Page 1

Hydraulic Through Frame Slideout

OWNER'S MANUAL

Rev: 07.09.2014

Page 1

Hydraulic Through Frame Slideout Owners Manual

Page 2

TABLE OF CONTENTS

Warning, Safety, and System Requirement Information 4

Description 4

Safety Information 4

Prior to Operation 5

Operation 5

Extending Slideout Room 5

Retracting Slideout Room 5

Maintenance 6

Inspection 6

System Maintenance 6

Electrical System Maintenance 6

Mechanical Maintenance 6

Troubleshooting 7

Troubleshooting Introduction 7

Hydraulic slideout cylinder retract test 8

Hydraulic slideout cylinder extend test 8

Fluid Filling Procedure 9

Comparing 14.5° and 20° Rack and Pinion Gears 10

Gear Pack Replacement Instructions 11

Corrective Action for Squeaking Gear Packs 12

Motor troubleshooting 13

Wiring Diagram 14

Room Bar Measurement Chart 15

Adjusting room so it seals in the IN position 16

Adjusting room so it seals in the OUT position 16

Mechanical Room Adjustment 17

Horizontal adjustment 17

Vertical adjustment 17

Synchronizing Room Travel 17

Extend and retract cylinder port locations 18

Manual Override 18

Rev: 07.09.2014

Page 2

Hydraulic Through Frame Slideout Owners Manual

Page 3

2x2 Hydraulic Through Frame Slideout Assembly 19

2x2 Hydraulic Through Frame Slideout Components 20

2x2 Hydraulic Through Frame Slideout Components 21

2x2 Hydraulic Through Frame Slideout Components 22

2x2 Hydraulic Through Frame Slideout Drive Components 23

2x3 Hydraulic Through Frame SLideout Assembly 24

2x3 Hydraulic Through Frame Slideout Assembly 25

2x3 Hydraulic Through Frame Slideout Components 26

2x3 Hydraulic Through Frame Slideout Drive Components 27

2.5x2.5 Hydraulic Through Frame Slideout Assembly 28

2.5x2.5 Hydraulic Through Frame Slideout Components 29

2.5x2.5 Hydraulic Through Frame Head Assemblies (Standard) 30

2.5x2.5 Hydraulic Through Frame Head Assemblies (V-Tech) 31

2.5x2.5 Hydraulic Through Frame Slideout Components 32

2.5x2.5 Hydraulic Through Frame Slideout Drive Components 33

Notes 34

Rev: 07.09.2014

Page 3

Hydraulic Through Frame Slideout Owners Manual

Page 4

Warning, Safety, and System Requirement Information

Description

The Lippert Hydraulic Through Frame Slideout System is a rack and pinion guide system, utilizing a hydraulic

cylinder to move the room assembly. The power unit drives the cylinder rod in a forward and backward motion to

move the slide room in and out. The Lippert Hydraulic Slideout System is designed to operate as a negative ground

system.

Safety Information

The “WARNING” symbol above is a sign that a service or maintenance procedure has a safety risk involved and may

cause serious injury or death if not performed safely and within the parameters set forth in this manual.

Always wear eye protection when performing service or maintenance to the vehicle. Other safety equipment to

consider would be hearing protection, gloves and possibly a full face shield, depending on the nature of the service.

This manual provides general service and maintenance procedures. Many variables can change the circumstances

of the service procedure, i.e., the degree of difficulty involved in the service operation and the ability level of the

individual performing the operation. This manual cannot begin to plot out procedures for every possibility, but will

provide the general instructions for effectively servicing the vehicle. In the event the skill level required is too high

or the procedure is too difficult, a certified technician should be consulted before performing the necessary service.

Failure to correctly service the vehicle may result in death, serious injury or voiding the warranty. The owner’s

manual for the unit may have more procedures for service and maintenance.

Failure to act in accordance with the following may result in death, serious injury, coach or property

damage.

The Lippert Hydraulic Through Frame Slideout System is intended for the sole purpose of extending and retracting

the slideout room. Its function should not be used for any other purpose or reason than to actuate the slideout

room. To use the system for any reason other than what it is designed for may result in damage to the coach and/

or cause serious injury or even death.

Before actuating the system, please keep these things in mind:

1. Parking locations should be clear of obstructions that may cause damage when the slideout room is

actuated.

2. Be sure all persons are clear of the coach prior to the slideout room actuation.

3. Keep hands and other body parts away from slideout mechanisms during actuation. Severe injury or

death may result.

4. To optimize slideout actuation, park coach on solid and level ground.

Rev: 07.09.2014

Page 4

Hydraulic Through Frame Slideout Owners Manual

Page 5

Prior to Operation

Prior to operating the Lippert Hydraulic Through Frame Slideout System, follow these guidelines:

1. Coach should be parked on the most level surface available.

2. Leveling or stabilizing system should be actuated to ensure coach will not move during operation of

slideout system.

3. Be sure battery is fully charged.

4. Be sure to keep all persons and pets clear of slideout system during operation.

Always make sure that the slideout room path is clear of people and objects before and during operation

of the slideout room. Always keep away from the slide rails when the room is being operated. The gear

assembly may pinch or catch on loose clothing causing personal injury.

NOTE: Install transit bars (if so equipped) on the slideout room during storage and transportation.

