Page 1

LCI Level-Up® Motorhome

Leveling (2013-Present)

OWNER'S MANUAL

Rev: 07.02.2018 Level-Up® Motorized Leveling LCD Owner's Manual

Page 2

TABLE OF CONTENTS

System Information 3

Prior To Operation 3

System Description 3

Component Description 4

Maintenance 4

Fluid Recommendation 4

Preventative Maintenance Procedures 4

Aluminum Jacks 5

Power Unit Components 6

Touch Pad Controls 7

Level Zero Point Calibration 8

For Diesel Units With Air Bag Suspensions ONLY: 8

Miscellaneous 8

Low Voltage Signal 9

Error Mode 9

Excess Angle 9

Error Mode 9

Operation 10

Selecting A Site 10

Automatic Leveling Procedure 10

Automatic Leveling Descriptive Logic 10

Manual Leveling Procedure 11

Jack Retract Procedures 11

Manual Override - Jacks 12

Manual Override - Power System 12

Automatic Safety Shuto 13

Drive Away Protection System 13

“Jacks Down" Alarm 13

Fluid Recommendation 13

Wiring Diagram 15

Plumbing Diagram 16

Bill of Materials 17

Level-Up® Motorized Leveling 18

Level-Up® Motorized Leveling 19

Level-Up® Motorized Leveling 20

Level-Up® Motorized Leveling 21

Level-Up® Motorized Leveling 22

Level-Up® Motorized Leveling 23

Level-Up® Motorized Leveling 24

Notes 25

Rev: 06.29.18

Page 2

CCD-0001535

Page 3

System Information

Failure to act in accordance with the following may result in serious personal injury or death.

The use of the LCI Level-Up® Motorhome Leveling System to support the coach for any reason other than

which it is intended is prohibited by Lippert's Limited Warranty. The LCI Level-Up® Motorhome Leveling

System is designed as a "Leveling" system only and should not be used to provide service for any reason

under the coach, such as changing tires or servicing the leveling system.

Lippert Components Inc. recommends that a trained professional be employed to change the tires on the

coach. Any attempts to change tires or perform other services while coach is supported by the LCI Level-

Up® Motorhome Leveling System could result in death, serious injury and/or damage to the motor home.

Prior To Operation

The leveling system shall only be operated under the following conditions:

1. The coach is parked on a reasonably level surface.

2. The coach “PARKING BRAKE” is engaged.

3. The coach transmission should be in the neutral or park position.

4. Be sure all persons, pets and property are clear of the coach while LCI Level-Up® Motorhome Leveling

System is in operation.

5. Clear all jack landing locations of debris and obstructions. Locations should also be free of depressions.

6. When parking the coach on extremely soft surfaces, utilize load distribution pads under each jack.

7. Be sure to keep hands and other body parts clear of fluid leaks. Oil leaks in the LCI Level-Up®

Motorhome Leveling System may be under high pressure and can cause serious skin penetrating

injuries.

8. Never lift the coach completely off the ground. Lifting the coach so the wheels are not touching the

ground will create an unstable and unsafe condition.

NOTE: After starting the automatic leveling cycle it is very important that you do not move around in the

coach until the unit is level and the green LCI logo light illuminates in the center of the touch pad.

Failure to remain still during the leveling cycle could have an effect on the performance of the

leveling system.

System Description

The LCI Level-Up Motorhome Leveling System is an electric/hydraulic system. A 12V DC electric motor

drives a hydraulic pump that moves fluid through a system of hoses, fittings and jacks to level and stabilize

the coach.

Mechanical portions of the LCI Level-Up Motorhome Leveling System are replaceable. Contact Lippert

Components, Inc. to obtain replacement parts.

Rev: 06.29.18

Page 3

CCD-0001535

Page 4

Component Description

The LCI Level-Up Motorhome Leveling System consists of the following major components:

Lippert jacks are rated at a lifting capacity appropriate for your coach. Each jack has a 9” diameter

(63.5-square-inch) shoe on a ball swivel for maximum surface contact on all surfaces. (12” dia. - 113-squareinch shoe also available.)

Each jack is powered from a central 12V DC motor/pump assembly, which also includes the hydraulic oil

reservoir tank, control valve manifold, and solenoid valves.

The LCI Level-Up Motorhome Leveling System is controlled electronically from the driver’s seat of the

coach. The control panel is mounted in the dash. The system can be operated in a manual mode or a fully

automatic mode.

Maintenance

Fluid Recommendation

The LCI Level-Up Motorhome Leveling System is pre-filled, primed and ready to operate direct from the

manufacturer. Automatic transmission fluid (ATF) with Dexron III or Mercon 5 or a blend of both is recommended

by Lippert Components, Inc. Specific fluid information can be found on Page 15.

NOTE: In colder temperatures (less than 10° F) the jacks may extend and retract slowly due to the fluid’s

molecular nature. For cold weather operation, fluid specially formulated for low temperatures may

be desirable. Please consult fluid specifications on Page 14.

