FEATURES

■

OP-07 Type Performance:

at 1/8th of OP-07’s Supply Current

at 1/20th of OP-07’s Bias and Offset Currents

■

Guaranteed

■

Guaranteed

■

Guaranteed

■

Low Noise, 0.1Hz to 10Hz: 0.5µV

■

Guaranteed

■

Guaranteed

■

Guaranteed

■

Guaranteed

Offset Voltage: 25µV Max

Bias Current: 100pA Max

Drift: 0.6µV/°C Max

P-P

Low Supply Current: 500µA Max

CMRR: 114dB Min

PSRR: 114dB Min

Operation at ±1.2V Supplies

U

APPLICATIO S

■

Replaces OP-07 While Saving Power

■

Precision Instrumentation

■

Charge Integrators

■

Wide Dynamic Range Logarithmic Amplifiers

■

Light Meters

■

Low Frequency Active Filters

■

Thermocouple Amplifiers

LT1012A/LT1012

Picoamp Input Current,

Microvolt Offset,

Low Noise Op Amp

U

DESCRIPTIO

The LT®1012 is an internally compensated universal

precision operational amplifier which can be used in

practically all precision applications. The LT1012

combines picoampere bias currents (which are

maintained over the full –55°C to 125°C temperature

range), microvolt offset voltage (and low drift with time

and temperature), low voltage and current noise, and

low power dissipation. The LT1012 achieves precision

operation on two Ni-Cad batteries with 1mW of power

dissipation. Extremely high common mode and

power supply rejection ratios, practically unmeasurable

warm-up drift, and the ability to deliver 5mA load current

with a voltage gain of one million round out the LT1012’s

superb precision specifications.

The all around excellence of the LT1012 eliminates the

necessity of the time consuming error analysis procedure

of precision system design in many applications; the

LT1012 can be stocked as the universal internally

compensated precision op amp.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Protected by U. S. patents 4,575,685 and 4,775,884

U

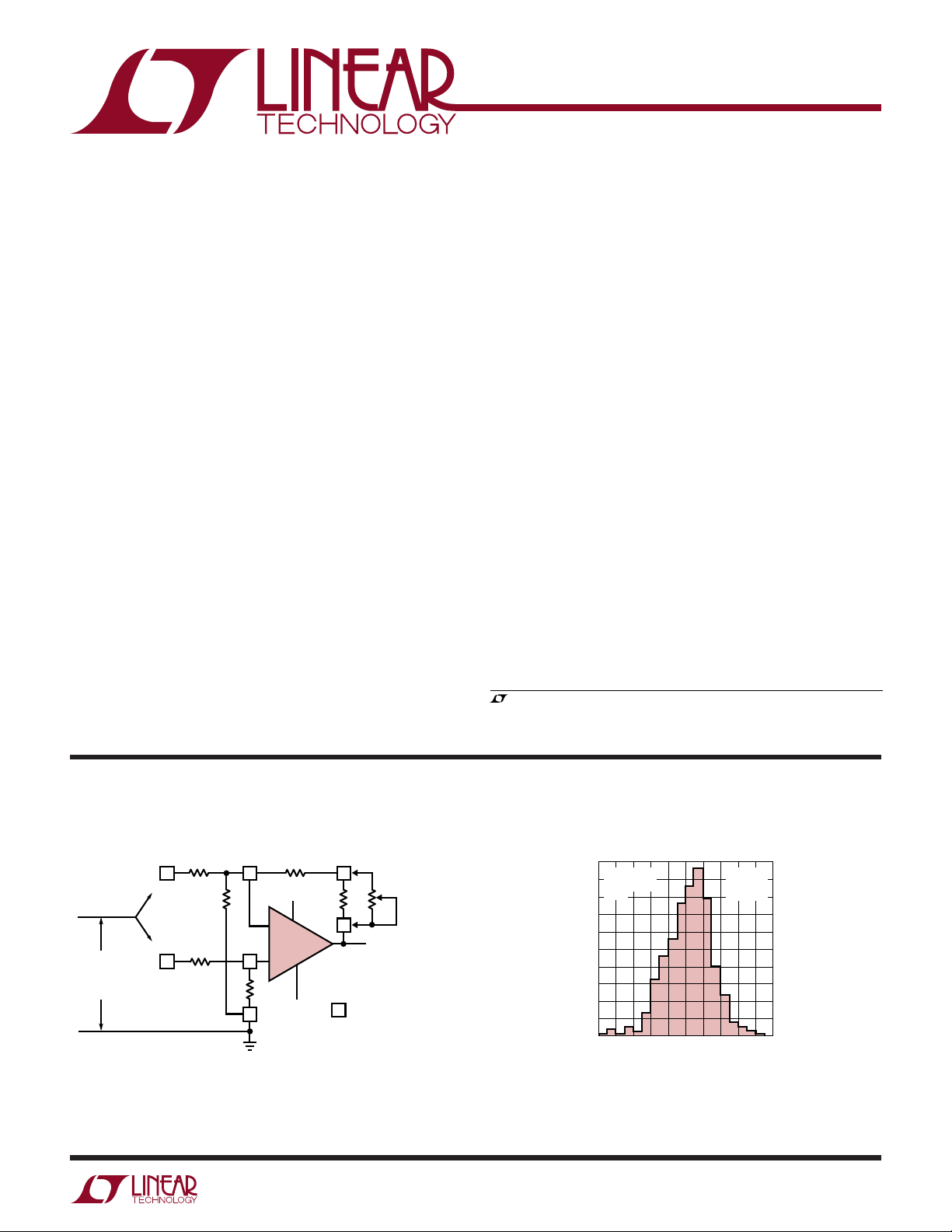

TYPICAL APPLICATIO

±250V Common Mode Range Instrumentation Amplifier (AV = 1)

R1

1M

3 4 1

–IN

R2

20k

R3

COMMON

MODE

INPUT

±250V

COMMON MODE REJECTION RATIO = 74dB (RESISTOR LIMITED)

WITH OPTIONAL TRIM = 130dB

OUTPUT OFFSET (TRIMMABLE TO ZERO) = 500µV

OUTPUT OFFSET DRIFT = 10µV/°C

INPUT RESISTANCE = 1M

+IN

1M

7

6

R4

19.608k

5

6V TO 18V

2

–

LT1012

3

+

–6V TO –18V

R5

975k

R6

25k

7

2

6

4

R1 TO R6: VISHAY 444

ACCUTRACT THIN FILM

SIP NETWORK

: VISHAY 444 PIN NUMBERS

X

VISHAY INTERTECHNOLOGY, INC

63 LINCOLN HIGHWAY

MALVERN, PA 19355

LT1012A • TA01

OUT

50k

OPTIONAL

CMRR

TRIM

Typical Distribution of Input

Offset Voltage

200

1140 UNITS

FROM THREE

RUNS

160

120

80

NUMBER OF UNITS

40

0

–40

–20

INPUT OFFSET VOLTAGE (µV)

0

VS = ±15V

= 25°C

T

A

V

CM

20 40

LT1012A • TA02

= 0V

sn1012 1012afbs

1

LT1012A/LT1012

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage ......................................................± 20V

