Page 1

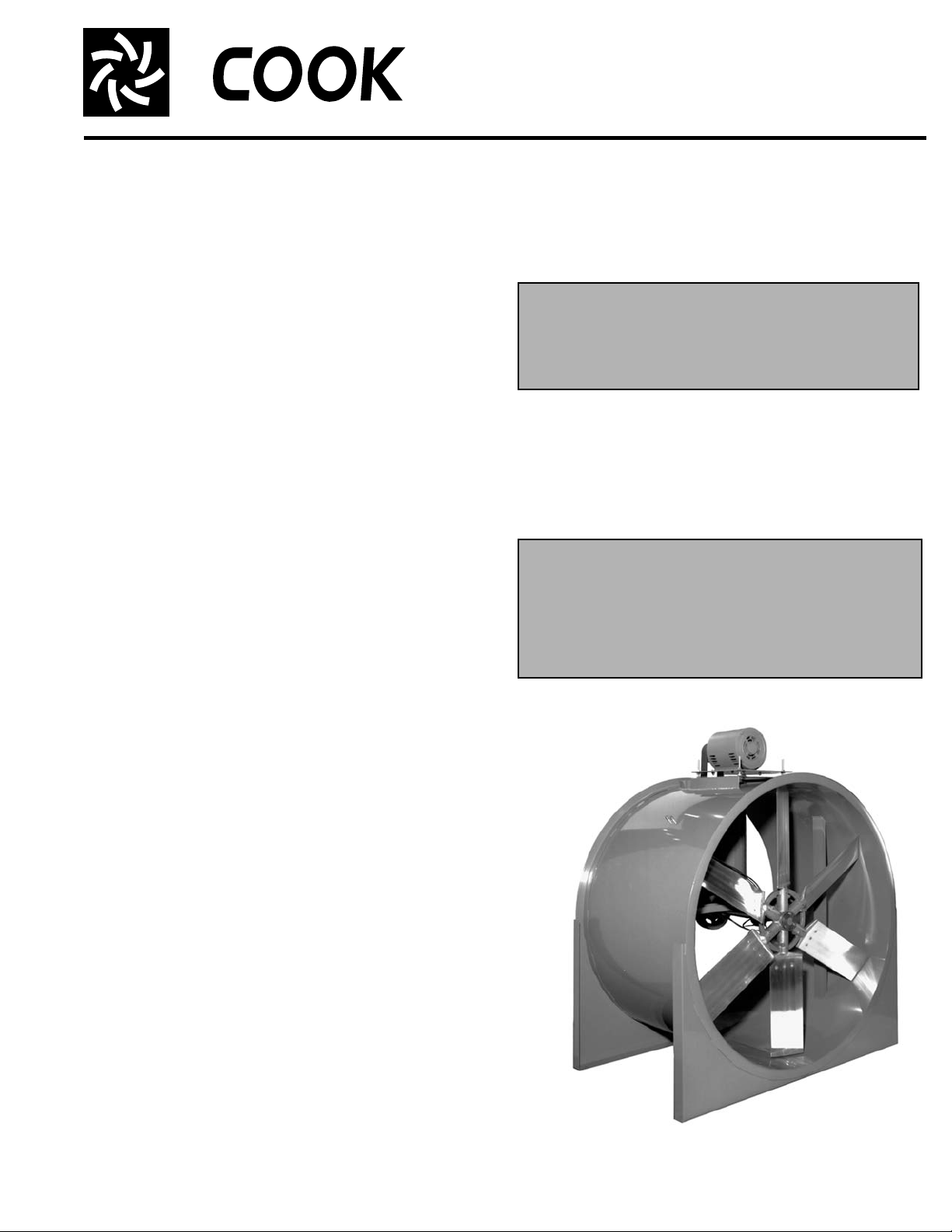

Propeller Inline

Tube Axial Fans

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation

and maintenance procedures for standard units of the

Tube Axial Fans:

• AD

• ED

• TID

• TIB

Carefully read this publication prior to any installa-

tion or maintenance procedure.

Loren Cook catalog, Propeller Inline, provides additional

information describing the equipment, fan performance,

available accessories and specification data.

For additional safety information, refer to AMCA publication 410-96, Safety Practices for Users and Installers of

Industrial and Commercial Fans.

All of the publications listed above can be obtained from

Loren Cook Company by phoning (417)869-6474, extension 166; by FAX at (417)832-9431; or by e-mail at

info@lorencook.com.

