Page 1

Essential

Essential Plus

Elite 36

Elite 64

Access Control System

Document Number: 620-100239, Rev. D

Installation Guide

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

Page 2

Notices

All rights strictly reserved. No part of this document may be reproduced, copied, adapted, or

transmitted in any form or by any means without written permission from Linear LLC.

Standards Approvals

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own expense.

Corporate Office

Linear LLC

1950 Camino Vida Roble, Suite 150

Carlsbad, CA 92008-6517

Tel: (800) 421-1587 / 760-438-7000

Fax: (800) 468-1340 / 760-931-1340

Technical Support

Tel: (800) 421-1587

Hours: 5:00 AM to 4:30 PM Pacific Time, Monday - Friday

Notice

It is important that this instruction manual be read and understood completely before installation

or operation is attempted. It is intended that the installation of this unit will be performed only

by persons trained and qualified in the installation of access control equipment. The important

safeguards and instructions in this manual cannot cover all possible conditions and situations

which may occur during installation and use. It must be understood that common sense and

caution must be exercised by the person(s) installing, maintaining and operating the equipment.

Page 3

Contents

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Access Control Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Installation Overview Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 Control Panel Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Control Panel Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Installing the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Mounting the Essential Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Mounting the Essential Plus and Elite. . . . . . . . . . . . . . . . . . . . . . . . . 7

4.0 System Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Essential Power Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Essential Plus and Elite Power Connection . . . . . . . . . . . . . . . . . . . . . 10

4.3 PoE Connection (optional). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 System Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Wiring the Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 System Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.4 Door Lock Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.0 Readers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Wiring the Readers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

7.0 Network Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.1 Preparing for the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7.2 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7.3 Adding a Client. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

7.4 Configuring the Client and Server on the Network . . . . . . . . . . . . . . . . 21

7.5 Programming the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.0 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.0 Test, Maintenance and Service . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.1 Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.3 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

9.4 Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

www.linearcorp.com 1 Essential & Elite Installation Manual

Page 4

1.0 Introduction

is manual contains information regarding the basic installation, wiring and con guration of

the e3 Essential, e3 Essential Plus and e3 Elite browser-based access control systems. e e3

Essential is enclosed in a space-e cient and durable plastic housing. e e3 Essential Plus and e3

Elite are enclosed in a heavy-duty steel cabinet and feature a self-contained battery back-up with

a supervised power supply. All systems use the same control panel layout and system wiring.

1.1 Access Control Overview

Access control systems are designed to monitor and control access throughout a building or

restricted area. An access control system involves the use of an access device (card, PIN code,

etc.), which is presented at an entry device (reader/keypad) to gain access. When access is granted,

a door is unlocked for a pre-programmed amount of time and a transaction is recorded in a

database for reporting or tracking purposes.

1.2 System Overview

e e3 Essential / Plus is a one door, two reader access control system with immediate expansion

capability to four doors, eight readers via an optional software license (P/N ES-1DL or ES1DLB w/reader). e e3 Elite is capable of managing access for up to 72 doors and 144 readers

without an additional software license. e e3 Essential / Plus and e3 Elite include Ethernet

support, an integrated web server and Power over Ethernet (PoE) support.

Specifications

Processor Cortex 1GHz

On-board RAM 512MB DDR2 (333MHz)

Storage 4 GB Micro SD

Power

Operating system Embedded Linux

Transactions per second > 30

Plastic enclosure (W x H x D): 12.25 in x 11.1 in x 2.23 in

Steel enclosure (W x H x D) 17.75 in x 14.25 in x 6.5 in

Temperature specification -4°F to 120°F (-20°C to 50°C)

Features

Doors/Portals

Maximum readers 8 (4 in/4 out) 72 (36 in / 36 out)* 128(64in/64out)*

Inputs 12 108* 192*

Outputs 8 72* 128*

Card holders (users) 1,000 5,000 5,000

Access cards 8,000 80,000 80,000

Cards per person 12 32 32

Card formats 32 32 32

Access levels 25 125 125

Time Schedules 25 125 125

Simultaneous system users 8 16 16

Online transactions 15,000 30,000 30,000

Elevator N/A Yes* Yes*

* NOTE: Using optional expansion controllers

Linear 12VDC/24W (2A) PIP; P/N 0-291312RU

Linear 12VDC/60W (5A) PIP; P/N 0-299177RU (required for UL installations)

e3 Essential / Plus e3 Elite 36 e3 Elite 64

1 (scalable to 4 with optional key upgrades)

36* 64*

www.linearcorp.com 2 Essential & Elite Installation Manual

Page 5

Note: The checklist

provides a logical

sequence for installing a

system.

1.3 Installation Overview Checklist

e following list presents the steps required for successfully installing an e3 system.

ᆖ Mount the enclosure

ᆖ Connect the readers

ᆖ Wire the inputs and outputs

ᆖ Connect power to the system

ᆖ Obtain IP address and other TCP/IP information from network administrator

ᆖ Con gure the e3’s network settings

ᆖ Connect the e3 to a local area network (LAN)

