Page 1

LIPPERTCOMPONENTS, INC.

HYDRAULIC LANDING GEAR - 14K ALUMINUM

OPERATION MANUAL

FAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING MA Y RESUL T IN SERIOUS PERSONAL INJURY OR DEA TH.

THE USE OF THE LIPPERT HYDRAULIC LANDING GEAR TO SUPPORT THE COACH FOR ANY REASON OTHER THAN WHICH IT IS

INTENDED IS PROHIBITED BY LIPPERT’S LIMITED WARRANTY. THE LIPPERT HYDRAULIC LANDING GEAR SYSTEM IS DESIGNED

AS A SYSTEM TO DROP THE UNIT OFF OF A TRUCK, LEVEL THE UNIT FROM FRONT T O BACK AND STABILIZE THE FRONT OF

THE UNIT ONLY AND SHOULD NOT BE USED TO PROVIDE SERVICE FOR ANY REASON UNDER THE COACH SUCH AS

CHANGING TIRES OR SERVICING THE LANDING GEAR.

LIPPERT COMPONENTS, INC. RECOMMENDS THA T A TRAINED PROFESSIONAL BE EMPLOYED TO CHANGE THE TIRE ON THE

COACH. ANY A TTEMPTS TO CHANGE TIRES OR PERFORM OTHER SER VICE WHILE COACH IS SUPPORTED BY THE LIPPERT

HYDRAULIC LANDING GEAR COULD RESULT IN DAMAGE T O THE COACH AND/OR CAUSE SERIOUS PERSONAL INJURY OR

DEATH.

• BE SURE TO PARK THE COACH ON SOLID, LEVEL GROUND.

• CLEAR ALL JACK LANDING LOCA TIONS OF DEBRIS AND OBSTRUCTIONS. LOCA TIONS SHOULD ALSO BE FREE OF

DEPRESSIONS.

• WHEN PARKING THE COACH ON EXTREMEL Y SOFT SURF ACES, UTILIZE LOAD DISTRIBUTION P ADS UNDER EACH JACK.

• PEOPLE AND PETS SHOULD BE CLEAR OF COACH WHILE OPERA TING LIPPERT HYDRAULIC LANDING GEAR SYSTEM.

• BE SURE TO KEEP HANDS AND OTHER BODY P ARTS CLEAR OF FLUID LEAKS. OIL LEAKS IN THE LIPPER T HYDRAULIC

LANDING GEAR MAY BE UNDER HIGH PRESSURE AND CAN CAUSE SERIOUS SKIN PENETRA TING INJURIES.

• NEVER LIFT THE COACH COMPLETELY OFF THEGROUND. LIFTING THE COACH SO THE WHEELS ARE NOT TOUCHING

GROUND WILL CREATE AN UNST ABLE AND UNSAFE CONDITION.

The LIPPERT HYDRAULIC LANDING GEAR shall only be operated under the following conditions:

1. The unit is parked on a reasonably level surface.

2.. The towing vehicle is disengaged from the unit.

3. Be sure all persons, pets and property are clear of the coach while LIPPERT HYDRAULIC LANDING GEAR is in operation.

• Please read and study the operating manual before you operate the LIPPERT HYDRAULIC LANDING GEAR.

• The LIPPERT HYDRAULIC LANDING GEAR is an electric/hydraulic system. A 12V DC electric motor drives a hydraulic pump that

moves fluid through a system of hoses, fittings and jacks to level and stabilize the coach.

• There are no serviceable parts within the electric motor. If the motor fails, it must be replaced.

• Disassembly of the motor voids the warranty.

• Mechanical portions of the LIPPERT HYDRAULIC LANDING GEAR are replaceable. Contact Lippert Components, Inc. to obtain

replacement parts.

The LIPPERT HYDRAULIC LANDING GEAR consists of the following major components:

• LIPPERT HYDRAULIC LANDING GEAR are rated at a lifting capacity appropriate for your coach.

• LIPPERT HYDRAULIC LANDING GEAR is powered from a central 12VDC motor/pump assembly, which also includes the hydraulic oil

reservoir tank, control valve manifold, and solenoid valves.

