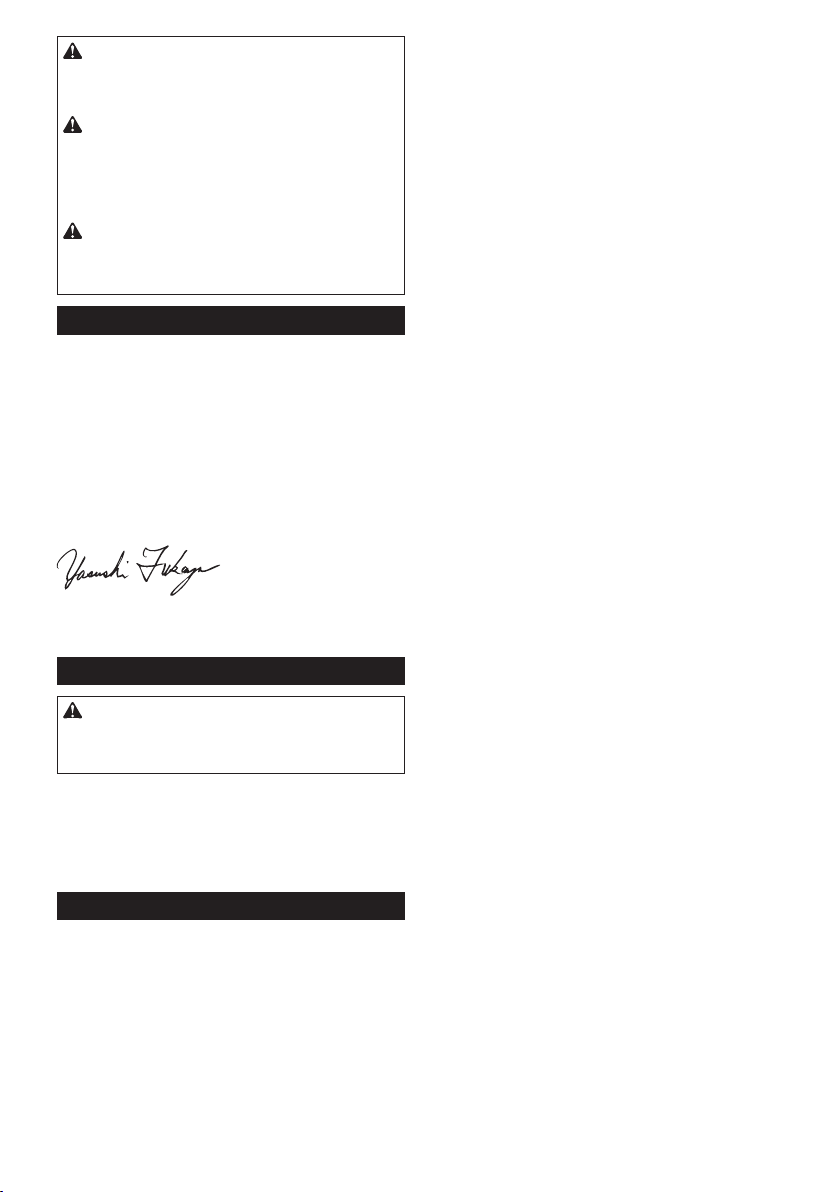

SPECIFICATIONS

Model: DGA408 DGA458 DGA508

Wheel diameter 100mm (4″) 115mm (4-1/2″) 125mm (5″)

Max. wheel thickness 6.4mm

Spindle thread M10 M14 or 5/8″ (country specic)

Rated speed (n) 8,500min

Overall length With battery cartridge

Net weight With battery cartridge

Rated voltage D.C.18 V

BL1815N, BL1820,

BL1820B

With battery cartridge

BL1830, BL1840,

BL1840B, BL1850,

BL1850B, BL1860B

BL1815N, BL1820,

BL1820B

With battery cartridge

BL1830, BL1840,

BL1840B, BL1850,

BL1850B, BL1860B

2.2kg 2.4kg

2.5kg 2.6kg

• Due to our continuing program of research and development, the specications herein are subject to change

without notice.

• Specications and battery cartridge may differ from country to country.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

Intended use

The tool is intended for grinding, sanding and cutting of

metal and stone materials without the use of water.

Noise

The typical A-weighted noise level determined according to EN60745:

Model DGA458

Sound pressure level (L

Uncertainty (K) : 3 dB(A)

) : 80 dB(A)

pA

Model DGA508

Sound pressure level (L

Uncertainty (K) : 3dB(A)

) : 79 dB(A)

pA

The noise level under working may exceed 80 dB (A).

WARNING: Wear ear protection.

Vibration

The vibration total value (tri-axial vector sum) determined according to EN60745:

Model DGA458

Work mode: surface grinding with normal side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

) : 5.5 m/s

h, AG

2

Work mode: surface grinding with anti vibration side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

) : 5.0 m/s

h, AG

2

2

2

Uncertainty (K) : 1.5 m/s

Work mode: disc sanding with anti vibration side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

Model DGA508

Work mode: surface grinding with normal side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

Work mode: surface grinding with anti vibration side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

Work mode: disc sanding with normal side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

Work mode: disc sanding with anti vibration side grip

Vibration emission (a

Uncertainty (K) : 1.5 m/s

NOTE: The declared vibration emission value has

been measured in accordance with the standard test

method and may be used for comparing one tool with

another.

NOTE: The declared vibration emission value

may also be used in a preliminary assessment of

exposure.

Work mode: disc sanding with normal side grip

Vibration emission (a

) : 2.5 m/s2 or less

h, DS

6 ENGLISH

-1

348mm

362mm

2

) : 2.5 m/s2 or less

h, DS

2

) : 6.0 m/s

h, AG

2

) : 5.5 m/s

h, AG

2

) : 2.5 m/s2 or less

h, DS

2

) : 2.5 m/s2 or less

h, DS

2

2

2

Page 7

WARNING: The vibration emission during actual

use of the power tool can differ from the declared

emission value depending on the ways in which the

tool is used.

WARNING: Be sure to identify safety measures

to protect the operator that are based on an estima-

tion of exposure in the actual conditions of use (taking

account of all parts of the operating cycle such as

the times when the tool is switched off and when it is

running idle in addition to the trigger time).

WARNING: The declared vibration emission

value is used for main applications of the power tool.

However if the power tool is used for other applications, the vibration emission value may be different.

EC Declaration of Conformity

For European countries only

Makita declares that the following Machine(s):

Designation of Machine: Cordless Angle Grinder

Model No./ Type: DGA458, DGA508

Conforms to the following European Directives:

2006/42/EC

They are manufactured in accordance with the following

standard or standardized documents: EN60745

The technical le in accordance with 2006/42/EC is

available from:

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

11.8.2015

Yasushi Fukaya

Director

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgium

General power tool safety warnings

WARNING: Read all safety warnings and

all instructions. Failure to follow the warnings and

instructions may result in electric shock, re and/or

serious injury.

Save all warnings and instructions for future reference.

The term "power tool" in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Cordless grinder safety warnings

Safety Warnings Common for Grinding, Sanding,

Wire Brushing, or Abrasive Cutting-Off Operations:

1. This power tool is intended to function as a

grinder, sander, wire brush or cut-off tool.

Read all safety warnings, instructions, illus-

trations and specications provided with this

power tool. Failure to follow all instructions listed

below may result in electric shock, re and/or

serious injury.

2. Operations such as polishing are not recommended to be performed with this power

tool. Operations for which the power tool was not

designed may create a hazard and cause personal injury.

3. Do not use accessories which are not speci-

cally designed and recommended by the tool

manufacturer. Just because the accessory can

be attached to your power tool, it does not assure

safe operation.

4. The rated speed of the accessory must be at

least equal to the maximum speed marked on

the power tool. Accessories running faster than

their rated speed can break and y apart.

5. The outside diameter and the thickness of your

accessory must be within the capacity rating

of your power tool. Incorrectly sized accessories

cannot be adequately guarded or controlled.

6. Threaded mounting of accessories must

match the grinder spindle thread. For acces-

sories mounted by anges, the arbour hole of

the accessory must t the locating diameter

of the ange. Accessories that do not match the

mounting hardware of the power tool will run out of

balance, vibrate excessively and may cause loss

of control.

7.

Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged accesso-

ries will normally break apart during this test time.

8. Wear personal protective equipment.

Depending on application, use face shield,

safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors,

gloves and workshop apron capable of stopping small abrasive or workpiece fragments.

The eye protection must be capable of stopping

ying debris generated by various operations.

The dust mask or respirator must be capable of

ltrating particles generated by your operation.

Prolonged exposure to high intensity noise may

cause hearing loss.

9. Keep bystanders a safe distance away from

work area. Anyone entering the work area

must wear personal protective equipment.

Fragments of workpiece or of a broken accessory

may y away and cause injury beyond immediate

area of operation.

10. Hold the power tool by insulated gripping

surfaces only, when performing an operation

where the cutting tool may contact hidden

wiring. Contact with a "live" wire will also make

exposed metal parts of the power tool "live" and

could give the operator an electric shock.

11. Never lay the power tool down until the accessory has come to a complete stop. The spinning

accessory may grab the surface and pull the

power tool out of your control.

7 ENGLISH

Page 8

12. Do not run the power tool while carrying it at

your side. Accidental contact with the spinning

accessory could snag your clothing, pulling the

accessory into your body.

13. Regularly clean the power tool’s air vents. The

motor’s fan will draw the dust inside the housing

and excessive accumulation of powdered metal

may cause electrical hazards.

14. Do not operate the power tool near ammable

materials. Sparks could ignite these materials.

15. Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

Kickback and Related Warnings

Kickback is a sudden reaction to a pinched or snagged

rotating wheel, backing pad, brush or any other accessory. Pinching or snagging causes rapid stalling of the

rotating accessory which in turn causes the uncontrolled power tool to be forced in the direction opposite

of the accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel that is

entering into the pinch point can dig into the surface of

the material causing the wheel to climb out or kick out.

