Page 1

834LWC VIPER PLUS WITH CONTACT

FRAME MOUNT GLASSBREAK/SELECTIVE VIBRATION DETECTOR

IEI 834LWC GLASSBREAK/VIBRATION DETECTOR

The IEI 834LWC Viper Plus with Contact is a frame mount

glassbreak/selective vibration detector that incorporates a normally closed

window/door contact. The Viper Plus contains a custom integrated circuit

designed specifically to detect vibration signals associated with forced entry in

a wide variety of surfaces including: windows, doors, walls and glass of all

types. You can adjust the Viper Plus for sensitivity over a wide range, but it’s

immune to low frequency vibration. The Viper Plus is a standalone sensor

with no additional processor required. The door/window contact allows the

Viper Plus to monitor the opening of a point of entry.

IEI 834LWC Viper Plus Features

• Patented Integrated Circuit Design

• Solid-State Piezoelectric Device

• No Separate Processor Required

• Latching Alarm LED

• Auto Reset Alarm Relay

• Simplified Calibration Test Mode

• Cover Tamper Contact

• Door/Window Contact

• Double Knock Feature For Alarm Verification

• Immune to Low Frequency Vibration

• High-Low Sensitivity Jumper

Auto-Reset Relay

When the Viper Plus goes into alarm, the relay contact remains open for 8

seconds before re-closing to detect a second independent attack, if

necessary.

Cover Tamper Contact

The cover is monitored against unwanted sensitivity changes or tampering

with a switch mounted on the circuit board. This switch is internally wired in

series with the alarm relay. No additional wiring is necessary.

Double Knock Mode

Most unwanted signals fade within 200 milliseconds. Prolonged attack or

breaking glass exceeds this time. When Double Knock Mode is enabled and

the Viper Plus detects a signal above set sensitivity level it enters the active

mode but ignores all levels of signal for approximately 200 milliseconds. If the

vibration remains above the set sensitivity level for more than 200

milliseconds, or a second attack exceeds the set sensitivity level within 8

seconds, the Viper Plus goes into alarm.

Calibration Test Mode

The first time you trip your Viper Plus there is an 8 second delay before the

LED turns on (the relay opens for 8 seconds as it normally does). After this

first trip the LED remains on and shows each subsequent trip by turning off for

8 seconds. When you are finished testing, interrupt the power to reset the

LED for normal operation.

Document # 6103400, Rev. 3.1

Specifications

Operating Voltage: 10-15VDC (filtered and regulated)

Power Consumption: 6mA (normal); 13mA (alarm)

Range: Up to 10 ft. radius

Voltage Monitor: Low or No Voltage cause alarm activation

Voltage Supervision: Alarm Relay

Relay Activation Time: 8 seconds

Alarm LED: Latch or auto-reset

Alarm Relay: SPST (form A) contacts, 0.5A @ 30VDC

Installation: Hardwire 4 wires

Operating Temperature: 0 ° to 120 ° F (-20° to 50°C)

Mounting: Surface – screws included

Sensor Size: 3.35” long x 0.90” wide x 1.00” high

Magnet Size: 3.35” long x 0.39” wide x 1.00” – 1.40” (max)

