Page 1

988-0176-06_A

HDS unit installation instructions

Read the following instructions carefully before attempting any installation.

Transducer installation recommended tools and supplies

(not included)

If you plan to route the transducer cable through the transom, you will need either

a 1" drill bit or a 5/8" drill bit depending on the size of the transducer cable connector. Each transom mount requires a high quality, marine grade above- or belowwaterline sealant/adhesive compound. The following installations also call for these

recommended tools and supplies.

One-piece bracket transom installation:

Tools: two adjustable wrenches or socket wrench, drill, #29 (0.136") drill bit, screwdriver. Supplies: none.

Two-piece bracket transom installation:

Tools: two adjustable wrenches or socket wrench, drill, #20 (0.161") drill

bit, screwdriver. Supplies: four, 1" long, #12 stainless steel wood screws.

TMB-S bracket trolling motor installation:

Tools: two adjustable wrenches or socket wrench, screwdriver. Supplies:

plastic cable ties.

Skimmer Transducer shoot-through hull installation:

Supplies: alcohol wipes, 60 and 160 grit sandpaper, and marine grade

above- or below-waterline epoxy adhesive.

Pod Transducer shoot-through hull installation:

Supplies: alcohol wipes, 60 and 160 grit sandpaper, and marine grade

above- or below-waterline epoxy adhesive.

1

Page 2

Skimmer Transducer installation instructions

Transducer location and installation is one of the most critical steps in sonar installation.

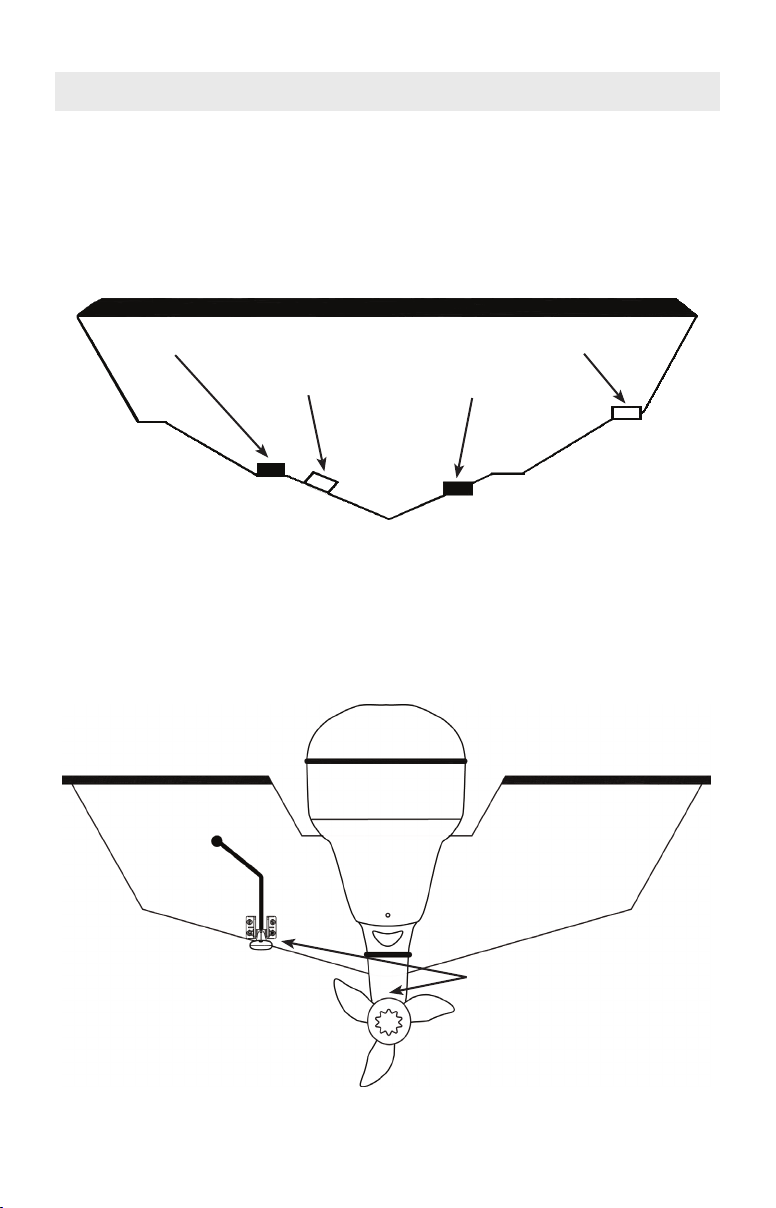

1. Select a transducer location

To function properly the Skimmer transducer must be in the water at all times and in a

location that has a smooth ow of water when the boat is moving.

Good location

Poor location

Aluminum boats with strakes or ribs on the hull can create large amounts of

turbulence at higher speeds. A good transducer location on these types of

boats is between the ribs closest to the engine.

Good location

Poor location

If the transducer is not placed in a smooth ow of water, interference caused by

bubbles and turbulence may show on-screen in the form of random lines or dots.

The unit also could lose bottom signal when the boat is on plane.

Do not mount the transducer

closer than approximately one

foot from the engine’s lower

unit. This will prevent cavitation

interference from the prop.

When mounting the transducer, make sure it does not interfere with the haul-

ing of the boat.