ᆖ (Optional) Add licenses for additional doors and readers

www.linearcorp.com 3 Essential & Elite Installation Manual

Page 6

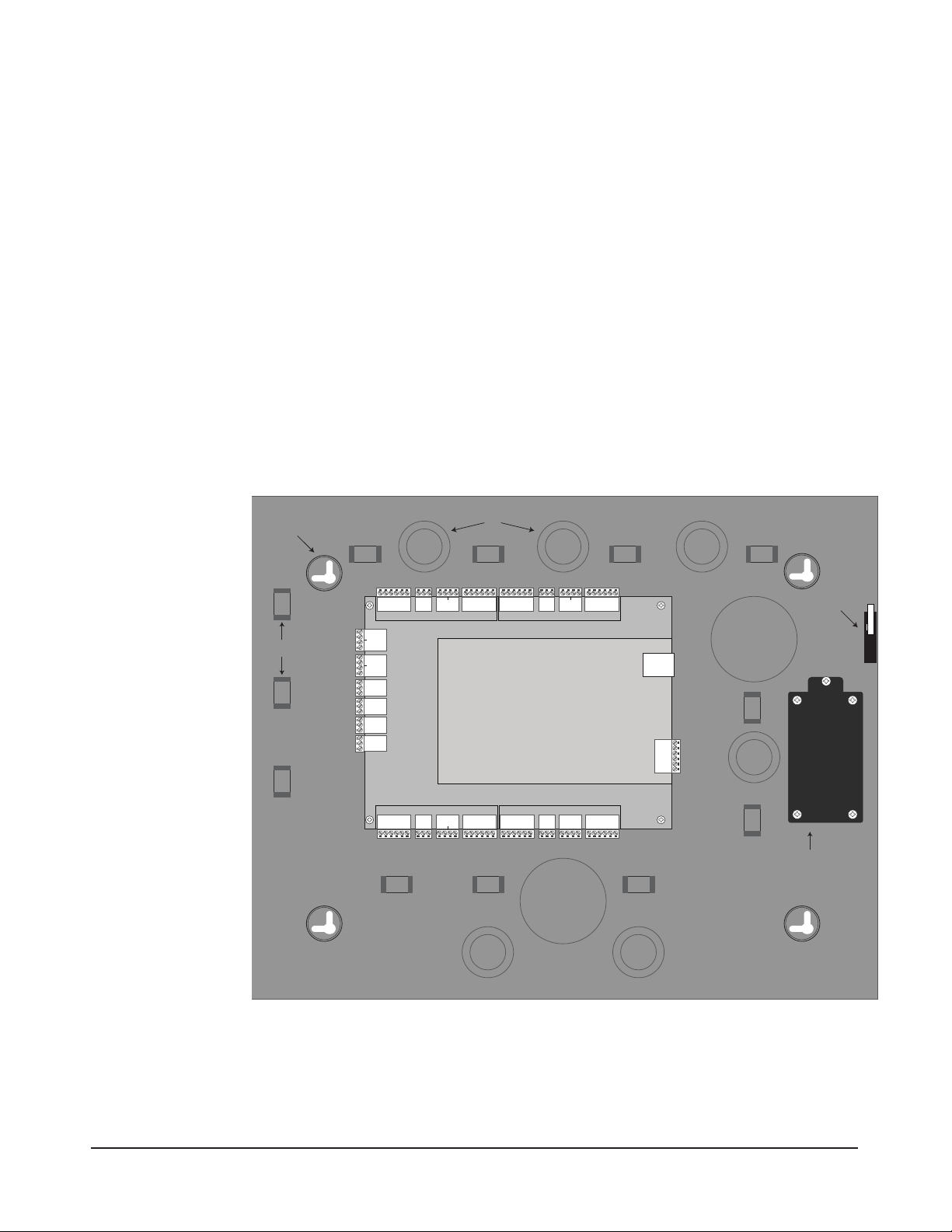

2.0 Control Panel Layout

2.1 Control Panel Components

e following illustration shows the e3 control panel wiring and components.

AUX INPUT 4

AUX INPUT 3

AUX INPUT 2

AUX INPUT 1

AUX RELAY 4

AUX RELAY 3

AUX RELAY 2

AUX RELAY 1

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

Note: The terminals

are designed to accept

16-22 AWG, solid or

stranded wire.

Note: To factory default

the system, press & hold

S1 for 20 seconds. When

released, the system

will start the factory

default process. It is

VERY important to wait

2-3 minutes for a solid

blue LED (DL1) before

programming the system.

All information including

license keys will need to

be re-entered.

DOOR 3

CONTACT

REX 3

DOOR 3

LOCK

INPUT

GND

INPUT

GND

NCCNO

DOOR 3DOOR 4

DOOR 1DOOR 2

l

NCCNO

DOOR 1

LOCK

REX 1

INPUT

GND

INPUT

DOOR 1

CONTACT

AUX IN 4

GND

AUX IN 3

GND

AUX IN 2

GND

AUX IN 1

GND

NC

C

NO

NC

C

NO

NC

C

NO

NC

C

NO

OUT READER 4

D0

D1

l

12V

S2: Hardware reset

S1: Factory default

12V

+

D0

DOOR 4

CONTACT

REX 4

IN READER 4

DOOR 4

LOCK

INPUT

GND

INPUT

GND

NCCNO

+

1

RESET

D1

l

NCCNO

DOOR 2

LOCK

INPUT

REX 2

GND

LED BANK

DL17

DL16

DL15

DL14

DL13

DL12

DL11

DL10

DL9

S2

S1

3

INPUT

GND

DOOR 2

CONTACT

D0

D1

l

12V

DL8

DL7

DL6

DL5

DL4

DL3

DL2

DL1

12V

+

IN READER 2OUT READER 2

D0

+

D1

l

OUT READER 3

D0

D1

l

12V

Micro SD

SLOT

12V

+

D0

+

D1

Figure 2.1. Board Layout

Table 2.1: LED Indicators Table 2.2: Default I/O States

LED Condition

1 DL17 Red On = Power On Middle Board

2 D9 Red On = Power On Bottom Board

3 DL1 Blue On = System is Rebooted

DL1 to DL16 Blue On = System is Booting

4 DL19, DL18 Blue Blink = Network Connection

NOTE: System start up time is approx. 60 secs.

