Lincoln Electric LN-8, LN-9 User Manual

LN-8 and LN-9

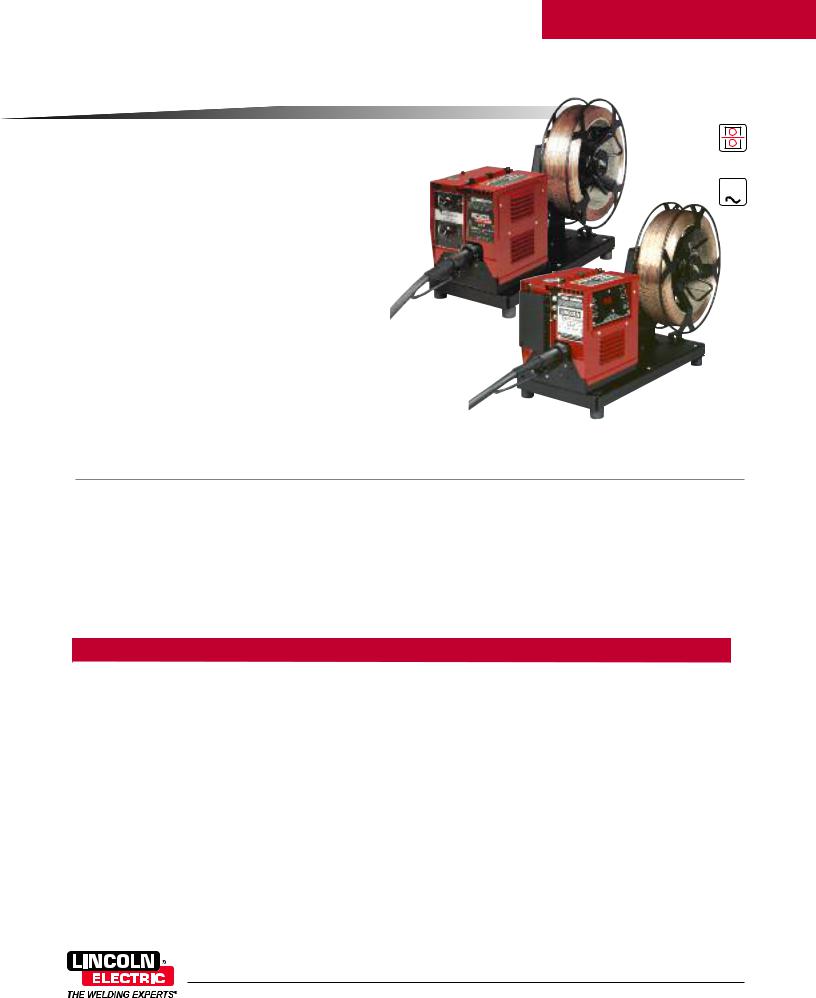

SEMIAUTOMATIC WIRE FEEDERS

Output

Semiautomatic Wire Feeders

The LN-8 and LN-9 are semiautomatic wire feeders providing dependable performance and reliable operation, making them ideal for shop or field operations. For precise wire feeding and quality welds, the LN-8 and LN-9 feature controlled wire feed speed and voltage during starting for clean, positive starts and reduced stubbing, skipping and spatter.

Solid state control compensates for wire drag and input line variations to maintain accurate wire feed speed. These wire feeders are easy to use with a quick release gun and cable connection for easy set up, and large wire feed and voltage control knobs that are easy to adjust with gloved hands.

Processes

Flux-Cored, Submerged Arc

LN-8

LN-9

LN-8 and LN-9 shown with options.

Input

115

VAC

Advantage Lincoln

•Completely enclosed case protects the heavy duty wire drive mechanism from damage, yet allows easy access to drive rolls.

•Rugged and durable design recognized throughout the industry for its long life and years of trouble-free wire feeding.

•Solid state control compensates for wire drag and input line variations to maintain accurate wire feed speed.

•Standard digital meter can be set to read volts, inches or meters/minute on the LN-9.

•Control of wire feed speed and voltage at the wire feeder eliminates the need to return to the power source to adjust procedures.

•Three-year warranty on parts and labor. Two-year extended warranty available in the U.S.