Magnetic Contact Gap: 5/16” max

Weight: 2.1 ounces

Color: White

Installation Instructions

Page 2

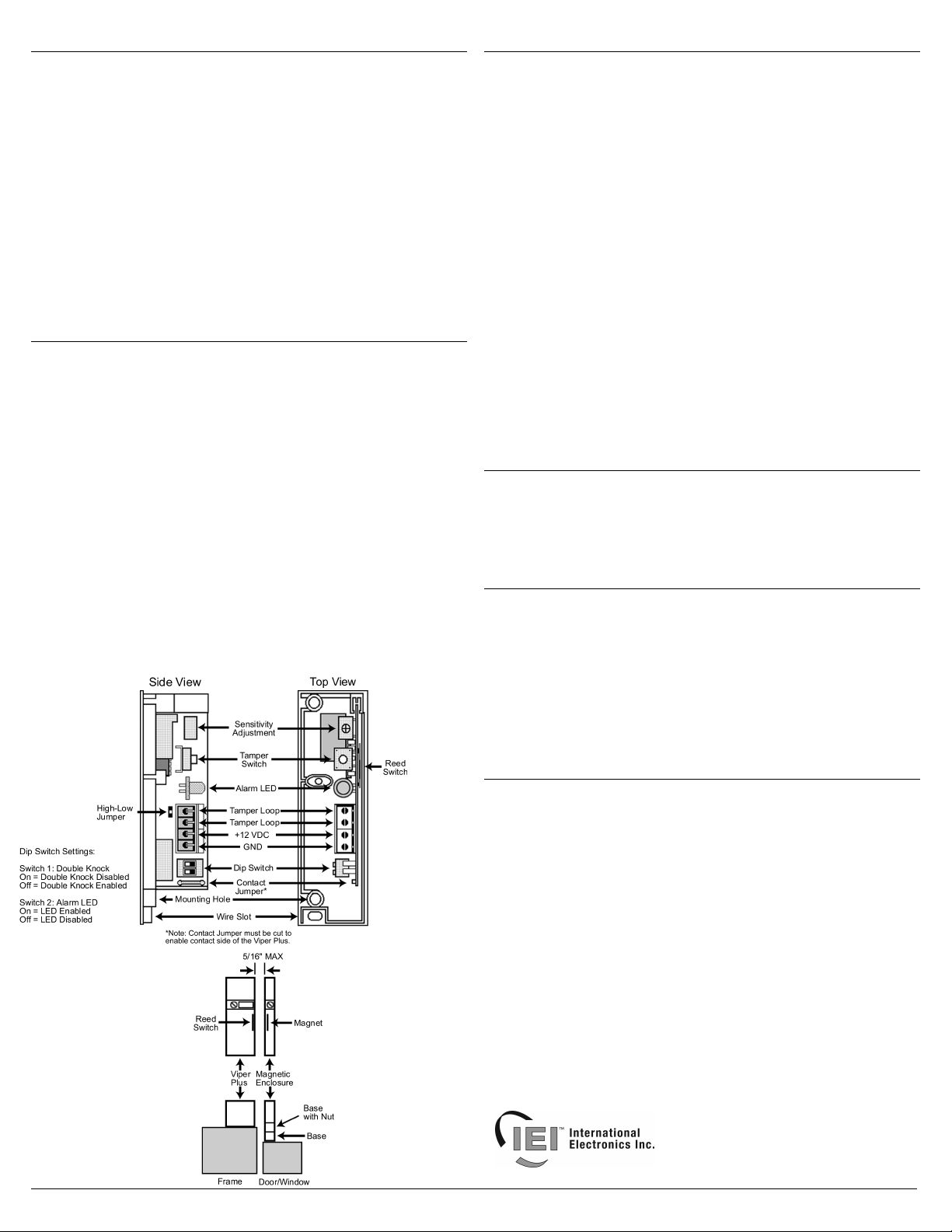

Mounting the Viper Plus

Mount the Viper Plus on the door or window frame, as shown in the illustrated

examples. Do not install across structural members or at joints in construction

in frames or bridge any other two components in a structure. Make sure you

mount the Viper Plus on a flat surface, clear of bumps or grit. Also verify the

mounting surface is in good physical condition with no loose or rattling parts.

You must take additional care when installing in areas accessible to the

public. In areas where protection is required for larger areas and low

sensitivity desired for better false alarm rejection (such as windows adjacent

to a public sidewalk) use two Vipers.

To remove the cover, unscrew the retaining screw on the front. The unit

consists of two pieces, the cover and the base plate with the circuit board.

Position the base plate on the surface and mark the mounting holes. The selftapping screws are suitable for most materials. For metal frames, drill a 3/32”

pilot hole. Be careful not to damage the circuit board in the base plate when

driving screws.

Note: When mounted, the cover must not make contact with another surface.

Wiring the Viper Plus

You can run the wires either through the back of the base plate using the wire

slot (for concealed wiring - see diagram), or through the bottom of the cover

using the rubber grommet. To use the grommet you must cut out the area on

the bottom of the cover indicated by the indentations on the inside.

When mounting vertically install the Viper Plus so the wires enters from the

bottom of the unit, to prevent water entry. When mounting horizontally,

remember to add a drip to loop to prevent water from running along the wires

and entering the case.

