Page 1

eMerge 50P

eMerge 5000P

Hardware Installation Guide

May 2013

Linear LLC

1950 Camino Vida Roble

Carlsbad, CA 92008

www.linearcorp.com

Suite 150

Page 2

Copyright

© Linear LLC. All rights reserved.

This guide is protected by copyright and all rights are reserved by Linear LLC. It may not, in

whole or in part, except insofar as herein directed, be copied, photocopied, reproduced,

translated or reduced to any electronic medium or machine-readable form without prior written

consent of Linear LLC.

eMerge™ is a registered trademark of Linear LLC.

233190 X3 Linear LLC ii May 2013

Page 3

Contents

Introduction ........................................................................................................................................... 1

Where to Go for More Information .................................................................................................. 1

Installation Notes .............................................................................................................................. 2

Preparing to Install ............................................................................................................................... 3

eMerge System Overview ................................................................................................................ 3

Topology Considerations.................................................................................................................. 3

System Requirements ....................................................................................................................... 5

Network Requirements .............................................................................................................. 5

Browser Requirements ............................................................................................................... 5

Power Requirements .................................................................................................................. 5

Environmental Requirements ..................................................................................................... 6

Static Electricity Precautions ..................................................................................................... 6

Installation Overview Checklist ....................................................................................................... 7

eMerge Part Numbers ....................................................................................................................... 7

Mounting the Cabinet ........................................................................................................................... 8

Installing Additional Blades ................................................................................................................. 9

How Slot and Position Numbers are Determined ............................................................................. 9

Connecting Readers, Inputs, Outputs, and Temperature Sensors ................................................. 12

Wiring Readers ............................................................................................................................... 12

Connecting Readers ........................................................................................................................ 13

Wiring Inputs .................................................................................................................................. 14

Connecting Inputs ........................................................................................................................... 15

Input Supervision Types ................................................................................................................. 16

Normally Closed Parallel Resistor Input Circuits .................................................................... 17

Normally Closed Series Resistor Input Circuits ...................................................................... 17

Normally Closed Unsupervised Input Circuits ........................................................................ 18

Normally Open Parallel Resistor Input Circuits ...................................................................... 18

Normally Open Series Resistor Input Circuits ......................................................................... 19

Normally Open Unsupervised Input Circuits ........................................................................... 19

Wiring Outputs ............................................................................................................................... 20

Connecting Outputs ........................................................................................................................ 22

Wiring Temperature Sensors .......................................................................................................... 23

Connecting Temperature Sensors ................................................................................................... 25

Wiring the Network Connection ........................................................................................................ 26

Wiring Power ...................................................................................................................................... 27

Wiring the PI P ................................................................................................................................ 27

Wiring a DC Power Source ............................................................................................................ 27

Adding a Backup Battery ................................................................................................................... 29

Setting Up a Small Configuration Network ...................................................................................... 30

Testing and Troubleshooting ............................................................................................................. 32

The Mini-ITX Network Controller ................................................................................................. 32

Interpreting the System Status LED on the Cabinet Door .............................................................. 33

233190 X3 Linear LLC iii May 2013

Page 4

Contents

Interpreting Beeps ......................................................................................................................... 33

The Access Control Blade .............................................................................................................. 34

Input, Output, and Temperature Blades ......................................................................................... 34

Interpreting Access Control, Input, Output, and Temperature Blade LEDs ............................ 35

Removing Blades ........................................................................................................................... 35

Using the Power, Reset, and Revert Buttons on the eMerge50/5000P .......................................... 36

Hardware and Third-Party Device Specifications ........................................................................... 39

Environmental Requirements ......................................................................................................... 39

Power Requirements ....................................................................................................................... 39

Reader Power Available from the eMerge System ........................................................................ 39

Wiring Requirements and Specifications ....................................................................................... 39

Readers ........................................................................................................................................... 40

Cameras .......................................................................................................................................... 40

Temperature Sensors ...................................................................................................................... 41

Software Protocols and Standards .................................................................................................. 41

Single Facility Maximum Capacities ............................................................................................. 41

Minimum System Configuration .................................................................................................... 41

Index ..................................................................................................................................................... 42

233190 X3 Linear LLC iv May 2013

Page 5

Introduction

This guide describes the hardware installation for a Linear eMerge system. It

includes:

• A system overview and topology considerations (page 3), and system

requirements (page 5).

• Instructions for mounting the cabinet (page 8).

• Instructions for adding any required additional blades (page 9).

• Instructions for connecting readers, inputs, outputs, and temperature sensors

(page 12).

• Instructions for wiring the network connection (page 26).

• Instructions for wiring power (page 27).

• Instructions for adding a backup battery (page 29).

• Instructions for setting up a small network, if necessary, which can be used to

complete the initial software setup before the system is connected to the

corporate network (page 30).

• Testing and troubleshooting information (page 32).

• Information on interpreting the various system LED states and beeps

(page 32).

• Hardware and third-party device specifications (page 39).

Note: Check the Linear web site (www.linearcorp.com) for updated

specifications, lists of supported devices, and software updates.

Where to Go for More Information

When the hardware installation is complete, refer to the following publications:

• The “Initial Software Setup Guide” for information on setting initial IP

values and logging into the security application.

• The “Network Node Hardware Installation Guide” for information on

installing additional Network Nodes and application extension blades.

233190 X3 Linear LLC 1 May 2013

Page 6

Introduction

Installation Notes

Note to Installers

Install according to ANSI/NFPA70 and local codes and use only UL Listed

equipment.

CAUTION

OBSERVE STATIC ELECTRICITY PRECAUTIONS WHEN HANDLING

AND INSTALLING SYSTEM COMPONENTS. THESE COMPONENTS CAN

BE DAMAGED BY STATIC DISCHARGE.

Disclaimer

Linear LLC provides this publication “as is,” without warranty of any kind, either

expressed or implied. Linear LLC shall not be liable for errors contained herein

or for incidental or consequential damages in connection with the furnishing,

performance, or use of this guide.

233190 X3 Linear LLC 2 May 2013

Page 7

Preparing to Install

eMerge System Overview

eMerge is a web-based system that does not require a computer to operate. A

computer is required only for system setup, programming, and monitoring.

eMerge is provided in a contro ller cab ine t containing the following:

• A Mini-ITX Network Controller running the controller application software.

• A SAM-E module providing network connectors and power buttons.

• A Network Node blade running the node application software.

• An access control blade that supports up to two card readers.

You can add up to three additional application extension blades to the

cabinet. For more information, see “Connecting Readers, Inputs, Outputs,

and Temperature Sensors” on page 12.

Note: The cabinet for the supported eMerge expansion node is the same except

that it does not contain a Mini-ITX Network Controller.

Topology Considerations

Issues to consider when selecting a topology for the installation include

simplicity, security, wiring requirements, bandwidth requirements, site distances,

current network topology, and the number of security system resources to be

wired.

