Page 1

INSTALLATION AND

OWNER’S MANUAL

AUD

ADVANCED U-SERIES DRAWBAR COMMERCIAL

VEHICULAR DOOR OPERATORS

107093

As of date of manufacture,

meets all ANSI/UL 325

Safety Requirements for

Vehicular door operators

Serial #:

Date Installed:

Your Dealer:

READ THIS MANUAL

CAREFULLY BEFORE

INSTALLATION OR USE

SAVE THESE INSTRUCTIONS !

Page 2

TABLE OF CONTENTS

Model AUD Drawbar Operator Features & Applications ......................................... 3

Preparation................................................................................................................. 4

Figure 1 - Component Identification Pictorial.......................................................... 4

Important Installation Warnings (Things To Do Before & During Installation)...... 5

Table 1 - Component Identification Listing.............................................................. 5

Rail/Chain Assembly Instructions ............................................................................ 6

Installation Instructions........................................................................................ 7-10

Section C: Installing the Operator ........................................................................... 9

Setting The Limits.................................................................................................... 10

Electrical Wiring Instructions.................................................................................. 11

Figure 16 - Pneumatic Door Edge Installation ....................................................... 12

Figure 17 - Field Wiring ........................................................................................... 12

Operation and Adjustment Instructions ............................................................ 13-17

Important Safety Instructions for Owner................................................................ 13

Wiring Terms............................................................................................................ 13

Wiring Types ............................................................................................................ 14

Clutch Adjustment ................................................................................................... 15

Brake Adjustment .................................................................................................... 16

Testing...................................................................................................................... 16

Maintenance ............................................................................................................ 17

Figure 20 - Operator Dimensions............................................................................ 17

Wiring Diagrams/Schematics (Single & Three Phase) ..................................... 18-19

Warranty ................................................................................................................... 20

2

READ THESE STATEMENTS CAREFULLY AND FOLLOW THE

The Warning and Caution boxes throughout this manual are there to protect you and

your equipment. Pay close attention to these boxes as you follow the manual.

WARNING

Indicates a MECHANICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

INSTRUCTIONS CLOSELY.

CAUTION

Indicates a MECHANICAL hazard

of DAMAGE to your operator or

equipment. Gives instructions to

avoid the hazard.

WARNING

Indicates an ELECTRICAL

hazard of INJURY OR

DEATH. Gives instructions

to avoid the hazard.

CAUTION

Indicates an ELECTRICAL hazard

of DAMAGE to your operator or

equipment. Gives instructions to

avoid the hazard.

Page 3

3

PRODUCT FEATURES

The purpose of this booklet is to provide assembly,

installation and operation information concerning Allstar

Model AUD Commercial Vehicular Garage Door Operators

and related Accessory Products.

NOTICE

IT IS IMPORTANT THAT THIS INSTRUCTION

MANUAL BE READ AND UNDERSTOOD

COMPLETELY BEFORE INSTALLATION OR

OPERATION IS ATTEMPTED. IT IS

INTENDED THAT THE INSTALLATION OF

THIS UNIT WILL BE DONE ONLY BY

PERSONS TRAINED AND QUALIFIED IN

THE INSTALLATION, ADJUSTMENT AND

SERVICE OF COMMERCIAL OVERHEAD

DOORS AND DOOR OPERATORS AND BY

QUALIFIED ELECTRICIANS.

NOTICE

THE IMPORTANT SAFEGUARDS AND

INSTRUCTIONS IN THIS MANUAL CANNOT

COVER ALL POSSIBLE CONDITIONS AND

SITUATIONS WHICH MAY OCCUR DURING

ITS USE. IT MUST BE UNDERSTOOD THAT

COMMON SENSE AND CAUTION MUST BE

EXERCISED BY THE PERSON(S) INSTAL-

LING, MAINTAINING AND OPERATING THE

EQUIPMENT DESCRIBED HEREIN. DO NOT

USE THIS EQUIPMENT FOR ANY OTHER

THAN ITS INTENDED

PURPOSE - OPERATING OVERHEAD

COMMERCIAL VEHICULAR GARAGE

DOORS.

MODEL AUD OPERATOR APPLICATIONS:

Drawbar operators are for commercial and industrial use

on sectional overhead doors which use horizontal track

with normal radius. A draw bar operator is not suitable for

doors with high lift exceeding 24 inches or vertical lift

doors. The installation requires a minimum clearance of 5

inches above the high arc of the door (the highest point

reached by the door at any part of its travel). For backroom requirement refer to Figure 20, Page 17. When

properly installed a drawbar operator effectively locks the

door in the closed position.

The Model AUD drawbar operators are used in the

following applications:

-Continuous Duty, Medium Cycle Commercial

installations only

-Indoor Use Only

-Up to 22 foot high doors with a maximum area of 480

square feet for 3/4 HP, 280 square feet for 1/2 HP and

200 square feet for 1/3 HP - maximum area slightly

higher for lighter doors - consult factory

-Use with foam or pneumatic reversing edge door

components - REQUIRED where the 3 button station is

out of sight of the door or any other automatic, remote

or manual control is used to activate the door.

STANDARD FEATURES:

Limit Switches: Driven limit switches, easily adjusted over

a wide range. The motor may be removed without affecting

the limit switch adjustments

Manual Release: Permits manual operation of the door in

the event of a power failure.

Control Circuit: Standard three button open, close and stop.

24 Volts AC.

Connections For Auxiliary Entrapment Protection

Devices:

components or a photoelectric beam (across the opening)

devise.

Constant Contact To Close: Feature can be activated by

simply moving a wire on the terminal strip.

Momentary Contact To Open and Close: Standard

operation.

Use with foam or pneumatic reversing door edge

OPTIONAL FEATURES:

Digital Radio Controls: Open, Close and Stop operation.

Radio units are available to control up to 27 doors from one

transmitter

Digital Timer to Close: Adjustable from 0 to 17 minutes

in one second intervals.

Keyless Entry System: Connection terminals provided for

hard wired or wireless keyless entry system.

Brake: Optional on 1/3 & 1/2HP, Standard on 3/4 &

1HP.

Can be added in the field.

