Page 1

Laboratory Exhaust

Vari-Plume® and Laboratory Exhaust Products

SUPPLEMENTAL INSTALLATION AND MAINTENANCE MANUAL

This publication contains supplemental installation and

maintenance instructions for Vari-Plume

Exhaust units:

• CPSLE • QMXLE • TCNHBLE

• CAVP • QMXVP

Carefully read this publication prior to any installation or

maintenance procedure. Refer to the appropriate Installation,

Operation, and Maintenance Manual for items not specifically

covered here, such as handling, storage, start-up, etc.

Loren Cook brochure, Vari-Plume

vides additional information describing the equipment, fan perfo rmance, available accessories, and specification data.

For additional safety information, refer to AMCA Publication

410-96, Safety Practices for Users and Installers of Industrial and

Commercial Fans.

WARNING

This unit has rotating parts. Safety preca utions sho uld

be exercised at all times during installation, operation,

and maintenance.

ALWAYS disconnect power prior to working on fan.

®

®

and Laboratory

Laboratory Exhaust, pro-

Handling and Lifting

Always lift fan by lifting lugs. Never lift unit by shaft, motor,

housing, or nozzle.

The units may be shipped in sections and each section should

be lifted into place using the provided lifting lugs. If the unit is to

be lifted assembled, lift the unit with lifting lugs attached to the fan

housing using a spreader bar as required to ensure no damage is

incurred on the nozzle assembly.

All Vari-Plume® and Laboratory Exhaust units are designed to

be self-supporting, without the use of guy wire, when installed

according to the instructions within this document. The roof curb

must be securely installed prior to fan installation according to the

curb manufacturer’s recommendations.

Unit Assembly

If unit is shipped in sections, assemble unit starting at the low-

est level moving up the assembly. Each section should have a

pre-installed gasket that must be present to ensure proper sealing

of unit. If the gasket is damaged or missing, caulk may be used to

seal the sections by applying between the bolted sections. Once

the gasket/caulk has been verified, assemble the sections and

bolt together with the provided ha rd w are .

Installation

The unit should be installed on a curb/base that is securely

attached to the roof structure per contract documents and local

codes. If the curb is provided by Loren Cook, the curb should be

attached per the provided submittal document by welding to the

roof structure.

For curb mounted assemblies, the unit should be securely fas-

tened to the curb using minimum ¼” x ¾” sheet metal screws

using pre-punched holes in the curb cap. If pre-punch ed holes

are not provided, use a minimum of 2 screws per side and a maximum of 12” spacing.

Drain Connections

Loren Cook lab exhaust fans all have drains as standard construction features. These drains should be properly connected

to a drainage system to ensure that the run off from the units is

disposed of properly. The connection should include a trap system (Figure 5) that is sized adequately to not allow for air leakage under the system pressure. Dimension A and B should be

double the total static pressure for the unit.

FIGURE 5

Finger-Tight Plug

Clean Out

Finger-Tight Plug

B

CPSLE

CAVP

Drain Pipe

Drain Trap

QMXVP

(6" Min)

QMXLE

Clean Out

Slope To

Drain

TCNHBLE

A

(6" Min)

