Page 1

Installation

Instructions

Refrigerators and freezers, built-in

Instructions

de montage

Réfrigérateurs et congélateurs,

encastrables

Instrucciones

de montaje

Frigoríficos y congeladores,

empotrables

R 1410/ RB 1410/ F 1051

301013 7084602 - 01

Page 2

General safety information

Contents

1 General safety information........................... 2

2 Setting up the appliance............................... 2

3 Planning information..................................... 4

4 Cabinet Opening Dimensions...................... 7

5 Air circulation in the kitchen cabinet........... 7

6 Door swing clearance................................... 8

7 Changing the door hinges............................ 13

7.1 Remove soft stop mechanism (top).................. 13

7.2 Remove soft stop unit (bottom)........................ 13

7.3 Remove door................................................... 14

7.4 Swapping bearing parts................................... 14

7.5 Swapping the handle........................................ 15

7.6 Fitting the door................................................. 15

7.7 Fitting the soft stop mechanism (bottom)......... 15

7.8 Fitting soft stop mechanism (top)..................... 16

7.9 Aligning the door.............................................. 16

8 Water connection........................................... 16

9 Anti-tip device................................................ 17

10 Single unit installation.................................. 17

11 Side-by-side installation............................... 20

12 Adjusting the door opening angle............... 24

13 Installing the water filter............................... 25

14 Connecting the appliance............................. 26

The manufacturer is constantly working to improve all

models. Therefore please understand that we reserve the

right to make design, equipment and technical modifications.

To get to know all the benefits of your new appliance,

please read the information contained in these instructions carefully.

The instructions apply to several models, so there may be

differences. Sections which only apply to certain appliances are indicated with an asterisk (*).

Instructions for action are marked with a

results of action are marked with a .

, the

-

The socket must be easily accessible so that

the appliance can be disconnected from the

mains quickly in an emergency. It must not be

behind the back of the appliance.

DANGER indicates a hazardous situation,

which if not avoided, will result in

death or serious injury.

WARNING indicates a hazardous situation,

which if not avoided, could result in

death or serious injury.

CAUTION indicates a hazardous situation,

which if not avoided, will result in

minor or moderate injury.

NOTICE indicates a hazardous situation,

which if not avoided, could result in

damage to property.

Note indicates useful advice and tips.

2 Setting up the appliance

WARNING

Risk of fire due to moisture!

If live parts or the power cord get wet, this can cause a

short circuit.

u

The appliance is designed for use in enclosed spaces.

Do not operate the appliance in open space or in damp

areas or where there is spray.

u

Only operate the appliance after it has been installed.

WARNING

Risk of fire due to short circuit.

If the power cable or plug of the appliance or another

appliance and the back of the appliance touch each other

the power cable or plug will be damaged by the vibrations

of the appliance which could lead to a short circuit.

u

Install the appliance so that it does not touch any plugs

or power cables.

u

Do not connect the appliance or other appliances to the

sockets on the back of the appliance.

1 General safety information

-

Read and follow these instructions. They

contain safety advice which is important for

Danger of fire and damage!

u

WARNING

Do not place devices that give off heat, e.g. microwaves, toasters, etc. on the appliance.

safe and problem-free installation and operation. Always read and follow the safety advice.

-

It is important that the guidelines and instructions in this manual are followed so that the

appliance is correctly installed and operates

Risk of personal injury!

u

CAUTION

Have two people move this appliance into place.

properly Read and understand all information

in this manual before the appliance is installed

2 * Depending on model and options

Page 3

NOTICE

Risk of damage caused by condensation

Installing the appliance next to any other refrigerator or

freezer can cause condensation or damage to the

Liebherr appliance.

u

Do not install this appliance next to any other refrigerator or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation.

They are equipped with a heating system to eliminate

condensation when refrigerators or freezers are

installed side-by-side.

NOTICE

Risk of damage for the finished floor surface!

u

Protect the finished floor surface before you uncrate the

unit.

Verify that:

q

The floor under the appliance is flat and level.

q

The floor can support the appliance's weight plus

approximately 1200 pounds (544 kg) of food weight.

q

The appliance is not placed in direct sunlight or near

the stove, range top, radiators and similar heat

sources.

q

The kitchen cabinet that the appliance is installed in is

shimmed to the floor level if the floor heights are not

equal.

Setting up the appliance

q

Cutout dimensions are accurate.

q

Electrical outlet is in correct location.

q

The air flow is not restricted. Air flow must be provided

for the appliance to operate properly. The factory air

vents provide 31 square inches (200 cm2) of air flow

per appliance. If you are replacing the air vents with an

overlay, the air flow must be the same or greater than

the factory air vents.

u

Examine the unit and packaging for shipping damage.

Contact the carrier immediately if you suspect there is

any damage.

u

Note the type (model, number), index, appliance/serial

number, date of purchase and where purchased .

u

Remove anything attached to the rear or side walls of

appliance that would prevent proper installation or

impede proper ventilation.

u

Remove the protective film from the outside of the

appliance.

Note

u

Clean the appliance .

If the appliance is set up in humid areas, condensation

may build on the outside of the appliance.

u

Always ensure proper ventilation.

u

Assemble appliances according to separate installation

instructions.

* Depending on model and options 3

Page 4

Planning information

3 Planning information

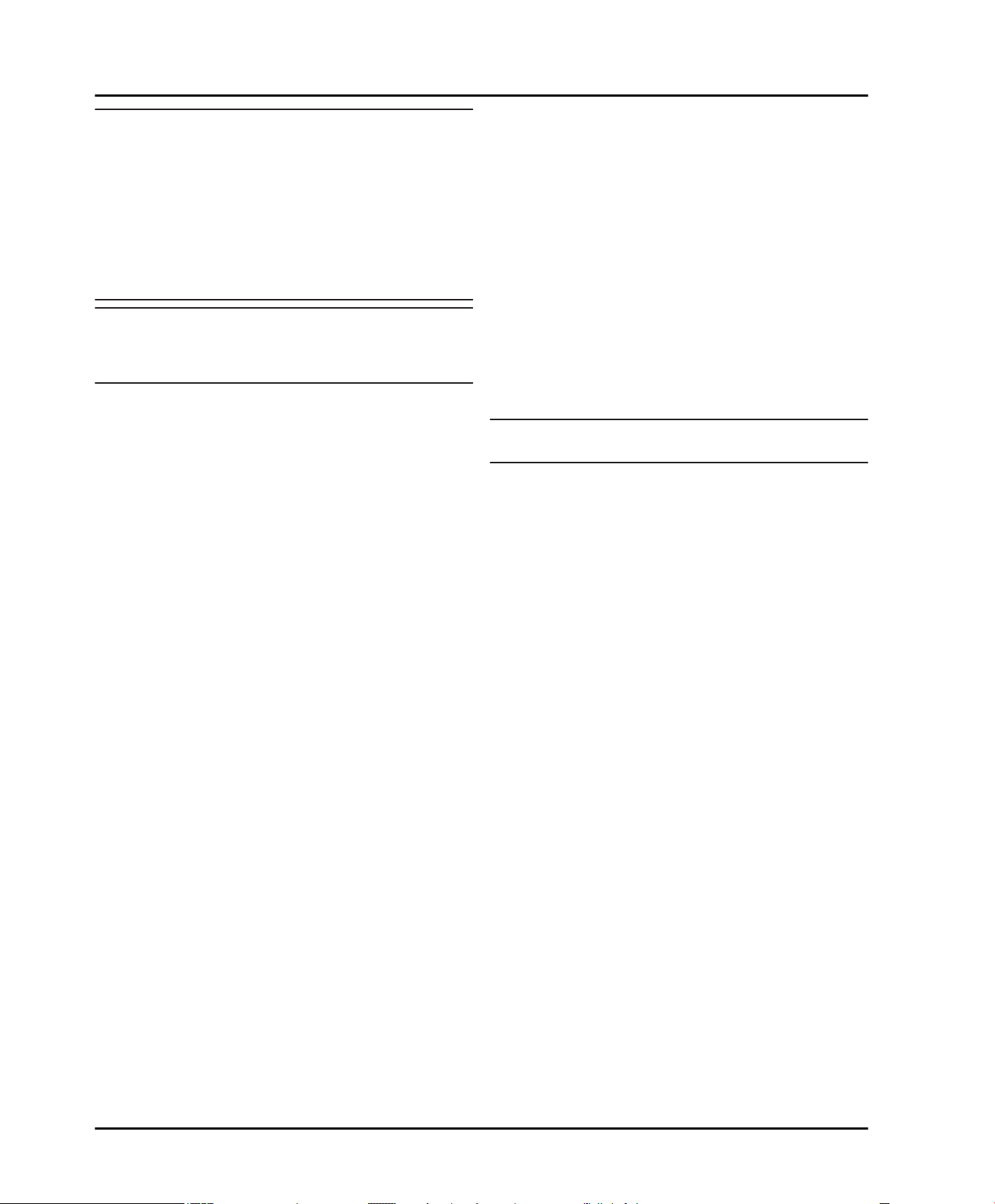

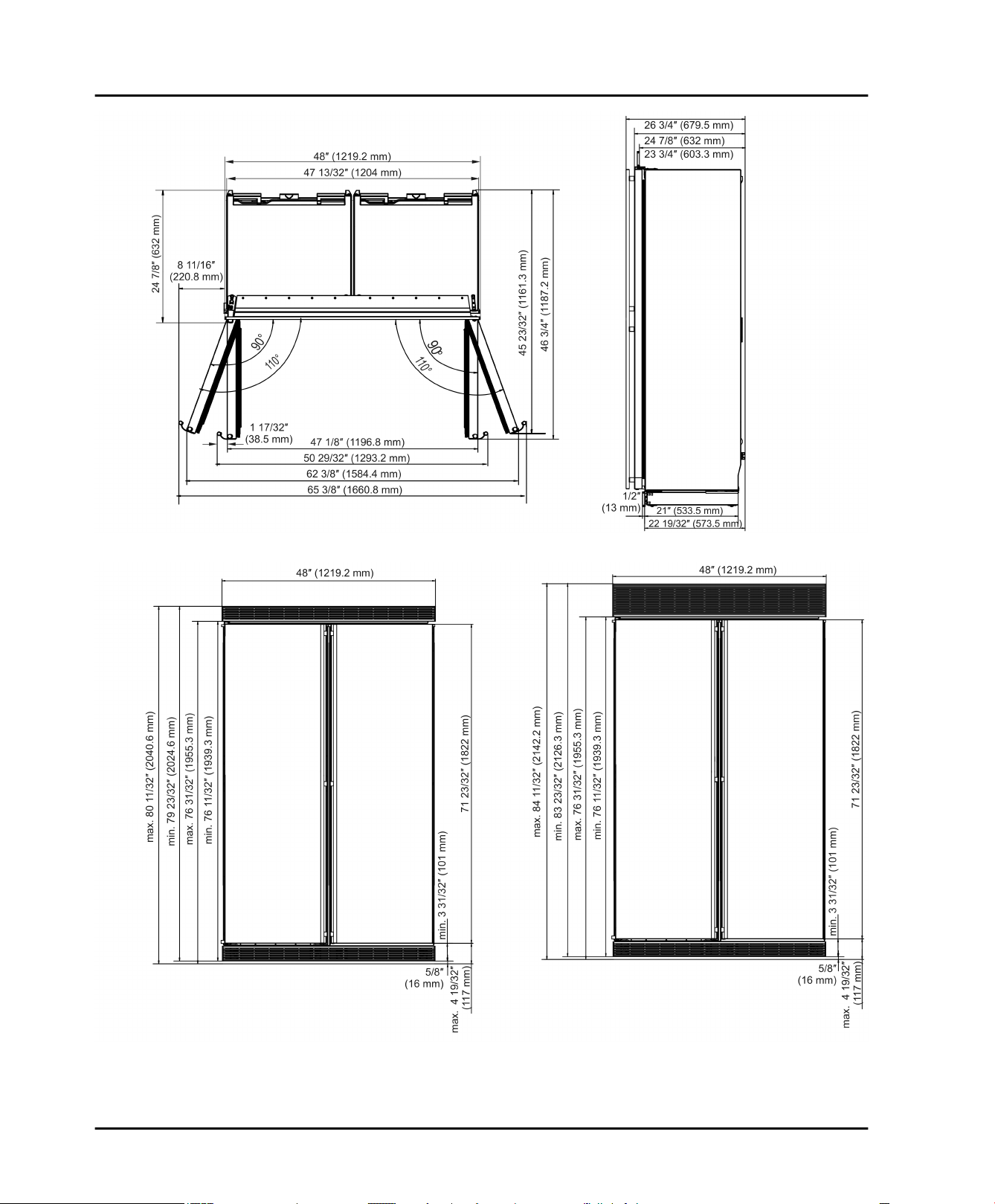

Fig. 1 Single-

unit installation

4 * Depending on model and options

Page 5

Planning information

Fig. 2 Side-by-side installation: SBS 241, SBS246, SBS 243

Fig. 3 Side-by-side installation: SBS 243 with 80” or 84” ventilation grille

* Depending on model and options 5

Page 6

Planning information

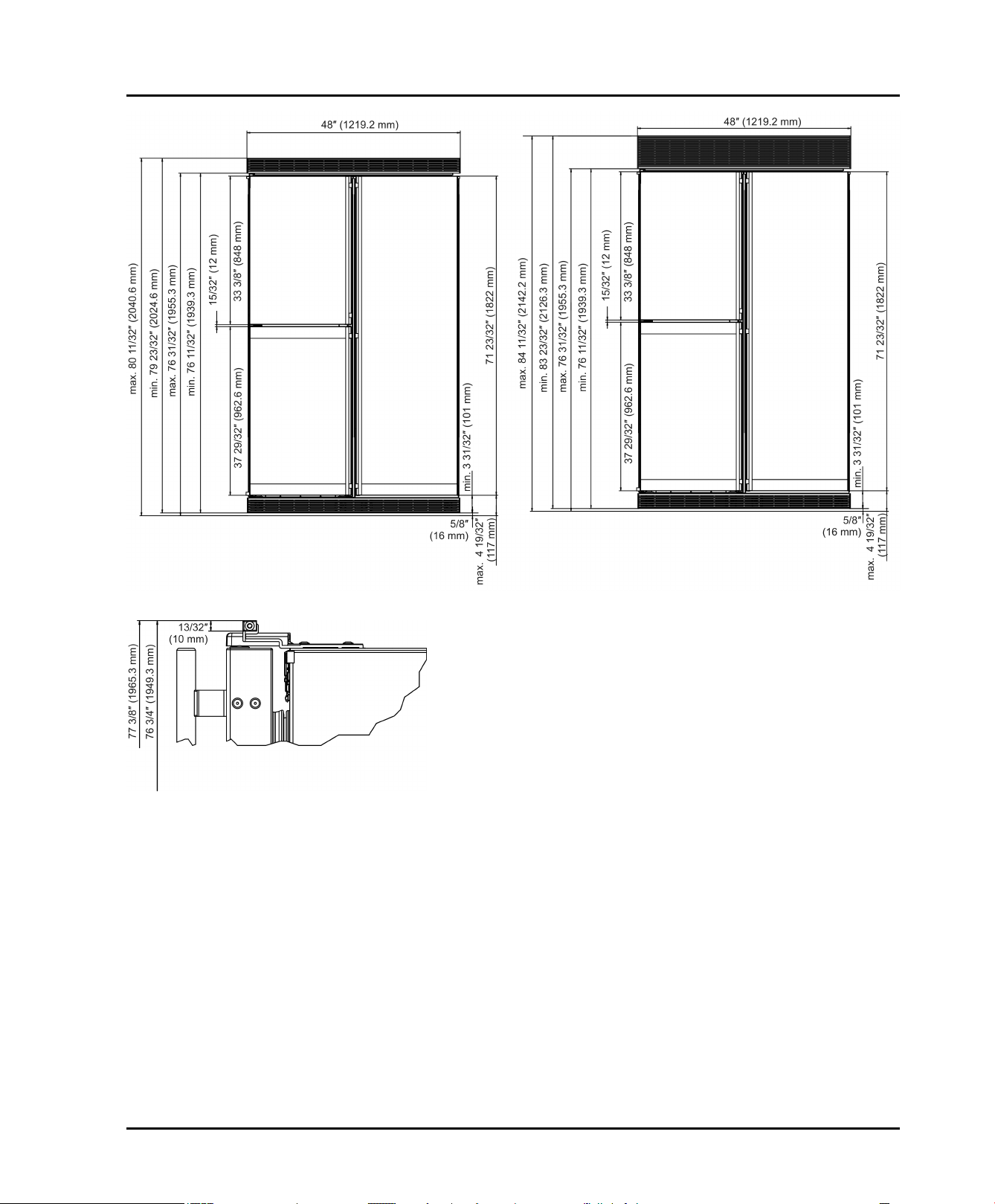

Fig. 4 Side-by-side installation: SBS 246 and SBS 241 with 80” or 84” ventilation grille