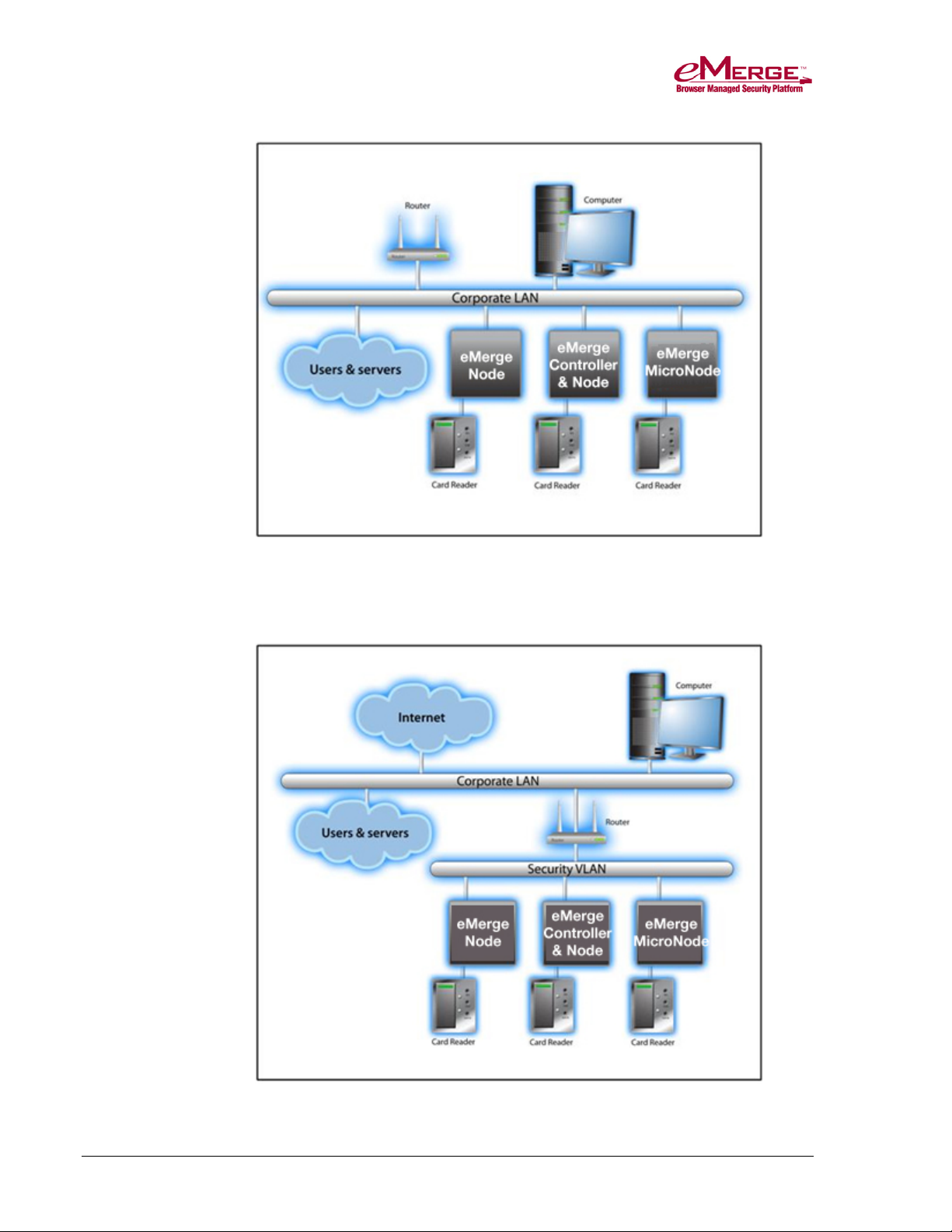

The simplest topology, shown in Figure 1, will be the most common case for

small systems. All users and network resources share the same LAN.

233190 X3 Linear LLC 3 May 2013

Page 8

Preparing to Install

Figure 1. The simplest topology for a eMerge installation. (Not Evaluated

by UL)

This topology shown in Figure 2 is somewhat more complicated, but it is

inherently more secure.

Figure 2. A more secure topology that includes a VLAN. (Not Evaluated

by UL)

233190 X3 Linear LLC 4 May 2013

Page 9

Preparing to Install

In this case, a security VLAN is used to create a subnet for the security system.

As a result, the corporate LAN does not directly carry traffic between the Nodes

and the Controller.

The advantages to this topology are increased network security and decreased

bandwidth requirements. The disadvantages include potentially increased wiring,

and greater complexity.

System Requirements

Network Requirements

The application is designed to work with Ethernet networks using TCP/IP.

Although it will operate on 10baseT networks, 100baseT is preferred. A

100baseT network may be required for good performance if IP cameras and/or

digital video are used.

Note: Networking is not evaluated by UL, only standalone systems.

Before beginning the installation, obtain the following information from the

customer’s network administrator.

Static IP addresses for the blade running combination Controller application

software, and for each blade running node-only application software.

Subnet mask for the controller and nodes.

Gateway IP address.

DNS (Domain Name Server) IP address(es), if any.

Browser Requirements

The application is designed to work with the following web browsers:

• Microsoft Internet Explorer Versions 8 and 9 (recommended)

• Mozilla Firefox Versions 10 and 11

• Apple Safari Version 5

Power Requirements

• DC power is provided via a Listed UL 603 power-limited supply and must

have 12V± 1% DC at a minimum of 5 amps. Source power must come from

a separate circuit with its own breaker and an isolated earth ground.

233190 X3 Linear LLC 5 May 2013

Page 10

Preparing to Install

Environmental Requirements

• Operating temperature range: 32° F to 120° F (0° C to 49° C).

• Operating relative humidity range: Up to 85% non-condensing.

Static Electricity Precautions

The system components can be damaged by static discharge. Observe the

following precautions when handling and installing these components:

• Discharge by touching a ground before handling components.

• Wear a grounded wrist strap or stand on a grounded mat.

• Limit movement to limit static buildup.

233190 X3 Linear LLC 6 May 2013

Page 11

Preparing to Install

Installation Overview Checklist

The major steps required for installing an eMerge system are as follows:

Review the information in this section to prepare for the installation.

Mount the cabinet (page 8).

Install any required additional blades (page 9).

Connect readers, inputs, outputs, and temperature sensors (page 12).

Wire the network connection (page 26).

Connect the system to a power source (page 12).

Add a backup battery (page 29).

Set up a small configuration network, if necessary (page 30).

This checklist presents a logical sequence for completing the installation.

Although it is not necessary to perform the steps in exactly this order, everything

should be plugged in BEFORE powering the unit.

CAUTION: Observe static electricity precautions when handling and

installing system components. These components can be damaged

by static discharge.

eMerge Part Numbers

Network Node Blade 0-587009

Access Control Blade 0-580100-L

Input Blade 0-580110

Output Blade 0-580120

Temperature Blade 0-580130

eMerge50P 230219P

eMerge5000P 230220P

Expansion Node 0-587004

233190 X3 Linear LLC 7 May 2013

Page 12

Mounting the Cabinet

There are three holes in the back of the eMerge cabinet for mounting it to the

wall, as shown in Figure 3.

Figure 3. Wall mount eMerge cabinet.

The two mounting holes near the top of the cabinet are keyholes and should be

mounted first. The lower hole can then be drilled using the cabinet as a template.

Mounting hardware should be sufficient to hang a 25 pound (11.34 kg) load.

Wall space required to fully open the cabinet doors is twice the width of the

cabinet. The door opens from right to left as you face the cabinet. It is

recommended that the cabinet be mounted in a location where the door can be

fully opened.

