Page 1

NAPGB01

GLASS BRE AK

DETECTOR

TRANSMITTER

Installation Instructions

PRODUCT DESCRIPTION

The NAPGB01 is a battery powered glass break detector with a built-in transmitter

designed for use with NAPCO® GEM and GEM-C systems. This transmitter is used

for perimeter protection in wireless security applications.

The NAPGB01 can send fi ve different signal types: fault, restore, low battery, status,

and tamper. Receivers must be programmed to the transmitter’s code before system

testing and operation. Refer to the receiver’s instructions for details on programming.

In a typical installation, the detector is mounted on a wall or ceiling within 15 feet of

the protected glass window(s). The unit uses dual-stage digital audio processing to

detect the sound of breaking glass in a 360° area around the device. If the unit detects

breaking glass, a fault signal is sent to the receiver followed by a restore signal.

FEATURES

RED TEST AND

2ND STAGE

INDICATOR

GLASS BREAK

DETECTOR

DETECTION

MICROPHONE

Being supervised, about every 65 minutes the unit sends a status signal to update the

receiver. If the battery tests low, a low battery signal is included with any transmission.

The transmitter is powered from two 3-Volt CR123A lithium batteries (included).

An internal switch senses if the detector is removed from its base. Removing the

REMOVABLE

MOUNTING

BASE

BASE

ALIGNMENT

INDICATORS

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

detector will send a tamper signal to the receiver.

Three screws and screw anchors are provided for mounting the detector.

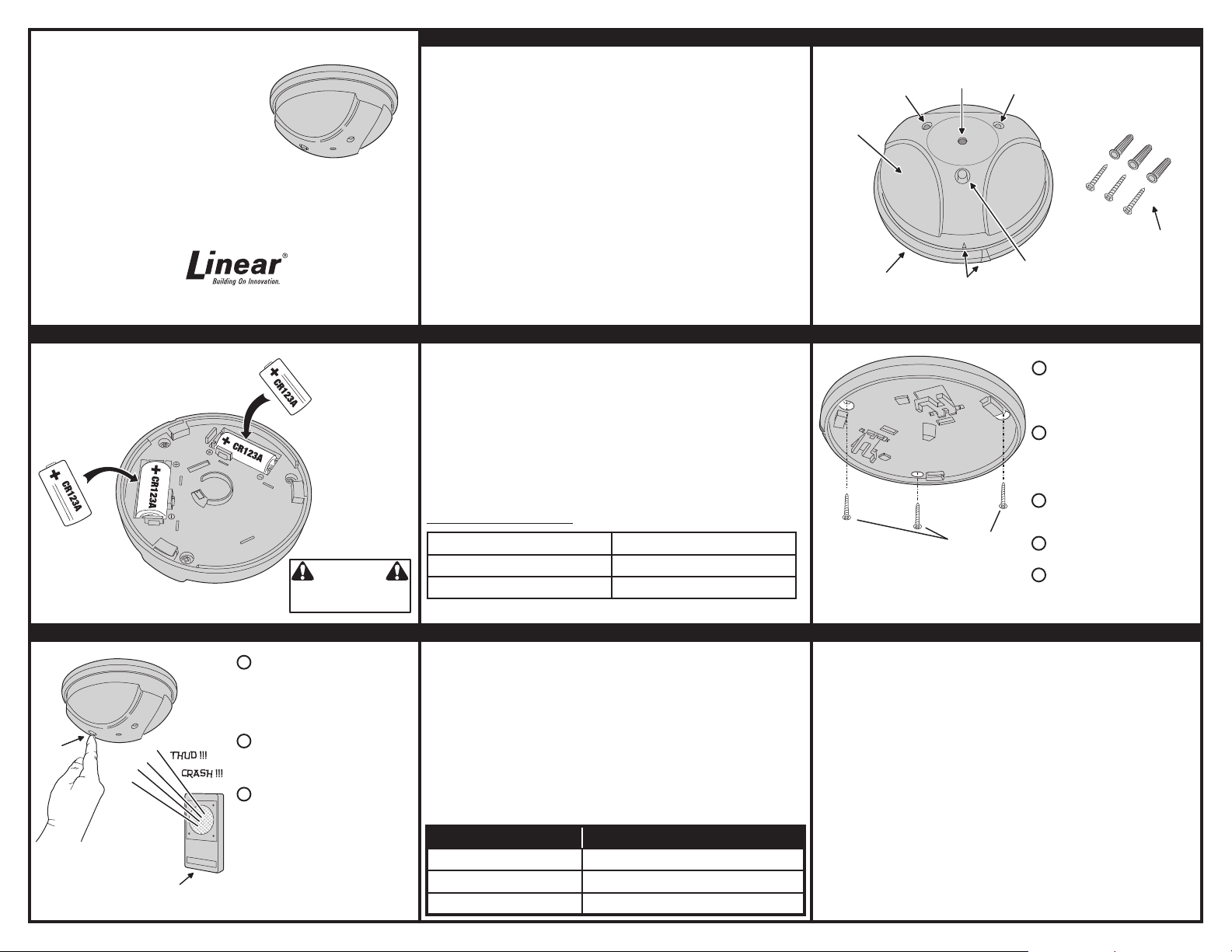

INSTALLING OR CHANGING BATTERIES PROGRAMMING MOUNTING THE DETECTOR

For a detail programming guide, the instruction manual should be consulted for

INSERT TWO

CR123A BATTERIES

INTO BATTERY

HOLDERS

OBSERVE

POLARITY !!!

that panel. The below guide should only be used as a reference and not as a

replacement for using the programming instructions.