TECHNICAL SPECIFICATIONS

|

|

|

|

Wire Feed |

|

Wire Size |

|

Dimensions |

Net |

Product |

Product |

Input |

Output Capacity |

Speed Range |

|

Range |

|

H x W x D |

Weight |

Name |

Number |

Power |

Current/Duty Cycle |

ipm (m/min) |

|

in. (mm) |

|

in. (mm) |

lbs. (kg) |

|

|

|

|

|

Cored |

Solid |

Hardfacing |

|

|

LN-8 |

K297 |

115 VAC |

600A @ 60% |

50-600 |

.045-.120 |

.040-3/32 |

7/64 |

10.9 x 9.8 x 9.6 |

36 |

|

|

50/60 Hz |

|

(1.3-15.2) |

(1.2-3.0) |

(1.0-2.4) |

(2.8) |

(227 x 248 x 244) |

(16.2) |

LN-9 |

K357-1 |

|

|

|

|

|

|

11.5 x 11.3 x 11.5 |

42 |

|

|

|

|

|

|

|

|

(292 x 287 x 292) |

(19) |

|

|

|

|

|

|

|

|

|

|

Publication E8.30 08/08

www.lincolnelectric.com

A CLOSER LOOK

FEATURES

•Large wire feed speed and voltage controls that are easy to adjust with gloved hands.

•Can be boom mounted or use optional Universal Wire Reel Stand, Casters, and/or Swivel Platform and mount on power source for extra versatility.

Key Controls

A)Lockable Control Panel Cover

B)Digital Meters on LN-9

C)Voltage Control

D)2-Step Trigger Interlock

E)Amperage Control

F)Gun Trigger Connector

G)Wire Feeding Direction Switch

C

B |

D |

|

LN-9

E

A

F

•Compatiblewith many Lincoln Electric power sources including the CV-400,CV-655,DC-400, DC-600, DC-655, Ranger® 250, Classic® 300, Ranger® 305, Vantage® 300, Vantage® 500, and

Air Vantage® 500.

•Optional burnback kit provides adjustabledelay of power source output shut off to prevent the electrodefrom sticking in the weld metal when using high wire feed speeds.

LN-8

G

REQUIRED OPTIONS

|

|

|

DRIVE ROLL AND GUIDE TUBE KITS |

|

|

CONTROL CABLES |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Steel Wire Sizes |

LN-8 and LN-9 |

|

Cable Type |

|

Description |

|

||||

|

Solid Wire: |

|

|

Wire Feeder Control Cable |

|

|

||||||

|

|

.040, .045 - .052 (1.0 - 1.4 mm) |

KP502-052 |

|

K1820-10 |

|

Male 9 pin to female 14 pin |

|||||

|

|

1/16 (1.6 mm) |

KP502-1/16 |

|

Wire Feeder Control Cable Extensions |

|

|

|||||

|

Cored Wire: |

|

|

|

|

|||||||

|

|

|

K1797-10 - 10 ft. (3.0 m) |

Male 14 pin to female 14 pin |

||||||||

|

|

.045 - .052 (1.0 - 1.4 mm) |

KP502-052C |

|

K1797-25 - 25 ft. (7.5 m) |

|

|

|||||

|

|

1/16 - .062 (1.6 mm) |

KP502-1/16C |

|

K1797-50 - 50 ft. (15.2 m) |

|

|

|||||

|

|

7/64 - .120” (2.8 - 3.0 mm) |

KP502-120 |

|

K1797-100 - 100 ft. (30.4 m) |

|

|

|||||

|

Solid or Cored Wire: |

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

||||||

|

|

.068 - 3/32” (1.7 - 2.4 mm) |

KP502-3/32 |

|

|

|

|

|

||||

|

|

|

WELD POWER CABLES |

|||||||||

|

Hardfacing: |

|

|

|

||||||||

|

|

|

|

|

|

|

||||||

|

|

7/64” (2.8 mm) |

KP502-7/64H |

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

Order No. |

Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

K1840-10 |

Twist-Mate™ to Lug, 1/0, 350A, 60% duty cycle, 10 ft. (3.0 m) |

||

|

|

|

|

|

|

|

|

|

K1842-10 |

Lug to Lug, 3/0, 600A, 60% duty cycle, 10 ft. (3.0 m) |

||

|

|

|

|

|

|

|

|

|

K1842-35 |

Lug to Lug, 3/0, 600A, 60% duty cycle, 35 ft. (10.6 m) |

||

|

|

|

|

|

|

|

|

|

K1842-60 |

Lug to Lug, 3/0, 600A, 60% duty cycle, 60 ft. (18.2 m) |

||

|

|

|

|

|

|

|

|

|

K1842-110 |

Lug to Lug, 4/0, 600A, 60% duty cycle, 110 ft. (33.5 m) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LN-8 and LN-9 |

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

[2] |

|

|

www.lincolnelectric.com |

|

|

|

|

|

|

|

|

|

|

|

|||

Loading...

Loading...