Preventative Maintenance Procedures

1. Check fluid in reservoir every 12 months. If fluid is a clear, red color, do not change. If fluid is milky, pink

and murky, and not clear red in color, drain reservoir and add new fluid. Use recommended fluid (see

Page 14).

A. Check fluid only when all jacks are fully retracted.

B. When checking fluid level, fill to within ¼ to ½ inch of fill spout.

2. Inspect and clean all Power Unit electrical connections every 12 months. If corrosion is evident, spray

unit with WD-40 or equivalent.

3. Remove dirt and road debris from jacks as needed.

Your coach should be supported at both front and rear axles with jack stands before working underneath.

Failure to do so may result in personal injury or death.

4. If jacks are down for extended periods, it is recommended to spray exposed leveling jack rods with a

silicone lubricant every seven days for protection. If your coach is located in a salty environment, it is

recommended to spray the rods every 2 to 3 days.

NOTE: OEM to install attachment brackets for leveling jacks.

Rev: 06.29.18

Page 4

CCD-0001535

Page 5

Aluminum Jacks

Fig. 1

Fig. 2 Fig. 3

Fig. 1 - 433458

CAPACITY - 8,000 lb.

STROKE - 15.00 in.

BORE - 2.00 in.

H - 21.375 in.

ROD DIA. - 1.50 in.

9” FOOTPAD-STANDARD

12” FOOTPAD-OPTION - 117238

Fig. 2 - 236560

CAPACITY - 14,000 lb.

STROKE - 15.13 in.

BORE - 2.50 in.

H - 21.50 in.

ROD DIA. - 1.875 in.

9” FOOTPAD-STANDARD

12” FOOTPAD-OPTION - 117238

Fig. 3 - 258550

CAPACITY - 20,000 lb.

STROKE - 16.00 in.

BORE - 3.00 in.

H - 23.063 in.

ROD DIA. - 2.25 in.

9” FOOTPAD-STANDARD

12” FOOTPAD-OPTION - 117238

Rev: 06.29.18

Page 5

CCD-0001535

Page 6

Power Unit Components

Motor Solenoid

12V DC

Power

Fig. 4

12V DC Motor

Ground

Power

Pressure

Fill Cup

Switch

Disconnect for

Fig. 5

Flush and Fill

Extend

Fittings

Quick

Disconnect for

Flush and Fill

Quick

Hydraulic

Manifold

Valve and

Valve Coil

Return

Fittings

1. Fittings - High Pressure O-Ring Face - Size 4

2. Hose - ¼" I.D. 3000PSI - W.P. Rated

NOTE: Fittings are labeled with port assignments found stamped into the manifold for easy identification.

Rev: 06.29.18

Page 6

CCD-0001535

Page 7

Touch Pad Controls

Fig. 6

A

E

K

B

C

F

H

G

D

I

J

Callout Description

A Up Arrow - Scrolls up through the menu on LCD.

B Down Arrow - Scrolls down through the menu on LCD.

C Enter - Activates modes and procedures indicated on LCD.

D Retract - Places leveling system into retract mode. - Manual mode ONLY

E LCD Display - Displays procedures and results.

F Auto Level - Places leveling system into auto level mode.

G Front Jack Button - Activates both front jacks in manual mode.

H Left Jack Button - Activates both left jacks in manual mode.

I Right Jack Button - Activates both right jacks in manual mode.

J Rear Jack Button - Activates both rear jacks in manual mode.

K Power Button - Turns leveling system on and off.

Rev: 06.29.18

Page 7

CCD-0001535

Page 8

Level Zero Point Calibration

Before auto leveling features are available, the Level Zero point MUST be set. This is the point to which the

system will return when an auto leveling cycle is initiated.

To set the zero point (controller module MUST be fully secured in production-intent location), first run a

manual leveling sequence to get the vehicle to the desired level point. Then activate the Level Zero point

configuration mode.

This mode is enabled by performing the following sequence:

1. Turn panel off.

2. Press the Front switch 10 times (On Winnebago units, press FRONT 5 times).

3. Press the Rear switch 10 times (On Winnebago units, press REAR 5 times).

4. At this point, a tone will sound and the display will read ZERO POINT CALIBRATION.

5. Press ENTER to set the zero point.

6. Screen will then display Zero Point Stability Check and PLEASE WAIT.

7. Tone will sound and the screen will display ZERO POINT SUCCESSFUL.

8. Control will then turn off.

For Diesel Units With Air Bag Suspensions ONLY:

The leveling control will automatically detect an air bag system. If the unit does not use air bags, the display

will read “NO” for air bag control. If the display reads "NO," but an air bag system is present on the unit:

1. Confirm harness is connected properly.

2. Run Auto-Level function.

3. Recalibrate the Zero Point.

4. If the air bag system is still not being detected, contact the OEM for more information.

User Alarm Mode

If the alarm system detects that the park brake has been disengaged while at least one jack is not fully

retracted and the sensor value changes in any axis more than a predefined amount, the panel will signal this

error to the user.