233190 X3 Linear LLC 8 May 2013

Page 13

Installing Additional Blades

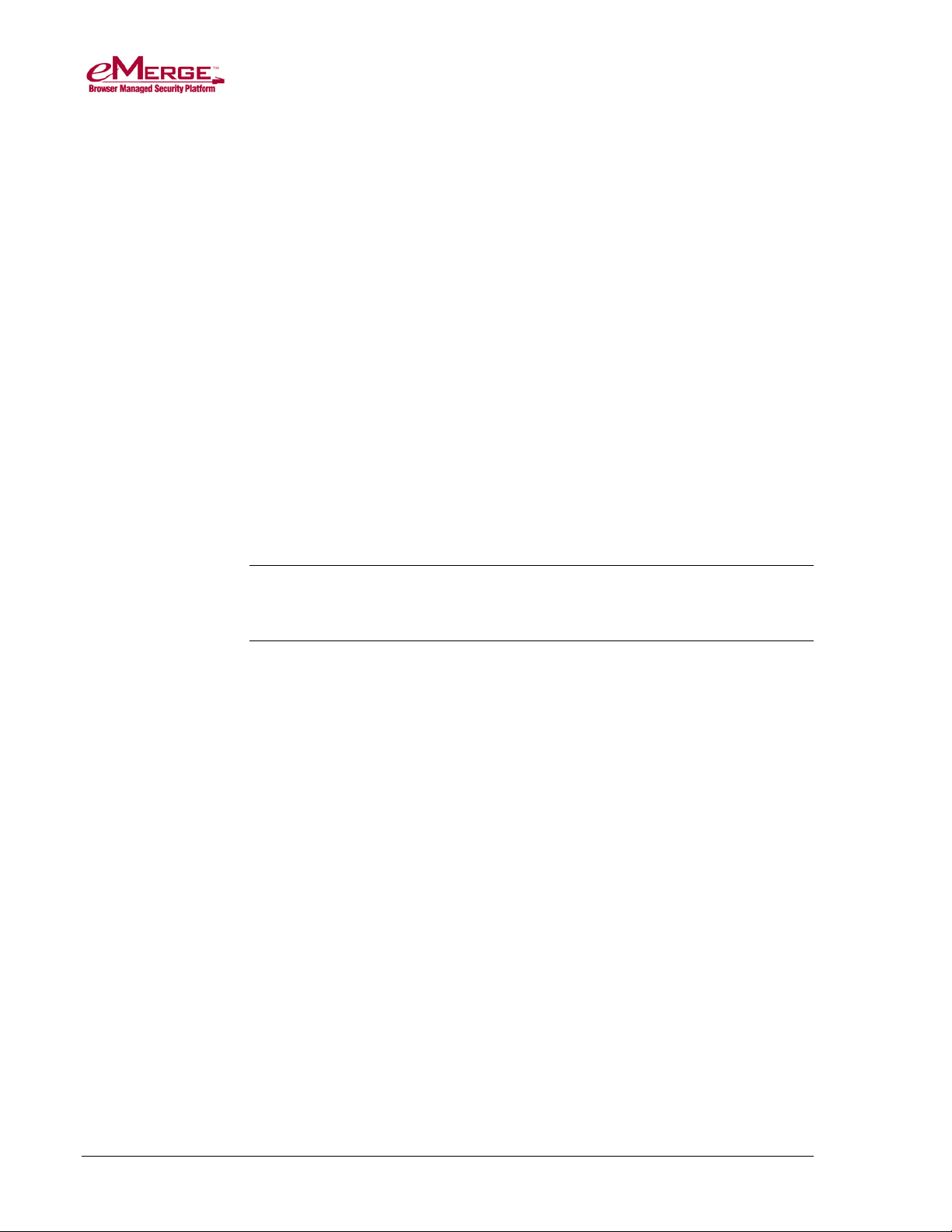

The eMerge cabinet has five slots in the aluminum chassis. The le ftmost slot is

reserved for the Network Node blade running the node application softwa re. Th e

access control blade provided is mounted to its right, in slot 1.

The remaining slots, numbered 2 through 4, can hold any combination of access

control, input, output, and temperature application extension blades.

Figure 4. Slots for installing application extension blades.

You can use the slots in any sequence you choose. Note that the slots are physical

mounting points only. The electrical connection is made through the ribbon

cable, shown in Figure 5 on page 10.

How Slot and Position Numbers are Determined

Regardless of the physical slot in which a blade is mounted, its slot number is

determined by the ribbon-cable connector you plug into the blade. This is

because the ribbon cable (shown in Figure 5) is a bus, and a blade’s position on

the bus determines its slot number.

For example, even if a blade is mounted in physical slot 3, if it is attached to

ribbon cable connector 4, the application will see it in slot 4 on the bus.

233190 X3 Linear LLC 9 May 2013

Page 14

Installing Additional Blades

Important: The blade running the node application software must be attached

to the leftmost connector on the ribbon cable.

Figure 5. Ribbon cable bus viewed from above.

Position numbers are determined by the connector position on the blade itself.

For more information, see the sections “Connecting Readers” (page 12),

“Connecting Inputs” (page 14), and “Connecting Outputs” (page 20).

CAUTION: Blades are not hot-swappable. Before connecting or disconnecting

blades in the cabinet, be sure to remove power from the system,

after stopping all processes.

To install a slot-mounted blade in the cabinet:

1. Log into the application.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

system.

Using the Shutdown utility will ensure that the security database is saved.