Page 2

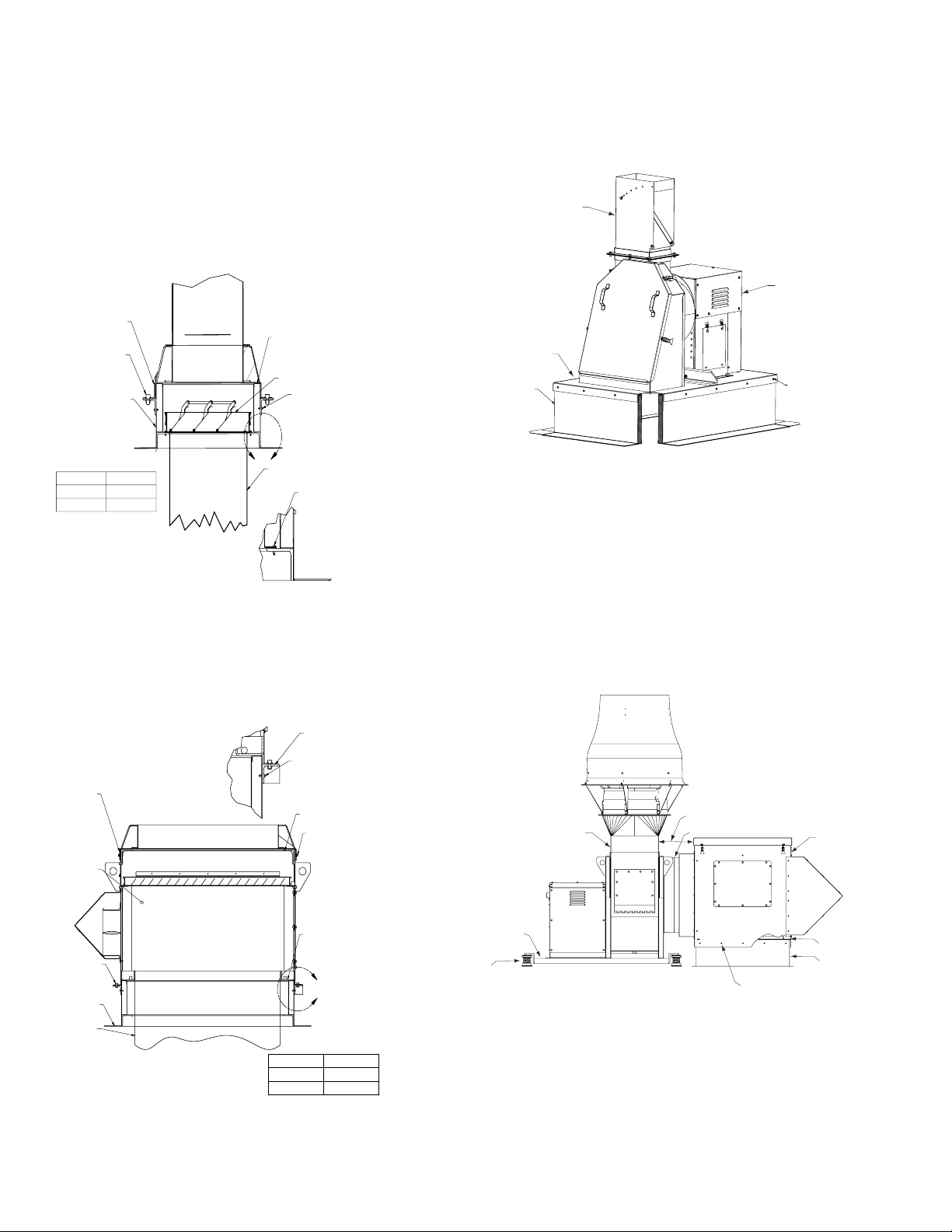

Typical Installations

QMXVP QMXLE, TCNHBLE

Typical installations for QMXVP, QMXLE, and TCNHBLE

are shown below utilizing the Loren Cook LE curb. Figure 1

shows a unit without mixing box and an optional curb mounted

isolation damper. The curb should be secured to the roof

structure per project documents and then the isolation damper

mounted in the curb as required. Ensure that the curb gasket

is present and not damaged once the curb has been p roperly

installed on the roof. Then the unit should be installed on the

curb using the supplied mounting brackets and recommended

fasteners.

CURB CAP

PVC GASKET

3/8-16 STAINLESS

STEEL BOLT

LE CURB

ISOLATION DAMPER

A x 3/4”

SELF TAPPING SHEET

METAL SCREWS

(BY OTHERS)

CPSLE

Figure 3 shows a typical CPSLE installation on a Cook RCG

curb. The RCG curb should be securely mounted to the roof per

project documents. Ensure that the curb gasket is in place once

the curb has been installed on the roof. The unit should then be

installed on the curb using the fasteners recommended in figure

3, Use a minimum of 2 screws per side and a maximum of 12”

spacing.

NOZZLE

CPSLE UNIT

CURB CAP

1/4" SELF-TAPPING

LOREN COOK

RCGH CURB

SHEET METAL

SCREWS

(BY OTHERS)

C

SIZE A

60-330 1/4

365+ 3/8

FIGURE 1

DUCT WORK

SELF TAPPING SHEET

METAL SCREWS

(BY OTHERS)

DETAIL C

Figure 2 shows a typical installation using a mixing box/

plenum and the Loren Cook LE curb. Similar to above the

curb should be installed first per project documents and then

the unit installed on the curb using recommended fasteners.

DETAIL B

ANGLE

FRAME

A x 3/4”

SELF-TAPPING

SHEET METALS SCREWS

CURB CAP

MIXING BOX

(BY OTHERS)

PVC

GASKET

3/8-16 STAINLESS

STEEL BOLT

FIGURE 3

CAVP

A typical installation for a CAVP with mixing box is shown in

figure 4. The CAVP unit is installed on either isolation rails or

base as defined in the project documents. This unit is then

installed on the roof using the correct vibration isolators per the

isolator installation instructions. The mixing box is installed on a

roof curb using the fasteners recommended in figure 4 and the

roof curb should be mounted securely to the roof per the project

documents. The final connection between th e fan and mixing

box is made using the supplied flex duct connector.