When in alarm mode, all LEDs will flash and the buzzer will beep. The Status LEDs will show the system

status.

The system performs an automatic retract.

No other features are available in this mode.

Miscellaneous

• The system will automatically shut down after 4 minutes of no operation.

• Auto leveling cycle cannot be started until all jacks are fully retracted. Make sure jacks are retracted

before attempting to auto level. (Unit will perform full retract automatically if jacks are down on the

request of an auto cycle.)

• System will refuse any operation when a low voltage condition is present.

• System will automatically alarm and retract if park brake is disengaged and jacks are not retracted

with any change in sensor readings. In alarm mode, the only available feature is to retract all jacks.

• Please note WAIT display shows the status of Air/Auxiliary features.

NOTE: The LEDs blink differently when in special controller modes (error, alarm, and configuration).

Learning how to recognize these modes is important. Excess angle LED blinks whenever the Y axis

(vehicle length) is over 5o from programmed level point.

Rev: 06.29.18

Page 8

CCD-0001535

Page 9

Low Voltage Signal

1. The vehicle requires 12.7V DC to operate in the AUTO mode. If the voltage is too low, the screen will

display LOW VOLTAGE. If voltage drops below 12.7V DC, the system will only operate in the MANUAL

MODE and continue to display LOW VOLTAGE.

2. Minimum Voltage - If voltage drops below 9.5V DC during AUTO or MANUAL operation LOW VOLTAGE

will appear in the screen and the system will cease operating.

Error Mode

Excess Angle

1. The control will not operate at extreme slopes, i.e. 3.5 degrees fore and aft and 3.5 degrees side to

side.

2. If the coach indicates “EXCESS ANGLE” or “JACKS STROKED OUT“ during an auto level cycle, move the

coach to a more level spot.

Error Mode

NOTES:

• If an error occurs before or during operation, the error will be displayed in the LCD and an alarm will

sound. To reset all error or service displays, push RETRACT and ENTER at the same time.

• All normal functions will be disabled when the system is in Error Mode.

• Auto Level can only commence if running voltage is 12.7V DC or above.

• Auto Level operation will halt if running voltage drops to 9.5V DC.

• Manual Level operation can be performed at all running voltages above 9.5V DC.

Error Text Description

Excess Angle Excess slope for auto leveling

Feature Disabled Control not zeroed

External Sensor Remote sensor short or disconnected

Out of Stroke

Check campsite for even, level ground and turn engine

on - Check battery voltage under load.

Low Voltage Turn engine on - Check battery voltage under load.

Function Aborted Panic stop

Jack Timeout Auto mode/Retract timeout

Auto Level Fail Unable to level

Not Configured Control not zeroed

Zero Not Set Control not zeroed

Battery Voltage Turn engine on - Check battery voltage under load

Apply Park Brake to Auto Level Set parking brake

Unit has retracted for longer

than 50 seconds

Retract timeout, return leveling jacks for service.

Latched retract mode

Unable to Finish Leveling Move coach to a more level site

Check Wiring

Touch Pad is powered, but not communicating with

the controller. Check pin 1 and 2 of touch pad harness.

Caution, Excess Run Time Pump run too long in manual mode

Latched Retract / Service

Rev: 06.29.18

Check for leaking jack hose or fitting, reset by pressing

retract and enter at the same time.

Page 9

CCD-0001535

Page 10

Operation

Selecting A Site

When the coach is parked on an excessive slope the leveling requirements may exceed the jack lift stroke

capability. If the coach is parked on an excessive slope, the coach should be moved to a more level surface

before the leveling system is deployed.

EXCESS ANGLE will appear on the LCD screen if the coach is 3.5 degrees out of level front to rear or side to

side. See Page 9.

Automatic Leveling Procedure

NOTE: Coach MUST be running for LCI Electronic Leveling System to operate.

1. Push ON/OFF button on Control Panel. The system is now operational and the electronic level lights

will become active.

2. Check to see that the Control Pad ENGAGE PARK BRAKE is engaged.

3. Push the AUTO LEVEL button to begin the automatic leveling cycle.

4. Push ON/OFF button to de-energize the system.

Automatic Leveling Descriptive Logic

Grounding: Steps 1-3 describe the process of how the AUTO LEVEL LOGIC extends the jacks to the ground:

1. Depending on which end of the coach is lowest to the ground, the level sensor in the brain will

activate the jacks, one at a time on the lowest end first, either front or rear.

A. Ground lowest side jack first; i.e., front passenger side.

B. Ground remaining side jack next; i.e., front driver side.

2. Together, both jacks will lift lowest end until level; i.e., front of coach will lift briefly until the coach is

level.