Fig. 5 Side-by-side installation: without ventilation grille

6 * Depending on model and options

Page 7

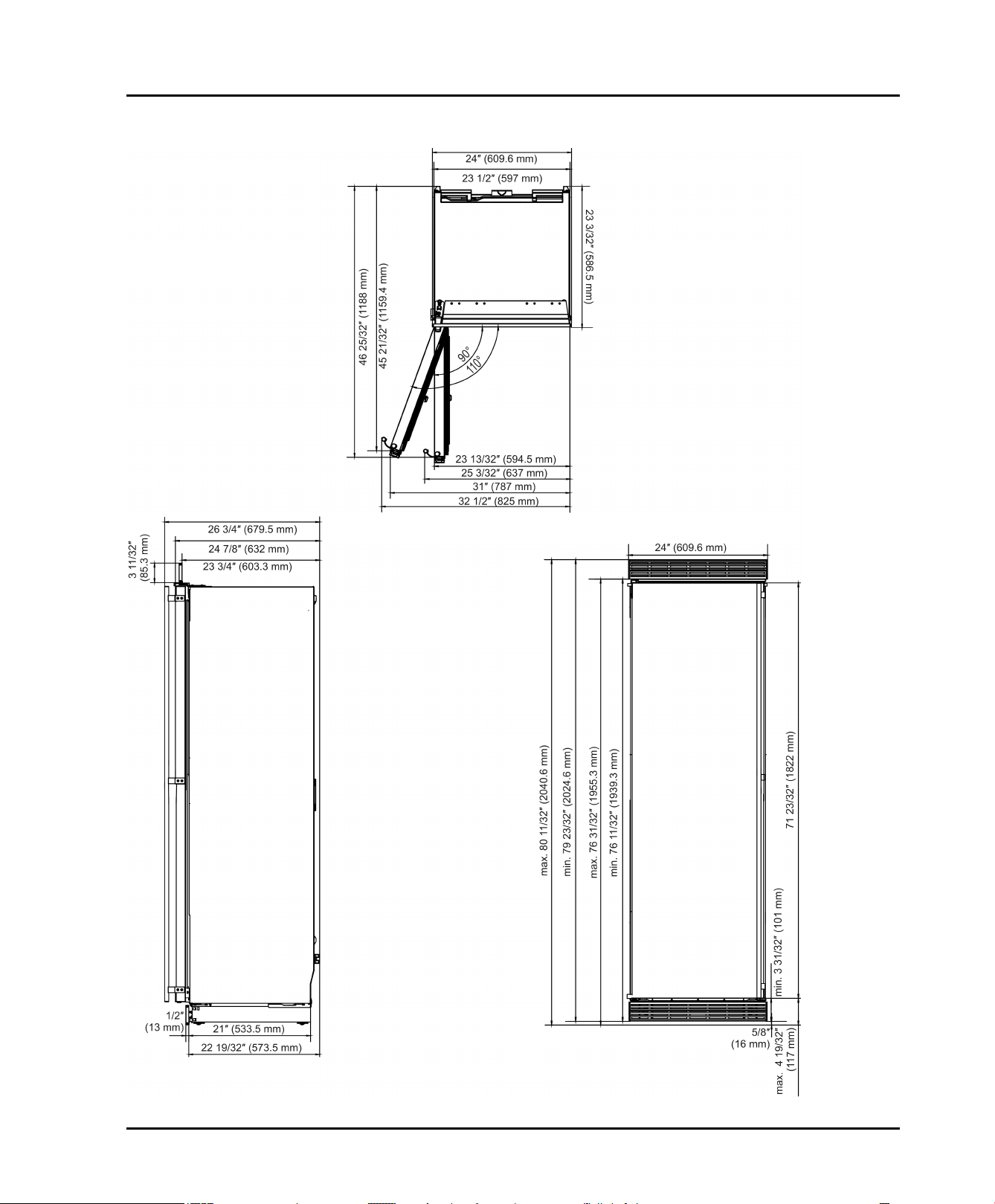

4 Cabinet Opening Dimensions

Cabinet Opening Dimensions

Fig. 6 Single installation

Fig. 7 Side-by-side installation:

The door must be able to be opened at least 90° to allow

the drawers to be pulled out properly. If the door opening

angle is 90° it may be difficult to remove the drawers due

to the door racks.

If the appliance will be installed in a corner please leave a

gap of at least 3-3/4 in. (95 mm) from the wall.

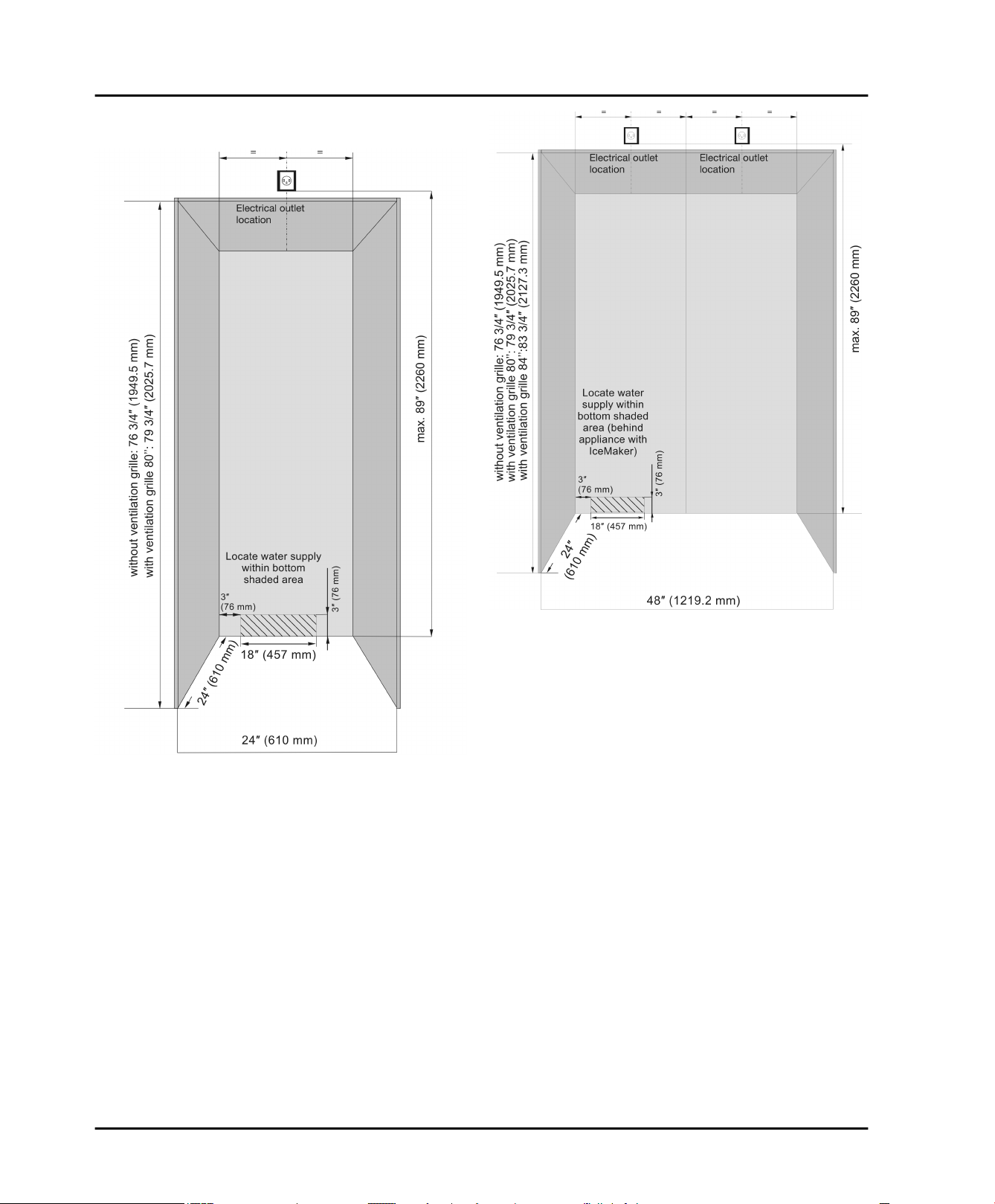

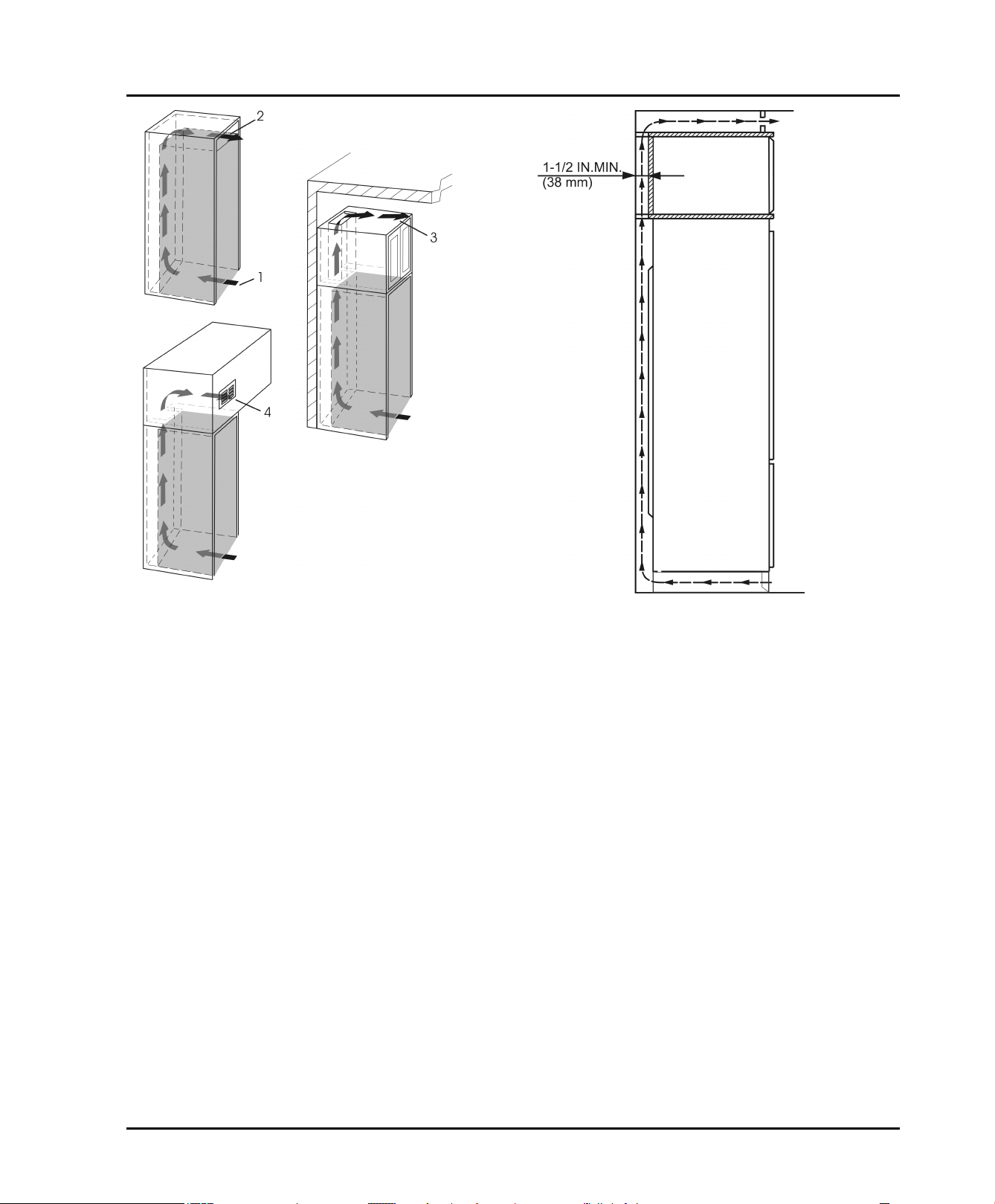

5 Air circulation in the kitchen cabinet

This is a built-in refrigerator-freezer with stainless steel

doors.

The unit is not intended for freestanding use and has to

be installed inside a cabinet. This type of cabinet must be

carefully constructed using the proper dimensions and it

must provide proper ventilation to ensure proper appliance operation.

* Depending on model and options 7

Page 8

Door swing clearance

Fig. 8

- An effective ventilation cross-section of at least 31 in

(200 cm2) per unit must be present at the air intake

Fig. 8 (1)

- The upper ventilation cross-section can be set up

directly above the appliance with an optional ventilation

grille

or as an air vent in an intermediate ceiling

and air outlet

Fig. 8 (2)

Fig. 8 (2)

, near the ceiling above a cabinet

.

Fig. 8 (4)

Fig. 8 (3)

.

2

- An unobstructed air way with a depth of at least

1 1/2 in. (38 mm) must be ensured at the back of the

kitchen cabinet.

u

The air-circulation clearances indicated above must be

maintained.