Differential Input Current (Note 1) ......................± 10mA

Input Voltage .........................................................± 20V

Output Short Circuit Duration .......................... Indefinite

UU

W

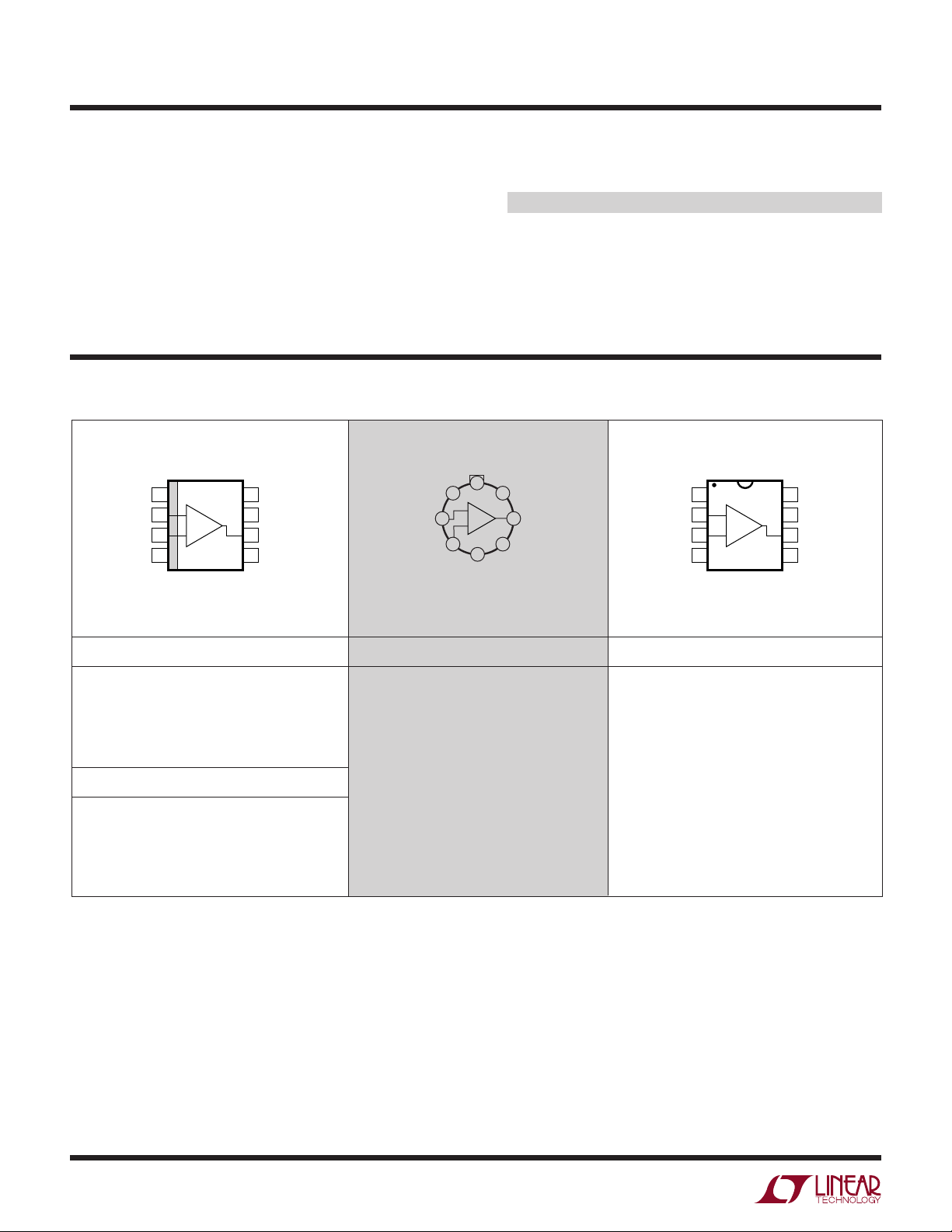

PACKAGE/ORDER I FOR ATIO

V

OS

TRIM

–IN

+IN

–

V

T

JMAX

TOP VIEW

1

2

–

3

+

4

S8 PACKAGE

8-LEAD PLASTIC SO

=

100°C, θJA = 170°C/W

V

OS

8

TRIM

+

7

V

6

OUT

OVER

5

COMP

V

OS

TRIM

1

2

–IN OUT

+IN OVER

H PACKAGE

8-LEAD TO-5 METAL CAN

= 150°C, θJA = 150°C/W, θJC = 45°C/W

T

JMAX

Operating Temperature Range

LT1012AM/LT1012M (OBSOLETE)....– 55°C to 125°C

LT1012I/LT1012AI ............................. – 40°C to 85°C

LT1012AC/LT1012C

LT1012D/LT1012S8 ................................ 0°C to 70°C

Storage Temperature Range ................. – 65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

TOP VIEW

V

OS

–

V

TRIM

8

–

+

4

(CASE)

7

53

+

V

6

COMP

V

OS

TRIM

–IN

+IN

V

TOP VIEW

1

2

–

3

–

T

+

4

N8 PACKAGE

8-LEAD PDIP

= 100°C, θJA = 130°C/W

JMAX

8

7

6

5

V

OS

TRIM

+

V

OUT

OVER

COMP

ORDER PART NUMBER

LT1012S8

LT1012IS8

LT1012ACS8

LT1012AIS8

ORDER PART NUMBER

LT1012AMH

LT1012MH

LT1012ACH

LT1012CH

LT1012DH

S8 PART MARKING

1012

1012I

1012A

1012AI

Consult LTC Marketing for parts specified with wider operating temperature ranges.