3. The system will then ground remaining jacks, one at a time; i.e., rear jacks.

A. Ground lowest side jack first; i.e., rear passenger side.

B. Ground remaining side jack next; i.e., rear driver side.

Leveling: Steps 4-6 describe the process of how the AUTO LEVEL LOGIC levels the coach once the jacks

have been grounded. This process may repeat several times until level.

4. Fore/Aft

5. Side/Side

6. Individual

A. Minor adjustments to limit/prevent twist

NOTE: After starting the automatic leveling cycle, it is very important that you do not move around in the

coach until the unit is level and the green LCI logo light illuminates in the center of the touch pad.

Failure to remain still during the leveling cycle could have an effect on the performance of the

leveling system.

Never lift all the wheels off the ground to level the coach! Lifting all wheels off the ground may result in

serious personal injury or death.

Rev: 06.29.18

Page 10

CCD-0001535

Page 11

Manual Leveling Procedure

NOTE: When leveling your coach, the coach should be leveled from FRONT TO REAR first (step 2-4). When

the coach is level from FRONT TO REAR, then level the coach from LEFT TO RIGHT (step 5).

NOTE: Coach requires 12.7V DC to commence auto leveling function. If voltage at the power unit is not

12.7V DC, run the engine.

1. Push ON/OFF button on control panel. The system is now operational and the ON/OFF light will be lit.

2. Push DOWN ARROW to display MANUAL LEVEL on the screen. Push ENTER to set.

3. Push FRONT button until jacks contact the ground and lift the front of the coach 1-2 inches.

4. Push REAR button until jacks contact the ground and lift rear of coach. Keep button depressed until

level indicator displays level.

5. Push LEFT or RIGHT button. If level indicator is toward left of coach, push RIGHT button. If level

indicator is toward right of coach push LEFT button. Keep button depressed until level indicator

displays level.

NOTE: The right and left jacks are used to level the coach side to side. Pushing the LEFT button on the

control panel will extend both left jacks. Pushing the RIGHT button on the control panel will extend

both right jacks. Jacks always work in pairs, both front jacks; both right side jacks, etc.

6. Repeat steps 2 through 5 if needed.

7. Turn power off to leveling system by pushing ON/OFF button.

8. Visually inspect all jacks to ensure all shoes are touching the ground. Should one of the rear jack

shoes not be touching the ground, press the corresponding LEFT or RIGHT button to lower the noncompliant jack to the ground.

Never lift all the wheels off the ground to level the coach! Lifting all wheels off the ground may result in

serious personal injury or death.

Jack Retract Procedures

1. Energize the system by pushing ON/OFF button on control panel. The LCD screen will display JACKS

DOWN.

2. Push DOWN ARROW to display AUTO RETRACT on the screen.

3. Push ENTER to begin automatically retracting the jacks.

NOTE: If you wish to stop the jacks from retracting, turn the system off and back on again by pushing

the ON/OFF button twice. The coach can then be manually leveled by following steps 1-5 in the

MANUAL LEVELING PROCEDURE section above. Press ENTER to acknowledge.

4. When the JACKS DOWN display goes off, push the ON/OFF button on the Control Panel to de-energize

the system. After a brief visual inspection around the coach to verify the jacks are fully retracted, you

may proceed to travel.

NOTE: To retract in the MANUAL mode, push the RETRACT button until it lights. By pushing any of the JACK

buttons, the jacks will retract in pairs, i.e. FRONT button, both front jacks will retract, etc.

5. “AUTO RETRACT” can also be commenced by pushing and holding the “RETRACT“ button for 1 second.

NOTE: In cold weather operation, always check to make sure all jacks, slide rooms and steps are fully

retracted before travel.