2

Page 3

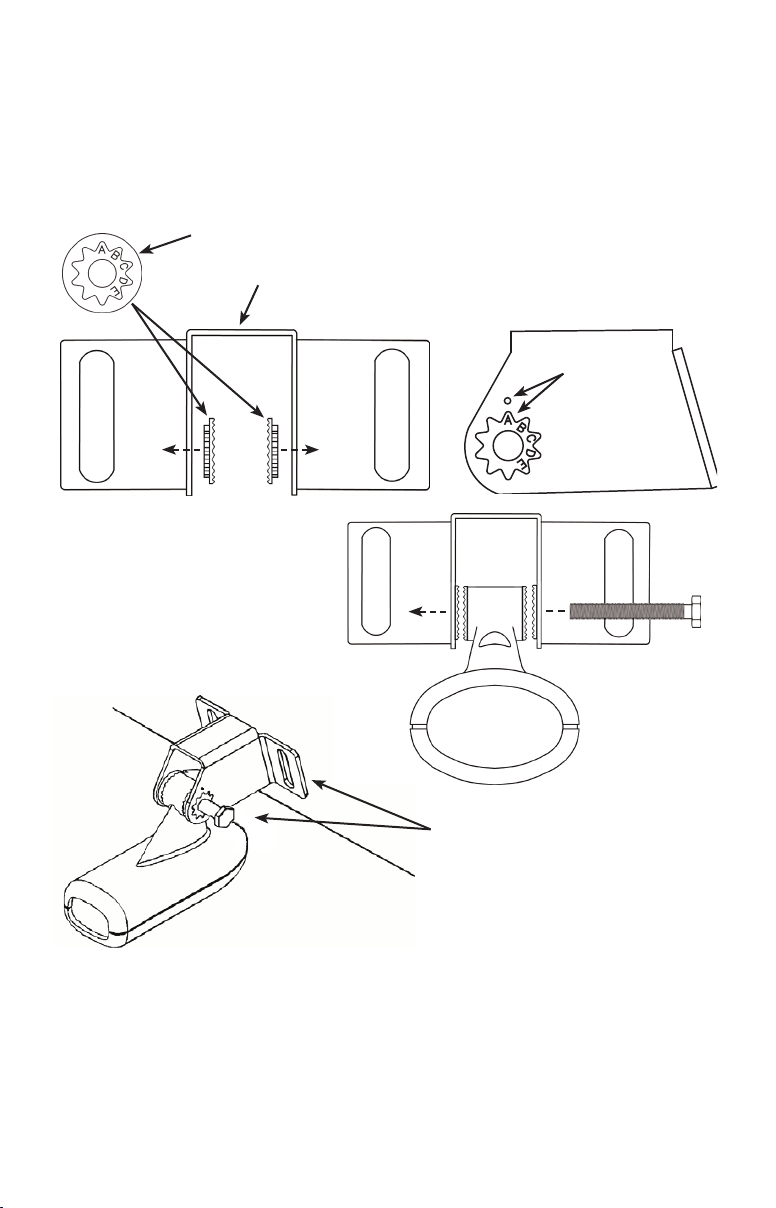

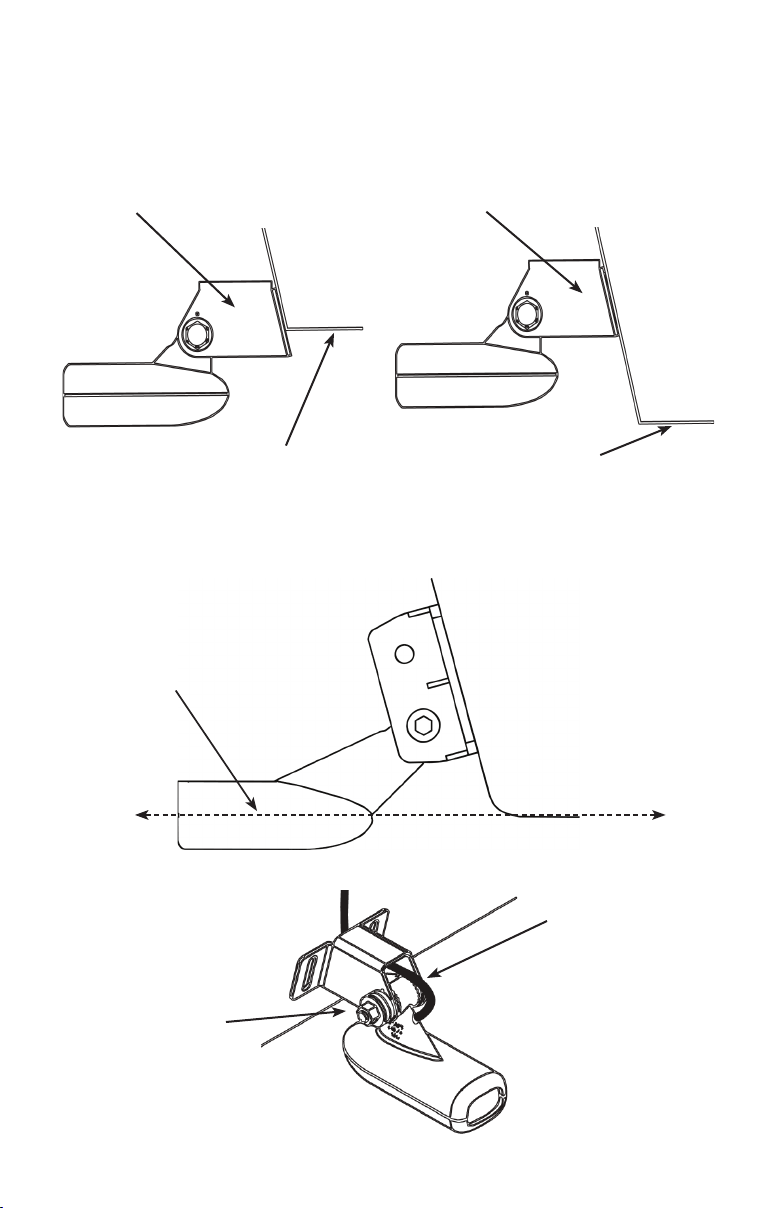

2. Aligning Ratchets on Transducer bracket

Aligning ratchets on one-piece bracket:

The one-piece bracket assembly includes two black plastic ratchets. The ratchets

are used to align the transducer with the boat hull. Each ratchet has the letters A-E

molded into it.

Ratchet

Bracket

2. Slide the transducer in the

bracket and temporarily slide

the bolt through the transducer

bracket, as shown in the image

at right.

1. Insert the ratchets in the bracket with the letter

"A" aligned with the dot stamped on the outside

of the transducer bracket, as shown in the fol-

lowing series of diagrams.

Align dot and

letter "A".