Fig. 9

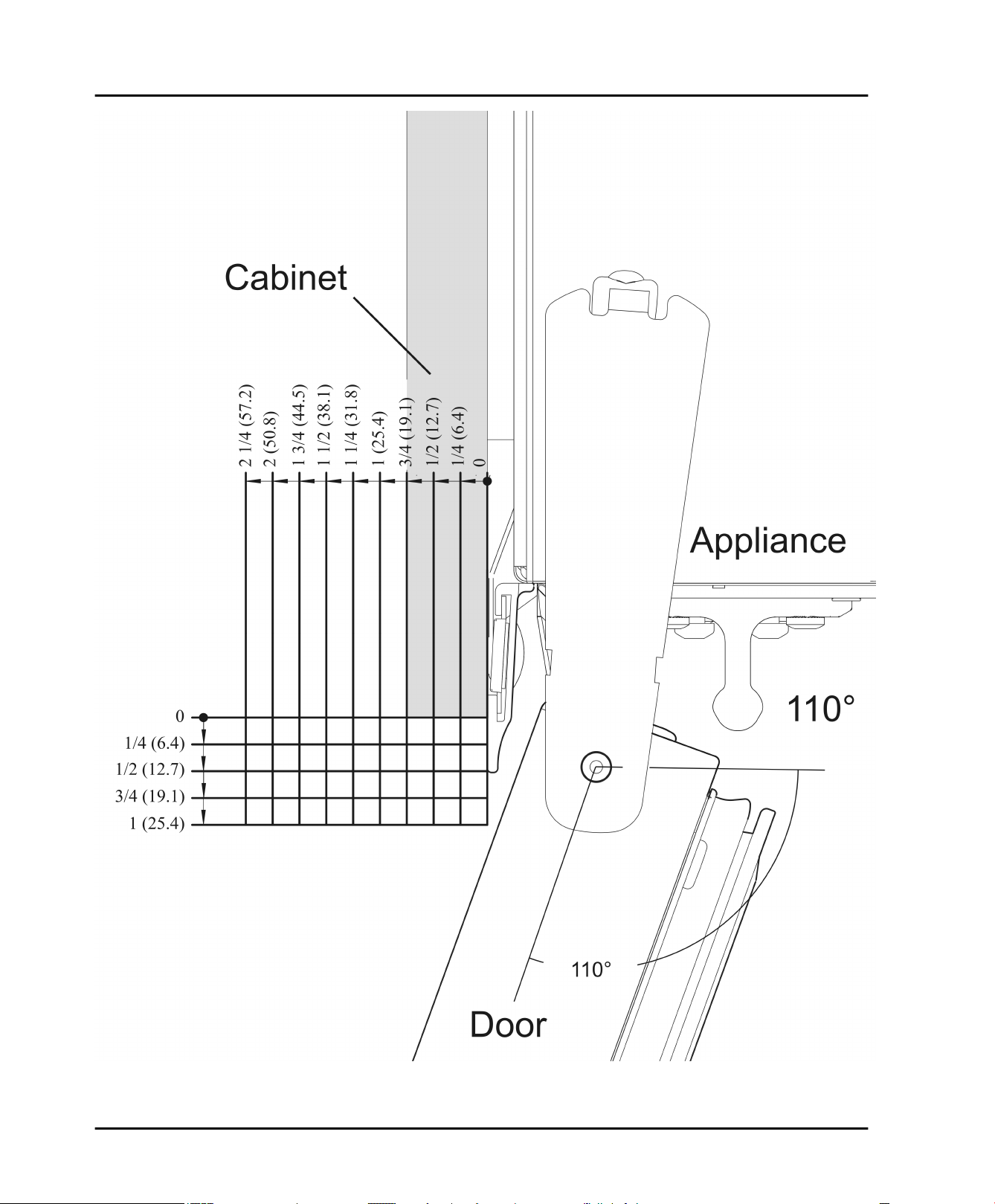

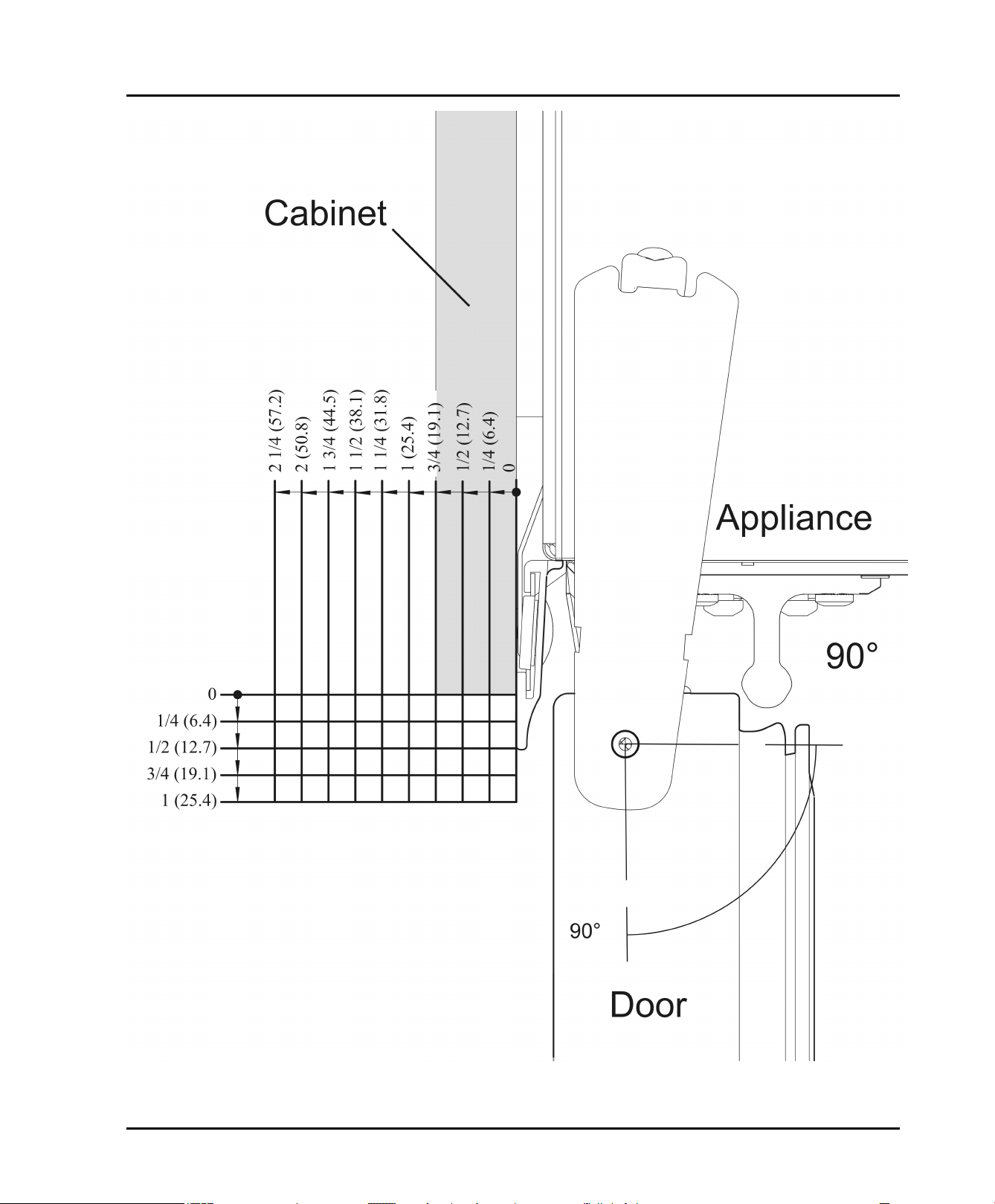

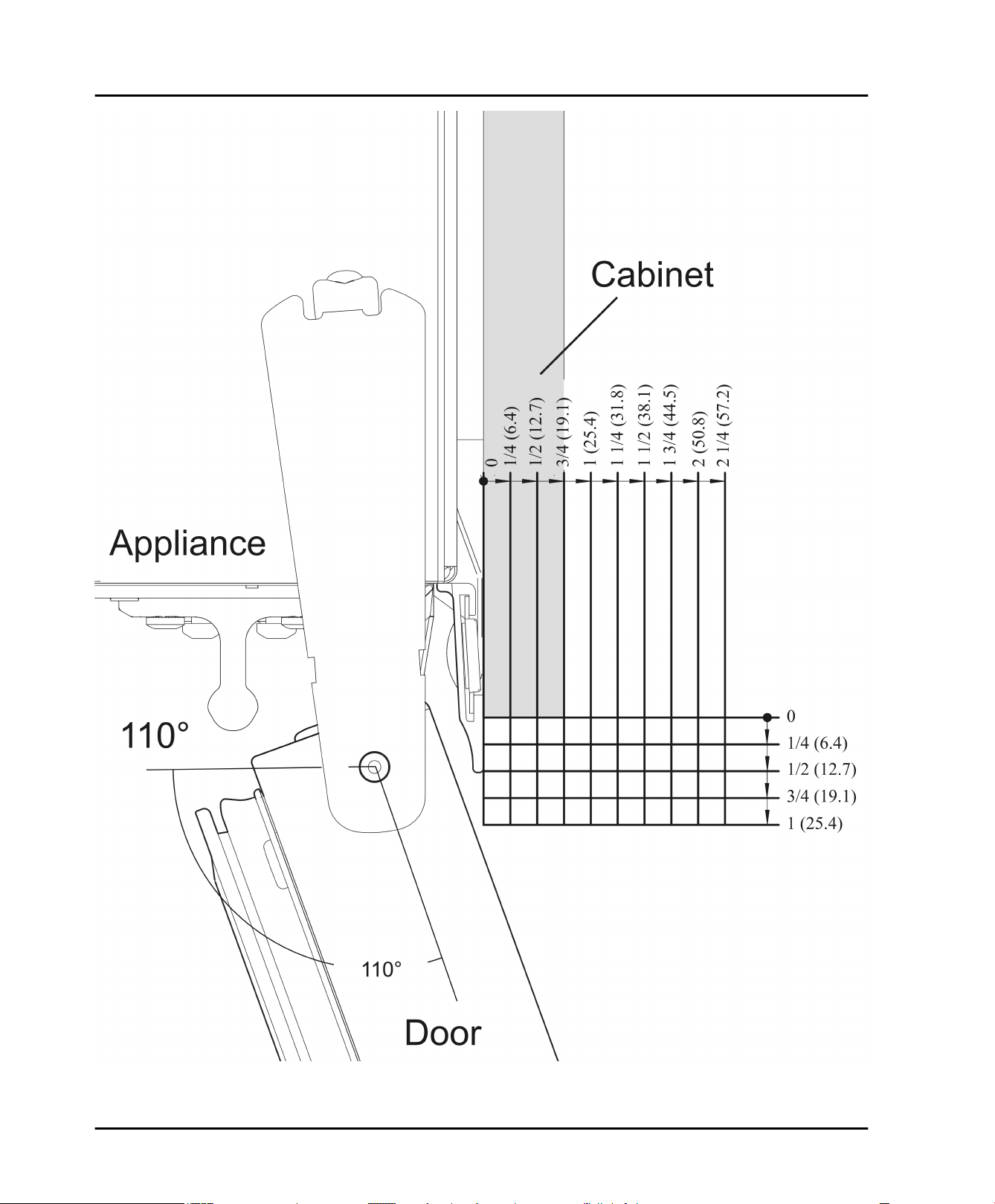

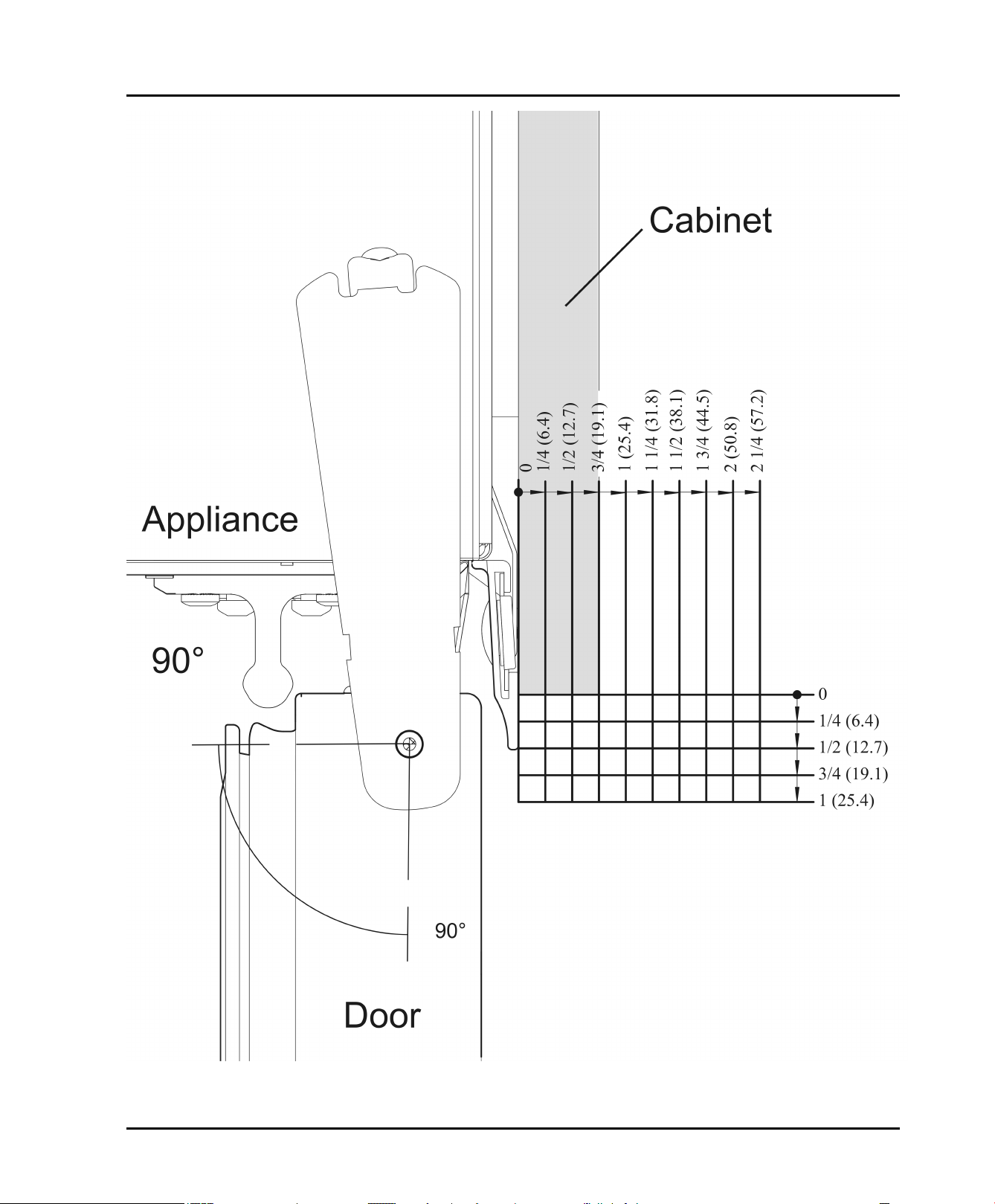

6 Door swing clearance

Frameless cabinets: The casing trim overlaps the cabinets at the side and top. Cabinets may require filler strips

to prevent interference with the cabinet door swing. The

door opening must allow for filler strips.

The factory setting for the door to swing open is 110°. The

optional setting for the door to swing open is 90°. Use the

following illustrations (1:1) to ensure other cabinets or

counters do not interfere with the door opening.

8 * Depending on model and options

Page 9

Door swing clearance

Fig. 10 110°, hinges on left

* Depending on model and options 9

Page 10

Door swing clearance

Fig. 11 90°, hinges on left

10 * Depending on model and options

Page 11

Door swing clearance

Fig. 12 110°, hinges on right

* Depending on model and options 11

Page 12

Door swing clearance

Fig. 13 90°, hinges on right

12 * Depending on model and options

Page 13

Changing the door hinges

7 Changing the door hinges

You can reverse the door hinges, if necessary:

Make sure you have the following tools on hand:

q

Torx 25

q

Torx 15

q

Screwdriver

q

Cordless screwdriver, if necessary

q

Another person to help with the installation, if necessary

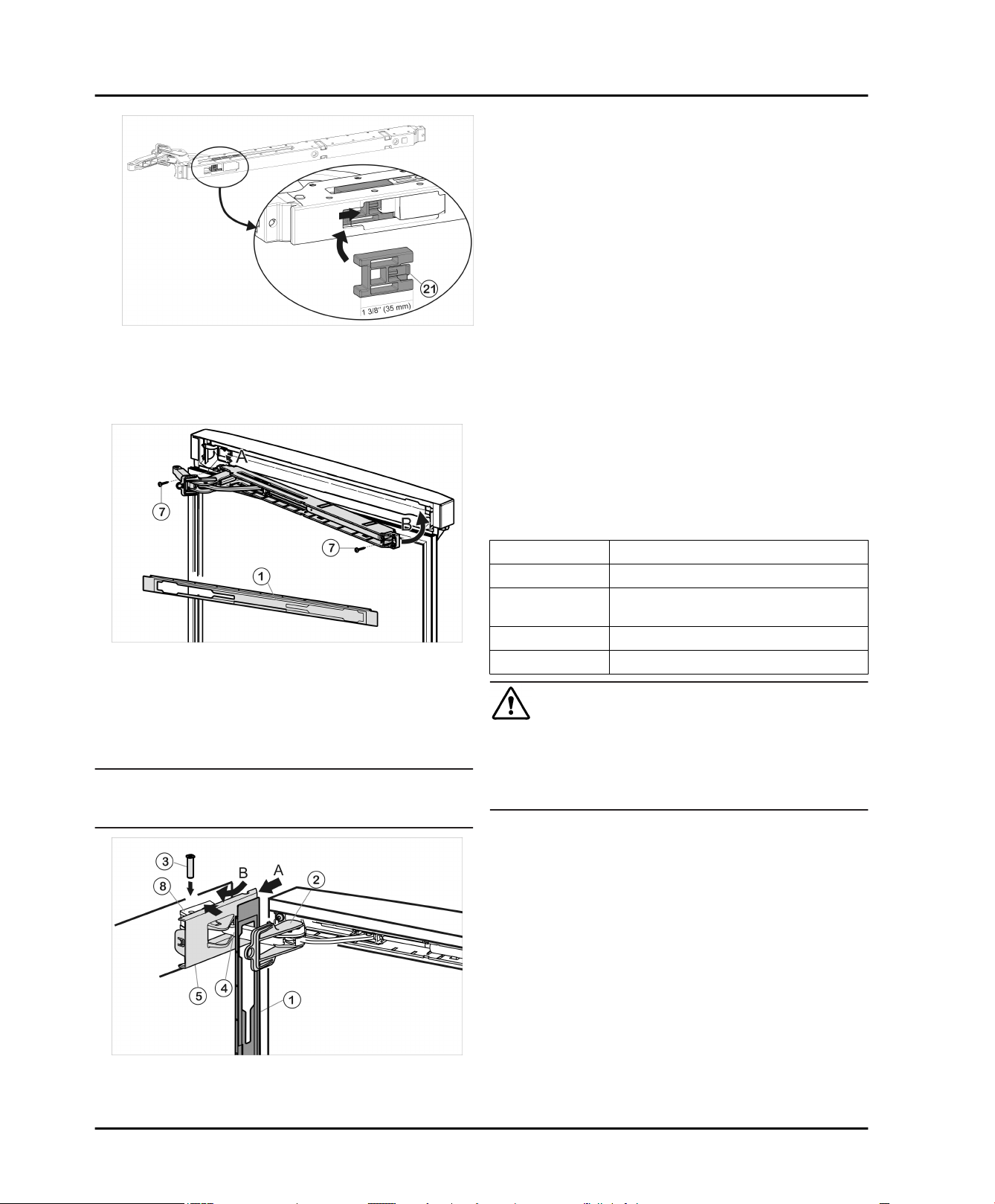

7.1 Remove soft stop mechanism (top)

WARNING

Risk of injury if the soft stop mechanism contracts!

If the locking device is not fitted, the soft stop mechanism

contracts during disassembly and can jam your fingers.

u

Fit the locking device!

u

Engage locking device

oblong hole.

w

The locking device prevents the hinge from snapping

shut.

u

Unscrew cover that is on the hinge side

the first notch using a screwdriver.

w

The bolt will become visible.

u

Push bolt

u

Press damper bracket

door.

u

Completely loosen cover that is on the hinge side

Fig. 15 (5)

u

Remove panel

u

Loosen cover that is on

the hinge side

using a screwdriver and

remove by pulling

outwards.

