Page 1

2.

3.

2.

1.

1.

1.

2.

3.

9.

8.

6.

7.

4.

5.

ERV Evaporator Coil Supplement

ENERGY RECOVERY VENTILATOR

INSTALLATION, OPERATION, AND MAINTENANCE MANUAL

This publication contains supplemental installation, operation and maintenance instructions for an ERV-with optional

evaporator coil.

Carefully read this publication and the installation, operation, and maintenance instruction for standard units of the

ERV- Energy Recovery Ventilators publication prior to any

installation or maintenance procedure.

Loren Cook catalog, ERV , provides additional information

describing the equipment, fan performance, available accessories,

and specification data.

For additional safety information, refer to AMCA Publication

410-96, Safety Practices for Users and Installers of Industrial and

Commercial Fans .

All of the publications listed above can be obtained from Loren

Cook Company by phoning (417)869-6474, extension 166; by FAX

at (417)832-9431; or by e-mail at info@lorencook.com.

For information on special equipment, contact Loren Cook Company Customer Service Department at (417)869-6474.

Mounting

Position the coil such that the suction header is at the entering air-side of the coil and the distributor tubes are at the leaving

air-side of the coil. This orientation provides counterflow heat

exchange which is required for proper coil performance.

The suction connection is located at the bottom of the coil

when properly installed.

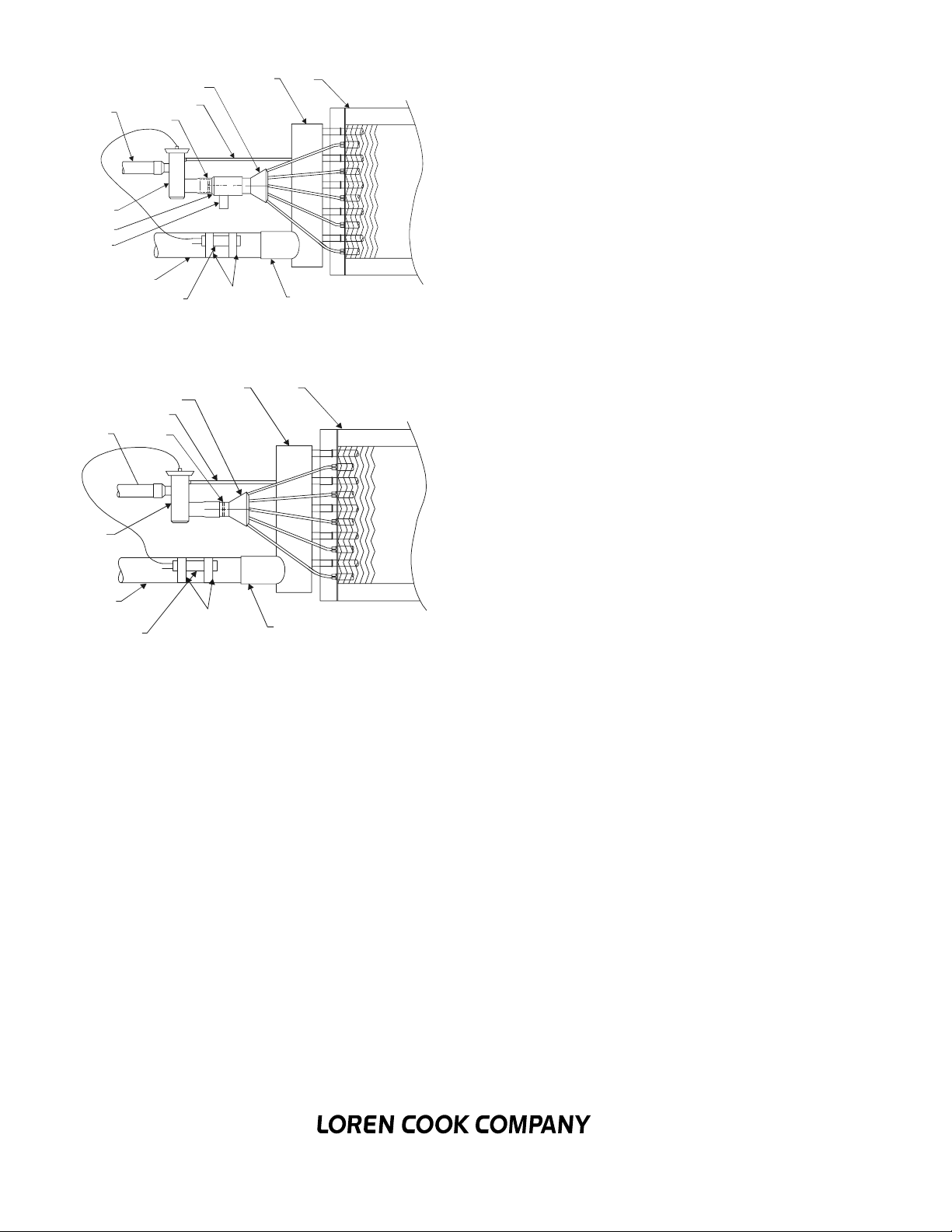

See Figure 1 - Evaporator Coils.

Coil Types

Model EN

coils are used for

applications where

capacity control is

not required. Single or multiple distributors are available depending on the number of circuits

required. Model EN evaporators utilize dual suction connections

when multiple distributors are used.