Transom

3. Hold the transducer assembly

against the transom. Look at the

transducer from the side. Try to

adjust the transducer so its face

is parallel to the ground. If it does,

then the "A" position is correct.

If the transducer will not adjust with its face parallel to the ground, remove the

transducer and ratchets from the bracket. Reinsert the ratchets into the bracket, this

time with the letter "B" aligned with the dot stamped in the bracket. Reassemble the

transducer and bracket and place it against the transom. Again, check to see if the

transducer will adjust so its face is parallel with the ground. Repeat this process until

the transducers face will adjust so that it is parallel with the ground.

3

Page 4

Aligning ratchets on two-piece bracket:

The two-piece bracket includes four black plastic ratchets. The ratchets are used to align the transducer with the boat hull. Each ratchet has

the letters A-F molded into it.

1. Place two of the ratchets in each side of the bracket

with the letter "A" aligned with the alignment mark molded

into each bracket.

2. Now place the other two ratchets on

Alignment

mark

Bracket

3. Slide the transducer in the bracket

and temporarily slide the bolt through

the transducer bracket.

the transducer with the letter "A" aligned

in the 12 o'clock position on the trans-

ducer stem.

4. Hold the transducer assembly

against the transom. Look at the

transducer from the side. Try to

adjust the transducer so its face

is parallel to the ground. If it does,

then the "A" position is correct.

Ratchet

Transom

If the transducer will not adjust with its

face parallel to the ground, remove the

transducer and ratchets from the bracket. Reinsert the ratchets into the bracket,

this time with the letter "B" aligned with

the dot stamped in the bracket. Reassemble the transducer and bracket and place it

against the transom. Again, check to see if the transducer will adjust so its face is

parallel with the ground. Repeat this process until the transducers face will adjust so

that it is parallel with the ground.

4

Page 5

3. Assembling the Transducer bracket

After determining the correct position for the ratchets, loosely assemble the transducer and bracket assembly as shown in one of the two diagrams below.

One-piece bracket assembly:

Metal washer

Lock nut

Rubber washers

Metal washer

Ratchets

Bolt

Do not tighten the transducer bracket assembly until you have aligned the

transducer and bracket on the transom.

Two-piece bracket assembly:

Ratchets

Bolt

Small at washer

Thick rubber washer

Do not tighten the transducer bracket assembly until you have aligned the

transducer and bracket on the transom.

Large at

washer

Lock nut

5

Page 6

4. Aligning and Attaching the Transducer on the Transom

Adjust the transducer so that its "face" is parallel with the ground and its center line

is even with the bottom of the boat hull.

Transducer bracket

mounted too low.

Transom

Bottom of hull.

When mounting the transducer to the transom, there are two extremes you

should avoid, rst, do not let the edge of the mounting bracket extend below

the bottom of the hull, left image, above. Second, do not let the bottom of the

transducer rise above the bottom of the hull, right image, above.

The center line of the transducer

should be level with the bottom of

the boat hull and its "face" parallel

with the ground.

Transducer bracket

mounted too high.

Transom

Bottom of hull.

Transom

Transducer face

Do not over tighten

the transducer bracket

lock nut. If you do, the

transducer may not

"kick-up" if it strikes an

object in the water.

Bottom of hull.

For single frequency

transducers, with a

one-piece bracket,

assemble it with the

cable passing over

the bolt and through

the bracket, as shown

here.

6

Page 7

1. Hold the transducer and bracket assembly against the transom.

When the transducer and bracket

are properly aligned mark its posi-

tion on the hull.

2. Drill the mounting holes for the

transducer bracket. For the onepiece bracket use a #29 bit (for

the #10 screws). For the two-piece

bracket use a #20 bit (for the #12

screws).

Use the provided screws to secure the transducer assembly to the transom.

Be sure to use a below-waterline

marine grade sealant on all of the

transducer bracket screw holes.

When mounting a Skimmer transducer

to a boat with a veehull, make sure the

transducer center line is aligned to the

bottom of the boat hull, as shown here.

Water line

Clamp the transducer cable to

the transom near the transducer.

This will help keep the cable

secure.

If you drill a hole in the transom

for the transducer cable, make

sure it is located above the

waterline. Seal the hole with

an above- or below-waterline

marine grade sealant.

7

Page 8

If you drill a hole in the transom for the transducer cable, make sure it is located

above the waterline. Seal the hole with an above or below waterline marine grade

sealant. Route the transducer cable to the sonar unit. Make sure to leave some slack

in the cable near the transducer.

Use caution when routing the transducer cable near other wiring and cables. If you

need to drill a hole in the transom to pass the connector through, the hole size will

depend on the connector on the end of the transducer’s cable.