• The LIPPERT HYDRAULIC LANDING GEAR is controlled electronically from the switch near the pump.

WARNING!

PRIOR TO OPERATION

SYSTEM DESCRIPTION

COMPONENT DESCRIPTION

rev052010

The LIPPERT HYDRAULIC LANDING GEAR has been designed to require very little maintenance. T o ensure the long life of your slideout

system, read and follow these few simple procedures.

1. Check the fluid level every month.

a) Check fluid only when jacks are fully retracted.

b) Always fill the reservoir with the jacks in the fully retracted position. Filling reservoir when jacks are extended will cause reservoir to

overflow into its compartment when jacks are retracted.

c) When checking fluid level, fluid should be within ¼” of fill spout lip.

2. Inspect and clean all Pump Unit electrical connections every 12 months.

3. Remove dirt and road debris from Landing Gear as needed.

YOUR COACH SHOULD BE SUPPORTED A T BOTH FRONT AND REARAXLES WITH JACK ST ANDS BEFORE WORKING

4. If jacks are down for extended periods, it is recommended to spray exposed Landing Gear rod with a silicone lubricant every seven

days for protection. If your coach is located in a salty environment, it is recommended to spray the rods every 2 to 3 weeks.

UNDERNEATH. FAILURE TO DO SO MA Y RESUL T IN PERSONAL INJURY OR DEA TH.

PREVENTATIVE MAINTENANCE PROCEDURES

WARNING!

Page 2

FAILURE TO ACT IN ACCORDANCE WITH THE FOLLOWING MA Y RESUL T IN SERIOUS PERSONAL INJURY OR DEA TH.

The LIPPERT HYDRAULIC LANDING GEAR has been static tested to over 6,000 continuous cycles without any noticeable wear to rotating

or sliding parts. It is recommended that when operating in harsh environments and conditions (road salt, ice build-up, etc.) the moving parts

be kept clean and can be washed with mild soap and water. No grease or lubrication is necessary and in some situations may be detrimental

to the environment and long-term dependability of the system.

MECHANICAL COMPONENTS

Although the system is designed to be almost maintenance-free, actuate the landing gear once or twice a week to keep the seals and internal

moving parts lubricated.

Check for any visible signs of “leaking” before and after movement of the system and the coach.

When the Landing Gear is down, visually inspect the Inner and Outer Assemblies. Refer to Fig. 3, for location of inner assemblies. Check

for excess build-up of dirt or other foreign material; remove any debris that may be present.

If the system squeaks or makes any noises it is permissible to apply a coat of lightweight oil or silicone lubricant spray to the hydraulic rod

but remove any excess oil so dirt and debris do not build-up. DO NOT USE GREASE.

ELECTRICAL COMPONENTS

For optimum performance, the landing gear system requires full battery current and voltage. The battery must be maintained at full capacity .

Other than good battery maintenance, check the terminals and other connections at the battery, the control switch and the pump motor for

corrosion and loose or damaged terminals. Check motor leads under the coach chassis. Since these connections may be subject to

damage from road debris, be sure they are in good condition.

NOTE - The LIPPERT HYDRAULIC LANDING GEAR is designed to operate as a negative ground system. A negative ground system

utilizes the chassis frame as the ground source. An independent ground wire back to the battery is not needed. It is important the electrical

components have good wire to chassis contact. Over 90% of unit electrical problems can be attributed to bad ground connections.

NOTE - For long-term storage: It is recommended that the room be closed (retracted) and if your unit is equipped with the IRC room

control, it is recommended all of the control knobs be kept in the closed position.

