Loren Cook CPL Installation Manual

CPL

Centrifugal Plenum Fans

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains the installation, operation and maintenance instructions for standard units of the

CPL-Centrifugal Plenum Fans. Carefully read this publication prior to any installation or maintenance procedure.

Loren Cook catalog, CPL, provides additional information describing the equipment, fan performance, available accessories, and specification data.

For additional safety information, refer to AMCA publication 410-96, Safety Practices for Users and Installers of Industrial and Commercial Fans.

All of the publications listed above can be obtained from Loren Cook Company by phoning 417/869-6474, extension 166; by FAX at 417/832-9431; or by e-mail at info@lorencook.com.

For information on special equipment, contact Loren Cook Company Customer Service Department at 417/8696474.

Receiving and Inspection

Carefully inspect the fan and accessories for any damage and shortage immediately upon receipt of the fan.

•Turn the wheel by hand to ensure it turns freely and does not bind.

•Inspect dampers (if supplied) for free operation of all moving parts.

•Record on the Delivery Receipt any visible sign of damage.

Handling

Lift the fan by the base or lifting eyes on the housing.

Never lift by the shaft, wheel, or motor.

WARNING

This unit has rotating parts. Safety precautions should be exercised at all times during installation, operation, and maintenance.

ALWAYS disconnect power prior to working on fan.

Storage

If the fan is stored for any length of time prior to installation, completely fill the bearings with grease or moistureinhibiting oil (refer to Lubricants on page 5). Rotate the wheel several revolutions every three to five days to keep a coating of grease on all internal bearing parts.

Store the fan in its original crate and protect it from dust, debris and the weather.

Outdoor Storage

To maintain good working condition of the fan when it is stored outdoors, follow the additional instructions below.

•Coat the shaft with grease or a rust preventative compound.

•Wrap bearings for weather protection.

•Cover the entire fan to prevent the accumulation of dirt and moisture in the fan.

•Periodically rotate the wheel and operate the dampers (if supplied).

•Periodically inspect the fan to prevent damaging conditions.

Personal Safety

Disconnect switches are recommended. Place the disconnect switch near the fan in order that the power can be swiftly cut off in case of an emergency, and in order that maintenance personnel are provided complete control of the power source.

Installation

Most motors are shipped mounted on the fans with belts and drives installed. However, extremely heavy motors and drives are shipped separately and some motors are shipped separately due to height limitations. These motors and drives will require field installation. Please refer to page 4.

CPL

Foundation

This fan requires a strong, level foundation of reinforced poured concrete. A correctly designed concrete foundation provides the best means for mounting floor units. The foundation’s size is determined by fan size and arrangement, motor size and position, and the specific location of the installation.

Use the following guidelines to calculate foundation size:

•The overall dimensions of the foundation should extend at least 6 inches beyond the outline of the fan and its motor.

•The weight of the foundation should be 2 to 3 times the weight of the fan and its motor.

Isolation

Isolation Base

If supplied, mount the fan on the rigid isolation base that runs the entire length of the fan base angle.

When the motor is not an integral part of the unit, mount the fan and its motor to a common rigid base running the full length of the fan and motor.

The base must have sufficient rigidity to resist belt pull and prevent drive distortion which can lead to excessive belt and bearing wear. Isolators should be located between this rigid base and the floor.

Note

Although a certain amount of vibration is inherent in operating centrifugal fans, extreme vibration is a serious problem that may cause structural and mechanical failure.

Isolators

Floor Mounted Spring Isolators

•Mount fan and motor on an isolation base (if supplied).

•Elevate fan (or isolation base) to operating height and insert blocks to hold in position.

•Position isolators under the fan and/or isolation base and vertically align by inserting leveling bolt through mounting holes in the fan or the base. The isolator must be installed on a level surface.

•Adjust the isolators by turning the leveling nut counter clockwise several turns at a time alternately on each isolator until the fan weight is transferred onto the isolators and the fan raises uniformly off the blocks. Then remove the blocks.

•Turn lock nut onto leveling bolt and secure firmly in place against the top of the mounting flange or frame.

•Secure isolators to mounting surface.