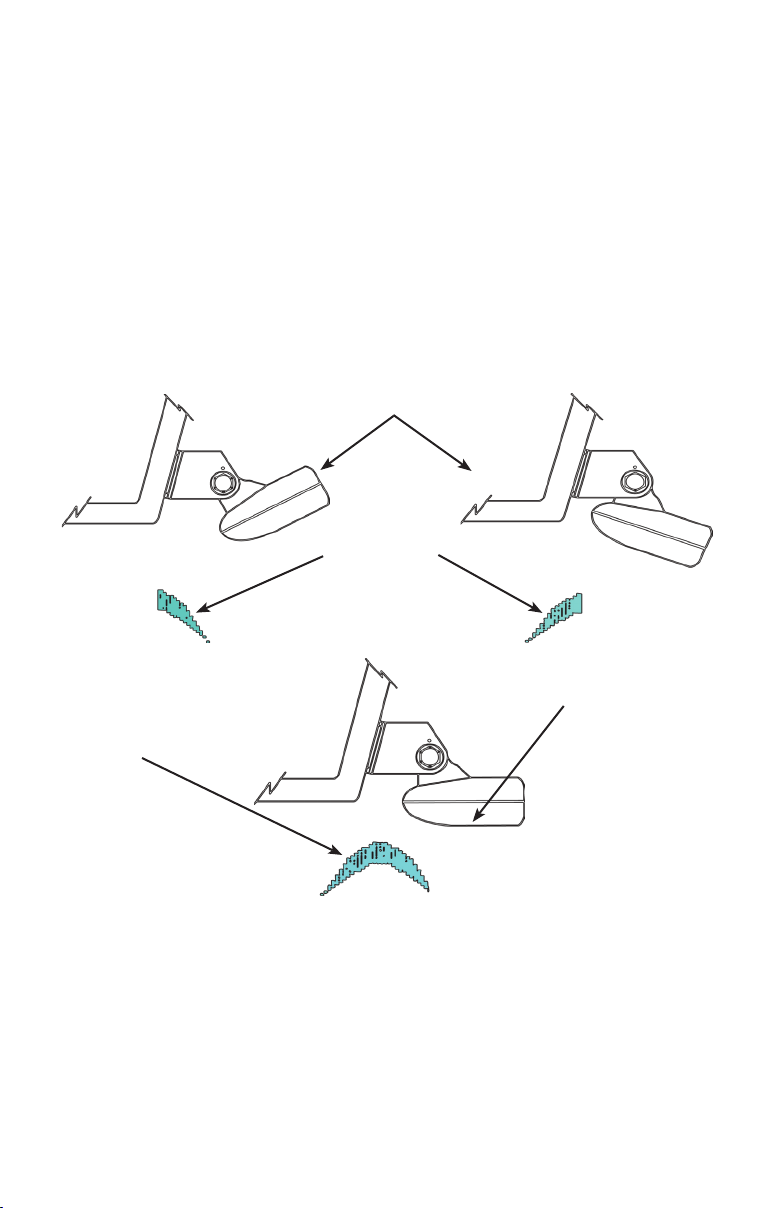

5. Make a test run to determine the results

At times you may need to adjust the transducer higher or lower. The slots in the

mounting brackets allow you to loosen the screws and slide the transducer up or

down.

Improper transducer angles

Partial sonar

sh arches

Transducer face parallel

with the bottom.

Full sonar sh arch

If the sonar screen is displaying partial sh arches, as shown in the previous top

two images, the transducer could be at an improper angle. Check the transducer

and make sure its face is parallel with the bottom, as shown in the bottom example.

If you frequently lose bottom signal lock the transducer may be coming out of the

water as the boat crosses waves or wakes.

Move the transducer a little lower in the water to see if that improves sonar perfor-

mance. When shing around underwater structure the transducer may be kicked up

from object strikes. If the transducer is being kicked up too often, try moving it a

little higher for more protection.