Fig. 15 (3)

and remove.

Fig. 15 (1)

Fig. 16 (6)

Fig. 15 (2)

out from below.

Fig. 15 (4)

.

in the direction of the

into place inside

Fig. 15 (5)

until

Fig. 14

u

Open the door.

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

u

Do not damage the door seal with the screwdriver!

u

Release panel

remove.

w

The panel hangs above the damper bracket.

u

Push panel forward over the damper bracket

in the direction of the appliance.

Fig. 14 (1)

using slotted screwdriver and

Fig. 15

Fig. 15 (4)

Fig. 16

u

Unscrew soft stop unit (2 x Torx 15)

u

Slightly pull out soft stop unit, push it towards the

handle side and open it out.

u

Set soft stop unit to the side.

u

Unscrew bearing part

Fig. 17 (8)

move it to the opposite

side. Make preliminary

holes (optional) or use a

cordless screwdriver.

, turn it 180° and

Fig. 15 (7)

.

Fig. 17

7.2 Remove soft stop unit (bottom)

Not for F 1051

Fig. 18

u

Open the door.

* Depending on model and options 13

Page 14

Changing the door hinges

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

u

Do not damage the door seal with the screwdriver!

u

Release panel

remove.

w

The panel hangs above the damper bracket.

u

Push panel forward over the damper bracket

in the direction of the appliance.

WARNING

Risk of injury if the soft stop mechanism contracts!

If the locking device is not fitted, the soft stop mechanism

contracts during disassembly and can jam your fingers.

u

Fit the locking device!

u

Engage locking device

oblong hole.

w

The locking device prevents the hinge from snapping

shut.

u

Lift off cover

driver and remove by pulling outwards.

u

Push bolt

u

Press damper bracket

door.

u

Remove panel

u

Unscrew entire soft stop unit (2 x Torx 15)

u

Slightly pull out soft stop unit, push it towards the

handle side and open it out.

u

Set soft stop unit to the side.

Fig. 18 (1)

Fig. 19 (52)

Fig. 19 (54)

Fig. 19 (51)

using slotted screwdriver and

Fig. 19 (55)

Fig. 19 (53)

from the outside using a screw-

out from below.

Fig. 19 (55)

.

into place inside

in the direction of the

Fig. 19 (56)

Fig. 19

.

u

Close the door.

u

Pull cover

remove.

u

Lift off cover

Risk of injury if the door tips out!

u

Keep a steady grip on the door.

u

Set the door down carefully.

u

Unscrew upper bearing bracket

Fig. 20 (13)

u

Lift the door upwards to remove and set it to the side.

Fig. 20 (10)

Fig. 20 (11)

CAUTION

and pull it upwards to remove.

forward and then upwards to

.

Fig. 20 (12)

(2 x Torx 25)

7.4 Swapping bearing parts

Fig. 20

7.3 Remove door

Note*

u

To prevent food items from falling out, take all food out

of the door racks before removing the door.

14 * Depending on model and options

u

Unscrew bearing bracket

bearing pin

doing so, hold panel

not drop.

u

Carefully lift off the cover on the handle side

and the plug

side.

u

Unscrew screw

side. When doing so, hold panel steady so that it does

not drop.

Fig. 21 (27)

Fig. 21 (24)

Fig. 21 (25)

Fig. 21 (20)

(3 x Torx 25)

Fig. 21 (22)

and move them to the opposite

steady so that it does

and move it to the opposite

together with

Fig. 21 (21)

Fig. 21

. When

Fig. 21 (23)

Page 15

u

Unscrew bearing part

tighten

Fig. 21 (29)

u

Remove the bearing pin

side along with the bearing disc and bearing ring

Fig. 21 (26)

u

Using a cordless screwdriver if necessary, tightly

secure

new hinge side again by applying a screw torque of

3 lb-ft (4 Nm) . First fit the lower center screw, then the

other screws.

and secure tightly to 3 lb-ft (4 Nm) .

Fig. 21 (21)

Fig. 21 (28)

.

Fig. 21 (27)

the bearing bracket

, move it to the other

, turn it 180° and

Fig. 21 (20)

7.5 Swapping the handle

on the

Changing the door hinges

u

Loosen cover

insert on the other side.

u

With the hinge of the soft stop unit facing the door

hinge side, engage the soft stop unit (A) and swivel

inwards (B).

w

The holes on the left and right must lie exactly above

each other.

u

Tighten soft stop unit (2 x Torx 15)

Fig. 23 (57)

from the panel

Fig. 23 (56)

Fig. 23 (51)

.

Fig. 23

and

Fig. 22

u

Pull plugs

and move them to the other side.

u

Detach the door handle

and move them to the opposite side.

Fig. 22 (31)

out of the door bearing bushes

Fig. 22 (30)

and plug

Fig. 22 (32)

7.6 Fitting the door

u

Ensure that the bearing discs

lower bearing pin

u

Position the door from above onto the bearing pins

below

Fig. 21 (27)

u

Close the door.

u

Insert the upper bearing bracket

hinge side into the door.

u

Secure the upper bearing bracket

applying a torque of 3 lb-ft (4 Nm) (2 x Torx 25)

Fig. 20 (13)

cordless screwdriver.

u

Snap both cover

place on the opposite side.

Fig. 21 (27)

.

. Make preliminary holes (optional) or use a

Fig. 20 (10)

Fig. 21 (26)

.

Fig. 20 (12)

Fig. 20 (12)

and cover

are on the

on the new

tightly by

Fig. 20 (11)

7.7 Fitting the soft stop mechanism (bottom)

Not for F 1051

into

Fig. 24

u

Hook panel

that the detent hooks are pointing forward and the front

side is facing the appliance.

u

Pull damper bracket

Fig. 24 (28)

that the square is resting in the recess.

u

Place cover

w

Check that the cover is positioned correctly such that

the door can close properly and the bolt is secured.

u

Remove locking device

u

Snap panel

u

Close the door.

Fig. 24 (51)

and insert bolt

Fig. 24 (52)

Fig. 24 (51)

into the damper bracket such

Fig. 24 (55)

on top and snap into place.

Fig. 24 (53)

into place on the door.

towards bearing part

Fig. 24 (54)

from above such

by twisting it.

* Depending on model and options 15

Page 16

Water connection

7.8 Fitting soft stop mechanism (top)

Fig. 25

u

Loosen cover

insert on the other side.

u

With the hinge of the upper soft stop unit facing the

door hinge side, engage the soft stop unit (A) and

swivel inwards (B).

w

The holes on the left and right must lie exactly above

each other.

u

Tighten soft stop unit (2 x Torx 15)

Note

u

Follow the correct sequence. First hang the panel over

the damper bracket, then the cover.

Fig. 25 (9)

from the panel

Fig. 25 (7)

Fig. 25 (1)

.

and

u

Snap panel

u

Turn cover

on top from the outside and snap into place.

Fig. 26 (1)

Fig. 16 (6)

into place on the door.

180° from the handle side, place it

7.9 Aligning the door

u

Unscrew center screw on lower part of bearing bracket

Fig. 21 (20)

u

Align the doors flush with the appliance housing using

the two oblong holes in the lower bearing bracket

Fig. 21 (20)

Risk of bodily injury due to the door falling off.

If the bearing parts are not installed with the proper

torque, the door may fall off. In addition, the door may not

close, thus impairing the cooling performance of the appliance.

u

Securely tighten the bearing brackets/bearing pins by

applying a torque of 3 lb-ft (4 Nm).

u

Check all screws and retighten if necessary.

.

as a guide if needed.

WARNING

8 Water connection*

WARNING

Electrical Shock Hazard!

u

Do not make the water connection while the appliance

is connected to an electrical outlet.

u

Disconnect the water supply before connecting the

water lines for the IceMaker.

u

The connection to the water supply may only be made

by a trained and licensed plumber.

WARNING

Poisoning Hazard!

u

The water quality must comply with the drinking water

regulations for the geographical area where the appliance is located.

u

Fig. 26

u

Hook panel

such that the detent hooks are pointing inwards and the

front side is facing the appliance.

u

Push on cover

over the bearing part

u

Place cover

place until the first notch.

w

The openings for the bolts lie above each other after

positioning the damper bracket.

u

Pull damper bracket

insert bolt

resting in the recess.

u

Now snap cover

bearing part

w

Check that the cover is positioned correctly such that

the door can close properly and the bolt is secured.

u

Remove locking device

16 * Depending on model and options

Fig. 26 (1)

Fig. 26 (5)

Fig. 26 (5)

Fig. 26 (3)

Fig. 26 (5)

Fig. 26 (8)

into the damper bracket

from the outside (A) and pivot

Fig. 26 (8)

on top and allow to snap into

Fig. 26 (4)

from above such that the square is

.

Fig. 26 (2)

(B).

towards bearing part and

completely into place on the

by twisting it.

Fig. 26 (4)

The IceMaker is designed exclusively to make ice

cubes in quantities needed by a household and must

only be operated with water appropriate for this

purpose.

Water pressure:

psi MPa (bars)

21.76 to 87.02 0.15 to 0.6 (1.5 to 6)

If a water filter is used, the instructions on water pressure

in the Installing the water filter section (see 13) apply.

- Water must be supplied to the appliance through a cold

water pipe that complies with hygiene standards and

can withstand the operating pressure.

- All devices and equipment used to supply water must

comply with the regulations in force in the respective

country.

Page 17

Anti-tip device

- The solenoid valve is located at the bottom of the back

of the appliance. It has a metric R3/4 connecting

thread.

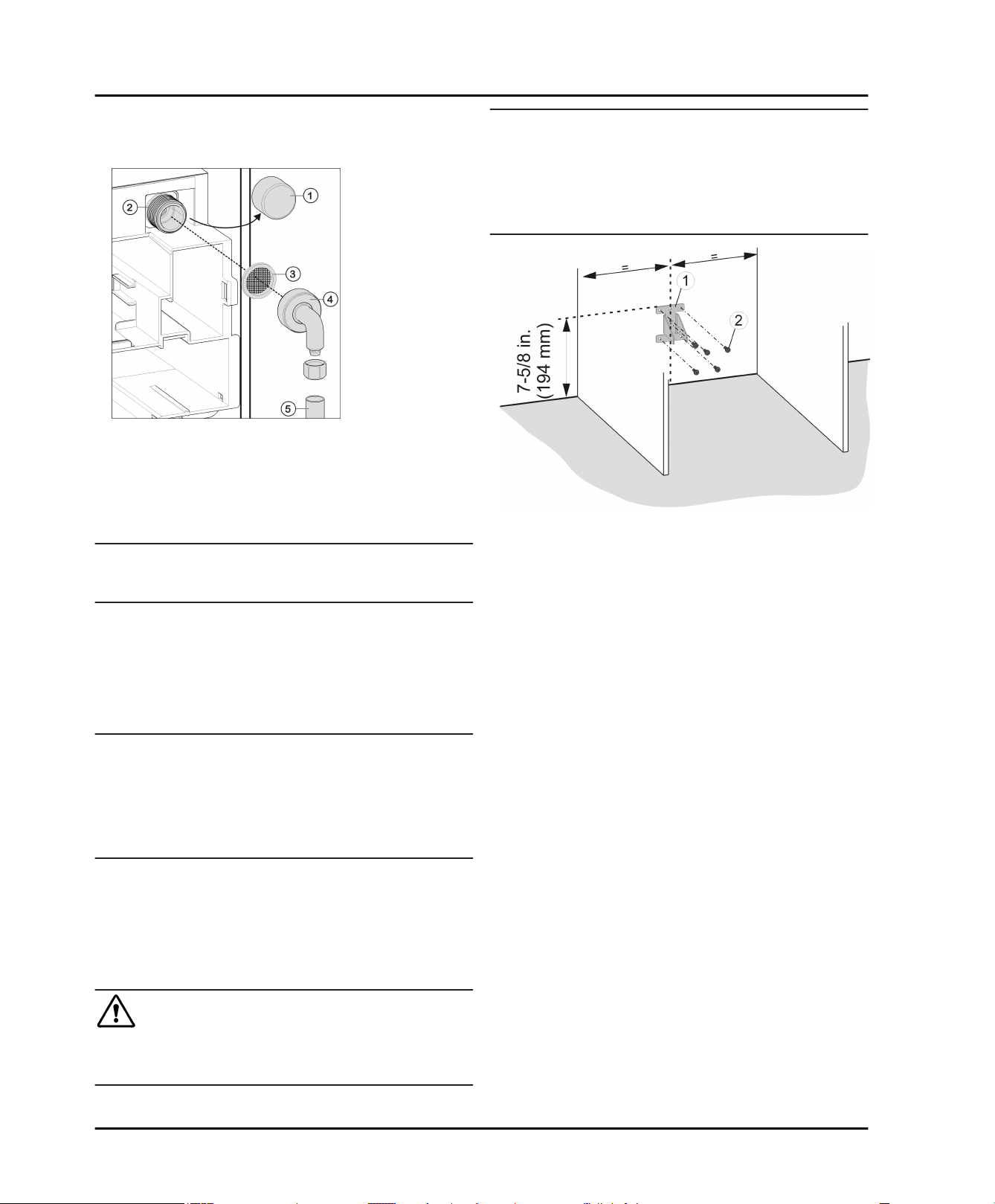

Fig. 27

u

Remove the cap

Fig. 27 (2)

u

Ensure that the gasket

elbow connection

u

Connect the elbow adapter

valve

wrench, for example.

NOTICE

Risk of thread damage!

u

Do not overtighten.

.

Fig. 27 (2)

Fig. 27 (1)

Fig. 27 (4)

and tighten with an open-ended

from the solenoid valve

Fig. 27 (3)

supplied.

Fig. 27 (4)

is inserted in the

to the solenoid

NOTICE

Risk of damage due to leaking water!

If the tilt safety device has been fitted in another position

than the one given, the water hoses may be damage

when pushing the appliance into the niche.

u

Only fit the tilt safety device in the position shown in the

diagram.

Fig. 28

u

Mark the installation position for the anti-tip device on

the wall or back of the unit.

u

Install the anti-tip device

screws

Fig. 28 (2)

.

Fig. 28 (1)

using appropriate

u

Connect the domestic water supply

copper pipe) to the elbow connector

Before fitting into the cabinet:

u

Check the whole water system for leaks.

Before using for the first time:

u

Have the water line bled (remove air) by a competent

professional.

NOTICE

Malfunction of the water intake!

If the water intake is shut off during operation but the

IceMaker remains in operation, the water intake pipe may

ice up.

u

Switch off the IceMaker if the water supply is interrupted (e.g. holiday).

Fig. 27 (5)

Fig. 27 (4)

(e.g.

.

9 Anti-tip device

The screws for fastening the anti-tip device are not

supplied with the appliance. Appropriate screws must be

used for the material (wood, concrete, etc.) in which the

safety device is mounted.

WARNING

Risk of injury if the appliance tips over!

u

Install the anti-tip device to prevent the appliance from

tipping over when the fully loaded door is open.

10 Single unit installation

Make sure you have the following tools on hand:

q

Torx screwdriver 10, 20

q

Cordless screwdriver, if necessary

q

1/4 in. bit attachment

q

Spirit level

Kit 9900306 is required for the installation.