Spring Isolator |

Rubber-In-Shear Isolator |

Figure 1 - Floor Mount Isolators

Floor Mounted Rubber-In-Shear (RIS) Isolators

•Mount fan and motor on an isolation base (if supplied).

•Elevate fan to provide room to insert isolators between base and foundation or between the fan and foundation and block in position.

•Position isolators under isolation base or fan and secure bolts.

•Remove blocks and allow unit to rest on floor. Isolators must be installed on a level surface (leveling should not be required).

•Secure isolators to mounting surface.

Duct Installation

Efficient fan performance relies on proper installation. If the fan has an open inlet (no duct work), be sure it is placed one fan wheel diameter away from walls and bulk-

heads. Refer to figure 2.

Refer to the CPL catalog for discharge wall proximity factors.

Minimum

1 wheel

1 wheel diameter

diameter

Figure 2 - Non-ducted Inlet Clearance

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper fan performance. This clearance should be verified before initial start-up since rough handling during shipment could cause a shift in fan components. Refer to wheel/inlet drawing for correct overlap.

Adjust the overlap by loosening the wheel hub and moving the wheel along the shaft to obtain the correct value.

A uniform radial gap (space between the edge of the cone and the edge of the inlet) is obtained by loosening the inlet cone bolts and repositioning the inlet cone.