Page 4

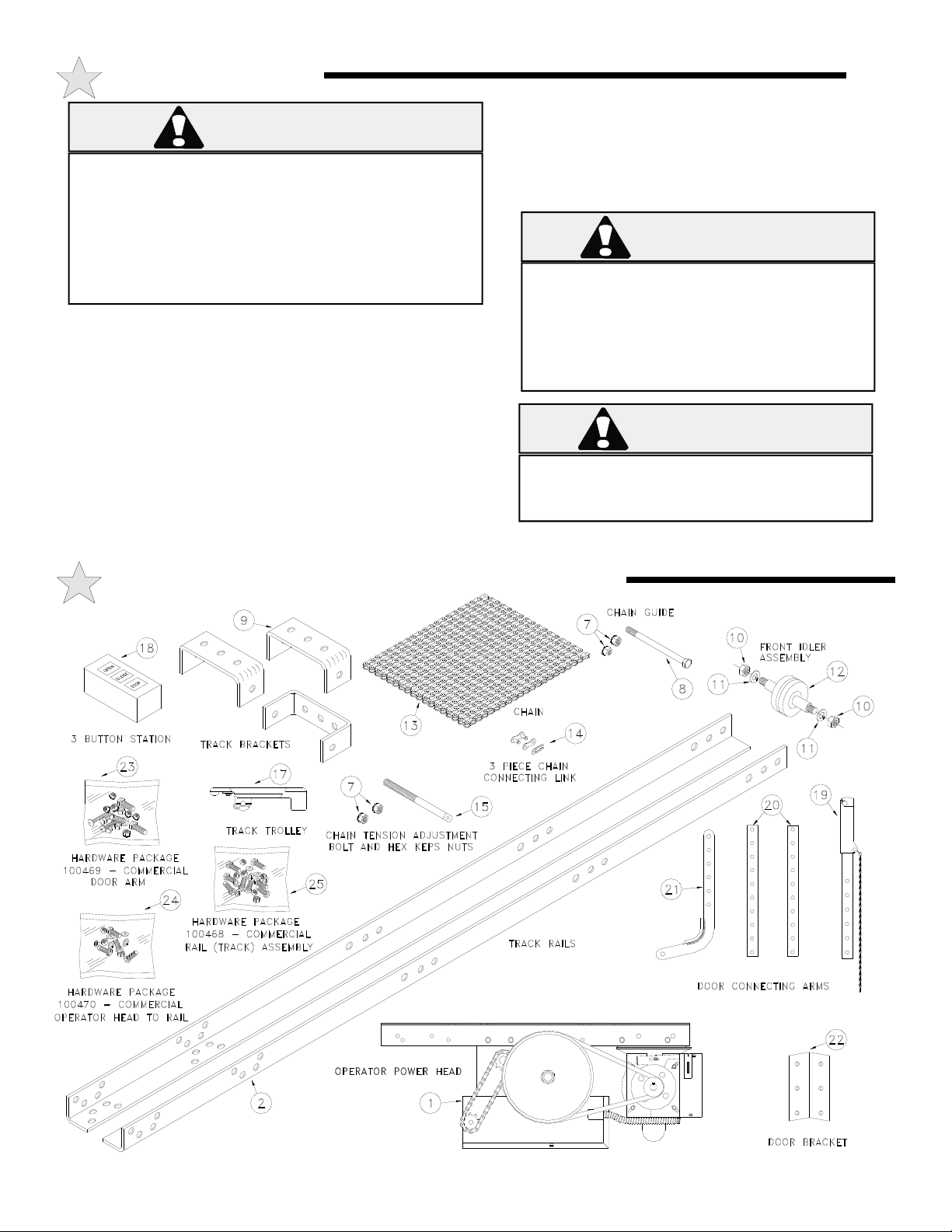

PREPARATION

WARNING

ELECTRIC DOOR OPENERS ARE DESIGNED

FOR DOORS IN GOOD WORKING CONDITION,

PROPERLY COUNTERBALANCED AND

PROPERLY ADJUSTED IN ACCORDANCE WITH

THE DOOR MANUFACTURER'S INSTALLATION

INSTRUCTIONS.

Before starting the installation of the operator, the door must be in

good working condition and properly counterbalanced. Inspect the

door and track for loose or missing hardware. Test the door

manually for balance and ease of operation. Lubricate door hinges

and rollers. If necessary, adjust the springs for proper

counterbalance of the door.

Before removing the operator powerhead from the shipping carton,

inspect the nameplate on the cover of the operator control box to

verify that it is the correct model for the intended application and

that the voltage and phase are in accordance with electrical power

provided at the job site.

4

The rails and drawbar chain/hardware package are shipped

separately from the powerhead. Warning: Rope off the area

to keep personnel and vehicles clear of the door and floor

space in the vicinity of the operator during the

installation.

WARNING

SPRINGS ARE SUBJECT TO VERY

HIGH FORCES AT ALL TIMES AND

ADJUSTMENTS MUST BE MADE ONLY

BY A QUALIFIED PROFESSIONAL

DOOR INSTALLER.

WARNING

REMOVE OR DISABLE ANY LOCKING

DEVICES FROM DOOR AND REMOVE

ALL ROPES

COMPONENT IDENTIFICATION PICTORIAL

107100

Page 5

5

WARNING

IMPORTANT INSTALLATION NOTES

TO REDUCE THE RISK OF SEVERE INJURY

OR DEATH: READ AND FOLLOW ALL

INSTALLATION INSTRUCTIONS!

• Install only on a properly balanced garage

door. An improperly balanced door could cause

severe injury. Have a qualified service person

make repairs to cables, spring assemblies and

other hardware before installing the opener.

• Remove all ropes and remove or make

inoperative all locks (unless mechanically and/or

electrically interlocked to the power unit) that are

connected to the garage door before installing the

opener.

• Lightweight doors (fiberglass, aluminum etc.)

must be reinforced to avoid door damage. Check

the door manufacturer’s instruction manual for a

bracing procedure or the availability or a

Reinforcement Kit. See Page 9.

• Allstar Model AUD is a Commercial

Vehicular Door Operator and as such IS NOT

recommended for pedestrian traffic. In

installations where it is known that pedestrians

will be nearby ensure a pedestrian door is

available for entrance and exit to the building. In

addition YOU MUST install an auxiliary

entrapment protection device (reversing door edge

or photoelectric beam device).

• Connect an auxiliary entrapment protection

device (reversing edge or photoelectric device

across the door opening). a device of this type is

STRONGLY ADVISED FOR ALL commercial

operator installations. An auxiliary entrapment

protection device is REQUIRED when the three

button control station is out of sight of the door

or any other automatic or manual control is

used.