EJ coils come with interlaced circuiting. This form of capacity control utilizes two distributors with each feeding every other

tube in the first row of the coil. Each distributor has a separate

suction connection.

EN

Figure 1 - Evaporator Coils

EJ

Installation

Inspect the

refrigerant distributor and verify that

the nozzle is in

place. The nozzle

is generally held in

place by a retaining ring or it is an

integral part of the

distributor itself

(see Figure 2 Distributor). If a

hot gas bypass kit

was ordered with

the coil, the nozzle

Retainer

Ring

Figure 2 - Distributor

Figure 3 - Hot

Gas Bypass Kit

Nozzle

Distributor

will be located in it rather than the distributor (see Figure 3 - Hot

Gas Bypass Kit).

All field brazing and welding should be performed using high

quality materials and an inert gas purge (such as nitrogen) to

reduce oxidation of the internal surface of the coil.

If a hot gas bypass kit was ordered with the coil install it now.

Complete installation instructions are in the box that contains the

hot gas bypass kit. Align the side port with the hot gas line prior to

brazing into place.

Connect the suction line and suction connection.

Install the expansion valve. Follow the expansion valve manufacturer’s recommendations for installation to avoid damaging the

valve. If the valve is externally equalized, use a tubing cutter to cut

off the plugged end of the factory installed equalizer line. Next, use

a de-burring tool to remove any loose metal from the equalizer line

and attach it to the expansion valve. If the valve is internally equalized, the factory installed equalizer line can be left as is or it can be

cut back and sealed.

The expansion valve’s remote sensing bulb should be

securely strapped to the horizontal run of the suction line at the 3 or

9 o’clock position and insulated.

Connect the liquid line to the expansion valve. Pressurize the

coil, expansion valve assembly and suction connection to 100 psig

with dry nitrogen or other suitable gas. The coil should be left pressurized for a minimum of 10 minutes.

If the coil holds pressure, the hook-up can be considered leak

free. If the pressure drops by 5 psi or less, repressurize the coil and

wait another 10 minutes. If the pressure drops again, there are

more than likely one or more small leaks, which should be located

and repaired. Pressure losses greater than 5 psi would indicate a

larger leak, which should be isolated and repaired. Be sure to check

valves and fittings as potential sites for leakage or bleed. If the coil

is found to be leaking, contact your local representative. Unauthorized repair of the coil may void the coil’s warranty (see warranty

policy on back cover).

Use a vacuum pump to evacuate the coil and any interconnecting piping that has been open to atmosphere. Measure the vacuum in the piping using a micron gauge located as far from the

pump as possible (the vacuum at the pump will be greater than the

rest of the system). Evacuate the coil to 500 microns or less then

close the valve between the pump and the system. If the vacuum

holds to 500 microns or less for one minute, the system is ready to

be charged or refrigerant pumped down in another portion of the

system can be opened to the coil. A steady rise in microns would

indicate that moisture is still present and that the coil should be further vacuumed until the moisture has been removed.

10. Failure to obtain a high vacuum is indicative of a great deal

of moisture or a small leak. Break the vacuum with a charge of dry

nitrogen or other suitable gas and recheck for leaks (soapy water

works well). If no leaks are found, continue vacuuming the coil until

the desired vacuum is reached.

11. All field piping must be self-supporting.

Page 2

g

y

4.

3.

2.

1.

2.

3.

1.

12. Refer to Figure 4 - Hot Gas Bypass Kit Installed and Fig-

ure 5 - General Diagram, for general piping.

Liquid Line

Expansion Valve

Hot Gas B

Hot Gas Side Port

-Pass

Remote Sensing Bulb

Equalizer Line

Suction Line

Nozzle

Distributor

Suction Header

Straps

Coil

Suction Connection

Figure 4 - Hot Gass Bypass Kit Installed

Liquid Line

Expansion Val v e

Distributor

Equal izer Line

Nozzle

Suction Head er

Coil

Operation

Proper air distribution is vital to coil performance. Air flow

anywhere on the coil face should not vary by more than 20%.

Air velocities should be maintained between 200 and 550

feet per minute.

The drain pan should be designed and installed such that

there is no standing water.

Maintenance

Filters should be inspected on a regular basis and changed

as needed. Maintaining clean filters is a cost-effective way to help

maintain maximum coil performance and service life.

Periodic inspection of the coil for signs of corrosion and for

leaks is recommended. Small leaks can be detected using a

Halide torch. Repair and replacement of the coil and the connecting piping, valves, etc., should be performed as needed by a qualified individual(s).

Should the coil surface need cleaning, caution should be

exercised in selecting the cleaning solution as well as the cleaning

equipment. Improper selection can result in damage to the coil

and/or health hazards. Clean the coil from the leaving air-side so

that foreign material will be washed out of the coil rather than

pushed further in. Be sure to carefully read and follow the manufacturer’s recommendations before using any cleaning fluid.

The use of filter-dryers in the system piping is recommended

along with a sight glass that has a moisture indicator. Replace the

filter dryer(s) as needed.

Note: Refrigerant conversions are beyond the scope of this

manual and should only be performed by qualified parties.

Suction Line

Remote Sensin

Bulb

Straps

Figure 5 - General Diagram

Suc tion Connection

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

lorencook.com

2

ERV Evaporator Coil IOM Supplement- December 2002

Loading...

Loading...