8

Page 9

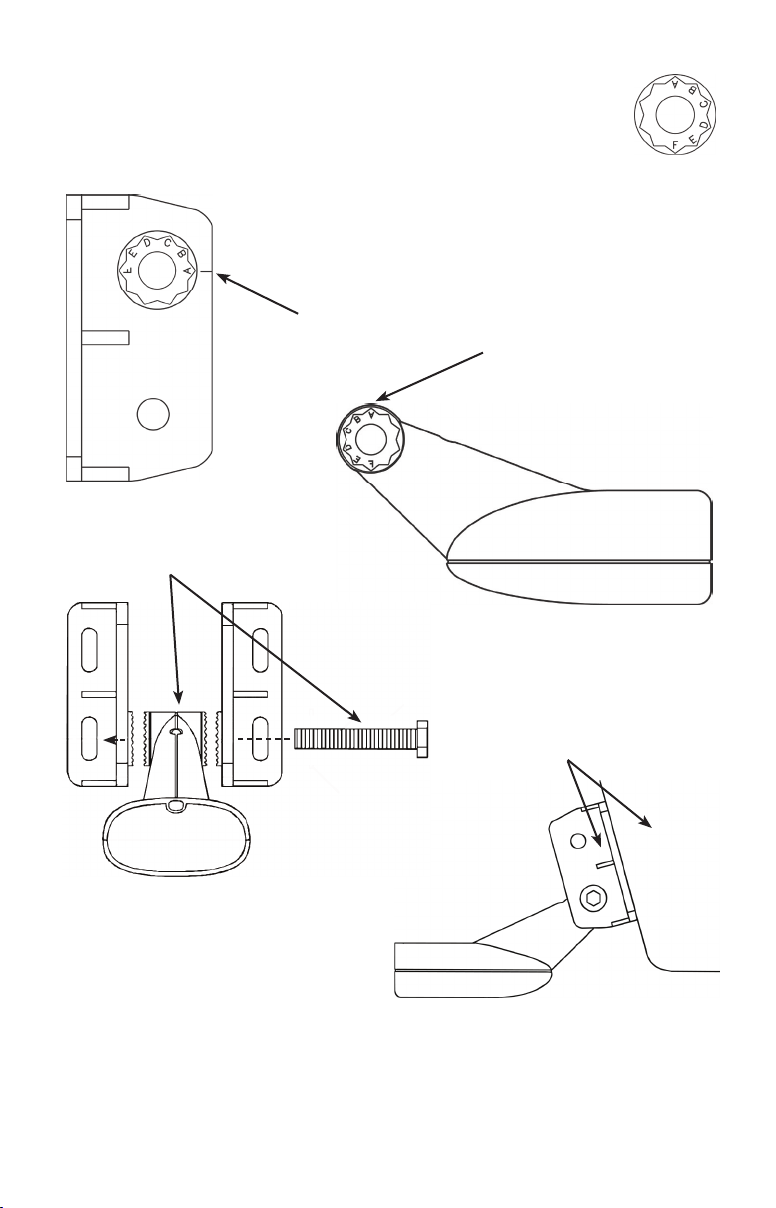

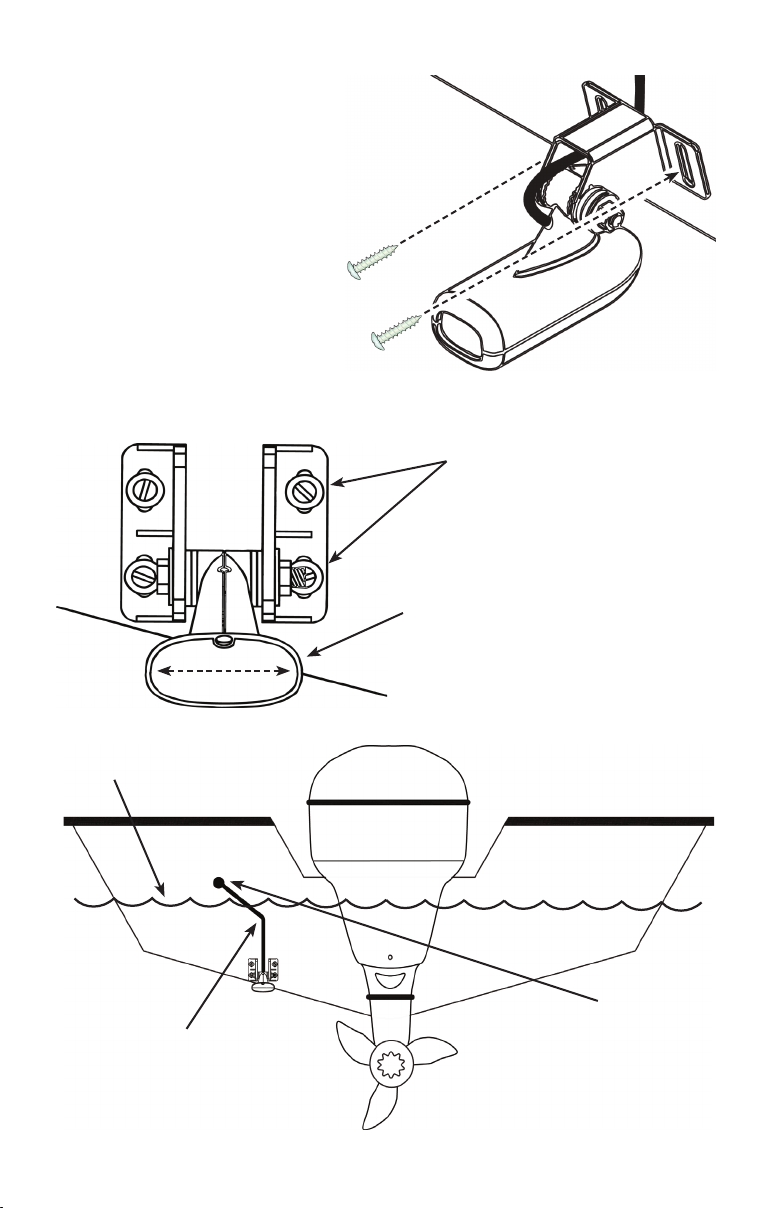

TMB-S trolling motor bracket installation

The TMB-S bracket is designed for one-piece bracket transducers only.

The TMB-S trolling motor bracket (Part No. 51-45) is an optional accessory and is

available through LEI Extras at www.lei-extras.com. The TMB-S bracket is used

to attach a one-piece bracket transducer to a trolling motor. If you regularly sh in

water with a lot of underwater structure, such as rocks, stumps and trees, you may

consider using a Pod transducer for trolling motor installation. Pod transducers cannot be "kicked up" by underwater structure.

Internal tooth washer

Plastic bracket

Bolt

Lock nut

Flat washer

Using the components supplied with the TMB-S bracket (adjustable strap, internal tooth washer and plastic bracket) attach it to the transducer as shown

in the diagram above.

Adjustable strap

Route the transducer cable along the trolling motor shaft. Use plastic ties

(not included) to secure

the cable to the shaft.

Slide the adjustable strap through the plastic bracket as shown above, left,

then slip the strap around the trolling motor as shown in the image, at right.

Position the transducer so its "face" is pointing straight down when the trolling motor is in the water. Tighten the adjustable strap securely to the trolling

motor. Make sure there is enough slack in the transducer cable for the trolling

motor to turn freely.

9

Page 10

Skimmer Transducer shoot-thru-hull installation

Before attempting any installation on boats with otation material sandwiched

within the hull, consult the boat manufacturer. In a shoot-thru-hull installation the

transducer is epoxied to the inside of the boat hull.

WARNING: Do not remove any material from the inner hull.

Careless grinding or cutting on the hull could damage the integrity of the hull. Contact the boat dealer or manufacturer to

conrm hull specications

.

Transducer

Transducer epoxied to hull.

The previous image shows a Skimmer transducer epoxied to a at, solid portion of the boat hull near the transom. The circled image is a close-up view of

the transducer epoxied to the hull.

On vee hulls try to place the transducer

where the dead rise is 10° or less.

Epoxy

Hull

NOTE: While you can epoxy a Skimmer transducer to the

inside of a boat hull, we recommend using a Pod transducer for this type of installation. Use care when mounting a

transducer inside a boat hull. Once epoxied into position,

the transducer can be very difcult to remove.

10

Page 11

A transducer can not shoot through wood or metal hulls. Wood and metal hulls

require either a transom mount or "thru-hull" installation. For shoot-thru-hull appli-

cations many boat hulls have a at keel pad that offers a good transducer mounting

surface.

If you are using a Skimmer transducer versus a Pod transducer for this installation,

make sure the Skimmer transducer is oriented so the nose of the transducer is facing

the bow (front) of the boat. Also, if the transducer has a built in temp sensor, it will

only show the temperature of the hull, not the water temp.

Before you epoxy the transducer to the hull, make sure the area is clean, dry and free

of oil or grease. The surface of the hull must be at so the entire transducer face is

in contact with the hull. Also, make sure the cable is long enough to reach the sonar

unit.

Sand both the inside surface of the hull,

1. Sand face

of transducer

and bottom of

hull.

where the transducer is to be epoxied, and

the face of the transducer.

Start with a rougher grit sandpaper, such

as 60 grit, and nish with a smoother grit,

such as 160 grit, sandpaper. Sand the inside surface of the hull until it is smooth

to the touch.

2. Apply epoxy to face

of transducer

and bottom of

hull.

The sanded area should be about 1-1/2

times the diameter of the transducer. After sanding, clean the hull and face of the

transducer with an alcohol wipe to remove

any sandpaper grit and dust.