OBSOLETE PACKAGE

Consider the S8 or N8 Packages for Alternate Source

ORDER PART NUMBER

LT1012ACN8

LT1012AIN8

LT1012CN8

LT1012DN8

LT1012IN8

2

sn1012 1012afbs

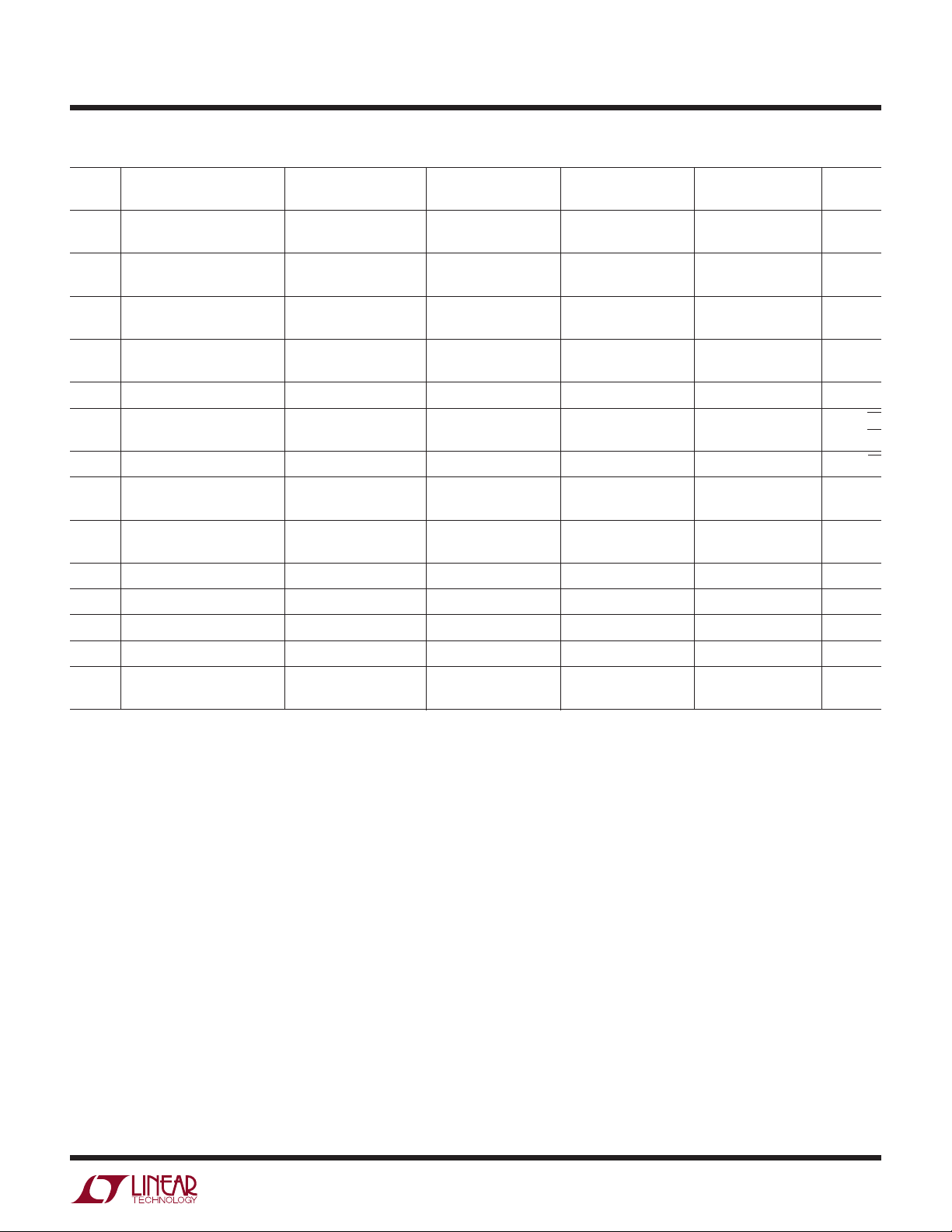

LT1012A/LT1012

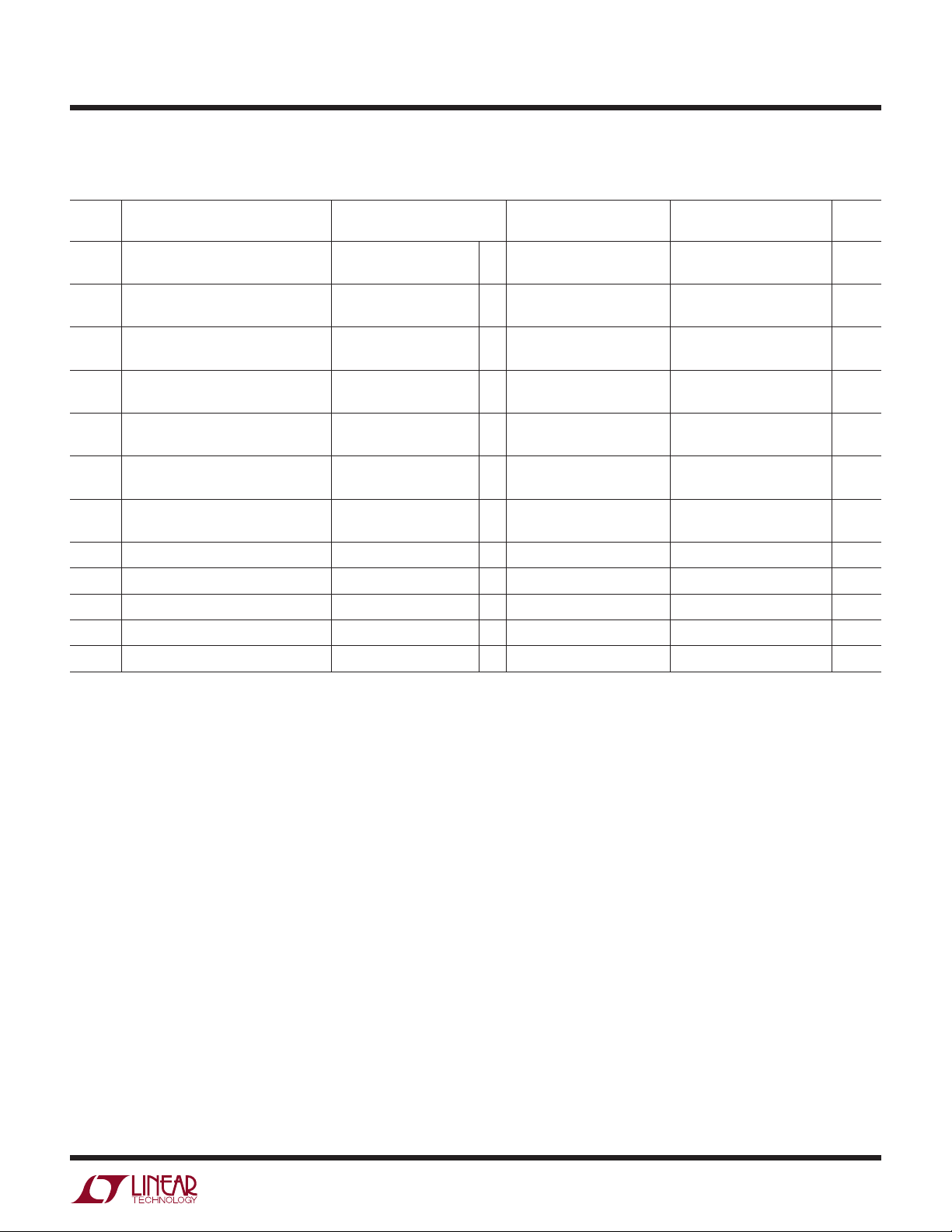

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX MIN TYP MAX UNITS

V

OS

I

OS

I

B

e

n

e

n

i

n

A

VOL

CMRR Common Mode Rejection VCM = ±13.5V 114 132 114 132 110 132 dB

PSRR Power SuppIy Rejection Ratio VS = ±1.2V to ±20V 114 132 114 132 110 132 dB

V

OUT

I

S

Input Offset Voltage 8 25 8 35 10 50 µV

(Note 3) 20 90 20 90 25 120 µV

Long Term lnput Offset 0.3 0.3 0.3 µV/month

Voltage Stability

Input Offset Current 15 100 15 100 20 150 pA

(Note 3) 25 150 25 150 30 200 pA

Input Bias Current ±25 ±100 ±25 ±100 ±30 ±150 pA

(Note 3) ±35 ±150 ±35 ±150 ±40 ±200 pA

Input Noise Voltage 0.1Hz to 10Hz 0.5 0.5 0.5 µV

Input Noise Voltage Density fO = 10Hz (Note 4) 17 30 17 30 17 30 nV√Hz

f

= 1000Hz (Note 5) 14 22 14 22 14 22 nV√Hz

O

Input Noise Current Density f

Large Signal Voltage Gain V

Ratio

Input Voltage Range ±13.5 ±14 ±13.5 ±14 ±13.5 ±14 V

Output Voltage Swing RL = 10kΩ±13 ±14 ±13 ±14 ±13 ±14 V

Slew Rate 0.1 0.2 0.1 0.2 0.1 0.2 V/µs

Supply Current 370 500 380 380 µA

10Hz 20 20 20 fA/√Hz

O =

= ±12V, RL ≥ 10kΩ 300 2000 300 2000 200 2000 V/mV

OUT

V

= ±10V, RL ≥ 2kΩ 300 1000 200 1000 200 1000 V/mV

OUT

(Note 3) 380 600 380 600 380 600 µA

VS = ± 15V, VCM = OV, TA = 25°C, unless otherwise noted.