For information and instructions on special equipment,

contact Loren Cook Company at (417)869-6474.

Receiving and Inspection

Carefully inspect the fan and accessories for any damage and shortage immediately upon receipt of the fan.

• Turn the propeller by hand to ensure it turns freely an

does not bind.

• Record on the Delivery Receipt any visible sign of damage.

Handling

Lift tube axial fans by placing a sling around the fan

housing or mounting brackets. Never lift by the shaft or

motor.

Storage

If the fan is stored for any length of time prior to installation,

rotate the propeller several revolutions every three to five

days. This keeps a coating of grease on all internal bearing

parts. Block propeller to prevent natural rotation and store it

in its original shipping crate and protect it from dust, debris

and the weather.

Outdoor Storage

To maintain good working condition of the fan when it is

stored outdoors or at a construction site, follow the additional instructions below.

• Coat the shaft and bearings with grease or rust preventative compound to help seal out moisture.

• Periodically rotate the propeller and dampers (if sup-

plied) to keep a coating of grease on all internal bearing

parts.

• Periodically inspect the fan to prevent damaging conditions.

• Block propeller to prevent natural rotation.

• Cover the unit with some type of weather cover to prevent moisture, corrosion, dirt or dust accumulation.

WARNING

This unit has rotating parts. Safety precautions

should be exercised at all times during installation,

operation, and maintenance.

ALWAYS disconnect power prior to working on fan.

Installation

Motor Installation

To prevent damage to the fan during shipping, motors 5

HP and larger, and extremely heavy motors (cast iron or

severe duty) are shipped loose and must be field mounted

by bolting the motor on the motor mounting plate in the

existing mounting slots.

Personal Safety

Disconnect switches are recommended. Place

the disconnect switch near the fan in order that

the power can be swiftly cut off in case of an

emergency, and in order that maintenance personnel are provided complete control of the

power source.