• Install the opener at least 8 feet or more

above the floor.

• Do not connect the opener to the source of

power until instructed to do so.

• Locate the control station:

a) within sight of the door and;

b) at a minimum height of five feet above

the floor and;

c) away from all moving parts of the door.

• Do not overtighten the clutch adjustment to

compensate for a poorly working door.

• Securely attach any WARNING signs or

placards to either the door or above the control

station as directed (see page 11).

• After installing the opener, all safety features

must be tested for proper operation (see page

16).

COMPONENT IDENTIFICATION LISTING

ITEM # PART# DESCRIPTION QUAN.

1 Operator Power Head 1

2 Track Rails 2

7 006031 3/8-16 Keps Hex Nut 6

8 101315 3/8 - 16 X 6-1/2 Hex Head Blot 1

9 107049 Track Bracket AR

10 006034 1/2 - 15 Hex Nut 2

11 006049 1/2 Split Lockwasher 2

12 106265 Front Idler Assembly 1

13 Chain For Track Rail 1

14 3 Piece Chain Connecting Link 1

15 006084 Chain Tension Adjustment Bolt 1

16 006031 3/8 - 16 Keps Hex Nut 2

17 100512 Track Trolley 1

—— AR - As Required

ITEM # PART# DESCRIPTION QUAN

18 005031 3 Button Station 1

19 100513 Release Door Arm 1

20 100236 Extension Door Arm 2

21 100235 Curved Door Arm 1

22 100108 Door Bracket 1

23 100469 Hardware Pkg Com. Door Arm 1

26 3/8 - 16 X 2-1/2 Carriage Bolt 2

16 3/8 - 16 X 1 Hex Head Bolt 1

27 3/8 Nylon Insert Locknut 1

28 5/16 - 18 X 1-1/4 Hex Head Bolt 4

29 5/16 - 18 Keps Hex Nuts 4

25 100468 Hardware Pkg Com. Track Assy 1

4 3/8 - 16 Hex Nut AR

5 3/8 Split Lockwasher AR

6 3/8 - 16 X 1-1/2 Hex Head Bolt AR

Page 6

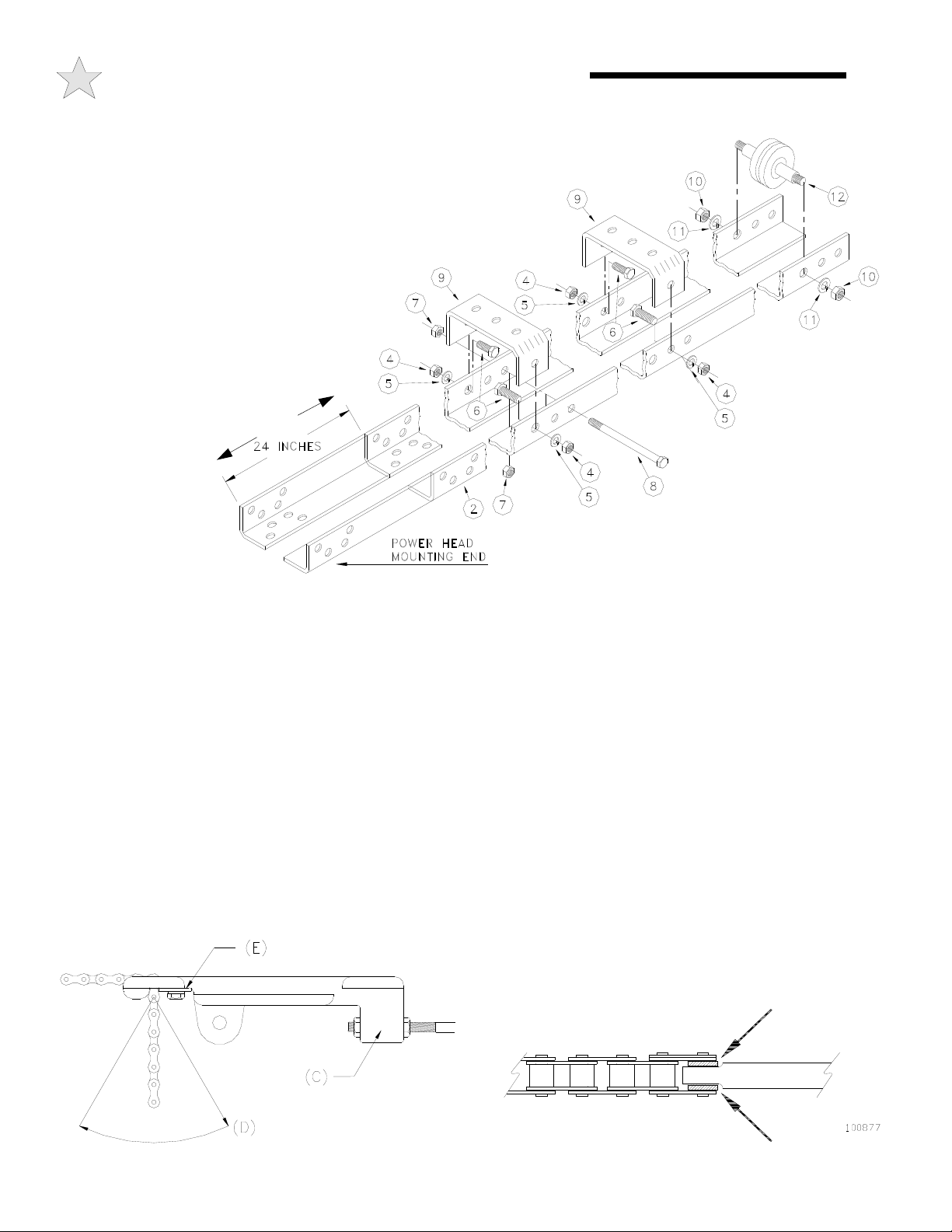

RAIL/CHAIN ASSEMBLY INSTRUCTIONS

RAIL/CHAIN ASSEMBLY

Refer to Figure 1 parts illustrations. The part names and item numbers are

referenced identically to the part names and numbers in the assembly procedures

that follow. Before starting assembly of the operator track check for the

proper length. The tracks are supplied for 8 Foot, 10/12/14 Foot,

16/18 Foot and 20/22 Foot high doors. The tracks should be

three (3) feet longer than the door height. If the tracks

supplied with the operator are longer than the door

height plus 3 feet, it will be necessary to cut off two

feet (or 4 feet for 10 Foot rail) from the power head

mounting end as shown in Figure 2.