3. Epoxy transducer to hull.

Epoxy

Apply a thin layer of epoxy (about 1-16"

or 1.5 mm) on the face of the transducer

and the sanded area on the hull. Make

sure there are no air pockets in the epoxy layers.

Hull

Press the transducer into the epoxy, twist-

To bow

ing and turning it to force any air bubbles

out from under the transducer face. Stop

pressing when it bottoms out on the hull.

Apply pressure to hold the transducer in place while the epoxy sets. Be careful not

to move the transducer while the epoxy is setting. Allow the epoxy to set before

moving the boat. When nished, the face of the transducer should be parallel with

the hull with a minimum amount of epoxy between the hull and transducer. After the

epoxy has set, route the transducer cable to the sonar unit.

11

Page 12

Pod Transducer installation instructions

The following instructions explain how to install a Pod transducer inside a hull or

on a trolling motor. Read the following instructions carefully before attempting any

installation. Use extreme care when mounting a transducer inside a boat hull. Once

epoxied into position, the transducer can be very difcult to remove.

NOTE: Transducer location and installation is one of the

most critical steps in sonar installation.

Pod Transducer shoot-thru-hull installation

Before attempting any installation on boats with otation material sandwiched within the hull, consult the boat manufacturer.

WARNING: Do not remove any material from the inner hull.

Careless grinding or cutting could damage the integrity of the

hull. Contact the boat dealer or manufacturer to conrm hull

specications

A transducer can not shoot through wood or metal hulls. Wood and metal hulls

require either a transom mount or "thru-hull" installation. For shoot-thru-hull appli-

cations many boat hulls have a at keel pad that offers a good transducer mounting

surface.

.

Transducer

Transducer epoxied to hull.

The previous image shows a Pod transducer epoxied to a at, solid portion of

the boat hull near the transom. The transducer should be installed as close to

the transom as possible, close to the center line.

Epoxy

Hull

Before you epoxy the transducer to the hull, make sure the area is clean, dry and free

of oil or grease. The surface of the hull must be at so the entire transducer face is

in contact with the hull. Also, make sure the cable is long enough to reach the sonar

unit before the transducer is epoxied into place.

12

Page 13

On vee hulls try to place the transducer

where the deadrise is 10° or less.

3. Epoxy transducer to hull.

Epoxy

1. Sand face

of transducer

and bottom of

hull.

2. Apply epoxy to face

of transducer

and bottom of

hull.

Sand both the inside surface of the hull,

where the transducer is to be epoxied,

and the face of the transducer.

You may want to start with a rougher

grit sandpaper, such as 60 grit, and nish with a smoother grit, such as 160 grit,

sandpaper. Sand the inside surface of the

hull until it is smooth to the touch.

The sanded area should be about 1-1/2

times the diameter of the transducer. After sanding, clean the hull and face of the

transducer with an alcohol wipe to remove any sandpaper grit and dust.

Apply a thin layer of epoxy (about 1-16"

or 1.5 mm) on the face of the transducer

and the sanded area on the hull. Make

sure there are no air pockets in the epoxy layers.

Press the transducer into the epoxy, twisting and turning it to force any air bubbles

out from under the transducer face. Stop

pressing when it bottoms out on the hull.

Hull

After the epoxy has set, route the

transducer cable to the sonar unit.

Apply pressure to hold the transducer in

place while the epoxy sets. Be careful not

to move the transducer while the epoxy

is setting. Allow the epoxy to set before

moving the boat.

When nished, the face of the transducer

should be parallel with the hull with a

minimum amount of epoxy between the

hull and transducer.