Attribute Default State

Door Status Inputs

Normally Open, Unsupervised, 8 Sec. Held Open Time

REX Inputs Normally Open, Momentary, Unsupervised

Auxiliary Inputs Normally Open, Unsupervised

Door Lock Outputs Not Energized, Single Pulse, 3 Second Unlock Time

Aux Outputs Not Energized, Single Pulse, 3 Seconds On

GND

IN READER 3

D0

D1

l

12V

12V

+

IN READER 1OUT READER 1

2

+

4

D9

DL19

LAN LED

DL18

ETHERNET

TMP TMP +

FLT FLT +

-

+

JP1

D0

D1

l

EARTH

GROUND

LEAD

TAMPER

PWR FAULT

+12VDC

INPUT

JP1 - Power Input

External

POE

+12VDC

(Default)

www.linearcorp.com 4 Essential & Elite Installation Manual

Page 7

3.0 Installing the Control Panel

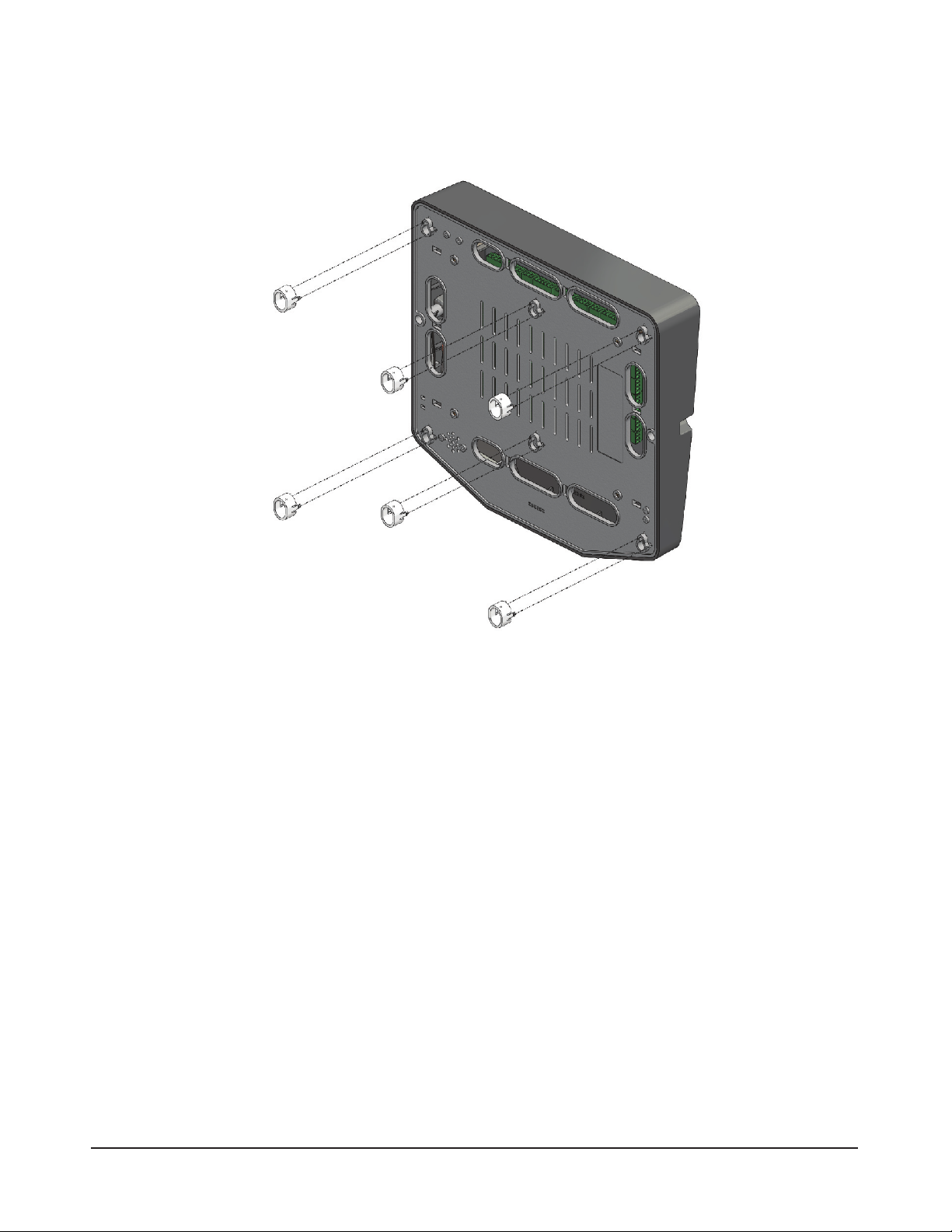

3.1 Mounting the Essential Panel

Note: This device

complies with Part

15 of the FCC Rules.

Operation is subject

to the following two

conditions: (1) this device

may not cause harmful

interference, and (2) this

device must accept any

interference received,

including interference

that may cause

undesired operation.

e Essential housing is designed to accommodate the necessary wiring connections for most

installations. Knock-outs are provided at the back-plate of the housing. e enclosure should be

mounted vertically on a wall, in a secure location within normal temperature and humidity levels.

Installing the Panel

1. Run all necessary wires to the panel location.

2. Remove the enclosure’s cover by removing the two screws in the front of the housing.

3. Level the enclosure on a sturdy wall. Mark the mounting holes with a pencil.

4. Partially insert screws into the top two mounting holes and hang the enclosure on the screws.

5. Pull all wires through the knock-out holes in the enclosure. Label each wire according to its use.

6. Recheck for level, insert the two lower screws, and tighten all four mounting screws.

Note: Choose a centrally

located, secure, clean

and dry area near an

AC power source. Avoid

mounting the panel within

6 feet of any equipment

that generates electrical

interference.