The wheel may either jump toward or away from the

operator, depending on direction of the wheel’s movement at the point of pinching. Abrasive wheels may also

break under these conditions.

Kickback is the result of power tool misuse and/or

incorrect operating procedures or conditions and can be

avoided by taking proper precautions as given below.

1. Maintain a rm grip on the power tool and

position your body and arm to allow you to

resist kickback forces. Always use auxiliary

handle, if provided, for maximum control over

kickback or torque reaction during start-up.

The operator can control torque reactions or kickback forces, if proper precautions are taken.

2. Never place your hand near the rotating accessory. Accessory may kickback over your hand.

3. Do not position your body in the area where

power tool will move if kickback occurs.

Kickback will propel the tool in direction opposite

to the wheel’s movement at the point of snagging.

4. Use special care when working corners, sharp

edges etc. Avoid bouncing and snagging the

accessory. Corners, sharp edges or bouncing

have a tendency to snag the rotating accessory

and cause loss of control or kickback.

5. Do not attach a saw chain woodcarving blade

or toothed saw blade. Such blades create fre-

quent kickback and loss of control.

Safety Warnings Specic for Grinding and Abrasive

Cutting-Off Operations:

1. Use only wheel types that are recommended

for your power tool and the specic guard

designed for the selected wheel. Wheels for

which the power tool was not designed cannot be

adequately guarded and are unsafe.

2. The grinding surface of centre depressed

wheels must be mounted below the plane of

the guard lip. An improperly mounted wheel that

projects through the plane of the guard lip cannot

be adequately protected.

3. The guard must be securely attached to the

power tool and positioned for maximum safety,

so the least amount of wheel is exposed

towards the operator. The guard helps to protect

the operator from broken wheel fragments, accidental contact with wheel and sparks that could

ignite clothing.

4.

Wheels must be used only for recommended

applications. For example: do not grind with the

side of cut-off wheel. Abrasive cut-off wheels are

intended for peripheral grinding, side forces applied

to these wheels may cause them to shatter.

5. Always use undamaged wheel anges that are

of correct size and shape for your selected

wheel. Proper wheel anges support the wheel

thus reducing the possibility of wheel breakage.

Flanges for cut-off wheels may be different from

grinding wheel anges.

6. Do not use worn down wheels from larger

power tools. Wheel intended for larger power tool

is not suitable for the higher speed of a smaller

tool and may burst.

Additional Safety Warnings Specic for Abrasive

Cutting-Off Operations:

1. Do not “jam“ the cut-off wheel or apply excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility of kickback or wheel breakage.

2. Do not position your body in line with and

behind the rotating wheel. When the wheel, at

the point of operation, is moving away from your

body, the possible kickback may propel the spinning wheel and the power tool directly at you.

3. When wheel is binding or when interrupting

a cut for any reason, switch off the power

tool and hold the power tool motionless until

the wheel comes to a complete stop. Never

attempt to remove the cut-off wheel from the

cut while the wheel is in motion otherwise

kickback may occur. Investigate and take correc-

tive action to eliminate the cause of wheel binding.

4. Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed and

carefully re-enter the cut. The wheel may bind,

walk up or kickback if the power tool is restarted in

the workpiece.

5. Support panels or any oversized workpiece to

minimize the risk of wheel pinching and kickback. Large workpieces tend to sag under their

own weight. Supports must be placed under the

workpiece near the line of cut and near the edge

of the workpiece on both sides of the wheel.

6. Use extra caution when making a “pocket cut”

into existing walls or other blind areas. The

protruding wheel may cut gas or water pipes, electrical wiring or objects that can cause kickback.

Safety Warnings Specic for Sanding Operations:

1. Do not use excessively oversized sanding

disc paper. Follow manufacturers recommendations, when selecting sanding paper. Larger

sanding paper extending beyond the sanding

pad presents a laceration hazard and may cause

snagging, tearing of the disc or kickback.

8 ENGLISH

Page 9

Safety Warnings Specic for Wire Brushing

Operations:

1. Be aware that wire bristles are thrown by the

brush even during ordinary operation. Do not

overstress the wires by applying excessive

load to the brush. The wire bristles can easily

penetrate light clothing and/or skin.

2. If the use of a guard is recommended for wire

brushing, do not allow any interference of the

wire wheel or brush with the guard. Wire wheel

or brush may expand in diameter due to work load

and centrifugal forces.

Additional Safety Warnings:

1.

When using depressed centre grinding wheels,

be sure to use only berglass-reinforced wheels.

2. NEVER USE Stone Cup type wheels with this

grinder. This grinder is not designed for these

types of wheels and the use of such a product

may result in serious personal injury.

3. Be careful not to damage the spindle, the

ange (especially the installing surface) or the

lock nut. Damage to these parts could result in

wheel breakage.

4. Make sure the wheel is not contacting the

workpiece before the switch is turned on.

5. Before using the tool on an actual workpiece,

let it run for a while. Watch for vibration or

wobbling that could indicate poor installation

or a poorly balanced wheel.

6. Use the specied surface of the wheel to per-

form the grinding.

7. Do not leave the tool running. Operate the tool

only when hand-held.

8. Do not touch the workpiece immediately after

operation; it may be extremely hot and could

burn your skin.

9. Observe the instructions of the manufacturer

for correct mounting and use of wheels.

Handle and store wheels with care.

10. Do not use separate reducing bushings or

adaptors to adapt large hole abrasive wheels.

11. Use only anges specied for this tool.

12. For tools intended to be tted with threaded

hole wheel, ensure that the thread in the wheel

is long enough to accept the spindle length.

13.

Check that the workpiece is properly supported.

14. Pay attention that the wheel continues to

rotate after the tool is switched off.

15.

If working place is extremely hot and humid, or

badly polluted by conductive dust, use a short-circuit breaker (30 mA) to assure operator safety.

16. Do not use the tool on any materials containing asbestos.

17. When use cut-off wheel, always work with

the dust collecting wheel guard required by

domestic regulation.

18. Cutting discs must not be subjected to any

lateral pressure.

19. Do not use cloth work gloves during operation.

Fibers from cloth gloves may enter the tool, which

causes tool breakage.

SAVE THESE INSTRUCTIONS.

WARNING: DO NOT let comfort or familiarity

with product (gained from repeated use) replace

strict adherence to safety rules for the subject

product. MISUSE or failure to follow the safety

rules stated in this instruction manual may cause

serious personal injury.

Important safety instructions for

battery cartridge

1. Before using battery cartridge, read all instructions and cautionary markings on (1) battery

charger, (2) battery, and (3) product using

battery.

2. Do not disassemble battery cartridge.

3. If operating time has become excessively

shorter, stop operating immediately. It may

result in a risk of overheating, possible burns

and even an explosion.

4. If electrolyte gets into your eyes, rinse them

out with clear water and seek medical attention right away. It may result in loss of your

eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any con-

ductive material.

(2) Avoid storing battery cartridge in a con-

tainer with other metal objects such as

nails, coins, etc.

(3) Do not expose battery cartridge to water

or rain.

A battery short can cause a large current

ow, overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50 °C (122 °F).

7. Do not incinerate the battery cartridge even if

it is severely damaged or is completely worn

out. The battery cartridge can explode in a re.

8. Be careful not to drop or strike battery.

9. Do not use a damaged battery.

10. The contained lithium-ion batteries are subject

to the Dangerous Goods Legislation requirements.

For commercial transports e.g. by third parties,

forwarding agents, special requirement on packaging and labeling must be observed.

For preparation of the item being shipped, consulting an expert for hazardous material is required.

Please also observe possibly more detailed

national regulations.

Tape or mask off open contacts and pack up the

battery in such a manner that it cannot move

around in the packaging.

11. Follow your local regulations relating to disposal of battery.

SAVE THESE INSTRUCTIONS.

9 ENGLISH

Page 10

CAUTION: Only use genuine Makita batteries.

Use of non-genuine Makita batteries, or batteries that

have been altered, may result in the battery bursting

causing res, personal injury and damage. It will

also void the Makita warranty for the Makita tool and

charger.

Tips for maintaining maximum

battery life

1. Charge the battery cartridge before completely

discharged. Always stop tool operation and

charge the battery cartridge when you notice

less tool power.

2. Never recharge a fully charged battery cartridge. Overcharging shortens the battery

service life.

3. Charge the battery cartridge with room temperature at 10 °C - 40 °C (50 °F - 104 °F). Let

a hot battery cartridge cool down before

charging it.

4. Charge the battery cartridge if you do not use

it for a long period (more than six months).