LT1O12AM/AC/AI LT1O12M/I LT1O12C

P-P

sn1012 1012afbs

3

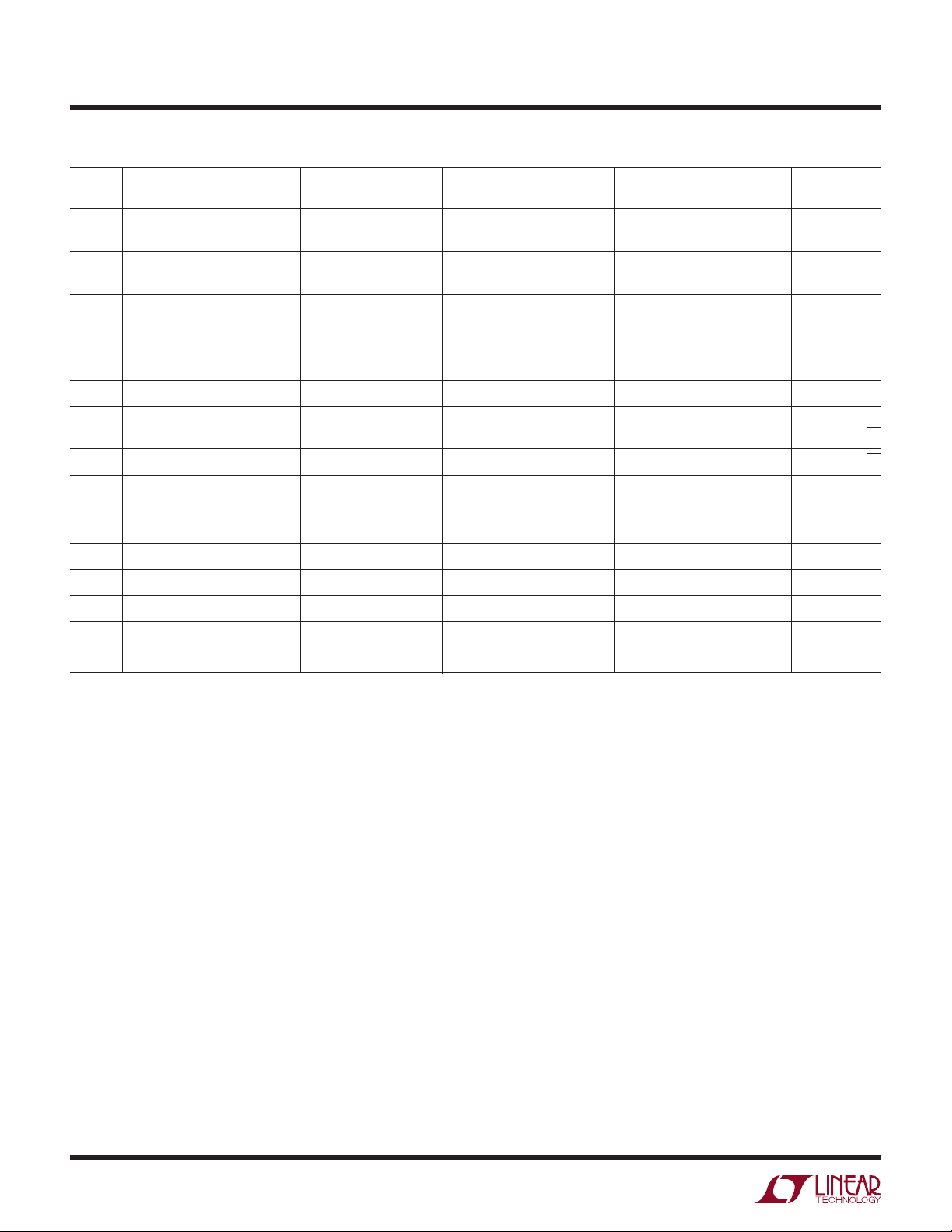

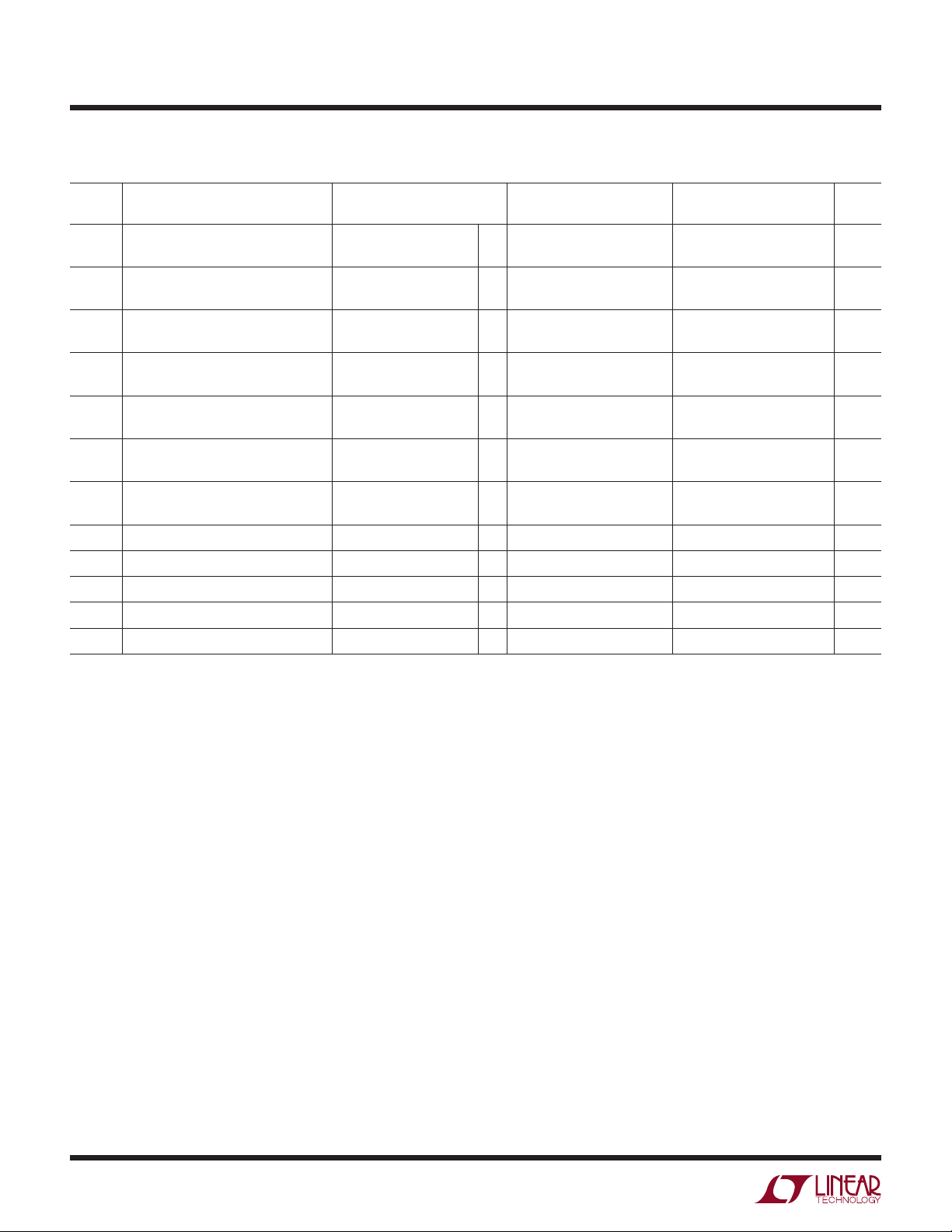

LT1012A/LT1012

ELECTRICAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

l

OS

I

B

e

n

e

n

i

n

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V 110 132 110 132 dB

PSRR Power Supply Rejection Ratio VS = ±1.2V to ± 20V 110 132 110 132 dB

V

OUT

I

S

Input Offset Voltage 12 60 15 120 µV

(Note 3) 25 25 180 µV

Long Term Input Offset 0.3 0.4 µV/month

Voltage Stability

Input Offset Current 20 150 50 280 pA

(Note 3) 30 60 380 pA

Input Bias Current ±30 ± 150 ±80 ±300 pA

(Note 3) ±40 ±120 ±400 pA

Input Noise Voltage 0.1Hz to 10Hz 0.5 0.5 µV

Input Noise Voltage Density fO = 10Hz (Note 5) 17 30 17 30 nV√Hz

f

= 1000Hz (Note 5) 14 22 14 22 nV√Hz

O

lnput Noise Current Density fO = 10Hz 20 20 fA/√Hz

Large-Signal Voltage Gain V

Input Voltage Range ±13.5 ±14.0 ±13.5 ±14.0 V

Output Voltage Swing RL = 10kΩ±13 ±14 ±13 ±14 V

Slew Rate 0.1 0.2 0.1 0.2 V/µs

Supply Current (Note 3) 380 600 380 600 µA

±12V,RL ≥ 10kΩ 200 2000 200 2000 V/mV

OUT =

±10V,RL ≥ 2kΩ 200 1000 120 1000 V/mV

V

OUT =

VS = ± 15V, VCM = 0V, TA = 25°C, unless otherwise noted.