4. Once you hear a double beep, remove power from the system.

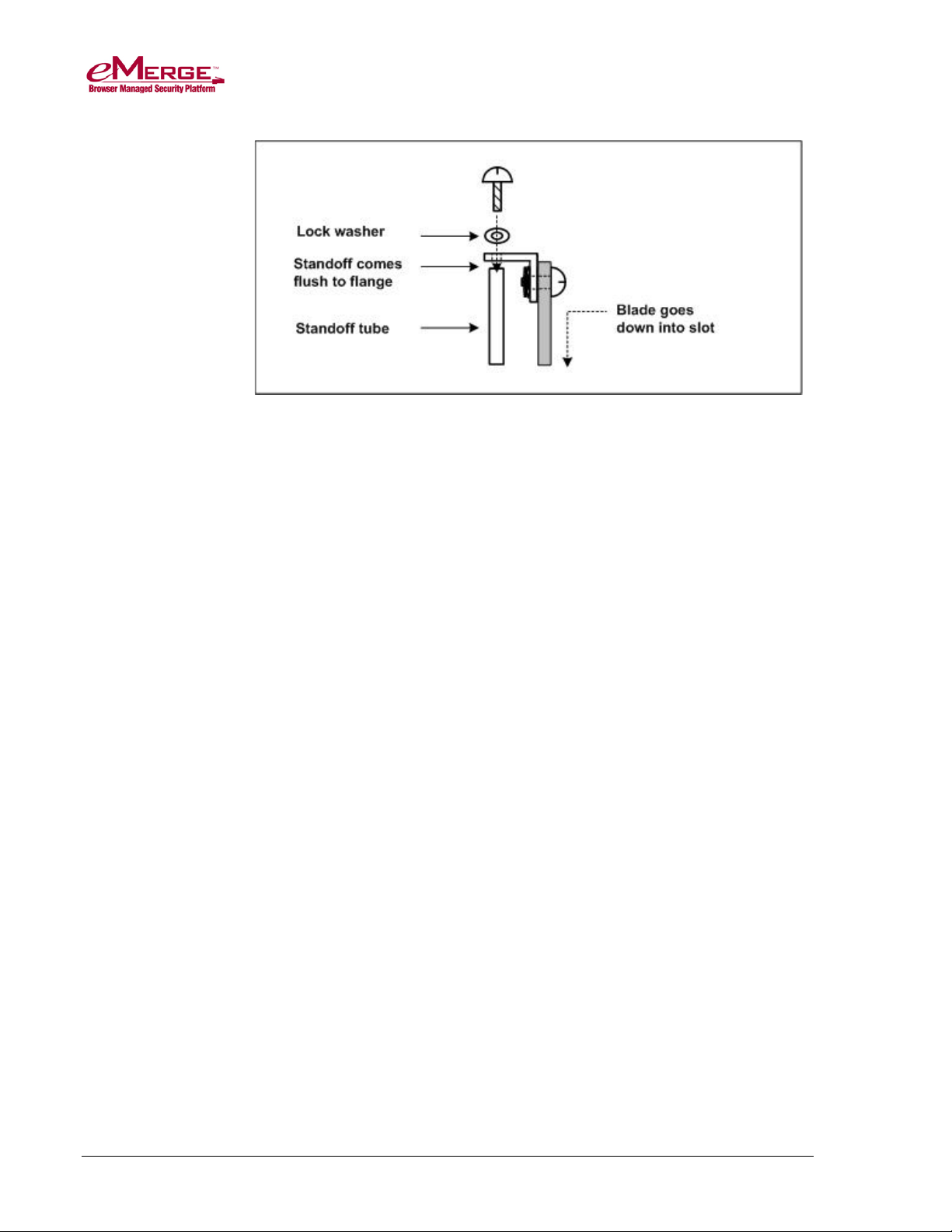

5. Thread the provided standoff tube down onto the threaded post on the

chassis, next to the slot where you will insert the additional blade.

6. Be sure that you are grounded, and then insert the additional blade into the

slot on the chassis with the ribbon cable connector toward the bottom of the

cabinet. See the following diagram.

7. Place the provided lock washer over the top of the standoff, and thread the

provided screw through the flange and down into the top of the standoff and

snugly down onto the lock washer. See the following diagram.

233190 X3 Linear LLC 10 May 2013

Page 15

Installing Additional Blades

Figure 6. Installing a slot-mounted blade.

8. Connect the ribbon cable from the blade in the leftmost slot to the newly

installed blade.

The connector is polarized. Make sure that the center bump fits into the

opening for it on the connector located on the blade.

9. Press the connector firmly into place until you hear the click of the extraction

levers snapping into vertical position. You may have to press the extraction

levers into full vertical position before you will hear the click.

233190 X3 Linear LLC 11 May 2013

Page 16

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Each eMerge supports up to four application extension blades in any

combination. There are four types of application extension blades:

• Access control blade: Includes two Wiegand reader interfaces, four

supervised inputs, and four relay outputs. (6V / 70mA)

o An access control blade is included in the cabinet.

o An access control blade is compatible with UL listed 26 bit, 128 bit, and

200 bit Wiegand readers.

• Input blade: Includes eight supervised inputs. (6V / 60mA)

• Output blade: Includes eight relay outputs. (6V / 55mA)

• Temperature blade: Includes eight temperature input points. (Not UL listed.)

You can easily add application blades to your system in the future by following

the steps on page 10.

This section describes how to connect readers, inputs, outputs, and temperature

sensors.

Wiring Readers

CAUTION: Make sure all power is removed from the Network Node prior to

To wire readers:

1. Log into the application.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

4. Once you hear a double beep, remove power from the system.

wiring and/or connecting any reader to a blade.

system.

Using the Shutdown utility will ensure that the security database is saved.

Note: Steps 1-4 apply only to cabinets containing both a Mini-ITX

Network Controller and a Network Node. Expansion Node cabinets

simply require that you remove power before connecting any reader.

5. Be sure that you are grounded, and then pull the wiring through a knockout

in the cabinet.

233190 X3 Linear LLC 12 May 2013

Page 17

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Bpr

Grn LED control

Red LED control

D1

(white)

D0

(green)

Gnd

(black)

Pwr

(red)

Wire specification: Twisted, shielded 22 AWG Belden #9536 (6 conductor)

or equivalent. Maximum distance: 500 feet (152 meters).

6. Connect the reader wires to the 7-pin reader connector provided, as shown in

the following diagram.

Figure 7. The 7-pin reader connector.

Note: Refer to the documentation provided by the reader m anufacturer for

LEDs and Bpr (Beeper) wire colors.

7. Be sure there is no power to the system.

8. Plug the connector into a reader position on the access control blade.

Connecting Readers

CAUTION: Make sure all power is off before connecting any reader to a

Access control blades have two , 7-pin reader connectors mounted on the blade,

as shown in the following figu re.

blade.

Figure 8. The two 7-pin reader connections on the access control blade.

233190 X3 Linear LLC 13 May 2013

Page 18

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Note: Each access control blade provides a maximum of 400mA peak power to

the readers, 1 x 400mA or 2 x 200mA per board (1.6A maximum is

supplied). If the reader(s) connected to the access control blade draw

more than 400mA, external power must be supplied to these readers by a

UL603 Power Limited Supply .

The access control blade will not function properly if the reader(s) draw

more than 400mA peak.

The color-coded wires from the reader wiring harness must be connected to

the 7-pin connector. The color-coding for Power (red), Ground (black), Data 0

(green), and Data 1 (white) is Security Industry Association (SIA) standard.

• Reader Beeper control: This varies by manufacturer and model. Refer to

the documentation provided by the reader manufacturer for details on your

particular reader. Typically, the reader will beep for the duration of a

momentary unlock, or until the door is opened. This occurs whether the door

is unlocked by a valid card read or from the application. If no beeper is

desired, do not connect the beeper control wire.

• Reader LED control: Th is varies by manufacturer and model. Some use

two-wire LED control and some use one-wire control. Refer to the

documentation provided by the reader manufacturer for details on your

particular reader. Control involving signal pulsing to change LED color is

not supported.

The access control blade has both red and green LED control connections. The 7pin reader connector wiring is shown in Figure 7 on page 13.

Note: LED display behavior for your particular reader may vary. Refer to the

Wiring Inputs

Inputs are dry contact only. An input looks for a change in resistance, not a

change in voltage.

CAUTION: Make sure all power is removed from the Network Node prior to

To wire inputs:

1. Log into the application.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

reader manufacturer documentation.

wiring and/or connecting any input to a blade.

system.

Using the Shutdown utility will ensure that the security database is saved.

4. Once you hear a double beep, remove power from the system.

233190 X3 Linear LLC 14 May 2013

Page 19

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Ribbon cable

connector

2-pin inputs

1 2 3 4

positions

Note: Steps 1-4 apply only to cabinets containing both a Mini-ITX

Network Controller and a Network Node blade. Expansion Node

cabinets simply require that you remove power before connecting

any input.