13

Page 14

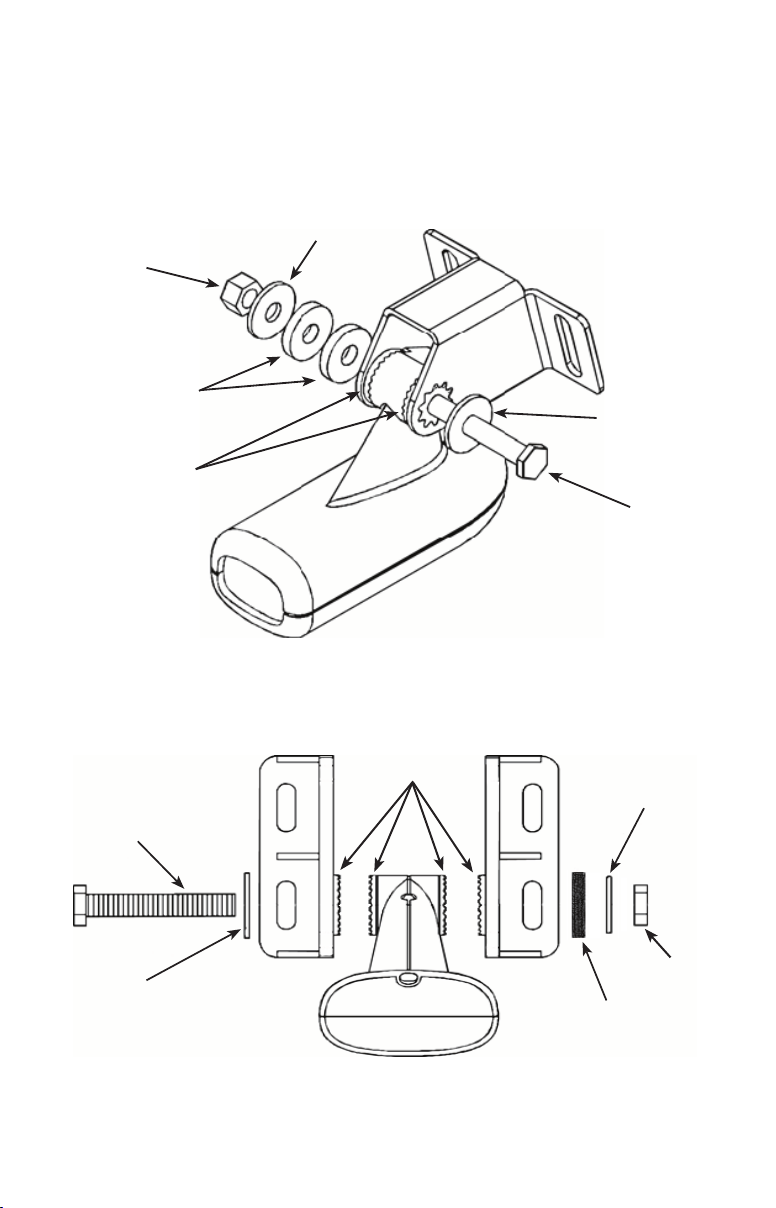

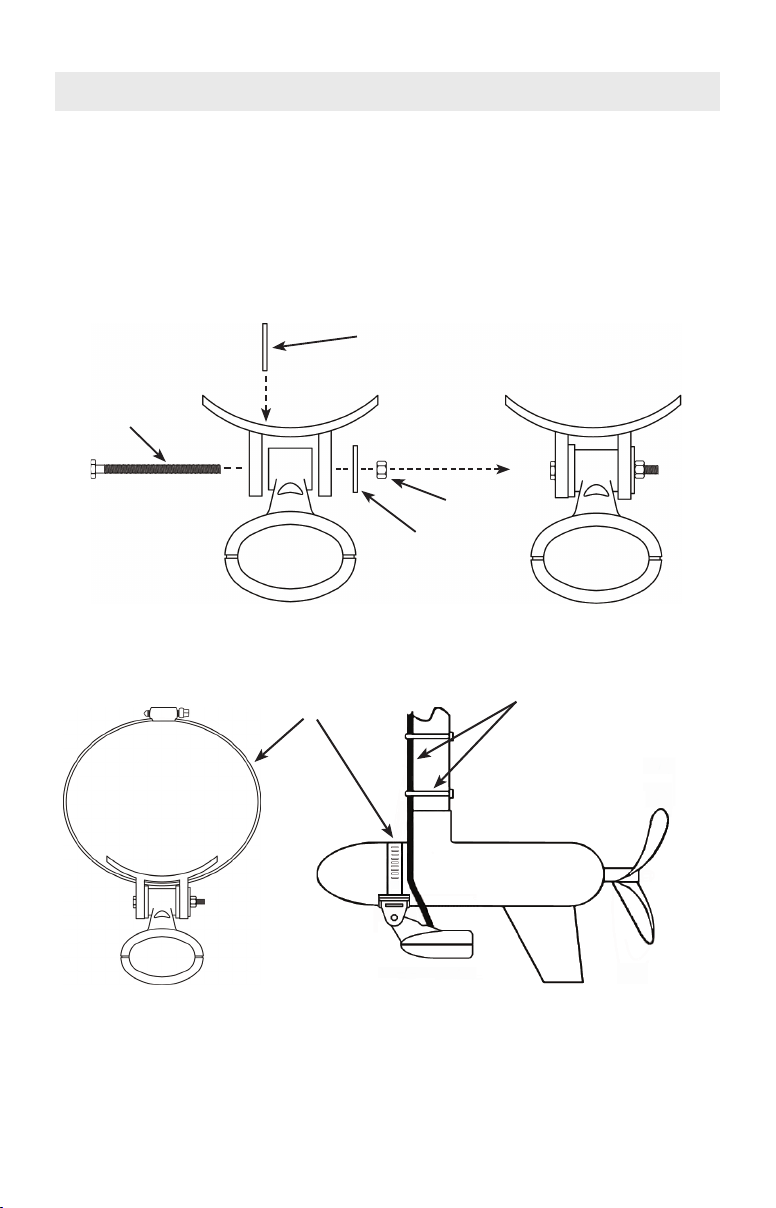

Pod Transducer trolling motor installation

The top of the

transducer is

curved to t

the contour

of the trolling

motor.

You will need a hose clamp large enough to

t over the trolling motor. The hose clamp

is NOT included with the Pod transducer.

Before you attach the transducer to the

trolling motor, make sure there is enough

slack in the transducer cable for the trolling

motor to turn freely.

1. Slide the hose clamp

through the Pod transducer

brackets, as shown below.

The transducer should be mounted ahead of the trolling motor n. Position

the transducer to so its face is pointing straight down when the trolling motor

Cable ties Cable ties

2. Slip the clamp around the trolling motor, as

shown below. Tighten the hose clamp securely to

the trolling motor.

is in the water.

Hose

clamp

Transducer

Route the transducer cable along the trolling motor shaft. Use plastic ties

(not included) to secure the cable to the shaft.

Hose

clamp

14

Page 15

Transducer maintenance

Periodically wash the face of the transducer with soap and water to remove any oil

lm or debris build-up. Oil and other materials on the transducer's face can hamper

its performance. Cleaning will ensure longevity and proper performance of the device.

15

Page 16

Mounting the Unit: Gimbal bracket or In-dash

The unit comes with a gimbal bracket so you can mount it on a dash. The unit also

ships with an in-dash template and four screws for in-dash installations. Determine

the mounting location for the unit. Screws to secure the gimbal bracket to a dash are

not included with the unit.

Gimbal bracket installation

NOTE: Before beginning any installation, read the

following instructions carefully and double check all

cable lengths to make sure the cables will reach the

power source, unit, GPS antenna-receiver module,

transducer, etc.

Holes in the gimbal bracket’s base allow for wood screw or through-bolt mounting.

When mounting the unit using the gimbal bracket, make sure there is enough clearance behind the unit to allow for tilting of the unit and connection of the various

cables.

The gimbal bracket arms

should slope toward the

front of the unit.

1. Use the gimbal bracket as a template

and mark the mounting holes, including

the center hole for the cables.

2. Drill a 1-inch (25.4 mm) hole for the sonar, power/data, Ethernet and network

cables. The large center hole in the gimbal bracket will be used to pass these

cables through.

16

Page 17

3. Use screws or bolts to secure the gimbal bracket to the mounting surface.

4. Pass all the cable connectors through the 1-inch hole in the center of the gimbal

bracket. Leave enough slack in the cables to allow for tilting of the unit.

