Page 1

H

YDRO-SYNC SLIDEOUT SYSTEM

O

PERATION AND SERVICE MANUAL

Page 2

TABLE OF CONTENTS

SYSTEM……………………………………………........….…..

Warning…………………………………........……....

Description………………………………........……..

Prior to Operation…………………….......………

OPERATION…………………………………........……………

Main Components........................................

Mechanical......................................

Electrical.........................................

Operating System......................................

Extending Slideout Room…............

Retracting Slideout Room……........

Manual Operation...........................

Preventative Maintenance........................

SERVICE…………………………..……………........………

Fluid Fill Procedure………............…………..

Troubleshooting…………………….........………

Chart...............................................

Power Unit......................................

Bad Cylinder...................................

Wiring Diagram…………………….….......………

Ordering Parts…………......………………………

3

3

3

4

4

5

5

5

5

6

9

9

10

12

12

13

14

15

16

17

18

2

Page 3

SYSTEM

WARNING

FAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING

MAY RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

The Lippert Hydro-Sync Slideout System is intended for the

sole purpose of extending and retracting the slideout

room. Its function should not be used for any other

purpose or reason than to actuate the slideout room. To

use the system for any reason other than what it is

designed for may result in damage to the coach and/or

cause serious injury or even death.

Before actuating the system, please keep these things in

mind:

1. Parking locations should be clear of obstructions that

may cause damage when the slideout room is actuated.

2. Be sure all persons are clear of the coach prior to the

slideout room actuation.

3. Keep hands and other body parts away from slideout

mechanisms during actuation. Severe injury or death

may result.

4. To optimize slideout actuation, park coach on solid and

level ground.

DESCRIPTION

The Lippert Hydro-Sync Slideout System is a hydraulic cylinder drive

system. Utilizing a bidirectional electric motor to actuate the pump,

moving fluid from the reservoir into the hydraulic cylinders to extend the

room and pumping fluid back to the reservoir to retract the slideout. The

Lippert Hydro-Sync Slideout System is designed as a negative ground

system.

There are no serviceable parts within the power unit. If the motor,

manifold, pump or reservoir fails, the entire power unit must be replaced.

Disassembly of the motor voids the warranty.

Mechanical portions of the slideout system are replaceable. Contact

Lippert Components, Inc. to obtain replacement parts.

3

Page 4

PRIOR TO OPERATION

Prior to operating the Lippert Hydro-Sync Slideout System, follow these

four (4) guidelines:

1. Coach should be parked on the most level surface available.

2. The PARKING BRAKE must be engaged.

3. The coach’s transmission must be in NEUTRAL or PAR K.

4. The coach’s ignition must be in the RUN position or the coach’s

engine must be running.