5. Be sure that you are grounded, and then pull the wiring through a knockout

in the cabinet.

Wire specification: Twisted, shielded 22 AWG Belden #9462 or equivalent.

Maximum distance: 2000 feet (610 meters).

6. Connect the input wires to the 2-pin input connector provided.

7. Be sure there is no power to the system.

8. Plug the connector into an input position on an access control blade or input

blade. These connectors are polarized and can only be inserted one way.

9. If you are connecting previously wired or previously installed inputs,

determine the input supervision type: normally open (NO) or normally closed

(NC); zero, one, or two resistors; or single resistors in parallel or series.

You will need this information for the software setup of the input. See the

section, “Input Supervision Types” on page 16.

Note: The system supports the use of 1k Ohm resistors only.

10. If you are installing the input device, refer to the input device m anual to

determine if the device circuit is normally open (NO) or normally closed

(NC).

11. Select the input supervis ion type you want, then install the supervision

resistor(s) at the end of the input line.

Connecting Inputs

CAUTION: Make sure all power is off before connecting inputs to blades.

Inputs can be connected either to an access control blade or to an input blade.

Access control blades have four male, 2-pin input connectors mounted on the

blade as shown in Figure 9.

233190 X3 Linear LLC 15 May 2013

Figure 9. Input connectors mounted on the access control blade.

Page 20

Connecting Readers, Inputs, Outputs, and Temperature Sensors

NO dual resistor

NC dual resistor

Input blades have eight male, 2-pin input connectors mounted on the blade, as

shown in Figure 10.

Figure 10. Input connectors mounted on the input blade.

Input blades and temperature blades look very much alike. To tell them apart,

look at the bar code sticker on the back of the blade. The numerals on the bar

code sticker for an input blade begin with “01,” as shown above The numerals on

the bar code sticker for a temperature blade begin with “08.”

If more inputs are required beyond the four provided on the access control blade

or the eight provided on the input blade, additional access or input blades can be

installed in the cabinet. For instructions, see “Installing Additional Blades” on

page 9.

Input Supervision Types

Note: The system supports the use of 1k Ohm resistors only.

Dual Resistor Input Circuits

Figure 11. Normally open and normally closed dual resistor input circuit.

233190 X3 Linear LLC 16 May 2013

Page 21

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Input State

Resistance Values

Input State

Resistance Values

NC Series Resistor

NC Parallel Resistor

The configuration of resistors shown in Figure 11 must be installed for

supervised input resistance values to be properly read by the system. The four

states of the dual resistor input circuits are read according to the values in the

following table.

Normal 1k Ohms

Alarm 0.5k Ohms or 2k Ohms

Short 0k Ohms

Open No current (∞ Ohms)

Normally Closed Parallel Resistor Input Circuits

Figure 12. Normally closed parallel resistor input circuit.

The three states of the normally closed parallel resistor input circuit are read

according to the values in the following table.

Normal 0k Ohms

Alarm 1k Ohms

Open No current (∞ Ohms)

Normally Closed Series Resistor Input Circuits

233190 X3 Linear LLC 17 May 2013

Figure 13. Normally closed series resistor input circuit.

Page 22

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Input State

Resistance Values

Input State

Resistance Values

NO Parallel Resistor

NC Unsupervised

The three states of the normally closed series resistor input circuit are read

according to the values in the following table.

Normal 1k Ohms

Alarm No current (∞ Ohms)

Short 0k Ohms

Normally Closed Unsupervised Input Circuits

Figure 14. Normally closed unsupervised input circuit.

The two states of the normally closed unsupervised input circuit are read

according to the values in the following table.

Normal 0k Ohms

Alarm No current (∞ Ohms)

Normally Open Parallel Resistor Input Circuits

Figure 15. Normally open parallel resistor input circuit.

233190 X3 Linear LLC 18 May 2013

Page 23

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Input State

Resistance Values

Input State

Resistance Values

NO Unsupervised

NO Series Resistor

The three states of the normally open parallel resistor input circuit are read

according to the values in the table below.

Normal 1k Ohms

Alarm 0k Ohms

Open No current (∞ Ohms)

Normally Open Series Resistor Input Circuits

Figure 16. Normally open series resistor input circuit.

The three states of the normally open series resistor input circuit are read

according to the values in the following table.

Normal No current (∞ Ohms)

Alarm 1k Ohms

Short 0k Ohms

Normally Open Unsupervised Input Circuits

233190 X3 Linear LLC 19 May 2013

Figure 17. Normally open unsupervised input circuit.

Page 24

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Input State

Resistance Values

The two states of the normally open unsupervised input circuit are read according

to the values in the following table.

Normal No current (∞ Ohms)

Alarm 0k Ohms

Wiring Outputs

CAUTION: Make sure all power is off before wiring and connecting outputs.

To wire outputs:

1. Log into the application.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

system.

Using the Shutdown utility will ensure that the security database is saved.

4. Once you hear a double beep, remove power from the system.

Note: Steps 1-4 apply only to cabinets containing both a Mini-ITX

Network Controller and a Network Node blade. Expansion Node

cabinets simply require that you remove power before connecting

any output.

5. Be sure that you are grounded, and then pull the wiring through a knockout

in the cabinet.

Wire specification: Twisted, shielded 22 AWG Belden #9462 or equivalent.

Maximum distance: 2000 feet (610 meters).

6. Refer to the output device manual to determine if the device is normally

energized or normally not energized, and if it is DC or AC powered.

7. Connect the output wiring to the 3-pin output connector Pin 1 is normally

closed (NC). Pin 2 is common. Pin 3 is normally open (NO).

8. Be sure there is no power to the system.

9. Plug the connector into an output position on an access control blade or an

output blade. These connectors are polarized and can only be inserted

one way.

233190 X3 Linear LLC 20 May 2013

Page 25

Connecting Readers, Inputs, Outputs, and Temperature Sensors

10. If the output device is DC powered and normally not energized, use the

circuit shown in the following diagram.

11. If the output device is AC powered and normally not energized, use the

circuit shown in the following diagram.

12. If the output device is DC powered and normally energized, use the circuit

shown in the following diagram.

233190 X3 Linear LLC 21 May 2013

Page 26

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Ribbon cable

connector

3-pin outputs 1 2 3 4

13. If the output device is AC powered and normally energized, use the circuit

shown in the following diagram.

Connecting Outputs

CAUTION: Make sure all power is off before connecting outputs to blades.

Outputs can be connected either to an access control blade or to an output blade.

Access control blades have four, 3-pin output connectors mounted on the blade

as shown in Figure 18, dry contacts rated at 24V/2A.

Figure 18. Output connectors mounted on the access control blade.

Note: Output positions on the access control blade are output numbers 1, 2, 3,

and 4.

If more outputs are required beyond the four provided on the access control

blade, additional access control blades or output blades can be installed in the

node cabinet. For instructions, see “Installing Additional Blades” on page 9.

233190 X3 Linear LLC 22 May 2013

Output blades have eight male, 3-pin output connectors mounted on the blade, as

shown in Figure 19. Outputs support any output devices that operate on the

following maximum electrical ratings: 24V/2A.

Page 27

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Figure 19. The output blade.

