Page 1

Page 2

TABLE OF CONTENTS

APPLICATION .............................................................................................................................................1

FEATURES ..................................................................................................................................................1

DESCRIPTION.............................................................................................................................................1

WORKSHEET ..............................................................................................................................................2

SETTING PRESET A...................................................................................................................................3

SETTING PRESET B...................................................................................................................................3

SETTING THE COUNTER...........................................................................................................................3

SETTING THE RATEMETER ......................................................................................................................4

SETTING LOCKOUT CODE........................................................................................................................4

SETTING THE COM. OUTCARD ................................................................................................................5

SETTING RATE OR COUNT FOR ANALOG OUTPUT ..............................................................................6

SETTING OUTPUT PULSE FREQUENCY .................................................................................................6

SETTING RELAY FUNCTION & ON TIMES ...............................................................................................7

VIEWING RATE, BATCH TOTAL, GRAND TOTAL.....................................................................................7

SETTING 16-POINT K-FACTOR .................................................................................................................8

SPECIFICATIONS .......................................................................................................................................9

TERMINATION ............................................................................................................................................9

OPERATIONS............................................................................................................................................10

K-FACTOR.................................................................................................................................................10

COUNTER .................................................................................................................................................10

APPLICATION ...........................................................................................................................................11

MOUNTING DIMENSIONS........................................................................................................................11

PULSE INPUTS .........................................................................................................................................11

ANALOG INPUTS ......................................................................................................................................11

SETTING K FACTOR FOR ANALOG INPUT ............................................................................................12

ANALOG INPUT EXCHANGE/CALIBRATION ..........................................................................................12

RESET .......................................................................................................................................................12

FACTOR/"DATALOST"/"RFFF" .................................................................................................................12

PRESETS ..................................................................................................................................................13

RELAY OUTPUT TIMING ..........................................................................................................................13

SCALED OUTPUT/DATALOST .................................................................................................................13

RATEMETER .............................................................................................................................................13

TING RATE K-FACTOR FOR PULSE INPUT ...........................................................................................13

LOCKOUT..................................................................................................................................................14

REMOVING THE CASE.............................................................................................................................14

INPUT CARD MODIFICATION ..................................................................................................................14

OUTCARD RS232/RS422 SERIAL INTERFACE ......................................................................................14

RS232 ELECTRICAL REQUIREMENTS ...................................................................................................14

RS422 ELECTRICAL REQUIREMENTS ...................................................................................................15

RS232/RS422 SERIAL INPUT CODES.....................................................................................................15

SERIAL INTERFACE OPERATION...........................................................................................................15

STROBE ADDRESS OPERATION............................................................................................................16

STROBE INPUT ELECTRICAL REQUIREMENTS ...................................................................................16

232 WIRING...............................................................................................................................................16

STROBE WIRING FOR RS232 .................................................................................................................16

RS422 INPUT WIRING ..............................................................................................................................17

STROBE WIRING FOR RS422 .................................................................................................................17

ANALOG OUTPUT ....................................................................................................................................17

OPTIONAL 16-POINT LINEARIZATION OF VARIABLE K-FACTOR........................................................17

WIRING ILLUSTRATION............................................................................................................................20

Page 3

APPLICATION

Batch control, cut to length, packaging, blending. The

display may be toggled between total, rate, and grand total.

Programmable K-factor makes keying - in engineering units

easy. Unit accepts pulse, contact closures or analog input

and provides two separate preset controls.

1 2 3

54 6

FEATURES

* Pulse or Analog Input (with Totalizing

Integration)

* Display Total, Rate or Grand Total

* 2 Presets - User Selectable for Total, Rate or

Grand Total

* Pulse Input to 20 KHz Count Frequency

* 16 Point Linearization

* K - Factor Programmable to 8 Places

* Security Lockout

* 2 way RS232/422/422M Communications

* NEMA 4X Front Panel

* Scaleable 4 - 20mA Output of Rate

* Scaled Pulse Out, Frequency Selectable

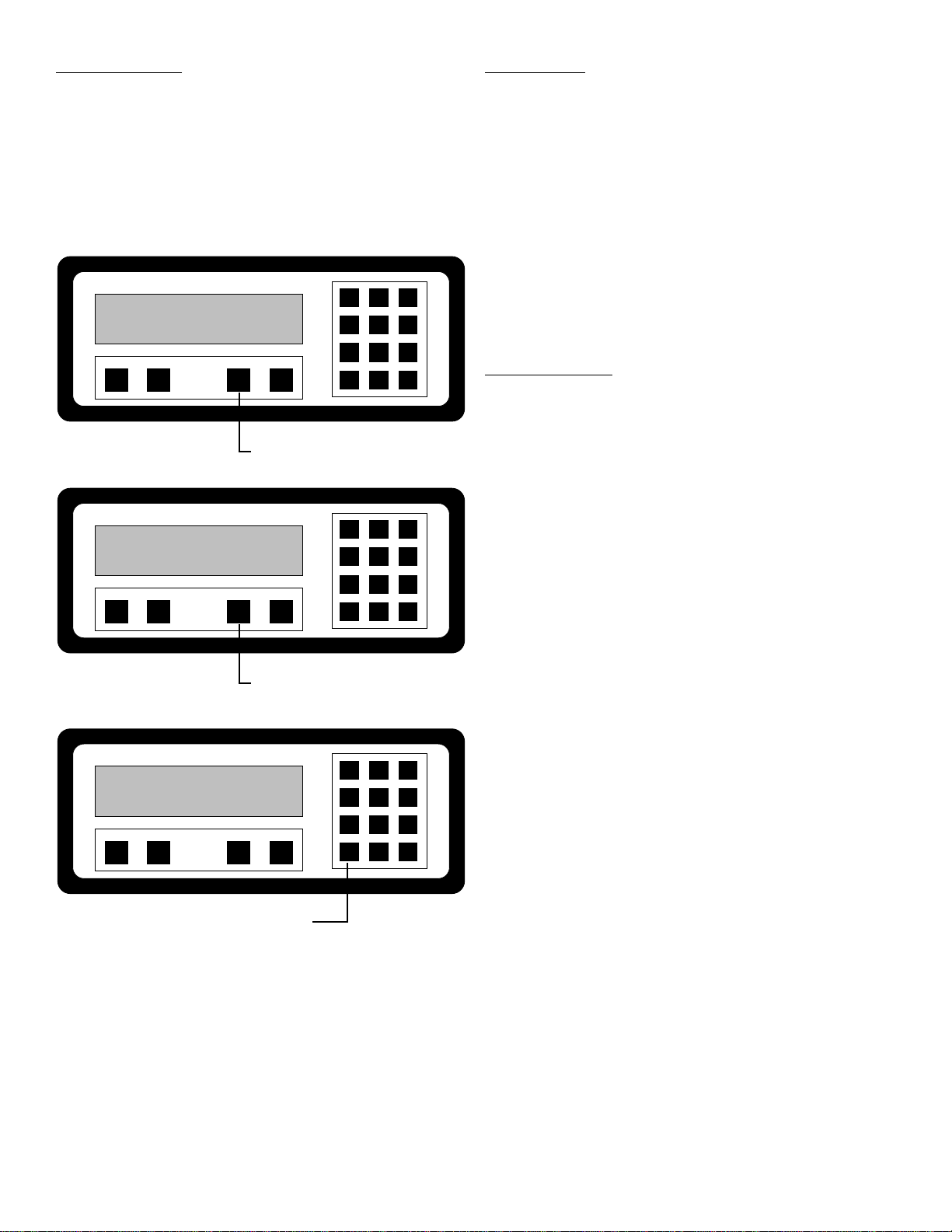

PRE A PRE B RATE/T OT AL MENU

AB CD

PRESS "C" TO SEE RATE

PRE A PRE B RATE/T OT AL MENU

AB CD

PRESS "C" AGAIN TO SEE

BATCH TOTAL.

PRE A PRE B RATE/T OT AL MENU

AB CD

PRESS "ENT" TO SEE

GRAND TOTAL

87 9

ENT CLR

0

1 2 3

54 6

87 9

ENT CLR

0

1 2 3

54 6

87 9

ENT CLR

0

DESCRIPTION

Featuring 8 digits of bright, .55”, alphanumeric display, the

pulse input version of the unit can accept up to 20,000

pulses per second. The analog input version accepts

inputs, such as 4 to 20mA or 1 to 5V. It uses a highly linear

integrator (V to F converter) to generate 0 to 10KHz digital

pulses. The unit has two separate, 8 digit, floating decimal,

“K” factors to convert the inputs to meaningful count and

rate data. The user, with the push of a button, can toggle

back and forth to view the total of the batch, the rate of flow

and the grand total count.

Two controls outputs can be assigned independently by the

user to activate at preset batch count, rate or grand total for

.1 to 9.9 seconds or until reset externally.

A scaled pulse output is also provided by an open collector

driver. Since the output frequency is user selectable at 10,

200, 2K or 20KHz, the unit can transmit the count data to

electromechanical or electronic counters as well as computers, programmable controllers or other monitor equipment.

An optional analog 4 to 20mA output, selectable between

rate or total, allows the user to select 4mA and 20mA rate

settings to control strip chart recorders or other peripherals.

Up to 15 units can be connected to optional RS232 or

RS422 communications port to set control points or access

data. With RS422M up to 256 units can be linked together

and addressed separately to transmit unit states or accept

new set points. The Baud rate is “Auto Ranging” from 300

to 19.2K. It is also OPTOMUX Compatible.