4

Page 5

OPERATION

MAIN COMPONENTS

MECHANICAL

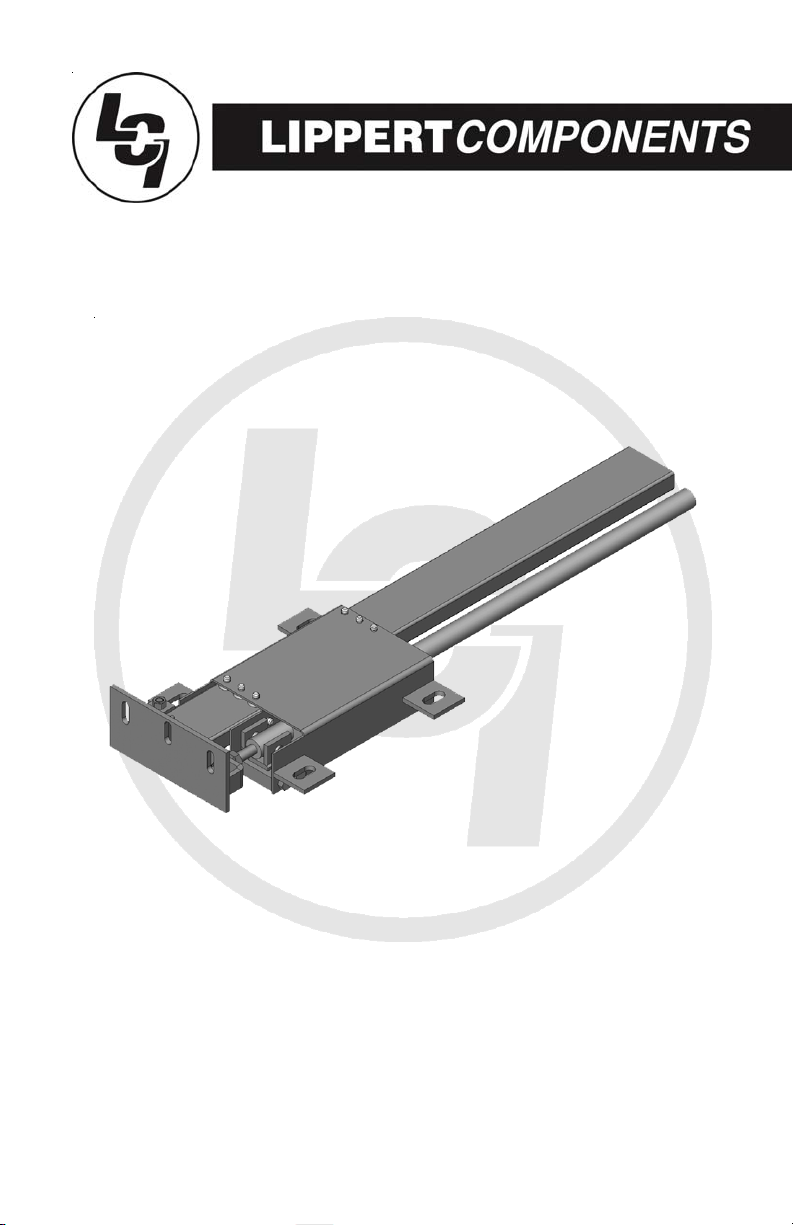

Hydraulic Cylinder

Outer Assembly

Fig. 1

Inner Assembly

5

Page 6

ELECTRICAL

POWER UNIT – 12V DC MOTOR W/PUMP & RESERVOIR

12V DC Motor

Fig. 2

WALL SWITCH

Switch Plate

“IN” Slideout Operation

Trombeta

Fig. 3

Pump Manifold

“E” Port - Extend

Pump – Housed inside Reservoir

Reservoir

Pump Switch

Bi-directional Rocker Switch

“OUT” Slideout Operation

RELAY - TROMBETTA

Motor 1 Terminal – 6 gauge

Fig. 4

Switch Lead 1 – 14

6

Positive Lead (+)-(Hot) 6 gauge

Motor 2 Terminal – 6 gauge

Switch Lead 2 – 14 gauge

Negative Lead (+) (Ground) 6 gauge

Page 7

OPERATING SYSTEM

WARNING

FAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING MAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

ALWAYS MAKE SURE THAT THE SLIDEOUT ROOM PATH IS CLEAR

OF PEOPLE AND OBJECTS BEFORE AND DURING OPERATION OF

THE SLIDEOUT ROOM.

ALWAYS KEEP AWAY FROM THE SLIDE RAILS WHEN THE ROOM IS

BEING OPERATED. THE GEAR ASSEMBLY MAY PINCH OR CATCH

ON LOOSE CLOTHING CAUSING PERSONAL INJURY.

INSTALL TRANSIT BARS (IF SO EQUIPPED) ON THE SLIDEOUT

ROOM DURING STORAGE AND TRANSPORTATION.

EXTENDING SLIDEOUT ROOM

1. Level the unit.

2. Verify the battery is fully charged and hooked-up to the electrical

system.

3. Remove the transit bars (if so equipped).

4. Press and hold the IN/OUT switch (Fig. 5B) in the OUT position

until the room is fully extended and stops moving.

5. Release the switch, which will lock the room into position.

NOTE: If the slideout switch is held after the room in fully

extended, the control will sense that the room has stopped and

will shut off the motor after a few seconds.