Caution: This equipment

includes electronic

components that are

highly sensitive to

static electricity. Please

discharge by touching

an earth ground before

installing or handling this

equipment.

Note: The plastic housing

will not accommodate a

backup battery. If using

a backup battery, a

separate housing must

be installed.

Cover Screw

Enclosure

Knockouts

Mounting Hole

Enclosure Knockouts

EARTH

GROUND

DOOR 3DOOR 4

DOOR 1DOOR 2

LEAD

Cover Screw

Cover

Tamper

Figure 3.1. e3 Essential Enclosure

www.linearcorp.com 5 Essential & Elite Installation Manual

Page 8

Mounting Extensions

If running surface wires, 6 extension legs may be snapped onto the back of the enclosure to

provide additional space behind the enclosure for the wires.

Figure 3.2. Essential Mounting Feet / Extensions

www.linearcorp.com 6 Essential & Elite Installation Manual

Page 9

Note: Choose a centrally

located, secure, clean

and dry area near an

AC power source. Avoid

mounting the panel within

6 feet of any equipment

that generates electrical

interference.

Caution: This equipment

includes electronic

components that are

highly sensitive to

static electricity. Please

discharge by touching

an earth ground before

installing or handling this

equipment.

3.2 Mounting the Essential Plus and Elite

e e3 Essential Plus and e3 Elite enclosure is designed to accommodate one or two 12VDC 7Ah

backup batteries and the necessary wiring connections for most installations. Conduit knock-outs

are provided on all sides of the enclosure. e enclosure should be mounted vertically on a wall in

a secure location within normal temperature levels. A minimum of 12 inches of space around all

sides of the enclosure is recommended.

Installing the Panel

1. Run all necessary wires to the panel location.

2. Remove the enclosure’s cover by removing the door of the housing. Unlock the door and

disconnect the ground wire. e door may be lifted out of the hinge slots.

3. Remove the metal cabinet knock-outs required for wire entry.

4. Level the enclosure on a sturdy wall. Mark the mounting holes with a pencil. ( e cabinet

can be vertically or horizontally mounted depending on space requirements.)

5. Partially insert screws into the top two mounting holes and hang the enclosure on the screws.

6. Pull all wires through the knock-out holes in the enclosure. Label each wire according to its use.

7. Recheck for level, insert the two lower screws, and tighten all four mounting screws.

8. Install bushings as needed in cabinet knockouts to protect wires from damage.

9. Re-install the door and connect the ground wire to the door.

Cabinet knockouts

Mounting holes

Cover Tamper

DOOR 3DOOR 4

Tie wrap holders

DOOR 1DOOR 2

Figure 3.3. Essential Plus and Elite Enclosure

Power Supervision

& Battery Charger

Module

www.linearcorp.com 7 Essential & Elite Installation Manual

Page 10

4.0 System Power

e Essential panel requires a 12VDC, 2A supply (not included). For UL installations, a Linear

Plug in Power supply (PIP) is required (see below). e Essential may also be powered by a high

Power over Ethernet (PoE) injector using an optional Linear PoE module.

♦ Linear 12VDC/24W (2A) PIP; P/N 0-291312RU

♦ Linear 12VDC/60W (5A) PIP; P/N 0-299177RU (required for UL installations)

♦ Linear e3 PoE module; P/N 620-100159 (requires additional high power PoE injector).

4.1 Essential Power Connection

Power Supply Connection

Caution: A 12VDC power

supply MUST be used.

Incorrect voltage will

damage the product and

void the warranty.

Note: Power should only

be applied to the system

when all connections are

secured and tested.

Cable Specifi cations

for power: 16 AWG

Belden (2 conductor) or

equivalent. Maximum

distance: 6 feet (1.8

meters).

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

1. Connect the +12VDC from the power supply to the +12VDC terminal on the panel.

2. Connect the -12VDC from the power supply to the -12VDC terminal on the panel.

3. Connect an earth ground to the green earth ground lead provided in the enclosure.

4. Turn on the power supply. If using a PIP for the power supply, it must be plugged into a

dedicated receptacle that is not controlled by a switch.

5. e power LEDs (DL17 and DL9) on the panel will turn on to indicate power is present..

Note: A green wire pigtail for

earth ground is provided in all

e3 enclosures

Connection for Linear PIP

12VDC/24W PIP 12VDC/60W PIP

1 2 3

Earth

+–

GND

12 VDC

1 2 3 4

Earth

+–

GND

12 VDC

TMP TMP +

FLT FLT +

–

+

EARTH

GROUND

LEAD

12 VDC

Figure 4.1. Power Connection

www.linearcorp.com 8 Essential & Elite Installation Manual

Page 11

Note: The settings in the

Essential must match the

requirement (normally

open or normally closed)

of the power fault

detection device.

Power Fault Connection

e controller is equipped with a power fault input that can be utilized as follows:

1. Determine whether your power fault input device uses a normally closed or normally open

con guration. Please refer to instructions provided by the manufacturer.

2. Connect the power fault input device to PIN 3 and PIN 4 on the terminal strip.

3. Verify that the power fault input device is functioning properly.

TMP TMP +

FLT FLT +

–

+

Power Fault Input

Figure 4.2. Essential Power Fault Connection

Tamper Protection

A tamper switch is mounted inside the enclosure and is pre-wired to the tamper input on the

terminal strip. If the Essential cover is removed for any reason the tamper switch will activate,

triggering a condition that can be linked to an event action in programming (e.g., send an e-mail

or generate an output).

www.linearcorp.com 9 Essential & Elite Installation Manual

Page 12

4.2 Essential Plus and Elite Power Connection

e Essential Plus and Elite include a factory installed power supervision module as shown in

Figure 4.3.

Power Supply Connection

Caution: A 12VDC power

supply MUST be used.