1

Page 4

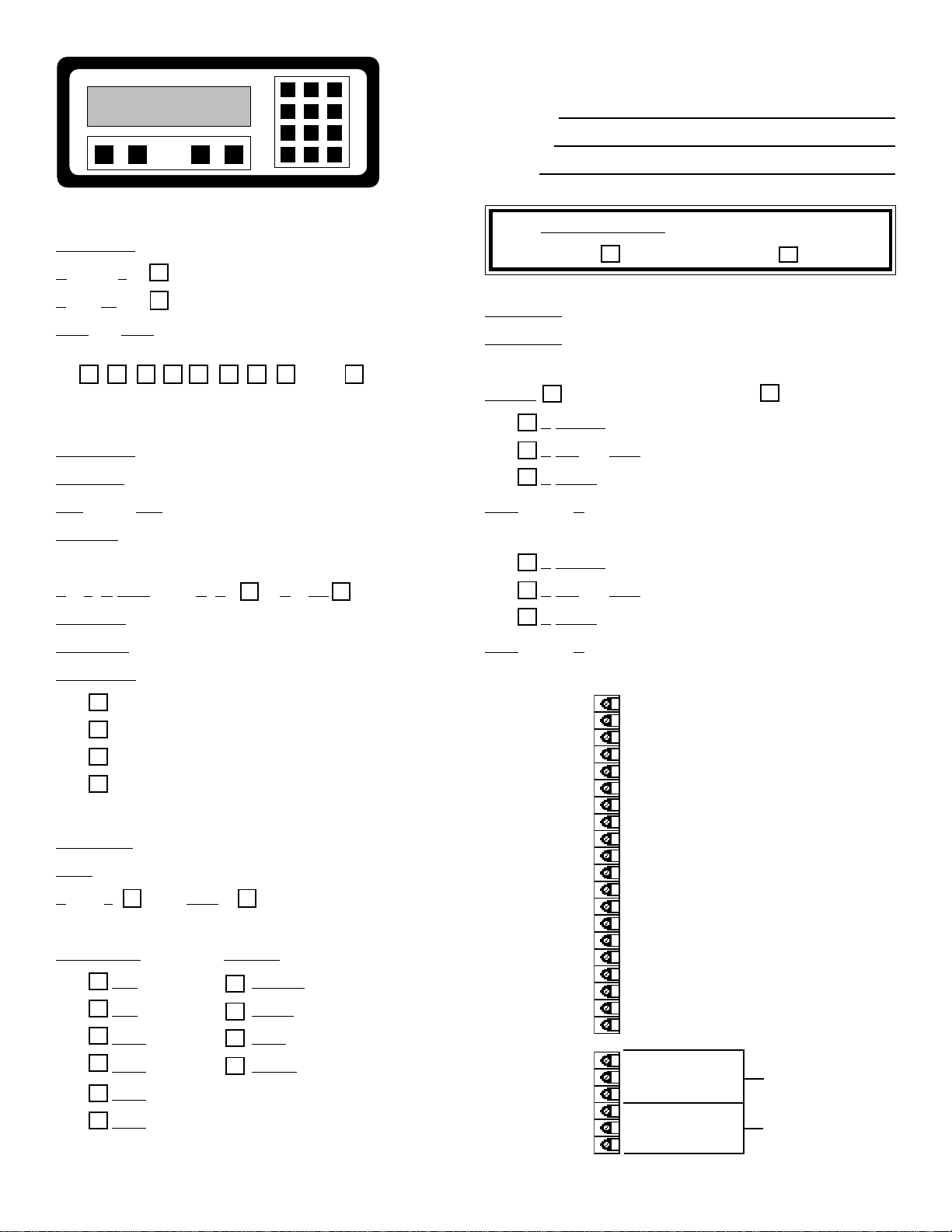

PRE A PRE B RATE/TOT AL MENU

AB CD

1 2 3

54 6

87 9

ENT CLR

0

WORKSHEET

MODEL #

SERIAL #

UNIT #

COUNTER

K-FACTOR __ __ __ __ __ __ __ __

Reset to 0

Set to Preset

DECimal LOCation (0-8)

876543210

none

RATEMETER

K-FACTOR __ __ __ __ __ __ __ __

WINDOW (02-24) __ __

SIGnificant FIGures (1-6) __ __

WEIGHT (00-99) __ __

AnaLoG OUTput RaTe CouNT

SET LOW rate 4mA __ __ __ __ __ __ __ __

SET HIGH rate 20mA __ __ __ __ __ __ __ __

LOCKOUT CODE __ __ __ __

PR-LCK PR-UNLK

PRESET A __ __ __ __ __ __ __ __

PRESET B __ __ __ __ __ __ __ __

RELAY Open Collector

A TOTAL

A GRand TOTal

A RATE

DURation of A (0.0-9.9) __ . __

B TOTAL

B GRand TOTal

B RATE

DURation of B (0.0-9.9) __ . __

OUT FREQuency

20000

2000

200

10

OUTCARD

UNIT (00-15) __ __

ParalleL or SERial

(RS422M)

BAUDRATE PARITY

300 SPACE

600 EVEN

1200 ODD

2400 MARK

4800

9600

1- NOT USED

2- SCALED OUTPUT O.C.

3- ANALOG OUTPUT (SINK)

4- INPUT A (PULSE/ANALOG)

5- RESET INPUT

6- NOT USED

7- NOT USED

8- NOT USED

9- NOT USED

10- NOT USED

11- GROUND (-DC)

12- GROUND (-DC) INPUT COMMON

13- +12 VDC OUT

14- +DC POWER IN

15- ISOLATED -12VDC

16- ISOLATED +12VDC

17- AC IN

18- AC IN

19- PRESET B OPEN COLLECTOR

20- PRESET A OPEN COLLECTOR

R1- N.O

R2- N.C. A

R3- COMMON

R4- N.O

R5- N.C. B

R6- COMMON

2

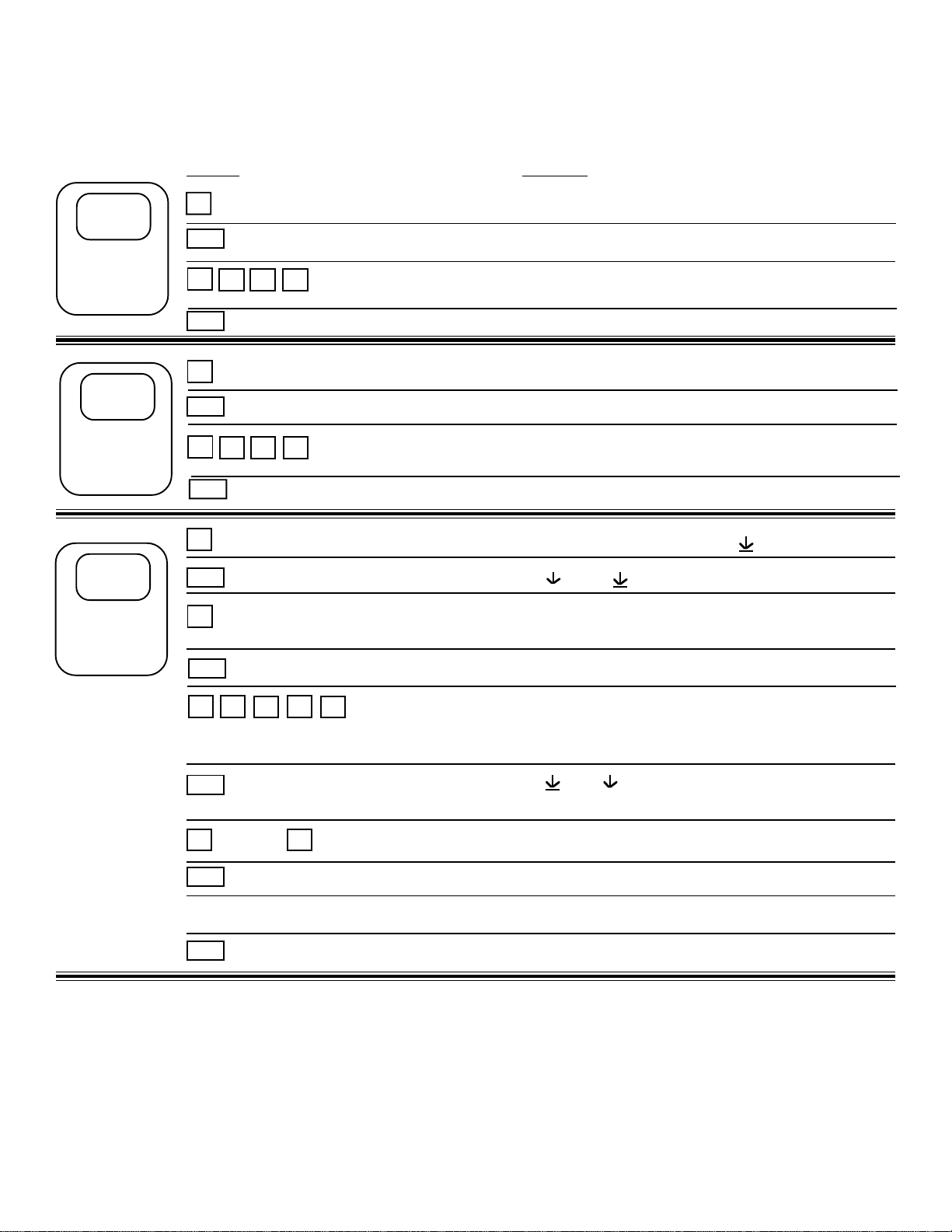

Page 5

STEP

1

SETTING

PRESET A

SETUP PROCEDURE

NOTE: Start here and finish to the end. If you make a mistake, press

ENT until you reach the beginning.

PRESS DISPLAY

A

CLR

1

(SAMPLE PRESET)

ENT

(FINAL PRESET) THEN FLASHING PRESET #

2 3 4

PRESET A

0 FLASHES

1 2 3 4 PRESET FLASHES

1 2 3 4 IS ENTERED

STEP

2

SETTING

PRESET B

STEP

3

SETTING

THE

COUNTER

B

CLR

1

(SAMPLE PREWARN)

ENT

D

ENT

D

CLR

(PRESS D FOR DECIMAL POINT)

K FACTOR IS DIVIDER. IT CONVERTS INPUT TO ENGINEERING UNITS.