The diagram below shows the four terminal strip connections. Attach power

leads to +12VDC and GND terminals. When connecting the power, you must

observer polarity. Also, use a filtered and regulated power supply, with at

least four hours of standby time. You should also provide a switch or other

circuit to interrupt power to reset a latched alarm LED (if selected).

Attach a normally closed loop, from your control panel, to the remaining

tamper loop terminals. These are “open” until the Viper Plus is powered up.

The cover tamper switch and magnetic reed switch are in series with the

alarm relay circuit. These must be in place for the circuit to close.

When finished wiring, secure the cover onto the base plate and turn on the

power.

Document # 6103400, Rev. 3.1

Calibrating the Viper Plus

The Viper Plus has a test feature that eliminates the need to manually reset

power during testing. The first time you trip the Viper Plus there is an 8

second delay before the LED turns on (the relay opens for 8 seconds as it

normally does). After the first trip the LED remains on and shows each

subsequent trip by turning off for 8 seconds. When finished with testing,

interrupt power to reset the LED for normal operation. To disable the LED

turn dipswitch 2 off.

You should set the sensitivity as low as possible to reduce the change of false

alarms. The Viper Plus has a High-Low jumper setting to increase or

decrease its sensitivity. With the jumper in place, the Viper is set for Low

sensitivity mode. By removing the jumper, the Viper becomes more sensitive.

To set the sensitivity, use the IEI-815 calibration tool. This device puts a

predetermined amount of shock into the window or doorframe. If you don’t

have the IEI-815 tool, simply protect the surface and impact it with a hard

object like a small hamper or the back of a screwdriver, taking care not to

damage the surface.

Trip the Viper Plus at the limit of protection desired. Remember that the Viper

Plus will respond to one large blow or several small ones. Where it’s likely

that more than one blow is required to breach a window or door, apply several

“hits” of the IEI 815 within an 8 second period to simulate the shock to set the

sensitivity. Calibrate around the extremities of the area and progressively

decrease sensitivity by rotating the sensitivity adjustment potentiometer

counter clockwise. When you reach a point where the Viper Plus no longer

trips, slightly increase the sensitivity until the LED response is obtained.

DO NOT USE THE CALIBRATION TOOL DIRECTLY ON GLASS!

Double Knock Setting

For increased resistance to false alarms use the “double knock” feature.

After the initial shock, the Viper Plus continues to analyze the signal for

another 8 seconds. If another large shock or several smaller ones occur

within the next 8 seconds the Viper Plus goes into alarm. To enable this

feature set dipswitch 1 to off. This feature is ideal for laminated and

bulletproof glass.

Additional Mounting Instructions

You must mount the magnet enclosure within 5/16” of the Viper Plus and

locate it on the right side of the Viper Plus. As shown in the diagram, the

magnet inside the enclosure lies adjacent to the reed switch located on the

rear of the circuit board.

You must mount the magnet enclosure so the face of it lines up with the face

of the Viper Plus as close as possible. You can vary the height of the magnet

enclosure by adding the spare bases supplied.

One of the three supplied bases has a nut inserted into the middle hole. The

magnet enclosure cover must screw directly into this one. The other two

bases are used to extend the height and these are held in place by the two

mounting screws.

IEI Limited Warranty

Because the manufacturer does not install or connect this security device the

manufacturer cannot guarantee its performance. Therefore, there are not

warranties, expressed or implied (except as stated below), attached to the

sale of this product.

The manufacturer warrants against defects in material an workmanship in this

device for 3 years from the date of manufacture. During the warranty period

the manufacturer, at its sole option, will repair or replace free of charge any

defective unit returned freight prepaid. This warranty shall remain in force and

effect for 3 years provided the unit was properly installed and operated, has

not been subject to misuse and has not been repaired or altered other than by

the original manufacturer.

The forgoing states the buyer’s sole and exclusive remedy for any breach of

warranty or for any claim, whether sounding in contract, tort, strict liability, or

negligence, based upon any defect in this security device.

The manufacturer shall in no event be responsible for any incidental or

consequential damages incurred by the buyer.

This warranty supersedes all previous warranties.

International Electronics, Inc.

427 Turnpike St.

Canton, MA 02021

1-800-343-9502

www.ieib.com

Loading...

Loading...