Incorrect voltage will

damage the product and

void the warranty.

Cable Specifi cations

for power: 16 AWG

Belden (2 conductor) or

equivalent. Maximum

distance: 6 feet (1.8

meters).

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

1. Connect the +12VDC from the power supply to the red lead on the panel.

2. Connect the -12VDC from the power supply to the black lead on the panel.

3. Connect an earth ground to the green earth ground lead provided in the enclosure.

4. Turn on the power supply. If using a PIP for the power supply, it must be plugged into a

dedicated receptacle that is not controlled by a switch.

5. e power LEDs (DL17 and DL9) on the panel will turn on to indicate power is present.

6. Connect the leads to the battery (see below).

DUAL BATTERY INSTALLATION

To Power Supervisor &

Battery Charger Module

BLACKBLACK

Use minimum of 12GA stranded wire.

TMP TMP +

FLT FLT +

+

Earth

Ground

Lead

-

+

-

12VDC

- +

Connect Batteries in Parallel !!!

BATTERY #1 BATTERY #2

RED RED

Use insulated terminals on battery terminals.

Figure 4.3. Essential Plus and Elite Power Connection

Note: The system will

not power up using the

backup battery. The

12VDC power must be

present to power up the

system.

Battery Connection

e Essential Plus and Elite provide charging and space for up to two 12VDC/7Ah sealed lead-

acid batteries (not included). e battery provides standby power when the primary power source

is lost. e control panel will utilize backup battery until the battery voltage reaches 11VDC at

which point the entire system shuts down.

Connecting Batteries in Parallel

Note: Replace the backup

battery every 2 to 3 years.

Connecting batteries in parallel will double the capacity (amp hours) of the backup while

maintaining the proper voltage. Parallel connected battery connection is shown in Figure 4.3.

Note: Parallel connected batteries will take approximately twice as long to charge as a single battery.

Warnings:

♦ Use caution when installing batteries. Incorrect use can damage the battery, controller or can

cause a re.

♦ Connect a maximum of two identical batteries in parallel. DO NOT connect batteries in

series. is will damage your system and void the warranty.

♦ Properly dispose of old batteries.

www.linearcorp.com 10 Essential & Elite Installation Manual

Page 13

To determine standby battery time:

C

Note: Each e3 controller

consumes 200 mA of

current at 12VDC (2.4W).

Note: When a power

fault is detected, and the

battery backup is used,

the e3 may be confi gured

to back up database and

log fi les to the microSD

card.

Note: A PoE module

is required for each

controller that will use the

PoE option.

1. Determine the total standby load of the system by adding the maximum and standby current

draw of the devices connected to the panel. For example, if the system consists of the control

panel (200 mA) and one 75 mA reader the total standby load is 275 mA (200 mA+ 75 mA).

2. Divide the total standby load by 1000 to convert it to amps. For example, 275 / 1000 = .275.

3. Divide the amp-hour rating of the battery by the total standby load to determine the standby

time for the system. For example, 7.0 / .275 = 25.5 hours standby time using a 7 AH battery

with a system that consists of the control panel and one 75 mA reader.

Power Fault

If AC power loss is detected, the power supervision module will automatically switch to the

backup battery and activate the fault input. e fault input can be con gured via programming to

trigger an event such as e-mail or popup message. e transaction will be logged in the history of

the controller.

Tamper Protection

A tamper switch is mounted inside the enclosure and is pre-wired to the tamper input on the

terminal strip. If the cover is removed for any reason the tamper switch will activate, triggering a

condition that can be linked to an event action in programming (e.g., send an e-mail or generate

an output).

4.3 PoE Connection (optional)

All e3 systems can be powered using Power over Ethernet (PoE), which is a method for providing

power via Ethernet cabling. To place the controller in PoE mode, move the Power Input Jumper

to the left position as illustrated in Figure 4.4.

A Power over Ethernet installation must use a high-power 30W PoE injector and the Linear

E3-POE module. Refer to the PoE module’s installation guide for speci c installation information.

Note: Linear E3-POE

module; P/N 620-100159

(requires additional high

power injector) Linear

30W PoE injector:

POE-PLUS

JP1

POE

e3 PoE Module Installed

(Default)

EXTERNAL 12VD

Figure 4.4. Power Input Jumper

www.linearcorp.com 11 Essential & Elite Installation Manual

Page 14

5.0 Inputs and Outputs

5.1 System Inputs

All e3 systems have the capability of monitoring door status (door contact) inputs, request to exit

(REX) inputs, and auxiliary general purpose inputs.

All inputs are assigned default features that can be con gured as needed. e following table

shows the default states for each of the inputs:

Table 5.1: Default Input States

Input Default State

Door Status Inputs Normally Open, Unsupervised, 8 Second Held Open Time

REX Inputs Normally Open, Momentary, Unsupervised

Auxiliary Inputs Normally Open, Unsupervised

Door Status Input

e door status input monitors whether the door is in an open or closed state. A door status

switch (typically a magnetic reed switch) will change states when the door is opened or closed.

e door status input does not require any programming to enable however, you will have to

select either normally open (NO) or normally closed (NC) operation in the panel. Simply

connect a magnetic reed switch to the appropriate door input as shown in the control panel

illustration, Figure 2.1.

Request To Exit

e Request to Exit (REX) input is a momentary input closure that activates the door output

relay for the same amount of time as a valid card swipe or keypad entry. REX devices can include

a press-to-exit switch on the inside of a door or a passive infrared detector (motion detector),

which allows convenient egress. e REX input does not require any programming. Simply

connect a normally open, momentary input device to the REX inputs as shown in the control

panel illustration, Figure 2.1.