ENT

(PREWARN) THEN FLASHING PRESET #

2 0 0

(SET UP COUNTER) K FACTOR FLASHES; THEN SHOWS

1

2

D

(K FACTOR ENTERED) R0 SP (RESET TO 0 "ADD" OR SET TO

8

7

PRESET B

0 FLASHES

1 2 0 0 PRESET FLASHES

1 2 0 0 IS ENTERED

MENU FLASHES TO DEV TYP

RT CNT (RATE OR COUNT)

CURRENT K-FACTOR

0 FLASHES

1 . 2 7 8 FLASHES

PRESET "SUBTRACT")

B

ENT

PRESS ANY NUMBER DECIMAL POINT MOVES TO THAT POSITION

ENT

OR SELECTS R0 OR SP

SELECTION ENTERED DEC LOC (DECIMAL LOCATION)

D

LAST COUNT READING

3

Page 6

PRESS DISPLAY

STEP

4

SETTING

THE

RATEMETER

D

ENT

B

CLR

(PRESS D FOR DECIMAL POINT)

K FACTOR IS DIVIDER. IT CONVERTS INPUT TO ENGINEERING UNITS.

ENT

CLR

5

(EXTENDS THE SAMPLING WINDOW TO 5 SECONDS)

ENT

CLR

(SET UP RATEMETER) K FACTOR FLASHES; THEN SHOWS

1

D

7

(K FACTOR ENTERED) WINDOW ##

(AS AN EXAMPLE) WINDOW 05

(WINDOW ENTERED) SIG FIG ##

8

MENU FLASHES TO DEV TYP

RT CNT (RATE OR COUNT)

CURRENT K-FACTOR

0 FLASHES

1 7 . 8 FLASHES

WINDOW 00

SIG FIG 00

STEP

5

SETTING

LOCKOUT

CODE

6

(SIG FIG INDICATES HOW MANY MEANINGFUL DIGITS ARE SHOWN

TRAILING ZEROS ARE INSERTED IF NECESSARY)

ENT

CLR

WEIGHT IS AN AVERAGING FACTOR. HIGHER SETTINGS PROVIDE MORE AVERAGING, FOR A

MORE STABLE DISPLAY. DERIVED FROM:

ENT

D

ENT

CLR

1

(AS AN EXAMPLE) SIG FIG 06

(SIG FIG ENTERED) WEIGHT #.#

WEIGHT 0.0

99

(AS AN EXAMPLE) WEIGHT 9.9

(OLD DATA x "WEIGHT" + NEW DATA)

(WEIGHT ENTERED) LAST COUNT READING

MENU FLASHES TO DEV TYP

LOCKOUT

(LOCKOUT SELECTED) CODE FLASHES; THEN SHOWS OLD CODE #.

0 FLASHES

(AS AN EXAMPLE) 1 1 1 1 FLASHES

1 1 1

("WEIGHT" + 1)

ENT

ENT

1

1

(CODE ENTERED) PR LCK PR UNLK

(LOCKOUT OF (LOCKOUT OF ALL FRONT

FRONT PANEL) BUTTONS EXCEPT

PRESETS A, B AND CLR)

(LOCKOUT SELECTION ENTERED) LAST COUNT READING

1 1 1

1 1 1

4

LOCK ON FLASHES

(APPROPRIATE PANEL CHANGES LOCKED OUT)

LOCK OFF FLASHES

(PANEL CHANGES ALLOWED)

Page 7

PRESS DISPLAY

STEP

6

SETTING

THE COM.

OUT CARD

SKIP IF NOT

USED

D

D

D

ENT

CLR

1 2

ENT

ENT

D

D

D

D

MENU FLASHES TO DEV TYP

LOCKOUT

OUTCARD

(OUTCARD SELECTED) UNIT ##

UNIT 00

(AS AN EXAMPLE) UNIT 12

(UNIT LABELED 12) PL SER *

BAUDRATE FLASHES THEN LAST

BAUDRATE USED.

300

600

1200

2400

D

D

ENT

D

D

D

D

ENT

4800

9600 (PRESS D TO GO BACK TO 300)

(PRESS AS DESIRED) PARITY FLASHES THEN LAST PARITY SELECTED

EVEN

ODD

MARK

SPACE (PRESS D TO GO BACK TO EVEN)

(PRESS AS DESIRED) LAST COUNT READING

* UNIT ALWAYS SHOULD BE SER. PL IS DISABLED

5

Page 8

PRESS DISPLAY

STEP

7

SETTING

RATE OR

COUNT FOR

ANALOG

OUTPUT

SKIP IF NOT

USED

D

D

D

D

ENT

D

ENT

CLR

1 2

(PRESS D FOR DECIMAL POINT)

AS AN EXAMPLE (IN THIS CASE 125.5 = 4mA)

ENT

(ANALOG SETUP SELECTED) ANLG RT (4-20mA OUTPUT FOR RATE)

(PRESS D TO TOGGLE ANLG CT (4-20mA OUTPUT FOR COUNT)

BETWEEN SELECTIONS)

(ANLG RT OR ANLG CT SELECTED) SET LOW FLASHES THEN CURRENT

5

(LOW SET AT 125.5) SET HIGH FLASHES THEN CURRENT HIGH

5

D

MENU FLASHES TO DEV TYP

LOCKOUT

OUTCARD

ALG OUT

LOW SETTING

0 FLASHES

1 2 5 . 5 FLASHES

SETTING

STEP

8

SETTING

OUTPUT

PULSE

FREQUENCY

CLR

1 5

(PRESS D FOR DECIMAL POINT)

AS AN EXAMPLE (IN THIS CASE 150.7 = 20 mA)

ENT

D

D

D

D

D

ENT

D

D

0

(HIGH SET AT 150.7) LAST COUNT READING

(OUT FREQUENCY SELECTED) 2000 (DISPLAYS LAST SELECTION)

7

D

0 FLASHES

1 5 0 . 7 FLASHES

MENU FLASHES TO DEV TYP

LOCKOUT

OUTCARD

ALG OUT

OUT FREQ

200

10

D

ENT

20000 (PRESS D TO GO TO 2000)

(PRESS AS DESIRED) LAST COUNT READING

6

Page 9

PRESS DISPLAY

STEP

9

SETTING

RELAY

FUNCTION

AND

ON TIMES

D

D

D

D

D

D

ENT

D

D

ENT

CLR

1

MENU FLASHES TO DEV TYP

LOCKOUT

OUTCARD

ALG OUT

OUT FREQ

RELAY

(RELAY SELECTED) A GR TOTAL (RELAY A SET TO GRAND TOTAL)

A RATE (IF RATE SELECTED, DURATION

IS DISABLED)

A TOTAL (RELAY A SET TO TOTAL)

(PRESS AS DESIRED) DUR A #.#

DUR A 0.0

(AS AN EXAMPLE) DUR A 1.2 (RELAY ACTIVATES FOR 1.2 SEC.)

2

VIEWING

RATE,

BATCH

TOTAL,

GRAND

TOTAL

ENT

D

D

ENT

CLR

5

ENT

C

C

ENT

ENT

(ON TIME ENTERED) B RATE (IF RATE SELECTED, DURATION

IS DISABLED)

B TOTAL (RELAY B SET TO TOTAL)

B GR TOTAL (RELAY B SET TO GRAND TOTAL)

(PRESS AS DESIRED) DUR B #.#

DUR B 0.0

(AS AN EXAMPLE) DUR B 5.5 (RELAY ACTIVATES FOR 5.5 SEC.)

5

(ON TIME ENTERED) LAST COUNT READING

R ###### (RATE READING)

######## (BATCH TOTAL)

PRESS C TO GO BACK TO RATE AGAIN

GR TOTAL FLASHES THEN THE GRAND TOTAL

VALUE FLASHES

######## (BATCH TOTAL)

PRESS C TO GO BACK TO RATE AGAIN

PRESS ENT TO GO BACK TO GRAND TOTAL

7

Page 10

PRESS DISPLAY

SETTING

16 POINT

K-FACTOR

16 POINT

ONLY

APPEARS

ON UNITS

WITH

16 POINT

OPTION

NOTE: If TEST

is entered, point

data can be

entered exactly

as in selected

time entries.

However, when

the unit "runs"

in Test Mode

"K-factor is

always 1.

"Rate" (R)

displays

frequency

(inputs per

second).

Counter displays 1 count

per each input.

NOTE: "BAD

SEQ" will

appear if

frquencies are

not in ascending order with

point numbers.

After 2 seconds, the first

point number

with error will

appear so data

can be viewed

and corrected.

D

D

D

D

D

D

D

ENT

D

D

D

ENT

1

ENT

CLR

1 0 0

ENT

CLR

1 0 0

ENT

CLR

ENT

MENU FLASHES TO DEV TYP

LOCKOUT

OUTCARD

ALG OUT

OUT FREQ

RELAY

16 POINT

(16 POINT SELECTED) MINUTES

HOURS

TEST

SECONDS (PRESS D TO GO TO MINUTES)

(PRESS AS DESIRED) POINT 00 (ENTER POINT 00 TO GO TO RUN

MODE)

(SELECT POINT 1) POINT 01 (KEY IN POINT DESIRED)

F ## (SHOWS FREQUENCY IN MEMORY)

F 0

(AS AN EXAMPLE) F 100 (FREQUENCY FOR POINT 1 IS 100)

K ## (SHOWS K-FACTOR IN MEMORY)

K 0

(AS AN EXAMPLE) 100 (K-FACTOR FOR POINT 1 IS 100)

POINT 02 (ENTER POINT DATA AS DESIRED)

POINT 00 (ENTER POINT 00 TO EXIT SETUP)

LAST COUNT READING

8

Page 11

SPECIFICATIONS

Display

8 Digit, .55” Segment, Red Orange, LED.

Input Power

A: 110 VAC ±15% or 12 to 27 VDC

B: 220 VAC ±15% or 12 to 27 VDC

Current

Maximum 280 mA DC or 5.3 VA at rated AC voltage.