EDB

Page 2

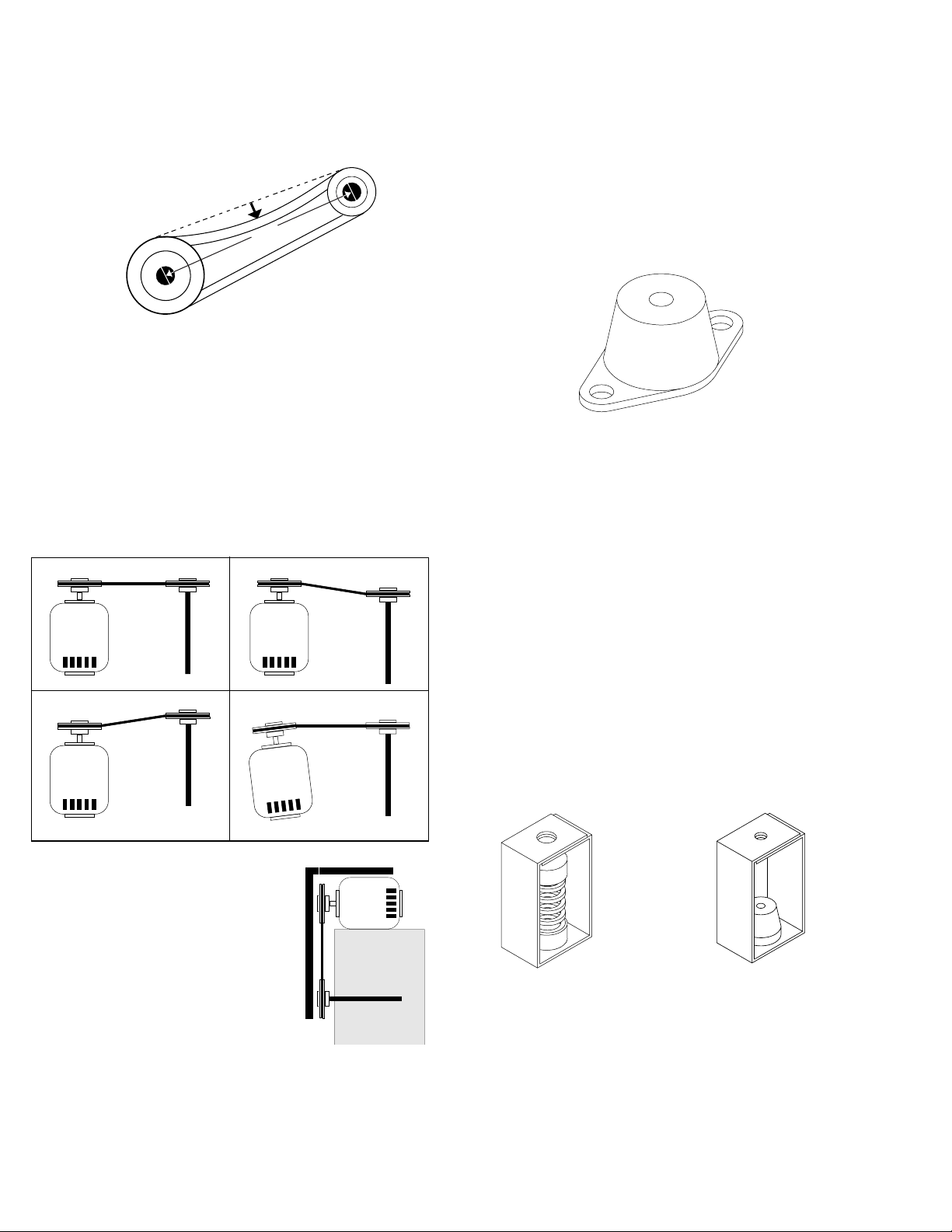

Belt and Pulley Installation

1 foot

1/4 inch

If your fan is a direct drive, proceed to Isolator Installation.

Belt tension is determined by the sound of the belts when

the fan is first started. The belts will produce a loud squeal,

which dissipates after the fan is operating at full capacity. If

belt tension is too tight or too loose, lost efficiency and damage can occur.

Figure 1

Do not change the pulley pitch diameter to change tension. The change will result in a different fan speed.

a. Loosen the motor plate adjustment nuts on motor base

and move motor plate in order that the belts can easily

slip into the grooves on the pulleys. Never pry, roll, or

force the belts over the rim of the pulley.

b. Adjust the motor plate until proper tension is reached.

For proper tension, a deflection of approximately 1/4”

per foot of center distance should be obtained by firmly

pressing the belt. Refer to Figure 1.

c. Lock the motor plate adjustment nuts in place.

d. Ensure pulleys are properly aligned. Refer to Figure 2.

Correct

Incorrect Incorrect

Incorrect

Isolator Installation

Floor Mounted Fans

If the fan is being mounted to a metallic base, isolation

pads should be used between the unit and its base to

reduce vibration and noise.

Floor Mounted Rubber-In-Shear (RIS) Isolators

a. Elevate the fan to provide room to insert isolators

between the fan and foundation and block in position.

b. Position isolators under the fan and secure bolts.

c. Remove blocks and allow the fan to rest on floor. Isola-

tors must be installed on a level surface so leveling

should not be required.

d. Secure isolators to mounting surface.

Floor Mounted Rubber-In-Shear Isolator

Ceiling Mounted Fans

The most common method used to mount a ceiling fan to

its support structure is with ceiling mounted spring and rubber-in-shear (RIS) isolators.

a. Elevate the fan to operating height and brace.

b. Attached threaded rod to overhead support structure

directly above each mounting hole. The rod should

extend to within a few feet of the fan.

c. Attach isolator to end of threaded rod using a nut on

each side of the isolator bracket.

d. Insert another section of threaded rod through the fan

mounting hole and isolator.

e. Attach two nuts to threaded rod in isolator.

f. Place adjusting nut and locking nut on threaded rod

near fan mounting bracket.

g. Alternately rotate adjusting nut at each mounting loca-

tion until the fan weight is uniformly transferred to the

isolators. Remove bracing.

h. Turn locking nut and secure firmly in place against

mounting bracket.

Figure 2

Pulley Alignment

Pulley alignment is adjusted by loosening the motor pulley setscrew and by

moving the motor pulley on the motor

shaft or by moving the entire motor

along the motor mounting bracket.

Figure 2 illustrates correct and incorrect pulley alignment. A recommended

method of inspecting the pulley alignment is shown in Figure 3. With the

shorter leg of a carpenter’s square or

Figure 3

other straight edge lying along the case of the motor, adjust

the position of the motor pulley (or the motor) until the

longer leg of the square is parallel to the belt.