* Depending on model and options 17

Page 18

Single unit installation

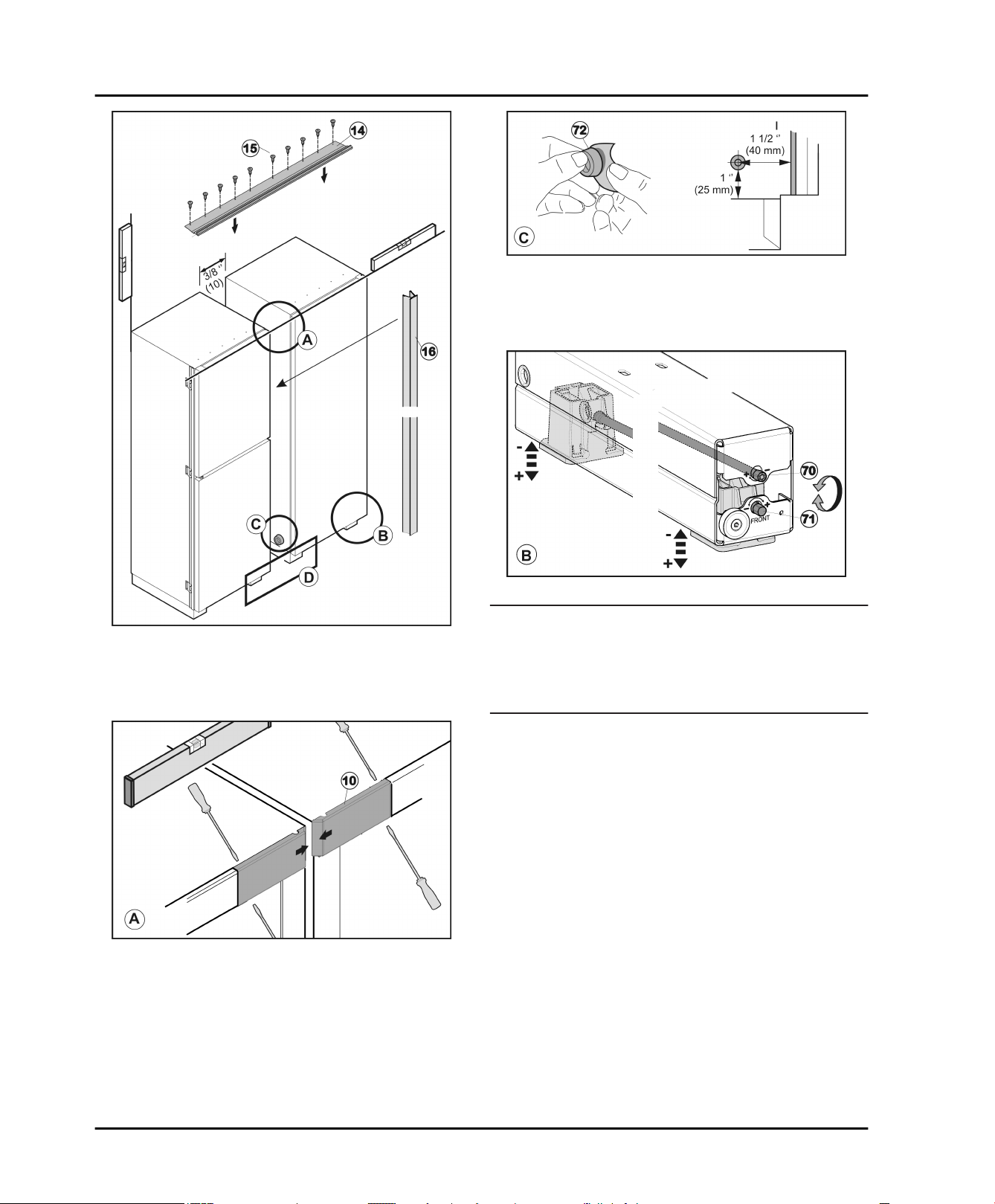

Fig. 29

The accessories kit 9900302 may be required depending

on the height of the recess. (see 4)

u

Fit retaining plate

Fig. 32 (1)

to the lower part of the

handle side by inserting two screws

pre-cut holes.

u

Slide installation strip

Fig. 32 (1)

u

Push second retaining plate

tion strip

from above.

Fig. 32 (3)

Fig. 32 (3)

Fig. 32 (4)

from above and screw to the center

of the side wall.

u

Push third retaining plate

strip

Fig. 32 (3)

from above and screw to the top part of

Fig. 32 (4)

the side wall.

Fig. 32

Fig. 32 (2)

into the

into the retaining plate

onto the installa-

onto the installation

Fig. 30

u

Install anti-tipping device inside the recess (see 9) .

Fig. 31

u

Screw on the upper installation contour

means of four screws

Fig. 31 (6)

inserted through the

Fig. 31 (5)

pre-cut holes in the profile and appliance.

Fit side installation strip:

Note

u

Depending on the recess height you will need to install

a ventilation grille or an end strip. Observe the necessary ventilation cross-sections (see 5) .

Fit upper ventilation grille (80”):

by

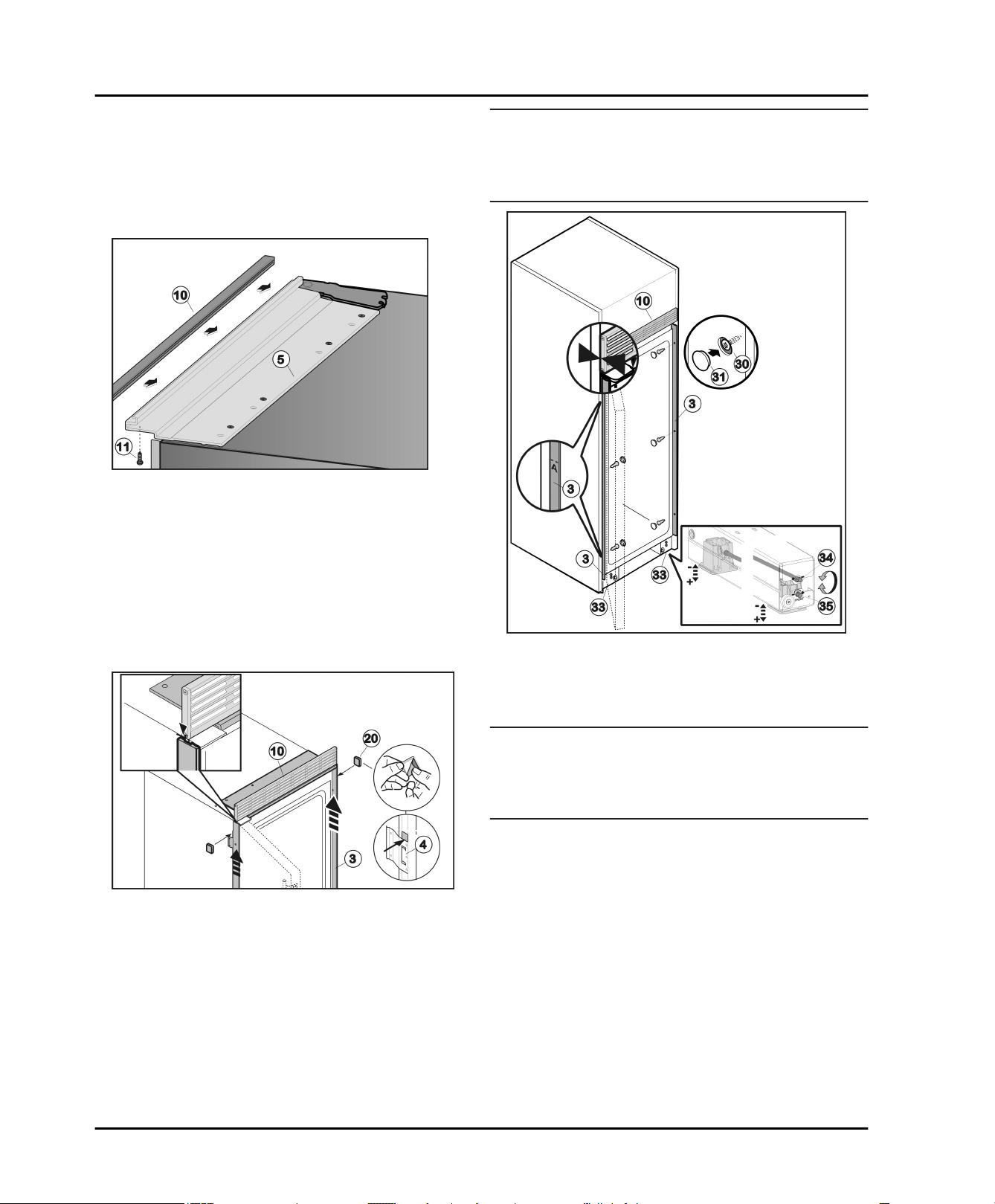

Fig. 33

u

Open the door.

18 * Depending on model and options

Page 19

u

Position ventilation grille

contour

Fig. 33 (5)

Fig. 33 (10)

over the installation

and align it such that the holes in

ventilation grille and installation contour are above

each other.

u

Screw ventilation grille

Fig. 33 (5)

from below using three screws

Fig. 33 (10)

to installation contour

Fig. 33 (11)

.

Install end strip:

Fig. 34

u

Open the door.

u

Position end strip

contour

Fig. 34 (5)

Fig. 34 (10)

over the installation

and align it such that the holes in

ventilation grille and installation contour are above

each other.

u

Screw end strip

Fig. 34 (5)

from below using three screws

Fig. 34 (10)

to installation contour

Fig. 34 (11)

.

Secure side installation strips:

carry out the following steps for the hinge-side and the

handle-side strip:

Single unit installation

NOTICE*

Risk of damage due to leaking water!

u

When pushing the appliance into the recess ensure

that the water connection does not kink or become

damaged.

Fig. 36

u

Push the appliance into the recess until the rear edge

of the ventilation grille

Fig. 36 (10)

edge of the side wall of the cabinet.

u

Open the door.

is flush with the front

NOTICE

Risk of damage to the castors.

u

Do not use a power tool to adjust the leveling rollers as

it will damage the leveling mechanism or disengage the

rod – instead use a hand ratchet.

u

Align appliance inside the recess above the roller

bases

Fig. 36 (33)

ment setting (1/4”)

foot and lower adjustment setting (1/4”)

Fig. 35

u

Remove adhesive tape from the side installation strip

Fig. 35 (3)

u

Push installation strip

touching the ventilation grille

u

Glue the adhesive plates

plate

respectively to the installation strip

.

Fig. 32 (1)

Fig. 35 (3)

Fig. 35 (20)

upwards until it is

Fig. 35 (10)

.

above the retaining

and the retaining plates

Fig. 35 (3)

Fig. 35 (4)

such that

it cannot slide downwards.

Install the appliance in the recess:

u

Connect appliance to the water supply (see 8) .*

u

Insert the power cable into the socket (see 14) .

* Depending on model and options 19

the front adjustable foot respectively. Turn clockwise to

raise and counterclockwise to lower. Maximum adjustable height: 5/8 in (16 mm).

u

At the top and bottom of the recess check the gap A

between the front edge of the installation strip

and the front edge of the side wall of the unit. It must be

1/2 ” (13 mm). Realign the appliance in the recess if

required.

u

Secure appliance inside the recess using three screws

Fig. 36 (30)

respectively. Do not scratch the side installation strip

Fig. 35 (3)

u

Place cover caps

when doing so.

using a spirit level: Use upper adjust-

Fig. 36 (34)

for the rear adjustable

Fig. 36 (35)

for

Fig. 36 (3)

on the handle side and the hinge side

Fig. 36 (31)

over the screws.

Page 20

Side-by-side installation

Fig. 37

If a water filter is used:

u

Insert water filter (see 13) .*

If no water filter is used:

u

Fit lower ventilation grille

such that the rubber lip is at the top. It is held in place

via magnets.

u

If necessary set the door opening angle (see 12) .

Fig. 37 (32)

flush with the floor

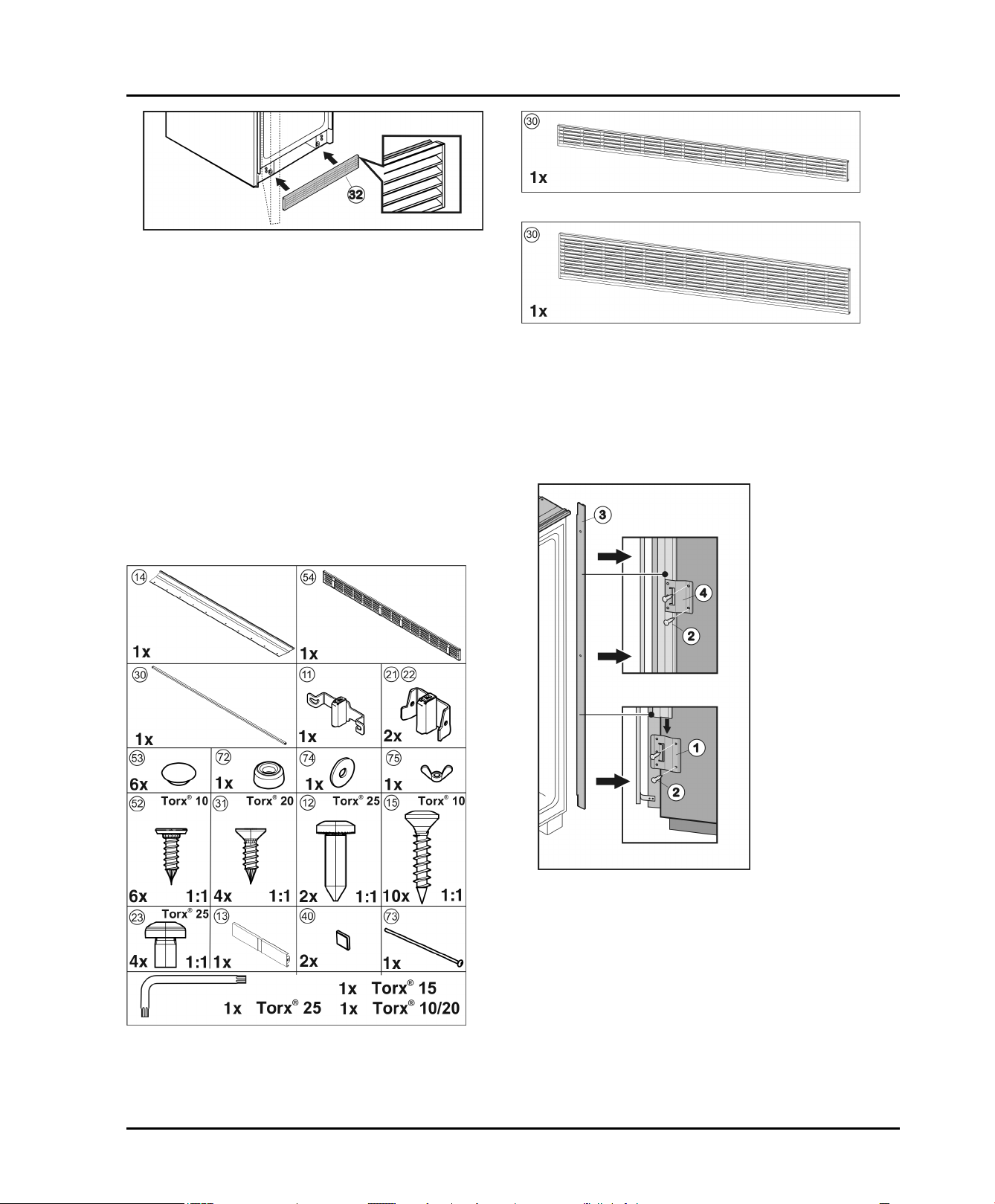

11 Side-by-side installation

The appliance with the ice maker must be on the left when

viewed from the front, the refrigerator unit on the right.

Make sure you have the following tools on hand:

q

Torx screwdriver 10, 15, 20, 25

q

Cordless screwdriver, if necessary

q

1/4 in. bit attachment

q

Spirit level

Fig. 39

Fig. 40

The accessories kit 9900304 or 9900344 may be required

depending on the height of the recess. (see 4)

u

Install anti-tipping device inside the recess (see 9) .

Fit side installation strips:

If the side on which the door hinges are located has been

changed, move the side installation strip to the hinge side

for both appliances.