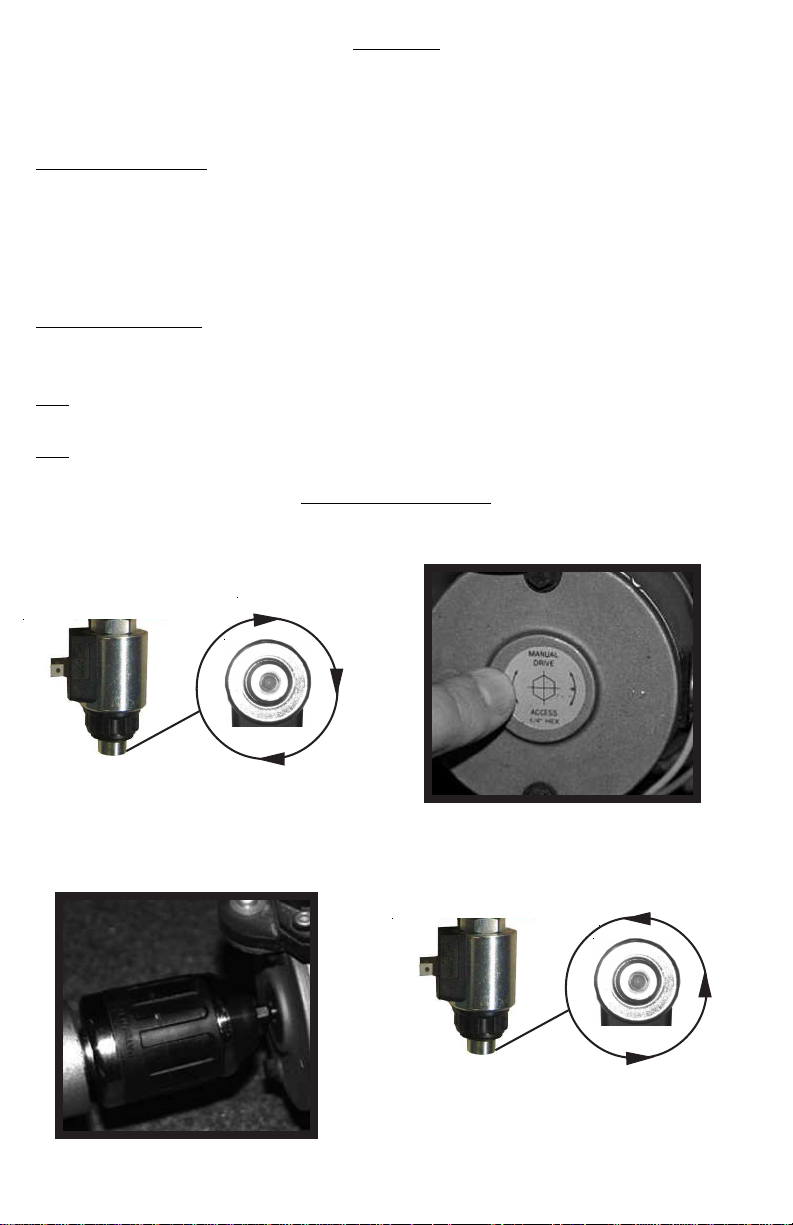

The LIPPERT HYDRAULIC LANDING GEAR can be run with power devices like electric drills or cordless screwdrivers. In the event of

electrical or system failure, this manual method of extending and retracting the jacks can be used. A standard handheld cordless or power

drill is all that is required. See the instructions below:

DO NOT WORK ON YOUR SLIDEOUT SYSTEM UNLESS THE BA TTERY IS DISCONNECTED.

WARNING!

AUXILIARY OPERATION

Fig. 2

1. Locate the blocking valve on the top cap of either of the

landing gear jacks.

2. Using a 5/32” Allen wrench, manual open the valve by turn

the manual override set screw in the end of the valve clockwise.

5. Insert hex bit into coupler found under protective label, Fig. 2.

6. Run drill forward or clockwise to extend jacks and in reverse or

counterclockwise to retract jacks.

3. Remove protective label. (See Fig 1).

4. Using a standard hex bit, insert into auxiliary drive device,

i.e. cordless drill or power drill

7. be sure to turn manual override set screw back to the

counterclockwise position after extnding or retracting

landing gear.

Page 3

NOTE: NOT ALL COMPONENTS LISTED IN THE BILL OF MA TERIALS

ARE AV AILABLE AS REPLACEMENT P ARTS.