1. Enter Panel Programming

2. Select Zone #

3. Enter 6 Digit ID number (located on back of unit)

4. Enter Check sum (0-9 ; A-F) (located on back of unit). Digit that follows ¨:¨ on

the Serial ID. For A-F use 0-5 (See Below)

5. Enter Point ¨3¨ - for Glass Break

6. Push On/Off to Save

Alpha Numeric Conversion

MOUNTING

SCREWS

WARNING

DANGER OF EXPLOSION IF BATTERIES ARE

INSTALLED INCORRECTLY. REPLACE ONLY

WITH THE SAME OR EQUIVALENT TYPE

RECOMMENDED BY THE MANUFACTURER.

A = *0 D = *3

B = *1 E = *4

C = *2 F = *5

NOTE: IF THE BATTERIES ARE NOT

INSTALLED, THE DETECTOR WILL

NOT ALLOW MOUNTING TO THE BASE

GREEN TEST AND

1ST STAGE

INDICATOR

TEST

BUTTON

LOCATE THE DETECTOR ON THE

1

ADJACENT OR OPPOSITE WALL

OR ON THE CEILING

15 FEET OF THE WINDOW BEING

PROTECTED

USE THE MOUNTING BASE AS A

2

TEMPLATE TO MARK THE LOCATION

OF THE THREE MOUNTING HOLES

NOTE: WHEN WALL MOUNTING,

ORIENT THE TEST BUTTON DOWN

DRILL 3/16" PILOT HOLES FOR THE

3

SCREW ANCHORS AND PUSH

THE ANCHORS INTO THE HOLES

ATTACH THE MOUNTING BASE

4

WITH THE THREE SCREWS

ATTACH THE DETECTOR TO THE

5

BASE, MATCH THE ALIGNMENT

MARKS AND TURN CLOCKWISE

MOUNTING

SCREWS

AND ANCHORS

WITHIN

DETECTOR TESTING SPECIFICATIONS

Operating Temperature: 32° to 120° F (0° to 49° C)

Operating Relative Humidity: 5 to 95%, non-condensing

Operating Frequency: 319.5 MHz

Battery Type: Two 3-Volt CR123A Lithium Batteries

Sensor Type: Single microphone,

dual-stage (thud & crash)

Approved Glass Break Simulator: Intellisense Model FG-701

The minimum size for all glass types is 11” x 11” (28 cm x 28 cm) square. Glass must

be framed, in a wall of the room or mounted in a barrier of 36” (91 cm) minimum width.

GLASS TYPE MINIMUM TO MAXIMUM THICKNESS

PLATE 1/8” TO 1/4” (3.2 mm TO 6.4 mm)

TEMPERED 1/8” TO 1/4” (3.2 mm TO 6.4 mm)

SEALED, INSULATING 1/8” TO 1/4” (3.2 mm TO 6.4 mm)

TEST

BUTTON

INTELLISENSE

MODEL FG-701

GLASS BREAK

SIMULATOR

PRESS AND HOLD THE TEST BUTTON

1

FOR 2 SECONDS, THEN RELEASE. THE

RED LED WILL LIGHT WHILE THE

BUTTON IS PRESSED, THE GREEN

LED WILL BLINK ONCE INDICATING

AUTO TEST MODE FOR 90 SECONDS.

ACTIVATE THE GLASS BREAK

2

SIMULATOR IN THE AREA OF THE

WINDOW OR WINDOWS BEING

PROTECTED.

THE DETECTOR SHOULD FIRST

3

ACKNOWLEDGE THE DETECTION

OF A THUD SOUND BY LIGHTING THE

GREEN LED, THEN LIGHT THE RED

LED WHEN IT DETECTS THE CRASH

PORTION OF THE GLASS BREAKING

SOUND

NOTE: FOR RF TEST MODE, PRESS AND

HOLD THE TEST BUTTON FOR 5 SECONDS,

THE GREEN LED WILL BLINK TWICE

AND A TEST SIGNAL IS SENT FOR 90 SECONDS

LINEAR LIMITED WARRANTY

This Linear product is warranted against defects in material and workmanship for twelve (12) months. This

warranty extends only to wholesale customers who buy direct from Linear or through Linear’s normal

distribution channels. Linear does not warrant this product to consumers. Consumers should inquire from their

selling dealer as to the nature of the dealer’s warranty, if any. There are no obligations or liabilities on the part

of Linear LLC for consequential damages arising out of or in connection with use or performance of this

product or other indirect damages with respect to loss of property, revenue, or profi t, or cost of removal,

installation, or reinstallation. All implied warranties, including implied warranties for merchantability and implied

warranties for fi tness, are valid only until the warranty expires. This Linear LLC Warranty is in lieu of all other

warranties express or implied.

All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear

Technical Services at 1-800-421-1587 for an RPA# and other important details.

Linear radio controls provide a reliable communications link and fi ll an important need in portable wireless

signaling. However, there are some limitations which must be observed.

✴ For U.S. installations only: The radios are required to comply with FCC Rules and Regulations as Part 15

devices. As such, they have limited transmitter power and therefore limited range.

✴ A receiver cannot respond to more than one transmitted signal at a time and may be blocked by radio signals

that occur on or near their operating frequencies, regardless of code settings.

✴ Changes or modifi cations to the device may void FCC compliance.

✴ Infrequently used radio links should be tested regularly to protect against undetected interference or fault.

✴ A general knowledge of radio and its vagaries should be gained prior to acting as a wholesale distributor or

dealer, and these facts should be communicated to the ultimate users.

This device complies with FCC Part 15 and Canada Rules and Regulations. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference and (2) this device must accept any interference

received, including interference that may cause undesired operation.

Copyright © 2013 Linear Corporation 187-1133 C

IMPORTANT !!!

Loading...

Loading...