17

Page 18

Gimbal bracket

knob

4. Secure the unit to the gimbal bracket using the gimbal bracket knobs.

Cable

connectors

Gimbal bracket

knob

Sockets

Sockets

5. Match up the cable connectors to the sockets on the back of the unit. Each cable

and socket is labeled. Attach the proper connector to each socket. Power up the unit

to make sure all the connectors are securely fastened to the proper socket.

18

Page 19

In-dash installation

The unit ships with an in-dash template and four #6 – 20 X 1-1/2" screws. Before

cutting any holes in the mounting surface make sure there is enough room to attach

the cable connectors behind the unit. Begin by taping the in-dash template to the

mounting surface.

Use a #31 (0.120") drill bit

for the four pilot holes.

The template included with your unit will have the proper measurements writ-

ten on it, including the size of the hole saw to use to drill the corner holes

shown in the following step. Cut only on the dotted lines indicated by the

template.

The four corner holes

are indicated by these

shaded areas.

Use a hole saw to drill the four corner holes indicated by the shaded areas

on the template above. Using a hole saw to cut the four corners will ensure

smoother, and more rounded, corners for the in-dash installation.

19

Page 20

To remove the rest of

the material from the

mounting surface (in-

dicated by the shaded

area) cut along these

dotted lines.

After cutting the four corner holes, use a saw to cut along the dotted lines

from hole to hole. Be sure to cut along the inner dotted line, not the outer

solid line.

This diagram shows the sequence for

securing the unit to the mounting surface.

1) Place the unit in the hole cut into the

mounting surface. 2) Use the provided

screws to secure the unit to the mounting

surface.

Mounting surface

3) The face of the unit may

Bezel

If water penetration is a concern, use a marine grade sealant between the unit

and mounting surface.

or may not have adhesive

strips around it. If it does,

peel the plastic cover from

the adhesive strips before

attaching the bezel. 4) Attach

the bezel to the unit.

20

Page 21

Connectivity

Combination Sonar/GPS units

Sonar Network

Power/Data

ENET (Ethernet)

GPS only units

Power/Data

ENET (Ethernet)

Network

21

Page 22

Power / Data cable wiring diagram

Unit

The yellow wire is the

Accessory Wake Up line.

Power cable (3 wire)

Data cable (5 wire)

Power/Data cable

Red (+) wire

with fuse and

fuse holder.

Black (-) wire

Battery

The diagram above shows how the Power/Data cable connects to power.

Yellow TX (+)

Blue TX (-)

Orange RX (+)

Green RX (-)

Shield (ground)

The Data cable wires are used for

the NMEA 0183 and RS-422 hook

up; also, RS-232 and RS-422 for

HDS-8 and HDS-10 models. Refer

to the detailed drawings on the fol-

lowing pages.

22

Page 23

Multiple unit wiring diagram with devices

Ethernet cables

NEP-1

Fuse and fuse holder. The

red wire from each power ca-

ble should be fused between

the device and the battery.

The diagram above shows two HDS units and an LBS-1 connected via an

NEP-1. The power cable from each device contains a yellow wire. The yellow

wire is the Accessory Wake Up line. Connect the yellow wires together. When

the Accessory Wake Up line is used to connect units with the accessory wake

up feature, you can power up certain connected devices from one location,

including digital sonar optimizers and expansion ports.

The four yellow wires (Aces-

sory Wake Up lines) from

each power cable should be

LBS-1

wired together.

23

Page 24

Data cable wiring diagram: HDS-8 & HDS-10 units

NMEA 0183 wiring (data cable)

To exchange NMEA 0183 data, the HDS-8 and HDS-10 units have a NMEA 0183

version 2.0 (RS-422) communication port. Serial Communications Port one (Com

1) can be used to transmit or receive NMEA format data. Two RS-232 ports (Com 1

and Com 2) also are available via software selection. These ports transmit or receive

NMEA data.

The ve wires for the serial communications ports (Data cable) are combined with

the Power cable to form the Power/Data cable.

• Com 1 (RS-422) uses the yellow and blue wires to transmit, the

orange and green wires to receive and the shield (bare) wire for

signal ground.

Power/Data cable

Com 1 to unit

(RS-422)

Yellow TX (+)

Blue TX (-)

Orange RX (+)

Green RX (-)

Shield (ground)

24

Receive (+)

Receive (-)

Transmit (+)

Transmit (-)

Ground

Data cable

To device

Page 25

Data cable wiring diagram: HDS-8 & HDS-10 units

NMEA 0183 wiring (data cable)

• Com 1 (RS-232) uses the yellow wire to transmit, orange wire to

receive and shield (bare) wire for signal ground.

• Com 2 (RS-232) uses the blue wire to transmit, green wire to

receive and shield (bare) wire for signal ground.

Power/Data cable

Com 1 to unit

(RS-232)

Com 2 to unit

(RS-232)

Yellow TX

Orange RX

Shield (ground)

Blue TX

Green RX

Shield (ground)

Receive

Transmit

Ground

Receive

Transmit

Ground

Data cable

To device

To device

25

Page 26

Data cable wiring diagram: HDS-5 & HDS-7 units

NMEA 0183 wiring (data cable)

To exchange NMEA 0183 data, the HDS-5 and HDS-7 units have a NMEA 0183

version 2.0 (RS-422) communication port. Serial Communications Port one (Com

1) can be used to transmit or receive NMEA format data. The ve wires for the serial communications ports (Data cable) are combined with the Power cable to form

the Power/Data cable.

• Com 1 (RS-422) uses the yellow and blue wires to transmit, the

orange and green wires to receive and the shield (bare) wire for

signal ground.

Data cable

Power/Data cable

Com 1 to unit

(RS-422)

Yellow TX (+)

Blue TX (-)

Orange RX (+)

Green RX (-)

Shield (ground)

26

Receive (+)

Receive (-)

Transmit (+)

Transmit (-)

Ground

To device

Page 27

Blank Page

27

Page 28

www.lowrance.com

*988-0176-06*

Visit our website:

© Copyright 2008

All Rights Reserved

Navico Holding AS

28

Loading...

Loading...