Operation

Extending Slideout Room

5. Level the Unit.

6. Verify the battery is fully charged and hooked up to the electrical system.

7. Remove transit bars (if so equipped).

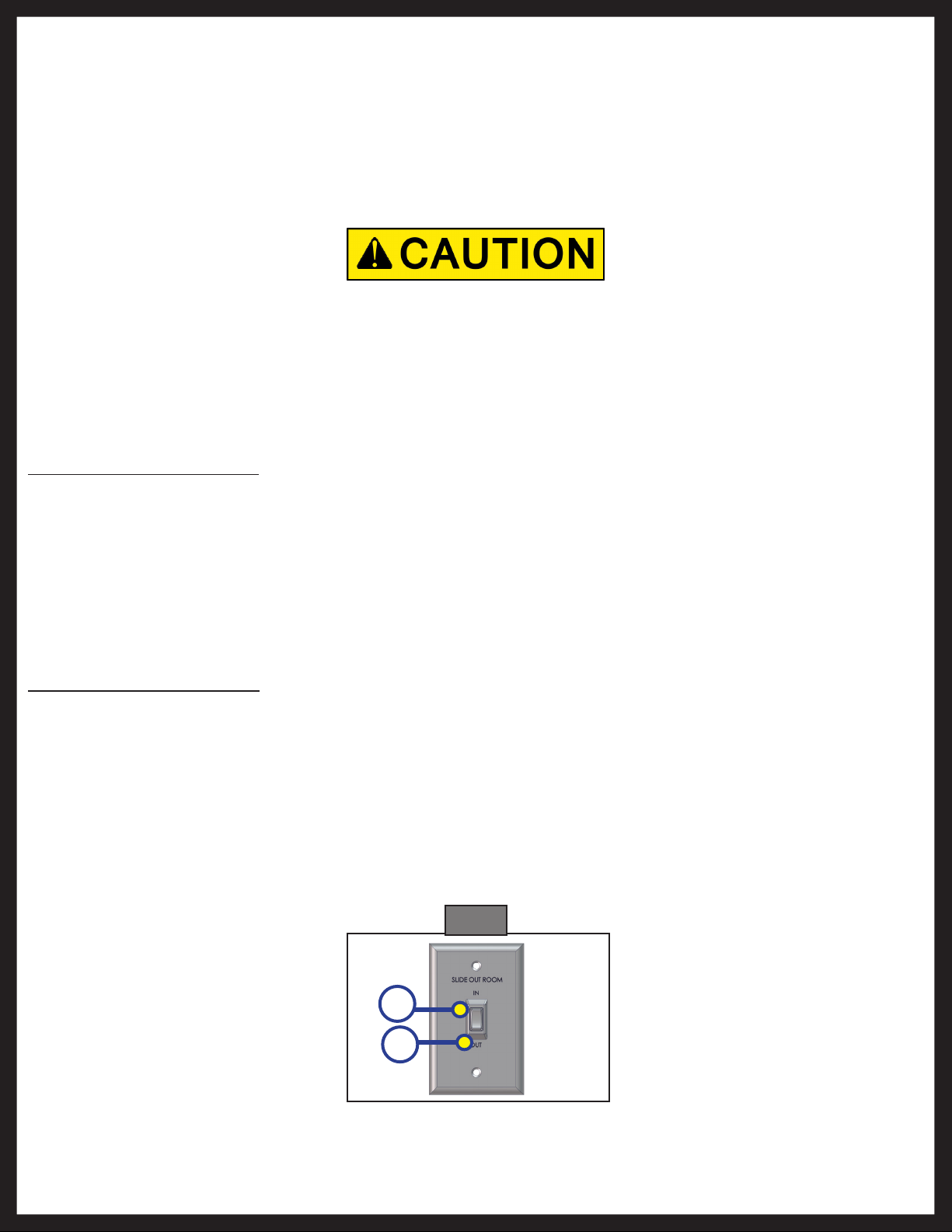

8. Press and hold the IN/OUT switch in the OUT position until room is fully extended and stops moving.

9. Release switch, which will lock the room into position.

NOTE: Only hold OUT switch until room stops.

Retracting Slideout Room

1. Verify the battery is fully charged and hooked up to the electrical system.

2. Press and hold the IN/OUT switch in the IN position until the room is fully retracted and stops moving.

3. Release the switch. This will lock the room into position.

NOTE: Only hold IN switch until room stops.

4. Install the transit bars (if so equipped).

Fig. 1

Rev: 07.09.2014

A

B

Page 5

Hydraulic Through Frame Slideout Owners Manual

Page 6

Maintenance

Inspection

After servicing the slideout system in any way, be sure to check the following:

1. Slideout stops are installed and adjusted properly.

2. Head assemblies are installed and adjusted properly.

3. System is mounted properly.

4. Cross shafts are mounted properly and clear all other components.

5. Gear packs function properly.

6. Manual override is accessible.

7. Outside seals compress when slideout is retracted.

8. Inside seals compress when slideout is extended.

9. Slideout extends and retracts smoothly.

10. Both sides of slideout are synchronized.

11. Any dirt or debris is cleaned from the interior or exterior of the coach.

System Maintenance

The Lippert Through Frame Slideout System has been static tested to over 4,000 continuous cycles without

any noticeable wear to rotating or sliding parts. It is recommended that when operating in harsh environments

(road salt, ice build up, etc.) the moving parts be kept clean. They can be washed with mild soap and water. No

grease or lubrication is necessary and in some situations may be detrimental to the environment and long term

dependability of the system.

Electrical System Maintenance

For optimum performance, the slideout system requires full battery current and voltage. The battery must be

maintained at full capacity. Other than good battery maintenance, check the terminals and other connections at

the battery, the control switch, and the system for corrosion, and loose or damaged terminals. Check motor leads

under the trailer chassis. Since these connections are subject to damage from road debris, be sure they are in good

condition.

NOTE: The Lippert Through Frame Slideout System is designed to operate as a negative ground system.

A negative ground system utilizes the chassis frame as a ground and an independent ground

wire back to battery is necessary. It is important that the electrical components have good wire to

chassis contact. To ensure the best possible ground, a star washer should be used. Over 90% of

unit electrical problems are due to bad ground connections.

Mechanical Maintenance

Although the system is designed to be almost maintenance free, actuate the room once or twice a month to keep

the seals and internal moving parts lubricated. Check for any visible signs of external damage after and before

movement of the travel trailer.

NOTE: For long-term storage: It is recommended that the room be closed (retracted).

Rev: 07.09.2014

Page 6

Hydraulic Through Frame Slideout Owners Manual

Page 7

Troubleshooting

Troubleshooting Introduction

This troubleshooting chart outlines some common problems, their causes and possible corrective actions. If any

part or serial number information is available, provide it to the service technician when asking for assistance.

The Lippert Slideout System is only one of four interrelated slideout room system components. These four

components are: chassis, room, coach, and Lippert Slideout System. Each one needs to function correctly with the

others or misalignment problems will occur.

Every travel trailer has its own personality and what may work to fix one trailer may not work on another even if the

symptoms appear to be the same.

When something restricts room travel, system performance will be unpredictable. It is very important that slide

tubes be free of contamination and allowed to travel full distance (Stroke). Ice or mud buildup during travel is an

example of some types of contamination that can occur.

When you begin to troubleshoot the system, make sure the battery is fully charged, there are no visible signs of

external damage to the system and that all connections are secure.

During troubleshooting, remember that if you change something, that change may affect something else. Be sure

any changes you make will not create a new problem.

You can obtain additional information on the Lippert Slideout System by visiting www.lci1.com/customerservice or

by calling 574-537-8900.