Ceiling Mounted Spring Isolator

Rubber-In-Shear Ceiling Isolators

Fan Installation

If your fan is a direct drive, proceed to Wiring Installation

before completing attachment to the duct.

Floor Mounted Units

a. Bolt down the fan.

b. When the fan is secure, attach the duct to the flanges.

c. Drill holes through the flanges to match the duct, then

bolt the duct and flanges together.

2

Page 3

Ceiling Mounted Units

a. Mount the fan to its support structure.

b. When all the installation supports have been removed

and the fan is supported only by the permanent structure, attach the duct work.

c. Drill holes through the flanges to match the duct, then

bolt the duct and flanges together.

Wiring Installation

All wiring should be in accordance with local ordinances

and the National Electrical Code, NFPA 70. Ensure the

power supply (voltage, frequency, and current carrying

capacity of wires) is in accordance with the motor nameplate. Refer to the Wiring Diagrams, next page.

Lock off all power sources before unit is wired to

power source.

Leave enough slack in the wiring to allow for motor

movement when adjusting belt tension. Some fractional

motors have to be removed in order to make the connection with the terminal box at the end of the motor.

Personal Safety

Disconnect switches are recommended. Place the

disconnect switch near the fan in order that the

power can be swiftly cut off in case of an emergency, and in order that maintenance personnel are

provided complete control of the power source.

Follow the wiring diagram in the disconnect switch

and the wiring diagram provided with the motor. Correctly label the circuit on the main power box and

always identify a closed switch to promote safety (i.e.,

red tape over a closed switch).

Belt Drive Fans

a. Run wire to the fan. Restrain wire to the housing or

motor plate to prevent it from being pulled into the shaft.

b. Pull the wire into the motor. For final connections, fol-

low the wiring diagram provided on the motor.

Direct Drive Fans

a. Drill a hole through the fan housing at a convenient

location and pull the wire through it or pull the wire

through the intake duct.

b. Pull the wire into the motor wiring box. Restrain the

wire to prevent it from being pulled into the shaft.

c. For final connections, follow the wiring diagram pro-

vided on the motor.