CAUTION

CUT THE TRACK ENSURE THE

ENDS ARE LINED UP AS IN

FIGURE 2.

1) Assemble the

operator track by

assembling the items

as shown in Figure 2.

2) After the track is assembled, position track assembly onto

the operator power head and attach with four 3/8”-16 x 1” bolts,

lock washers and nuts (supplied in a separate hardware package

#100470).

3) Referring to Figure 1 , 2 and 3 (below) , slide the trolley

onto the track with the chain take up bolt lug (C) toward the

power head. Thread one 3/8-16 keps nut (attached star washer)

onto the Chain take up bolt with the keps part (attached star

washer) away from the chain attachment end. Insert the chain

take up bolt threaded end through the lug hole on the trolley (C)

just far enough to start a second 3/8-16 keps nut. Attach one end

of the chain to the opposite end of the threaded stud using a 3piece chain link (provided). See Figure 3.

: WHEN NECESSARY TO

48” FOR 10FT RAIL

107068

the connecting link. One-third horsepower operators use the

narrower #65 chain and the use of the spacers is not required.

Install chain around drive sprocket at operator head then around

idler at front end of rail and thread through opening at front end

of carrier. If the rail is equipped with a chain guide-spacer near

its center (12 foot rail or longer only) pass the chain over it in one

direction and under it in the other direction to separate the two

lengths of chain. Apply initial tension by pushing forward on the

carrier while pulling chain tight through opening in the carrier in

the direction of D. When maximum tension has been applied by

this means, swing chain forward and insert retaining plate, E, in

place. Insert 1/4-20 x 5/8 hex head machine screw through

retaining plate, E, and tighten plate in place. Make final

adjustment of chain tension to remove excess sag by adjusting

nuts on threaded rod at chain lug, C.

6

Figure 2

NOTE: To keep #41 chain (used

on 1/2 and 3/4 H.P. operators) centered

on the threaded stud, place a .065" thick flat

washer (provided) on each side of the flat, as

indicated by the arrows in Figure 4, when installing

100461

Figure 3

Figure 4

Page 7

7

INSTALLATION INSTRUCTIONS

TO AVOID DAMAGE TO DOOR AND OPERATOR

ENSURE ALL DOOR LOCKS ARE DISABLED.

USE AN INTERLOCK SWITCH IF A LOCK IS

REQUIRED TO RETAIN FUNCTIONALITY.

1) Locate the center of the door and mark a line on the wall

directly above the door. Extend this line approximately 20” up

the wall. See Figure 5.

CAUTION

107094

A MINIMUM OF TWO PERSONS ARE

REQUIRED FOR OPERATOR

3) Using the projected lines for location, mount a suitable

wood block or angle iron, depending on the structure of the

building, to the wall above the door opening as shown in Figure

7. Ensure the block or angle iron used will provide a sound and

secure mounting pad for the operator rail front mounting bracket,

see CAUTION warning below.

ENSURE A SAFE RIGID WORKING

PLATFORM IS AVAILABLE.

CAUTION

INSTALLATION.

107096

Figure 5

2) Slowly raise the garage door and observe the action of the

top section. When the top section reaches the highest point

(high arc), use a level and project a line from this point to the

center of the door. See Figure 6.

107095

Figure 6

Figure 7

THE FRONT MOUNTING SURFACE FOR THE

OPERATOR MUST BE SOUND AND SECURE.

IF NECESSARY PROVIDE REINFORCEMENT

IN THIS AREA BEFORE MOUNTING THE

OPERATOR RAIL FRONT MOUNTING

CAUTION

BRACKET.

Page 8

INSTALLATION INSTRUCTIONS

8

4)

Mount the front mounting bracket (Item 9) to the mounting

pad as shown in Figure 8. The location of the door’s torsion

shaft may prevent you from placing the mounting pad in the

location shown. Mount the pad as close as possible to three (3)

107051

6) Swing the operator to a horizontal position above the door

guide rails (high enough to raise the door) and temporarily

secure by suspending from the ceiling with a suitable rope or

chain or support from the floor to the operator. Now open the

garage door slowly, being careful not to dislodge the temporary

support. Lower the operator until it is level. Make sure the

operator is aligned with the center of the door and the bottom of

the rail is at least 2” above the high arc of the door. See Figure

10.

WARNING

FAILURE TO SUSPEND THE OPERATOR

SECURELY MAY RESULT IN SERIOUS

PERSONAL INJURY OR DEATH.

Figure 8

5) With the door in the down position, loosely attach the rail

support to the mounting bracket using two (2) bolts, lockwashers

and nuts (Items 4, 5, 6). See Figure 9.

107053

Figure 9

SPRINGS, PULLEYS, CABLES AND MOUNTING HARDWARE USED TO

BALANCE YOUR GARAGE DOOR ARE UNDER EXTREME TENSION AT

ALL TIMES AND CAN CAUSE SEVERE INJURY OR DEATH IF DISTURBED.

WARNING

DO NOT ATTEMPT ADJUSTMENT.

107052

Figure 10

7) Tighten securely the two (2) bolts, nuts and washers that

were loosely attached in Step 5. See Figure 11.

107054

Figure 11

Page 9

9

INSTALLATION INSTRUCTIONS

8) Figure 12 details a typical method of hanging the operator

from the ceiling. Each installation will vary due to the

difference in building structures; but in all installations side

braces should be used to further strengthen the installation. If

the operator track (rail) is longer than 15 feet a mid support is

recommended.

107141

107142

Figure 12

9) Fully close the door and move the trolley to within 2

inches of the idler sprocket. Using Figure 13 as a guide,

connect the release arm (Item 19) to the trolley. Connect the

two extension arms (Item 20) and the door curved arm (Item 21)

to the door release arm with 5/16 inch bolts and keps nuts

(Items 28 & 29).

10) Refer to Figure 14. Attach the door bracket (Item 22) to

the curved arm using a 3/8 bolt and locknut (Items 16 & 27).

Tighten the bolt until snug then back off 1/4 to 1/2 turns so as to

allow the arm to pivot on the bolt freely. Position the door

bracket to the scribed center line on the door. Use suitable

hardware to attach the door bracket to the door.