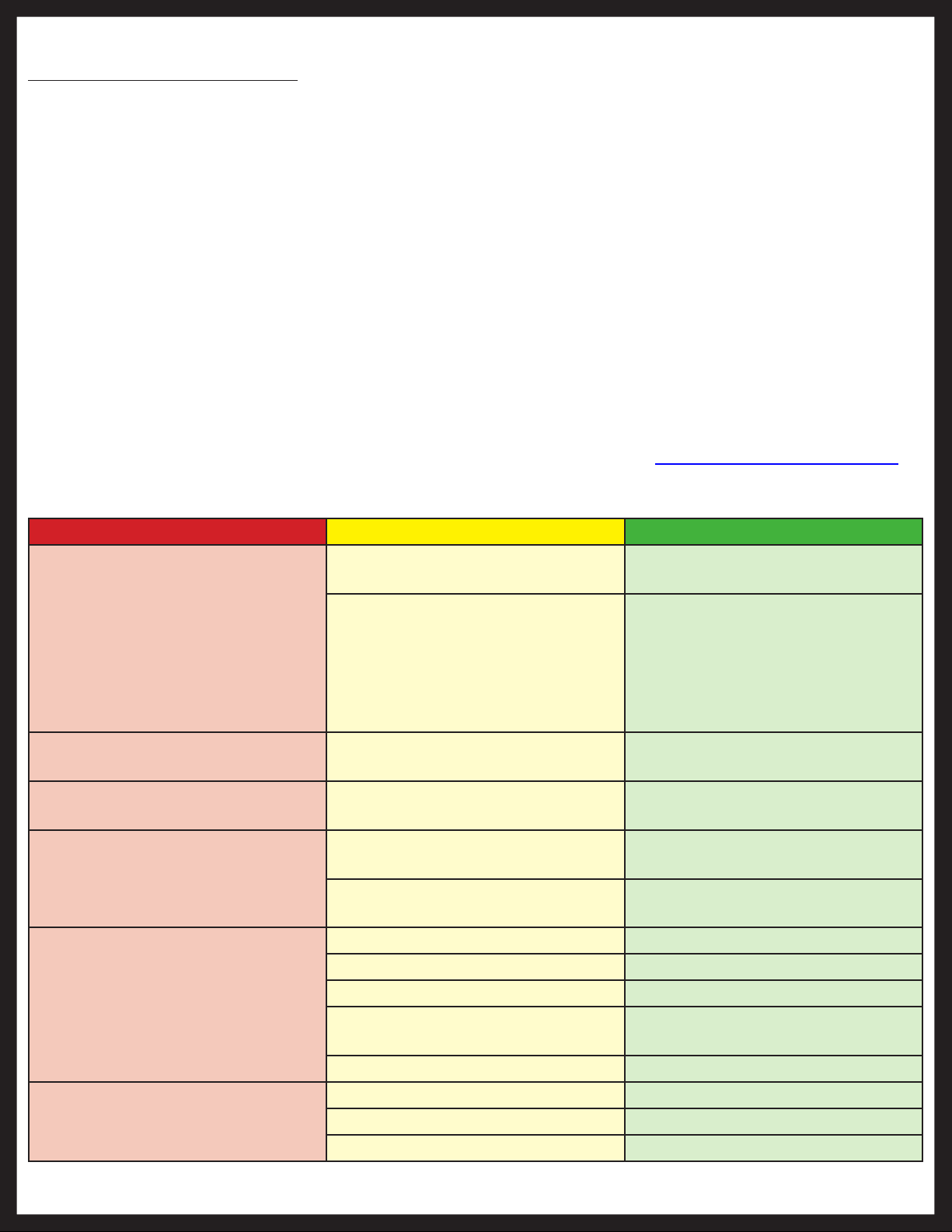

Problem Probable Cause Corrective Action

Restriction or obstruction inside or

outside of unit

Check for and clear obstruction

Check battery voltage and charge

Room doesn't move when switch is

pressed

Low battery voltage, blown fuse,

defective wiring

if needed. Find and check fuse,

replace if blown. Check battery

terminals and wiring. Look for

loose, disconnected or corroded

connectors.

Power unit runs but room does not

move

Power unit runs, room moves slowly

Room drifts in both the in and out

positions

Restrictions both inside and outside

of unit

Low battery, poor ground, extremely

low outdoor temperature

Check for leaks in the hydraulic

system

Air in system

Check for and clear restriction

Charge battery and check ground

wire

Tighten fittings

After checking all connections, cycle

pump several times in and out

Leaking cylinder seal See cylinder test next page

Fluid bypassing cylinder piston See cylinder test next page

In the closed position, room drifts

out

Hose from pump is leaking Tighten fitting or replace hose

Air in system

After checking all connections, cycle

pump several times in and out.

Loose mounting bolts Tighten mounting bolts.

Hose from pump is leaking Tighten fitting or replace hose

In the open position, room drifts in

Leaking cylinder seal See cylinder test on next page

Fluid bypassing cylinder piston See cylinder test on next page

Rev: 07.09.2014

Page 7

Hydraulic Through Frame Slideout Owners Manual

Page 8

Hydraulic slideout cylinder retract test

1. Retract (close) all slideouts (rooms) completely.

2. Disconnect all rooms from system (if coach is equipped with IRC, close all but one room).

3. Loosen hose from "E" (extend) port on the manifold of the power unit.

4. Plug opening on manifold to prevent drawing air into the system.

Do not attempt to run room out with the "E" port hose loose. The system will experience rapid fluid loss.

5. Energize the pump unit to retract (close) room.

6. When room is fully retracted, continue to run the room in and watch for fluid flow from hose/port "E".

Fluid flow greater than a few drops will indicate internal cylinder leaking (bypassing of piston seal). If

greater than a few drops leak from hose fitting, piston seal is bad and will need to be replaced. If there

is no fluid flow, reconnect hose to "E" port and tighten.

7. Repeat steps 2 through 6 for each slideout until all slideouts have been tested. Energize the pump unit

to retract (close) room.

Be sure to reconnect and tighten hose at the "E" port before attempting to extend (open) the room or the

system will experience rapid fluid loss.

Hydraulic slideout cylinder extend test

1. Extend (open) all slideouts (rooms) completely.

2. Disconnect all rooms from system (if coach is equipped with IRC, open all but one room).

3. Loosen hose from "R" (retract) port on the manifold of the power unit. Individual slideouts can be

tested if the unit is equipped with an IRC block. Close all valves in IRC except the one to be tested.

4. Plug opening on manifold to prevent drawing air into the system.

Do not attempt to run room in (retract) with the "R" port hose loose. The system will experience rapid

fluid loss.

5. Energize the pump unit to extend (open) room.

6. Continue to run the room out and watch for fluid flow from hose/port "R" (or IRC block if coach is

equipped with IRC). Fluid flow greater than a few drops will indicate internal leaking (bypassing of

piston seal). If greater than a few drops leak from hose fitting, piston seal is bad and will need to be

replaced. If there is no fluid flow, reconnect hose to "R" port and tighten.

7. Repeat steps 2 through 6 for each slideout until all slideouts have been tested.

Be sure to reconnect and tighten hose at the "R" port before attempting to retract (close) the room or the

system will experience rapid fluid loss.

