Makita BVF154, BVF104 User Manual [ru]

GB Cordless Garden Sprayer Instruction manual

CF Pulvérisateur de jardin sans fil Manuel d’instructions

LS Fumigador inalámbrico de uso Manual de instrucciones

agrícola

BZ Pulverizador a bateria Manual de instruções

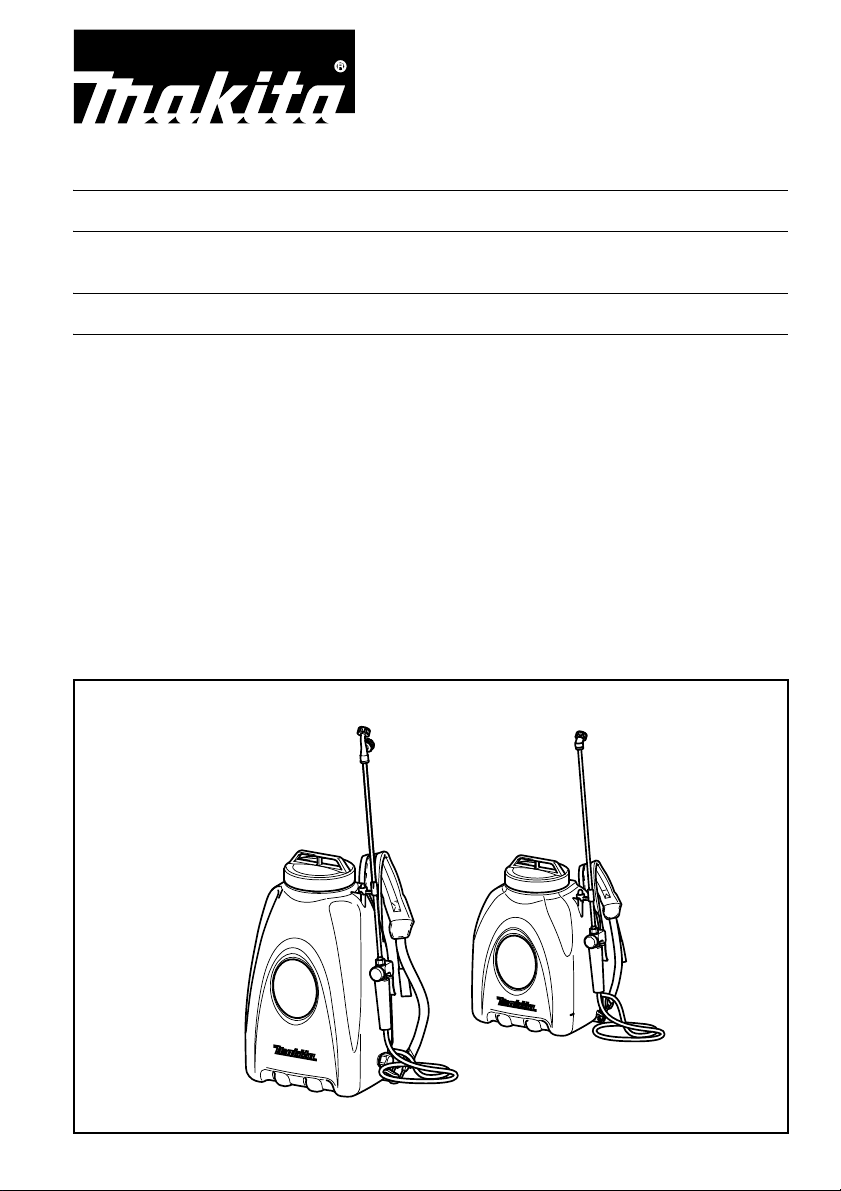

BVF104

BVF154

12

1

2

3

4

5

6

7

BVF104

BVF154

8

9

9

3

2

45

10

A

B

C

11

12

13

13

14

15

16

17

18

67

89

10 11

3

12 13

19

20

14

4

ENGLISH

Explanation of general view

1. Button

2. Red part

3. Battery cartridge

4. Battery pack cover

5. Spray pipe

6. Lever cock

7. Nozzle

8. Pass the belt part of the back

strap through the slot on the

sprayer.