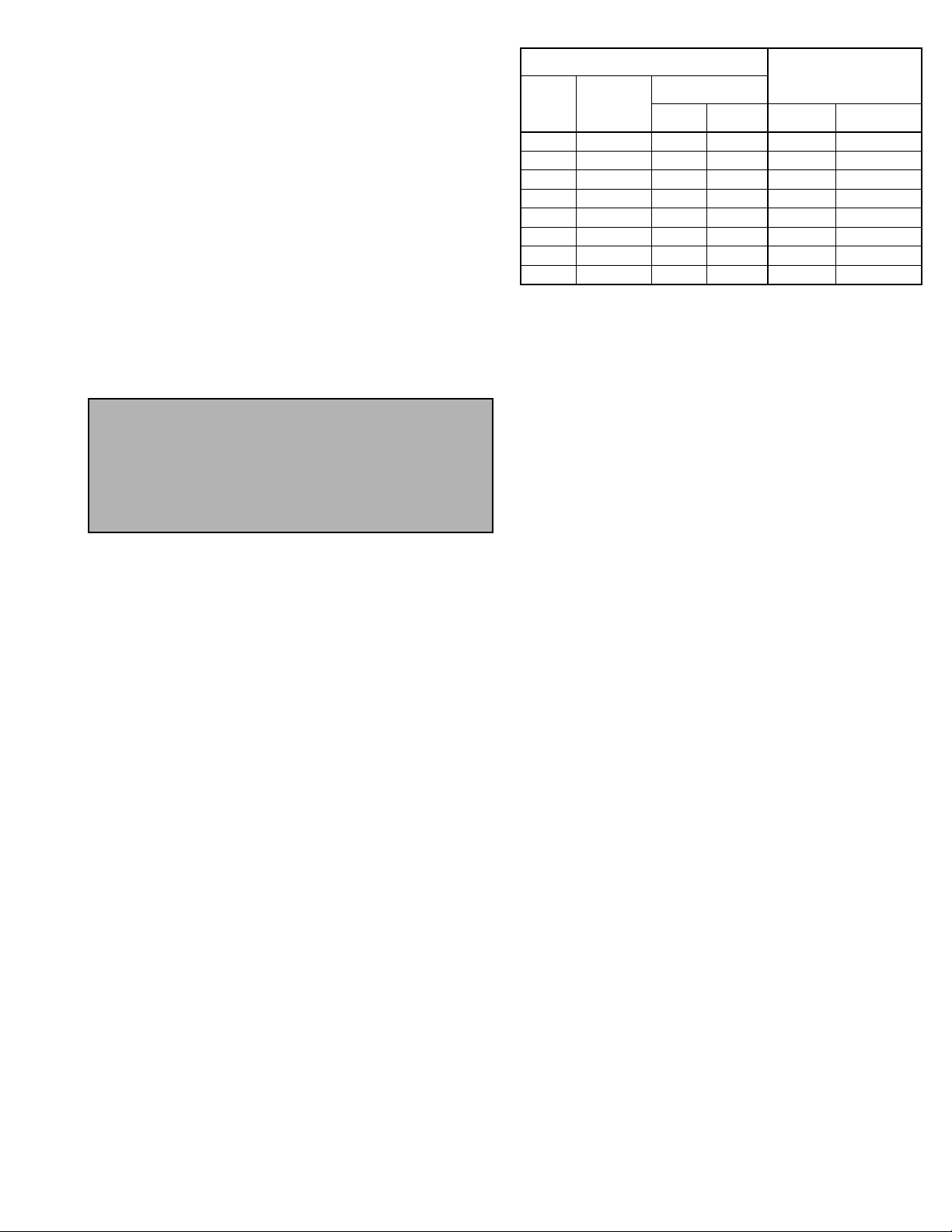

Final Installation Steps

a. Inspect fasteners and setscrews, particularly fan

mounting and bearing fasteners, and tighten according

to the recommended torque shown in the table, Rec-

ommended Torque for Setscrews/Bolts.

b. Inspect for correct voltage with voltmeter.

c. Ensure all accessories are installed.

d. Test the fan to be sure the rotation is the same as indi-

cated by the arrow marked Rotation.

Do not allow the fan to run in the wrong direction.

This will overheat the motor and cause serious damage. For 3-phase motors, if the fan is running in the

wrong direction, check the control switch. It is possible to interchange two leads at this location so that the

fan is operating in the correct direction.

Recommended Torque for Setscrews/Bolts (IN/LB.)

Setscrews

Size

No.10 3/32” 28 33 3/8”-16 240

1/4” 1/8” 66 80 1/2”-13 600

5/16” 5/32” 126 156 5/8”-11 1200

3/8” 3/16” 228 275 3/4”-10 2100

7/16” 7/32” 348 384 7/8”-9 2040

1/2” 1/4” 504 600 1”-8 3000

5/8” 5/16” 1104 1200 1-1/8”-7 4200

3/4” 3/8” 1440 1800 1-1/4”-7 6000

Key Hex

Across

Flats

Recommended

Torque

Min. Max. Size

Hold Down Bolts

Wrench

Torque

Operation

Pre-Start Checks

a. Lock out all the primary and secondary power sources.

b. Inspect fasteners and setscrews, particularly those

used for mounting the unit, and tighten if necessary.

c. Inspect belt tension and pulley alignment. (Remember,

if belt tension is correct, a loud squeal occurs as the

fan increases to full power.)

d. Inspect motor wiring.

e. Ensure the belt touches only the pulleys.

f. Rotate the prop to ensure it does not rub against the

venturi.

g. Ensure fan and ductwork are clean and free of debris.

h. Test the fan to ensure the rotation of the propeller is

the same as indicated by the rotation label.

i. Close and secure all access doors.

j. Restore power to unit.

Start Up

Turn the fan on. In variable speed units, set the fan to its

lowest speed. Inspect for the following:

• Direction of rotation.

• Excessive vibration.

• Unusual noise.

• Bearing noise.

• Improper belt alignment or tension (listen for a continu-

ous squealing noise).

• Improper motor amperage or voltage.

If a problem is discovered, immediately shut off the

fan. Lock out all electrical power and check for the

cause of the trouble. Refer to Troubleshooting, page 6.

Inspection

Inspection of the fan should be conducted at the first 30

minute, 8 hour and 24 hour intervals of satisfactory opera-

tion. During the inspections, stop the fan and inspect as per

directions below.

30 Minute Interval

Inspect bolts, setscrews, and motor mounting bolts.

Adjust and tighten as necessary.

8 Hour Interval

Inspect belt alignment and tension. Adjust and tighten as

necessary.