Rev: 06.29.18

Page 11

CCD-0001535

Page 12

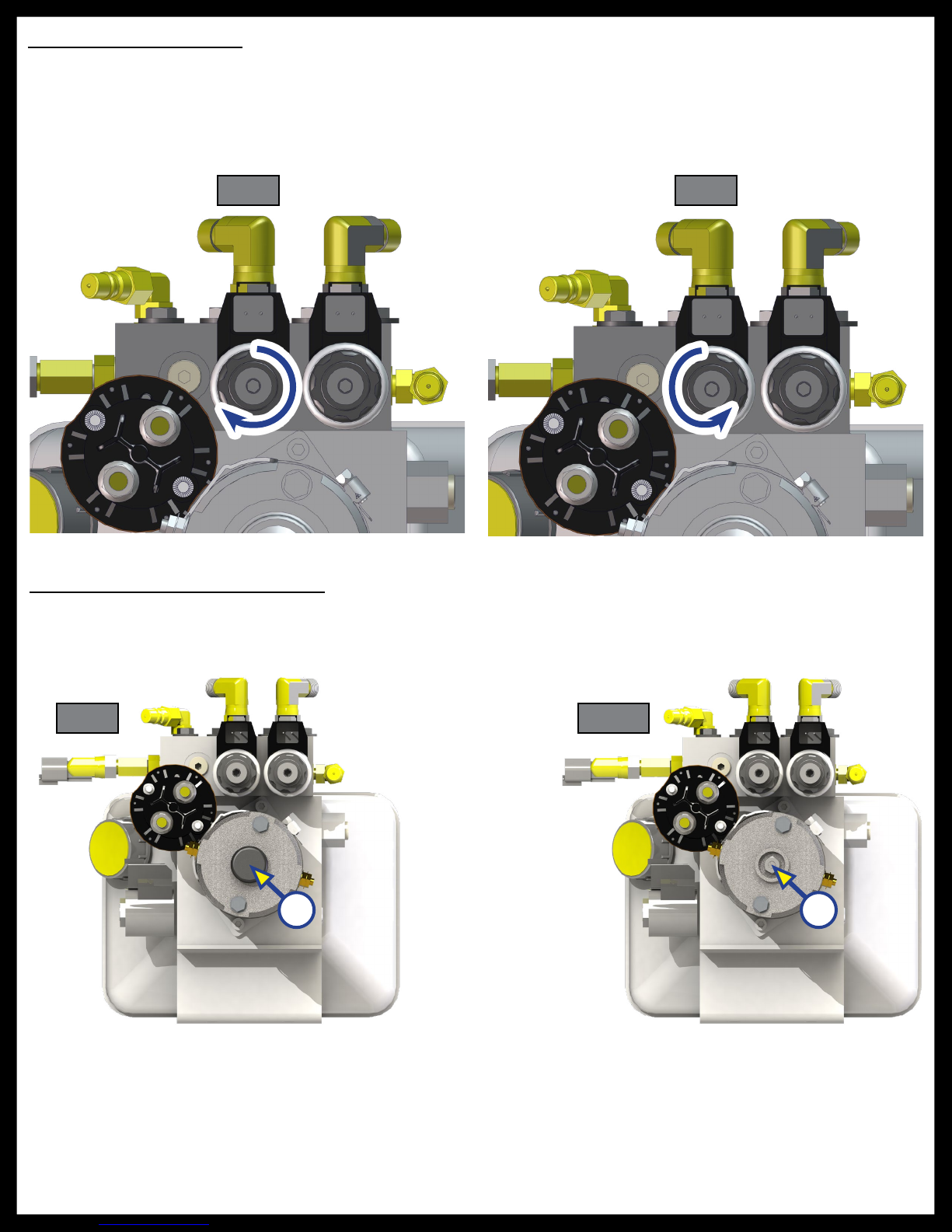

Manual Override - Jacks

In the event that the jacks will not extend or retract, the valves can be manually overridden by using a ⁄”

hex wrench to turn the manual override clockwise on the valve (See Fig. 7). The leveling jacks can then be

extended or retracted. Remember to turn the manual override completely counterclockwise (See Fig. 8)

until it will no longer turn to close the valve after the jacks have been completely extended or retracted. Do

not over-tighten override set screws, as this can damage the valves.

Fig. 7 Fig. 8

Clockwise for manual override

Counterclockwise for normal operation

Manual Override - Power System

The Lippert LCI Level-Up Motorhome Leveling System can be run with auxiliary power devices like cordless

or power drills. In the event of electrical or system failure, this manual method of extending and retracting

the jacks can be used. A standard handheld drill is all that is required. See the instructions below.

Fig. 9 Fig. 10

AA

1. Remove plastic cap (Fig. 9A).

2. Disconnect or shield power cables on the motor.

3. Using a ½” socket and auxiliary drive device, i.e. cordless or power drill, insert ½” socket onto coupler

found under plastic cap (Fig. 10A).

4. Run drill in reverse or counterclockwise to retract jacks.

Rev: 06.29.18

Page 12

CCD-0001535

Page 13

Automatic Safety Shutoff

If the control panel is left on and inactive for four minutes it will shut off automatically. To reset the system,

the coach ignition MUST be turned off, then back on, and the ON/OFF button MUST again be pushed.

Drive Away Protection System

If the ignition is in the “RUN” position, jacks are down, and the operator releases the parking brake, all

indicator lights will flash and the alarm beeper will activate. The system will then automatically retract the

jacks until the jacks are fully retracted or the operator resets the parking brake.

The power unit will also operate to keep the jacks retracted in the event the leveling system loses pressure

as the coach is being driven.