RETRACTING SLIDEOUT ROOM

1. Verify the battery is fully charged and hooked-up to the electrical

system.

2. Press and hold the IN/OUT switch (Fig. 5C) in the IN position

until the room is fully retracted and stops moving.

3. Release the switch, which will lock the room into position.

NOTE: If the slideout switch is held after the room in fully

retracted, the control will sense that the room has stopped and

will shut off the motor after a few seconds.

4. Install the transit bars (if so equipped).

7

Page 8

C

B

Fig. 5

MANUAL OPERATION

The Lippert Hydro-Sync Slideout System can be run with auxiliary power

devices like electric drills, ratchet wrenches or cordless screwdrivers. In

the event of electrical or system failure, this manual method of extending

and retracting the slideout room can be used. A standard handheld drill

is all that is required. A standard 38" room will take approximately 45

seconds to retract. See the instructions below.

Fig. 6

1. Remove protective label. (See Fig 6).

2. Using a standard hex bit, insert into auxiliary

drive device, i.e. cordless drill or

screwdriver or ratchet wrench.

8

Page 9

Fig. 7

3. Insert hex bit into coupler found under

protective label. (See Fig. 7)

4. Run drill forward or clockwise to extend

slideout room and in reverse or

counterclockwise to retract slideout room.

9

Page 10

PREVENTATIVE MAINTENANCE

The Lippert Hydro-Sync Slideout System has been designed to require

very little maintenance. To ensure the long life of your slideout system,

read and follow these few simple procedures.

WARNING

DO NOT WORK ON YOUR SLIDEOUT SYSTEM UNLESS

THE BATTERY IS DISCONNECTED.

FAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING MAY

RESULT IN SERIOUS PERSONAL INJURY OR DEATH.

The Lippert Hydro-Sync Slideout System has been static tested to over

6,000 continuous cycles without any noticeable wear to rotating or sliding

parts. It is recommended that when operating in harsh environments

and conditions (road salt, ice buildup, etc.) the moving parts be kept

clean and can be washed with mild soap and water. No grease or

lubrication is necessary and in some situations may be detrimental to the

environment and long-term dependability of the system.

MECHANICAL

Although the system is designed to be almost maintenance-free, actuate

the room once or twice a week to keep the seals and internal moving

parts lubricated.

Check for any visible signs of “leaking” before and after movement of

the system and the coach.

When the room is out, visually inspect the Inner and Outer Assemblies.

Refer to Fig. 1 for location of inner assemblies. Check for excess

buildup of dirt or other foreign material; remove any debris that may be

present.

If the system squeaks or makes any noises it is permissible to apply a

coat of lightweight oil to the drive shaft and roller areas but remove any

excess oil so dirt and debris do not buildup. DO NOT USE GREASE.

ELECTRICAL

For optimum performance, the slideout system requires full battery

current and voltage. The battery must be maintained at full capacity.

Other than good battery maintenance, check the terminals and other

connections at the battery, the control switch and the pump motor for

corrosion and loose or damaged terminals. Check motor leads under

the coach chassis. Since these connections are subject to damage from

road debris, be sure they are in good condition.

Page 11

Note: The Lippert Hydro-Sync Slideout System is designed to operate

as a negative ground system. A negative ground system utilizes the

chassis frame as the ground source. An independent ground wire back

to the battery is not needed. It is important the electrical components

have good wire to chassis contact. To ensure the best possible ground,

a star washer should be used. Over 90% of unit electrical problems can

be attributed to bad ground connections.

Note: For long-term storage: It is recommended that the room be

closed (retracted) and if your unit is equipped with the IRC room control,

it is recommended all of the control knobs be kept in the closed position.

IF YOU HAVE ANY PROBLEMS OR QUESTIONS CONSULT YOUR

LOCAL AUTHORIZED DEALER OR CALL LIPPERT AT:

(866) 524-7821.

