Lincoln Electric AC-DC1000 User Manual

For over 50 years, Lincoln

Electric has offered its

Submerged Arc Welding (SAW)

customers high deposition rates,

reliable penetration, and smooth

bead appearance.

Now, Lincoln brings you the first

advance in SAW technology that

provides the option of variable

polarity. Changes in the balance

of positive and negative polarity

of the AC waveform enable the

operator to change penetration

and deposition, without changing

the current or voltage settings.

Lincoln’s AC/DC Submerged Arc

process with the Power Wave

power source gives the operator

real-time control. Instead of

making a weld, stopping and

re-programming the new

parameters, and running a test

weld to make sure they worked,

changing the face of a weld is as

easy as turning a knob.

MODULAR

The Power Wave AC/DC1000 is designed for easy paralleling, overcoming the

problems typically associated with synchronization of AC waveforms for

increased amperage applications.

MULTI-ARC

AC/DC welding is designed for applications that require up to five

independently controlled welding arcs.

EASY INTEGRATION

Digital Communications provide a simple solution for the integration of the

welding power source to the motion controlling Programmable

Logic Controller (PLC).

INCREASED PROCESS CONTROL

Digital Communications also enable the use of software tools to record the

actual welding values for each weld as well as monitoring the status of the

welding system.

WAVEFORM CONTROL TECHNOLOGY

The Power Wave AC/DC 1000 is equipped with factory-programmed

procedures for fast setup.

AC/DC Submerged Arc Welding

PROCESS

WAVEFORM CONTROL TECHNOLOGY

®

The Power Wave

®

AC/DC 1000™ takes Submerged Arc Welding to the next

level. In addition to conventional benefits of SAW, such as high deposition

rates and good penetration, heightened control and faster responses to

the arc are unique to the design of the Power Wave

®

AC/DC 1000™.

NX-2.30 3/06

The future of welding is here.

®

advantages

© Copyright 2006 The Lincoln Electric Company. All rights reserved.

Patented. This product is protected by one or more of the following United States patents: 6,809,292;

6,795,778; 6,700,097; 6,697,701; 6,683,278; 6,660,966; 6,600,134; 6,683,278; 6,596,570; 6,570,130;

6,536,660; 6,489,952; 6,472,634; 6,636,776; 6,486,439; 6,441,342; 6,365,874; 6,291,798; 6,207,929;

6,111,216; 4,927,041; 4,861,965 and other pending U.S. patents. Similar patents are maintained in

other countries.

Improves Productivity, Quality and Safety

PROCESS

2/6

AC/DC Submerged Arc Welding

A Submerged Arc Welding

(SAW) option that combined

the advantages of AC and DC

SAW welding was not possible

until now.

A Lincoln inverter power

source coupled with Waveform

Control Technology provides

control over the ratio of

positive to negative amplitude,

as well as the amount of time

spent at each polarity.

The limiting factor for SAW AC

welding has always been that

it takes too long to cross from

electrode positive (EP) to

electrode negative (EN). This

lag can cause arc instability,

penetration, and deposition

problems in certain

applications.

The Lincoln Power Wave

AC/DC 1000 with Waveform

What

Is AC/DC Submerged Arc?