9. Clip on back strap hooks

10. Switch

11. B uck le

12. Lift up buckle

13. Pull

14. Water absorption strainer

15. Lever cock cap

16. Strainer

17. Spray pipe holder

18. Hooking holder onto post on

shoulder of tank

19. Hooking holder onto metal ring of

back strap

20. Insert water hose here

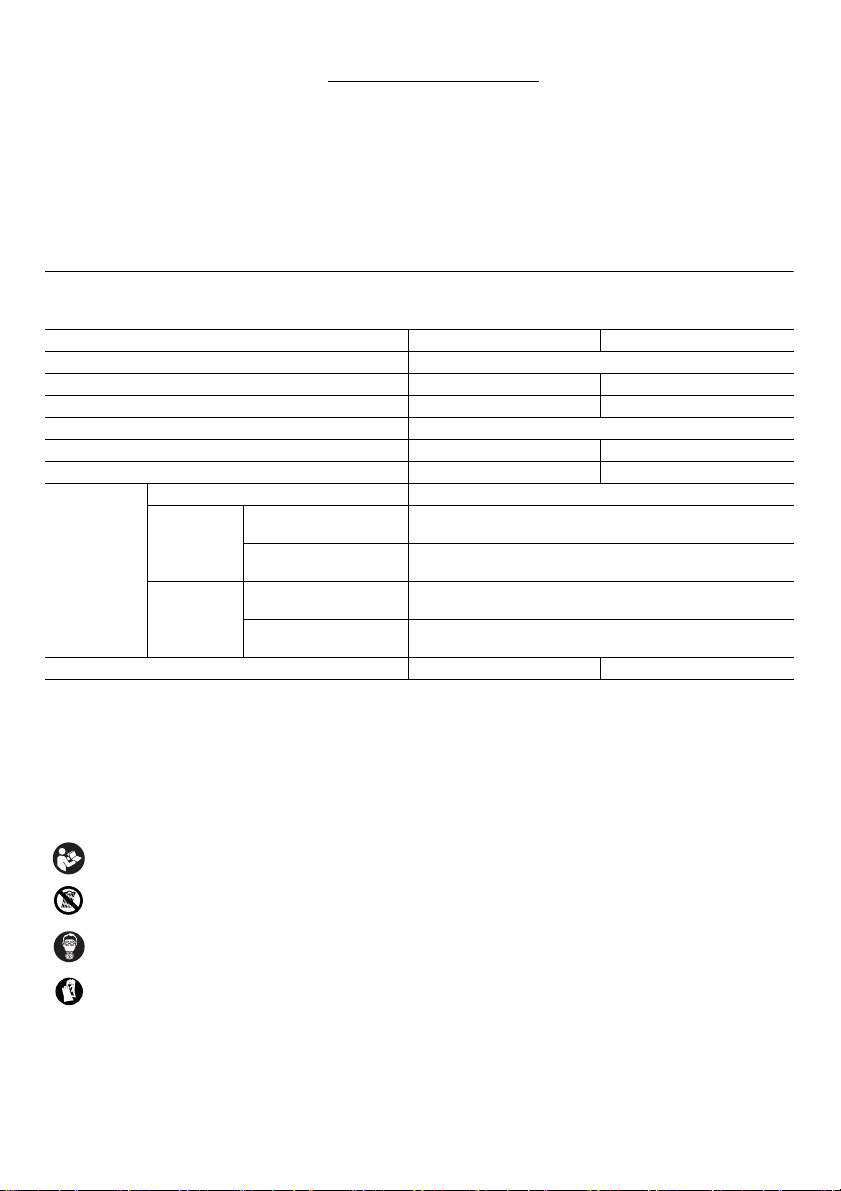

SPECIFICATIONS

Model BVF104 BVF154

Pump type Ceramic gear system

Chemical tank capacity 10L 15L

Tank drain Without With

Spray valve Integral grip lever

Dimension (W X L X H) 315 mm x 225mm x 415 mm 345 mm x 235 mm x 525 mm

Net weight 3.8 kg 4.1 kg

Maximum pressure 0.3 Mpa

Upright double-headed

Discharge

Performance

Continuous

work time

Rated voltage D.C. 18 V D.C. 18 V

• Due to our continuing programme of research and development, the specifications herein are subject to change without

notice.

• Specifications and battery cartridge may differ from country to country.

• Weight, with battery cartridge, according to EPTA-Procedure 01/2003

Symbols

The following show the symbols used for the equipment.

Be sure that you understand their meaning before use.

............. Read instruction manual.

............. Do not use in rain.

nozzle

Wide-angle herbicide

nozzle

Upright double-headed

nozzle

Wide-angle herbicide

nozzle

END007-1

General Power Tool Safety

Warnings

WARNING Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or

serious injury.

0.8 L / min.

1.3 l / min.

125 min.

200 min.

GEA006-2

Save all warnings and

............. Wear protective mask.

............. Wear protective gloves.

Intended use

The tool is intended for spraying agricultural and

horticultural chemicals for pest and weed control.

ENE071-1

instructions for future reference.

The term “power tool” in the warnings refers to your

mains-operated (corded) power tool or battery-operated

(cordless) power tool.

Work area safety

1. Keep work area clean and well lit. Cluttered or dark

areas invite accidents.

2. Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

5

3. Keep children and bystanders away while

operating a power tool. Distractions can cause you

to lose control.

Electrical safety

4. Power tool plugs must match the outlet. Never

modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power

tools. Unmodified plugs and matching outlets will

reduce risk of electric shock.

5. Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

6. Do not expose power tools to rain or wet

conditions. Water entering a power tool will increase

the risk of electric shock.

7. Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase

the risk of electric shock.

8. When operating a power tool outdoors, use an

extension cord suitable for outdoor use. Use of a

cord suitable for outdoor use reduces the risk of

electric shock.

9. If operating a power tool in a damp location is

unavoidable, use a ground fault circuit interrupter

(GFCI) protected supply. Use of an GFCI reduces

the risk of electric shock.

Personal safety

10. Stay alert, watch what you are doing and use

common sense when operating a power tool. Do

not use a power tool while you are tired or under

the influence of drugs, alcohol or medication. A

moment of inattention while operating power tools

may result in serious personal injury.

11. Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

12. Prevent unintentional starting. Ensure the switch

is in the off-position before connecting to power

source and/or battery pack, picking up or carrying

the tool. Carrying power tools with your finger on the

switch or energising power tools that have the switch

on invites accidents.

13. Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key left

attached to a rotating part of the power tool may result

in personal injury.