Output Power

(On AC powered units only): +12 VDC at 100mA. Separate

isolated 12 VDC at 100mA to allow +12 VDC or +12 VDC

regulated ±5% worst case.

Memory

EEPROM stores all program and count data for minimum of

10 years if power is lost.

Pulse Inputs

Standard, High impedance pulse input. Open or 0 to 1 VDC

(low) 3 to 30 VDC (high) 10K Ohm impedance 20 KHz max.

input speed (min. on/off 25 usec.).

Control Outputs

(Each of two outputs)

1) NPN Transistor Version: (Optional)

Open collector sinks max. 250mA from 30

VDC when active. (When relay is used, 10

VDC is provided at transistor outputs through

relay coil. If greater than 2mA is used, relay

will remain energized. Applying greater than

10 VDC may destroy unit. Transistor will sink

100mA in “ON” state).

2.) SPDT Relay Version:

10A 120/240 VAC or 28 VDC (Standard)

Analog Output

Digital or analog inputs (except square law) can be ordered

with a 4mA to 20mA output of the rate or total reading.

User keys in the 4mA and 20mA settings at set-up. A

sinking driver generates a corresponding linear current

through the external devices, updating with each update of

the rate or total. Accuracy is ±100 uA worst case. Compliance voltage must be 3 to 24 VDC, non-inductive. (The

unit can provide the DC source as long as the drop across

any device being driven does not exceed 21 V).

Analog Inputs

The current loop or voltage input is converted to a highly

linear 0 to 10KHz frequency. This frequency can then be

scaled by the 8 digit K - Factors to count or display rate in

separate engineering units.

Accuracy over full temperature range:

Zero error: ±0.175% full scale max.

Overall error: ±0.5% full scale max.

Reset

Front push button: “CLR” resets displayed number and

control output.

Remote: 3 to 30 VDC positive edge resets batch counter

and control output.

Impedance: 10K to ground (-DC)

Minimum pulse: 5 msec

Temperature

Operating: +32ºF (0ºC) to +130ºF (+54ºC)

Storage: -40ºF (-40ºC) to+200ºF (+93ºC)

Factored Output

The unit gives one pulse out for each factored count. Open

collector sinks 30 VDC maximum to 1 volt maximum at

100mA maximum. Output speed is user selectable (see

Table below). An internal buffer holds up to 10,000 pulses

for output at the selected frequency before “DATALOST”

flashes, indicating pulses are lost. If factored rate exceeds

7 digits, “RFF...” flashes. These alarms indicated that

speed has been exceeded.

Speed (Hz) 10 200 2000 20000

Min. on/off (msec) 47.5 2.0 0.2 0.013

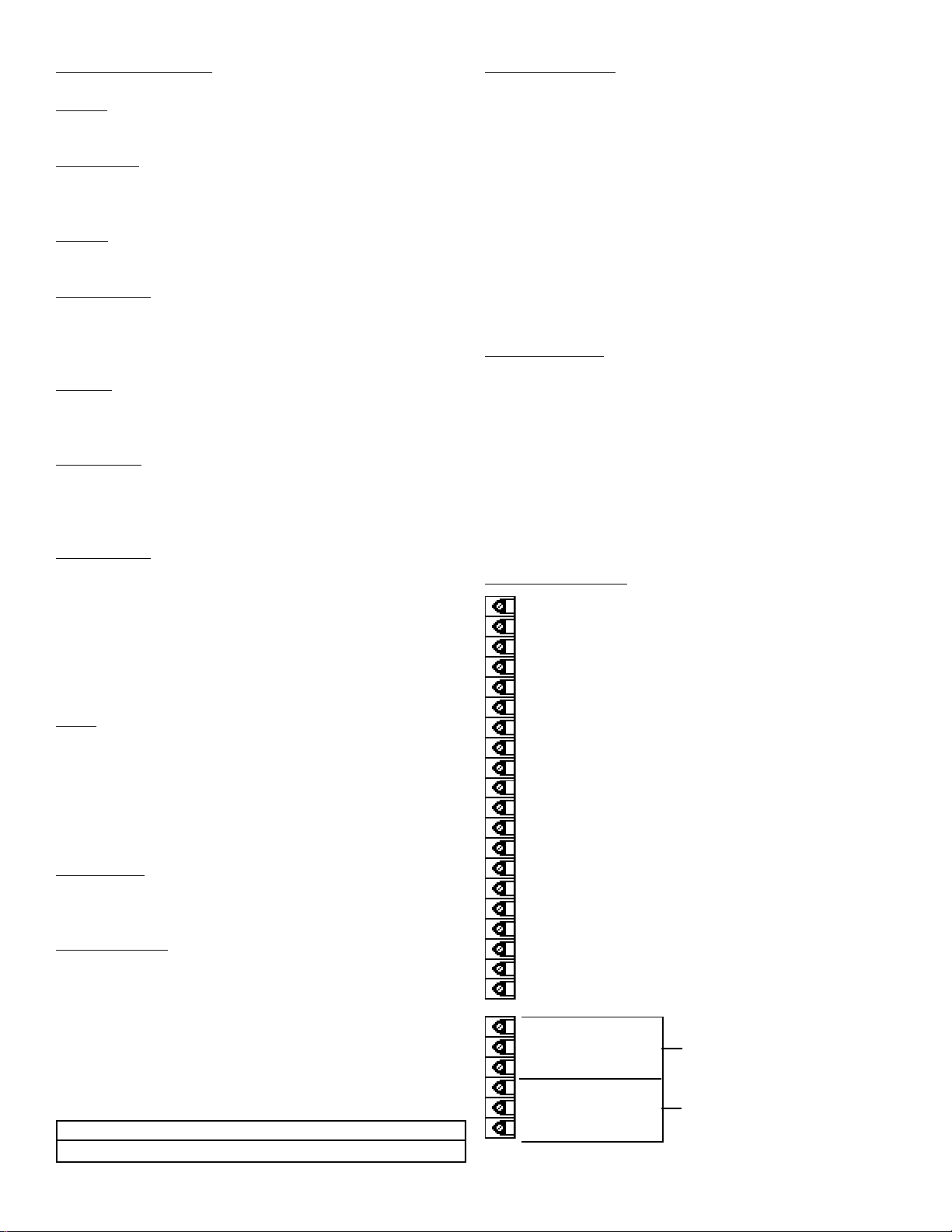

TERMINATIONS

1- NOT USED

2- SCALED OUTPUT O.C.

3- ANALOG OUTPUT (SINK)

4- INPUT A (PULSE/ANALOG)

5- RESET INPUT

6- NOT USED

7- NOT USED

8- NOT USED

9- NOT USED

10- NOT USED

11- GROUND (-DC)

12- GROUND (-DC) INPUT COMMON

13- +12 VDC OUT

14- +DC POWER IN

15- ISOLATED -12VDC

16- ISOLATED +12VDC

17- AC IN

18- AC IN

19- PRESET B OPEN COLLECTOR

20- PRESET A OPEN COLLECTOR

R1- N.O

R2- N.C. A

R3- COMMON

R4- N.O

R5- N.C. B

R6- COMMON

9

Page 12

OPERATIONS

Presets

Two control presets are provided on the unit. The preset

numbers can be made to flash without interrupting the

control function by pressing “A” (Preset A) or “B” (Preset B).

Press “ENT” to return to rate or total display. Change the

preset by clearing the flashing preset number and keying in

a new number before pressing the “ENT” button. (Count

pulses may be lost if the preset is changed while pulses are

coming in.) In the “Relay Set-Up” the user selects either

one or both preset outputs to be activated the total, grand

total, or rate. If selected for total or grand total the outputs

can be set to activate the preset relay for 0.1 to 9.9 seconds or latch (0.0 setting) until reset. If selected for rate

control, the rate will be compared with the preset at each

display update and the output activated if the rate is equal

or grater than the preset. The output drops out again only if

the rate drops below the preset. If the rate goes out of

scale, the display will show all “F” and the output will

remain in the state prior to going out of scale.

Outcard

RS232 or RS422 serial two way communication options are

available. Up to 15 units can be linked together and

addressed separately to transmit unit status or accept new

set points in the standard ASCII format. Baud rates of 300,

600, 1200, 2400, 4800 or 9600 as well as choice of odd,

even, space or mark parity can be selected by keypad

control.

OPTION 1: RS232 Serial Interface

OPTION 2: RS422 Serial Interface

OPTION 5: RS422M Serial Interface

Lockout

Unauthorized front panel changes can be prevented by

entering a user selected 4-digit code, in the “LOCKOUT”

mode. A (2) level “LOCKOUT” offers the user the option to

“LOCKOUT” all front panel changes or “LOCKOUT” all but

preset A, B, and CLR. The status of the unit can be

observed but, “LOCK ON” appears if changes are attempted. Entering the code returns the unit to “LOCK OFF”

status.

Press the “C” button while the units is displaying the batch

to display the rate; “R” is displayed on the left side of the

display.

K-FACTOR

The K-Factor is used to convert the input pulses or frequency generated internally by the analog input to engineering units. The 8 digit K-Factor dividers, with decimal

keyed into any position, allow easy direct entry of any KFactor greater than 0.0001 to 99999999.

Separate K-Factors may be entered for the count and rate

section. Thus, you may batch and total in gallons and

display rate in liters per hour. The maximum factored count

speed is 20,000 Hz. The maximum factored rate is 7 digits.

A 16-Point Linearization variable K-factor option makes

flow systems more accurate and often extends their usable

range by allowing users to dial in different K-factors for

different flow rates. It works with either pulse input or

standard analog current loop or voltage input.

It is recommended for flow meters whose K-factors change

with different rates of flow. This option can also be used to

display static volume in irregular shaped vessels by interfacing level or pressure transducers to the analog input.

From 3 to 16 points of frequency from 0 to 10,000 Hz and

K-factors greater than .0001 to 999,999 are dialed in at set

up. The unit uses 8-digit floating math to interpolate between settings. Rate per second, per minute or per hour

programmability eliminates the need to calculate separate

K-factors for total and rate.