8" to 16"

CAVP

ASSEMBLY

FLEX DUCT CONNECTOR

MIXING BOX

WIZZ BOLT

CURB

DUCT WORK

Figure 2

PVC

GASKET

B

SIZE A

60-330

365+

1/4

3/8

ISOLATION

RAIL

ISOLATORS

2

FIGURE 4

PVC GASKET

1/4" SELF TAPPING

SHEETMETAL SCREWS

(BY OTHERS)

RCGH CURB

Page 3

CPSLE Parts List

QMXLE Parts List

1

1

2

5

4

Parts

No.

2

3

CPSLE

1 CPSLE Adjustable Nozzle

2 CPS Unit (See CP IOM for details)

3 Latches

4 Curb Cap and Low Loss Inlet Box

5 Inlet Box Door

CA VP Parts List

1

7

Mixing Box/Plenum

(Optional)

3

4

5

6

8

9

10

Mixing Box/Plenum

2

4

Parts

No.

3

CAVP (with Optional Mixing Box/Plenum)*

1 Vari-Plume

(Optional)

6

5

14

13

®

Nozzle

7

2CA Unit (See CA/CF/CP IOM for details)

3 Isolation Rails (Optional)

4 Isolators (Optional)

5 Flex-Duct Connector

6 Isolation Damper Cover

7 Mixing Box Lid

8 Mixing Box

9 Bypass Damper

10 Bypass Weatherhood

11 Curb (Optional)

12 Manual Bypass Handle

13 Mixing Box Access Door (2)

14 Isolation Damper (Optional)

*Optional Mixing Box/Plenum - Parts 5 through 14.

13

12

8

9

10

Parts

No.

QMXLE (with Optional Mixing Box/Plenum)*

11

1 Lifting Lug

2 Windband

3 Stack Damper

11

12

4 Adapter Plate

5 Middle Section

6QMX Unit (See QMX IOM for details)

7 Curb Cap

8 Isolation Damper (Optional)

9 Isolation Damper Cover

10 Bypass Weather Cover

11 Bypass Damper

12 Manual Bypass Handle

13 Mixing Box Access Door (3)

*Optional Mixing Box/Plenum - Parts 8 through 13.

3

Page 4

QMXVP Parts List

TCNHBLE Parts List

4

Mixing Box/Plenum

(Optional)

10

1

2

3

Mixing Box/Plenum

(Optional)

5

6

7

5

1

2

3

4

10

9

8

6

7

9

Parts

No.

QMXVP (with Optional Mixing Box/Plenum)*

1 Vari-Plume

2 Drain/Transition

3QMX Unit (See QMX IOM for details)

4 Curb Cap

5 Isolation Damper (Optional)

6 Isolation Damper Cover

7 Bypass Weather Cover

8 Bypass Damper

9 Manual Bypass Handle

10 Mixing Box Access Door (3)

*Optional Mixing Box/Plenum - Parts 5 through 10.

Limited Warranty

Loren Cook Company warrants that your Loren Cook fan was manufactured free of defects in materials and workmanship, to the extent stated herein. For a period of one (1) year

after date of shipment, we will replace any parts found to be defective without charge, except for shipping costs which will be paid by you. This warranty is granted only to the

original purchaser placing the fan in service. This warranty is void if the fan or any part thereof has been altered or modified from its original design or has been abused, misused,

damaged or is in worn condition or if the fan has been used other than for the uses described in the company manual. This warranty does not cover defects resulting from normal

wear and tear. To make a warranty claim, notify Loren Cook Company, General Offices, 2015 East Dale Street, Springfield, Missouri 65803-4637, explaining in writing, in detail,

your complaint and referring to the specific model and serial numbers of your fan. Upon receipt by Loren Cook Company of your written complaint, you will be notified, within thirty

(30) days of our receipt of your complaint, in writing, as to the manner in which your claim will be handled. If you are entitled to warranty relief, a warranty adjustment will be completed within sixty (60) business days of the receipt of your written complaint by Loren Cook Company. This warranty gives only the original purchaser placing the fan in service

specifically the right. You may have other legal rights which vary from state to state.

®

Nozzle

8

Parts

No.

TCNHBLE (with Optional Mixing Box/Plenum)*

1 TCNHBLE Nozzle Cone

2 Drum Extension

3 TCNHB Unit (See TCN IOM for details)

4 Curb Cap

5 Plenum Access Door

6 Manual Bypass Handle

7 Bypass Damper

8 Bypass Weatherhood

9 Isolation Damper Cover

10 Isolation Damper (Optional)

*Optional Mixing Box/Plenum - Parts 5 through 10.

Corporate Offices: 2015 E. Dale Street Springfield, MO 65803 417.869.6474

lorencook.com

4

Laboratory Exhaust IOM - July 2007

Loading...

Loading...