LT1012D LT1012S8

P-P

4

sn1012 1012afbs

LT1012A/LT1012

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range of –55°C ≤ TA ≤ 125°C for LT1012AM and LT1012M, and –40°C ≤ TA≤ 85°C for LT1012AI and LT1012I.

VS = ± 15V, VCM = 0V, unless otherwise noted.

LT1012AM/AI LT1012M/I

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

I

OS

I

B

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V ● 110 128 108 128 dB

PSRR Power Supply Rejection Ratio VS = ±1.5V to ± 20V ● 110 126 108 126 dB

V

OUT

I

S

Input Offset Voltage ● 30 60 30 180 µV

(Note 3)

Average Temperature Coefficient of ● 0.2 0.6 0.2 1.5 µV/°C

Input Offset Voltage

Input Offset Current ● 30 250 30 250 pA

(Note 3)

Average Temperature Coefficient of ● 0.3 2.5 0.3 2.5 pA/°C

Input Offset Current

Input Bias Current ● ±80 ±600 ±80 ±600 pA

(Note 3)

Average Temperature Coefficient of ● 0.6 6.0 0.6 6.0 pA/°C

Input Bias Current

Large-Signal Voltage Gain V

Input Voltage Range ● ±13.5 ±13.5 V

Output Voltage Swing RL = 10kΩ ● ±13 ±14 ±13 ±14 V

Supply Current ● 400 650 400 800 µA

= ±12V, RL ≥ 10kΩ ● 200 1000 150 1000 V/mV

OUT

= ±10V, RL ≥ 2kΩ ● 200 600 100 600 V/mV

V

OUT

● 40 180 40 250 µV

● 70 350 70 350 pA

● ±150 ±800 ±150 ±800 pA

sn1012 1012afbs

5

LT1012A/LT1012

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range of 0°C ≤ TA ≤ 70°C. VS = ± 15V, VCM = 0V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

I

OS

I

B

A

VOL

CMRR Common Mode Rejection Ratio VCM = 13.5V ● 110 130 108 130 dB

PSRR Power Supply Rejection Ratio VS = ±1.3V to ± 20V ● 110 128 108 128 dB

V

OUT

I

S

Input Offset Voltage ● 20 60 20 100 µV

(Note 3)

Average Temperature Coefficient of ● 0.2 0.6 0.2 1.0 µV/°C

Input Offset Voltage

Input Offset Current ● 25 230 35 230 pA

(Note 3)

Average Temperature Coefficient of ● 0.3 2.5 0.3 2.5 pA/°C

Input Offset Current

Input Bias Current ● ± 35 ± 230 ± 35 ± 230 pA

(Note 3)

Average Temperature Coefficient of ● 0.3 2.5 0.3 2.5 pA/°C

Input Bias Current

Large-Signal Voltage Gain V

Input Voltage Range ● ±13.5 ±13.5 V

Output Voltage Swing RL = 10kΩ ● ±13 ±14 ±13 ±14 V

Supply Current ● 400 600 400 800 µA

= ±12V, RL ≥ 10kΩ ● 200 1500 150 1500 V/mV

OUT

= ±10V, RL ≥ 2kΩ ● 200 1000 150 800 V/mV

V

OUT

● 30 160 30 200 µV

● 40 300 45 300 pA

● ± 50 ± 300 ± 50 ± 300 pA

LT1012AC LT1012C

6

sn1012 1012afbs

LT1012A/LT1012

ELECTRICAL CHARACTERISTICS

The ● denotes the specifications which apply over the full operating

temperature range of 0°C ≤ TA ≤ 70°C. VS = ± 15V, VCM = 0V, unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

V

OS

I

OS

I

B

A

VOL

CMRR Common Mode Rejection Ratio VCM = ±13.5V ● 108 130 108 130 dB

PSRR Power Supply Rejection Ratio VS = ±1.3V to ± 20V ● 108 128 108 128 dB

V

OUT

I

S

Input Offset Voltage ● 25 140 30 200 µV

(Note 3)

Average Temperature Coefficient of ● 0.3 1.7 0.3 1.8 µV/°C

Input Offset Voltage

Input Offset Current ● 35 380 60 380 pA

(Note 3)

Average Temperature Coefficient of ● 0.35 4.0 0.4 4.0 pA/°C

Input Offset Current

Input Bias Current ● ± 50 ± 420 ±100 ± 420 pA

(Note 3)

Average Temperature Coefficient of ● 0.4 5.0 0.5 5.0 pA/°C

Input Bias Current

Large-Signal Voltage Gain V

Input Voltage Range ● ±13.5 ±13.5 V

Output Voltage Swing RL = 10kΩ ● ±13 ±14 ±13 ±14 V

Supply Current ● 400 800 400 800 µA

= ±12V, RL ≥ 10kΩ ● 150 1500 150 1500 V/mV

OUT

= ±10V, RL ≥ 2kΩ ● 150 800 100 800 V/mV

V

OUT

● 40 45 270 µV

● 45 80 500 pA

● ± 65 ±150 ± 550 pA

LT1012D LT1012S8

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: Differential input voltages greater than 1V will cause excessive

current to flow through the input protection diodes unless limiting

resistance is used.

+

V

5k TO 100k POT

1

2

3

–

LT1012

+

V

8

7

6

OUT

5

4

–

C

S

LT1012A • EC01

Note 3: These specifications apply for V

≤ V

–13.5V

0°C to 70°C, ± 1.5V from – 55°C to 125°C.

Note 4: 10Hz noise voltage density is sample tested on every lot. Devices

100% tested at 10Hz are available on request.

Note 5: This parameter is tested on a sample basis only.

≤ 13.5V (for VS = ± 15V). V

CM

≤ VS ≤ ± 20V and

MIN

= ±1.2V at 25°C, ± 1.3V from

MIN

Optional Offset Nulling and Overcompensation

Circuits

Input offset voltage can be adjusted over a ± 800µV range

with a 5k to 100k potentiometer.

