Lightolier CAM250ND User Manual

Addressable Track Dimming Module Lytespan® Track Lighting System CAM25OND

Page 1 of 2

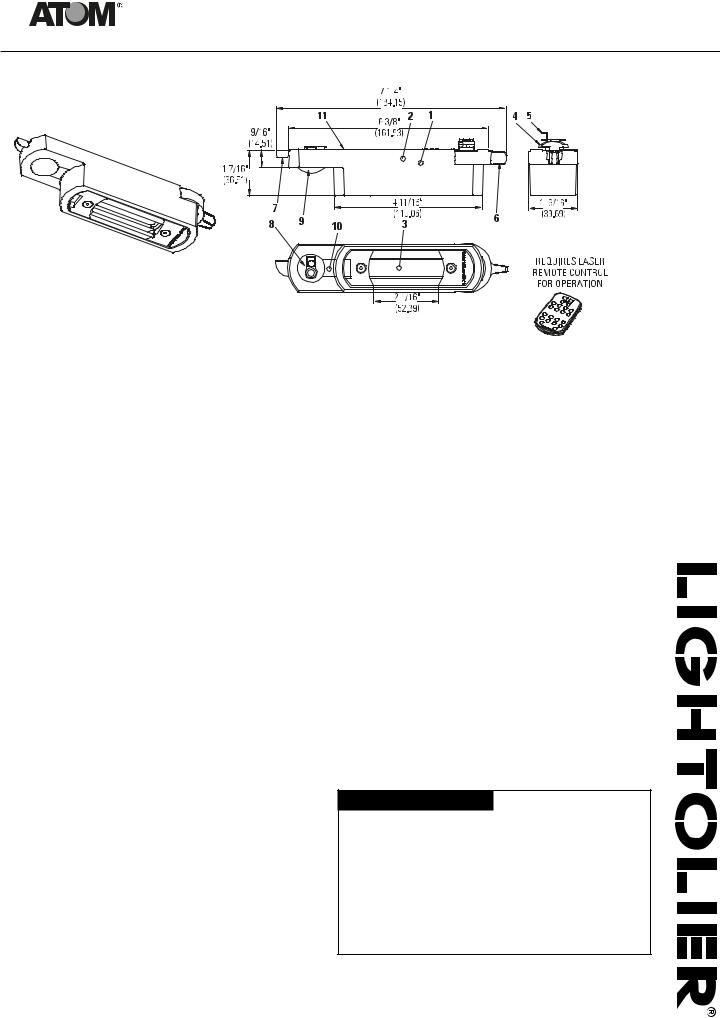

( ) Denotes Dimensions in MM

CAMLRC

Ordered separately

Ordering Information

Catalog No. |

Finishes |

Track Mounting |

Luminaire Compatibility |

CAM250NDWH |

Matte White |

Compatible with Lytespan Basic®, Radius®, |

Any Lytespan incandescent line voltage, incandescent |

CAM250NDBK |

Matte Black |

& Advent® (when used on one circuit) Track Systems, |

low voltage, metal halide, & fluorescent luminaire, 250W |

|

|

DO NOT USE with Extension Wands, Sloped Ceiling |

MAX. DO NOT USE with Power Jack, Sof-Tech Metal |

|

|

Adapter, All Monopoints, & Prospec Track. |

Halide Lytespots, Powerwash T5 Track Mount, Lyteflood |

|

|

|

L40 & L39, or Convenience outlet Units. |

|

|

|

|

Description

Individually addressable module that mounts anywhere along the track and accepts any Lytespan Line & Low Voltage Incandescent, fluorescent, and metal halide luminaire (see luminaire compatibility for exceptions) for the purpose of addressing a selected single luminaire for switching On/Off, while powered by the same track. Programmable to store desired light levels (On or Off) of single luminaires or to group with two or more luminaires within the same system for the purpose of creating light scenes and effects.

Features

1.Module Housing: High-temperature impact resistant thermoplastic.

2.PCB: High temperature resistant programmable electronics with smart module microprocessor.

3.Basic Lytespan Track Strip: Die cast aluminum, with high-temperature impact resistant thermoplastic insulator, supporting electrical contacts. Accepts Lytespan luminaires for individual control.

4.Track Attachment Fitting: High-temperature impact resistant polycarbonate, rotates into track; integral polarity keyguard.

5.Moveable Brass Contact: Extends for 2nd circuit in two circuit Lytespan track systems.

6.Attachment Lever: Impact resistant polycarbonate.For mechanical/ electrical connection to track.

7.Locking Lever: Steel, safety locking lever locks and supports module in track.

8.IR & Laser Sensors: Sensor devices for receiving information from ATOM Remote Control.

9.Sensor Cover: Clear Polycarbonate, protects sensors from damage.

10.LED: Red indicator light, provides visual response to operation modes.

11.Top Cover Heat Sink: Die cast aluminum, for structural support and heat dissipation.

Electrical

Unit is polarized and continuously grounded throughout. 250W load capacity.

Options & Accessories

ATOM Track Master Module (CAMTM): Used on track to cycle Module scenes & to send out signals to multiple modules from a single location on the track.

ATOM Wall Remote Control (CAMWRC): Used to activate programmed scenes from wall location.

Lightolier Controls COMPOSE™ PLC In-Line Filter (CPLCILF20):

Recommended for each track circuit with an ATOM installation. Reduces unwanted electrical noise on track circuit.

Lightolier Controls COMPOSE™ Firewall, 4 & 8 circuit (CPLCFW4, CPLCFW8): Used when multiple circuits are to be controlled.

Lightolier Controls COMPOSE™ Master Control Station (CP5ESPLC):

Ellipse Series 5, Scene Master

The ATOM System is compatible with all Lightolier Controls COMPOSE™ PLC system.

Labels

UL, cUL, Patent Pending

Job Information |

Type: |

Job Name:

Cat. No.:

Lamp(s):

Notes:

Lightolier a Genlyte company www.lightolier.com 631 Airport Road, Fall River, MA 02720 • (508) 679-8131 • Fax (508) 674-4710 We reserve the right to change details of design, materials and finish.

© 2005 Genlyte Group LLC • C0705

Loading...

Loading...