Auxiliary Inputs

e auxiliary inputs are general purpose inputs that can be used with a variety of input devices

including CO2 detectors, alarm system integration, etc. ese inputs can be con gured via

programming to trigger a de ned action such as to activate an auxiliary output.

www.linearcorp.com 12 Essential & Elite Installation Manual

Page 15

5.2 Wiring the Inputs

All inputs may be con gured for normally open or normally closed contacts with supervision

or non-supervision. Use standard 1k ohm resistors for supervision. Refer to Figure 5.1 for the

acceptable wiring con gurations.

Cable Specifi cations:

22 AWG Belden or

equivalent. Maximum

distance: 2000 feet.

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

SUPERVISED UNSUPERVISED

Resistor Value = 1k Ohm

Normally Open

Normally Closed

Normally Open

Normally Closed

Figure 5.1. Input Circuit Confi gurations

Tamper Protection

A tamper switch is mounted inside the enclosure for connection to pin 5 and pin 6 on the

terminal strip. If the cover is removed for any reason the tamper switch will activate, triggering a

condition that can be linked to an event action in programming (e.g., send an e-mail or generate

an output).

TMP TMP +

FLT FLT +

12VDC

–

+

Factory

Installed

Tamper

Figure 5.2. Tamper Input Wiring

www.linearcorp.com 13 Essential & Elite Installation Manual

Page 16

5.3 System Outputs

All e3 systems have door lock relays and auxiliary output relays that may be activated in response

to reader activity, time schedules or input conditions. All relays are Form-C SPDT and provide

non-powered dry contacts rated for 1A. e number of available door lock relays and auxiliary

output relays will depend on the number of licensed doors.

Output Defaults

All outputs are assigned default features that can be con gured as needed. e following table

shows the default states for each of the outputs:

Table 5.2: Default Output States

Output Default State Default Response

Door Lock Outputs Not Energized, Single Pulse

Aux Outputs Not Energized, Single Pulse No default response. Must be configured via programming.

3 second unlock time in response to corresponding reader

activity (Reader 1 activates door 1 lock relay)

Wiring Requirements

e cable must be the proper gauge for the current load and should not be routed in parallel

with other wiring especially high voltage or AC wiring. Refer to the Table 5.3 for wiring

recommendations:

Table 5.3: Recommended Wiring Requirements

Total Amps Voltage (AC or DC)

.5 A

1.00 A

2.00 A

3.00 A

12V 1500 ft 1000 ft 600 ft 375 ft 225 ft

24V 2000 ft 1200 ft 750 ft 450 ft 300 ft

12V 800 ft 500 ft 300 ft 200 ft 100 ft

24V 1000 ft 600 ft 400 ft 200 ft 150 ft

12V 400 ft 240 ft 150 ft 90 ft 60 ft

24V 480 ft 300 ft 180 ft 120 ft 70 ft

12V 260 ft 160 ft 100 ft 60 ft

24V 320 ft 200 ft 120 ft

Wiring Gauges and Distance

14 16 18 20 22

www.linearcorp.com 14 Essential & Elite Installation Manual

Page 17

Caution: Do not use the

control panel’s power

supply for the locking

device.

A separate power

supply must be used

.

5.4 Door Lock Outputs

e door lock outputs can be con gured to operate in fail-secure or fail-safe modes.

Wiring the Door Locks

Connect locking devices to the door relay as shown in Figures 5.3 through 5.5. Refer to the door

strike speci cations to determine the appropriate voltage and con guration. WAR NING : Do not

use the control panel’s power supply for the locking device. A separate power supply must be used.

CONTROL PANEL’S

DOOR LOCK RELAY

NC

C

NO

Caution: The diode or

MOV must be installed as

shown in the illustrations.

Failure to install these

protection devices may

damage the control board

or erratic operation.

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

DC POWER

SUPPLY

+

-

DIODE 1N4933

OR

EQUIVALENT

+

-

DC DOOR STRIKE

Figure 5.3. Fail Secure DC Door Strike (without power, door strike is locked)

CONTROL PANEL’S

DOOR LOCK RELAY

NC

C

NO

DC POWER

SUPPLY

+

-

DIODE 1N4933

OR

EQUIVALENT

+

-

DC DOOR STRIKE

Figure 5.4. Fail Safe DC Door Strike (without power, door strike is unlocked)

CONTROL PANEL’S

DOOR LOCK RELAY

NC

C

NO

AC POWER

SUPPLY

MOV SNR-D56K2

OR

EQUIVALENT

AC DOOR STRIKE

Figure 5.5. Fail Secure AC Door Strike (without power, door strike is locked)

www.linearcorp.com 15 Essential & Elite Installation Manual

Page 18

6.0 Readers

6.1 Wiring the Readers

e control panel can accept up to 8 readers or keypads. Each reader port on the panel supports a

12VDC reader with Wiegand output format. Readers can be installed as primary (entry) readers

for each door as well as optional secondary (exit) readers.

e maximum power available for individual reader is 750 mA @ 12 VDC with a combined

maximum of 1.5A for the controller. Determine the reader’s power consumption by referring to

the documentation included with the reader. Exceeding the maximum current for individual readers

or for the controller will damage the protection fuses and void the warranty.

Wiring Readers

Caution: Improper

power wiring will damage

the fuse and void the

warranty.

Cable Specifi cations:

Twisted, shielded 22

AWG (250 ft.) or 18

AWG (500 ft.) Belden

#9535 (5 conductor) or

equivalent. Please follow

manufacturers installation

requirements.

Note: Wiring methods

shall be in accordance

with the National

Electrical Code/NPFA 70

and all local codes.

1. Remove power from the control panel.

2. Pull the reader wiring through a knock-out in the panel’s enclosure.

3. Connect the color-coded wires from the reader’s wiring harness to the appropriate location

of terminal strip as shown in Figure 6.1.