The LT1012 is internally compensated for unity gain

stability. The overcompensation capacitor, CS, can be

used to improve capacitive load handling capability, to

narrow noise bandwidth, or to stabilize circuits with gain

in the feedback loop.

sn1012 1012afbs

7

LT1012A/LT1012

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Offset Voltage vs Source

Resistance (Balanced or

Unbalanced)

1000

V

= ±15V

S

100

Typical Distribution of Input Bias

Current

200

160

VS = ±15V

= 25°C

T

A

= 0V

V

CM

1020 UNITS

FROM THREE

RUNS

Typical Distribution of Input

Offset Current

200

VS = ±15V

T

= 25°C

A

= 0V

V

CM

160

1020 UNITS

FROM THREE

RUNS

–55°C TO 125°C

10

INPUT OFFSET VOLTAGE (µV)

1

1k

SOURCE RESISTANCE (Ω)

Input Bias Current vs

Temperature

100

50

0

–50

INPUT BIAS CURRENT (pA)

–100

–150

–50

UNDERCANCELLED UNIT

OVERCANCELLED

0

–25 25

TEMPERATURE (°C)

25°C

UNIT

120

80

NUMBER OF UNITS

40

0

–120

100k10k 300k 1M 3M 10M30k3k

LT1012A • TPC01

–60

INPUT BIAS CURRENT (pA)

0

60 120

LT1012A • TPC02

120

80

NUMBER OF UNITS

40

0

–120

INPUT OFFSET CURRENT (pA)

–60

0

60 120

LT1012A • TPC03

Offset Voltage Drift vs Source

Input Bias Current Over Common

Mode Range

60

VS = ±15V

= 25oC

T

A

40

20

0

–20

INPUT BIAS CURRENT (pA)

–40

50

75

100

125

LT1012A • TPC04

–60

–15

–10

COMMON MODE INPUT VOLTAGE

DEVICE WITH POSITIVE

INPUT CURRENT

R

IN CM

DEVICE WITH NEGATIVE

INPUT CURRENT

I

B

V

CM

–5 0 5

= 2 X 1012Ω

–

+

10 15

LT1012A * TPC5

Resistance (Balanced or

Unbalanced)

100

10

1.0

MAXIMUM

TYPICAL

0.1

1k

OFFSET VOLTAGE DRIFT WITH TEMPERATURE (µV/°C)

100k10k 1M 10M 100M

SOURCE RESISTANCE (Ω)

LT1012 • TPC06

8

Warm-Up Drift

5

= ±15V

V

S

= 25°C

T

A

4

3

2

1

CHANGE IN OFFSET VOLTAGE (µV)

0

0

METAL CAN (H) PACKAGE

DUAL-IN-LINE PACKAGE

PLASTIC (N) OR SO (S)

1

TIME AFTER POWER ON (MINUTES)

3

2

4

LT1012A • TPC07

Long Term Stability of Four

Representative Units

10

8

6

4

2

0

–2

–4

–6

CHANGE IN OFFSET VOLTAGE (µV)

–8

–10

5

1

0

TIME (MONTHS)

3

4

2

5

LT1012A • TPC08

Offset Voltage Drift with Temperature

of Four Representative Units

60

40

20

0

–20

OFFSET VOLTAGE (µV)

–40

–60

–50

–25 0

TEMPERATURE (°C)

50 100 125

25 75

LT1012A • TPC09

sn1012 1012afbs

LOAD RESISTANCE (kΩ)

1

100k

300k

1M

10M

3M

VOLTAGE GAIN

521020

VS = ±15V

V

0

= ±10V

25°C

125°C

–55°C

LT1012A • TPC18

TOTAL NOISE DENSITY (µV/√Hz)

SOURCE RESISTANCE (Ω)

10

2103104105106107

0.01

1.0

10.0

10

8

0.1

TA = 25°C

V

S

= ±1.2V TO ±20V

LT1012A • TPC12

RS = 2R

R

R

+

–

AT 10Hz

AT 1kHz

RESISTOR NOISE

ONLY

AT 10Hz

AT 1kHz

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT1012A/LT1012

0.1Hz to 10Hz Noise

TA = 25°C

V

= ±1.2V TO ± 20V

S

NOISE VOLTAGE 400nV/DIVISION

2

0

TIME (SECONDS)

6

4

Supply Current vs Supply Voltage

500

400

SUPPLY CURRENT (µA)

300

0

25°C

125°C

–55°C

±5

±10

SUPPLY VOLTAGE (V)

LT1012A • TPC10

±15

LT1012A • TPC13

Noise Spectrum

1000

TA = 25°C

= ±1.2 TO ±20V

V

S

100

CURRENT NOISE

VOLTAGE NOISE

10

1/f CORNER

2.5Hz

CURRENT NOISE DENSITY (fA√Hz)

VOLTAGE NOISE DENSITY (nV√Hz)

8

10

1

1

10 100 1000

FREQUENCY (Hz)

1/f CORNER

120Hz

LT1012A • TPC11

Common Mode Rejection vs

Frequency

140

120

100

80

60

40

20

VS = ±15V

COMMON MODE REJECTION RATIO (dB)

±20

= 25°C

T

A

0

1

10 100

FREQUENCY (Hz)

10k 1M

1k 100k

LT1012A • TPC14

Total Noise vs Source Resistance

Power Supply Rejection vs

Frequency

140

120

100

80

VS = ±15V

= 25°C

T

A

110

POSITIVE

SUPPLY

FREQUENCY (Hz)

60

40

POWER SUPPLY REJECTION RATIO (dB)

20

0.1

NEGATIVE

SUPPLY

1k 100k 1M

100 10k

LT1012A • TPC15

Voltage Gain vs Frequency Voltage Gain vs Load Resistance

140

120

100

80

60

40

VOLTAGE GAIN (dB)

20

VS = ±15V

0

= 25°C

T

A

–20

0.01

0.1

GAIN (dB)

1

100 1k 10k 100k 1M 10M

10

FREQUENCY (Hz)

LT1012A • TPC16

Gain, Phase Shift vs Frequency

40

30

20

GAIN

10

PHASE MARGIN

= 70°C

0

VS = ±15V

= 25°C

T

A

–10

0.01

0.1 1 10

FREQUENCY (MHz)

PHASE

LT1012A • TPC17

100

120

PHASE SHIFT (DEGREES)

140

160

180

200

sn1012 1012afbs

9

LT1012A/LT1012

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Small-Signal Transient Response Large-Signal Transient Response

20mV/DIV

A

C

= +1

V

LOAD

= 100pF

5µs/DIV

Small-Signal Transient Response

20mV/DIV

A

C

= +1

V

LOAD

= 1000pF

5µs/DIV

2V/DIV

A

V

= +1

20µs/DIV

Slew Rate, Gain Bandwidth

Output Short-Circuit Current

vs Time

20

15

10

5

0

–5

–10

SHORT-CIRCUIT CURRENT (mA)

–15

SINKING SOURCING

–20

0

TIME FROM OUTPUT SHORT (MINUTES)

VS = ±15V

1

–55°C

25°C

125°C

125°C

25°C

–55°C

2

3

LT1012A • TPC19

Product vs Overcompensation

Capacitor Closed-Loop Output Impedance

1

GBW

SLEW

0.1

0.01

SLEW RATE (V/µs)

VS = ±15V

= 25°C

T

A

0.001

1 100 1000 10,000

10

OVERCOMPENSATION CAPACITOR (pF)

LT1012A • TPC20

1000

100

10

1

1000

GAIN BANDWIDTH PRODUCT (kHz)

100

10

1

0.1

OUTPUT IMPEDANCE (Ω)

0.01

0.001

10 100 1 10

1

AV = 1000

FREQUENCY (Hz)

A

V

T

I

V

= +1

= 1mA

0

= ±15V

S

= 25°C

A

LT1012A • TPC21

100

10

Common Mode Range and Voltage

Swing at Minimum Supply Voltage

+

V

+

– 0.3

V

+

– 0.6

V

+

– 0.9

V

+

– 1.2

V

–

+ 1.2

V

–

+ 0.9

V

–

V

+ 0.6

–

V

+ 0.3

–

V

COMMON MODE RANGE OR OUTPUT VOLTAGE (V)

–50

0 25 125

–25 100

TEMPERATURE (°C)

SWING R

SWING R

SWING R

50

CM RANGE

L

CM RANGE

75

= 2k

L

= 10k

= 2k

L

LT1012A • TPC22

Minimum Supply Voltage,

Voltage Gain at V

±1.8

±1.6

±1.4

±1.2

±1.0

±0.8

MINIMUM SUPPLY VOLTAGE (V)

–50

RL = 10k

RL = 2k

0

–25

TEMPERATURE (°C)

25

MIN

50

75

100

LT1012A • TPC23

400k

SUPPLY VOLTAGE (V/V)

300k

200k

100k

0

125

VOLTAGE GAIN AT MINIMUM

sn1012 1012afbs

WUUU

APPLICATIO S I FOR ATIO

LT1012A/LT1012

The LT1012 may be inserted directly into OP-07, LM11,

108A or 101A sockets with or without removal of external

frequency compensation or nulling components. The

LT1012 can also be used in 741, LF411, LF156 or OP-15

applications provided that the nulling circuitry is

removed.