CAUTION: The diodes and varistors shown in the diagrams that follow must

be installed as indicated. They are designed to protect the output

circuits from induced voltage spikes, which can damage the

output circuitry on the blade.

Wiring Temperature Sensors

CAUTION: Make sure all power is off before wiring and connecting

temperature sensors.

Wiring temperature sensors are not investigated by UL.

To wire temperature sensors:

1. Log into the application.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

system.

Using the Shutdown utility will ensure that the security database is saved.

4. Once you hear a double beep, remove power from the system.

233190 X3 Linear LLC 23 May 2013

Page 28

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Black wire to pin 2

White wire to pin 1

2-pin

temperature

inputs

1

2

3

4

5

6

7

8

Pin 1

Pin 2

Note: Steps 1-4 apply only to cabinets containing both a Mini-ITX

Network Controller board and a Network Node blade. Expansion

Node cabinets simply require that you remove power before

connecting any temperature sensor.

5. The cable lead from the white temperature sensor wire must connect to pin

one, and the cable lead from the black temperature sensor wire must connect

to pin two, of the temperature input connector. See the following diagram.

Note: For distances up to 500 feet (152.4 meters), use Category 3 cable.

For distances over 500 feet up to 1000 feet (304.8 meters), use

Category 5 cable.

233190 X3 Linear LLC 24 May 2013

6. Be sure th at you are grou n ded.

7. Pull the cable through a knockout in the cabinet. Connect the 2-pin

temperature input connector to the temperature blade.

Page 29

Connecting Readers, Inputs, Outputs, and Temperature Sensors

Connecting Temperature Sensors

CAUTION: Make sure all power is off before connecting temperature sensors

to blades.

A temperature sensor must be connected only to a temperature blade.

Temperature blades and input blades look very much alike. The numerals on the

bar code sticker on the back of the temperature blade beg in with “08,” as shown

in Figure 20.

Note: Temperature blades are not UL Listed.

Figure 20. Identifying a temperature blade.

233190 X3 Linear LLC 25 May 2013

Page 30

Wiring the Network Connection

To wire the network connection:

1. P ull the Ethernet cable through a knockout in the cabinet.

Cable specification: CAT 5 or better with an RJ-45 connector wired straight

through connecting to a network hub, switch, or router.

2. Plug the RJ-45 connector into the network switch port on the SAM-E module

mounted in the upper left side of the cabinet.

If the network connection is functioning properly, the Amber LED on the

network switch will light.

Figure 21. The SAM-E module

233190 X3 Linear LLC 26 May 2013

Page 31

Wiring Power

This section describes how to wire the supplied PIP (Plug-in-Power supply) or a

DC power source.

The PIP has not been investigated by UL, nor is it UL Listed.

WARNING: Do not apply power to the system until all connections have been

Wiring the PIP

Wire specification: Twisted 16 AWG Belden (2 conductor) or equivalent.

Maximum distance: 10 feet (3.048 meters).

made for readers, inputs, outputs, and temperature sensors.

To wire the PIP:

1. Remove the supplied PIP from its packaging.

2. Attach the black, ground wire to the negative pin (pin 4) on the PIP.

3. Attach the red, positive wire to the positive pin (pin 1) on the PIP.

4. Prior to plugging in the PIP, pull the wiring through a knockout in the

cabinet.

5. Connect the ground (black) wire to the left side of the terminal block.

6. Connect the positive (red) wire to the right side of the terminal block.

7. Plug in the PIP.

Wiring a DC Power Source

Source power must come from a Listed UL 603 power-limited supply with its

own breaker and an isolated earth ground.

If DC power is provided directly to the terminal block via a Listed UL 603

power-limited supply it must have 12V± 1% DC at a minimum of 5 Amps.

To wire DC power:

1. Ensure that the DC power source is off, and then and pull the wiring through

a knockout in the cabinet.

2. Connect the ground (black) wire to the left side of the terminal block, as

shown in the following figure.

233190 X3 Linear LLC 27 May 2013

Page 32

Wiring Power

Figure 22. Wiring DC power.

3. Connect the positive (red) wire to the right side of the terminal block.

233190 X3 Linear LLC 28 May 2013

Page 33

Adding a Backup Battery

To install a battery backup for node and additional blades:

Battery standby power has not been investigated by UL.

The network node does not include a battery, but one can be provided and

mounted on the floor of the wall mount cabinet. The recommended battery is a

12 Volt Sealed or Valve Regulated Lead Acid type with a capacity of either 7AH

or 12AH.

The battery cable is included but is not pre-installed. This cable has a 3-pin

connector for the node (with the center position empty) and two quick connectors

for the battery term in al tabs.

CAUTION: Do not connect the battery terminals and the node until power is

supplied to the node.

The specified battery is not meant to function as a UPS, but rather to supply

sufficient power for two to six hours of system function in case of power failure.

Do not connect a battery before external power is supplied. It will imme diate ly

power up the node and begin to drain the limited battery power. Once external

power is supplied, you can connect the battery and it will charge at 12V via the

connection with the node.

Figure 23. Network Node battery backup installed.

233190 X3 Linear LLC 29 May 2013

Page 34

Setting Up a Small Configuration Network

Before connecting the controller to the corporate network, be sure to review the

following information. You may need to set up a small network between the

eMerge system and a PC that can be used to configure the system before it is

connected to the corporate network.

Network Setup has not been evaluated by UL.

The system is configured with a factory default IP address of 192.168.0.250:

• If this is a valid address on a corporate network that is available for use, you

can connect the system, in its factory default state, to the corporate network

before configuring it. The corporate IT organization will be able to tell you if

the default IP address is available on the corporate network.

• If the system’s default IP address is not available on the network, it will need

to be changed during the initial software setup, to an address provided by the

corporate IT organization.

Important: Do not connect the system to the corporate network until its IP

address has been changed to a valid address on that network.

To allow the person who will complete the initial software setup to change the

system’s IP address before connecting it to the network, you should create a

small network between the eMerge system and the configuration PC.

To set up a configuration network:

1. Put an Ethernet switch between the eMerge system and the PC that will be

used for the initial software setup, as shown in the following figure.

Figure 24. A configuration network.

233190 X3 Linear LLC 30 May 2013

Page 35

Setting Up a Small Configuration Network

The Ethernet switch can be of any size, but you should not use a switch that

is already being used for another purpose.

2. Ensure that the person who will perform the initial software setup knows that

the IP address of the configuration PC must be changed to a static value of

192.168.0.x (where x is a number between 100 and 200). For more

information, refer to the “Initial Software Setup Guide.”

233190 X3 Linear LLC 31 May 2013

Page 36

Testing and Troubleshooting

For testing and troubleshooting purposes, this section shows the layout of the

DN2800MT board and the application extension blades. It also describes how to:

• Interpret various LEDs and beeps.

• Remove blades.

• Use buttons on the SAM-E module to start up, shut down, and reboot the

system, and to reset the controller network and login factory defaults.

The Mini-ITX Network Controller

The Mini-ITX Network Controller is shown in the following figure.

Figure 25. The Mini-ITX Network Controller.

Note: The single LED on the Mini-ITX Network Controller is green when the

power is on and off when there is no power to the system.