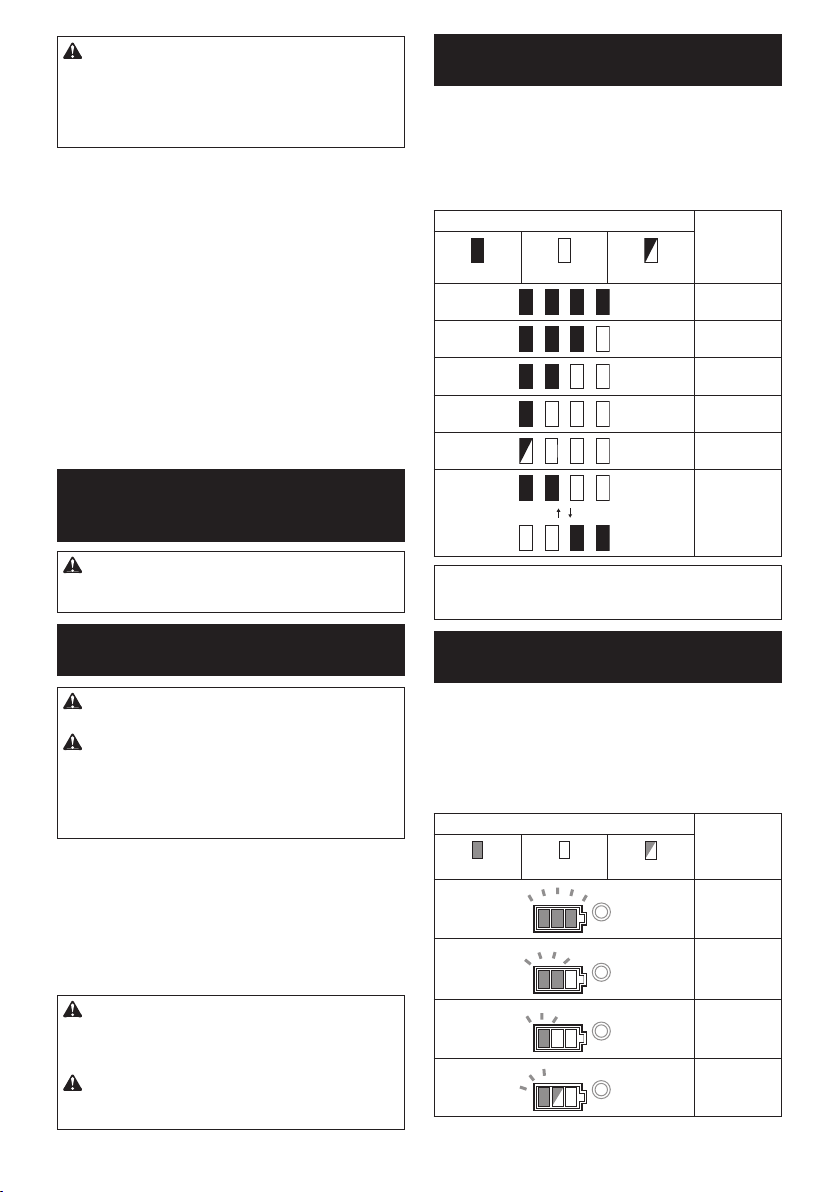

FUNCTIONAL

DESCRIPTION

Indicating the remaining battery

capacity

Only for battery cartridges with "B" at the end of the

model number

► Fig.2: 1. Indicator lamps 2. Check button

Press the check button on the battery cartridge to indi-

cate the remaining battery capacity. The indicator lamps

light up for few seconds.

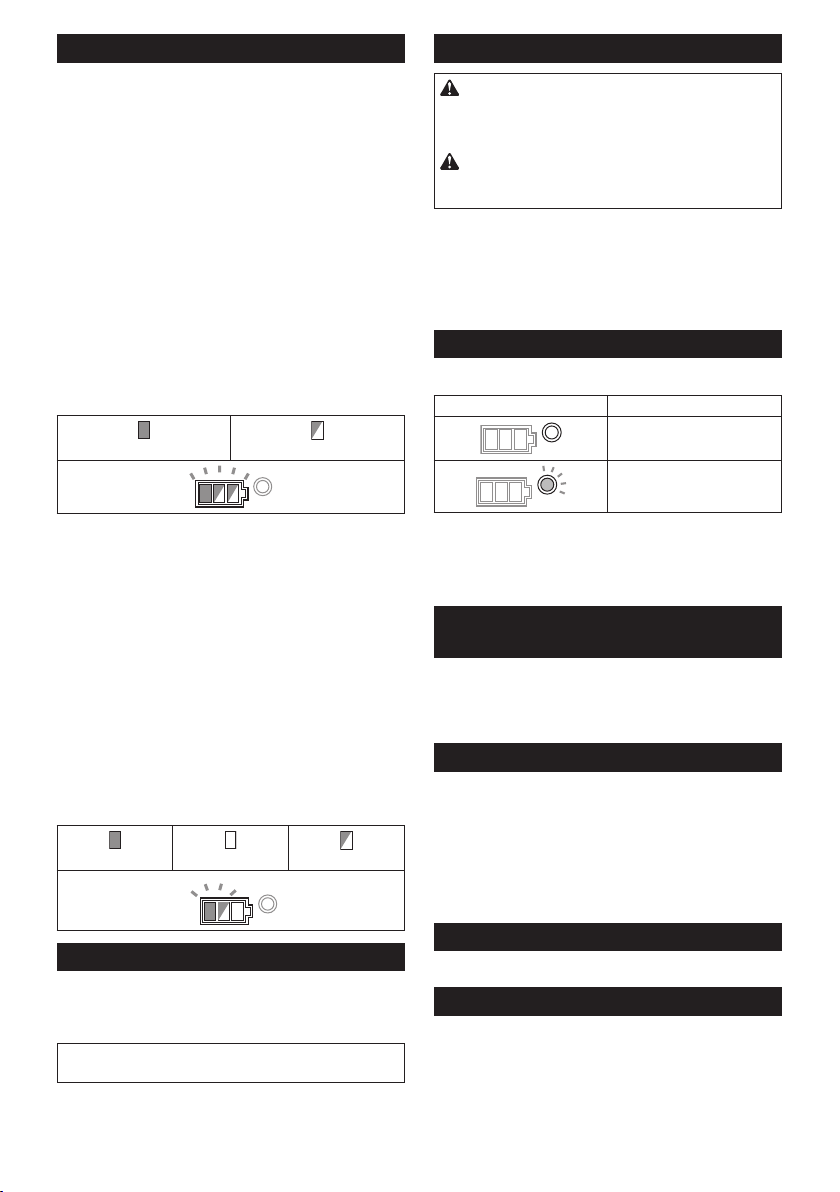

Indicator lamps Remaining

Lighted Off Blinking

capacity

75% to 100%

50% to 75%

25% to 50%

0% to 25%

Charge the

battery.

The battery

may have

malfunctioned.

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing or removing battery

cartridge

CAUTION: Always switch off the tool before

installing or removing of the battery cartridge.

CAUTION: Hold the tool and the battery car-

tridge rmly when installing or removing battery

cartridge. Failure to hold the tool and the battery

cartridge rmly may cause them to slip off your hands

and result in damage to the tool and battery cartridge

and a personal injury.

► Fig.1: 1. Red indicator 2. Button 3. Battery cartridge

To remove the battery cartridge, slide it from the tool

while sliding the button on the front of the cartridge.

To install the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Insert it all the way until it locks in place

with a little click. If you can see the red indicator on the

upper side of the button, it is not locked completely.

CAUTION: Always install the battery cartridge

fully until the red indicator cannot be seen. If not,

it may accidentally fall out of the tool, causing injury to

you or someone around you.

CAUTION: Do not install the battery cartridge

forcibly. If the cartridge does not slide in easily, it is

not being inserted correctly.

NOTE: Depending on the conditions of use and the

ambient temperature, the indication may differ slightly

from the actual capacity.

Indicating the remaining battery

capacity

Country specic

When you turn the tool on, the battery indicator shows

the remaining battery capacity.

► Fig.3: 1. Battery indicator

The remaining battery capacity is shown as the follow-

ing table.

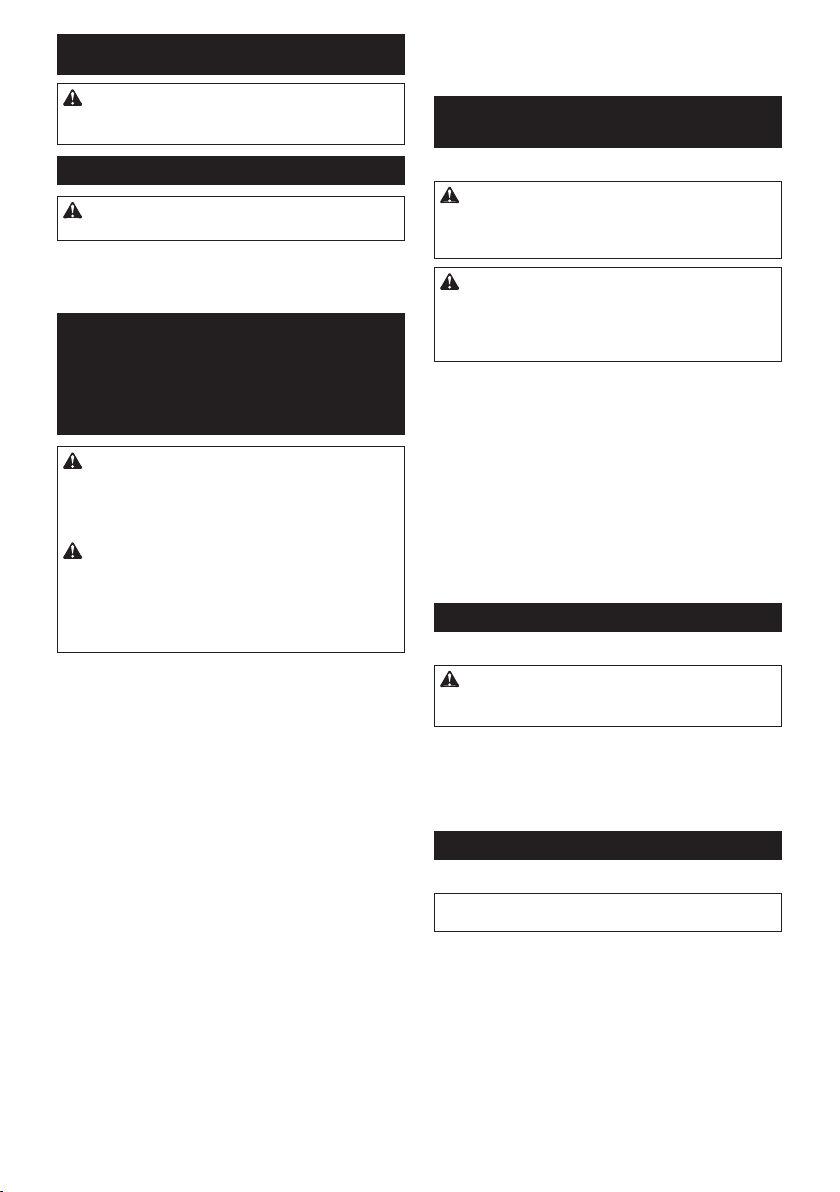

Battery indicator status Remaining

On

Off

Blinking

battery

capacity

50% - 100%

20% - 50%

0% - 20%

Charge the

battery

10 ENGLISH

Page 11

Tool / battery protection system

The tool is equipped with a tool/battery protection

system. This system automatically cuts off power to

the motor to extend tool and battery life. The tool will

automatically stop during operation if the tool or battery

is placed under one of the following conditions. In some

conditions, the indicators light up.