Although the OP-97 is a copy of the LT1012, the LT1012

directly replaces and upgrades OP-97 applications. The

LT1012C and D have lower offset voltage and drift than the

OP-97F. The LT1012A has lower supply current than the

OP-97A/E. In addition, all LT1012 grades guarantee

operation at ±1.2V supplies.

Achieving Picoampere/Microvolt Performance

In order to realize the picoampere/microvolt level

accuracy of the LT1012, proper care must be exercised.

For example, leakage currents in circuitry external to

the op amp can significantly degrade performance. High

quality insulation should be used (e.g. Teflon, Kel-F);

cleaning of all insulating surfaces to remove fluxes and

other residues will probably be required. Surface coating

may be necessary to provide a moisture barrier in high

humidity environments.

Board leakage can be minimized by encircling the input

circuitry with a guard ring operated at a potential close

to that of the inputs: in inverting configurations the

guard ring should be tied to ground, in non-inverting

connections to the inverting input at Pin 2. Guarding both

sides of the printed circuit board is required. Bulk leakage

reduction depends on the guard ring width. Nanoampere

level leakage into the offset trim terminals can affect offset

voltage and drift with temperature.

OFFSET TRIM

+

V

8

OUTPUT

OVER COMP

7

4

GUARD

1

2

3

PUTS

IN

LT1012A * AI01

6

5

–

V

Microvolt level error voltages can also be generated in

the external circuitry. Thermocouple effects caused by

temperature gradients across dissimilar metals at the

contacts to the input terminals can exceed the inherent

drift of the amplifier. Air currents over device leads should

be minimized, package leads should be short, and the two

input leads should be as close together as possible and

maintained at the same temperature.

Noise Testing

For application information on noise testing and calculations, please see the LT1008 data sheet.

Frequency Compensation

The LT1012 can be overcompensated to improve

capacitive load handling capability or to narrow noise

bandwidth. In many applications, the feedback loop around

the amplifier has gain (e.g. Iogarithmic amplifiers);

overcompensation can stabilize these circuits with a single

capacitor.

The availability of the compensation terminal permits

the use of feedforward frequency compensation to

enhance slew rate. The voltage follower feedforward

scheme bypasses the amplifier’s gain stages and slews at

nearly 10V/µs.

The inputs of the LT1012 are protected with back-to-back

diodes. Current limiting resistors are not used, because

the leakage of these resistors would prevent the realization

of picoampere level bias currents at elevated temperatures. In the voltage follower configuration, when the input

is driven by a fast, large signal pulse (>1V), the input

protection diodes effectively short the output to the input

during slewing, and a current, limited only by the output

short-circuit protection will flow through the diodes.

The use of a feedback resistor, as shown in the voltage

follower feedforward diagram, is recommended because

this resistor keeps the current below the short-circuit

limit, resulting in faster recovery and settling of the output.

sn1012 1012afbs

11

LT1012A/LT1012

WUUU

APPLICATIO S I FOR ATIO

Test Circuit for Offset Voltage

and its Drift with Temperature

*

50k

15V

7

2

–

*

100Ω

*

50k

*RESISTORS MUST HAVE LOW THERMOELECTRIC

POTENTIAL

LT1012

3

+

–15V

V0 = 1000V

6

4

0S

V

0

LT1012A • AI02

TYPICAL APPLICATIO S

Follower Feedforward Compensation

50pF

10k

2

–

5k

IN

3

LT1012

+

0.01µF

5

U

Ampmeter with Six Decade Range

Pulse Response of Feedforward

Compensation

5V/DIV

6

OUT

LT1012A • AI03

Photoo

10k

5µs/DIV

15V

10k

CURRENT INPUT

Q1, Q2, Q3, Q4, RCA CA3146 TRANSISTOR ARRAY.

CALIBRATION: ADJUST R1 FOR FULL-SCALE

DEFLECTION WITH 1µA INPUT CURRENT

AMPMETER MEASURES CURRENTS FROM 100pA

TO 100µA WITHOUT THE USE OF EXPENSIVE

HIGH VALUE RESISTORS. ACCURACY AT 100µA

IS LIMITED BY THE OFFSET VOLTAGE BETWEEN

Q1 AND Q2 AND, AT 100pA, BY THE INVERTING

BIAS CURRENT OF THE LT1012

10k

Q3

1nA

R1

2k

1.2k

549Ω

549Ω

549Ω

549Ω

549Ω

549Ω

LT1004C

LT1012A • TA03

100µA

METER

0.1µF

15V

2

3

–

+

LT1012

–15V

7

6

4

PIN 13

CA3146

Q1

33k

Q4

100pA

RANGE

Q2

10nA

100nA

1µA

10µA

100µA

12

sn1012 1012afbs

TYPICAL APPLICATIO S

1.018235V

U

Saturated Standard Cell Amplifier

2N3609

3

+

2

–

+

SATURATED

STANDARD

CELL

#101

EPPLEY LABS

NEWPORT, R.I.

THE TYPICAL 30pA BIAS CURRENT OF THE LT1012 WILL

DEGRADE THE STANDARD CELL BY ONLY 1ppm/YEAR.

NOISE IS A FRACTION OF A ppm. UNPROTECTED GATE

MOSFET ISOLATES STANDARD CELL ON POWER DOWN

R1

LT1012

LT1008

–15V

R2

LT1012A/LT1012

15V

7

6

4

OUT

LT1012A • TA05

100k

100k

Amplifier for Bridge Transducers

R5

R6

56M

56M

2

–

LT1012

3

+

6

VOLTAGE GAIN ≈ 100

OUT

LT1012A • TA06

+

V

S1

T

100k

R1

S2

T

R2

100k

R3

510k

R4

510k

sn1012 1012afbs

13

LT1012A/LT1012

TYPICAL APPLICATIO S

R1

5M

1%

S1

λ

R2

5M

1%

2

–

LT1012

3

+

6

V

OUT =

U

10V/µA

LT1012A • TA07

OUT

15V

LM399

Buffered Reference for A-to-D ConvertersAmplifier for Photodiode Sensor

7k

3

2

6.5k

1k

7

+

LT1012

–

4

*THE 1k PRELOAD

MINIMIZES GLITCHES

INDUCED BY TRANSIENT

LOADS

1k

6

3k

200

2N3904

OUT

10V

1k*

LT1012A • TA08

Instrumentation Amplifier with ±100V Common Mode Range Low Power Comparator with <10µV Hysteresis

100k

100Ω

OUT

LT1012A • TA09

+IN

–IN

10k

10k

5V

1k

330k

7

2

–

LT1012

3

+

1

3

4

–5V

620k

6

100k

100k

OUT

2N3904

LT1012A • TA10

–IN

+IN

100M

100M

10M

15V

2

3

10M

7

–

LT1012

+

4

–15V

AV = 100

ALL RESISTORS 1% OR BETTER

6

14

sn1012 1012afbs

TYPICAL APPLICATIO S

Air Flow Detector Input Amplifier for 4.5 Digit Voltmeter

15V

R2

1

100k

2

3

–

+

LT1012

3

–15V

8

4

15V

+

R1

TYPE J

1k

–

COLD

JUNCTION

AT AMBIENT

MOUNT R1 IN AIRFLOW.