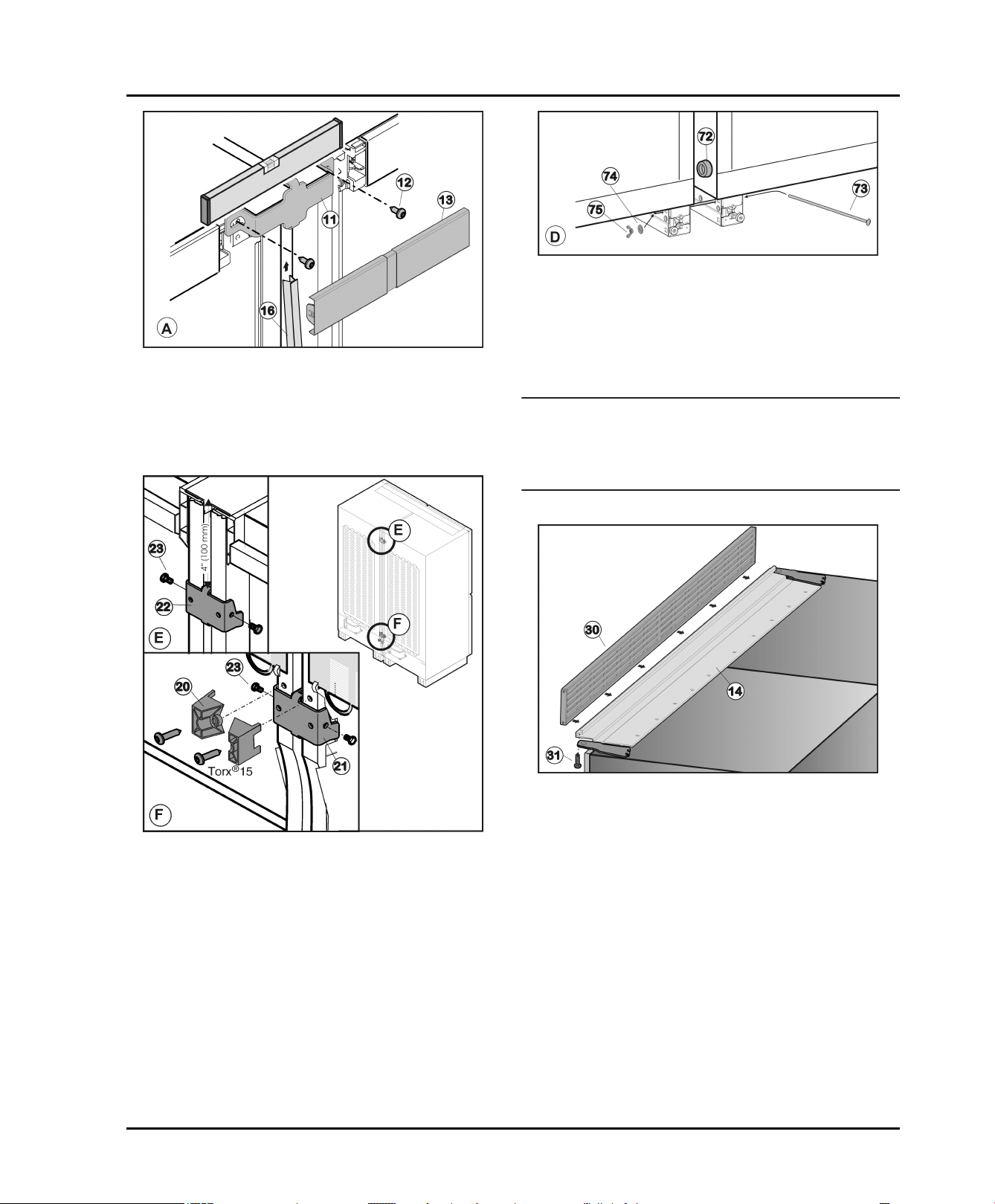

Fig. 41

u

Unscrew retaining plates

Fig. 41 (3)

u

Fit retaining plate

hinge side by inserting two screws

pre-cut holes.

u

Slide rail

from above.

u

Push second retaining plate

above and screw onto the center of the side wall.

u

Fig. 38

Kit 9900308 is required for the installation.

20 * Depending on model and options

Push third retaining plate

above and screw onto the top part of the side wall.

Join appliances:

.

Fig. 41 (1)

Fig. 41 (3)

Fig. 41 (1,4)

to the lower part of the

into the retaining plate

Fig. 41 (4)

Fig. 41 (4)

and remove rail

Fig. 41 (2)

onto the rail from

onto the rail from

into the

Fig. 41 (1)

Page 21

Side-by-side installation

Fig. 44

u

Glue spacer

wall on the handle side, approximately 1.5 in. (40 mm)

as measured inwards from the front edge of the appliance.

Fig. 44 (72)

onto the lower part of the side

Fig. 42

u

Position the appliances next to each other with a gap of

approximately 13/32 '' (10 mm) such that they are flush

at the front.

u

Open the door.

Fig. 43

u

Loosen covers

Fig. 43 (10)

using a screwdriver and pull

inwards to remove.

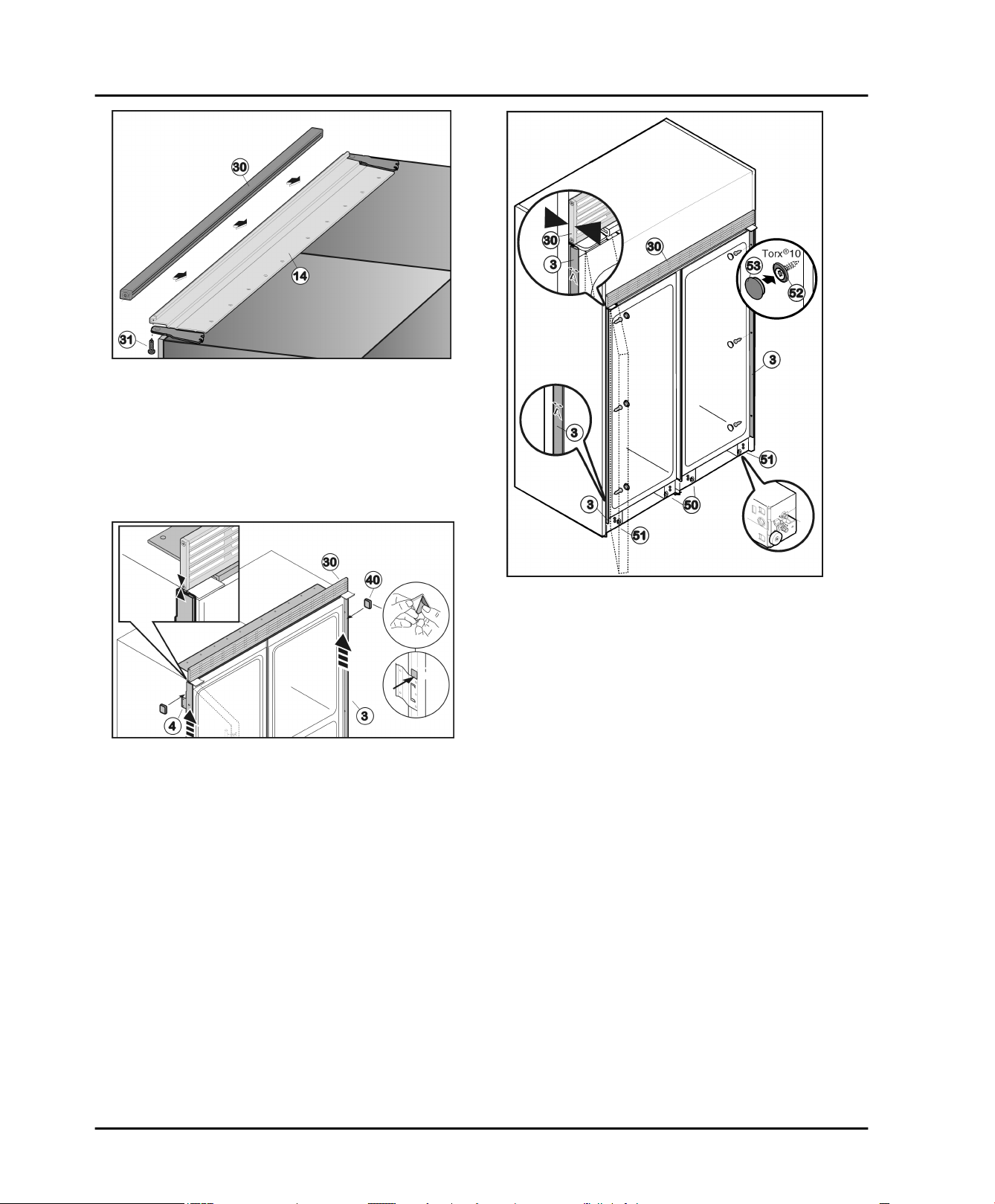

Fig. 45

NOTICE

Risk of damage to the castors.

u

When aligning appliance do not use a cordless screwdriver on the castors or the height adjustment mechanism will be damaged or the adjusting rod may come

loose. Adjust the castors by hand.

u

Align the height of both appliances evenly using the

four roller bases. Use the upper adjustment setting

(1/4")

Fig. 45 (70)

lower adjustment setting (1/4")

for the rear adjustment foot and the

Fig. 45 (71)

for the front

adjustment foot. Turn clockwise to raise and counterclockwise to lower. Maximum adjustable height: 5/8 in

(16 mm).

u

Position end strip

Fig. 42 (14)

over the installation

contour and align it such that the holes in ventilation

grille and installation contour are above each other.

u

Screw on upper installation contour

the pre-cut holes using screws

Fig. 42 (14)

Fig. 44 (15)

through

.

* Depending on model and options 21

Page 22

Side-by-side installation

Fig. 46

u

Secure upperconnecting element

screws

Fig. 46 (12)

. Make preliminary holes (optional) or

use a cordless screwdriver.

u

Clip on cover panel

u

Push appliances together at the bottom and realign if

Fig. 46 (13)

necessary.

Fig. 46 (11)

.

using two

Fig. 48

u

Insert long carriage bolt

u

Push washer

Fig. 48 (74)

screw. Tighten nut until the spacer

Fig. 48 (73)

and nut

.

Fig. 48 (75)

Fig. 48 (72)

onto the

touching the opposite side wall.

u

Fit strip

Fig. 46 (13)

u

Tighten the screws

Fig. 46 (16)

, push it slightly under the top cover

and then press it downwards into the gap.

Fig. 47 (23)

.

Note

u

Depending on the recess height, you will need to install

a ventilation grille (80”), a ventilation grille (84”) or an

end strip. Observe the necessary ventilation crosssections (see 5) .

Fit upper ventilation grille (80 or 84”):

is

Fig. 49

u

Open the door.

u

Position ventilation grille

Fig. 47

u

Remove the spacers

Fig. 47 (20)

from the lower reverse

side of the appliances.

u

Position the upper connecting piece and

Fig. 47 (23)

u

Position upper connecting piece

Fig. 47 (23)

22 * Depending on model and options

screw

Fig. 47 (21)

on from the side.

on from the side.

Fig. 47 (22)

and screw

contour

ventilation grille and installation contour are above

each other.

u

Screw ventilation grille

from below using four screws

Fit end strip:

Fig. 42 (14)

Fig. 49 (30)

over the installation

and align it such that the holes in

Fig. 49 (30)

to installation contour

Fig. 49 (31)

.

Page 23

Fig. 50

u

Open the door.

u

Position end strip

contour

Fig. 42 (14)

Fig. 50 (30)

over the installation

and align it such that the holes in

ventilation grille and installation contour are above

each other.

u

Screw end strip

below using four screws

Fig. 50 (30)

Fig. 50 (31)

to installation contour from

.

Secure side installation strip:

Side-by-side installation

Fig. 51

u

Remove adhesive tape from the side installation strip

Fig. 51 (3)

u

Push installation strip

touching the ventilation grille

u

Glue the adhesive plates

plate

respectively to the installation strip

.

Fig. 41 (1)

Fig. 51 (3)

Fig. 51 (40)

upwards until it is

Fig. 51 (30)

.

above the retaining

and the retaining plates

Fig. 51 (3)

Fig. 51 (4)

such that

it cannot slide downwards.

Install the appliance in the recess:

u

Connect appliance to the water supply (see 8) .*

u

Insert the power cable into the socket (see 14) .

Fig. 52

u

Push the appliance into the recess until the rear edge

of the ventilation grille

Fig. 52 (30)

is flush with the front

edge of the side wall of the cabinet.

u

Open the door.

u

Completely screw in the two centre roller bases

Fig. 52 (50)

at the front and rear such that the appliance

is only resting on the outer roller bases. This enables

the two appliances connected to each other to be

aligned jointly like a single appliance.

u

Align appliance inside the recess by adjusting the outer

roller bases

u

At the top and bottom of the recess check the gap A

between the front edge of the installation strip

Fig. 52 (51)

and using a spirit level.

Fig. 52 (3)

and the front edge of the side wall of the unit. It must be

1/2 ” (13 mm). Realign the appliance in the recess if

required.

u

Secure appliance inside the recess using three screws

Fig. 52 (52)

the side installation strip

u

Place cover caps

u

Being careful not to affect the level, lower the levelling

wheels in the center roller bases

hinge side of each appliance. Do not scratch

Fig. 52 (3)

Fig. 52 (53)

when doing so.

over the screws.

Fig. 52 (50)

until they

are resting on the floor.

* Depending on model and options 23

Page 24

Adjusting the door opening angle

Fig. 53

If a water filter is used:

u

Insert the water filter (see 13) .*

If no water filter is used:

u

Fit lower ventilation grille

such that the rubber lip is at the top. It is held in place

via magnets.

u

If necessary set the door opening angle (see 12) .

Fig. 52 (54)

flush with the floor

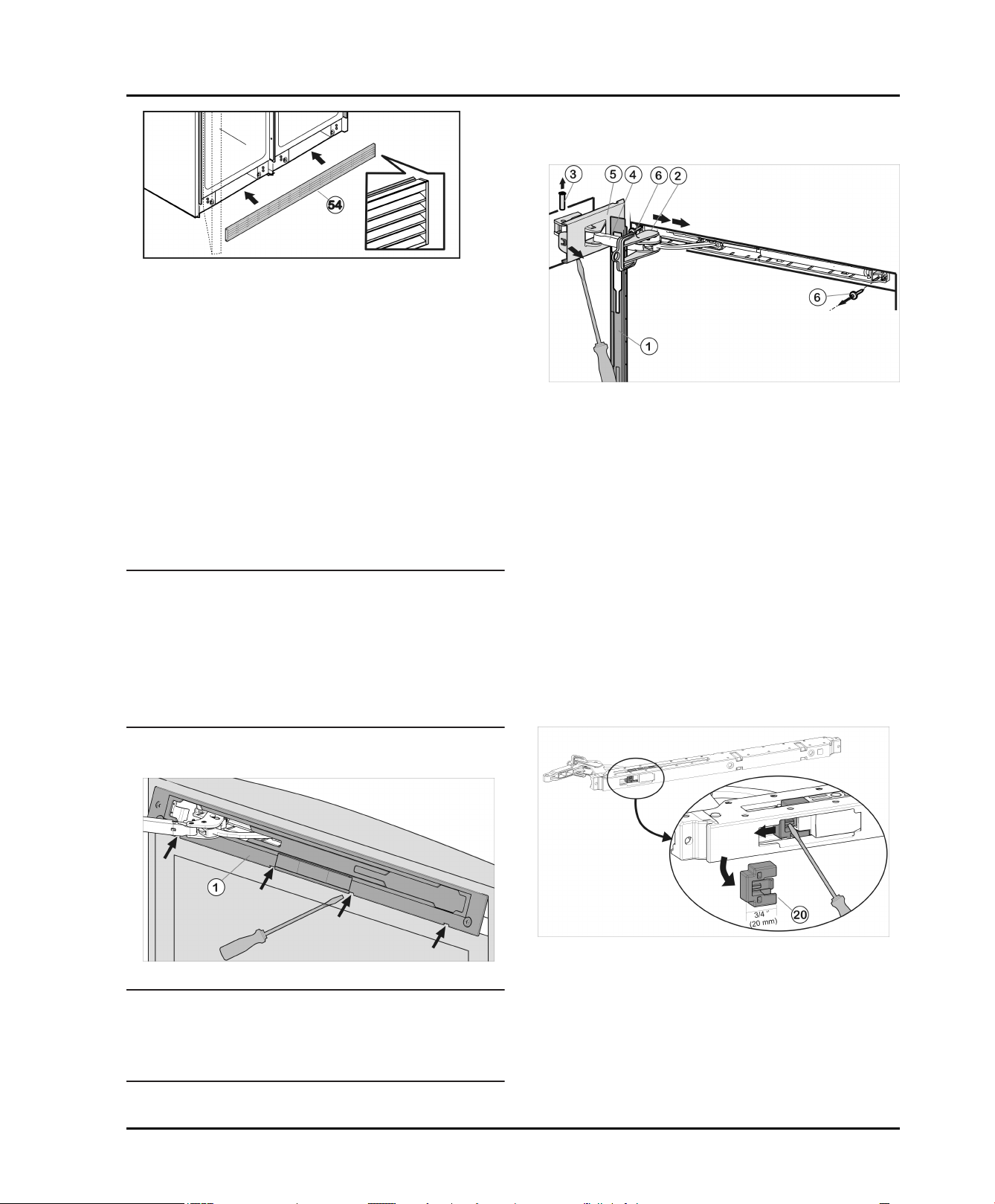

12 Adjusting the door opening angle

The appliance is delivered with a door opening angle of

110°. If the angle needs to be limited to 90° an opening

limiter must be used on the soft stop mechanism. Carry

out the following steps for all soft stop mechanisms on the

appliance (the top soft stop mechanism is illustrated):

NOTICE

Risk of damage for the door!

If no opening limiter is fitted and the door is opened, it can

hit the side installation strip and scratch as a result. For

this reason the appliance is already equipped with an

opening limiter (110°) as delivered from the factory.

u

Always fit an opening limiter (110° or 90°)!

u

When fitting the opening limiter open the door carefully

and do not allow it to hit anything!

u

Release panel

remove.

w

The panel hangs above the damper bracket.

u

Push panel forward over the damper bracket

in the direction of the appliance.

u

Engage locking device

oblong hole.

w

The locking device prevents the hinge from snapping

shut.

u

Unscrew cover that is on the hinge side

the first notch using a screwdriver.

w

The bolt will become visible.

u

Push bolt

u

Press damper bracket

door.

u

Completely loosen cover that is on the hinge side

Fig. 55 (5)

u

Remove panel

u

Unscrew soft stop unit (2 x Torx 15)

u

Slightly pull out soft stop unit, push it towards the

handle side and open it out.