Overload protection

When the tool is operated in a manner that causes it to

draw an abnormally high current, the tool automatically

stops without any indication. In this situation, turn the

tool off and stop the application that caused the tool to

become overloaded. Then turn the tool on to restart.

Overheat protection

When the tool is overheated, the tool stops automatically and the battery indicator shows following state. In

this situation, let the tool cool before turning the tool on

again.

On

Blinking

Switch action

CAUTION: Before installing the battery car-

tridge into the tool, always check to see that the

switch lever actuates properly and returns to the

"OFF" position when released.

CAUTION: Do not pull the switch lever hard

without pulling the lock-off lever. This can cause

switch breakage.

To prevent the switch lever from being accidentally

pulled, a lock-off lever is provided.

To start the tool, pull the lock-off lever toward the operator and then pull the switch lever.

To stop the tool, release the switch lever.

► Fig.5: 1. Lock-off lever 2. Switch lever

Automatic speed change function

► Fig.6: 1. Mode indicator

Mode indicator status Operation mode

High speed mode

High torque mode

If the tool does not start, the battery may be overheated.

In this situation, let the battery cool before starting the

tool again.

Overdischarge protection

When the battery capacity is not enough, the tool stops

automatically. In this case, remove the battery from the

tool and charge the battery.

Releasing protection lock

When the protection system works repeatedly, the tool

is locked and the battery indicator shows the following

state.

In this situation, the tool does not start even if turning

the tool off and on. To release the protection lock,

remove the battery, set it to the battery charger and wait

until the charging nishes.

On

Off

Blinking

Shaft lock

Press the shaft lock to prevent spindle rotation when

installing or removing accessories.

► Fig.4: 1. Shaft lock

NOTICE: Never actuate the shaft lock when the

spindle is moving. The tool may be damaged.

This tool has "high speed mode" and "high torque

mode". It automatically changes operation mode

depending on the work load. When mode indicator

lights up during operation, the tool is in high torque

mode.

Accidental re-start preventive

function

Even if installing the battery cartridge while pulling the

switch lever, the tool does not start.

To start the tool, rst release the switch lever. Then pull

the lock-off lever, and pull the switch lever.

Electronic torque control function

The tool electronically detects situations where the

wheel or accessory may be at risk to be bound. In the

situation, the tool is automatically shut off to prevent

further rotation of the spindle (it does not prevent

kickback).

To restart the tool, switch off the tool rst, remove the

cause of sudden drop in the rotation speed, and then

turn the tool on.

Soft start feature

Soft start feature reduces starting reaction.

Electric brake

Electric brake is activated after the tool is switched off.

The brake does not work when the power supply is shut

down, such as the battery is removed accidentally, with

the switch still on.

11 ENGLISH

Page 12

ASSEMBLY

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before adjusting or checking function on the tool.

Installing side grip (handle)

CAUTION: Always be sure that the side grip is

installed securely before operation.

Screw the side grip securely on the position of the tool

as shown in the gure.

► Fig.7

Installing or removing wheel guard

(For depressed center wheel, ap

disc, ex wheel, wire wheel brush

/ abrasive cut-off wheel, diamond

wheel)

WARNING: When using a depressed center

wheel, ap disc, ex wheel or wire wheel brush,

the wheel guard must be tted on the tool so that

the closed side of the guard always points toward

the operator.

WARNING: When using an abrasive cut-off

/ diamond wheel, be sure to use only the special

wheel guard designed for use with cut-off wheels.

(In some European countries, when using a diamond

wheel, the ordinary guard can be used. Follow the

regulations in your country.)

For tool with locking screw type

wheel guard

Mount the wheel guard with the protrusions on the

wheel guard band aligned with the notches on the bearing box. Then rotate the wheel guard to such an angle

that it can protect the operator according to work. Be

sure to tighten the screw securely.

To remove wheel guard, follow the installation procedure in reverse.

► Fig.8: 1. Wheel guard 2. Bearing box 3. Screw

For tool with clamp lever type wheel

guard

Loosen the screw, and then pull the lever in the direction of the arrow. Mount the wheel guard with the protrusions on the wheel guard band aligned with the notches

on the bearing box. Then rotate the wheel guard to such

an angle that it can protect the operator according to

work.

► Fig.9: 1. Wheel guard 2. Bearing box 3. Screw

4. Lever

Pull the lever in direction of the arrow. Then tighten the

wheel guard with fastening the screw. Be sure to tighten

the screw securely. The setting angle of the wheel

guard can be adjusted with the lever.

► Fig.10: 1. Screw 2. Lever

To remove wheel guard, follow the installation proce-

dure in reverse.

Installing or removing depressed

center wheel or ap disc

Optional accessory

WARNING: When using a depressed center

wheel or ap disc, the wheel guard must be tted

on the tool so that the closed side of the guard

always points toward the operator.

CAUTION: Make sure that the mounting part

of the inner ange ts into the inner diameter of

the depressed center wheel / ap disc perfectly.

Mounting the inner ange on the wrong side may

result in the dangerous vibration.

Mount the inner ange onto the spindle.

Make sure to t the dented part of the inner ange onto

the straight part at the bottom of the spindle.

Fit the depressed center wheel / ap disc on the inner

ange and screw the lock nut onto the spindle.

► Fig.11: 1. Lock nut 2. Depressed center wheel

3. Inner ange 4. Mounting part

To tighten the lock nut, press the shaft lock rmly so

that the spindle cannot revolve, then use the lock nut

wrench and securely tighten clockwise.

► Fig.12: 1. Lock nut wrench 2. Shaft lock

To remove the wheel, follow the installation procedure

in reverse.

Installing or removing ex wheel

Optional accessory

WARNING: Always use supplied guard when

ex wheel is on tool. Wheel can shatter during use

and guard helps to reduce chances of personal injury.

► Fig.13: 1. Lock nut 2. Flex wheel 3. Back up pad

4. Inner ange

Follow instructions for depressed center wheel but also

use back up pad over wheel. See order of assembly on

accessories page in this manual.

Installing or removing abrasive disc

Optional accessory

NOTE: Use sander accessories specied in this manual. These must be purchased separately.

For 100 mm (4″) model

► Fig.14: 1. Sanding lock nut 2. Abrasive disc

3. Rubber pad 4. Inner ange

1. Mount the inner ange onto the spindle.

2. Mount the rubber pad onto the spindle.

3. Fit the disc on the rubber pad and screw the sand-

ing lock nut onto the spindle.

12 ENGLISH

Page 13

4. Hold the spindle with the shaft lock, and securely

tighten the sanding lock nut clockwise with the lock nut

wrench.

To remove the disc, follow the installation procedure in

reverse.

For 115 mm (4 - 1/2″) / 125 mm (5″)

model

► Fig.15: 1. Sanding lock nut 2. Abrasive disc

3. Rubber pad

1. Mount the rubber pad onto the spindle.

2. Fit the disc on the rubber pad and screw the sand-

ing lock nut onto the spindle.

3. Hold the spindle with the shaft lock, and securely

tighten the sanding lock nut clockwise with the lock nut

wrench.

To remove the disc, follow the installation procedure in

reverse.

OPERATION

WARNING: It should never be necessary to

force the tool. The weight of the tool applies ade-

quate pressure. Forcing and excessive pressure

could cause dangerous wheel breakage.

WARNING: ALWAYS replace wheel if tool is

dropped while grinding.

WARNING: NEVER bang or hit grinding disc

or wheel onto work.

WARNING: Avoid bouncing and snagging

the wheel, especially when working corners,

sharp edges etc. This can cause loss of control and

kickback.

WARNING: NEVER use tool with wood cutting

blades and other saw blades. Such blades when

used on a grinder frequently kick and cause loss of

control leading to personal injury.

CAUTION: Never switch on the tool when it

is in contact with the workpiece, it may cause an

injury to operator.

CAUTION: Always wear safety goggles or a

face shield during operation.

CAUTION: After operation, always switch off

the tool and wait until the wheel has come to a

complete stop before putting the tool down.

CAUTION: ALWAYS hold the tool rmly with

one hand on housing and the other on the side

handle.

Grinding and sanding operation

► Fig.16

Turn the tool on and then apply the wheel or disc to the

workpiece.

In general, keep the edge of the wheel or disc at an

angle of about 15° to the workpiece surface.

During the break-in period with a new wheel, do not

work the grinder in forward direction or it may cut into

the workpiece. Once the edge of the wheel has been

rounded off by use, the wheel may be worked in both

forward and backward direction.

Operation with abrasive cut-off /

diamond wheel

Optional accessory

WARNING: When using an abrasive cut-off

/ diamond wheel, be sure to use only the special

wheel guard designed for use with cut-off wheels.

(In some European countries, when using a diamond

wheel, the ordinary guard can be used. Follow the

regulations in your country.)

WARNING: NEVER use cut-off wheel for side

grinding.

WARNING: Do not "jam" the wheel or apply

excessive pressure. Do not attempt to make an

excessive depth of cut. Overstressing the wheel

increases the loading and susceptibility to twisting

or binding of the wheel in the cut and the possibility

of kickback, wheel breakage and overheating of the

motor may occur.

WARNING: Do not start the cutting operation

in the workpiece. Let the wheel reach full speed

and carefully enter into the cut moving the tool

forward over the workpiece surface. The wheel

may bind, walk up or kickback if the power tool is

started in the workpiece.

WARNING: During cutting operations, never

change the angle of the wheel. Placing side pres-

sure on the cut-off wheel (as in grinding) will cause

the wheel to crack and break, causing serious personal injury.

WARNING: A diamond wheel shall be oper-

ated perpendicular to the material being cut.

► Fig.17: 1. Lock nut 2. Abrasive cut-off wheel / dia-

mond wheel 3. Inner ange 4. Wheel guard

for abrasive cut-off wheel / diamond wheel

As for the installation, follow the instructions for

depressed center wheel.