ADJUST R2 SO OUTPUT GOES

HIGH WHEN AIRFLOW STOPS

10M

U

7

6

LT1012A • TA11

OUT

IN

900k

90k

10k

9M

0.1V

1V

10V

100V

1000V

2

100k

5%

3

FN507

ALLEN BRADLEY

DECADE VOLTAGE

DIVIDER

LT1012A/LT1012

15V

7

–

LT1012

+

5

* RATIO MATCH ±0.01%

6

4

–15V

1000pF

0.1V

1V

10V

9k*

100V

TO 1V FULL SCALE

1000V

ANALOG TO DIGITAL

1k*

THIS APPLICATION REQUIRES LOW

BIAS CURRENT AND OFFSET VOLTAGE,

LOW NOISE, AND LOW DRIFT WITH

TIME AND TEMPERATURE

CONVERTER

LT1012A • TA12

“No Trims” 12-Bit Multiplying DAC Output AmplifierResistor Multiplier

R

DAC

FEEDBACK

I

OUT1

I

OUT2

WHEN THE REFERENCE INPUT DROPS TO 0.1V,

THE LEAST SIGNIFICANT BIT DECREASES TO

THE MICROVOLT/PICOAMPERE RANGE

2

–

LT1012

3

+

6

OUT

LT1012 • TA14

R

IN

1G

R1

10M

R2

1k

R3

100k

3

+

LT1012

2

–

R

IN

10k

= R1

6

V

OUT

R3

1 +

(

)

R2

LT1012 • TA13

REFERENCE IN

0.1V TO 10V

12-BIT CMOS

MULTIPLYING

sn1012 1012afbs

15

LT1012A/LT1012

W

SCHE ATIC DIAGRA

TRIM TRIM

1 8 5

800Ω 800Ω

22k 22k

–IN

+IN

Q7

Q5

2

Q9

Q10

3

Q8

30pF

Q6

Q16

Q13

SS

Q1

Q17

4.3k

–

V

4

W

1.5k

S

OVER

COMP

1.3k

Q15Q2

Q39

4.8k

1.3k 4.2k

Q14

2.5k

Q3

3.3k 3.3k

S

Q4

Q11

Q23

50k 1.5k

Q12

Q19Q18

Q22

Q21

Q24

3k

Q31

3.7k

20k

Q34 Q35

3.7k 16k3.7k

+

V

7

Q20

Q29

Q25

J1

Q33

Q32

Q36

320Ω

Q30

Q27

Q28

1.5k

Q26

Q40

1.5k

40Ω

Q37

Q38

330Ω

Q41

Q43

Q42

40Ω

100Ω

40Ω

OUT

6

LT1012A • SD01

16

sn1012 1012afbs

PACKAGE DESCRIPTIO

SEATING

PLANE

(0.254 – 1.143)

45°TYP

U

H Package

8-Lead TO-5 Metal Can (.200 Inch PCD)

(Reference LTC DWG # 05-08-1320)

.335 – .370

(8.509 – 9.398)

DIA

.305 – .335

(7.747 – 8.509)

.016 – .021**

(0.406 – 0.533)

PIN 1

.010 – .045*

.028 – .034

(0.711 – 0.864)

.040

(1.016)

MAX

.050

(1.270)

MAX

.027 – .045

(0.686 – 1.143)

GAUGE

PLANE

.200

(5.080)

TYP

LT1012A/LT1012

.165 – .185

(4.191 – 4.699)

REFERENCE

.500 – .750

(12.700 – 19.050)

PLANE

.110 – .160

(2.794 – 4.064)

INSULATING

STANDOFF

*

LEAD DIAMETER IS UNCONTROLLED BETWEEN THE REFERENCE PLANE

AND THE SEATING PLANE

**

FOR SOLDER DIP LEAD FINISH, LEAD DIAMETER IS

.016 – .024

(0.406 – 0.610)

OBSOLETE PACKAGE

H8(TO-5) 0.200 PCD 0801

sn1012 1012afbs

17

LT1012A/LT1012

PACKAGE DESCRIPTIO

U

N8 Package

8-Lead PDIP (Narrow .300 Inch)

(Reference LTC DWG # 05-08-1510)

.255 ± .015*

(6.477 ± 0.381)

.400*

(10.160)

MAX

876

5

12

.300 – .325

(7.620 – 8.255)

.065

(1.651)

.008 – .015

(0.203 – 0.381)

+.035

.325

–.015

+0.889

8.255

()

–0.381

NOTE:

1. DIMENSIONS ARE

*THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .010 INCH (0.254mm)

INCHES

MILLIMETERS

TYP

.045 – .065

(1.143 – 1.651)

.100

(2.54)

BSC

3

4

.130 ± .005

(3.302 ± 0.127)

.120

(3.048)

MIN

.018 ± .003

(0.457 ± 0.076)

.020

(0.508)

MIN

N8 1002

18

sn1012 1012afbs

PACKAGE DESCRIPTIO

.050 BSC

N

U

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

.189 – .197

.045 ±.005

(4.801 – 5.004)

8

NOTE 3

7

LT1012A/LT1012

5

6

.245

MIN

1 2 3 N/2

.030 ±.005

TYP

RECOMMENDED SOLDER PAD LAYOUT

.010 – .020

(0.254 – 0.508)

.008 – .010

(0.203 – 0.254)

NOTE:

1. DIMENSIONS IN

2. DRAWING NOT TO SCALE

3. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .006" (0.15mm)

×

45

.016 – .050

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.160

±.005

°

0°– 8° TYP

.228 – .244

(5.791 – 6.197)

.053 – .069

(1.346 – 1.752)

.014 – .019

(0.355 – 0.483)

TYP

N

.150 – .157

(3.810 – 3.988)

N/2

1

3

2

NOTE 3

4

.004 – .010

(0.101 – 0.254)

.050

(1.270)

BSC

SO8 0502

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

sn1012 1012afbs

19

LT1012A/LT1012

TYPICAL APPLICATIO

U

Kelvin-Sensed Platinum Temperature Sensor Amplifier

10V

REFERENCE

LT1021-10

R2

100k

–15V

10M

392k*

235k*

5k*

ROSEMOUNT

EQUIVALENT

R1

5k

78S

OR

100Ω

AT

R

S

0°C

182k

4.75k

*

R

6.65M

2

200k

3

619k

F

654k

20V

7

–

LT1012

+

–15V

* = WIRE WOUND RESISTORS

ALL OTHER RESISTORS ARE 1% METAL FILM

TRIM R2 AT 0°C FOR V

TRIM R3 AT 100°C FOR V

TRIM R4 AT 50°C FOR V

IN THE ORDER INDICATED

POSITIVE FEEDBACK (R1) LINEARIZES THE

INHERENT PARABOLIC NONLINEARITY OF

THE PLATINUM SENSOR AND REDUCES

ERRORS FROM 1.2°C TO 0.004°C OVER

THE –50°C TO 150°C RANGE

6

4

= 0V

0

0

R3

1k

V

–50°C TO 150°C

= 10V

0

= 5V

24.3k

= 100mV/°C

OUT

R4

5k

LT1012A • TA04

10k

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

sn1012 1012afbs

LW/TP 1202 1K REV B • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1991

Loading...

Loading...