Fit opening limiter:

Fig. 54 (1)

Fig. 55 (3)

and remove.

out from below.

Fig. 55 (1)

using slotted screwdriver and

Fig. 55 (4)

Fig. 55 (2)

Fig. 55 (4)

.

into place inside

Fig. 55 (5)

in the direction of the

Fig. 55 (6)

.

Fig. 55

until

Removing the soft stop unit

u

Open the door.

Fig. 56

u

Fig. 54

NOTICE

Risk of damage!

If the door seal is damaged the door may not close properly and the level of cooling is insufficient.

u

Do not damage the door seal with the screwdriver!

24 * Depending on model and options

Remove opening limiter (110°)

mechanism: Press down notch using screwdriver and

pull off opening limiter

Fig. 56 (20)

Fig. 56 (20)

.

on soft stop

Page 25

u

Fit opening limiter (90°)

Fig. 57 (21)

supplied: insert it

into the soft stop mechanism from the side and push in

until it audibly snaps into place.

Re-attaching the soft stop mechanism:

Fig. 57

Installing the water filter

u

Hook panel

Fig. 59 (1)

into the damper bracket

Fig. 59 (4)

such that the detent hooks are pointing inwards and the

front side is facing the appliance.

u

Push on cover

over the bearing part

u

Place cover

Fig. 59 (5)

Fig. 59 (8)

Fig. 59 (5)

from the outside (A) and pivot

(B).

on top and allow to snap into

place until the first notch.

w

The openings for the bolts lie above each other after

positioning the damper bracket.

u

Pull damper bracket

insert bolt

Fig. 59 (3)

Fig. 59 (4)

towards bearing part and

from above such that the square

head is resting in the recess.

u

Now snap cover

bearing part

w

Check that the cover is positioned correctly such that

Fig. 59 (5)

Fig. 59 (8)

completely into place on the

.

the door can close properly and the bolt is secured.

u

Remove locking device

u

Snap panel

Fig. 59 (1)

Fig. 59 (2)

by twisting it.

into place on the door.

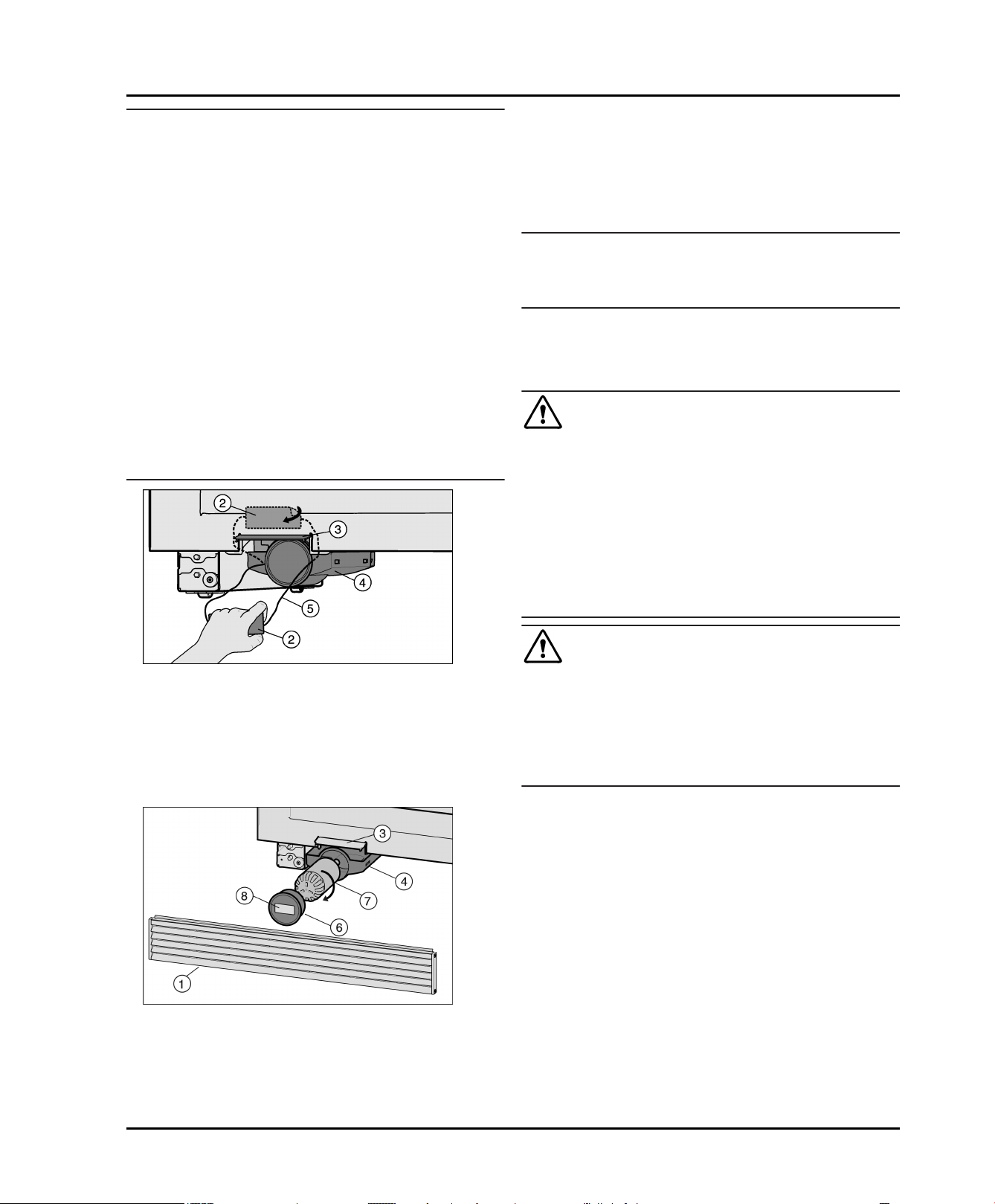

13 Installing the water filter*

The water filter guarantees optimal water quality and

should be installed the first time you use the appliance.

Alternatively, the appliance can also be operated without

the water filter.

Fig. 58

u

With the hinge of the upper soft stop unit facing the

door hinge side, engage the soft stop unit (A) and

swivel inwards (B).

w

The holes on the left and right must lie exactly above

each other.

u

Tighten soft stop unit (2 x Torx 15)

Fig. 58 (7)

.

Note

u

Follow the correct sequence. First hang the panel over

the damper bracket, then the cover.

Flow rate 0.5 gpm (1.89 lpm)

Water connection Drinking water

Water pressure 40 psi - 90 psi ( 2.8 bar - 6.2 bar/ 0.28 MPa

- 0.62 MPa )

Water temperature 33 °F - 100 °F ( 0.6 °C - 37 °C )

Capacity 300 gal. (1.14 l)

WARNING

Consuming contaminants can be harmful to your health!

u

If there is a chance the water may contain harmful

bacteria or if the water quality is unknown, do not use

this system without appropriate disinfection measures

upstream or downstream of the system.

Fig. 59

* Depending on model and options 25

Page 26

Connecting the appliance

NOTICE

Leakage water may damage the system!

u

Do not install this system on hot water lines. The

maximum operating temperature of the water in this

system is 100 °F (37.7 °C).

u

This system MUST be installed and used in compliance with federal and local installation regulations.

u

Do not install under water hammer conditions. A water

hammer arrestor must be used to prevent water

hammering. If you are unsure how to check these

conditions, consult a professional installer.

u

Do not install with a water pressure greater than 90 psi

(6.2 bar). If your water pressure exceeds 80 psi, install

a pressure limiting valve. If you are unsure how to

check the water pressure, consult a professional

installer.

u

Protect against frost; if temperatures below 33 °F

(0.6 °C) are expected, remove the filter.

u

When used as indicated, the disposable filter

cartridges must be replaced every 6 months or whenever you notice a considerable decrease in the flow

rate.

u

Write the date of the next filter replacement on the label

Fig. 61 (8)

Fig. 61 (6)

u

Close the filter change flap

u

Fit ventilation grille

u

Make sure the filter is leak-tight and no water is coming

out.

Note

New water filters may contain particulate matter.

u

Do not consume or use ice cubes produced within 72

hours after replacing the filter.

w

The water filter is now ready for use.

supplied and affix it to the filter cover

.

Fig. 61 (1)

Fig. 60 (3)

.

.

14 Connecting the appliance

WARNING

Electrical shock hazard!

u

Start-up should only take place once the appliance has

been installed according to these instructions.

u

Electrically ground appliance.

u

Do not ground to a gas pipe.

u

Check with a qualified electrician if you are not sure the

appliance is properly grounded.

u

Do not have a fuse in the neutral or grounding circuit.

u

Do not use an extension cord, power bar or a multiple

socket adapter.

u

Do not use a power cord that is frayed or damaged.

u

If necessary, remove ventilation grille

u

Remove any labels

u

Open the filter change flap

u

Carefully pull out drawer

Fig. 60 (5)

u

Cut off the string

Fig. 60 (2)

be disposed of.

u

Remove the filter cover

u

Insert water filter

100° clockwise as far as it will go.

u

Insert the drawer

u

Place the cover

.

and pull out. It is no longer required and can

Fig. 60 (2)

Fig. 60 (5)

Fig. 61 (6)

Fig. 61 (7)

Fig. 61 (4)

Fig. 61 (6)

from the appliance.

Fig. 60 (3)

Fig. 60 (4)

and turn it approximately

.

on the filter.

Fig. 60

Fig. 61 (1)

.

by the string

together with the label

.

.

Fig. 61

WARNING

Electrical shock hazard!

This appliance is equipped with a three-prong (grounding)

polarized plug for your protection against possible shock

hazards. Electrical Grounding Required.

u

Do not remove the round grounding prong from the

plug.

u

Use only an grounded adapter.

Wait 1 hour after installation before you plug in the

appliance. This allows the refrigerant and system lubrication to reach equilibrium.

Make sure incoming voltage is the same as the appli-

ance rating. A 110-120 Volt, 60 Hz, 15 Amp electrical

supply (20 Amp for side-by-side installations) circuit

that is controlled by a circuit breaker or fuse is required.

We recommend using a dedicated circuit for this appli-

ance to prevent electrical overload.

Follow all Federal, State and local electrical, fire and

building codes and ordinances when installing the

receptacle and / or the appliance.

In some communities, a wall switch is required to turn

power to the appliance ON and OFF.

To reduce the risk of fire, electric shock, or personal

injury, installation work and electrical wiring must be

done by a qualified electrician in accordance with all

applicable codes and standards, including fire-rated

construction.

26 * Depending on model and options

Page 27

The Power Plug must be easily accessible so that the

appliance can be disconnected from the mains quickly

in an emergency. It must not be behind the back of the

appliance.

The top of the electric outlet must be located within

82-5/8 in. (2100 mm) from the top of the base in the

cabinet.

Connecting the appliance

* Depending on model and options 27

Page 28

Instructions

de montage

Réfrigérateurs et congélateurs,

encastrables

R 1410/ RB 1410/ F 1051

301013 7084602 - 01

Page 29

Consignes de sécurité générales

Sommaire

1 Consignes de sécurité générales................ 29

2 Mise en place de l'appareil........................... 29

3 Informations de planification....................... 31

4 Dimensions du placard (Cabinet Opening

Dimensions)................................................... 34

5 Aération et ventilation du placard................ 34

6 Liberté de mouvement de la porte............... 35

7 Inversion du sens d'ouverture de la porte.. 40

7.1 Retirer l'amortisseur de fermeture (du haut)..... 40

7.2 Retirer l'amortisseur de fermeture (du bas)...... 40

7.3 Enlever la porte................................................ 41

7.4 Mettre les éléments pivotants de l'autre côté... 42

7.5 Inverser la poignée........................................... 42

7.6 Assembler la porte........................................... 42

7.7 Monter l'unité de l'amortisseur de fermeture

(en bas)............................................................ 42

7.8 Monter l'amortisseur de fermeture (en haut)..... 43

7.9 Mettre la porte à niveau.................................... 43

8 Prise d'eau...................................................... 44

9 Sécurité anti-basculement............................ 44

10 Montage d'un appareil seul.......................... 45

11 Montage du combiné Side-by-Side.............. 47

12 Régler l'angle d'ouverture de porte............. 52

13 Installer le filtre à eau.................................... 53

14 Brancher l'appareil........................................ 54

Lisez et respectez toujours ces consignes de

sécurité !

-

Il est important de respecter les directives et

consignes de ces instructions afin d'assurer

l'installation et le fonctionnement corrects de

l'appareil. Lisez et comprenez toutes les informations de ces instructions avant d'installer

l'appareil.

-

La prise de courant doit être bien accessible

afin de pouvoir débrancher rapidement l'appareil en cas d'urgence. Elle doit se situer en

dehors de la partie arrière de l´appareil.

DANGER indique une situation dangereuse

imminente entraînant la mort ou des

blessures corporelles graves si elle

n'est pas évitée.

AVERTISSEMENT

PRUDENCE indique une situation dangereuse

ATTENTION indique une situation dangereuse

Remarque indique les remarques et conseils

indique une situation dangereuse

susceptible d'entraîner la mort ou

des blessures corporelles graves si

elle n'est pas évitée.

susceptible d'entraîner des blessures corporelles moyennes ou

légères si elle n'est pas évitée.

susceptible d'entraîner des

dommages matériels si elle n'est

pas évitée.

utiles.

Le fabricant travaille constamment au développement de

tous les types et modèles d'appareils.C'est pourquoi nous

nous réservons le droit de modifier la forme, l'équipement

et la technique de nos appareils. Nous vous remercions

de votre compréhension.

Afin de découvrir tous les avantages de votre nouvel

appareil, nous vous prions de lire attentivement ces

instructions de montage.

Ces instructions de montage sont valables pour plusieurs

modèles, des différences sont donc possibles.Les paragraphes ne concernant que certains appareils sont indiqués par un astérisque (*).

Les instructions de manipulation sont indiqués par

, les résultats de manipulation par un .

un

1 Consignes de sécurité générales

-

Lire et respecter les instructions suivantes.

Elles contiennent des consignes de sécurité

importantes pour une installation et un fonctionnement sûrs et parfaits de votre appareil.

2 Mise en place de l'appareil

AVERTISSEMENT

Risque d'incendie dû à l'humidité !

Lorsque des pièces sous tension ou le câble de raccordement au secteur deviennent humides, un court-circuit

peut se produire.

u

L'appareil a été conçu pour être placé dans des locaux

fermés. Ne pas exploiter l'appareil dehors ou dans des

endroits humides non à l'abri de projections d'eau.

u

Uniquement exploiter l'appareil à l'état monté.

* selon le modèle et l‘équipement 29

Page 30

Mise en place de l'appareil

AVERTISSEMENT

Danger de brûlures par court-circuit!

Lorsque les câbles de raccord / fiches de l´appareil se

trouvent en contact avec la partie arrière d´un autre appareil, ils peuvent être endommagés à cause des vibrations

de l´appareil et par la suite causer un court-circuit.

u

Placer l'appareil de façon à ce qu'il n'y ait pas de

contact avec la fiche ou le câble d´alimentation.

u

Ne pas brancher d´appareils ni autres dispositifs sur

les prises de courant situées sur la partie arrière de l

´appareil.

AVERTISSEMENT

Risque d'endommagement et d'incendie !

u

Ne pas placer un appareil diffusant de la chaleur (p.ex.

four à micro-ondes, grille-pain, etc.) sur l'appareil !

PRUDENCE

Danger de blessure!

u

L’appareil doit être porté par deux personnes à son lieu

d’emplacement.

ATTENTION

Risque de dommage par eau de condensation

Si votre appareil Liebherr est placé à côté d’un autre réfrigérateur ou congélateur, il risque d’être endommagé par

la formation d’eau de condensation.

u

Eviter d’installer votre appareil à côté d’autres réfrigérateurs ou congélateurs à moins qu’il ne s’agisse également d’appareils de la marque Liebherr. Les appareils

Liebherr sont conçus pour une mise en place côte à

côte. Ils sont équipés d’un dispositif chauffant éliminant

l’eau de condensation au cas où des réfrigérateurs ou

congélateurs seraient disposés côte à côte.

ATTENTION

Risque de dommage pour le sol!

u

Protéger le sol en le couvrant avant de retirer les matériaux d'emballage de l’appareil.