11

Page 12

SERVICE

FLUID FILLING PROCEDURE

Breather/Fill Cap

Fig. 8

The Lippert Hydro-Sync Slideout System uses automatic transmission

fluid (ATF). Any ATF can be used. A full synthetic or synthetic blend

works best such as Dexron III or Mercon 5. For best operation, fill

system within ½” of the top when all slideouts are completely retracted.

The see through reservoir makes it easy to check oil level. It is

recommended that the oil level be checked prior to operating the

system. Make sure the breather cap is free of contamination before

removing, replacing or installing.

FILLING DIRECTIONS

Remove Breather/Fill Cap

Pour ATF into Breather/Fill opening.

Note: Do not allow any contamination into reservoir during fill process.

Note: Standard reservoir holds approximately 2 quarts (1.89 liters) of

ATF.

Fill to within ½” of top.

Replace Breather/Fill cap when finished.

Note: System is self-purging. By simply cycling the system 2-3 times,

any air in the system will be forced back to the reservoir and out of

the Breather/Fill cap.

12

Page 13

TROUBLESHOOTING

The Lippert Hydro-Sync Slideout System is only one of four interrelated

slideout room system components. These four components are as

follows: chassis, slideout room, coach and Lippert Hydro-Sync Slideout

System. Each one needs to function correctly with the others or

misalignment problems will occur.

Every coach has it’s own personality and what may work to fix one coach

may not work on another even if the symptoms appear to be the same.

When something restricts room travel, system performances will be

unpredictable. It is very important that slide rails, inner and outer, be free

of contamination and allowed to travel freely the full distance or

“STROKE.” Ice or mud buildup during travel is an example of some

types of contamination that may occur.

When beginning to troubleshoot the system, make sure the battery is

fully charged, there are no visible signs of external damage to the

actuator, motor or rails and that the motor is wired properly and all

connections are secure.

You can adjust room extension by modifying the position of the

adjustment coupler.

During troubleshooting, remember, by changing, altering or adjusting one

thing, it may affect something else. Be sure any changes do not create a

new problem.

Additional information on the Lippert Hydro-Sync Slideout System

by calling 866-524-7821 and asking for technical assistance.

13

Page 14

TROUBLESHOOTING CHART

The following troubleshooting chart outlines some common problems, their causes and

possible corrective actions. When reference is made to a “Power Unit,” the term

includes the motor and the actuator as a complete unit. All Power Units are shipped

from the factory with a serial number and date code, which should be given to the

service technician when asking for assistance.

ROOM DOESN' T MOVE WHEN SWITCH IS P RESSED

PROBABLE CAUSE CORRECTIVE ACTI ON

Rest r ic ti o ns bot h i nsi de and o uts ide o f unit Check fo r and cl ear res t ri ct i on

Low bat ter y vo lt age, bl o wn fuse, defective wi ri ng Check bat ter y. Charge bat t er y or add auxi l iar y

power s our ce. Chec k bat t ery t ermi nals , and al l

ot her wiring. Look for loose or corroded

co nnec t i ons

Power Unit no t f unc ti o ning See " Power Unit Tr oubl esho ot i ng" page 13

POWER UNIT RUNS, ROOM DOES NOT MOVE

Rest r ic ti o ns bot h i nsi de and o uts ide o f unit Check fo r and cl ear res t ri ct i on

POWER UNIT RUNS, ROOM MOVES SLOWLY

Low bat ter y, po or gro und, ext remely l ow Charge bat t ery, and check gro und wire

out do or t emper atur e.

Leaki ng cyl i nder See " Checki ng f or Bad Cyl inder " page 14

ROOM DRIF TS IN BOTH IN & OUT POSITIONS

Check f or l eak s i n the hydr auli c s yst em Ti ght en fi t t ings

Air i n system Aft er checking all connections, cycle pump

several t imes in and out

IN THE CLOSED P OSITI ON, ROOM DRI FTS OUT

Leaki ng cyl i nder s eal See " Checki ng f or Bad Cyl inder " page 14

Fl uid bypas si ng cyl inder pi st on See " Checki ng f or Bad Cyl inder " page 14