233190 X3 Linear LLC 32 May 2013

Page 37

Testing and Troubleshooting

LED State

Meaning

# of Beeps

Meaning

Interpreting the System Status LED on the Cabinet Door

OFF System is down

BLINKING RED System is starting up or shutting down, but the controller

does not see a gateway to a network

ON RED System is up, but the controller does not see a gateway

to a network

BLINKING BLUE System is starting up or shutting down and the controller

sees a gateway to the network

ON BLUE System is up and the controller sees a gateway to the

network

Interpreting Beeps

Shutting Down:

Two beeps

Powering Up:

One beep

Resetting System IP and Login Factory Defaults (via the hardware)

Three beeps

Resetting System Configuration Factory Defaults (via the software)

Three beeps The system configuration factory defaults have

Note: Unlike the controller, Network Nodes do not beep at any time. If

readers are connected, you m ay hear beeps from the readers as they

power up.

Most operating tasks have been completed and the

file system is about to be un-mounted. After waiting

a few seconds, you can remove power.

Startup is complete and you can log into the system.

This may take several minutes.

The IP and login factory defaults have been reset

via the REVERT button (see page 38).

been reset via the Initmode page in the UI, and the

system is about to reboot.

233190 X3 Linear LLC 33 May 2013

Page 38

Testing and Troubleshooting

The Access Control Blade

Figure 26. Access Control Blade.

Input, Output, and Temperature Blades

Figure 27. Input, output, and temperature blades.

233190 X3 Linear LLC 34 May 2013

Page 39

Testing and Troubleshooting

LED

Meaning

Interpreting Access Control, Input, Output, and Temperature Blade LEDs

The two LEDs located on an access control, input, output, or temperature blade

are described in the following table.

LED #1 RUN

LED #2 I2C ON RED, BLINKS OFF indicates a state change on the input

Removing Blades

The procedure for removing blades will be necessary only if you need to swap

out a blade for service reasons.

CAUTION: Blades are not hot-swappable. Before connecting or disconnecting

To remove a blade from the unit:

1. Log into the application.

ON GREEN means the blade is powered and has been

initialized.

OFF means either the blade is not powered (check the ribbon

cable connection) or the board is not initialized (reboot the

node).

and/or output.

This LED is normally OFF.

blades in the cabinet, be sure to remove power from the system,

after shutting down the system.

2. Select Setup : System Maintenance : Utility.

3. Click the Shutdown now button to perform an orderly shutdown of the

system.

Using the Shutdown utility will ensure that the security database is saved.

4. Once you hear a double beep, remove power from the system.

5. Be sure that you are grounded and remove all reader, output, and input

connectors attached to the blade and label each with their connector position.

6. Unplug the ribbon cable by pushing outward on the two extraction levers.

This will release out the cable connector.

7. Unthread the screw from the top of the standoff and remove the screw and

lock washer.

8. Remove the blade from the slot in the chassis.

233190 X3 Linear LLC 35 May 2013

Page 40

Testing and Troubleshooting

Using the Power, Reset, and Revert Buttons on the eMerge 50P/5000P

This section describes how to use the Power, Reset, and Revert buttons to:

• Start and shut down the system.

• Reboot the system if the software is unavailable.

• Reset the controller network and login factory defaults if you are unable

to log into the system.

Figure 28. Power, Reset, and Revert buttons.

Using the Power Button

When the system is not running, pressing the Power button starts the system. The

system status LED blinks while the system is starting up. You will hear a single

beep when the startup process is complete.

233190 X3 Linear LLC 36 May 2013

Page 41

Testing and Troubleshooting

Rebooting Using the Software

Rebooting Using the RESET Button

When the system is running, you can use the Power button to perform an orderly

or hard shutdown:

• Momentarily pressing the Power button performs the same function as an

orderly shutdown performed through the software. The system status LED

starts to blink, indicating a shutdown of services. You will hear a double

beep once the shutdown process is complete.

To restart the controller after an orderly shutdown, momentarily press the

Power button again.

• Holding down the Power button for longer than 5 seconds performs a hard

shut down of the controller, killing all process es immediately. The system

status LED blinks until the controller has shut down, at which point you can

release the button. You will hear no beeps.

To restart the controller after a hard shutdown, press the Power button

momentarily, or power cycle the controller by turning off power to the

system and then turning it back on. The system status LED will blink while

the system is starting up, just as for a normal startup.

Note: If after 30 seconds following a power cycle the system status LED

does not start to blink, momentarily press the Power button to start

the controller.

Using the Reset Button

Although you should use the software to reboot the system, you can use the Reset

button if the software is unavailable. The results of the reboot operation will be

slightly different, however, as described in the table below.

Pressing the Reset button performs the same function as a reboot performed

through software, except that you will not hear a double beep indicating a reset.

The system status LED goes out, and then starts blinking. Once the LED remains

on and is not blinking, and you hear a single beep, the reset is complete.

Performs an orderly shutdown of

the database.

Shuts down the system.

Restarts the controller.

Restarts communication between

the controller and all the nodes.

Using the Revert Button

If you are unable to log in to the security application because the system IP

address or login name and password are unknown, you will need to use the

hardware to revert to the controller network and login factory defaults.

Stops all processes without shutting

down the database.

The database will recover on startup, but

the system must NOT be powered down

or reset again while it recovers.

Restarts the controller.

Restarts communication between the

controller and all the nodes.

233190 X3 Linear LLC 37 May 2013

Page 42

Testing and Troubleshooting

Pressing the Revert button causes the controller to begin the revert process,

indicated by a blinking system status LED. You will hear the following beeps:

• A triple beep indicating the factory defaults listed below have been restored.

• A double beep indicating the controller is restarting.

• A single beep indicating the revert process is complete, and you can login

using the default, out-of-box settings.

The revert process does the following:

• Resets all controller network settings to their factory defaults:

o The IP address is reset to 192.168.0.250.

o The subnet mask is reset to 255.255.255.0.

o The gateway, DNS 1, and DNS 2 are each reset to 192.168.0.1.

• Resets the web server port to port 80.

• Resets the password for the default administrator account to admin.

• Re-enables the administrator account, if necessary.

• Reassigns full system administrator rights to the default administrator

account.

• Resets the interface language to English.

Note: Once the controller network and login factory defaults have been reset,

you can change them at any time by selecting Setup : Site Settings :

Network Controller. Click the Initmode link to change the network

settings and the web server port number. Click the Localization link to

change the interface language.

233190 X3 Linear LLC 38 May 2013

Page 43

Hardware and Third-Party Device Specifications

Check the Linear web site (www.linearcorp.com) for updated specifications,

lists of supported devices, and software updates.

Environmental Requirements

• Operating temperature range: 32° F to 120° F (0° C to 49° C).

• Operating relative humidity range: Up to 85% non-condensing.

Power Requirements

• If DC power is provided directly to the node board, it must have 12V± 1%

DC at a minimum of 5 amps. Source power must come from a separat

ci

rcuit with its own breaker and an isolated earth ground via a UL 603 Power

Limited supply.

e

Reader Power Available from the eMerge System

The total current that one eMerge system can provide to all readers is 1600

milliamps. Each access control blade can supply up to a total of 400 milliamps at

12VDC to readers. For example, an access control blade can supply 400

milliamps to one reader or 200 milliamps to each of two readers. If the readers

require more current, or a different voltage, then power must be provided by a

separate UL603 Limited-power supply.