|

|

|

|

|

|

|

|

|

|

|

|

Size |

Overlap |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

|

|

|

|

|

|

|

|

|

|

120 |

|

|

|

|

|

|

|

|

|

|

|

|

|

135 |

5/8” |

|

|

|

|

|

|

|

|

|

|

|

|

150 |

|

|

|

|

|

|

|

|

|

|

|

|

|

165 |

|

|

|

|

|

|

|

|

|

|

|

|

|

180 |

|

|

|

|

|

|

|

|

|

|

|

|

|

195 |

|

|

|

|

|

|

|

|

|

|

|

|

|

210 |

|

|

|

|

|

|

|

|

|

|

|

|

|

225 |

3/4” |

|

|

|

|

|

|

|

|

|

|

|

|

245 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

270 |

|

|

|

|

|

|

|

|

|

|

|

|

|

300 |

|

|

|

|

|

|

|

|

|

|

|

|

|

330 |

1” |

|

|

|

|

|

|

|

|

|

|

|

|

365 |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

402 |

|

|

|

|

|

|

|

|

|

|

|

|

|

445 |

|

Radial Clearance |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

490 |

|

|||

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Overlap |

540 |

1-1/4” |

||

|

|

|

|

|

|

|

|

|

600 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

Wheel/Inlet Overlap |

|

|

|

|

660 |

|

|||||||

|

|

|

|

730 |

|

||||||||

Wiring Diagrams

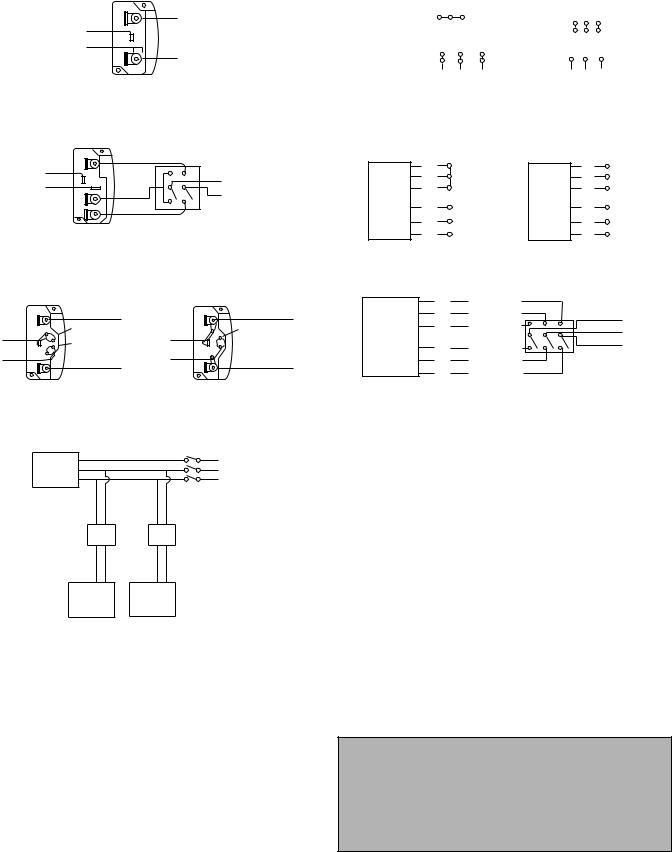

Single Speed, Single Phase Motor

Ground A

L1

T-1

Line

T-4

L2

Ground B

When ground is required, attach to ground A or B with no. 6 thread forming screw. To reverse, interchange T-1 and T-4.

2 Speed, 2 Winding, Single Phase Motor

Ground A

High Speed

T-1

T-4 L1 Line

L2

Low Speed

Ground B

When ground required, attach to ground A or B with No. 6 thread forming screw. To reverse, interchange T-1 and T-4 leads.

Wiring Diagrams

3 Phase, 9 Lead Motor

Low Voltage

208/230 Volts

4 |

5 6 |

|

1 |

2 |

3 |

7 |

8 |

9 |

L1 L2 L3

To reverse, interchange any 2 line leads.

High Voltage

460 Volts

4 5 6

7 8 9

1 2 3

L1 L2 L3

2 Speed, 1 Winding, 3 Phase Motor

High Speed |

|

Low Speed |

L1 |

|

1 |

|

|

1 |

|

2 |

Together |

2 |

L2 Line |

|

3 |

|

|

3 |

L3 |

Motor |

L1 |

|

Motor |

|

4 |

|

4 |

|

|

5 |

L2 |

Line |

5 |

Open |

6 |

L3 |

|

6 |

|

To reverse, interchange any 2 line leads. Motors require magnetic control.

Single Speed, Single Phase, Dual Voltage

|

Ground A |

|

|

Ground A |

|

L1 |

|

L1 |

|

T-5 |

Link A |

|

T-5 |

Link A & B |

Link B Line |

Line |

|||

J-10 |

Low Voltage L |

2 |

J-10 |

L |

|

|

|||

|

|

|

2 |

|

Ground B |

|

|

Ground B |

|

When ground required, attach to ground A or B with No. 6 thread forming screw. To reverse, interchange T-5 and J-10 leads.

2 Speed, 2 Winding, 3 Phase

|

T3 |

Low Speed |

|

|

|

T2 |

Low Speed |

L1 |

|

|

T1 |

Low Speed |

Line |

|

Motor |

L2 |

|||

|

T |

High Speed |

L3 |

|

|

11 |

High Speed |

|

|

|

T |

|

|

|

|

12 |

High Speed |

|

|

|

T |

|

|

|

|

13 |

|

|

|

To reverse: High Speed-interchange leads T11 and T12.

Low Speed-interchange leads T1 and T2. Both Speeds-interchange any 2 line leads.

Typical Damper Motor Schematic

Fan |

L3 |

|

L2 |

||

Motor |

||

L1 |

||

|

Transformer** |

Transformer** |

|

Damper |

Second |

|

Damper |

||

Motor* |

||

Motor |

||

|

For 3 phase, damper motor voltage should be the same between L1 and L2. For single phase application, disregard L3. *Damper motors may be available in 115, 230 and 460 volt models. The damper motor nameplate voltage should be verified prior to connection. **A transformer may be provided in some installations to correct the damper motor voltage to the specified voltage.

Wiring Installation

All wiring should be in accordance with local ordinances and the National Electrical Code, NFPA 70. Ensure the power supply (voltage, frequency, and current carrying capacity of wires) is in accordance with the motor nameplate.

Lock off all power sources before unit is wired to power source.

Leave enough slack in the wiring to allow for motor movement when adjusting belt tension. Some fractional motors have to be removed in order to make the connection with

the terminal box at the end of the motor. To remove motor, remove bolts securing motor base to power assembly. Do not remove motor mounting bolts.

Personal Safety

Disconnect switches are recommended. Place the disconnect switch near the fan in order that the power can be swiftly cut off in case of an emergency, and in order that maintenance personnel are provided complete control of the power source.

Loading...

Loading...