Hos e fr om pump is l eaki ng Ti ghten f i tt i ng or r eplac e hose

Air i n system Aft er checking all connections, cycle pump

several t imes in and out

Loo se mount i ng bol ts Ti ghten mount i ng bol ts

IN THE OPEN POSITION, ROOM DRIFTS IN

Hos e fr om pump is l eaki ng Ti ghten f i tt i ng or r eplac e hose

Leaki ng cyl i nder s eal See " Checki ng f or Bad Cyl inder " page 14

Fl uid bypas si ng cyl inder pi st on See " Checki ng f or Bad Cyl inder " page 14

Page 15

TROUBLESHOOTING – POWER UNIT

Before attempting to troubleshoot the Power Unit, make sure an

adequate power source is available. The unit batteries should be fully

charged or the unit should be plugged into to A/C service with batteries

installed. Do not attempt to troubleshoot the Power Unit without

assuring a full 12V DC charge

The following tests require only a DC voltmeter (or DC test light) and a

jumper lead.

Step 1 - Attach voltmeter (or test light) leads to the negative and positive

switch terminals on back of wall switch (See Fig. 9). Does the meter

indicate 12V DC?

If YES, see Step 2; if NO see Step 3.

Step 2 - If YES, at the motor, check the incoming leads to 12V DC (if

necessary, disconnect leads at wire splices). Does meter indicate 12V

DC? If YES, Power Unit needs to be replaced. The motor is not field

serviceable. DO NOT ATTEMPT TO REPAIR. If NO, Inspect all wires

and connections between the wall switch and the motor. Repair

connections as necessary. Recheck as in Step 1.

Step 3 - If NO, Inspect all connections between battery and switch.

Inspect 50A Auto-reset Circuit Breaker (See Fig. 9).

Recheck as above in Step 1.

TROUBLESHOOTING - ELECTRICAL

Since there are no field serviceable parts in the motor of the Power Unit,

electrical troubleshooting and service is limited to replacing only those

components as previously outlined.

Thorough inspection of wiring and connections is the only other electrical

service that can be performed.

15

Page 16

TROUBLESHOOTING – CHECKING FOR BAD

CYLINDER

1. Retract (close) the slideout (room) completely.

2. Loosen hose from “E” (extend) port on the manifold of the Power

Unit.

WARNING-

Do not attempt to run room out with the “E” port hose loose.

The

system will experience RAPID FLUID LOSS.

3. Plug opening on manifold to prevent drawing air into the system.

4. Energize the Power Unit to retract (close) room.

5. Continue to run the room in and watch for fluid flow from hose/port

“E”. Fluid flow greater than a few drops will indicate internal cylinder

leaking (bypassing of piston seal). If there is no fluid flow, reconnect

hose to “E” port and tighten.

WARNING -

Be sure to reconnect and tighten hose at the “E” port before

attempting to extend (open) the room or the system will

experience RAPID FLUID LOSS.

Contact qualified technician if there is excessive fluid flow. The cylinder

should not be repaired in the field.

Refill the Power Unit Reservoir as recommended on page 12 of this

manual.

16

Page 17

WIRING DIAGRAM

Fig. 9

No wires connected

to this side of switch

Yellow – 16 gauge

Red “Hot” – 16 gauge

Green – 16 gauge

IN

the same way

switch get wired

SWITCH – Wall

switch and pump

RESERVOIR

MANIFOLD

OUT

REVERSES MOTOR

CHANGE OF POLARITY

50 AMP

BREAKER

AUTO-RESET

10 GA WIRE MINIMUM

BATTERY

- +

TROMBETA

MOTOR

17

Page 18

ORDERING PARTS

To assist the customer service when ordering parts, please provide the

following information:

1. Your Name

2. Company Name

3. Phone Number

4. Shipping Address

5. Billing Address

6. Purchase Order Number

7. Coach

A. Serial # and/or VIN #

B. Make

C. Model

8. Part Number

9. Description

10. Quantity

Please take your coach to an authorized service center for repairs.

Systems that have been modified, adjusted, repaired or augmented by

a party other than an authorized service center may void any warranty

claim with Lippert Components, Inc.

18

Loading...

Loading...