Rev: 07.09.2014

Page 8

Hydraulic Through Frame Slideout Owners Manual

Page 9

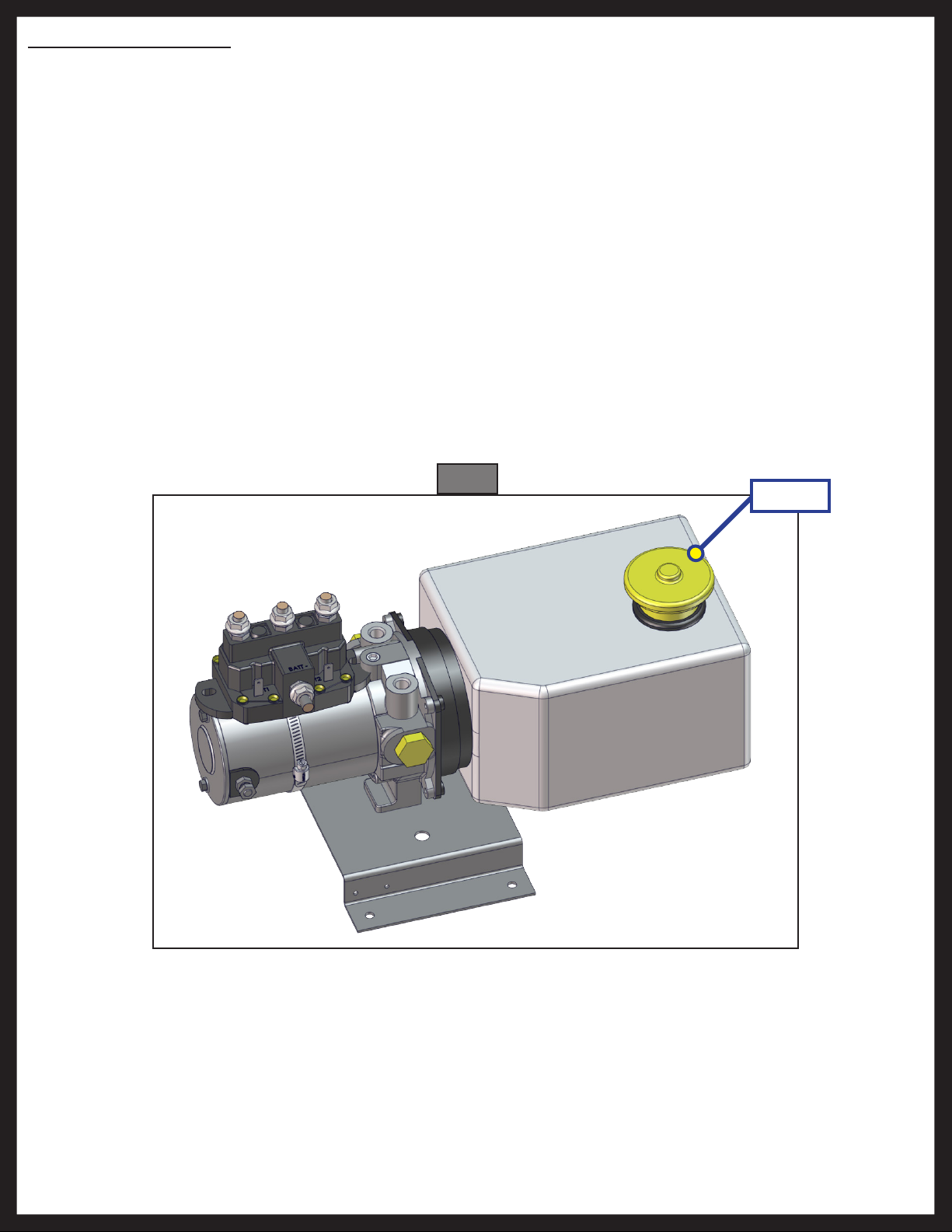

Fluid Filling Procedure

The Lippert Hydraulic Slideout System uses automatic transmission fluid (ATF). Any ATF can be used. A full

synthetic or synthetic blend works best such as Dexron III or Mercon 5. For best operation, fill system to within ½”

of the top when all slideouts are completely retracted. The see-through reservoir makes it easy to check oil level. It

is recommended that the oil level be checked prior to operating the system. Make sure the breather cap is free of

contamination before removing, replacing or installing.

1. Remove Breather/Fill Cap.

2. Pour ATF into Breather/Fill opening.

NOTE: Do not allow any contamination into reservoir during fill process.

NOTE: Standard reservoir holds approximately 2 quarts (1.89 liters) of ATF.

3. Fill to within ½” of top.

4. Replace Breather/Fill cap when finished.

NOTE: System is self-purging. By simply cycling the system 2-3 times, any air in the system will be forced

back to the reservoir and out of the Breather/Fill cap.