IMPORTANT

TO AVOID DAMAGE TO THE DOOR TOP

SECTION REINFORCE THE CENTER STILE

WITH A VERTICAL BRACE. ADDITIONAL

BRACING/REINFORCEMENT MAY BE

REQUIRED WHEN THE DOOR IS

CONTROLLED BY AN AUTOMATIC DOOR

OPERATOR; CONSULT THE DOOR

MANUFACTURER FOR INSTRUCTIONS.

Figure 13

107143

Figure 14

NOTE

BEFORE PROCEEDING RECHECK ALL

BOLTS, NUTS AND LAG SCREWS AND

ENSURE THEY ARE TIGHT.

Page 10

INSTALLATION INSTRUCTIONS

10

WARNING

TO AVOID RISK OF ENTRAPMENT AND

POSSIBLE DAMAGE TO THE DOOR AND

OPERATOR THE LIMITS MUST BE ADJUSTED

BEFORE APPLYING POWER TO THE

OPERATOR.

SETTING THE LIMIT SWITCHES

1) With the cover open on the electrical enclosure, reference

Figure 6 below. There are four (4) switches (A, B, C, and D)

mounted to the ‘V’ bracket (H). The limit switches are mounted

in a fixed position to the underside of the ‘V’ bracket; with the

Close Limit switch (B) on the right and the Open Limit switch (D)

on the left. The Reverse Cutout switch (A) and the Single Button

Selector switch (C, also could be Timer Engage switch depending

on the model) are mounted to the top side of the ‘V’ bracket as

shown. The switches are activated by the two limit nuts (E & G)

on the threaded shaft which move laterally along the shaft as the

operator opens and closes the door. When a limit nut nears the

end of the shaft it activates a set of switches, upper switch first

then the lower fixed limit switch.

2) If the door and operator trolley are at the

fully closed position (original installation), set

the Close limit as described in Step 5 and, as

described below, only move the Open Limit

Nut to the center of the threads.

Otherwise, depress the Limit Nut

Retention Plate (F) so it disengages

from the slots in the limit nuts and

move the Limit nuts to the center of

the threaded shaft.

C E

4) Depress the limit nut retaining bracket (F) so it disengages

from the slots in the limit nuts. Turn the OPEN limit nut (E) on

the shaft until it engages both the Single Button Selector switch

(C) and the Open Limit Switch (D). You will need to listen for

two audible clicks. Release the retaining bracket and be sure

that it engages in slots of both limit nuts.

5) Employing the operator’s large 8” pulley, manually lower

the door to the fully closed position and repeat Step #3 with the

Close Limit nut (G) and Reverse Cutout switch (A) and the

Close Limit switch (B).

6) Manually move the door to a half open position. With the

door in a mid position there will be time to stop the door if

something or someone were in the door path when initially

starting the door.

7) A final limit adjustment will be necessary after the

connection of the power supply in order to ensure the door stops

at the proper Open and Close positions.

Adjustment of the Reverse Cutout switch (A) or Single

Button Selector switch (C) is done at the factory and should not

be needed in the field. Moving the Reverse Cutout switch

closer to the center of the box will increase the point where the

reversing feature cuts out (to allow for irregularity in the floor,

etc.). The reverse cutout point is factory adjusted to approx. 4

inches off the floor.

F

107102

G

A

3) Employing the operator’s

large 8” pulley, manually raise the

door to a nearly open position.

Figure 15

Limit Assembly

A - REVERSE CUTOUT SWITCH

(LS4, ADJUSTABLE)

B - CLOSE LIMIT SWITCH

(LS2, FIXED POSITION)

C - SINGLE BUTTON SELECTOR

or TIMER ENGAGE SWITCH

(LS3, ADJUSTABLE)

D - OPEN LIMIT SWITCH

(LS1, FIXED POSITION)

E - OPEN LIMIT NUT

F - LIMIT NUT RETAINING BRCKT

G - CLOSE LIMIT NUT

H - “V” BRACKET

D

B

H

Page 11

11

ELECTRICAL WIRING INSTRUCTIONS

WARNING

TO PREVENT THE RISK OF PERSONAL INJURY

OR DEATH :

• DISCONNECT POWER AT THE FUSE BOX

BEFORE PROCEEDING.

• ELECTRICAL CONNECTIONS MUST BE MADE

BY A QUALIFIED INDIVIDUAL.

• OBSERVE LOCAL ELECTRICAL CODES WHEN

WIRING THE OPERATOR.

WARNING: Allstar's AU Series operators have been designed

and constructed for use with voltages from 115 Volts AC to 480

Volts AC, in single or three phase. Check the operator

nameplate label on the control box cover for the proper voltage

and phase. The application of an improper input voltage or

phase will result in catastrophic failure to the internal

electrical components.

Observe local electrical codes when wiring the operator.

When hard wiring, observe state and local electrical codes. A

wiring diagram is attached to the inside of the control box cover.

Connect the appropriate voltage and phase power leads to the

appropriate terminals as per the wiring diagram and connect a

ground wire to the grounding screw. On three phase units,

incorrect phasing of the power supply will cause the motor to

rotate in the wrong direction (open when CLOSE button is pushed

and vice versa). To correct this, interchange any two of the

incoming three phase conductors.

The wiring diagram attached inside the cover of the control box

details all of the field wiring terminal connections for the operator.

Always connect the wires to the push-button controls and auxiliary

devices exactly as shown.

Warning: Control voltage of the operator is 24 volts AC, class

2. Do not run the power leads and control circuit wiring in the

same electrical conduit.

Note: Most AU Series operators are pre-wired for door

WARNING

WARNING

RISK OF ENTRAPMENT THAT MAY

RESULT IN SERIOUS PERSONAL INJURY

OR DEATH. DISCONNECT POWER TO

THE OPENER BEFORE AND DURING

INSTALLATION OF AN ACCESSORY

REVERSING DOOR EDGE OR

PHOTOELECTRIC DEVICE. DO NOT

RECONNECT POWER TO OPENER UNTIL

INSTRUCTED TO DO SO. ENSURE

DOORWAY IS CLEAR BEFORE STARTING

TESTING OF UNIT.

reversing edge components. To comply with code

requirements, the door reversing edge components must be

installed and wired to the operator. Refer to Figure 16 and

17 for Edge component installation and wiring.