COUNTER

Each of the total and grand total counters have 8 digits. In

the set-up mode choose “RO” (reset to zero) for adding

operation or “SP” (set to preset) for subtracting operation.

While viewing the count, the display can be made to flash

the grand total. While flashing the grand total, CLR resets

the grand total counter.

RATEMETER

Accurate to 5 1/2 digits (±1 display digit). The rate meter

can be programmed to accept almost any number of pulses

per unit of measurement, sample from 2 to 24 seconds

maximum, and autorange up to 6 digits of significant

information. The rate meter with a “K” factor of 1 displays

the rate of pulses per second. Simply dial in the proper “K”

factor to display in minutes, hours or other units of measurement.

10

Page 13

APPLICATION

PULSE INPUTS

The unit accepts output pulses from most encoders, prox.

switches or contactors. Connect the pulse to Input A Pin 4.

The unit counts on the negative edge of a pulse: Low: 0 to

1 VDC, High: 3 to 30 VDC.

SOURCING INPUT - Has a 10K Ohm pull down resistor to

ground and must be driven high by a sourcing device such

as a PNP transistor or a contact to +DC, Pin 13.

SINKING INPUT- Has a 4.7K Ohm resistor to +12 VDC

and must be driven low by a sinking device such as a NPN

transistor or a contact to ground (Pin 12).

The unit monitors the power consumption and transmits the

rate, total or grand total usage upon command to a printer,

PLC or computer. Either control Relay A or Relay B can be

activated by rate, total or grand total readings. If Relay A is

set for rate, it can activate an alarm for load management if

the preset usage is exceeded. Relay B can be set to

activate at any rate, total or grand total alarm setting. The

customer has it his way when selecting the external devices to record the unit data. A frequency selectable pulse

output can drive any totalizer, PLC, computer or other pulse

input device from 10 to 20,000 Hz. With the analog output

option the customer keys in both the 4mA and 20mA rate

settings and the unit drives the strip chart recorder, load

shedding or other monitor devices. Finally, with the RS232/

RS422 or RS422M option the customer can have a printer

record any data or have a computer communicate with up

to 256 units to monitor the usage, change alarm points,

reset the internal counters, etc. from a remote location.

MOUNTING DIMENSION

Dimensions are in inches (mm)

7.349

(186.7)

7.055

(179.2)

ABCD

(207.5)

8.170

1 2 3

4 5 6

7 8 9

CLR0SET

3.305

(83.9)

PULSE SPEED

The Max input speed is specified by the 8th digit of the part

number based on a 50% on/off pulse. Although the unit

can accept pulses as short as 25 usec on/off if speed “E” is

selected, it is advised that only the maximum speed

needed be ordered. When lower speeds are specified,

additional filtering is added that make the inputs more

immune to electrical noise. “A” input speed should always

be used when pulsing with a switch contact to prevent

additional erratic count inputs.

INPUT SWITCH SELECTION

Inputs use an input signal conditioning board which is

plugged onto the main board just behind the display. It has

dip switches which set the debounce filtering (max. count

speed). (See section for “Removing Case” to get to the

input modules if changes on the pulse input board are

needed.)

S1, S2 determine debounce filtering and control max. input

speed,

(A) S1, S2-ON, 0-40 Hz (min. 12.5 msec on/off)

(C) S1-ON, S2-OFF, 0400 Hz (min. 1.25 msec on/off)

(E) S1, S2-OFF, 0-20K Hz (min. 25 usec on/off)

S3, S4 set the input characteristics as designated by the

5th and 6th digits of the part number.

SOURCING INPUT: S3, S4-OFF (needs sourcing input)

SINKING INPUT: S3-OFF, S4-ON (needs sinking input)

.525

(13.3)

7.365 ± .010

(187.0 ± .25)

PANEL

CUTOUT

6.000

(152.4)

2.496 ± .010

(187.0 ± .25)

2.480

(62.9)

ANALOG INPUTS

The analog input versions accept signals from transmitters

that give linear outputs. The input signal modules are

mounted just behind the display and are calibrated for the

input specified. Insure that the sensor output matches the

unit input. Connect the analog signal to input A (Pin 4) with

the return to ground (Pin 12).

SQUARE LAW: 4-20mA; 250Ω input impedance, the

square law input is a special input that compensates for

non-linear inputs. Specifically, inputs that require square

root extraction to provide accurate count and rate determinations. The input signal is converted to 0 to 10,000 pulses

per second input to the process (see Table below).

11

Page 14

4-20mA Square Law Table

mA Input Pulse/Sec mA Input Pulse/Sec

4 0000 10 6123

5 2500 12 7071

6 3535 16 8660

7 4330 18 9354

8 5000 20 10000

To calculate the Pulse/Sec for a particular input use the

following formula:

mA - 4 x 10000 = # Pulse/Sec to Processor

√

16

EXAMPLE: To calculate the Pulses/Sec for 9mA Input.

9 - 4 x 10000 = 5590 Pulses/Sec to Processor

16

√

CALCULATING THE K- FACTORS

The analog inputs are converted to a highly linear 0 to

10000 pulse per second frequency. The high level of any

analog input will generate this 10000 Hz frequency. The

pulses go directly to the central processor. The K- Factors

are used to convert the pulses into the correct units of

measurement.

Rate K- Factor: 10000/R, where R = high output rating

(20mA or 5V) of transmitter. 10000 divided by 20mA or 5V

rating of transmitter. Eg. 20mA rating of transmitter is 250

gal. per min. The rate K - Factor to key into the unit for gal.

per min. is 40 (10000 divided by 250).

If a rate is desired in a different unit of measure or a

different timebase, factor the transmitter rating to the unit of

measure and timebase desired and use the formula above.

Eg. 5V output rating of a transmitter is 300 gal. per min.

and rate desired is liters per hr. The factored rate for this

transmitter for liters per hr. is 68135.94 (300 x 3.78533 [gal.

to liters] x 60 [min. to hr.]. The rate K - Factor for liters per

hr. is 0.1467654 (10000 divided by 68135.94).

Counter K-Factor: = 10,000/R/Sec, where R = High output

rating (20mA or 5V) of transmitter factored to rate per

second. Eg. 20mA rating of transmitter is 500 gal. per min.

Rate per sec. is 8.3333333 (500 divided by 60). Counter KFactor to key into unit is 1200 (10000 divided by

8.3333333.

If a different unit of measure is desired, factor the given

transmitter rating to the desired unit of measure in units per

second and use the formula above. Eg. 5V rating of transmitter is 250 gal. per hr. and it is desired to totalize in liters.

Rate in liters per second is .2628701 (250 x 3.78533 [gal.

to liters] divided by 3600 [hr. to sec]). Counter K-Factor to

key into unit to totalize in liters from 250 gal. per hr. transmitter is: 38041.603 (10000 divided by .2628701).

ANALOG INPUT EXCHANGE/CALIBRATION

If an analog sensor cannot be obtained that matches the

unit input, it is recommended that the unit be returned to

have the analog input module exchanged and recalibrated.

Recalibration should only be attempted by someone who

has the equipment to generate a very accurate low and

high signal and who has the training to open the unit and

work with grounded equipment necessary to protect the

static sensitive CMOS circuitry.

Set the ratemeter as follows: K Factor = 1, sig. fig. = 6,

window = 02 and the weight = 0. See the section “Removing the Case” to get at the analog input card, mounted just

behind the display. There are two pots that set the “0”

(R3) and 10000 Hz (R15) frequency. R3 and R15 are

silkscreened just under the .3 inch square pots. While

inputing a very accurate high input signal. Set R15 so that

the display reads 9999 to 10000. Remove the input signal

and adjust R3 so that the display reads “0”. Readjust R15

until it is as close as possible to 10000. Go back and

readjust R3 to insure it is at “0”. Repeat this procedure

untill both the "0" and "span" pots are set properly.

RESET

REMOTE

The reset is positive edge active; once reset, the unit will

accept new data even if reset is held. Applying a 3 to

30VDC pulse of minimum 5 msec resets the batch counter

and control output. Impedance 10K to ground (-DC).

FRONT PUSH BUTTON RESET

Pressing the front CLR button will reset the control output

and any displayed number (load the “Preset A” number into

the display if “SP”, subtracting mode of operation, has been

selected).

AUTO RESET

To recycle the unit, choose the preset which is to activate

the reset and set it’s “Relay Duration” as short as possible.

Place a 10K Ohm resistor between reset (Pin 5) and the

chosen transistor output for the preset chosen (Pin 19 or

Pin 20). The relay acts as a pull up resistor and the unit

resets after the control output “times out”. After the unit is

reset it will operate even though the reset is high. The reset

is edge triggered and only resets when the input goes high.

Note that if Pin 5 is pulled high by a resistor, it must be

pulled low a min. of 5 msec and then allowed to go high to

reset the unit.

FACTOR/”DATALOST”/”RFFF...”

The K- Factor is used to convert the frequency generated

internally by the analog input to engineering units. The 8

digit K -Factor dividers, with decimals keyed into any

position by use of the “D” button, allows easy direct entry of

the desired K - Factor. A separate K - Factor may be

entered for the count and rate section. Thus you may batch

and total in gallons and display rate in liters per hour.

NOTE: If the counter K - Factor is .0001 or less or if the

factored count speed exceeds 20000 CPS, “DATALOST”

flashes. If the input divided by the rate K - Factor exceeds 7

digits “RFFF...” flashes. These alarms indicate that the

factored speed has been exceeded and data is invalid.

Increase the K - Factor divider.

12

Page 15

COUNTER

The unit accumulates up to 8 digits of batch and grand total

count. In the setup mode choose “R0” (Reset to Zero ) for

adding operation or “SP” (Set to Preset) for subtracting

operation. While running display can be made to display an

8 digit grand total by pressing “ENT” while the unit is

running. Activating “CLR” while the grand total is flashing,

resets the grand total counter.