4. Remove excess shield to ensure that it is not exposed. An exposed shield can cause interference.

Tape o any exposed shield with electrical tape.

12V

+

RED BRN GRN WHT BLK

D0

D1

SILVER

l

Note: A green wire pigtail for

earth ground is provided in all

e3 enclosures.

READER

Figure 6.1. Reader Wiring (typical)

www.linearcorp.com 16 Essential & Elite Installation Manual

Page 19

7.0 Network Connection

e e3 controller must be located in a trusted network environment where a protected network

Caution: The system is

exposed to potential risks

if installed on a network

without proper security

precautions. Consult the

appropriate on-site IT

administrator.

Note: If a DHCP server

is present, IP Addresses

are dynamically

assigned. A static IP

address is strongly

recommended for the

controller because a

DHCP Server may assign

a new IP Address.

security system ( rewall, etc.) is installed and maintained. Obtain the following information from

your network administrator before con guring the controller:

♦ IP address

♦ Subnet Mask

♦ Gateway

♦ DNS 1 and 2

7.1 Preparing for the Network

To allow for the e3 to be recognized on the local network, it is necessary to change the controller’s

IP address as follows:

1. Connect your programming computer directly to the Ethernet port of the controller as shown

in Figure 7.1. (You may also connect the computer and controller to an Ethernet Switch.)

LAN LED

ETHERNET

Figure 7.1. Connecting to the Control Panel

2. Assign a static IP address of 192.168.0.149 to the computer. (For instructions on how to

change the static IP address of a Windows computer, please visit: http://technet.microsoft.

com/en-us/library/ 710457).

3. After assigning the static IP address,

open a web browser and

enter the IP address of the

controller (Default = 192.168.0.250).

4. e controller presents the e3 page as shown in Figure 7.2. To log on, enter the default user

ID and password (admin/admin).

Figure 7.2. e3 Login Page

www.linearcorp.com 17 Essential & Elite Installation Manual

Page 20

5. Browse to the Network Con guration (IP address) page as shown in Figure 7.3. Enter the

static IP address, Subnet Mask, Gateway and DNS server so that it matches the requirements

of the local network. (Refer to the User Manual for complete programming information.)

Figure 7.3. Network Settings Page

Note: The system

data will be lost if the

controller is powered

down without performing

Save & Reboot.

Cable specifi cation:

CAT 5 or better with an

RJ-45 connector wired

straight through to a

network hub, switch or

router.

6. Click Save & Reboot and the system will reboot. (Reboot will take approximately 2 minutes.) Note:

e system data will be lost if the controller is powered down without performing Save & Reboot.

7. Disconnect the programming computer from the control panel. e e3 is now ready for the

local network.

7.2 Connecting to the Network

1. Pull an Ethernet cable through the opening in the enclosure nearest the Ethernet port.

2. Plug the RJ-45 connector into the Ethernet port on the controller.

3. Connect to the local area network (LAN) as shown in Figure 7.4.

Internet

eMerge e3

LAN

Router

Client Computer

Figure 7.4. Connecting the Essential to a LAN

If the network connection is functioning properly, the LAN LEDs on the control panel will

illuminate as shown in Figure 7.5. e local computers will then be able to access the system by

entering the IP address of the controller.

www.linearcorp.com 18 Essential & Elite Installation Manual

Page 21

Note: LAN connection

is only required for

monitoring, reporting

and confi guration. Once

confi gured, the Essential

will operate without a

LAN connection.

Figure 7.5. LAN LEDs

LAN LEDS

DL19

DL18

ETHERNET

www.linearcorp.com 19 Essential & Elite Installation Manual

Page 22

Note: The Server

and Client require

independent network

connections

7.3 Adding a Client

e e3 Elite provides the ability to add additional controllers to expand the amount of doors, inputs

and outputs. ese additional controllers are referred to as clients. A client can be mounted on top of

the main controller (server) or in a separate enclosure

Mounting a Client to a Server

1. Disconnect power from the controller.

2. Remove the 4 screws securing the shield over the controller.

3. Position the expansion board over the 4 existing stando s and fasten using the stando s included

with the new controller. Do not over-tighten or the expansion controller could be damaged.

4. Install the shield over the expansion board using the 4 screws removed in step 2.

5. Connect the client and server to the network and apply power. e client’s power connection

must be connected to the output of the power supervision module or you can use the approved

PoE module. See section 4 in this manual for power connections.

.

Shield

Standoffs

(Included with Expansion Controller)

Adhesive Label

Figure 7.6. Mounting Client to Server

Expansion Board (Client)

Main Controller Board (Server)

www.linearcorp.com 20 Essential & Elite Installation Manual

Page 23

7.4 Configuring the Client and Server on the Network

IP Installer is a utility located on a thumb drive shipped with all e3 systems. e purpose of

this utility is to locate the server and client on the network. It also provides a simple method of

changing the IP address of the controller(s).

Run IP Installer

Note: You will have to

change or modify the

fi re wall settings the fi rst

time IP installer is run.

Note: Consult the

appropriate on-site IT

Administrator when

changing the IP Address,

Subnet Mask and

Gateway.

1. Connect all eMerge e3 controllers to the local network.

2. Connect the thumb drive (included with the e3) to a Windows computer on the local network.

3. Locate IPInstaller.exe and double-click the le.

4. IP Installer will open. Click Scan to search the network for e3 controllers.

5. When controllers are identi ed they will be listed in IP Installer.

IP Addresses of Server and Client

Figure 7.7. IP Installer

Change the IP Address of Server and Client

e default IP address of the server and client is 192.168.0.250. To avoid con ict on the network,

the IP address of the client and server must be changed as follows:

1. Connect the server to the network.

2. Open IPInstaller.exe and click Scan.

3. Select the server from the list and click Set Network.

4. Enter a new IP address for the server. is information must be provided by the IT

Administrator.