Fig. 1

Fill Cap

Rev: 07.09.2014

Page 9

Hydraulic Through Frame Slideout Owners Manual

Page 10

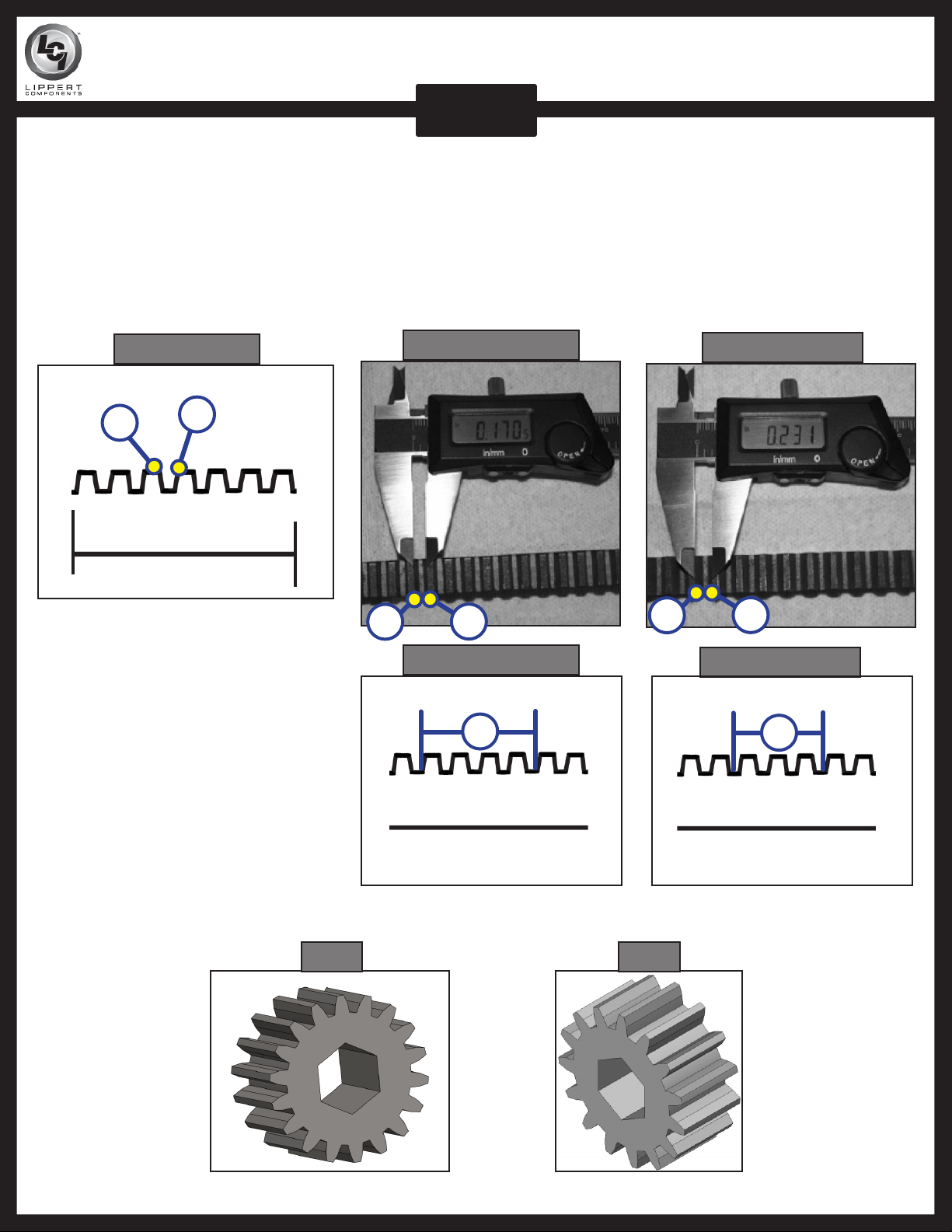

COMPARING 14.5° AND 20° RACK AND PINION GEARS

SLIDEOUTS

1. Start by measuring the distance between two individual adjacent teeth.

2. Using calipers or a steel rule, measure from the inside edge of one tooth (A), and then measure over to

the inside edge of the next tooth (B) shown in (Fig. 1).

3. The 14.5° rack will measure approximately 0.170 inches (Fig. 2.1). The 20° rack will measure

approximately 0.231 inches (Fig. 3.1).

4. The 14.5° rack will have 4 teeth per inch (Fig 2.2). The 20° rack will have 3 teeth per inch (Fig 3.2).

Fig. 1 Side View

A

B

Fig. 2.1 - 14.5° Rack

A

B

Fig. 2.2 - 14.5° Rack

1"

Fig. 3.1 - 20° Rack

A

B

Fig. 3.2 - 20° Rack

1"

4 teeth per inch

3 teeth per inch

The simplest way to differentiate between the 14.5° spur gear and the 20° spur gear is the number of teeth on the

gear. Spur gear 122739 (Fig. 4) has 18 teeth. Spur gear 101941 (Fig. 5) has 15 teeth.

Fig. 4 Fig. 5

Rev: 07.09.2014

Page 10

Hydraulic Through Frame Slideout Owners Manual

Page 11

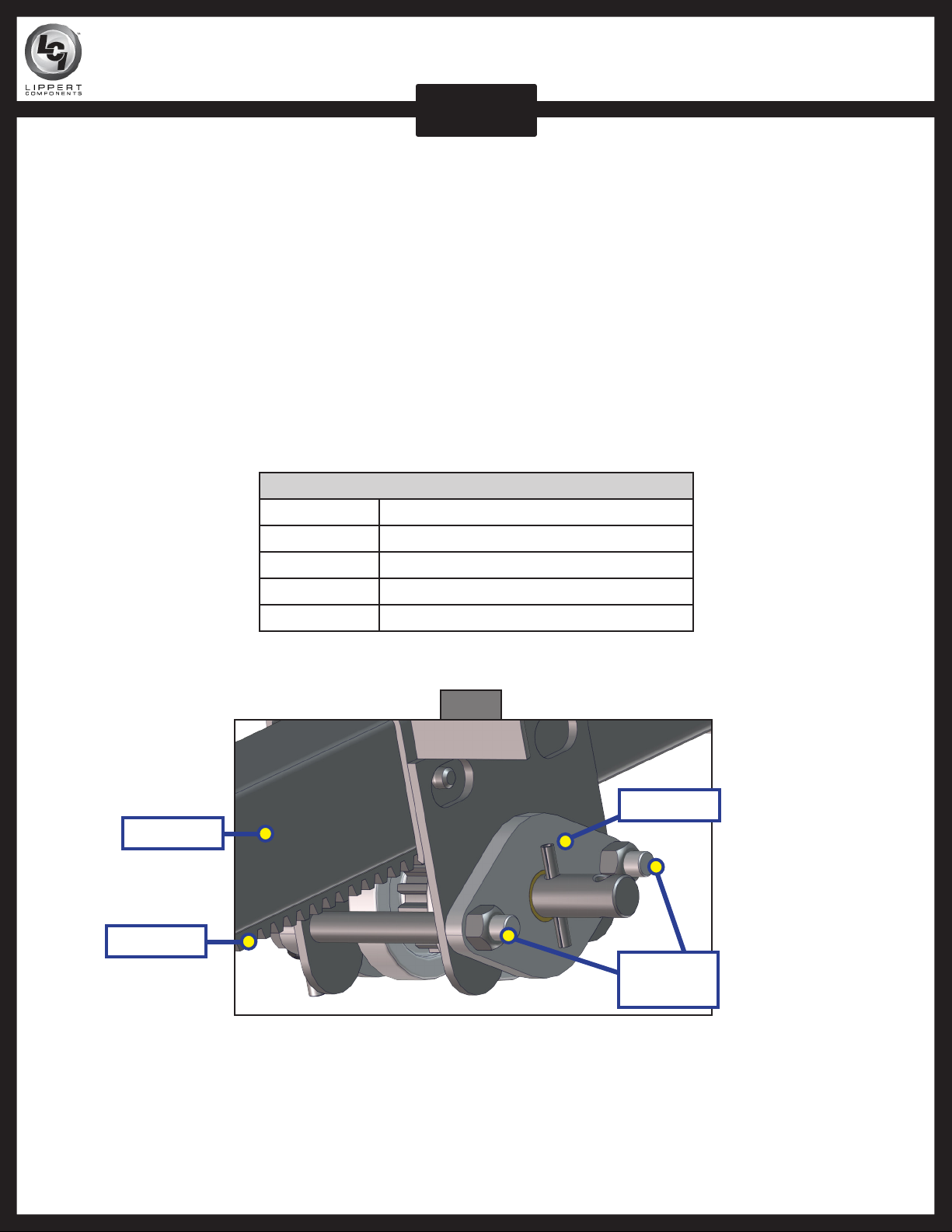

GEAR PACK REPLACEMENT INSTRUCTIONS

SLIDEOUTS

In the event a gear pack needs to be replaced, follow these steps:

1. Run slideout room half way out.

2. Place a jack under the inner arm of the slideout.

3. Jack room up just enough to remove pressure off the gear pack.

4. Remove drive bolt from the cross shaft.

5. Remove bolts which hold the gear pack assembly in place on the outer rail.

6. Drop out the damaged gear pack.

7. Install the new gear pack.

8. Install bolts to hold gear pack assembly in place on the outer rail.

9. Install cross shaft and bolt.

10. Gear pack assembly does not need to be torqued down, only adequately and securely tightened.

Gear Packs

281331 2 x 2

140409 2 x 3, 3 x 3

122837 Standard 2.5 x 2.5

123356 Heavy Duty 2.5 x 2.5

140418 Embedded Rack

Outer Rail

Gear Rack

Fig. 1

Gear Pack

Mounting

Bolts

Rev: 07.09.2014

Page 11

Hydraulic Through Frame Slideout Owners Manual

Page 12

CORRECTIVE ACTION FOR SQUEAKING GEAR PACKS

SLIDEOUTS

Fig. 1

Fig. 2

A

A

B

Fig. 3 Fig. 4

A

A

B

C

1. Loosen both gear packs bolts (Fig. 1A and Fig. 1B) until tension is off of the gear pack.

2. Using a manual pump oil can, pump 2-3 squints of synthetic motor oil onto gear pack drive shaft in

lubrication points (Fig. 2A), (Fig. 3A), (Fig. 4 A through D).

NOTE: Do not lubricate rack or pinion gear teeth, lubricate drive shaft only.

NOTE: LCI recommends Mobile One Fully Synthetic 10W-30 Motor Oil to lubricate gear pack.

3. Extend and retract slideout arms several times to work lubricant through gear pack.

D

Rev: 07.09.2014

Page 12

Hydraulic Through Frame Slideout Owners Manual

Page 13

Motor troubleshooting

Before attempting to troubleshoot the motor, make sure an adequate power source is available. The unit batteries

should be fully charged or the unit should be plugged into A/C service with batteries installed. Do not attempt to

troubleshoot the motor without assuring a full 12V DC charge.

The following tests require only a DC voltmeter (or DC test light) and a jumper lead.

1. Attach voltmeter (or test light) leads to the negative and positive switch terminals on back of wall

switch. Does the meter indicate 12V DC? If YES, see Step 2; if NO see Step 3.

2. If YES, at the motor, check the incoming leads to 12V DC (if necessary, disconnect leads at wire splices).

Does meter indicate 12V DC? If YES, motor needs to be replaced. The motor is not field serviceable.

DO NOT ATTEMPT TO REPAIR. If NO, Inspect all wires and connections between the wall switch and

the motor. Repair connections as necessary. Recheck as in Step 1.

3. If NO, Inspect all connections between battery and switch. Inspect 30A Auto-reset Circuit Breaker (See

Next Page). Recheck as above in Step 1.

4. Since there are no field serviceable parts in the motor, electrical troubleshooting and service is limited

to replacing only those components as previously outlined.

5. Thorough inspection of wiring and connections is the only other electrical service that can be

performed.

Fig. 1 Slideout Switch Color Codes

Red Jumper

Black Jumper

Green

Yellow

Black with

Black Jumper

Black - Power

Green - Motor CCW

Yellow - Motor CW

Red - Motor CW

Red with Red Jumper

Rev: 07.09.2014

Page 13

Hydraulic Through Frame Slideout Owners Manual

Page 14

Wiring Diagram

In

Switch - Wall switch

wired the same way

and pump switch get

Yellow

Reservoir

Out

Red "Hot"

Customer's

Green

source

choice 12VDC

polarity

Change of

reverses motor

Solenoid

Duel Polarity

Manufacturer

Supplied Breaker

Manifold

Battery

Motor

Rev: 07.09.2014

Page 14

Hydraulic Through Frame Slideout Owners Manual

Page 15

ROOM BAR MEASUREMENT CHART

SLIDEOUTS

Instructions:

1. Circle which side of your coach this room bar is for (Door Side or Off Door Side).

2. Enter the measurements for A, B, C, and D on the lines at the bottom.

DOOR SIDE

FRONT OF COACH

OFF DOOR SIDE

Room Bar

A

Room Bar

D

C

B

Rev: 07.09.2014

Brackets

A________ B________ C________ D________

Page 15

Hydraulic Through Frame Slideout Owners Manual

Page 16

Adjusting room so it seals in the IN position

1. Locate cylinder coming through the frame.

2. Run room partially out.

3. Hold Jam nut (Fig. 1A) in place with wrench.

4. Adjust Nylock nut (Fig. 1C) towards the bracket if the room does not seal or adjust the Nylock nut

(Fig. 1C) away from the bracket if the room is too tight and damages the fascia.

NOTE: Make small adjustments running the room in after each adjustment until proper seal is achieved.

Adjusting room so it seals in the OUT position

1. Locate cylinder coming through the frame.

2. Extend room completely out.

3. Check the inside fascia and seal positioning.

4. Partially retract room.

5. Loosen Jam nut (Fig. 1A) from Jam nut (Fig. 1B) and back off Jam nut (Fig. 1A) to give Jam nut (Fig. 1B)

room for adjustment.

6. Adjust Jam Nut (Fig. 1B) away from the bracket if the room extends to far and damages the inside

fascia or adjust Jam Nut (Fig. 1B) towards the bracket if the room does not seal.

NOTE: Make small adjustments running the room out after each adjustment until proper seal is achieved.

7. Tighten Jam Nut (Fig. 1A) to Jam Nut (Fig. 1B).

Fig. 1

A

C

B

2" - 3"

Free Travel

Rev: 07.09.2014

Page 16

Hydraulic Through Frame Slideout Owners Manual

Page 17

Mechanical Room Adjustment

NOTE: All slideout room adjustments must be performed by certified service technicians. Adjustments

made by non-certified persons may void any and all warranty claims.

Horizontal adjustment

1. Loosen carriage bolts (Fig. 2A) on each bracket located at the end of each guide tube.

2. Room is ready to be positioned horizontally by pushing on the outside, sidewall or by using a prying

device inserted into the opening between the room and coach.

NOTE: Use caution when using prying device so seals do not become damaged.