14. Do not overreach. Keep proper footing and

balance at all times. This enables better control of

the power tool in unexpected situations.

15. Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing, and gloves

away from moving parts. Loose clothes, jewellery or

long hair can be caught in moving parts.

16. If devices are provided for the connection of dust

extraction and collection facilities, ensure these

are connected and properly used. Use of dust

collection can reduce dust-related hazards.

Power tool use and care

17. Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

18. Do not use the power tool if the switch does not

turn it on and off. Any power tool that cannot be

controlled with the switch is dangerous and must be

repaired.

19. Disconnect the plug from the power source and/or

the battery pack from the power tool before

making any adjustments, changing accessories,

or storing power tools. Such preventive safety

measures reduce the risk of starting the power tool

accidentally.

20. Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the

power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands

of untrained users.

21. Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tool’s operation. If damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

22. Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges are

less likely to bind and are easier to control.

23. Use the power tool, accessories and tool bits etc.

in accordance with these instructions, taking into

account the working conditions and the work to

be performed. Use of the power tool for operations

different from those intended could result in a

hazardous situation.

Battery tool use and care

24. Recharge only with the charger specified by the

manufacturer. A charger that is suitable for one type

of battery pack may create a risk of fire when used

with another battery pack.

25. Use power tools only with specifically designated

battery packs. Use of any other battery packs may

create a risk of injury and fire.

26. When battery pack is not in use, keep it away from

other metal objects, like paper clips, coins, keys,

nails, screws or other small metal objects, that

can make a connection from one terminal to

another. Shorting the battery terminals together may

cause burns or a fire.

27. Under abusive conditions, liquid may be ejected

from the battery; avoid contact. If contact

accidentally occurs, flush with water. If liquid

contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or

burns.

Service

28. Have your power tool serviced by a qualified

repair person using only identical replacement

parts. This will ensure that the safety of the power tool

is maintained.

29. Follow instruction for lubricating and changing

accessories.

6

30. Keep handles dry, clean and free from oil and

grease.

SPECIFIC SAFETY RULES GEB044-3

DO NOT let comfort or familiarity with product (gained

from repeated use) replace strict adherence to

Garden Sprayer safety rules. If you use this tool

unsafely or incorrectly, you can suffer serious

personal injury.

Safety Warnings for Spraying Operation:

1. Do not use the sprayer for any other purpose than

spraying agricultural and horticultural chemicals

for pest and weed control.

2. Concerning the use of chemical sprays, be sure to

thoroughly read the chemical instructions, in

order to become fully acquainted with toxicities

and usage methods.

3. If chemical comes into contact with skin,

immediately wash thoroughly with soap.

4. Firmly close chemical tank lid to prevent leaking.

5. Never transfer chemical to another container.

6. Always thoroughly wash empty chemical

containers when mixing spray liquid and then

follow chemical manufacturer’s instructions to

correctly dispose of containers at all times.

7. Before using the sprayer, be sure to check there

are no abnormalities, such as displacement of

packing from connector, looseness of screws,

missing components, and/or cracked/worn/

damaged hose.

Using an incomplete sprayer may cause an accident

and/or injury.

8. People not involved in spraying should refrain

from approaching the worksite during spraying.

9. When transporting a chemical-loaded sprayer by

vehicle, there is a risk of leaking, so always firmly

tighten the chemical tank lid, and secure the

sprayer in an upright position.

10. Never use items such as strongly acidic

chemicals, paints, thinners, gasoline or benzene

with the sprayer, as there is a danger of burns or

fire.

11. Be sure to select the appropriate chemical (taking

into consideration usage method and

effectiveness) to deal with the pest or weed in

question.

12. An inappropriately mixed chemical may harm

humans as well as damage crops/plants. When

mixing chemical, thoroughly read chemical

instructions, and dilute chemical correctly prior to

use.

13. Always mix chemical before loading it into tank.

14. To prevent inhalation and/or contact with

chemical, be sure to wear safety clothing (hat,

protective goggles, protective mask, rubber

gloves, long-sleeved pest-control jacket, long

trousers and gumboots), so that skin is not

exposed when spraying.

15. Always load the tank with chemical or clean water

when operating the sprayer, as operating the

sprayer with an empty tank may damage the

pump.

16. If the sprayer stops running, or an abnormal

sound is emitted, immediately switch OFF the

sprayer, and discontinue use.

17. Constantly be aware of wind direction while

spraying, to ensure spraying from upwind to

downwind, in order to prevent direct chemical

contact with body. Also, be careful to keep

chemical from reaching surroundings, and stop

using the sprayer when the wind is strong.

18. As there is a risk of chemical poisoning when

spraying in a greenhouse, always ventilate while

spraying.

19. Avoid spraying when atmospheric temperature is

high.

20. Avoid prolonged operation of sprayer. Whenever

possible, rotate operators.

21. If even a slight headache or dizziness, etc.,

occurs, stop spraying work immediately, and

consult a doctor. Moreover, be sure to clearly

inform the doctor of the name of the agrochemical

being used, and the operating circumstances.

22. In cases where spray status deteriorates and

nozzle needs cleaning, there is a risk of the

chemical liquid coming into contact with the face,

so be sure to switch OFF the sprayer, and then

remove the nozzle to clean.

23. Be sure to dispose of wastewater generated from

washing used containers and chemical tank

appropriately in a location where it will not flow

into rivers and streams and/or contaminate

groundwater.