PLEASE CONSULT WITH A LIPPERT COMPONENTS CUSTOMER

SERVICE REPRESENTA TIVE FOR A V AILABLE P ARTS.

Page 4

Fill Cap

The LIPPERT HYDRAULIC LANDING GEAR uses automatic transmission fluid (ATF). Any A TF can be used. A full synthetic or synthetic

blend works best such as Dexron III or Mercon 5. For best operation, fill system within ½” of the top when all slideouts are completely

retracted. The see through reservoir makes it easy to check oil level. It is recommended that the oil level be checked prior to operating the

system. Make sure the breather cap is free of contamination before removing, replacing or installing.In colder temperatures (less than 10°

F) the jacks may extend and retract slowly due to the fluid’s molecular nature. For cold weather operation, fluid speciallyformulated for low

temperatures may be desirable. Please consult factory before using any other fluids.

FILLING DIRECTIONS

NOTE: Be sure landing gear are fully retracted prior to filling reservoir to prevent over-filling.

1. Remove Breather/Fill Cap

2. Pour A TF into Breather/Fill opening.

NOTE: Do not allow any contamination into reservoir during fill process.

NOTE: Standard reservoir holds approximately 2 quarts (1.89 liters) of A TF .

3. Fill to within ½” of top.

4. Replace Breather/Fill cap when finished.

NOTE: System is self-purging. By simply cycling the system 2-3 times, any air in the system will be forced back to the reservoir and

out of the Breather/Fill cap.

TROUBLESHOOTING

JACKS WILL NOT EXTEND TO GROUND, PUMP IS RUNNING

PROBABLE CAUSE CORRECTIVE ACTION

Little or no fluid in reservoir Fill reservoir with DEXRON III A TF

Leg valve is inoperative Clean, repair or replace

FLUID FILLING PROCEDURE

Electronic signal is lost between switch and leg valves Trace wires for voltage drop or loss of signal

ANY ONE OR TWO JACKS WILL NOT RETRACT

PROBABLE CAUSE CORRECTIVE ACTION

Hose damaged or unconnected Replace with new hose or reconnect hose

Return valve inoperative Replace inoperative return valve

Electronic signal is lost between switch and solenoid Attempt to retract jacks in MANUAL mode, if successful, replace

Before attempting to troubleshoot the Power Unit, make sure an adequate power source is available. The unit batteries should be fully

charged or the unit should be plugged into to A/C service with batteries installed. Do not attempt to troubleshoot the Power Unit without

assuring a full 12V DC charge.

The following tests require only a DC voltmeter (or DC test light) and a jumper lead.

Step 1-Attach voltmeter (or test light) leads to the negative and positive terminals on motor solenoid (See Fig. 7). Does the meter

indicate 12V DC? If YES, see Step 2; if NO see Step 3.

Step 2-If YES, at the motor, check the incoming leads to 12V DC (if necessary , disconnect leads at wire splices). Does meter indicate 12V

DC? If YES, Power Unit needs to be replaced. The motor is not field serviceable. Do not attempt to repair. If NO, Inspect all wires

and connections between the wall switch and the motor. Repair connections as necessary . Recheck as in Step 1.

Step 3-If NO, Inspect all connections between battery and solenoid. Inspect 30A Auto-reset Circuit Breaker (See Fig. 7 for location).

Recheck as above in Step 1.

NOTE: Since there are no field serviceable parts in the motor of the Power Unit, electrical troubleshooting and service is limited to

replacing only those components as previously outlined.

NOTE: Thorough inspection of wiring and connections is the only other electrical service that can be performed.

TROUBLESHOOTING – POWER UNIT

Repair or replace necessary wires or replace switch.

control pad; if not, test voltage drop between switch and leg valve

Repair bad wiring or replace defective board or valve.

IF YOU HAVE ANY PROBLEMS OR QUESTIONS CONSULT YOUR

LOCAL AUTHORIZED DEALER OR CONTACT LIPPERT:

Ph. - (574)537-8900 Fax- (573)534-7161 Email - warranty@lci1.com

Loading...

Loading...