For example, many Wiegand-compatible proximity readers from HID require

200 milliamps or less. The Node can power 8 readers, which is 8x200mA = 1.6A.

Long range proximity readers may require more power. Refer to the reader

manufacturer documentation for power specifications.

Other than readers, any other components in the system (such as magnetic locks)

must have power provided separately.

Wiring Requirements and Specifications

• Inputs and Outputs: Twisted, shielded 22 AWG Belden #9462 or

equivalent.

Maximum distance from input/output devices to the eMerge system: 2000

feet (610 meters).

233190 X3 Linear LLC 39 May 2013

Page 44

Hardware and Third-Party Device Specifications

• Readers: Twisted, shielded 22 AWG Belden #9536 (6 conductor) or

equivalent.

Maximum distance from a reader to the eMerge system: 500 feet (152

meters).

• Temperature Sensors (not evaluated by UL): Up to 500 feet (152 meters)

twisted Category 3; Over 500 feet up to 1000 feet (305 meters) twisted

Category 5.

Maximum distance from a temperature sensor to the eMerge system: 1000

feet (305 meters).

• Diodes required for output devices that are DC powered: 1N4002- 1 A, 50 V,

Fast Recovery Diode or equivalent.

• Varistors (MOV) required for output devices that are AC powered: 40 VAC,

56 VDC, 10 A Surge, Radial Leaded Varistor or equivalent, such as World

Products Inc. SNR-D56K2.

• Resistors required for input devices: 1k Ohms.

• Ethernet cable: CAT 5 cable or better with RJ-45 connector.

Readers

The eMerge system’s access control blade supports card readers that use the UL

listed 26 bit, 126 bit, and 200 bit Wiegand Reader Interface.

Cameras

Cameras have not been evaluated by UL.

The controller supports up to 128 cameras. The exact number will depend on

usage. IP video cameras may be connected directly to the network and driven by

the controller. For UL application, IP cameras were not investigated.

At this release, the controller is tested to work with the following camera models:

• Axis: All VAPI-compliant cameras and models 2120, 232D

• IQinVision: Various IQeye models

• Panasonic: Models WV-NM100, WV-NS324

• Sony: Models SNC-DF40N/DF40P, SNC-P1, SNC-RZ30N

• Vivotek: Model IP2111

233190 X3 Linear LLC 40 May 2013

Page 45

Hardware and Third-Party Device Specifications

Temperature Sensors

Operating

Range:

Accuracy: -1º/+5º C from -55º C to -30º C (-2º/+9º F from -67° F to -22° F)

-1º/+3º C from -30º C to 0º C (-2º/+5º F from -22° F to 32° F)

±0.5º C from 0º C to 70º C (±1º F from 32° F to 158° F)

±1º C from 70º C to 85º C (±2º F from 158° F to 185° F)

-2º/+1º C from 85º C to 100º C (-4º/+2º F from 185° F to 212° F)

Note: Temperature blades are not UL listed.

-55º C to 100º C (-67° F to 212° F)

Software Protocols and Standards

• DBMS compatibility: SQL

• Email support: POP, SMTP

• Encryption: SSL, SHA-1

• Network: NTP, TCP/IP

• Web: HTTP, HTTPS, XML

Single Facility Maximum Capacities

• Access control readers: 32 m aximum

• Access cards: 20,000

• Alarm monitoring points: 500

• Control point outputs: 500

• Digital video cameras: 32

• Temperature monitoring points: 500

• Network Nodes (fully populated): 32

Minimum System Configuration

The minimum functional eMerge system would include one Mini-ITX Network

Controller, one SAM-E module, one Network Node blade, and one application

extension blade.

233190 X3 Linear LLC 41 May 2013

Page 46

Index

A

access control blade

available power for readers · 39

connecting inputs · 15

connecting outputs · 22

LEDs · 34

additional blades, installing · 9

additional information, references to · 1

application extension blades

connecting inputs and outputs · 12

B

battery backup

for node and blades · 29

beeper control · 14

beeps, interpreting · 33

blades

access control · 13, 34

input · 16

installing · 9

removing · 35

temperature · 25

browser requirements · 5

bus, ribbon cable · 10

C

cabinet door LED · 33

cabinet, mounting · 8

cable specifications, Ethernet · 40

cameras supported · 40

card readers supported · 40

configuration network, setting up · 30

connecting to the network · 26

connectors, ribbon cable · 10

controller · 32

current, total available for readers · 39

E

encryption · 41

environmental requirements · 6

Ethernet cable specifications · 40

H

hard shutdown · 37

hardware specifications · 39

I

input blade

connecting inputs to · 15

LEDs · 34

input circuits

dual resistor · 16

normally closed parallel resistor · 17

normally closed series resistor · 17

normally closed unsupervised · 18

normally open parallel resistor · 18

normally open series resistor · 19

normally open unsupervised · 19

inputs

connecting · 15

specifications · 39

supervision types · 16

wiring · 14

installation overview checklist · 7

L

LED control, reader · 14

LEDs

on access control, input, output, and temperature

blades · 35

on cabinet door · 33

D

DC power supply, wiring · 5, 27, 39

device specifications · 39

diodes and varistors, specifications · 40

dual resistor input circuits · 16

M

Mini-ITX Network Controller · 3, 7, 15, 24, 32, 41

minimum system configuration · 41

mounting the cabinet · 8

233190 X3 Linear LLC 42 May 2013

Page 47

Index

N

network

connecting to · 26

for configuring the system · 30

requirements · 5

O

orderly shutdown · 37

output blade

connecting outputs to · 22

LEDs · 34

outputs

connecting · 22

specifications · 39

wiring · 20

overview

of the installation · 7

P

panel LED · 33

parallel resistor input circuits · 17, 18

part numbers for eMerge 2 · 7

position and slot numbers · 9

power requirements · 39

power source, wiring · 27

precautions and installation notes · 2

R

sensors, temperature · 25

series resistor input circuits · 17, 19

shutting down using the hardware · 37

slot and position numbers · 9

software protocols · 41

specifications, hardware and third-party devices · 39

static electricity precautions · 6

subnet · 5

system

requirements · 5

topology considerations · 3

system status LED · 33

T

temperature blade

identifying · 25

LEDs · 34

temperature sensors

connecting · 25

operating range and accuracy · 41

specifications · 40

wiring · 23

temperature, operating · 6, 39

testing and troubleshooting · 32

third-party device specifications · 39

topology considerations · 3

U

unsupervised input circuits · 18, 19

UPS · 29

readers

available power for · 39

beeper control · 14

connecting · 13

LED control · 14

specifications · 40

supported · 40

wiring · 12

rebooting the system · 37

requirements, system · 5

resetting network and login factory defaults · 37

resistor specifications · 40

restarting after a hard shutdown · 37

ribbon cable · 9, 11

ribbon cable connectors · 10

router, using to create a subnet · 4

S

SAM-E module · 26, 41

V

varistors and diodes, specifications · 40

W

where to go for more information · 1

wiring

DC power source · 27

inputs · 14

outputs · 20

Plug-in-Power supply (PIP) · 27

readers · 12

requirements · 39

temperature sensors · 23

the network connection · 26

233190 X3 Linear LLC 43 May 2013

Loading...

Loading...