24. After spraying, if chemical remains in the chemical

tank, spray hose, spray pipe and nozzle, it may

cause spray injury. Be sure to fully wash away

residual chemical with clean water - in particular,

after spraying with herbicide.

25.

Keep agrochemicals away from children. Be sure

to store residual chemicals in chemicaldesignated storage containers.

26. After completion of spraying, be sure to wash

(spray wash) equipment with clean water, drain off

the washing water, and store indoors away from

direct sunlight and freezing temperatures, and out

of reach of children.

27. After completion of spraying, be sure to

thoroughly wash entire body with soap, rinse

eyes, and gargle. During spraying period, change

clothes daily.

WARNING:

MISUSE or failure to follow the safety rules stated in

this instruction manual may cause serious personal

injury.

SAVE THESE INSTRUCTIONS.

IMPORTANT SAFETY

INSTRUCTIONS

ENC007-4

FOR BATTERY CARTRIDGE

1. Before using battery cartridge, read all

instructions and cautionary markings on (1)

battery charger, (2) battery, and (3) product using

battery.

7

2. Do not disassemble battery cartridge.

3. If operating time has become excessively shorter,

stop operating immediately. It may result in a risk

of overheating, possible burns and even an

explosion.

4. If electrolyte gets into your eyes, rinse them out

with clear water and seek medical attention right

away. It may result in loss of your eyesight.

5. Do not short the battery cartridge:

(1) Do not touch the terminals with any

conductive material.

(2) Avoid storing battery cartridge in a container

with other metal objects such as nails, coins,

etc.

(3) Do not expose battery cartridge to water or

rain.

A battery short can cause a large current flow,

overheating, possible burns and even a

breakdown.

6. Do not store the tool and battery cartridge in

locations where the temperature may reach or

exceed 50°C (122°F).

7. Do not incinerate the battery cartridge even if it is

severely damaged or is completely worn out. The

battery cartridge can explode in a fire.

8. Be careful not to drop or strike battery.

9. Do not use dropped or struck battery.

SAVE THESE INSTRUCTIONS.

Tips for maintaining maximum battery life

1. Charge the battery cartridge before completely

discharged.

Always stop tool operation and charge the battery

cartridge when you notice less tool power.

2. Never recharge a fully charged battery cartridge.

Overcharging shortens the battery service life.

3. Charge the battery cartridge with room

temperature at 10°C - 40°C (50°F - 104°F). Let a hot

battery cartridge cool down before charging it.

FUNCTIONAL DESCRIPTION

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before adjusting or

checking function on the tool.

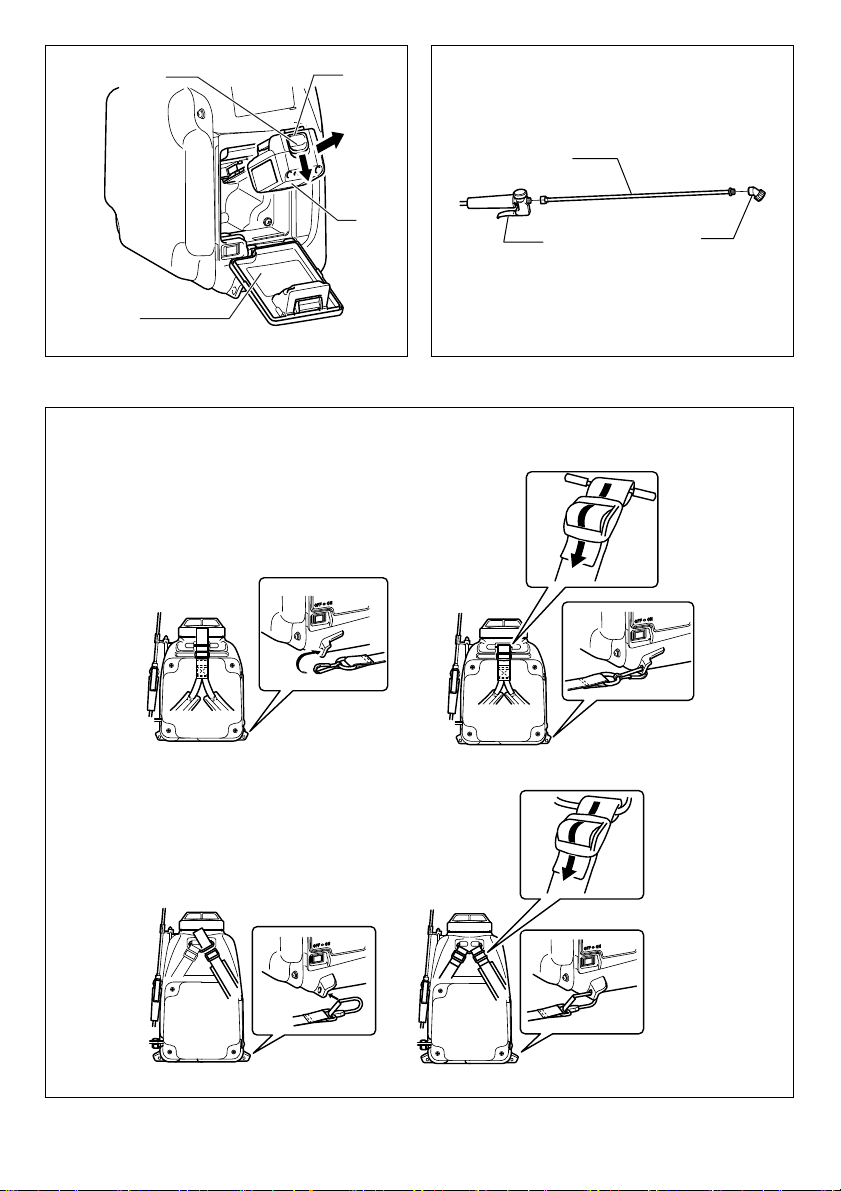

Installing or removing battery cartridge

(Fig. 1)

• Open Sprayer's battery pack cover.