For operator models not equipped with reversing edge

components ONLY ONE THREE BUTTON WALL

STATION AND NO OTHER MEANS OF CONTROL may

be used to control the operator. This is to comply with safety

requirements. In this case the pushbutton station must be located

WITHIN CLEAR SIGHT OF THE DOOR adjacent to a

placard (supplied with the operator) with this wording:

WARNING

TO PREVENT ENTRAPMENT

DO NOT START DOOR DOWNWARD

UNLESS DOOR WAY IS CLEAR

Operators which are equipped with a reversing edge circuit may

have one or more additional means of control which should be

wired in accordance with the diagram supplied in the operator.

To add a second three button station, refer to Figure 17.

Number 18 gauge wire or heavier must be used for wiring

the control stations and auxiliary control devices to the

operator. Smaller gauge wire may cause operational

problems, especially when multiple push-button stations are

used or during summer months.

TO PREVENT THE RISK OF PERSONAL

INJURY AND/OR DAMAGE TO DOOR OR

PROPERTY, ONLY OPERATE DOOR

CONTROL WHEN DOOR IS IN CLEAR VIEW.

IF CONTROL STATION CANNOT BE

LOCATED WHERE THE DOOR IS VISIBLE

OR IF ANY OTHER DEVICE IS USED TO

CONTROL THE DOOR AN AUXILIARY

ENTRAPMENT DEVISE (DOOR EDGE OR

PHOTOELECTRIC) MUST BE CONNECTED.

CAUTION

TO AVOID DAMAGE TO DOOR AND OPERATOR

ENSURE ALL DOOR LOCKS ARE DISABLED.

USE AN INTERLOCK SWITCH IF A LOCK IS

REQUIRED TO RETAIN FUNCTIONALITY.

Page 12

PNEUMATIC DOOR EDGE INSTALLATION - FIELD WIRING

12

Figure 16

Figure 17

Page 13

13

OPERATION & ADJUSTMENT INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS FOR OWNER

TO REDUCE THE RISK OF SEVERE INJURY OR

WARNING

• NEVER let children operate or play with door controls. Keep the Remote Control away from

children.

• ALWAYS keep a moving door in sight and keep people and objects away from the door area

until the door is completely closed. NO ONE SHOULD CROSS THE PATH OF A MOVING

DOOR.

• TEST THE DOOR OPENER’S REVERSING FEATURE (where applicable) MONTHLY. The

door MUST reverse upon contact with a 4” high object on the floor. After adjusting the

force setting (clutch) or the limit of travel, ALWAYS RETEST the Opener. Failure to ADJUST

THE OPENER PROPERLY may result in SERIOUS INJURY OR DEATH.

• DO NOT over adjust the force setting (clutch) to compensate for a poorly working door. See

page 16 for procedure to check the door operation and page 15 for proper clutch

adjustment.

• If possible, USE THE MANUAL RELEASE only when the door is closed. Use caution when

using the Release with the door open. WEAK OR BROKEN SPRINGS MAY ALLOW THE

DOOR TO CLOSE RAPIDLY, CAUSING SEVERE INJURY OR DEATH.

• KEEP THE GARAGE DOOR PROPERLY BALANCED. See the door owner's manual. An

improperly balanced door MAY CAUSE SEVERE INJURY OR DEATH. Have a QUALIFIED

SERVICE PERSON MAKE REPAIRS TO CABLES, SPRING ASSEMBLIES AND OTHER

HARDWARE. SAVE THIS INSTRUCTION MANUAL FOR END USER

DEATH: READ AND FOLLOW ALL INSTRUCTIONS!

NOTE: It is now necessary to turn on the power in

order to run the Opener to check for proper operation

and limit settings. Before doing so, ensure that all mounting

hardware is installed and has been properly tightened, that all

electrical connections are per local code requirements, and that

proper wiring practices have been followed. Also, double-check

that all ropes have been removed from the door and that the

doorway is clear.

WARNING

AVOID ELECTROCUTION:

DO NOT ROUTE LOW VOLTAGE WIRES IN

SAME CONDUIT AS HIGH VOLTAGE

WIRES. FOLLOW ALL LOCAL

ELECTRICAL CODES OR THE NATIONAL

ELECTRICAL CODE.

WARNING

FAILURE TO TEST REVERSING

SYSTEM COULD RESULT IN DEATH

OR SERIOUS INJURY. TEST THIS

SYSTEM ONCE A MONTH.

WIRING TERMS

MOMENTARY CONTACT: Button can be pushed and

then released and door will keep moving or stop without

maintaining pressure on the button.

CONSTANT PRESSURE: Constant pressure is required

on the button in order for continued door movement. When

the button is released the door will stop and possibly

reverse to full open depending on wiring type.

DOOR EDGE/PHOTOELECTRIC INPUT: The

operator wiring provides for input from an optional

pneumatic or electric door bottom edge or photoelectric

device that will cause a closing door to stop and may

reverse it to open depending on the wiring type.

OPEN OVERRIDE: When the door is closing a

momentary push of the OPEN button will reverse the door

to open.

Page 14

OPERATION & ADJUSTMENT INSTRUCTIONS

WIRING TYPES

14

NOTE: Check the marking on the operator outer carton and the

wiring diagram on the inside control box cover for the wiring

type.

B WIRING

To Open - Momentary Contact

To Close - Momentary Contact

To Stop- Momentary Contact

B1 WIRING

To Open - Momentary Contact

To Close - Momentary Contact

To Stop- Momentary Contact

Door Edge/Photoelectric Input will stop the door when closing.

B2 WIRING

To Open - Momentary Contact

To Close - Momentary Contact

To Stop- Momentary Contact

Open Override- Standard

Door Edge/Photoelectric Input will reverse a closing door to

full open - door can be stopped with the STOP button at all times.

Single Button Radio Control Input will open or close door and

reverse to open if closing but will not stop the door.

C WIRING

To Open - Momentary Contact

To Close - Constant Pressure:

Door will stop if pressure is released from CLOSE button

To Stop- Momentary Contact

C1 WIRING

To Open - Momentary Contact

To Close - Constant Pressure:

Door will stop if pressure is released from CLOSE button

To Stop- Momentary Contact

Door Edge/Photoelectric Input will stop the door when closing.

D WIRING - 2 Button Control

To Open - Momentary Contact

To Close - Constant Pressure

To Stop- Door will stop if pressure is released or when the

opener activates a limit switch at full open or full closed.