24 Hour Interval

Inspect belt tension. Adjust and tighten as necessary.

3

Page 4

Wiring Diagrams

Single Speed, Single Phase Motor

Ground A

L

T-1

T-4

Ground B

When ground is required, attach to ground A or B with no. 6 thread forming

Line

L

1

2

Wiring Diagrams

3 Phase, 9 Lead Motor

Y-Connection

Low Voltage

208/230 Volts

4

5

6

3

1

9

728

L2L

L

1

To reverse, interchange any 2 line leads.

3

High Voltage

460 Volts

456

789

3

12

L2L

L

3

1

3 Phase, 9 Lead Motor

Delta-Connection

Low Voltage

208/230 Volts

7

6

1

L

1

screw. To reverse, interchange T-1 and T-4.

2 Speed, 2 Winding, Single Phase Motor 2 Speed, 1 Winding, 3 Phase Motor

Ground A

T-1

T-4

Ground B

High Speed

Low Speed

L

1

Line

L

2

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-1 and T-4 leads.

Motor

To reverse, interchange any 2 line leads. Motors require magnetic control.

High Speed

1

Together

2

3

L

4

L

5

6

L

1

Motor

2

Line

3

Single Speed, Single Phase, Dual Voltage 2 Speed, 2 Winding, 3 Phase

Ground A

L

T-5

J-10

Link A

Link B

Low Voltage

Ground B

Line

L

1

T-5

J-10

2

Ground B

When ground required, attach to ground A or B with No. 6 thread forming

screw. To reverse, interchange T-5 and J-10 leads.

Ground A

Link A & B

L

Line

L

1

2

To reverse: High Speed-interchange leads T11 and T12.

Low Speed-interchange leads T

line leads.

and T2. Both Speeds-interchange any 2

1

Typical Damper Motor Schematic

Fan

Motor

L3

L2

L1

8

4

2

L

L

3

2

Low Speed

9

5

3

1

2

3

4

5

6

High Voltage

460 Volts

789

456

3

12

L1L

L

3

2

L

1

L

2

Line

L

3

Open

For 3 phase, damper motor voltage should be the same between L1 and

L

. For single phase application, disregard L3. *Damper motors may be

2

Transformer**

Transformer**

available in 115, 230 and 460 volt models. The damper motor nameplate

voltage should be verified prior to connection. ** A transformer may be provided in some installations to correct the damper motor voltage to the

specified voltage.

Damper

Motor*

Second

Damper

Motor

Maintenance

Establish a schedule for inspecting all parts of the fan.The

frequency of inspection depends on the operating conditions and location of the fan.

Inspect fans exhausting corrosive or contaminated air

within the first month of operation. Fans exhausting contaminated air (airborne abrasives) should be inspected every

three months. Clean the propeller and air inlets if material

build-up is excessive. Excessive build-up can cause imbalance and failure of the propeller. Always clean the entire

propeller as partial cleaning will cause imbalance and fan

failure.

Regular inspections are recommended for fans exhaust-

ing non-contaminated air.

It is recommended the following inspections be con-

ducted twice per year.

• Inspect bolts and setscrews for tightness. Tighten as

necessary.

• Inspect belt wear and alignment. Replace worn belts

with new belts and adjust alignment as needed. See

Belt and Pulley Installation, page 1.

• Bearings should be inspected as recommended in the

Conditions Chart, page 5.

• Inspect for cleanliness. Clean exterior surfaces only.

Removing dust and grease on motor housing assures

proper motor cooling.

4

Page 5

Lubricants

Loren Cook Company uses petroleum lubricant in a lithium base conforming to NLGI grade 2 consistency. Other

grades of grease should not be used unless the bearings

and lines have been flushed clean. If another grade of

grease is used, it should be lithium-based.

A NLGI grade 2 grease is a light viscosity, low-torque,

rust-inhibiting lubricant that is water resistant. Its temperature range is from -30°F to +200°F and capable of intermittent highs of +250°F.

Motor Bearings

Motor bearings are pre-lubricated and sealed. Under normal conditions they will not require further maintenance for

a period of ten years. However, it is advisable to have your

maintenance department remove and disassemble the

motor, and lubricate the bearings after three years of operation in excessive heat and or in a contaminated airstream

consisting of airborne abrasives.