Vertical adjustment

1. Loosen 2 carriage bolts (Fig. 2A) on each bracket located at the end of each guide tube.

2. Loosen jam nut.

3. For vertical adjustment turn vertical adjustment bolt (Fig. 3A) up or down to locate room height.

4. Once room is located, tighten carriage bolts (Fig. 2A) and Jam Nut bolts.

Fig. 2

A

A

Fig. 3

Jam Nut

Synchronizing Room Travel

The Lippert Hydraulic Slideout System room travel (both sides of the room traveling the same distance) can be

adjusted with specially designed synchronizing bracket mounted on the passive slide tube. The passive slide tube is

the one that is not powered. The active slide tube is the one that has the cylinder attached. If one side of the room

fails to seal adjust as follows:

1. Loosen bolts (Fig. 4A) on top of the passive slide tube (Fig. 4B).

2. Push or pull room (on the passive side) to align with the active side.

Rev: 07.09.2014

Fig.4

A

B

Page 17

A

Hydraulic Through Frame Slideout Owners Manual

Page 18

Extend and retract cylinder port locations

Standard Slideout Cylinder

Retract

Rod End Piston Rod

Retract

Rod End Piston Rod

Extend

Cap End Stud

Trunnion Slideout Cylinder

Extend

Cap End Stud

Manual Override

The Lippert Hydraulic Slideout System can be run with auxiliary power devices like electric drills, ratchet wrenches

or cordless screwdrivers. In the event of electrical or system failure, this manual method of extending and retracting

the slideout room can be used. A standard hand-held drill is all that is required. A standard 38" room will take

approximately 45 seconds to retract. See the instructions below.

1. Remove protective label (Fig. 1).

2. Using a standard hex bit, insert into auxiliary drive device (cordless drill, screwdriver, or ratchet

wrench).

3. Insert hex bit into coupler found under protective label (Fig. 2).

4. Run drill forward or clockwise to extend slideout room and in reverse or counterclockwise to retract

slideout room.

Fig. 1 Fig. 2

Rev: 07.09.2014

Page 18

Hydraulic Through Frame Slideout Owners Manual

Page 19

2X2 HYDRAULIC THROUGH FRAME SLIDEOUT ASSEMBLY

SLIDEOUTS

Outer Tube Assembly

Inner Tube Assembly

Head Assembly

Wear Pad

Roller Shaft

Stiffener

Hat

Gear Pack Assembly

Rear Roller

Inner Tube

Assembly

Rev: 07.09.2014

Page 19

Spur Gear

2x2 Hydraulic Through Frame Slideout Webpage

Page 20

2X2 HYDRAULIC THROUGH FRAME SLIDEOUT COMPONENTS

SLIDEOUTS

A

E

F

B

G

C

D

H

J

K

L

I

Callout Part # Description

A 103480 Wear Pad (x8)

B 277882 Wear Tab for 317322

C 104475 Rear Roller

D 105893 Roller Shaft

E 281331 Gear Pack

F 101941 Spur Gear (Current)

G 122739 Spur Gear (Obsolete)

H 102357 Stiffener

I 106059 Hat (x2)

J 113535 Front Trunion Bracket

K 106040 Rear Trunion Bracket

L 159279 Trim Plate

Rev: 07.09.2014

Page 20

2x2 Hydraulic Through Frame Slideout Webpage

Page 21

2X2 HYDRAULIC THROUGH FRAME SLIDEOUT COMPONENTS

SLIDEOUTS

D

B

C

A

F

G

E

NOTE: See Room Bar Measurement Chart

(LIP Sheet 0080)

Rev: 07.09.2014

Callout Part # Description

A 104851 Slideout Mounting Bracket

B 141792 1 3/8" Adjustable Head Assembly

C 159624 Standard Weld-On Head Assembly

D 163049 Flush Adjustable Head Assembly

E 173593 Standard Flush Fixed Head Assembly

F 173594 Standard Flush Adjustable Head Assembly

G

183949 Room Bar (Use for up to 80")

183950 Room Bar (Use for up to 154")

NOTE: Brackets can be shipped loose.

Page 21

2x2 Hydraulic Through Frame Slideout Webpage

Page 22

2X2 HYDRAULIC THROUGH FRAME SLIDEOUT COMPONENTS

SLIDEOUTS

A

B

C

D

E

F

G

Callout Part # Description

A

145735 Outboard Outer Arm (Idler)

145734 Outboard Outer Arm (Drive)

B 145736 Outboard Inner Arm

C 173204 Inboard Outer Arm 76" (Idler and Drive)

D 163778 Inboard Inner Arm

E 161014 Inboard Outer Arm 69" (Idler and Drive)

F 159389 Inboard Outer Arm 70" (Idler and Drive)

G 301393 Inboard Inner Arm (18 Teeth)

H 296090 Outboard Inner Arm (18 Teeth)

NOTE: Standard slideout arms have 15 teeth.

H

Rev: 07.09.2014

Page 22

2x2 Hydraulic Through Frame Slideout Webpage

Page 23

2X2 HYDRAULIC THROUGH FRAME

SLIDEOUT DRIVE COMPONENTS

SLIDEOUTS

A

C

D

B

E

Rev: 07.09.2014

F

Callout Part # Description

A 123603 Hydraulic Trunion 38"

B 125653 Hydraulic Trunion 24"

C 133874 Hydraulic Trunion 30"