5. Change the Subnet Mask and Gateway to meet the requirements of the local network.

6. Enter the IP Installer password (default = 4321) and click OK.

7. Connect the client to the network and repeat steps 1 through 4 to change the client’s IP

address.

www.linearcorp.com 21 Essential & Elite Installation Manual

Page 24

Assign the Server to Client (Elite Only)

After the controllers are located on the network, the client must be linked to the server as follows:

1. Using a web browser on a local computer, enter the IP address of the client as con gured in

IP Installer.

2. e browser presents the Linear page as shown.

3. To log on, enter the user name (default = admin) and password (default = admin).

4. After a successful log on, the browser presents the page as shown. Click Edit.

Click Edit

www.linearcorp.com 22 Essential & Elite Installation Manual

Page 25

Enter e3 Server IP address

Enter password and click Save

5. Enter the IP address of the server as entered in IP Installer.

6. Enter the password (default = admin) and click Save.

Link the Client to Server

1. Using a web browser on a local computer, enter the IP address of the server as listed in IP Installer.

2. e browser presents the Linear page as shown.

3. To log on, enter the user name (default = admin) and password (default = admin).

Click Client Management

4. After logging in, click Client Management.

www.linearcorp.com 23 Essential & Elite Installation Manual

Page 26

5. e client will appear in the list. Click the Use/Not Use button to link the client to the server.

e button will display Use when the client is successfully linked to the server.

6. Click the Door icon and verify that the client doors are listed. e client and server are now

linked together.

7.5 Programming the System

e e3 system provides the ability to access and manage the system from a web browser on

any local or remote computer. e system can be programmed using a simple Wizard tool,

which allows the user to con gure the basic settings of the eMerge system. Visit the Wizard

at any time by clicking icon

Refer to the User Programming Guide (P/N 620-100240) for speci c programming and

con guration instructions.

in the lower left corner of the Linear programming window.

www.linearcorp.com 24 Essential & Elite Installation Manual

Page 27

8.0 Troubleshooting

Table 8.1: Troubleshooting the System

Question Solution

The control panel does not

power up.

• Check setting of JP1 on middle board (near input power connector) to ensure that the

jumper is in the appropriate position for your desired power source.

• Measure input power for +12VDC

• If RED LED’s are off, then input fuse may be blown. This fuse is not field-replaceable.

The control panel powers up

but does not respond to card

readers or inputs.

No network communication

exists with the control panel.

I have an unlicensed

controller, how do I obtain a

license key?

How to reboot the system?

How to clear the memory

of the system and restore

factory defaults?

• Measure power at reader connectors. If no voltage is present, then reader fuse may be blown.

• Bring reader and/or input and connect directly at the panel. If it works at the panel, the

wire run may be faulty.

• If LAN LED’s are off or solid, then no physical network connection exists. Check network cabling.

• Verify the Subnet Mask, Gateway, DNS and IP address as provided by the network admin.

• The MAC address is printed on the controller. Using the MAC address, the license key can

be obtained by visiting http://www.e3upgrade.com/ and entering the MAC address.

• Hardware Reboot system: Momentarily press switch S2 on middle board (near bank of 16 LED’s).

• Press and Hold switch S1 for full 20 seconds on middle board (near bank of 16 LED’s).

• You may also reboot and factory default the system using the GUI software.

Note: If factory defaulted, all configuration information will be lost including the license key. To

retrieve the license key, visit www.e3upgrade.com and enter the MAC address of the controller

(MAC Address is printed on the product ).

For further troubleshooting assistance, please visit the following online resources:

♦ http://www.linearcorp.com/faq/

Linear Technical Support:

♦ Tel: (800) 421-1587;

♦ Hours: 5:00 AM to 4:30 PM Paci c Time, M-F

www.linearcorp.com 25 Essential & Elite Installation Manual

Page 28

9.0 Test, Maintenance and Service

9.1 Testing

Monthly testing of the e3 system is recommended.

♦ Check that all used inputs and outputs are correctly functioning with the connected devices.

♦ Check that system and log backups are occurring at scheduled times.

♦ Check for proper operation of backup battery. As a precaution, backup system data before

performing a battery test.

9.2 Maintenance

e e3 system requires very little maintenance. It is recommended to check the following every 6 months:

♦ Cover or door is secure

♦ Enclosure is clean and dry

♦ All wires are securely connected to the terminals

9.3 Service

ere are no user serviceable parts on the e3 controller or on the power supervision and battery

charger module. Contact technical service for assistance if you are experiencing operational

di culties.

Batteries used for the power backup should be replaced every 2-3 years. If using two batteries,

always replace both batteries with new, identical batteries.

9.4 Parts List

e3 Polycarbonate Shield ................................................................... 620-100070

e3 Essential Tamper Switch ............................................................. 620-100038

e3 Essential Plus Tamper Switch ..................................................... 2500-2347

e3 PoE module ................................................................................. 620-100159

Linear 30W PoE injector ................................................................. POE-PLUS

Linear 12VDC/24W PIP ................................................................ 0-291312RU

Linear 12VDC/60W PIP ................................................................ 0-299177RU

e3 Replacement Controller (will need new license key) ................... 620-100307

e3 Replacement Power Supervision/Battery Charger Module ..........

620-100002

www.linearcorp.com 26 Essential & Elite Installation Manual

Page 29

NOTES

www.linearcorp.com 27 Essential & Elite Installation Manual

Page 30

NOTES

www.linearcorp.com 28 Essential & Elite Installation Manual

Page 31

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

Copyright © 2014 Linear LLC 620-100239 D

Loading...

Loading...