“Jacks Down" Alarm

The LCI Level-Up Motorhome Leveling System is designed to sound an alarm and illuminate the control

panel in the event of two (2) possible scenarios:

1. A “RETRACT” hose leaks.

2. The pressure holding the jacks in the retracted position falls to approximately 1500 psi to sound the

alarm. If the alarm sounds and the control panel illuminates and flashes while driving the vehicle:

A. Immediately find an area to safely pull the vehicle off of the roadway.

B. Set the PARKING BRAKE.

C. Inspect all jacks, hoses, and valves for leaks. If no leaks are observed:

I. Turn control panel “ON.”

II. Push “RETRACT ALL JACKS” button.

III. Wait until “JACKS DOWN” light and alarm are off.

IV. Inspect jacks. If jacks are retracted and no leaks are observed, vehicle can be driven.

NOTE: If system is leaking or alarm does not subside after applying the above procedure, disconnect wires

from pressure switch and proceed immediately to a service center. The pressure switch is a blue

and gold colored valve located on the power unit manifold identified by the spark proof style

connector with yellow and black wires. (See Page 6, Fig. 5).

NOTE: For prolonged travel to the service center, be sure to stop and check the disposition of the leveling

jacks every so often to make sure they are not extending.

Fluid Recommendation

The Lippert Electronic Leveling System is pre-filled, primed and ready to operate direct from the

manufacturer. Type “A” Automatic Transmission Fluid (ATF) is utilized and will work. ATF with Dexron III® or

Mercon 5® or a blend of both is recommended by Lippert Components, Inc.

In colder temperatures (less than 10° F) the jacks may extend and retract slowly due to the fluid’s molecular

nature. For cold weather operation, fluid specially formulated for low temperatures may be desirable. For a

list of approved fluid specifications, see TI-188.

Rev: 06.29.18

Page 13

CCD-0001535

Page 14

What Is Happening? Why? What Should Be Done?

System will not turn on

and On/Off indicator

light does not illuminate.

Control panel turns on

but turns off when jack

button is pushed or

displays "Low Voltage."

Control panel turns on,

coach will not auto level,

"Jacks Down" displayed,

jacks are retracted.

Jacks will not extend

to ground, pump is

running.

Coach ignition not in

RUN position.

Turn ignition to RUN position.

Parking brake not set. Set parking brake.

Controls have been

on for more than four

minutes and have timed

Turn ignition OFF and then back ON.

out.

Low voltage on battery. Start coach to charge battery.

Change fluid level in reservoir. If fluid is low, add

Low fluid level.

fluid to ½" from top of reservoir with jacks retracted.

If JACKS DOWN light remains on, call Lippert Service.

Little to no fluid in

reservoir.

Add fluid as recommended. See Page 13.

Leg valve is inoperative. Clean, repair or replace.

Electronic signal is lost

between control and

leg valves.

Trace wires for voltage drop or loss of signal. Repair

or replace necessary wires or replace control pad.

Any one or two jacks will

not retract.

"Jacks Retracted" does

not display when all

jacks are retracted.

Alarm sounds and

"Jacks Down" light starts

flashing while traveling,

jacks are fully retracted.

Jack bleeds down after

being extended.

Control panel powers

up, screen displays "Low

Voltage."

Hose damaged or

unconnected.

Replace with new hose or reconnect hose.

Valve inoperative. Replace inoperative valve.

Electronic signal is lost

between control and

solenoid.

Attempt to retract jacks in MANUAL mode. If

successful, replace control pad. If not, test for voltage

drop between control pad and leg valve. Repair bad

wiring or replace defective board or valve.

Low fluid level. Add fluid as recommended. See Page 13.

Retract press switch

inoperable.

Check connection or replace.

Low fluid level. Add fluid as recommended. See Page 13.

Retract press switch

inoperable.

Valve Manual Override

open.

Check connection or replace.

Close override. See Page 12, Fig. 8.

Engine not running. Start coach engine.

No power to control

panel

Auto level function does

not finish

Rev: 06.29.18

Tripped circuit breaker. Reset.

Ignition not ON. Turn ignition ON.

Error code "Unable to

Finish Leveling".

Move coach to a more level site.

Page 14

CCD-0001535

Page 15

Wiring Diagram

Touch Pad

Main Power Harness

Controller

Touch Pad Harness

Interconnect Harness

Rear Sensor Harness

Power Unit

Power Unit Harness

Directional

Valve

Pressure Switch

Rev: 06.29.18

Manifold

Page 15

Valve

CCD-0001535

Page 16

Plumbing Diagram

Right Front

Jack

Left Front

Jack

Retract

NOTE: Orange - Retract

Black - Extend

Power Unit

Right

Rear Jack

Left Rear

Extend

Rev: 06.29.18

Jack

Page 16

CCD-0001535

Page 17

12-PIN WIRE HARNESS

1. WHITE (CHASSIS

POWER)

2. BLACK w/

WHITE(PUMP

SOLENOID)

3. RED (CURBSIDE REAR

VALVE)

4. GREEN (ROADSIDE

FRONT VALVE)

5. YELLOW (PSI SWITCH)

Bill of Materials

Description Part # Details Quantity

Power Unit

6. BLUE (ROADSIDE

REAR VALVE)