The direction for mounting the lock nut and the

inner ange varies by wheel type and thickness.

Refer to the following gures.

For 100 mm (4″) model

When installing the abrasive cut-off wheel:

► Fig.18: 1. Lock nut 2. Abrasive cut-off wheel

(Thinner than 4mm (5/32")) 3. Abrasive cut-

off wheel (4mm (5/32") or thicker) 4. Inner

ange

When installing the diamond wheel:

► Fig.19: 1. Lock nut 2. Diamond wheel (Thinner

than 4mm (5/32″)) 3. Diamond wheel (4mm

(5/32″) or thicker) 4. Inner ange

13 ENGLISH

Page 14

For 115 mm (4 - 1/2″) / 125 mm (5″)

model

When installing the abrasive cut-off wheel:

► Fig.20: 1. Lock nut 2. Abrasive cut-off wheel

(Thinner than 4mm (5/32")) 3. Abrasive cut-

off wheel (4mm (5/32") or thicker) 4. Inner

ange

When installing the diamond wheel:

► Fig.21: 1. Lock nut 2. Diamond wheel (Thinner

than 4mm (5/32″)) 3. Diamond wheel (4mm

(5/32″) or thicker) 4. Inner ange

Operation with wire cup brush

Optional accessory

CAUTION: Check operation of brush by run-

ning tool with no load, insuring that no one is in

front of or in line with brush.

CAUTION: Do not use brush that is damaged,

or which is out of balance. Use of damaged brush

could increase potential for injury from contact with

broken brush wires.

► Fig.22: 1. Wire cup brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire cup

brush onto spindle and tighten with supplied wrench.

NOTICE: Avoid applying too much pressure

which causes over bending of wires when using

brush. It may lead to premature breakage.

MAINTENANCE

CAUTION: Always be sure that the tool is

switched off and the battery cartridge is removed

before attempting to perform inspection or

maintenance.

NOTICE: Never use gasoline, benzine, thinner,

alcohol or the like. Discoloration, deformation or

cracks may result.

Air vent cleaning

The tool and its air vents have to be kept clean.

Regularly clean the tool's air vents or whenever the

vents start to become obstructed.

► Fig.24: 1. Exhaust vent 2. Inhalation vent

Remove the dust cover from inhalation vent and clean it

for smooth air circulation.

► Fig.25: 1. Dust cover

NOTE: Clean out the dust cover when it is clogged

with dust or foreign matters. Continuing operation

with a clogged dust cover may damage the tool.

Operation with wire wheel brush

Optional accessory

CAUTION: Check operation of wire wheel

brush by running tool with no load, insuring that

no one is in front of or in line with the wire wheel

brush.

CAUTION: Do not use wire wheel brush that

is damaged, or which is out of balance. Use of

damaged wire wheel brush could increase potential

for injury from contact with broken wires.

CAUTION: ALWAYS use guard with wire

wheel brushes, assuring diameter of wheel ts

inside guard. Wheel can shatter during use and

guard helps to reduce chances of personal injury.

► Fig.23: 1. Wire wheel brush

Remove the battery cartridge from the tool and place it

upside down allowing easy access to spindle.

Remove any accessories on spindle. Thread wire wheel

brush onto spindle and tighten with the wrenches.

NOTICE: Avoid applying too much pressure

which causes over bending of wires when

using wire wheel brush. It may lead to premature

breakage.

14 ENGLISH

Page 15

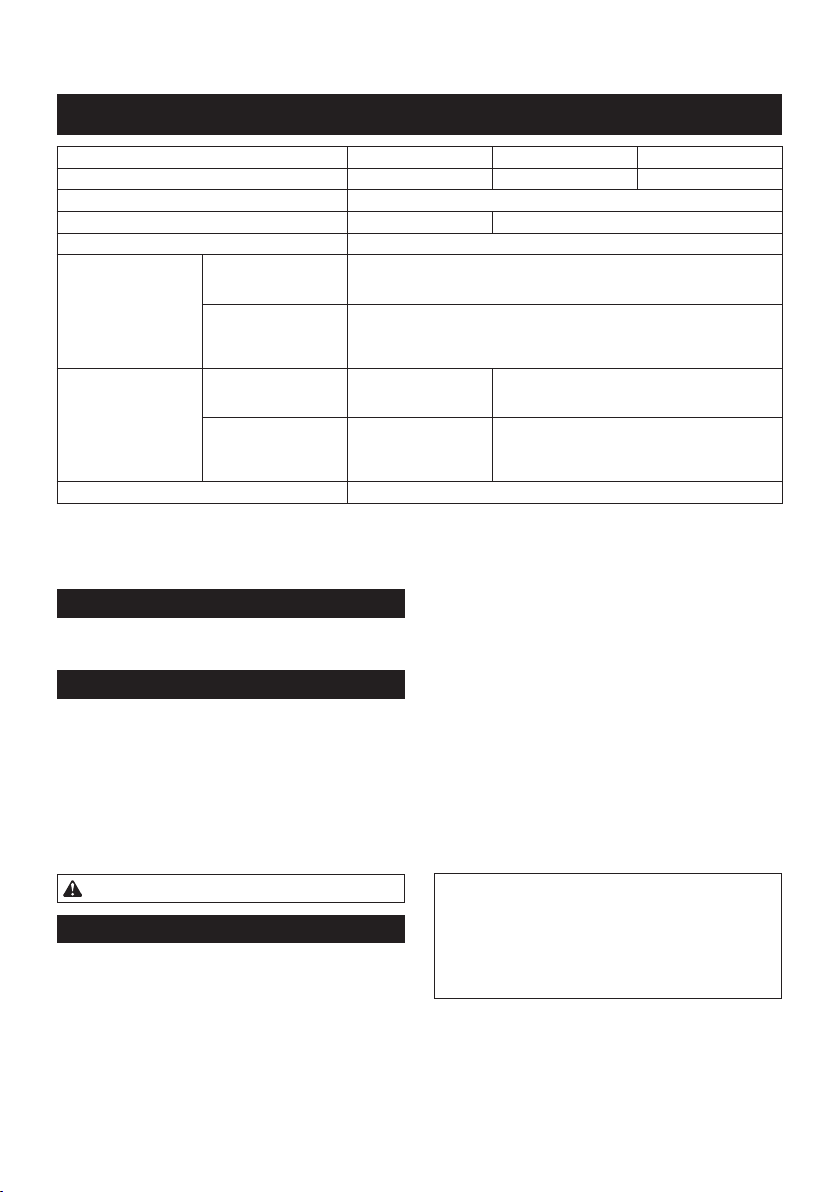

OPTIONAL ACCESSORIES

CAUTION: These accessories or attachments are recommended for use with your Makita tool spec-

ied in this manual. The use of any other accessories or attachments might present a risk of injury to persons.

Only use accessory or attachment for its stated purpose.

If you need any assistance for more details regarding these accessories, ask your local Makita Service Center.

• Makita genuine battery and charger

► Fig.26

- 100 mm (4″) model 115 mm (4-1/2″) model 125 mm (5″) model

1 Grip 36

2 Wheel Guard (for grinding wheel)

3 Inner ange

4 Depressed center wheel / Flap disc

5 Lock nut

6 Back up pad

7 Flex wheel

8 Inner ange and rubber pad 76 Rubber pad 100 Rubber pad 115

9 Abrasive disc

10 Sanding lock nut

11 Wire wheel brush

12 Wire cup brush

13 Wheel Guard (for cut-off wheel) *1

14 Abrasive cut-off wheel / Diamond wheel

- Lock nut wrench

NOTE: *1 In some European countries, when using a diamond wheel, the ordinary guard can be used instead of the

special guard covering the both side of the wheel. Follow the regulations in your country.

NOTE: Some items in the list may be included in the tool package as standard accessories. They may differ from

country to country.

15 ENGLISH

Page 16

FRANÇAIS (Instructions originales)

SPÉCIFICATIONS

Modèle : DGA408 DGA458 DGA508

Diamètre de meule 100 mm (4″) 115 mm (4-1/2″) 125 mm (5″)

Épaisseur max. de la meule 6,4 mm

Filetage de l’axe M10 M14 ou 5/8″ (selon le pays)

Vitesse nominale (n) 8 500 min

Longueur totale Batterie comprise

Poids net Batterie comprise

Tension nominale CC 18 V

BL1815N, BL1820,

BL1820B

Batterie comprise

BL1830, BL1840,

BL1840B, BL1850,

BL1850B, BL1860B

BL1815N, BL1820,

BL1820B

Batterie comprise

BL1830, BL1840,

BL1840B, BL1850,

BL1850B, BL1860B

2,2 kg 2,4 kg

2,5 kg 2,6 kg

• Étant donné l’évolution constante de notre programme de recherche et de développement, les spécications

contenues dans ce manuel sont sujettes à modication sans préavis.

• Les spécications et la batterie peuvent être différentes suivant les pays.

• Poids, avec la batterie, conformément à la procédure EPTA-01/2003

Utilisations

L’outil est conçu pour le meulage, le ponçage et la

coupe de matériaux en métal ou en pierre sans utiliser

d’eau.

Bruit

Niveau de bruit pondéré A typique, déterminé selon

EN60745 :

Modèle DGA458

Niveau de pression sonore (L

Incertitude (K) : 3 dB (A)

Modèle DGA508

Niveau de pression sonore (L

Incertitude (K) : 3 dB (A)

Le niveau de bruit en fonctionnement peut dépasser 80

dB (A).

AVERTISSEMENT : Portez un serre-tête

antibruit.