PRESETS

The unit has two independent presets. In the setup mode

the user selects whether the Counter, Rate Meter or Grand

Total counter activates either or both Preset A and Preset B

outputs. The preset numbers can be displayed or updated

at any time by pressing “A” (Preset A) or “B” (Preset B).

Enter the flashing preset number or press “CLR” and key in

a new number and “ENT” to enter it.

If the Total or Grand Total counter is set to control an

output, that output will activate for the time duration selected under “RELAY” when the counter reaches the

selected preset number.

If the Rate is set to control and output, that output will be

activated when the rate equals or exceeds the preset rate

and drop out again when the rate goes below the preset

rate. Note that the preset for rate can be entered with

decimal when keying in the rate preset number.

the unit is displaying the batch. “R” is displayed on the left

side of the display to indicate that rate is being displayed.

The unit calculates the rate from the period between

pulses. The unit measures the average time between

pulses, divides this by the K - Factor and a reciprocal math

calculation to find the rate per second. As long as pulses

come in faster than 3 per second the unit will update each

second. The 2 to 24 second “WINDOW” time, selected at

set up, is the maximum time the unit will wait for sufficient

pulses to make an accurate calculation before it displays

zero.

1 to 6 “SIG FIG” (significant figures) can be selected in the

set up mode. The unit will normally display the number of

digits selected. The unit is auto ranging and will place the

decimal within these digits to display the true factored rate.

If the rate, scaled by the K - Factor, has more digits to the

left of the decimal point than the number of significant digits

selected, additional zeros will be added to fill in digit spaces

to the left of the decimal place. Eg. Factored rate is

123.456. A: “SIG FIG” set 4, display reads 123.4 B. “SIG

FIG” set 2, display reads 120. This allows the user to show

either the exact rate with the least significant digits changing with only a slight rate change or to create a more stable

display by showing zeros in the less significant digits.

NOTE: If the rate exceeds 7 digits, the display shows

“RFF...” indicating speed has been exceeded.

RELAY - OUTPUT TIMING

Control output timing is selected by pressing D until the

RELAY mode is selected and entered. Any time duration

from .1 to 9.9 seconds or latch until reset (0.0 setting) may

be entered for the A and B outputs. Once the output has

been activated, the unit must be reset before another

output will occur.

SCALED OUTPUT/DATA LOST

The unit generates a pulse out for each factored count. An

NPN transistor output (Pin 2), capable of driving 100mA

from 30 VDC max., can drive external devices at rates of

10, 200, 2,000 or 20,000 counts per second as selected

through keypad menu. (Min. on/off times in milliseconds are

47.5, 2.0, 0.2 and 0.013 respectively). If the inputs scaled

by the K - Factor generate faster pulses than the output

speed selected, an internal buffer will store up to 9,999

counts before “DATALOST” flashes on the screen. This

indicates that the counts being totaled and the scaled

outputs may be incorrect. Note that all counts being totaled

and the scaled outputs may be incorrect. Note that all

counts stored in the internal buffer will be pulsed out at the

selected frequency even if the counter is reset.

RATE METER

Accurate to 5 1/2 digits (+ one display digit); the ratemeter

is autoranging and can be programmed by the K - Factor to

display almost any engineering unit of measurement. To

display the rate press the “C” (RATE/TOTAL) button while

SETTING RATE K - FACTOR FOR PULSE

INPUT

K - Factor (rate per sec.) = pulses per unit (gallon, foot,

revolution)

K - Factor (rate per min.) = pulses per unit

60

K - Factor (rate per hr.) = pulses per unit

3600

The rate meter with a K - Factor of 1 displays the rate of

incoming pulses per second. To display the frequency or

rate per second simply key in the number of pulses per

gallon, revolution, foot or other unit of measurement. This

will usually be the same as the K - Factor used for the

count. If it is desirable to display the rate per minute, or

hour, divide the pulses per unit of measurement stated on

the sensor by 60 (rate per minute) or 3600 (rate per hour).

Example: A sensor generates 850 pulses per gallon and

you want to display gallons per hour. Set the counter K Factor at 850 to batch in gallons. Set the rate K - Factor at

0.2361111 (850 divided by 3,600). To convert to other units

of measurement calculate the number of pulses for the

desired unit of measure and use the formula above.

Example: Sensor give 850 pulses per gallon and you want

to batch in liters and display in liters per minute. (Example

uses conversion 1 gallon equals 3.78533 liters). Counter KFactor = 224.55109 (Sensor gives 224.55109 pulses per

liter - 850 divided by 3.78533). To find the rate per minute K

- Factor divide the count K - Factor for liter (224.55109) by

60 (seconds per minute) = 3.7425181.

13

Page 16

LOCKOUT

Unauthorized front panel changes can be prevented by

entering a four digit code chosen by the user in the LOCKOUT setup mode. The unit leaves the factory with code

1,000. (If a code of less than 4 digits has been entered, the

unit adds prefix “0’s” to make a four digit code.) The

selected code should be recorded in a safe place. A choice

of two level lockout offers the user the option to lockout all

front panel changes or lock out all but presets A, B and

CLR. Entering the code in the set up mode does not

disable the keypad, but keying in the four digit code while in

the run mode will activate “LOCK ON”. The status of the

presets, rate and grand total can be viewed but “LOCK ON”

appears if changes are attempted. Only by keying in the

four digit code into the keypad while the unit is in the run

mode will the unit return to the “LOCK OFF” status.

REMOVING THE CASE

To install or change the input or data interface cards, the

case must be removed. Before opening case, remove all

power. CMOS logic is used. Use standard precautions

against damage by static discharge. If the unit has a data

interface option (RS232/422/422M), two screws in the

back, designed to secure the top left connector, may have

to be removed. Next remove the six (6) flat head 4-40 x 1/

4” screws behind the panel and lift off the panel/lens

assembly. Slide the main board display out the front of the

case. Once modifications are made, reverse the procedure

to re-assemble the unit, insuring that the main board is in

the track. The six (6) screws that hold the panel must be

tight to seal the rubber keypad panel assembly, approximately 0.6 in” lb. torque.

IINPUT CARD MODIFICATION

Follow “Removing the Case” procedure. The Input Card is

mounted just behind the display and plugs onto the 15 pin

post connector. Remove the board and make desired

changes. When installing the input card, insure that the

component side of the board is facing the front and that the

15 pin connector is mated to the proper pins and not offset

to the side. Replace the front panel.

INTERFACE INSTALLATION - RS232/RS422/RS422M

Follow “Removing the Case” procedure. The RS232 and

RS422 cards have a 15 contact ribbon cable that plugs into

the female connector next to the heat sink. Choose the

proper interface card. With components on top and subminature connector to the back, plug in the harness and

mount the card on the four (4) standoffs provided. After the

main board is inserted into the case, replace the front

panel.

OUTCARD RS232/RS422SERIAL INTERFACE

If the serial interface option is supplied, up to 15 units can

be linked together. (See “Strobe Input Operation” to link

more than 15 units). Units status and new set points can be

communicated by remote hook-up. Mode changes, however, must always be made on the front keypad. Data is

transmitted at selected baud rates using standard seven bit

ASCII characters and parity with two additional bits of

“Start” and “Stop” to make up the standard ten bit character. (See Unit setup to select and enter desired Code

Number, Baud Rate and Parity). RS422M has automatic

baud rate selection and uses an eight bit word, up to 256

units can be linked together.

UNIT CODE

Each Unit in the hook-up must be assigned a code number

from 1 to 15 through the front keypad in the “Outcard” set

up mode. Number “00” is reserved for a dedicated hook-up

to only one terminal and its transmit output line remains in

an “on” active state. (Units assigned other numbers have

outputs that remain in the “off” high impedance state until

addressed by their code number or brought on line by

positive edge of Strobe input). Once a unit is addressed, do

not address another unit until the data has been entered, a

“Carriage Return” has been sent and any data requested

has been transmitted back.

BAUD RATE

The baud rate is the speed at which data is transmitted,

expressed in bits per second. Baud rates of 300, 600,

1200, 2400, 4800 or 9600 are available. Use the front

keyboard to call up the “Outcard” set up mode and select

the desired baud rate that is compatible with the remote

terminal.

PARITY

Parity is a bit of information that is inserted before the stop

bit is used. It is used to help check that the transmission is

correct. In the “Outcard” set up mode, select between

“Odd” (Parity bit is logical zero if total number of logical 1’s

in the first seven data bits is odd)’ “Even” (Parity bit is

logical zero if total number of logical 1’s in the seven data

bits is even), “Mark” (Parity data bit always logical 1 - high/

Mark), “Space” (Parity data bit always logical 0’ low/Space).

If a “Mark” parity is chosen, it will appear that two (2) stop

bits are used. Use the “Mark” parity with terminals using

parity “OFF or “NONE”. These terminal ignore the parity.

The unit does not check the parity but does transmit the

parity chosen. If the parity requirements of the interface

terminal are not known, it is often practical to key in a

different parity until the correct one works.

RS232 ELECTRICAL REQUIREMENTS

Standard E1A specifications. Standard inputs must present

a load of 3000 to 7000 Ohms. A voltage level of +3V to

+25V (referenced to signal ground) is read as a “Space” or

“0” and indicates an active state (asserts a control line). A

voltage level of -3 to -25V is read as a “Mark” or “1” and

does not indicate and active state (does not assert a control

line). Outputs must send a voltage of +5 to +25V (referenced to signal ground) for a “Space” and a voltage of -5 to

-25V for a “Mark” when loaded with a 3000 Ohm load to

signal ground. Outputs must be capable of being shorted to

other signal lines without burning out. It is normally recommended that cable length be limited to 50 feet.