7. BROWN (GROUND)

10

11

9

8. PURPLE (CURBSIDE

FRONT VALVE)

12

9. GREY (PUMP

SOLENOID)

1

10. AUX

11. AUX

2

3

4

12. AUX

196471 Hydraulic Power Unit, Leveling Only 1

175249 Hydraulic Power Unit, Leveling Only 1

8

7

6

5

293559 Hydraulic Power Unit, Leveling Only 1

Motor

Solenoid

179327 12V DC Motor for Power Unit 1

161394 Motor Solenoid 1

177094 Blocking Valve 4

Valve

259524 Directional Valve 1

Coil

Pressure Switch

Pump Harness

174184

142927 2150 PSI Rated Pressure Switch 1

178373 Electrical Harness for Power Unit 1

Electromagnetic Coil for Blocking

Valve

Main Harness 178375 30' Hydraulic Leveling Main Harness 1

Touch Pad - Controller

Harness

Remote Sensor Harness

178279

241314 Remote Sensor to Brain Harness 1

Electrical Harness between Touch

Pad & Controller

Brain 289252 Control Module 1

Touch Pad

Remote Sensor 294287

234802 Touch Panel mounted in Dash 1

Secondary Level Sensor mounted

rearward

433458 8k Leveling Jacks *

Hydraulic Jacks

236560 14k Leveling Jacks *

258550 20k Leveling Jacks *

5

1

1

Footpad

*Jack quantities will either be 2 or 4 depending on OEM specified design.