Conditions Chart

RPM Temperature

100 Up to 120°F Clean 6 to 12 months

500 Up to 150°F Clean 2 to 6 months

1000 Up to 210°F Clean 2 weeks to 2 months

1500 Over 210°F Clean Weekly

Any

Speed

Any

Speed

Any

Speed

Any

Speed

Up to 150°F Dirty 1 week to 1 month

Over 150°F Dirty Daily to 2 weeks

Any Temperature Very Dirty Daily to 2 weeks

Any Temperature

Fan

Status

Extreme

Conditions

Greasing

Interval

Daily to 2 weeks

Fan Bearings

Fan bearings are lubricated through a grease connector

and should be lubricated by the schedule, Conditions Chart,

shown above.

For best results, lubricate the bearing while the fan is rotating. Slowly pump grease into the bearing until a slight bead

forms around the bearing seals. Excessive grease can burst

seals thus reduce bearing life.

In the event the bearing cannot be seen, use no more than

three injections with a hand-operated grease gun.

Motor Services

Should the motor prove defective within a one-year

period, contact your local Loren Cook representative or your

nearest authorized electric motor service representative.

Changing Shaft Speed

All belt driven Tube Axial fans with motors up to and

including 5HP are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

a. Loosen setscrew on driver (motor) pulley and remove

key, if equipped.

b. Turn the pulley rim to open or close the groove facing. If

the pulley has multiple grooves, all must be adjusted to

the same width.

c. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM limits

of the fan and the horsepower limits of the motor are maintained.

Pulley and Belt Replacement

a. Clean the motor and fan shafts.

b. Loosen the motor plate mounting bolts to relieve the

belt tension. Remove the belt.

c. Loosen the pulley setscrews and remove the pulleys

from the shaft.

If excessive force is required to remove the pulleys, a three-jaw puller can be used. This tool,

however, can easily warp a pulley. If the puller is

used, inspect the trueness of the pulley after it is

removed from the shaft. The pulley will need

replacement if it is more than 0.020 inch out of

true.

d. Clean the bores of the pulleys and place a light coat of

oil on the bores.

e. Remove grease, rust and burrs from the shaft.

f. Place fan pulley on the fan shaft and the motor pulley

on the motor shaft. Damage to the pulleys can occur

when excessive force is used in placing the pulleys on

their respective shafts.

g. After the pulleys have been correctly placed back onto

their shafts, tighten the pulley setscrews.

h. Install the belts on the pulleys. Align and adjust the

belts to the proper tension as described in Belt and Pul-

ley Installation, page 1.

Bearing Replacement

The fan bearings are pillow block ball bearings.

a. Loosen the motor plate mounting bolts and remove the

drive belts.

b. Gain access to the interior of the fan. Remove duct

work and/or guards as necessary.

c. Remove the propeller from the shaft.

d. Remove the bearing cover from the bearing plate.

e. Remove the four bearing hold-down bolts and then

remove the shaft, bearings, and driven sheave from the

unit as an assembly.

f. Mark the location of the bearings and sheave on the

shaft. This will aid the reassembly.

g. Remove the anti-corrosion coating from the shaft with a

suitable degreaser and then remove the pulley from the

shaft.

h. Remove the bearings from the shaft using a bearing

puller.

i. Clean the shaft and bearing bores thoroughly.

j. Place the bearings into position making sure they are

not on a worn section of the shaft. Tapping the inner

ring face with a soft driver may be required.

Do not hammer on the housing. This my cause

damage to the bearings.

5

Page 6

k. Install the pulley in the correct location on the shaft.

Secure the bearing hold-down bolts, but do not fully

tighten.

l. Align the setscrews on the top bearing with those on

the lower bearing. Tighten one of the setscrews on

each bearing.

m. Rotate the shaft to allow the bearing outer rings to find

their center of free movement. If your fan is supplied

with a lube line, attach it to the grease connection.

n. Install the propeller on the shaft and adjust bearing

position to center the propeller in the opening.

o. Tighten hold-down bolts to proper torque. Refer to the

torque chart on page 3.

p. Turn the shaft by hand. Resistance should be the same

as it was before hold-down bolts were fully tightened.

r. Re-assembly the fan.

After 24 hours of continuous operation, tighten the setscrews to the appropriate torque. This assures the full locking of the inner race to the shaft. Ensure the socket key or

driver is in good condition with no rounded corners. The key

should be fully engaged in the setscrew and held squarely

to prevent the rounding out of the setscrew socket when

applying maximum torque.