) : 80 dB (A)

pA

) : 79 dB (A)

pA

Mode de travail : meulage de surfaces avec poignée

latérale anti-vibration

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Mode de travail : ponçage au disque avec poignée

latérale normale

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Mode de travail : ponçage au disque avec poignée

latérale anti-vibration

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Modèle DGA508

Mode de travail : meulage de surfaces avec poignée

latérale normale

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Mode de travail : meulage de surfaces avec poignée

latérale anti-vibration

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Mode de travail : ponçage au disque avec poignée

latérale normale

Vibrations

Valeur totale de vibrations (somme de vecteur triaxial)

déterminée selon EN60745 :

Modèle DGA458

Mode de travail : meulage de surfaces avec poignée

latérale normale

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

h, AG

2

) : 5,5 m/s

2

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

Mode de travail : ponçage au disque avec poignée

latérale anti-vibration

Émission de vibrations (a

Incertitude (K) : 1,5 m/s

348 mm

362 mm

-1

) : 5,0 m/s

h, AG

2

) : 2,5 m/s2 ou moins

h, DS

2

) : 2,5 m/s2 ou moins

h, DS

2

) : 6,0 m/s

h, AG

2

) : 5,5 m/s

h, AG

2

) : 2,5 m/s2 ou moins

h, DS

2

) : 2,5 m/s2 ou moins

h, DS

2

2

2

2

16 FRANÇAIS

Page 17

NOTE : La valeur d’émission de vibrations déclarée

a été mesurée conformément à la méthode de test

standard et peut être utilisée pour comparer les outils

entre eux.

NOTE : La valeur d’émission de vibrations déclarée

peut aussi être utilisée pour l’évaluation préliminaire

de l’exposition.

AVERTISSEMENT : L’émission de vibrations

lors de l’usage réel de l’outil électrique peut être

différente de la valeur d’émission déclarée, suivant la

façon dont l’outil est utilisé.

AVERTISSEMENT : Les mesures de sécurité à

prendre pour protéger l’utilisateur doivent être basées

sur une estimation de l’exposition dans des conditions réelles d’utilisation (en tenant compte de toutes

les composantes du cycle d’utilisation, comme par

exemple le moment de sa mise hors tension, lorsqu’il

tourne à vide et le moment de son déclenchement).

AVERTISSEMENT : La valeur d’émission de

vibrations déclarée est utilisée pour les applications

principales de l’outil électrique. Toutefois si l’outil

électrique est utilisé pour d’autres applications, la

valeur d’émission de vibrations peut être différente.

Déclaration de conformité CE

Pour les pays européens uniquement

Makita déclare que la ou les machines suivantes :

Désignation de la machine : Meuleuse d’Angle sans Fil

N° de modèle/Type : DGA458, DGA508

sont conformes aux Directives européennes suivantes :

2006/42/CE

et sont fabriquées conformément aux normes ou aux

documents normalisés suivants : EN60745

La documentation technique conforme à la norme

2006/42/CE est disponible auprès de :

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

11.8.2015

Yasushi Fukaya

Directeur

Makita, Jan-Baptist Vinkstraat 2, 3070, Belgique

Consignes de sécurité générales

pour outils électriques

AVERTISSEMENT : Lisez toutes les

consignes de sécurité et toutes les instructions. Il

y a risque d’électrocution, d’incendie et/ou de graves

blessures si les mises en garde et les instructions ne

sont pas respectées.

Conservez toutes les mises en

garde et instructions pour référence ultérieure.

Le terme « outil électrique » dans les avertissements

fait référence à l’outil électrique alimenté par le secteur

(avec cordon d’alimentation) ou à l’outil électrique fonctionnant sur batterie (sans cordon d’alimentation).

Consignes de sécurité pour

meuleuse sans l

Consignes de sécurité communes aux travaux de

meulage, ponçage, brossage métallique ou tronçonnage abrasif :

1. Cet outil électrique est conçu pour être utilisé en tant que meuleuse, ponceuse, brosse

métallique ou outil de tronçonnage. Veuillez

lire les consignes de sécurité, instructions,

illustrations et spécications qui accompagnent cet outil électrique. Le non-respect de

toutes les instructions indiquées ci-dessous peut

entraîner une électrocution, un incendie et/ou de

graves blessures.

2. Il est déconseillé d’effectuer des travaux de

polissage avec cet outil électrique. Il y a risque

de danger et de blessure si l’outil électrique est

utilisé pour exécuter des travaux pour lesquels il

n’a pas été conçu.

3. N’utilisez pas d’accessoires qui n’ont pas été

conçus spéciquement et recommandés par le

fabricant de l’outil. Même si un accessoire peut

être xé sur l’outil électrique, cela ne garantit pas

qu’il fonctionnera de manière sûre.

4. La vitesse nominale de l’accessoire doit être

au moins égale à la vitesse maximum inscrite

sur l’outil électrique. Les accessoires tournant

plus vite que leur vitesse nominale peuvent se

casser et voler en éclats.

5. Le diamètre extérieur et l’épaisseur de l’accessoire ne doivent pas dépasser la capacité

nominale de l’outil électrique. Les accessoires

de taille incorrecte ne peuvent être protégés ou

contrôlés adéquatement.

6. Le letage des accessoires à monter doit

correspondre à celui de l’axe de la meuleuse.

Pour les accessoires montés à l’aide de

asques, la taille de l’alésage de l’accessoire

doit correspondre au diamètre du asque.

Les accessoires qui ne sont pas bien adaptés à

la taille de la pièce où ils sont montés sur l’outil

électrique se déséquilibreront, vibreront trop et

pourront entraîner une perte de maîtrise de l’outil.

7. N’utilisez jamais un accessoire endommagé.

Avant chaque utilisation, assurez-vous que

la meule abrasive est exempte de copeaux et

ssures, que la semelle n’est pas ssurée,

déchirée ou trop usée, ou que la brosse métal-

lique est exempte de ls métalliques lâches

ou cassés. Si vous lâchez l’outil électrique ou

un accessoire, assurez-vous qu’il n’est pas

endommagé ou bien remplacez l’accessoire

endommagé. Après avoir vérié et posé un

accessoire, assurez-vous que personne, y

compris vous-même, ne se trouve dans la

trajectoire de l’accessoire en rotation et faites

tourner l’outil électrique à vitesse à vide maximale pendant une minute. Les accessoires

endommagés se brisent généralement au cours

de cette période d’essai.

8. Portez un équipement de protection individuelle. Suivant le type de travail à effectuer,

utilisez un écran facial, des lunettes à coques

ou des lunettes de sécurité. Si nécessaire,

17 FRANÇAIS

Page 18

portez un masque anti-poussière, des protège-tympans, des gants et un tablier de travail

pouvant arrêter les particules abrasives ou les

fragments de pièce. La protection oculaire doit

pouvoir arrêter les débris volants produits par les

diverses opérations. Le masque anti-poussières

ou le masque ltrant doit pouvoir ltrer les particules générées lors des travaux. Une exposition

prolongée à un bruit d’intensité élevée peut entraîner une perte auditive.

9. Assurez-vous que les passants demeurent à

une distance sûre de la zone de travail. Toute

personne pénétrant dans la zone de travail

doit porter un équipement de protection individuelle. Des fragments de pièce ou un accessoire

cassé peuvent être éjectés et blesser les personnes au-delà de la zone immédiate de travail.

10. Tenez l’outil électrique uniquement par ses

surfaces de prise isolées, lors d’une opération au cours de laquelle l’outil de coupe peut

entrer en contact avec un l caché. Le contact

avec un l « sous tension » mettra également «

sous tension » les parties métalliques exposées

de l’outil électrique, pouvant ainsi causer un choc

électrique chez l’utilisateur.

11. Ne déposez jamais l’outil électrique avant que

l’accessoire ne se soit parfaitement arrêté.

L’accessoire en rotation peut accrocher la surface

et projeter l’outil électrique de telle sorte que vous

en perdiez la maîtrise.

12. Ne transportez pas l’outil électrique tout en le

laissant tourner. En cas de contact accidentel

avec l’accessoire en rotation, ce dernier risque

d’accrocher vos vêtements et d’être entraîné vers

votre corps.

13. Nettoyez régulièrement les orices d’aération

de l’outil électrique. Le ventilateur du moteur

aspire la poussière à l’intérieur du carter, ce qui

présente un danger électrique en cas d’accumulation excessive de poussières métalliques.

14. N’utilisez pas l’outil électrique près de maté-

riaux inammables. Les étincelles risqueraient

d’enammer ces matériaux.

15. N’utilisez pas d’accessoires nécessitant un

liquide de refroidissement. L’utilisation d’eau

ou d’un liquide de refroidissement comporte un

risque d’électrocution ou de choc électrique.

Mises en garde concernant le choc en retour et

autres dangers

Le choc en retour est une réaction soudaine qui survient lorsque la meule, la semelle, la brosse ou un autre

accessoire en rotation se coince ou accroche. Lorsque

l’accessoire en rotation se coince ou accroche, il s’arrête soudainement et l’utilisateur perd alors la maîtrise

de l’outil électrique projeté dans le sens contraire de sa

rotation au point où il se coince dans la pièce.

Par exemple, si une meule abrasive accroche ou se

coince dans la pièce, son tranchant introduit au point

de pincement risque d’y creuser la surface du matériau,

entraînant la sortie ou le déchaussement de la meule.

La meule peut alors dévier de sa trajectoire, vers l’utilisateur ou dans le sens opposé, selon la direction du

mouvement de la meule au point de pincement. Dans

ces conditions, la meule abrasive risque également de

se briser.

Le choc en retour est le résultat d’une utilisation

incorrecte de l’outil électrique et/ou de l’inobservation

des procédures ou conditions d’utilisation. Il peut être

évité en prenant les précautions adéquates indiquées

ci-dessous.

1. Maintenez une poigne ferme sur l’outil électrique et placez corps et bras de façon à pouvoir résister à la force exercée par les chocs

en retour. Utilisez toujours la poignée auxiliaire, s’il y en a une, pour avoir une maîtrise

maximale de l’outil en cas de choc en retour

ou de force de réaction exercée au moment du

démarrage. L’utilisateur peut maîtriser les forces

de réaction ou de choc en retour s’il prend les

précautions adéquates.

2. Ne placez jamais la main près d’un accessoire

en rotation. L’accessoire risquerait de passer sur

votre main en cas de choc en retour.

3. Ne vous placez pas dans la zone vers laquelle

l’outil électrique se déplacera en cas de choc

en retour. Le choc en retour projettera l’outil dans

le sens opposé au mouvement de la meule au

point où elle accroche dans la pièce.