14

Page 17

RS422 ELECTRICAL REQUIREMENTS

The input of the unit follows the standard E1A high impedance minimum of 12K Ohms. When the 422 + (A) input is

more positive than the 422 - (B) input by .2V to 6V, a “1” or

“Mark” condition is recognized. When the 422+ input .2V to

6V, a “0” or “Space” is recognized. Data is recognized by

the popularity of the voltage difference between the two

lines. Noise picked up on the line will make little difference

since the noise is usually added to each line, and the

voltage differential remains the same. The output driver

drives the transmit lines to a differential of 2 to 6V. It is

designed to handle loads up to 60mA of sink or source

current and features positive and negative current limiting

for protection from line fault conditions. Since the RS422 is

more immune to noise, cable links up to 1000 feet or more

can be used. Because of the high input impedance of

RS422, line terminating loads are recommended. For hook

up to a single unit a 150 to 200 Ohm resistor across

Receive Data + or - at the unit and at the remote terminal is

often sufficient. For multiple hook-up, other standard

terminations should be used. Total loading should not be

greater than 90 Ohms.

RS232/RS422 SERIAL INPUT CODES

DXX(S) (Device and address number followed

by space) activates the unit that has

been assigned that number. That unit

comes on line and transmits “Device

XX:”. Unit is now ready to receive a code

or string of codes separated by a space.

A “Carriage Return” (Enter) code enters

the codes and processing of requests

begins.

CODES

DC Will transmit count.

DR Will transmit rate.

DT Will transmit grand total.

KC Will transmit counter K-Factor.

KC(S)XXX Will load counter K-Factor

number.

KR Will transmit rate K-Factor.

KR(S)XXX Will load rate K-Factor number.

PA Will transmit Preset A.

PA(S)XXX Will load preset A number.

PB Will transmit Preset B.

PB(S)XXX Will load Preset B number.

RC Will reset counter to zero if in

“RO” mode (adding) or set

counter to Preset A if in “SP”

mode (subtracting). Output is

reset.

RC(S)XXX Will set counter to number (no

other change is made).

RT Will reset grand total to zero.

RT(S)XXX Will reset grand total to number.

SERIAL INTERFACE OPERATION

Data is received and transmitted over standard EIA RS232

or RS422 levels. Each 10 bit character is made up of a start

bit, 7 bit ASCII code, parity bit and stop bit. Unit number,

baud rate and parity are entered in the “Outcard” set up

mode and remain in memory even if power is off.

Note that the input impedance of RS232 is 3K or 7K Ohm

worst case. The terminal addressing the unit must be

capable of driving all loads in the loop. RS422 input impedance is much higher and there is usually no problem driving

15 units. Unit serial transmit line remains in a high impedance “OFF” state until addressed. Insure that only one unit

is addressed at a time.

To address unit, transmit a “D” (device) followed by the 1 to

15 code number and a “Space”. Once the “Space” has

been received, the unit becomes active and responds back,

“Device XX:” (Device number). (Once active, the unit works

in a full duplex, echo back mode, so that data sent from the

terminal will be transmitted back for verification). Once the

unit is “on line”, use the proper serial transmit codes to

request data or set a new value. (See RS232/RS422 Serial

Input Codes). Up to 80 characters of data may be linked

together and transmitted to the unit in a string as long as

there is a space between the different codes. If an error is

made, a correction can be made by back spacing and

retyping correct data before the “Carriage Return” (Enter) is

sent, the unit starts processing the data and will transmit

the requested data on a non-priority basis over the data

transmit line. A unit keypad entry or incoming data will halt

the data communication cycle. Therefore, there should be a

pause after data is requested to insure that all data has

been transmitted before another unit is addressed and

brought on line. (If the unit is not busy, It should not require

more than 5 msec to process each request. To find the

cycle time to process and transmit a request, calculate the

bit transmit time by dividing 1 by the baud rate; multiply by

the number of requests made. Example: Typical time to

transmit 1 uninterrupted request at 300 baud rate is .272

sec. (1-300) x (80) + .005.

This time will be extended if the unit must service the front

keypad or one of the inputs. In practice if transmission has

not started within 2 seconds after data is requested, It can

be assumed that there is a problem).

When transmitting, the unit will precede each data value

with a “Carriage Return” and “Line Feed” code and answer

only with requested data in the order the requests were

made. After all requested data has been transmitted any

new communication must be started again by DXX (Device

number) and space.

15

Page 18

Following are two examples of requests and responses.

RS232

DATA

OPT.

INTERFACE

STROBE

DATA

RD

TD

SIG. GROUND

RTS

CTS

DSR

RLSD

DTR

DL1

DL2

DL4

STROBE

2

3

7

4

5

6

8

20

9

10

11

18

Transmit from Receive from

Terminal Unit

STROBE INPUT LEVELS

0 or low: Open or 0 to 1VDC

1 or high: 3 to 30 VDC

Impedance: 1.5K Ohm

(S) = Space

Example A:

D13(S) Device #13

[Unit #13 Activated]

PA(S)76546(S)PA(S) PA 76546 PA

KC(S)1575(S)KC(S) KC 1575 KC

RC(ENTER) RC

[Unit presets and counter K-Factor are set, counter is reset]

76546

1575

Example B:

D7(S) Device #7

[Unit #7 Activated]

PA(S)12347(S)PA(S) PA12347 PA

RC(S)456789(S)DC(S) RC 456789 DC

RT(S)376(S)DT(ENTER) RT 376 DT

[Unit preset, counter and total count are set]

12347

456789

376

STROBE ADDRESS OPERATION

Another method of reading the status of a unit with either a

RS232 or RS422 option is by means of a separate strobe

address and a 3 bit data request code. Use of the strobe

address method does not allow the input of new set points

but theoretically hundreds of units could be linked together

to transmit the data in the unit over the serial transmit line

in the standard RS232 or RS422 format. The unit could be

assigned any code number other than “00”.

The 3 bit data request code would be latched in at the

positive edge of a 3 to 30 VDC strobe input that remain

high a minimum of 25 milliseconds. Requests are processed on a nonpriority basis. Normally data will begin to be

transmitted from the unit over the RS232 or RS422 serial

transmit line within 5 msc unless interrupted by a keypad

entry or other signal input.

No other unit should be brought on line until data requested

has been transmitted.

STROBE INPUT ELECTRICAL

REQUIREMENTS

Both the RS232 and RS422 interface option cards have

inputs that allow data to be requested over a separated

strobe input and a 3-bit data request code input. Any

number of the 3 data request code lines can be linked in

parallel as long as the source can drive the combined load

of all inputs linked together (1.5K Ohm divided by the total

number linked together). Data is transmitted over the serial

lines using standard RS232 or RS422 characteristics.

Strobe and data ground as reference:

STROBE INPUT CODES (Octal Code)

0: PA (Preset A request)

1: PB (Preset B request)

2: KC (K-Factor or counter request)

3: KR (K-Factor of rate request)

4: DC (Display of count request)

5: DT (Display of grand total request)

6: DR (Display of rate request)

HOOKUP

RS232/STROBE

(SUB-D 25 PIN CONN.)

RS232 WIRING

The unit requires only three wires for RS232 communica-

tion: Pin 7 (Signal Ground), Pin 2 (Receive Data), Pin 3

(Transmit Data). Pin 4 (Request to Send) are jumped

internally to echo back the signals. Pins 6 (Data Set

Ready), 8 (Received Line Signal Detector) and 20 (Data

Terminal Ready) are also jumped internally to echo back

any signal.

The unit RS232 option has a subminiature D25 pin female

connector and is wired as a DCE (Data Communications

Equipment) device. If it is connected to a DTE (Data

Terminal Equipment) device, the interconnect cable should

have wires 2 and 3 connected straight to the same pins on

each end. If it is connected to another DCE device, Pins 2

and 3 must be crossed so that the wire to Pin 2 on one end

goes to Pin 3 on the other end and Pin 3 on one end goes

to Pin 2 on the other end.

STROBE WIRING FOR RS232

The 3 data lines to generate the request code (DL 1: Pin 9,

DL 2: Pin 10, 2: DL 4 Pin 11) must be set and remain

constant while the positive strobe of at least 25 millisec-

onds is given on the strobe input (Pin 18). Data is transmit-

ted in RS232 serial format on Transmit Data Line (Pin 3).

16

Page 19

RS422 WIRING

The unit RS422 option has a subminiature D 37 pin female

connector and is wired as a DCE (Data Communication

Equipment) device. It is designed to be connected to a DTE

(Data Terminal Equipment) device. If it must be connected

to a DCE device, it will be necessary to cross wires 4 and 6

as well as 22 and 24 at one end of the connector harness.

The unit requires only 5 wires for RS422 communications;

Pin 22 [Receive Data + (A)], Pin 4 [Receive Data - (B)], Pin

24 [Transmit Data + (A)], Pin 6 [Transmit Data - (B)], Pin 20

(Sig. Ground). The following groups of pins have been

jumped internally to echo back the signals: (7, 9), (25, 27),

(11, 12, 13), (29, 30, 31). Signal ground (Pins 19, 20) must

be connected to provide a common reference

HOOKUP

RS422/Strobe (SUB-D 37 Pin Conn.)

22 RD+ (A)

4 RD- (B)

24 TD+ (A)

6 TD- (B)

7 RTS+

9 CTS+

25 RTS27 CTS11 DSR+

12 DTR+

13 RLSD+

29 DSR30 DTR31 RLSD21 DL 1

14 DL 2

10 DL 4

3 STROBE

19 SIG. GROUND

20 SIG. GROUND

RS 422

DATA

OPT

INTERFACE

STROBE

DATA

.

STROBE WIRING FOR RS422

The 3 data lines to generate the request code (DL1: Pin 21,

DL2: Pin 14, DL4: Pin10) must be set and remain constant

while the positive strobe of at least 12 milliseconds is given

on strobe input (Pin 3). Data is transmitted in RS422 serial

format on Transmit Data Lines (Pin 6-24).

ANALOG OUTPUT

When used with a digital input, the Analog Output module

is separate and plugs on just to the right of the input

module. When used with analog input (7A to 7E), the

Analog Output logic is combined on one analog input/

output module. (The white wire from the module plugs onto

pin J2-6). The output on external pin 3 is a 4mA to 20 mA

output corresponding to the selected rate readings. A

sinking driver generates a linear current across recorder,

PLC, computer, external meter. In the program set up

mode the user is prompted to “SET LOW” (4mA rate) and

“SET HIGH” (20mA rate).