• Always switch off the tool before insertion or removal of

the battery cartridge.

• To remove the battery cartridge, withdraw it from the

tool while sliding the button on the front of the cartridge.

• To insert the battery cartridge, align the tongue on the

battery cartridge with the groove in the housing and slip

it into place. Always insert it all the way until it locks in

place with a little click. If you can see the red part on

the upper side of the button, it is not locked completely.

Insert it fully until the red part cannot be seen. If not, it

may accidentally fall out of the tool, causing injury to

you or someone around you.

• Do not use force when inserting the battery cartridge. If

the cartridge does not slide in easily, it is not being

inserted correctly.

ASSEMBLY

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before carrying out any

work on the tool.

Spray pipe and nozzle assembly method

(Fig. 2)

• As shown in the diagram, assemble spray pipe and

then nozzle onto lever cock.

• Adjust direction of nozzle using nut on spray pipe.

• Firmly attach components to ensure there is no

leaking.

• Select nozzle according to type of spraying to be done.

NOTE:

• All connector units use packing. Before assembly,

always check to see that the units have packing.

• Check to make sure that the spray hose is not cracked,

worn and/or damaged.

• Firmly tighten on the spray pipe to prevent liquid leaks.

• If there is a leak from a connector unit, tighten further

using a hand tool (by approximately 45 degrees).

• Do not use a spray pipe that is longer than the standard

one provided. Doing so may cause leaking from

connector units.

Back strap attaching method (Fig. 3)

Use the diagram pointers to attach the back strap at top

and bottom, making sure there are no twists in the strap.

NOTE:

• Check to make sure that back strap is securely

attached to chemical tank.

OPERATION

CAUTION:

• Before inserting the battery cartridge into the tool,

always check to see that the tool is switched off.

Spraying

CAUTION:

• To prevent sudden spraying, be sure to set the lever

cock to STOP, before turning sprayer switch ON or

OFF.

• When spray work is interrupted, be sure to turn switch

OFF, to prevent inadvertent spraying. (Fig. 4)

Be sure to check the situation of surroundings before

turning sprayer switch ON.

Operate lever cock to spray.

Once spraying is complete, immediately set lever cock to

STOP, and then turn sprayer switch OFF.

How to use lever cock (Fig. 5)

1. Position “A” is the STOP position.

2. Position “B” is the spray position. Release the lever,

and it will return to position “A” and spraying will stop.

(Intermittent spraying)

8

3. Position “C” is the continuous spray position.

(Continuous spraying)

NOTE:

• Check to make sure the tank is loaded with chemical or

clean water when operating the sprayer, as continued

operation of the sprayer with an empty tank may burn

out the pump.

• Running the sprayer for prolonged periods with the

lever cock closed may have an adverse effect on the

pump as well as drain the battery. Be sure to turn

sprayer switch OFF whenever possible.

• If spray splutters, or pumps suddenly screeches, the

chemical tank is empty, so immediately turn sprayer

switch OFF.

• Do not spray with the battery cover open and/or with

the back-support cushioning removed, as there is a risk

of damage to electrical system. Moreover, do not point

the spray nozzle at the sprayer and spray.

• Do not forcibly handle the lever cock and/or the spray

pipe.

Mixing chemical

CAUTION:

• Never use Kelthane water dispersible powder

(acaricide) because it tends to harden due to heat

generated by pump during operation, which causes the

pump to stop. Use a Kelthane emulsion, Akar emulsion

or Osadan water dispersible powder as the acaricide.

• When using a water dispersible powder or lime sulfur,

be sure to dissolve well prior to use.

• Take maximum care when handling chemicals. Wash

away thoroughly if chemical comes into contact with

body.

• Chemicals are harmful. Always adhere to chemical

manufacturer instructions when handling chemicals.