4. Soyez tout particulièrement prudent lorsque

vous travaillez sur les coins, les arêtes vives,

etc. Évitez de laisser l’accessoire sautiller ou

accrocher. L’accessoire en rotation a tendance

à accrocher dans les coins, sur les arêtes vives

ou lorsqu’il sautille, ce qui comporte un risque de

perte de maîtrise ou de choc en retour.

5. Ne xez pas une chaîne de coupe, une lame à

sculpter le bois ou une lame de scie dentée. De

telles lames causent fréquemment des chocs en

retour et des pertes de maîtrise.

Consignes de sécurité spéciques aux opérations

de meulage et de tronçonnage abrasif :

1. Utilisez exclusivement les types de meule

recommandés pour votre outil électrique, et

le carter de protection conçu spéciquement

pour la meule sélectionnée. Les meules pour

lesquelles l’outil électrique n’a pas été conçu ne

pourront pas être protégées correctement et se

révèleront dangereuses.

2. La surface de meulage des meules à moyeu

déporté doit être montée sous le plan de la

lèvre du carter de protection. Si la meule n’est

pas bien montée et dépasse le plan de la lèvre du

carter de protection, celui-ci ne pourra pas assurer

une protection adéquate.

3. Le carter de protection doit être solidement

xé à l’outil électrique et placé de façon à

assurer une sécurité maximale en ne laissant

qu’une partie minimale de la meule exposée

du côté de l’utilisateur. Le carter de protection

permet de protéger l’utilisateur des éclats de

meule brisée, d’un contact accidentel avec la

meule et des étincelles qui pourraient enammer

ses vêtements.

4. Les meules ne doivent être utilisées que pour

les applications recommandées. Par exemple

: ne procédez pas au meulage avec le côté de

la meule à tronçonner. Les meules à tronçonner

abrasives étant conçues pour le meulage périphérique, elles risquent de voler en éclats si on leur

applique une force latérale.

18 FRANÇAIS

Page 19

5. Utilisez toujours des asques pour meule

en bon état, dont la taille et la forme correspondent à la meule sélectionnée. Des asques

pour meule adéquats soutiennent la meule et

réduisent ainsi les risques de rupture de la meule.

Les asques pour meules à tronçonner peuvent

être différents de ceux pour meules ordinaires.

6. N’utilisez pas de meules usées provenant

d’outils électriques plus grands. Les meules

conçues pour des outils électriques plus grands

ne conviennent pas à la vitesse supérieure d’un

outil plus petit et risquent d’éclater.

Consignes de sécurité supplémentaires spéciques

aux travaux de tronçonnage abrasif :

1. Évitez de « bloquer » la meule à tronçonner ou

d’appliquer une pression excessive. N’essayez

pas de couper trop profondément. Une meule

trop sollicitée subira une surcharge et risquera de

se tordre ou de se coincer dans la ligne de coupe,

ce qui comporte un risque de choc en retour ou de

bris de la meule.

2. Ne vous placez pas directement derrière ou

devant la meule en rotation. Lorsque la meule,

en cours de fonctionnement, s’écarte de votre

corps, le choc en retour potentiel risque de propulser la meule en rotation et l’outil électrique dans

votre direction.

3. Lorsque la meule se coince ou lorsque vous

interrompez la coupe pour une raison quelconque, mettez l’outil électrique hors tension

et maintenez-le immobile jusqu’à ce que la

meule cesse complètement de tourner. Ne

tentez jamais de retirer la meule à tronçonner

de la coupe pendant que la meule tourne,

sous peine de provoquer un choc en retour.

Identiez la cause du grippage de la meule et

prenez les mesures correctives pour y remédier.

4. Ne reprenez pas la coupe telle quelle dans

la pièce. Attendez que la meule ait atteint sa

pleine vitesse avant de la réintroduire soigneusement dans la ligne de coupe. Si vous

redémarrez l’outil électrique alors qu’il se trouve

encore dans la pièce à travailler, la meule risquera

de se coincer, de remonter hors de la ligne de

coupe ou de provoquer un choc en retour.

5. Soutenez les panneaux ou les pièces de

grande taille pour réduire les risques de coincement de la meule et de choc en retour. Les

pièces de grande taille ont tendance à ployer

sous leur propre poids. Il est nécessaire de placer

en dessous des cales à proximité de la ligne de

coupe et près du rebord de la pièce de chaque

côté de la meule.

6. Redoublez de précaution lorsque vous faites

une « coupe en plongée » dans un mur ou

toute autre surface pouvant cacher des structures. La meule, en dépassant derrière le mur ou

la surface, peut couper des conduites de gaz ou

d’eau, des ls électriques ou des objets pouvant

causer un choc en retour.

Consignes de sécurité spéciques aux travaux de

ponçage :

1. N’utilisez pas de feuilles de papier abrasif

trop grandes. Suivez les recommandations du

fabricant pour choisir le papier abrasif. Une

grande feuille de papier abrasif débordant du

coussin de ponçage présente un risque de lacération et pourrait déchirer le disque, l’accrocher ou

provoquer un choc en retour.

Consignes de sécurité spéciques aux travaux de

brossage métallique :

1. N’oubliez pas que des ls métalliques se

détachent de la brosse même lors de travaux

ordinaires. Ne soumettez pas les ls métalliques à une surcharge en appliquant une

pression excessive sur la brosse. Les ls métal-

liques pénètrent facilement dans les vêtements

légers et/ou dans la peau.

2. Si l’utilisation d’un carter de protection est

recommandée pour le brossage métallique,

assurez-vous que la meule ou brosse métallique ne gêne pas le carter de protection. Selon

la charge de travail et l’intensité de la force centrifuge, le diamètre de la meule ou brosse métallique

peut augmenter.

Consignes de sécurité supplémentaires :

1. Lors de l’utilisation des meules ordinaires à

moyeu déporté, assurez-vous d’utiliser exclu-

sivement des meules renforcées de bre de

verre.

2. N’UTILISEZ JAMAIS une meule boisseau pour

pierre avec cette meuleuse. Cette meuleuse

n’est pas conçue pour ces types de meule, et leur

utilisation peut entraîner de graves blessures.

3. Prenez garde de ne pas endommager l’axe, le

asque (tout particulièrement la surface d’installation) ou le contre-écrou. La meule risque

de casser si ces pièces sont endommagées.

4. Assurez-vous que la meule n’entre pas en

contact avec la pièce avant de mettre l’outil

sous tension.

5. Avant d’utiliser l’outil sur une pièce, faites-le

tourner un instant à vide. Soyez attentif aux

vibrations ou sautillements pouvant indiquer

que la meule n’est pas bien posée ou qu’elle

est mal équilibrée.

6. Utilisez la surface spéciée de la meule pour

meuler.

7. N’abandonnez pas l’outil alors qu’il tourne. Ne

faites fonctionner l’outil qu’une fois que vous

l’avez bien en main.

8. Ne touchez pas la pièce immédiatement après

avoir terminé le travail ; elle peut être très

chaude et vous brûler la peau.

9. Suivez les instructions du fabricant pour un

montage adéquat et une utilisation appropriée

des meules. Manipulez et rangez les meules

soigneusement.

10. N’utilisez pas de bagues de réduction ou

d’adaptateurs vendus dans le commerce pour

adapter des meules abrasives dont l’orice

central est grand.

11. N’utilisez que les asques spéciés pour cet

outil.

12. Pour les outils destinés à être équipés d’une

meule à orice leté, assurez-vous que le

letage dans la meule est sufsamment long

pour accueillir la longueur de l’axe.

19 FRANÇAIS

Page 20

13. Assurez-vous que la pièce à travailler est correctement soutenue.

14. N’oubliez pas que la meule continue de tourner une fois l’outil éteint.

15. Si le lieu de travail est extrêmement chaud et

humide, ou fortement pollué de poussières

conductrices, utilisez un disjoncteur (30 mA)

pour assurer la sécurité de l’utilisateur.

16. N’utilisez l’outil avec aucun matériau contenant de l’amiante.

17. Lorsque vous utilisez une meule à tronçonner,

travaillez toujours avec le carter de meule de

collecte de la poussière exigé par la réglementation locale.

18. Aucune pression latérale ne doit être exercée

sur les disques de coupe.

19. N’utilisez pas de gants de travail en tissu

pendant la tâche. Les bres des gants en tissu

peuvent pénétrer dans l’outil et le casser.

CONSERVEZ CES

INSTRUCTIONS.

AVERTISSEMENT : NE vous laissez PAS

tromper (au l d’une utilisation répétée) par un

sentiment d’aisance et de familiarité avec le

produit, en négligeant le respect rigoureux des

consignes de sécurité qui accompagnent le produit en question. La MAUVAISE UTILISATION de

l’outil ou l’ignorance des consignes de sécurité

indiquées dans ce mode d’emploi peut entraîner

de graves blessures.

Consignes de sécurité importantes

pour la batterie

1. Avant d’utiliser la batterie, lisez toutes les

instructions et précautions relatives (1) au

chargeur de batterie, (2) à la batterie, et (3) au

produit utilisant la batterie.

2. Ne démontez pas la batterie.

3. Cessez immédiatement l’utilisation si le temps

de fonctionnement devient excessivement

court. Il y a risque de surchauffe, de brûlures,

voire d’explosion.

4. Si l’électrolyte pénètre dans vos yeux, rincez-les à l’eau claire et consultez immédiatement un médecin. Il y a risque de perte de la

vue.

5. Ne court-circuitez pas la batterie :

(1) Ne touchez les bornes avec aucun maté-

riau conducteur.

(2) Évitez de ranger la batterie dans un

conteneur avec d’autres objets métalliques, par exemple des clous, des pièces

de monnaie, etc.

(3) N’exposez pas la batterie à l’eau ou à la

pluie.

Un court-circuit de la batterie peut provoquer

une intensité de courant élevée, une surchauffe, parfois des brûlures et même une

panne.

6. Ne rangez pas l’outil et la batterie dans un

endroit où la température risque d’atteindre ou

de dépasser 50 °C.