Propeller and Shaft Replacement Precautions

• If the shaft is dropped and bent, it may cause unbalanced operation of the fan.

• When handling the propeller separately from the shaft,

place a support through the hub for lifting, making sure

not to injure the finished bore of the propeller.

• Never allow the propeller to rest its entire weight on the

blades. The propeller and shaft can be lifted by slings

around the shaft on each side of the propeller so the

propeller is supported by its hub.

• If using a chain to lift the propeller, make sure there is

sufficient padding on the shaft and propeller. This prevents the scoring of the shaft or injury to the propeller.

The chain or cable should be spread with timbers, or

braced by some other method to prevent damage to the

propeller side plates.

Troubleshooting

Problem and Potential Cause

Low Capacity or Pressure

•Incorrect direction of rotation. Make sure the fan rotates in same direction

as the arrows on the motor or belt drive assembly.

•Poor fan inlet conditions. There should be a straight clear duct at the in-

let.

•Improper propeller alignment.

Excessive Vibration and Noise

•Damaged or unbalanced propeller.

•Belts too loose; worn or oily belts.

•Speed too high.

•Incorrect direction of rotation. Make sure the fan rotates in same direction

as the arrows on the motor or belt drive assembly.

•Bearings need lubrication or replacement.

•Fan surge.

Overheated Motor

•Motor improperly wired.

•Incorrect direction of rotation. Make sure the fan rotates in same direction

as the arrows on the motor or belt drive assembly.

•Cooling air diverted or blocked.

•Improper inlet clearance.

•Incorrect fan RPMs.

•Incorrect voltage.

Overheated Bearings

•Improper bearing lubrication

•Excessive belt tension.

6

Page 7

1

2

3

4

Airflow

ADD, EDD, and TID Parts List

1

2

1

2

ADD

TID

4

3

Airflow

4

Airflow

3

EDD

1

4

Airflow

3

2

Part No.

1 Motor (as required) Motor (as required) Motor (as required)

2 Cast Aluminum Propeller Extruded Aluminum Propeller Welded Steel Propeller

3 Housing/Power Assembly Housing/Power Assembly Housing/Power Assembly

4 Motor Plate Motor Plate Motor Plate

ADD Sizes 12-24 EDD Sizes 24-48 TID Sizes 20-60

Description

7

Page 8

1

2

3

4

5

7

8

9

10

1

12

6

Airflow

ADB, EDB, and TIB Parts List

1

12

2

3

4

5

1

2

5

3

12

4

11

10

9

8

ADB

12

11

10

9

111

10

9

8

7

1

Airflow

2

3

4

8

6

5

EDB

7

Airflow

6

TIB

Parts No.

7

Airflow

ADB 16-48 EDB 24-60 TIB 20-72

6

Description

1 Motor Motor Motor

2 Motor Plate Motor Plate Motor Plate

3 Motor Plate Studs (4) Motor Plate Studs (4) Motor Plate Studs (4)

4 Shaft Shaft Shaft

5 Weather Cover (optional) Weather Cover (optional) Weather Cover (optional)

6 Cast Aluminum Propeller Extruded Aluminum Propeller Welded Steel Propeller

7 Bearings Bearings Bearings

8 Housing/Power Assembly Housing/Power Assembly Housing/Power Assembly

9 Bearing Cover Bearing Cover Bearing Cover

10 Driven Sheave Driven Sheave Driven Sheave

11 Belt Set Belt Set Belt Set

12 Driver Sheave Driver Sheave Driver Sheave

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein. For a period of one (1)

year after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will be paid by you. This warranty is granted only

to the original purchaser placing the fan in service. This warranty is void if the fan or any part thereof has been altered or modified from its original design or has been

abused, misused, damaged or is in worn condition or if the fan has been used other than for the uses described in the company manual. This warranty does not cover

defects resulting from normal wear and tear. To make a warranty claim, notify Loren Cook Company, General Offices, 2015 East Dale Street, Springfield, Missouri 658034637, explaining in writing, in detail, your complaint and referring to the specific model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written

complaint, you will be notified, within thirty (30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This warranty gives

only the original purchaser placing the fan in service specifically the right. You may have other legal rights which vary from state to state.

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

lorencook.com

8

Propeller Inline IOM - June 2005

Loading...

Loading...