E WIRING - 2 Button Control

To Open - Momentary Contact

To Close - Constant Pressure:

If pressure is released door will reverse to full open

To Stop- Door will stop when the opener activates a limit switch

at full open or full closed. Door cannot be stopped in mid

travel.

E2 WIRING -2 Button Control

To Open - Momentary Contact

To Close - Constant Pressure:

If pressure is released door will reverse to full open

To Stop- Door will stop when the opener activates a limit switch

at full open or full closed. Door cannot be stopped in mid

travel.

Door Edge/Photoelectric Input will reverse a closing door to

full open and door cannot be stopped.

T1 WIRING

To Open - Momentary Contact

To Close - Momentary Contact

To Stop- Momentary Contact

Open Override- Standard

Door Edge/Photoelectric Input will reverse a closing door to

full open - door can be stopped with the STOP button at all

times..

Optional Adjustable Timer closes the door automatically. Time

interval resets when open button, open override, door edge or

auxiliary control is activated.

Optional Defeat Switch locks out timer when not required.

T2 WIRING

To Open - Momentary Contact

To Close - Momentary Contact

To Stop- Momentary Contact

Door Edge/Photoelectric Input will reverse a closing door to

full open - door can be stopped with the STOP button at all

times..

Optional Adjustable Timer closes the door automatically. Time

interval resets when door edge or auxiliary control is activated.

OPEN button will not start or reset timer.

Optional Defeat Switch locks out timer when not required.

Page 15

15

OPERATION & ADJUSTMENT INSTRUCTIONS

CLUTCH ADJUSTMENT

WARNING

RISK OF ENTRAPMENT THAT MAY

RESULT IN SERIOUS PERSONAL

INJURY OR DEATH. DISCONNECT

POWER TO THE OPENER BEFORE

SERVICING OR MAKING

ADJUSTMENTS. ENSURE DOORWAY

IS CLEAR BEFORE STARTING TESTING

OF OPERATOR.

The clutch serves to protect the door, the electric operator and

other equipment from undue stress or damage caused by starting

forces and/or an obstruction to the door. It should be set no

tighter than is necessary to smoothly and consistently move the

door throughout its full range of travel. When properly set, it will

slip freely if the door should encounter an obstruction, and it

should be possible to stop the travel of the door by hand.

WARNING: Before adjustment remove power to the

operator.

To adjust the clutch, loosen the jamb nut, , and turn the adjusting

nut, as shown at right Make adjustments in 1/4 turn increments.

Always re-tighten the jamb nut before running the operator to

prevent clutch from changing its setting.

CAUTION

NEVER COMPRESS CLUTCH SPRING BEYOND

POINT LIMITED BY THE DESIGN OF THE

OPERATOR OR REPLACE IT WITH A

HEAVIER SPRING

Due to changing conditions of the door and normal wear, it may

be necessary to occasionally readjust the clutch to obtain

dependable operation.

WARNING: BEFORE DOING SO BE CERTAIN THAT

THE DOOR IS IN GOOD WORKING CONDITION,

PROPERLY COUNTERBALANCED AND THAT THE

CLUTCH IS NOT SLIPPING BECAUSE OF LOOSE OR

MISSING HARDWARE, BINDING IN THE TRACK,

RUBBING AGAINST THE DOOR STOPS OR DEFECTIVE

OR MISADJUSTED SPRINGS. ANY SERVICE

REQUIRED TO THE DOOR, DOOR SPRINGS OR DOOR

OPERATOR MUST BE PREFORMED BY A QUALIFIED

PROFESSIONAL DOOR INSTALLER.

The fiber disk will wear during normal operation and should be

replaced when it becomes difficult or impossible to sufficiently

tighten the clutch to obtain smooth operation of the door when it

is in good working condition. To replace the fiber disk, first

loosen the motor mounting bolts and remove the V-belt then the

clutch adjusting nuts, spring and clutch pulley. Check condition

of V-belt before reassembly and replace if required. After

reassembly, adjust clutch as described above.

107101

Figure 18

WARNING

IMPROPER ADJUSTMENT OF CLUTCH

SETTING COULD CAUSE ENTRAPMENT,

INJURY OR DEATH.

SET CLUTCH ADJUSTMENT FOR JUST

ENOUGH FORCE TO OPERATE THE DOOR

RELIABLY, BUT NO STRONGER. Contact a

service professional to correct any binding,

sticking or other door problems. DO NOT

OVER-ADJUST CLUTCH SETTING TO

COMPENSATE FOR A POORLY WORKING

DOOR.

Page 16

OPERATION & ADJUSTMENT INSTRUCTIONS

BRAKE ADJUSTMENT

16

The solenoid operated brake may require occasional

adjustment. Adjustment is necessary if door tends to drift

downward after reaching the open limit. Follow the

instructions below and Figure 19.

(1) Loosen shoe adjusting screw and bottom bracket arm

of solenoid.

(2) Move tab until drum has a slight drag.

(3) Reverse drag slightly from tab and tighten shoe

adjustment screw.

TESTING

Following installation, the operator MUST be tested and

respond correctly to all controls as specified on the wiring

diagram. Keep personnel and equipment clear of the area

beneath the door when performing the tests. When testing the

3-button wall station, first observe that each button operates the

door in the direction indicated and that the STOP button

performs that function. With the door stopped at its full open

position, the OPEN button should be inoperative. This should

be verified and, likewise, the CLOSE button should be

inoperative with the door fully closed.

Certain operator control circuits use only a single button or a

two button control station and may be designed to function

differently than the more common three-button circuit

described above. Test the controls in accordance with the

description of operation as indicated on the wiring diagram and

on page 14, Wiring Types.

Observe the door when traveling in each direction for

smoothness of operation. Test the setting of the clutch by

restraining the door by hand. The clutch should slip. Re-check

the limit settings. The door should close tightly at the floor

without excessive impact. Likewise, it should fully clear the

door opening without the carrier striking the stops on the rail.

The AU series operators are equipped with a reversing edge

circuit and to conform with code, need to be connected to a

pneumatic or foam door edge or photoelectric device. To test an

edge for proper reversal, place an object beneath the leading

edge of the door. To test a photoelectric device for proper

reversal, start the door down and obstruct the beam. The door

should instantly reverse when it comes into contact with the

object provided the height of the object exceeds the cut out

107103

Figure 19

CAUTION

DO NOT STAND UNDER DOOR

TO TEST REVERSING EDGE

USE A CORRUGATED BOX

OR OTHER SIMILAR OBJECT

point built into the close limit switch (approx. four (4) inches).