7. Ne jetez pas la batterie au feu même si elle est

sérieusement endommagée ou complètement

épuisée. La batterie peut exploser au contact

du feu.

8. Évitez de laisser tomber ou de cogner la

batterie.

9. N’utilisez pas la batterie si elle est

endommagée.

10. Les batteries au lithium-ion contenues sont

soumises aux exigences de la législation sur

les marchandises dangereuses.

Lors du transport commercial par des tierces

parties ou des transitaires par exemple, des exigences spéciques en matière d’étiquetage et

d’emballage doivent être respectées.

Pour la préparation de l’article expédié, il est

nécessaire de consulter un expert en matériau

dangereux. Veuillez également respecter les

réglementations nationales susceptibles d’être

plus détaillées.

Recouvrez les contacts exposés avec du ruban

adhésif ou du ruban de masquage et emballez la

batterie de telle sorte qu’elle ne puisse pas bouger

dans l’emballage.

11. Suivez les réglementations locales en matière

de mise au rebut des batteries.

CONSERVEZ CES

INSTRUCTIONS.

ATTENTION : N’utilisez que des batteries

Makita d’origine. L’utilisation de batteries de marque

autre que Makita ou de batteries modiées peut provoquer l’explosion des batteries, ce qui présente un

risque d’incendie, de dommages matériels et corporels. Cela annulera également la garantie Makita pour

l’outil et le chargeur Makita.

Conseils pour assurer la durée

de vie optimale de la batterie

1. Chargez la batterie avant qu’elle ne soit complètement déchargée. Arrêtez toujours l’outil

et rechargez la batterie quand vous remarquez

que la puissance de l’outil diminue.

2. Ne rechargez jamais une batterie complètement chargée. La surcharge réduit la durée de

service de la batterie.

3. Chargez la batterie à une température

ambiante comprise entre 10 °C et 40 °C. Avant

de charger une batterie chaude, laissez-la

refroidir.

4. Rechargez la batterie si elle est restée inutilisée pendant une période prolongée (plus de

six mois).

20 FRANÇAIS

Page 21

DESCRIPTION DU

FONCTIONNEMENT

ATTENTION : Assurez-vous toujours que

l’outil est hors tension et que sa batterie est

retirée avant de l’ajuster ou de vérier son

fonctionnement.

Insertion ou retrait de la batterie

ATTENTION : Éteignez toujours l’outil avant

de mettre en place ou de retirer la batterie.

ATTENTION : Tenez fermement l’outil et la

batterie lors de la mise en place ou du retrait de

la batterie. Si vous ne tenez pas fermement l’outil

et la batterie, ils peuvent vous glisser des mains, et

s’abîmer ou vous blesser.

► Fig.1: 1. Voyant rouge 2. Bouton 3. Batterie

Pour retirer la batterie, faites-la glisser hors de l’outil

tout en faisant glisser le bouton à l’avant de la batterie.

Pour mettre en place la batterie, alignez la languette sur

la batterie avec la rainure sur le compartiment et insérez-la. Insérez-la à fond jusqu’à ce qu’un léger déclic

se fasse entendre. Si le voyant rouge sur le dessus du

bouton est visible, cela signie qu’elle n’est pas bien

verrouillée.

ATTENTION : Insérez toujours complètement

la batterie jusqu’à ce que le voyant rouge ne soit

plus visible. Sinon, elle pourrait tomber acciden-

tellement de l’outil, au risque de vous blesser ou de

blesser quelqu’un se trouvant près de vous.

ATTENTION : N’insérez pas la batterie de

force. Si elle ne glisse pas facilement, c’est que vous

ne l’insérez pas correctement.

Témoins Charge

Allumé Éteint Clignotant

NOTE : Selon les conditions d’utilisation et la tem-

pérature ambiante, l’indication peut être légèrement

différente de la capacité réelle.

restante

Chargez la

batterie.

Anomalie

possible

de la batterie.

Indication de la charge restante de

la batterie

Propre au pays

Lorsque vous mettez l’outil sous tension, le témoin de la

batterie indique la charge restante de la batterie.

► Fig.3: 1. Témoin de la batterie

La charge restante de la batterie est indiquée conformément au tableau ci-dessous.

Statut du témoin de la batterie Charge

Allumé

Éteint

Clignotant

restante de la

batterie

50 % à 100 %

20 % à 50 %

0 % à 20 %

Indication de la charge restante de

la batterie

Uniquement pour les batteries dont le numéro de

modèle se termine par « B »

► Fig.2: 1. Témoins 2. Bouton de vérication

Appuyez sur le bouton de vérication sur la batterie

pour indiquer la charge restante de la batterie. Les

témoins s’allument pendant quelques secondes.

Témoins Charge

Allumé Éteint Clignotant

restante

75 % à 100 %

50 % à 75 %

25 % à 50 %

0 % à 25 %

Système de protection de l’outil/la

batterie

L’outil est équipé d’un système de protection de l’outil/la

batterie. Ce système coupe automatiquement l’alimentation vers le moteur pour prolonger la durée de vie de

l’outil et de la batterie. Si l’outil ou la batterie se trouve

dans l’une des situations suivantes, l’outil cessera automatiquement de fonctionner. Dans certaines situations,

les témoins s’allument.

Protection contre la surcharge

Lorsque l’outil est utilisé d’une manière provoquant

un appel de courant anormalement élevé, l’outil s’arrête automatiquement sans indication. Dans ce cas,

éteignez l’outil et arrêtez la tâche ayant provoqué la

surcharge de l’outil. Puis rallumez l’outil pour reprendre

la tâche.

21 FRANÇAIS

Chargez la

batterie

Page 22

Protection contre la surchauffe

En cas de surchauffe de l’outil, celui-ci s’arrête automatiquement et le témoin de la batterie indique l’état suivant.

Dans ce cas, laissez l’outil refroidir avant de le rallumer.

Allumé

Si l’outil ne démarre pas, c’est que la batterie a peutêtre surchauffé. Dans ce cas, laissez la batterie refroidir

avant de redémarrer l’outil.

Clignotant

Protection contre la décharge totale

de la batterie

Lorsque la charge de la batterie est insufsante, l’outil

s’arrête automatiquement. Dans ce cas, retirez la batterie de l’outil et chargez-la.

Déverrouillage de la protection

Lorsque le système de protection s’enclenche à plusieurs reprises, l’outil est verrouillé et le témoin de la

batterie indique l’état suivant.

Dans ce cas, l’outil ne démarre pas même si vous l’éteignez, puis l’allumez. Pour déverrouiller la protection,

retirez la batterie, placez-la sur le chargeur de batterie

et patientez jusqu’à ce que la charge soit terminée.

Allumé

Éteint

Clignotant

Verrouillage de l’arbre

Avant de poser ou de retirer des accessoires, appuyez sur

le verrouillage de l’arbre pour empêcher l’axe de tourner.

► Fig.4: 1. Verrouillage de l’arbre

REMARQUE : N’activez jamais le verrouillage de

l’arbre pendant que l’axe tourne. Vous risqueriez

d’abîmer l’outil.

Interrupteur

ATTENTION : Avant d’insérer la batterie dans

l’outil, vériez toujours que la gâchette allongée

fonctionne bien et revient en position « Arrêt »

lorsque relâchée.

ATTENTION : Évitez d’appuyer sur la

gâchette allongée avec force lorsque le levier

de sécurité n’est pas enfoncé. Vous risqueriez de

briser la gâchette.

Un levier de sécurité est fourni pour prévenir l’activation

accidentelle de la gâchette allongée.

Pour démarrer l’outil, enfoncez le levier de sécurité puis

appuyez sur la gâchette allongée.

Pour arrêter l’outil, relâchez la gâchette allongée.

► Fig.5: 1. Levier de sécurité 2. Gâchette allongée

Fonction de changement

automatique de vitesse

► Fig.6: 1. Témoin de mode

Statut du témoin de mode Mode de fonctionnement

Mode grande vitesse

Mode couple élevé

Cet outil est pourvu d’un « mode grande vitesse » et

d’un « mode couple élevé ». Il change automatiquement

de mode de fonctionnement en fonction de la charge de

travail. Lorsque le témoin de mode s’allume pendant le

fonctionnement, l’outil est en mode couple élevé.

Fonction de prévention de

redémarrage accidentel

Même si vous insérez la batterie tout en tirant sur la

gâchette allongée, l’outil ne démarrera pas.

Pour démarrer l’outil, relâchez d’abord la gâchette

allongée. Tirez ensuite sur le levier de sécurité et

enclenchez la gâchette allongée.

Fonction de contrôle du couple

électronique

L’outil détecte électroniquement des situations où la

meule ou l’accessoire peuvent être exposés à un risque

de pincement. Dans ce cas, l’outil est automatiquement

éteint pour empêcher la rotation de l’axe (le choc en

retour n’est pas empêché).

Pour redémarrer l’outil, commencez par l’éteindre,

éliminez la cause de la baisse soudaine de la vitesse de

rotation, puis allumez l’outil.

Fonction de démarrage en douceur

La fonction de démarrage en douceur réduit le choc de

démarrage.

Frein électrique

Le frein électrique est activé une fois l’outil éteint.

Le frein ne fonctionne pas si l’alimentation est coupée (en cas de retrait accidentel de la batterie,

par exemple), alors que la gâchette est toujours

enclenchée.

ASSEMBLAGE

ATTENTION : Assurez-vous toujours que

l’outil est hors tension et que sa batterie est

retirée avant de l’ajuster ou de vérier son

fonctionnement.

22 FRANÇAIS

Page 23

Pose de la poignée latérale

ATTENTION : Avant l’utilisation, assu-

rez-vous toujours que la poignée latérale est

fermement posée.

Vissez fermement la poignée latérale sur la position de

l’outil comme indiqué sur la gure.

► Fig.7

Pose ou retrait du carter de meule

(pour meule à moyeu déporté,

disque à lamelles, meule exible,

brosse métallique circulaire/meule

à tronçonner abrasive, meule