The unit can supply the 24VDC to power the current loop.

(Connect Pin 15 to Pin 13. Pin 16 is now + 24VDC with

respect to Pin 12). With Pin 15 connected to Pin 13,

connect Pin 16 to the + DC side of the external device and

connect Pin 3 to - DC side of the external device.

OPTIONAL 16-POINT LINEARIZATION OF

VARIABLE K-FACTOR

DESCRIPTION

The 16 point K-Factor option allows the user to dial in from

3 to 16 different frequency points (inputs per second) and

different K-Factor dividers from 0.0001 to 99999999 for

each of these frequencies.

The 16 point unit determines the incoming frequency and

calculates a K-Factor line slope from the two closest data

points that had been entered. The “specific K-Factor” is

then proportionally interpolated using 8-position floating

math. This K-Factor is applied to all inputs until the next

frequency calculation, usually 1 second later. If a “0”

frequency is entered into “point 1”, the “point 1” K-Factor

will be applied to all inputs received before the first frequency calculation.

The rate can be displayed in 3 ways: “SECONDS _”,

“MINUTES _”, “HOURS _”, or “TEST _”. If “SECONDS” is

selected, the unit displays the “base rate” calculated from

the incoming frequency and the “specific K-Factor”. If

“MINUTES _” is selected, the rate displayed is 60 times the

“base” rate. If “HOURS _” is selected, the rate displayed is

3600 times the base rate.

POINT DATA FORMATTING

Each Frequency/K-Factor data entry is assigned a point

number. Any point number may be selected to view and/or

change the Frequency/K-Factor data as long as the frequencies of the ascending frequencies. “BAD FREQ” will

flash when exiting the set up mode if there is a sequence

error. The unit will then display the sequence error point #

so that corrections can be made.

17

Page 20

NOTE A: Unit defaults “0” K-Factor to K-Factor

of “1” since it is impossible to

divide by “0”.

NOTE B: “Point 01” will be the “low shut-off”

frequency. Below this frequency

no rate will be displayed nor

count recorded. Point 01 should be

assigned a frequency of “0” with a

K-Factor for lowest flow especially

if very slow flow is to be counted.

NOTE C: The entry of a frequency of “0” for

“Point 03” or above will tell the

unit to continue the K-Factor slope

line calculated from the two

previous Frequency/K-Factor points

and ignore any higher point data.

If a fixed K-Factor is desired, assign

the same K-Factor to two ascending

frequency points and enter a

frequency of “0” in the next higher

point entry.

A) Set the 16 point units to “TEST” and ENT

point 00 to go to the run mode.

B) At the lowest desired flow rate, rest the

counter and let the unit count the incoming

signal while the rate displayed is recorded.

C) Interrupt the input signal when the known

tested volume has gone through the

flow meter. Switch to count display and

read the number of counts that came in

from the known volume as displayed on

the unit. Divide the counts by the volume

that past through the meter to determine

the number of counts for 1 unit of measure,

gallon, cubic foot, etc.

D) Record this frequency and K-Factor for later

entry into point 1 or point 2.

(See NOTE B above to determine if data

should be entered in point 1 or 2).

E) Assign ascending point numbers to

correspondingly ascending frequencies

when recording frequency/K-Factor data.

A minimum of 3 points and a maximum of

16 points must be entered.

NOTE D: K-Factors are always positive

numbers. To avoid undesired

K-Factors projected around “0”

K-Factors, insure that a positive

K-Factor is assigned for the highest

used frequency.

NOTE E: The decimal in the “Total” and “Grand

Total” is a dummy. The K-Factor

should be calculated to show all

numbers as if there were no decimal

and then decimal added under DEC

LOC section of DEV TYP MENU.

Note that the autoranging decimal in the rate (R) display

will be shifted to the left as the “Dummy Decimal” is shifted

to the left so that the rate display will be the same as the

count. Example: A meter gives 33.4 pulses per gal. and it is

desired to display in 1/10 gal. Move K-Factor decimal place

to the left and key-in a decimal under DEC LOC MENU. KFactor for gal. and 1/10 is 3.34 Rate will show 3.34 with

decimal added while it would show 33.4 if no decimal were

added.

TEST MODE

A special “TEST” mode can be selected to help set-up the

points and K-Factors. If “TEST” is selected, the RATE (“R”

display) will show the frequency (pulses per second) of the

incoming signal. The TOTAL section will accumulate one

count for each incoming pulse.

TEST MODE K-FACTOR CALCULATION

Calculate the K-Factors for flow meters with pulse or

analog transmitters:

DATA ENTRY FOR 16-POINT

Press “D” until “16 POINT” appears on

display. ENT.

Press D to step through options:

SECONDS (Scaled rate per second selected)

MINUTES (Scaled rate per minute selected)

HOURS (Scaled rate per hour selected)

TEST (Test mode-rate per second with 1

count for each input (fixed K-Factor of 1)

selected)

Press ENT when selected option is displayed.

Point 00 will appear on the display. ENT “POINT 00” to exit

the set up and go to run mode or key in a point number

from 1 to 16 and ENT.

“K” will flash with present K-Factor for that point. ENT or

CLR and key on desired K-Factor.

Continue to step through the POINT numbers to view or

change data. If a frequency of 0 is entered, in POINT 3 or

above, the unit will ignore data above that point number. A

K-Factor generated from the line slope of the 2 previous

POINT entries will be applied to higher frequencies.

Exit “point set” routine by setting to POINT 00 and ENT.

Unit will go to run mode. “BAD FREQ” will flash when

exiting the set up mode if there is a sequence error. The

unit will then display the sequence error point # so that

corrections can be made.

If “TEST” is selected, point data can be entered into

memory but when running, unit will add one count per each

input (fixed K-Factor of “1”) and display frequency (rate per

second) of incoming signal. (See TEST MODE for more

information).

18

Page 21

COMMUNICATION FOR 16 POINT

When 16-Point option is supplied with either RS232 or

RS422 option, data can be read and changed as explained

under Communication Section of the manual.

Codes to address 16-point data: (F=frequency; K=K-Factor;

A to P = Point number 1 to 16)

FA = Frequency for A (Point 1)

KA = K-Factor for A (Point 1)

FB = Frequency for B (Point 2)

KB = K-Factor for B (Point 2)

- - = (Use of letters A to P for Points 1 to 16)

FP = Frequency for P (Point 16)

KP = K-Factor for P (Point 16)

IRREGULAR SHAPE VESSEL APPLICATION NOTE;

MEASURE VOLUME IN IRREGULAR SHAPED VESSELS

WITH 16-POINT LINEARIZATION OPTION.

In the past it was difficult to calculate the volume of liquid

and set up the equation or computer model to display the

volume in containers with odd shapes. It usually required

that a special electronic memory be made for each container.

The “16-Point” option allows a simple was to program the

unit to display correct volume with resolution to 10,000

parts.

all that is needed is the analog signal from a weight or level

transducer (4 to 20 or 0 to 20mA, 0 to 5, 1 to 5, 0 to 10

VDC).

To request a transmit of data, send a code for information

desired. To change data, send the desired address code

followed by a space and the new number desired.

Sample Code request and response:

Transmit from terminal Receive from unit

(S) = Space

Example A:

D13(S) (unit #13 activated) Device #13

FA(S)0(S)KA(S)123 (ENTER) FA 0 KA 123

(Frequency for A (Point 1) is set (Unit echoes back

to 0, K-Factor for A (Point 1) command as sent)

is set to 123)

Example B:

D11(S) (unit #11 is activated) Device #11

FC(S)500(S)KC(S)305(S) FC 500 KC 305

FC(S)KC(S)(ENTER) FC KC

(Frequency for C (Point 3) is set (Unit echoes back

to 500, K-Factor for C (Point 3) command as sent)

is set to 305,

Frequency of C (Point 3) is 500

sent, K-Factor of C (Point 3) 305

is sent. (Unit transmits

frequency and

K-Factor data for

C (Point 3).

CAUTION:

1) Frequency speed must increase with ascending point

numbers. A bad sequence can be entered over the serial

part. Unit will use calculated K-Factor based on first frequency match found, which may be wrong. Check by

requesting a transmit of all frequency points used: FA FB

FC FD to F_ to insure ascending sequence is entered or

enter “POINT 00” on front keypad and unit displays “BAD

SEQ” if there are errors.

The easiest way to set the 16 points is to use the “Test”

mode while filling the vessel. In this “Test” mode the unit

converts the analog signal to a 1 to 10,000 base frequency

reading.

Record the “Test” frequency reading in a column next to

actual amount put into the vessel. Choose 16 points where

there is a significant ratio change between the frequency

reading and the actual volume. Divide the “Test” frequency

by the actual volume to determine the the point K-Factor to

be entered with the “test” frequency. Simply key in these

point frequencies and K-Factors in order of ascending

frequencies. Volumes between the 16 points entered will be

interpolated from a K-Factor line slope generated from the

closest 2 points entered.

Once the “16-Point” frequencies and K-Factors are entered,

set the unit to “Second” reading of rate to display actual

volume in the vessel. Disregard the counter readings.

Two separate control relays can be set to activate at

different volume for monitoring or dispensing applications.

An optional 4 to 20mA output of the corrected volume can

be supplied to drive a strip chart recorder, remote meter or

other equipment.

CONCLUSION

This manual has attempted to cover all aspects of operation of the unit. It is written to cover most anticipated

problems and misunderstandings. if some questions still

arise or you feel some improvements can be made to this

manual, please feel free to contact your local representative.

We hope you will be pleased with our product. If you have

any questions concerning our warranty, repair, modification

or returned goods process, please contact your local

distributor.

2) After device is activated, there must be a delay to allow

“Device #--” to be transmitted by the device before new

commands are sent to the unit.

19

Page 22

20

Loading...

Loading...