D 141109 O-Ring Face Seal Straight Fitting

E 173738 O-Ring Face Seal Elbow Fitting

F 120639 Hydraulic Interior Slideout Switch

G 140530 6 Prong Interior Switch with Wall Plate

Page 23

G

2x2 Hydraulic Through Frame Slideout Webpage

Page 24

2X3 HYDRAULIC THROUGH FRAME SLIDEOUT ASSEMBLY

PRODUCT CATEGORY

2 x 3 Shorty Hydraulic Slideout

Hydraulic Cylinder

Cylinder Mounting Bracket

Inner Arm

Assembly

Front Roller

Assembly

Wear Tab

Outer Arm Assembly

Roller

Rod & Pin

Section Assembly

Rear

Roller

Roller

Shaft

Rev: 07.09.2014

Page 24

Front

Roller

2x3 Hydraulic Through Frame Slideout Webpage

Page 25

2X3 HYDRAULIC THROUGH FRAME SLIDEOUT ASSEMBLY

SLIDEOUTS

2 x 3 Bolt-In Hydraulic Slideout

See Page 1 for

Component

Descriptions

See Page 1 for

Component

Descriptions

2 x 3 Full Wall Hydraulic Slideout

Idler Arm

Rev: 07.09.2014

Page 25

2x3 Hydraulic Through Frame Slideout Webpage

Page 26

2X3 HYDRAULIC THROUGH FRAME SLIDEOUT COMPONENTS

SLIDEOUTS

A

B

D

G

C

H

Callout Part # Description

E

F

201709 16" Stroke Outer Arm Assembly

201708 30 ½" Stroke Outer Arm Assembly

A

I

158564 31 ½" Stroke Outer Arm Assembly

213654 36" Stroke Outer Arm Assembly

203468 30" Full Wall Drive Arm Outer Assembly

203470 30" Full Wall Passive Arm Outer Assembly

179024 16" Stroke Inner Arm Assembly

179124 30 ½" Stroke Inner Arm Assembly

B

158565 31 ½" Stroke Inner Arm Assembly

213655 36" Stroke Inner Arm Assembly

157692 30" Full Wall Drive Arm Inner Assembly

157294 30" Full Wall Passive Arm Inner Assembly

J

C 135435 Roller Assembly

D 101255 Roller

E 104474 Rear Roller

F 128926 Rod

G 118174 Roll Pin

H 105895 Roller Shaft

K

I 103480 Wear Tab

J 115034 Cylinder Mounting Bracket

K 115035 Cylinder Mounting Bracket

Rev: 07.09.2014

Page 26

2x3 Hydraulic Through Frame Slideout Webpage

Page 27

2X3 HYDRAULIC THROUGH FRAME

SLIDEOUT DRIVE COMPONENTS

SLIDEOUTS

A

E

B

F

C

D

G

Rev: 07.09.2014

H

Callout Part # Description

A 120639 Hydraulic Interior Switch

B 140530 6 Prong Interior Switch with Wall Plate

C 173738 O-Ring Face Seal Elbow Fitting

D 141109 O-Ring Face Seal Straight Fitting

E 213750 36 ½" Hydraulic Cylinder

F 158499 31 ½" Hydraulic Cylinder

G 138720 30 ½" Hydraulic Cylinder

H 140930 16 ½" Hydraulic Cylinder

Page 27

2x3 Hydraulic Through Frame Slideout Webpage

Page 28

2.5X2.5 HYDRAULIC THROUGH FRAME SLIDEOUT ASSEMBLY

SLIDEOUTS

Inner Arm

Assembly

Head

Assembly

Gear Pack

Assembly

Cross

Shaft Kit

Outer Arm

Assembly

Rear Cylinder

Mounting Bracket

Hydraulic

Cylinder

Front Cylinder

Mounting Bracket

Rev: 07.09.2014

Wear Tab

Rear Roller

Section View

Page 28

Spur Gear

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 29

2.5X2.5 HYDRAULIC THROUGH FRAME

SLIDEOUT COMPONENTS

SLIDEOUTS

D

A

E

B

C

F

G

H

I

Callout Part # Description

A 122837 Gear Pack (Standard)

B 123356 Gear Pack (Heavy Duty)

C 105892 Rear Roller

D 103480 Wear Tab

E 277882 Wear Tab for 317322

F 101941 Spur Gear

G 328044 Spur Gear Heavy Duty

H 113535 Front Cylinder Bracket

I 106040 Rear Cylinder Bracket

J 106030 Trim Plate

K 102357 Stiffener

J

K

Rev: 07.09.2014

Page 29

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 30

2.5X2.5 HYDRAULIC THROUGH FRAME

HEAD ASSEMBLIES (STANDARD)

SLIDEOUTS

C

A

E

B

F

G

D

H

I

Callout Part # Description

A 104851 Slideout Mounting Bracket

B 119047 Flush Adjustable Head Assembly

C 119048 Flush Fixed Head Assembly

D 122854 Adjustable Head Assembly (1 ¾")

E 122855 Fixed Head Assembly (1 ¾")

F 166536 Flush Floor End Condition

G 226347 Room Bar Slide Head Assembly (12")

H 105966 Room Bar Bracket

I

183949 Room Bar (Use for up to 80")

183950 Room Bar (Use for 81" to 154")

Rev: 07.09.2014

Page 30

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 31

2.5X2.5 HYDRAULIC THROUGH FRAME

HEAD ASSEMBLIES (V-TECH)

SLIDEOUTS

A

E

B

F

C

G

D

H

I

Callout Part # Description

A 118127 Flush Fixed Head Assembly

B 119157 Flush Adjustable Head Assembly

C 123999 Flush Adjustable, Tall & Extended Head Assembly

D 124000 Flush Fixed, Tall & Extended Head Assembly

E 145388 1 ⁄" Fixed Head Assembly

F 145389 1 ⁄" Adjustable Head Assembly

G 146612 Flush Fixed, Tall & Extended Head Assembly

H 151474 1 ⁄" Adjustable Head Assembly

I 151475 1 ⁄" Fixed Head Assembly

J 180461 Room Bar Assembly

K 105966 Room Bar Bracket

L 103139 Mounting Bracket

J

K

L

Rev: 07.09.2014

Page 31

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 32

2.5X2.5 HYDRAULIC THROUGH FRAME

SLIDEOUT COMPONENTS

SLIDEOUTS

B

A

C

E

D

F

Rev: 07.09.2014

Callout Part # Description

A

B 143707 Outboard Inner Arm

C

D 143710 Inboard Inner Arm

E 296121 Inboard Inner Arm (18 Teeth)

F 317322 Outboard Inner Arm (18 Teeth)

NOTE: Standard slideout arms have 15 teeth.

143674 Outboard Outer Arm (Idler)

143675 Outboard Outer Arm (Drive)

143676 Inboard Outer Arm (Idler)

143677 Inboard Outer Arm (Drive)

Page 32

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 33

2.5X2.5 HYDRAULIC THROUGH FRAME

SLIDEOUT DRIVE COMPONENTS

SLIDEOUTS

A

D E

B

C

F

Callout Part # Description

A 123603 Hydraulic Cylinder 38"

B 125653 Hydraulic Cylinder 24"

C 133874 Hydraulic Cylinder 30"

D 141109 O-Ring Face Seal Straight Fitting

E 173738 O-Ring Face Seal Elbow Fitting

F 120639 Hydraulic Interior Slideout Switch

G 140530 6 Prong Interior Switch with Wall Plate

G

Rev: 07.09.2014

Page 33

2.5x2.5 Hydraulic Through Frame Slideout Webpage

Page 34

Notes

Rev: 07.09.2014

Page 34

End of Book

Page 35

Rev: 07.09.2014

Page 35

End of Book

Page 36

All information contained within may be distributed as a full document only, unless otherwise permitted by

explicit consent of Lippert Components Inc. to distribute individual parts.

All information contained within is subject to change without notice. New editions will be posted on

www.lci1.com and can be downloaded for free. Information contained within is considered factual until made

obsolete by a *NEW* revision.

Please recycle all obsolete materials.

For all concerns or questions, please contact

Lippert Components, Inc.

Ph: (574) 537-8900 Web: www.lci1.com Email: warranty@lci1.com

Rev: 07.09.2014

Page 36

End of Book

Loading...

Loading...