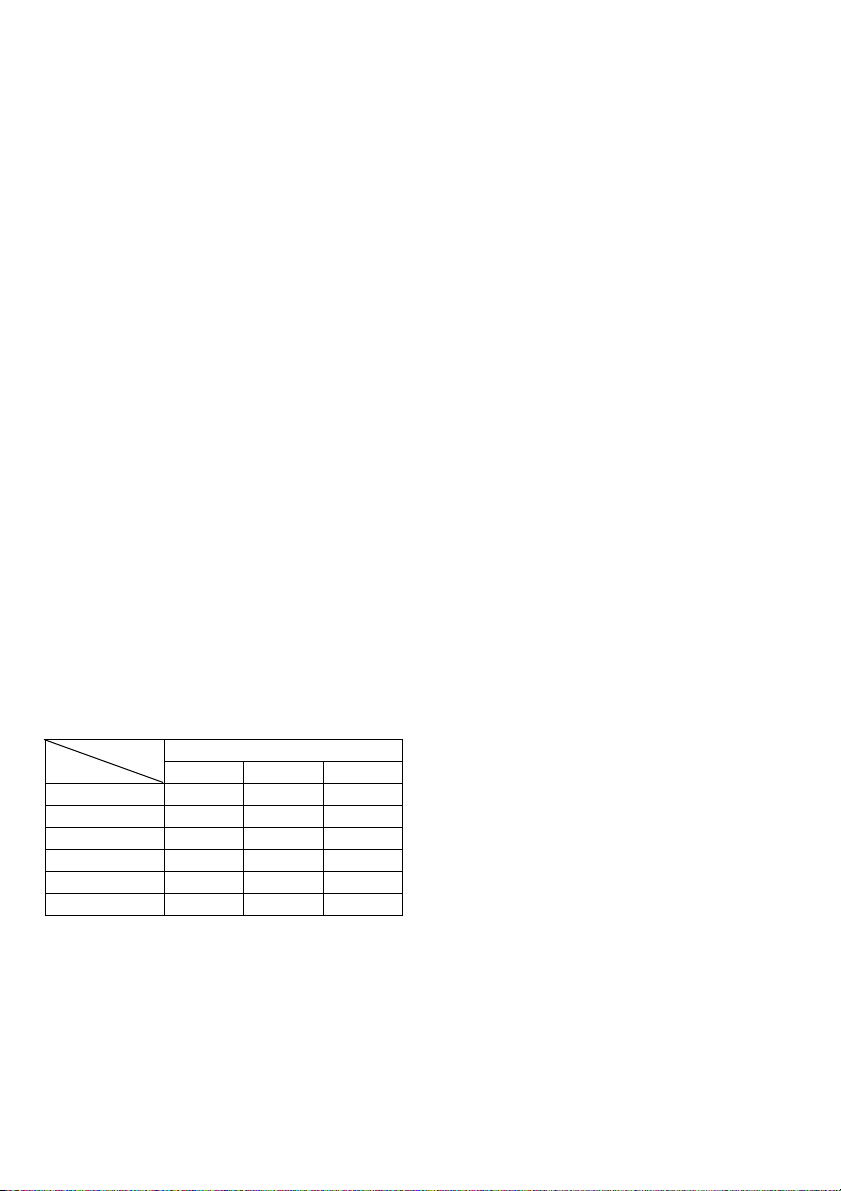

• See chart below for ratio information that is useful

when diluting chemicals.

• When using a water dispersible powder, etc., dissolve

thoroughly in a container such as a bucket.

Chemical Dilution ratio

Water 500 1,000 2,000

4 L 8 mL 4 mL 2 mL

6 L 12 mL 6 mL 3 mL

8 L 16 mL 8 mL 4 mL

10 L 20 mL 10 mL 5 mL

12 L 24 mL 12 mL 6 mL

15 L 30 mL 15 mL 7.5 mL

Chemical replenishment

WARNING:

• When changing chemical, be sure to carefully wash the

tank, pump, and nozzle, etc. with clean water. Residue

of the previous chemical may cause a spray injury.

Moreover, if chemicals mix, a chemical change may

occur, with the danger of generating a toxic gas.

• Be sure to wear protective gloves.

• Do not change chemical in poorly ventilated locale.

(prevent chemical poisoning)

Check to make sure the sprayer switch is OFF and

replenish chemical tank with mixed chemical.

When filling tank with chemical, always strain chemical

through equipped tank strainer.

The side of the chemical tank is marked with scale

divisions, so be sure to use these as operation guidelines.

Firmly tighten chemical tank lid to prevent leaking.

Back strap adjustment

Adjust back strap to a length that brings the sprayer as

close to the body as feasibly possible.

Lengthening strap

(1) Lift up buckle.

(2) Pull the belt on the side connected to the sprayer.

(Fig. 6)

Shortening strap

Pull the belt on the free side. (Fig. 7)

NOTE:

When shortening the strap, it will move relatively easily if

there is no weight exerted on the strap.

MAINTENANCE

CAUTION:

• Always be sure that the tool is switched off and the

battery cartridge is removed before attempting to

perform inspection or maintenance.

• For inspection and maintenance, always wear

protective gloves.

After-use maintenance

• After use, remove residual liquid from chemical tank,

and wash away clinging chemical from inside of tank

using clean water.

• Now fill up chemical tank with clean water and run the

sprayer for 2 to 3 minutes to wash out residual

chemical from the pump, hose, and nozzle, etc.

• Remove the residual liquid from inside the chemical

tank, restart the pump, and run the sprayer until

residual liquid ceases to come out of the nozzle, and

then turn sprayer switch OFF.

• Wipe away moisture and dirt from equipment, and then

check for damage and leaks.

Daily checks

• Before work, check to see whether or not fastened

units are loose and components are missing.

• Check to make sure the spray hose is not cracked,

worn and/or damaged.

• After use, always be sure to wipe dirt off of exterior,

and to check for damage and/or leaks.

Cleaning water absorption strainer

(Fig. 8)

After removing chemical from tank, remove the water

absorption strainer at the bottom of the tank, and clean it.

Cleaning lever cock strainer (Fig. 9)

Remove lever cock cap and clean strainer.

NOTE:

Water absorption strainer

• This is a filter used to prevent dirt and dust (that for

some reason has got passed the tank strainer into the

9

tank) from getting into the pump. If the water absorption

strainer becomes blocked, spraying will deteriorate,

and there is a risk of the pump being adversely

affected.