**Optional - Quantities will vary.

Rev: 06.29.18

113309 9” Footpad for Leveling Jacks 4

117238

12” Footpad for Leveling Jacks Optional

**

Page 17

CCD-0001535

Page 18

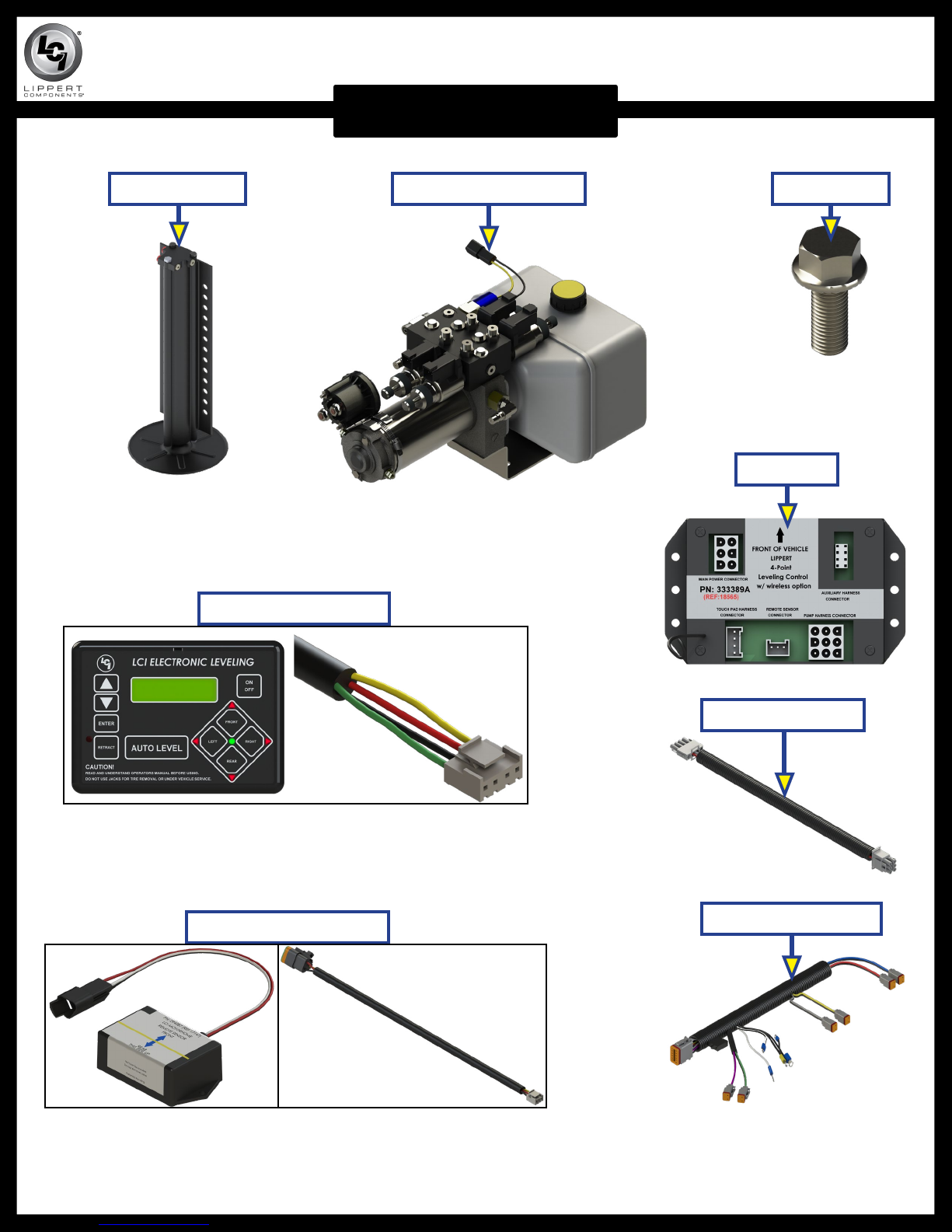

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

Bolt; ½" x13Hydraulic Power UnitLeveling Jacks

Controller

Touch Pad & Harness

Rear Sensor & Harness

Auxiliary Harness

Power Unit Harness

Rev: 06.29.18

Page 18

CCD-0001535

Page 19

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

A

C

D

B

Callout Part # Description

A

B

C

D

Rev: 06.29.18

196471 Hydraulic Power Unit, Leveling Only

175249 Hydraulic Power Unit, Leveling and Slides

179327 12V DC Motor for Power Unit

161394 Motor Solenoid

Page 19

CCD-0001535

Page 20

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

E F

G

H

I

Callout Part # Description

E 195860 8K Jack

F

G

236560 14K Jack

258550 20K Jack

H 113309 9” Footpad for Leveling Jacks

I 117238 12” Footpad for Leveling Jacks - Optional

Rev: 06.29.18

Page 20

CCD-0001535

Page 21

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

J

L

K

M

N

O

P

Q

Callout Part # Description

J

K

333389 Controller

234802 LCD Touch Pad

L 294287 Rear Sensor

M

N

178373 Power Unit Harness

241314 Rear Sensor Harness

O *178375 Main Harness (Winnebago Only)

P

Q

R

178279 Touch Pad Harness

178372 Main Harness

140524 Chassis Harness

NOTE: Parts shown with an asterisk (*) are for reference only.

The part is not available for individual replacement.

R

Rev: 06.29.18

Page 21

CCD-0001535

Page 22

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

W

T

U

X

S

V

Callout Part # Description

S *115567 Weld-On Jack Mounting Bracket

T 116471 Weld-On Jack Mounting Bracket

U 134989 Weld-On Jack Mounting Bracket

V 162349 Weld-On Jack Mounting Bracket

W

X

NOTE: Parts shown with an asterisk (*) are for reference only.

The part is not available for individual replacement.

Rev: 06.29.18

100345 Weld-On Jack Mounting Bracket

1170591 Bolt-On Jack Mounting Bracket

Page 22

CCD-0001535

Page 23

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

Y

Z

AC

AA

AB

Original Current

Callout Part # Description

Y

Z

AA

174184 12 Volt Deutsch Style Coil (Hydac)

140571 Isolator Valve

177094 Hydac Valve

AB *259524 Directional Valve

Pressure Switch (2150 PSI) (Original, No Longer Available)

AC

142927

Pressure Switch (2150 PSI) (Current)

NOTE: Parts shown with an asterisk (*) are for reference only. The part is not available for

individual replacement.

Rev: 06.29.18

Page 23

CCD-0001535

Page 24

LEVEL-UP® MOTORIZED LEVELING

LEVELING AND STABILIZATION

AD

AI

AE

AJ

AF

AK

AG

AL

AH

AM

AN

AO

Callout Part # Description

AD

AE

AF

AG

AH

AI

AJ

AK

AL

AM

AN

AO

140457 Quick Disconnect Fitting

141321 O-Ring to Pipe Straight Reducer Fitting

141109 Straight Face Seal Fitting

143108 Branch T-Fitting

141087 Face Seal T-Fitting

156846 Swivel Face Seal Elbow 90 Degree Fitting

141610 Face Seal Elbow 90 Degree Fitting

141331 Elbow 90 Degree Fitting

141323 ½" Hex Plug

140998 ¼" Hex Plug

118076 Bolt; ½" - 20 x 1 ½"

178210 Flange Nut, ½" - 20

Rev: 06.29.18

Page 24

CCD-0001535

Page 25

Notes

Rev: 06.29.18

Page 25

CCD-0001535

Page 26

The contents of this manual are proprietary and copyright protected by Lippert Components, Inc. (“LCI”).

LCI prohibits the copying or dissemination of portions of this manual unless prior written consent from an

authorized LCI representative has been provided. Any unauthorized use shall void any applicable warranty.

The information contained in this manual is subject to change without notice and at the sole discretion of LCI.

Revised editions are available for free download from lci1.com.

Please recycle all obsolete materials.

For all concerns or questions, please contact

Lippert Components, Inc.

Ph: (574) 537-8900 | Web: lci1.com | Email: customerservice@lci1.com

Rev: 07.02.2018 Level-Up® Motorized Leveling LCD Owner's Manual

Loading...

Loading...