If the operator is equipped with other means of control, such as

additional 3 button stations or radio controls, each of these should

be tested separately for proper operation.

Test the manual disconnect with the door in the fully closed

position. The door arm should freely fall away from the carrier

when the release chain is pulled. If it is difficult to release and the

door arm appears to be under compression, reset the CLOSE limit

slightly to reduce the travel of the carrier in the close direction.

WARNING

ALWAYS DISCONNECT POWER TO

THE OPERATOR BEFORE SERVICING,

CONNECTING ACCESSORY DEVICES

OR MAKING ADJUSTMENTS.

Page 17

17

MAINTENANCE

Normally, very little maintenance is required. A monthly visual

inspection must be made for loose or missing hardware and for

excessive slack in the V-Belt and drawbar chain. The clutch

must be tested periodically and adjustments made if necessary

(see page 15). The brake (where applicable) is adjusted at the

factory and will need periodic adjustment for wear. When

adjustment becomes necessary see Figure 19 on page 16 for

the adjustment procedure.

Test the reversing edge circuit at least once a month by

permitting the door to contact an obstruction while closing. To

test a pneumatic or foam door edge for proper reversal, place an

object beneath the leading edge of the door. To test a

photoelectric device for proper reversal, start the door down

and obstruct the beam. The door should instantly reverse when

it comes into contact with the object provided the height of the

object exceeds the cut out point built into the close limit switch

(approx. four (4) inches).

FIGURE 20 - OPERATOR DIMENSIONS

CAUTION

DO NOT STAND UNDER DOOR

TO TEST REVERSING EDGE

USE A CORRUGATED BOX

OR OTHER SIMILAR OBJECT

Lubrication of the operator is not required. It is important, for

trouble free service from the operator, that the door be kept free

from binding, properly counter balanced and periodically

lubricated. An annual inspection of the door by a qualified

overhead door professional is recommended.

Warning: Repairs and adjustments to the door and operator

should be performed only by someone qualified to service

commercial overhead doors and operators.

107093

Page 18

WIRING DIAGRAM/SCHEMATIC - SINGLE PHASE

18

106847

CONNECT REVERSING

EDGE & TEST MONTHLY.

A.O. SMITH BALDOR

IF USED, CONNECT BRAKE WIRES TO 2 & 4 (115V); L1 & L2 (230V).

TO REVERSE MOTOR, SWITCH LEADS 1 & 3 (115V); L1 & L2 (230V).

(312 SERIES)

230V 1P

CAUTION: DISCONNECT

POWER BEFORE ATTEMPTING

SERVICE OR ADJUSTMENTS.

(EPD) - ALLSTAR SERIES T, J, AND H

(AU) - ALLSTAR SERIES AUD, AUJ, AND AUH

DUAL VOLTAGE MOTOR - 115V 1P115 V 1P

TO REVERSE MOTOR DIRECTION, SWITCH

INCOMING LEADS TO TERMINALS 5 AND 8.

DUAL VOLTAGE MOTOR - 230V 1P

TO REVERSE MOTOR DIRECTION, SWITCH

INCOMING LEADS TO TERMINALS 5 AND 8.

BALDOR

107304

Page 19

A

19

S

JUS

WIRING DIAGRAM/SCHEMATIC - THREE PHASE

106848

CONNECT REVERSING EDGE

AND TEST MONTHLY.

3 PHASE MOTOR WIRING CHART

230 VOLTS, 3 PHASE

DUAL VOLTAGE MOTOR

TO REVERSE MOTOR DIRECTION, SWITCH

ANY TWO INCOMING LEADS.

CAUTION: DISCONNECT

POWER BEFORE ATTEMPTING

ERVICE OR AD

460 VOLTS, 3 PHASE

DUAL VOLTAGE MOTOR

TO REVERSE MOTOR DIRECTION, SWITCH

ANY TWO INCOMING LEADS.

TMENTS.

(EPD) - ALLSTAR SERIES T, J, AND H

(AU) - ALLSTAR SERIES AUD, AUJ, AND AUH

575 VOLTS, 3 PHASE

SINGLE VOLTAGE MOTOR

TO REVERSE MOTOR DIRECTION, SWITCH

NY TWO INCOMING LEADS.

107304

Page 20

20

Manufacturer’s Limited Warranty

Linear LLC warrants its Allstar brand commercial door operators to be free from defect in material and workmanship for a period of two (2)

years from the date of purchase. To obtain service contact your dealer.

To obtain service under this warranty the buyer must obtain authorization instructions for the return of any goods from Linear before

returning the goods. The goods must be returned with complete identification, with copy of proof-of-purchase, freight prepaid and in

accordance with Linear’s instructions or they will not be accepted. In no event will Linear be responsible for goods returned without proper

authorization or identification.

Goods returned to Linear for warranty repair within the warranty period, which upon receipt by Linear are confirmed to be defective and

covered by this limited warranty, will be repaired or replaced at Linear’s sole option, at no cost and returned pre-paid. Defective parts will

be repaired or replaced with new or factory rebuilt parts at Linear’s sole option.

This limited warranty does not cover non-defect damage, damage caused by unreasonable use, damage caused by improper installation or

care, vandalism or lightning, fire or excessive heat, flood or other acts of God (including, but not limited to misuse, abuse or alterations,

failure to provide reasonable and necessary maintenance), labor charges for dismantling or reinstalling a repaired or replaced unit, or

replacement batteries.

These warranties are in lieu of all other warranties, either expressed or implied. All implied warranties of merchantability and/or fitness for a

particular purpose are hereby disclaimed and excluded. Under no circumstances shall Linear be liable for consequential, incidental or special

damages arising in connection with the use or inability to use this product. In no event shall Linear’s liability for breach of warranty, breach

of contract, negligence or strict liability exceed the cost of the product covered hereby. No person is authorized to assume for Linear any

other liability in connection with the sale of this product.

This warranty gives you specific legal rights. You may also have other rights which vary from state to state. Warranty effective after

October 1st, 2007.

For Information:

877-441-9300 800-421-1587 www.allstarcorp.com

This Door Operator is built in the USA and

P/N 190-106861 Rev. M August 2007 Copyright © 2007 Linear LLC

complies with all requirements of

ANSI/UL Standard 325.

Loading...

Loading...