Lever cock strainer

• Spraying deteriorates if the lever cock strainer

becomes blocked.

Sprayer storage

• Wash the equipment using the after-use maintenance

procedures.

• In particular, when storing during the winter season,

breakdown or damage may occur due to freezing of

residual chemical and/or washing water in the pump.

Run the pump until all residual liquid has exited from

the nozzle, check to make sure there is no more

residual liquid, turn the sprayer switch OFF, and then

store the sprayer away.

CAUTION:

Store the Sprayer out of reach of children, in an indoor

locale that does not freeze, is away from direct sunlight,

and has good ventilation.

- Take full care in storing the sprayer, as, in some cases,

the plastic components will deteriorate markedly if left

in direct sunlight for a prolonged period; moreover,

product caution labels will discolor and/or come off.

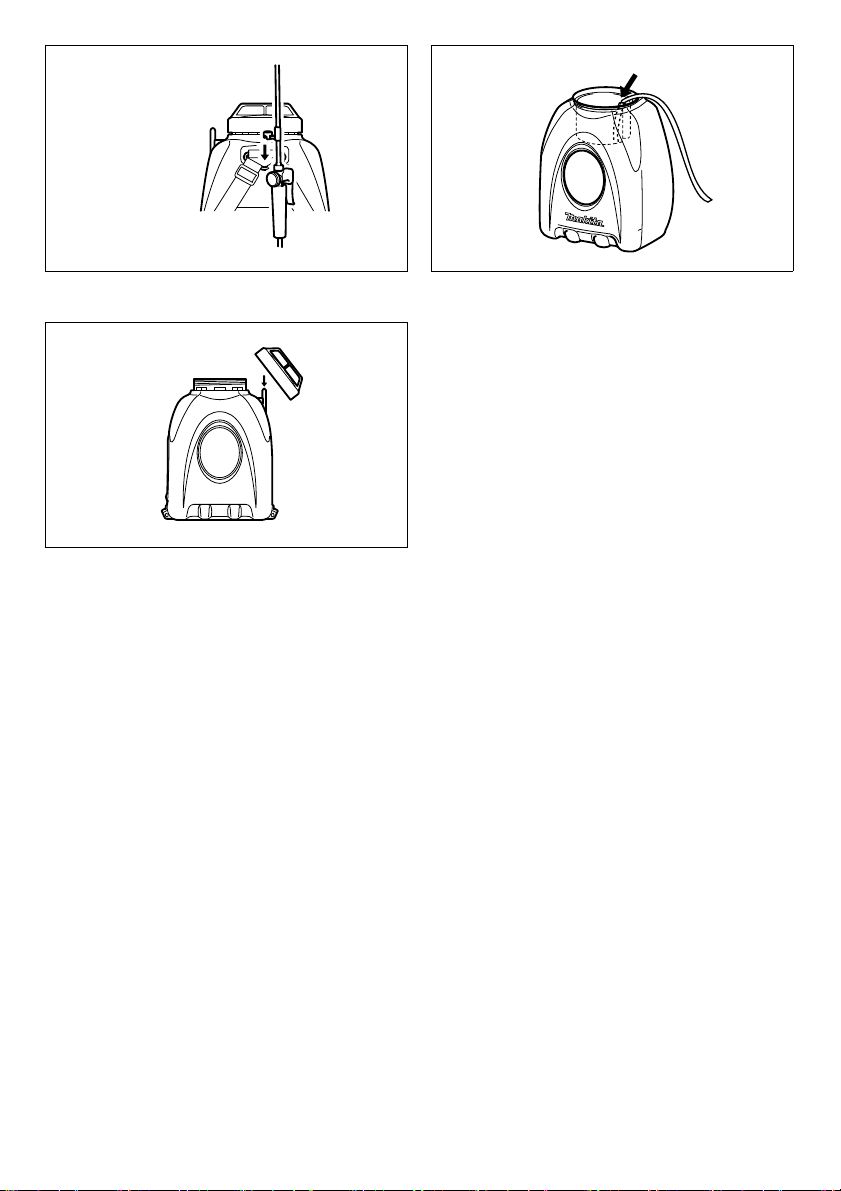

Useful Tips

Spray pipe holder

Be sure to attach the holder in the right direction. (Fig. 10)

NOTE:

• For configuration reasons, force is required in the

attaching process, but care should be taken not to

bend the spray pipe.

Use the holder when taking a rest, replenishing chemical

liquid, and at times of storage, etc. (Fig. 11)

For Model BVF154 only (Fig. 12)

Chemical tank holder post (Fig. 13)

The holder post also serves as a temporary holder for the

chemical tank lid, so please hook it onto this post.

(Fig. 14)

Tank strainer

Hands can be freed up by inserting the water hose in the

useful notched section of the tank strainer. (Fig. 14)

Main plant diseases and pests

Always adhere to chemical manufacturer instructions

when handling chemicals.Thoroughly dissolve chemical

prior to use.

What to do if you think there is a

breakdown

Before asking for repairs, first, conduct your own

inspection. If you find a problem that is not explained in

the manual, do not rashly dismantle the sprayer. Instead,

ask Makita Authorized Service Centers, always using

Makita replacement parts.