The AC/DC Submerged Arc Process

How

AC/DC Submerged Arc Works in a Single Arc Environment

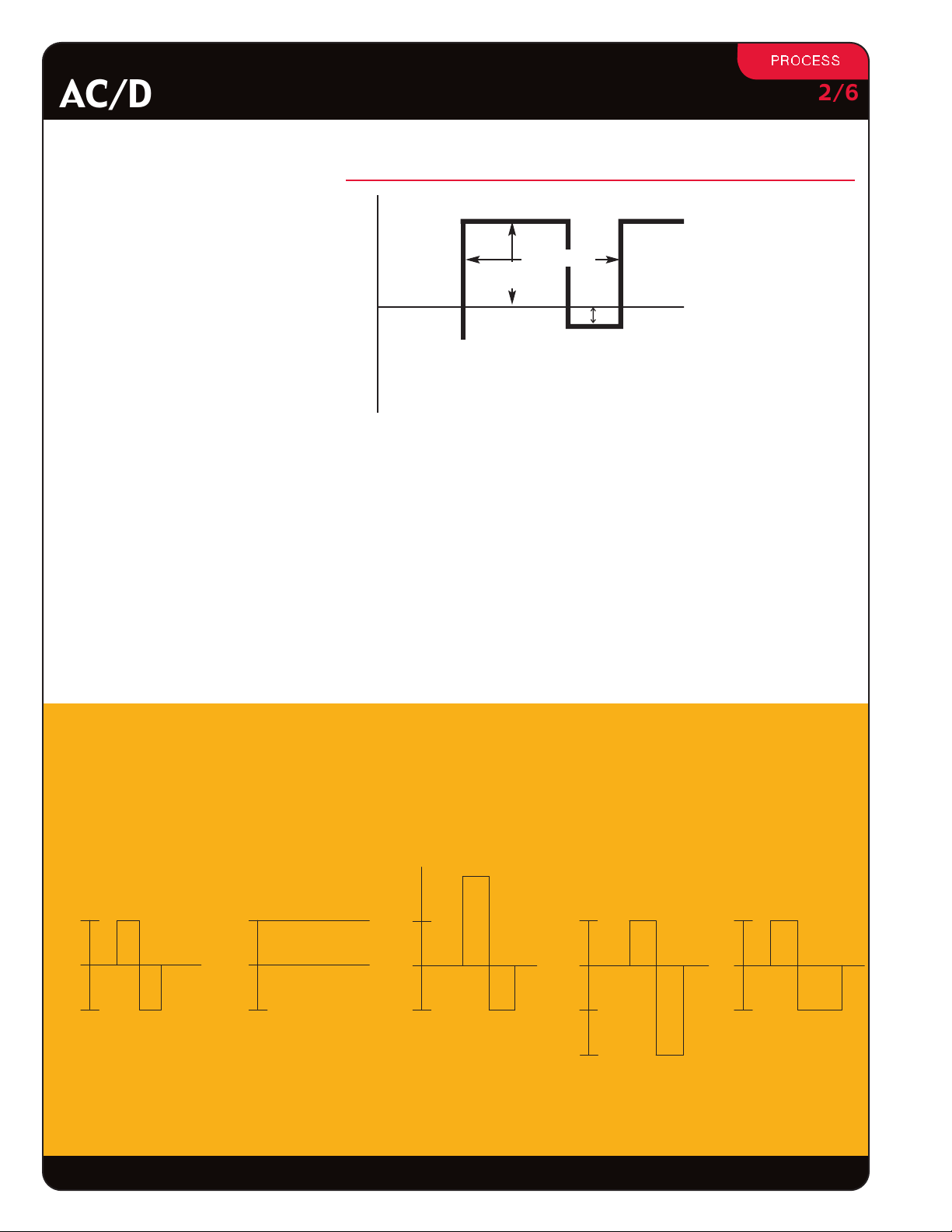

A balanced AC process

uses a combination of DC

positive and DC negative

amperage.

WAVEFORM CONTROL TECHNOLOGY

®

The future of welding is here.

®

Increasing the positive

amplitude of the

waveform increases

penetration.

Increasing the amplitude or time

balance of the negative amplitude

increases deposition and

decreases penetration.

Waveform Control Technology gives the operator the ability to change the positive and negative amplitude and

time intervals independently of each other, to achieve the penetration and deposition rate that suits their

application. In other words, if a weld requires greater penetration and reduced deposition, the operator would

add a positive DC offset, forcing an imbalance in the waveform. Adding negative current results in higher

deposition rates. Changing the balance of the positive or negative time intervals provides additional penetration

or deposition control.

500

-500

0

500

-500

0

500

-500

0

1000

500

-500

0

-1000

Current

Time

The above waveform represents the possible variations of an

AC/DC waveform with Waveform Control Technology.

Different parts of the waveform and wire feed speed may be

modulated at varying rates to achieve a smooth, stable arc.

Frequency

Positive

Current

Negative Current

+

500

-500

0

Adding positive or

negative DC offsets

change the deposition

and penetration

characteristics.

Control was designed specifically to

solve this problem, allowing the

operator to take full advantage of the

reduction in arc blow experienced with

AC, while maintaining the penetration

advantages of DC positive and the

advantageous deposition rate of DC

negative. Using these controls, the

shape of the output waveform is

changed, and in turn the welding

characteristics are controlled.

With the Power Wave AC/DC 1000,

you get the best of both worlds: the

speed, deposition rate, and penetration

that DC SAW offers, and the

resistance to arc blow that AC SAW

offers. In single arc processes, the

Power Wave AC/DC 1000 provides

flexibility with Waveform Control

Technology. In multiple arc processes,

that same flexibility is achieved

through control of phase shifting

between arcs.

=

Loading...

Loading...