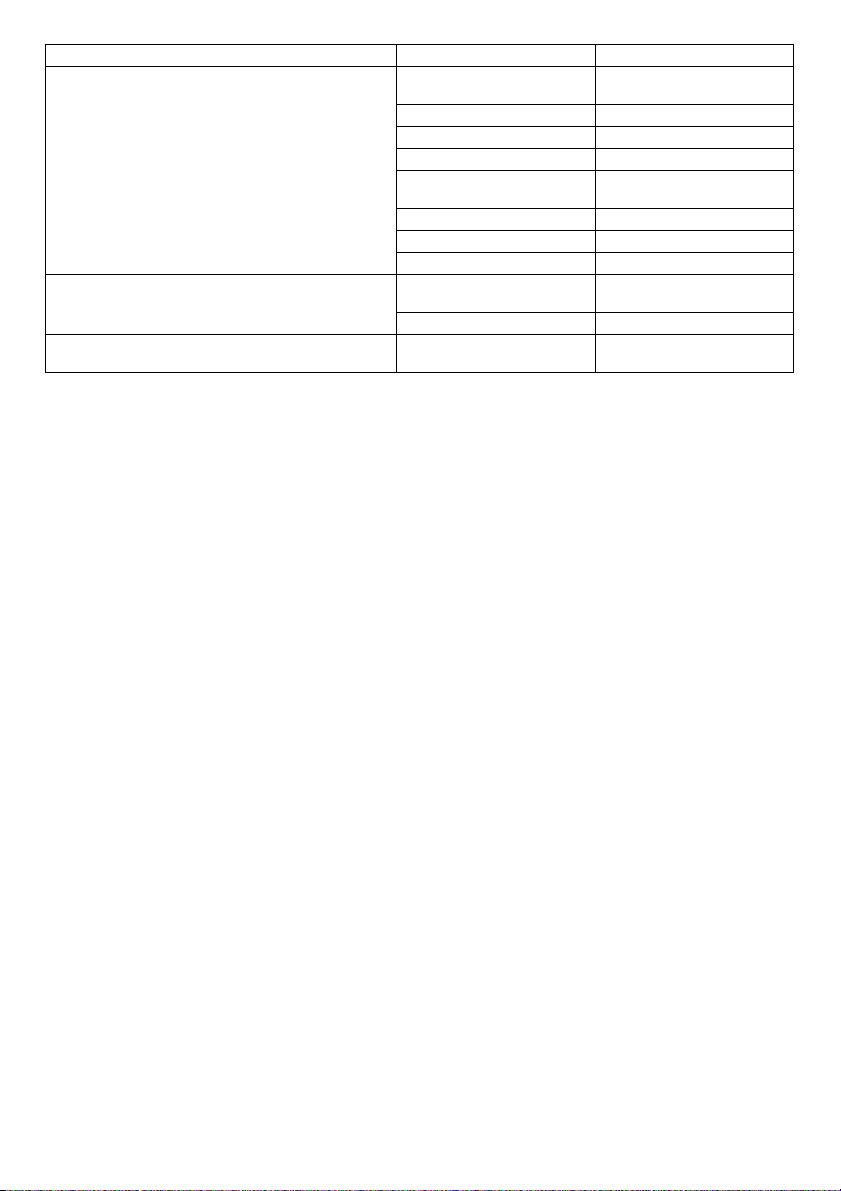

Malfunction status Cause Action

Switch OFF The switch is OFF Turn switch ON

Motor (pump) will not work

Pump is working but spray is not coming out

10

Switch ON

Battery problem (under

voltage)

Wiring connector is

disconnected

Wiring break Request an overhaul

Switch breakdown Request an overhaul

Motor breakdown Request an overhaul

Blown fuse Request an overhaul

Blocked nozzle Clean or replace

No liquid in chemical tank Replenish

Chemical tank lid's blowhole is

blocked

Blocked piping Request an overhaul

Broken or cracked piping Request an overhaul

Disconnected or broken piping Request an overhaul

Blocked water absorption

strainer

Recharge

If recharging is not effective,

replace battery.

Request an overhaul

Clean

Remove and clean

Malfunction status Cause Action

Sprayer sprays but is abnormal or spray pressure is

weak

A strange sound is emitted when switch is turned ON

When sprayer is left after being switched OFF, a large

amount of liquid flows out of the nozzle

To maintain product SAFETY and RELIABILITY, repairs,

any other maintenance or adjustment should be

performed by Makita Authorized Service Centers, always

using Makita replacement parts.

ACCESSORIES

CAUTION:

• These accessories or attachments are recommended

for use with your Makita tool specified in this manual.

The use of any other accessories or attachments might

present a risk of injury to persons. Only use accessory

or attachment for its stated purpose.

If you need any assistance for more details regarding

these accessories, ask your local Makita Service Center.

• Various nozzles

• Various type of Makita genuine batteries and chargers

Chemical tank lid's blowhole is

blocked

Blocked piping Request an overhaul

Broken or cracked piping Request an overhaul

Disconnected or broken piping Request an overhaul

Blocked water absorption

strainer

Blocked lever cock strainer Remove and clean

Abnormal pressure regulator Request an overhaul

Worn gear case Request an overhaul

Coupling that drives pump is

broken

Blocked nozzle Clean or replace

Lever cock is set to continuous

spray

Clean

Remove and clean

Request an overhaul

Set lever cock to STOP

11

Loading...

Loading...