S’assurer que:

q

le sol du lieu de mise en place de l’appareil est plat et

horizontal.

q

la capacité porteuse du sol est conçue pour le poids de

l’appareil ainsi que1200 livres (544 kg) de denrées.

q

l’appareil n’est pas exposé aux rayons de soleil directs

sur le lieu de sa mise en place et qu’il n’est pas installé

pas à proximité d’un four, d’un plan de cuisson, d’un

radiateur de chauffage ou autres sources de chaleur.

q

le meuble de cuisine dans lequel est monté l’appareil

est mis à niveau si le sol n’est pas plat.

q

le fusible est bien adapté.

q

la prise de courant est disposée selon les normes.

q

l’aération et la ventilation ne sont pas obstruées. Pour

un bon fonctionnement de l’appareil une aération et

ventilation suffisantes sont nécessaires. Les grilles

d’aération mises en place par l’usine assurent une

section d’aération efficace sur un appareil

de31 pouces2 (200 cm2). Si la grille d’aération est

remplacée par un panneau, sa section d’aération doit

au moins égale ou même plus élevée que la grille

d’aération du fabricant.

u

Vérifiez l’appareil et les matériaux d’emballage pour

dommages de transport. Consultez sans délai le fournisseur si des dommages quelconques sont constatés.

u

Notez le type (modèle, numéro), la désignation de

l’appareil, le numéro de l’appareil / de série, la date

d’achat et l’adresse du commerçant dans les champs

prévus à cet effet .

u

Retirez tous les matériaux de la face arrière ou des

parois latérales de l’appareil qui risqueraient d'empêcher une mise en place, une aération ou ventilation

correcte.

u

Retirer les films de protection des parois extérieures de

l'appareil.

Remarque

u

Nettoyer l'appareil .

Si l’appareil est mis en place dans un environnement très

humide, de l’eau de condensation risque de se former sur

l’extérieur de l’appareil.

u

Toujours assurer une bonne aération et ventilation sur

le lieu de la mise en place.

u

Assembler les appareils selon les instructions de

montage séparées.

30 * selon le modèle et l‘équipement

Page 31

3 Informations de planification

Informations de planification

Fig. 1 Installa-

tion d'un appareil seul

* selon le modèle et l‘équipement 31

Page 32

Informations de planification

Fig. 2 Installation Side-by-Side : SBS 241, SBS246, SBS 243

Fig. 3 Installation Side-by-Side : SBS 243 avec grille de ventilation de 80” ou 84”

32 * selon le modèle et l‘équipement

Page 33

Informations de planification

Fig. 4 Installation Side-by-Side : SBS 246 et SBS 241 avec grille de ventilation de 80” ou 84”

Fig. 5 Installation Side-by-Side : sans grille de ventilation

* selon le modèle et l‘équipement 33

Page 34

Dimensions du placard (Cabinet Opening Dimensions)

4 Dimensions du placard (Cabinet Opening Dimensions)

Fig. 6 Installation simple

Fig. 7 Installation Side-by-Side

Afin de pouvoir retirer les tiroirs sans problème, la porte

doit pouvoir être ouverte au moins à 90°. Si l'angle d'ouverture de la porte est de 90°, les balconnets de contreporte risquent de gêner le retrait des tiroirs.

Si l'appareil est installé dans un coin, respecter une

distance d'au moins 3-3/4 pcs (95 mm) par rapport au

mur.

5 Aération et ventilation du placard

Cet appareil est un appareil encastrable dont les portes

sont en acier inox.

L'appareil n'est pas prévu pour être installé en pose libre

et doit être intégré dans un placard. Le placard doit être

fabriqué selon les dimensions exactes de l'appareil et

disposer d'une aération et d'une ventilation suffisantes

afin de garantir son bon fonctionnement.

34 * selon le modèle et l‘équipement

Page 35

Liberté de mouvement de la porte

Fig. 8

- Une fente de ventilation efficace d'au moins 31 pcs

(200 cm2) par appareil doit être pratiquée pour l'arrivée

Fig. 8 (1)

- La fente de ventilation du dessus peut être réalisée

directement au-dessus de l'appareil avec une grille de

ventilation disponible en option

placard

bouche de sortie d'air dans un faux plafond

et la sortie d'air

Fig. 8 (3)

à proximité du plafond ou comme

Fig. 8 (2)

.

Fig. 8 (2)

, au-dessus du

Fig. 8 (4)

.

2

- Un conduit d'aération (sans obstacle) d'une profondeur

d'au moins 1-1/2 pcs (38 mm) doit être disponible sur la

paroi arrière du placard.

u

Respectez les espaces mentionnés ci-dessus pour la

ventilation.

Fig. 9

6 Liberté de mouvement de la porte

Placards sans cadre décoratif : la baguette de l'habillage

dépasse sur le côté et en haut du placard. Il peut être

nécessaire d'installer des cornières de compensation sur

les placards afin de ne pas gêner la liberté de mouvement

de la porte. L'ouverture de la porte doit permettre l'utilisation de cornières de compensation.

Au départ usine, l'angle d'ouverture des portes est réglé à

110°. Vous pouvez régler un angle d'ouverture de 90°.

Utilisez les illustrations ci-dessous (1:1) pour vous assurer

que les autres placards ou plans de travail n'entravent

pas l'ouverture de la porte.

* selon le modèle et l‘équipement 35

Page 36

Liberté de mouvement de la porte

Fig. 10 110°, ouverture de porte à gauche

36 * selon le modèle et l‘équipement

Page 37

Liberté de mouvement de la porte

Fig. 11 90°, ouverture de porte à gauche

* selon le modèle et l‘équipement 37

Page 38

Liberté de mouvement de la porte

Fig. 12 110°, ouverture de porte à droite

38 * selon le modèle et l‘équipement

Page 39

Liberté de mouvement de la porte

Fig. 13 90°, ouverture de porte à droite

* selon le modèle et l‘équipement 39

Page 40

Inversion du sens d'ouverture de la porte

u

7 Inversion du sens d'ouverture

Pousser le panneau au-dessus de l'étrier de l'amortisseur

Fig. 15 (4)

de la porte

vers l'avant, en direction de l'appareil.

Si vous le désirez, vous pouvez inverser le sens d'ouverture de la porte :

Assurez-vous d'avoir l'outillage suivant à portée de main :

q

Vis Torx 25

q

Vis Torx 15

q

Tournevis

q

Évent. visseuse sans fil

q

Si nécessaire, demander de l’aide à un tiers pour le

montage

7.1 Retirer l'amortisseur de fermeture (du haut)

Fig. 14

u

Ouvrir la porte.

AVERTISSEMENT

Risque de blessure lorsque l'amortisseur de fermeture se

contracte !

Si le dispositif d'arrêt n'est pas installé, l'amortisseur de

fermeture se contracte lors du démontage et risque de

vous coincer les doigts.

u

Installer le dispositif d'arrêt !

u

Encliqueter le dispositif d'arrêt

oblong.

w

Grâce au dispositif d'arrêt, l'articulation ne peut plus se

fermer.

u

Détacher le cache côté charnière

tournevis jusqu’au premier encliquetage.

w

Le pivot est visible.

u

Chasser le pivot

u

Pousser l'étrier de l'amortisseur

porte.

u

Défaire complètement le cache

nière et l’ôter.

u

Ôter le panneau

u

Détacher le cache côté

poignée

d'un tournevis, puis le

retirer en le tirant vers

l'extérieur.

Fig. 16 (6)

Fig. 15 (3)

Fig. 15 (1)

à l'aide

Fig. 15 (2)

Fig. 15 (5)

par le bas.

Fig. 15 (4)

Fig. 15 (5)

.

dans le trou

avec un

direction

côté char-

ATTENTION

Risque de détérioration !

Si le joint de porte est endommagé, la porte risque de ne

pas fermer correctement et la réfrigération ne sera plus

assurée.

u

Ne pas endommager le joint de la porte avec le tournevis !

u

Déclipser le panneau

fente, puis le retirer.

w

Le panneau est suspendu au-dessus de l’étrier de

l’amortisseur.

Fig. 14 (1)

à l'aide d'un tournevis à

Fig. 15

Fig. 16

u

Dévisser l’unité de l’amortisseur de fermeture (2 vis

Torx 15)

u

Tirer quelque peu l'unité de l'amortisseur de fermeture,

la pousser en direction du côté poignée et la sortir en

pivotant.

u

Mettre l'ensemble de l'unité de l'amortisseur de fermeture de côté.

u

Dévisser l'élément pivotant

tourné de 180° du côté

opposé. Pointer les trous

de vissage ou avoir

recours à une visseuse

sans fil.

Fig. 15 (7)

Fig. 17 (8)

.

et le placer

Fig. 17

7.2 Retirer l'amortisseur de fermeture (du bas)

Pas pour le modèle F 1051

40 * selon le modèle et l‘équipement

Page 41

Inversion du sens d'ouverture de la porte

Fig. 18

u

Ouvrir la porte.

ATTENTION

Risque de détérioration !

Si le joint de porte est endommagé, la porte risque de ne

pas fermer correctement et la réfrigération ne sera plus

assurée.

u

Ne pas endommager le joint de la porte avec le tournevis !

u

Dévisser l'ensemble de l'unité de l'amortisseur de

fermeture (2 vis Torx 15)

u

Tirer un peu l'unité de l'amortisseur de fermeture,

pousser en direction du côté poignée et la sortir en

pivotant.

u

Mettre l'ensemble de l'unité de l'amortisseur de fermeture de côté.

Fig. 19 (56)

.

7.3 Enlever la porte

Remarque*

u

Pour empêcher qu'elles ne tombent, retirer les denrées

des balconnets de contre-porte avant d'enlever la

porte.

u

Déclipser le panneau

fente, puis le retirer.

w

Le panneau est suspendu au-dessus de l’étrier de

l’amortisseur.

u

Pousser le panneau au-dessus de l'étrier de l'amortis-

Fig. 19 (55)

seur

AVERTISSEMENT

Risque de blessure lorsque l'amortisseur de fermeture se

contracte !

Si le dispositif d'arrêt n'est pas installé, l'amortisseur de

fermeture se contracte lors du démontage et risque de

vous coincer les doigts.

u

Installer le dispositif d'arrêt !

Fig. 18 (1)

vers l'avant, en direction de l'appareil.

à l'aide d'un tournevis à

Fig. 19

u

Fermer la porte.

u

Enlever le cache

vers le haut.

u

Retirer le cache

PRUDENCE

Risque de blessures lorsque la porte culbute !

u

Bien tenir la porte.

u

Déposer la porte prudemment.

u

Dévisser la charnière supérieure

25)

Fig. 20 (13)

u

Soulever la porte vers le haut et la mettre de côté.

Fig. 20 (10)

Fig. 20 (11)

et l'enlever par le haut.

en le tirant vers l'avant puis

.

Fig. 20 (12)

Fig. 20

(2 vis Torx

u

Encliqueter le dispositif d'arrêt

oblong.

w

Grâce au dispositif d'arrêt, l'articulation ne peut plus se

fermer.

u

Soulever le cache

l'aide du tournevis et l'enlever vers l'extérieur.

u

Chasser le pivot

u

Pousser l'étrier de l'amortisseur

porte.

u

Ôter le panneau

* selon le modèle et l‘équipement 41

Fig. 19 (52)

Fig. 19 (54)

Fig. 19 (51)

Fig. 19 (53)

par le côté extérieur à

par le bas.

Fig. 19 (55)

.

dans le trou

direction

Page 42

Inversion du sens d'ouverture de la porte

u

7.4 Mettre les éléments pivotants de l'autre côté

Fig. 21

u

Dévisser la charnière

Fig. 21 (27)

panneau

u

Soulever avec précaution le cache côté poignée

Fig. 21 (23)

l'autre côté.

u

Dévisser la vis

tout en tenant le panneau afin qu'il ne tombe pas.

u

Dévisser l'élément pivotant

Fig. 21 (29)

u

Dévisser le pivot

rondelle et l'anneau

de serrage de 3 lb-ft (4 Nm) .

u

Placer le support d'appui

côté charnière en utilisant une visseuse sans fil si

nécessaire, le revisser

serrage de 3 lb-ft (4 Nm) . Fixer d'abord la vis du

milieu inférieure, puis les autres vis.

(3 x Torx 25)

Fig. 21 (22)

et le bouchon

Fig. 21 (25)

tourné à 180.

Fig. 21 (27)

Fig. 21 (20)

Fig. 21 (21)

afin qu'il ne tombe pas.

Fig. 21 (24)

et la mettre de l'autre côté,

Fig. 21 (28)

, le mettre de côté avec la

Fig. 21 (26)

Fig. 21 (21)

et visser avec un couple

Fig. 21 (20)

avec le pivot

tout en tenant le

et les mettre de

et le revisser

sur le nouveau

avec un couple de

7.5 Inverser la poignée

Enlever le bouchon

porte et le mettre de l'autre côté.

u

Démonter la poignée de porte

bouchons

7.6 Assembler la porte

u

S'assurer que les rondelles

le pivot inférieur

u

Placer la porte par le haut sur le pivot inférieur

Fig. 21 (27)

u

Fermer la porte.

u

Placer la charnière supérieure

nouveau côté charnière dans la porte.

u

Visser le support d'appui supérieur

couple de serrage de 3 lb-ft (4 Nm) (2 Torx 25)

Fig. 20 (13)

visseuse sans fil.

u

Faire encliqueter le cache

Fig. 20 (11)

7.7 Monter l'unité de l'amortisseur de fermeture (en bas)

Pas pour le modèle F 1051

u

Détacher le cache

le remettre en place de l'autre côté.

u

Encliqueter l’unité de l’amortisseur de fermeture avec

l’articulation orientée vers le côté de la charnière (A) et

bien la guider pour la repositionner (B).

w

Les trous de vissage gauche et droit doivent se superposer avec exactitude.

u

Visser à fond l’unité de l’amortisseur de fermeture (2 vis

Torx 15)

Fig. 22 (31)

Fig. 22 (32)

.

. Pointer les trous de vissage ou utiliser une

du côté opposé.

Fig. 23 (56)

et les mettre de l'autre côté.

Fig. 21 (27)

Fig. 23 (57)

.

hors du coussinet de la

Fig. 22 (30)

Fig. 21 (26)

.

Fig. 20 (10)

du panneau

sont placées sur

Fig. 20 (12)

Fig. 20 (12)

et le cache

Fig. 23 (51)

et les

sur le

avec un

Fig. 23

et

Fig. 22

42 * selon le modèle et l‘équipement

Page 43

Inversion du sens d'ouverture de la porte

Fig. 24

u

Accrocher le panneau

tisseur de telle sorte à ce que le crochet d'arrêt pointe

vers l'avant et la face avant de l'appareil.

u

Tirer l'étrier de l'amortisseur

pivotant

Fig. 24 (54)

carré repose dans l'évidement.

u

Placer le cache

w

Veiller à ce que le cache soit bien positionné pour que

la porte puisse s’ouvrir correctement et que le pivot soit

sécurisé.

u

Retirer le dispositif d'arrêt

u

Faire encliqueter le panneau

u

Fermer la porte.

Fig. 24 (28)

à partir du haut, de telle sorte à ce que le

Fig. 24 (52)

7.8 Monter l'amortisseur de fermeture (en haut)

Fig. 24 (51)

et enfoncer à nouveau lepivot

et le bloquer.

Fig. 24 (53)

sur l'étrier de l'amor-

Fig. 24 (55)

Fig. 24 (51)

vers l'élément

en le tournant.

à la porte.

Remarque

u

Respecter l’ordre des consignes. Accrocher d’abord le

panneau au-dessus de l’étrier de l’amortisseur, puis

poser le cache.

Fig. 26

u

Accrocher le panneau

seur

Fig. 26 (4)

pointe vers l'intérieur et la face avant de l'appareil.

u

Pousser le cache

faire pivoter au-dessus de l'élément pivotant

(B).

u

Poser le cache

premier enclenchement.

w

Les orifices pour les pivots sont superposés après

positionnement correct de l’étrier de l’amortisseur.

u

Tirer l'étrier de l'amortisseur

pivotant et enfoncer à nouveau lepivot

du haut, de telle sorte à ce que le carré repose dans

l'évidement.

u

Bloquer maintenant lecache

sur l'élément pivotant

w

Vérifier le bon positionnement du cache pour que la

porte puisse s’ouvrir sans entrave et que le pivot soit

sécurisé.

u

Retirer le dispositif d'arrêt

u

Faire encliqueter le panneau

u

Placer le cache

à partir de l'extérieur et le bloquer.

, de telle sorte à ce que le crochet d'arrêt

Fig. 26 (1)

Fig. 26 (5)

Fig. 26 (5)

Fig. 26 (8)

Fig. 16 (6)

sur l'étrier de l'amortis-

depuis l'extérieur (A) et le

Fig. 26 (8)

et l'encliqueter jusqu'au

Fig. 26 (4)

Fig. 26 (5)

.

Fig. 26 (2)

Fig. 26 (1)

côté poignée tourné de 180°

vers l'élément

Fig. 26 (3)

complètement

en le tournant.

à la porte.

à partir

7.9 Mettre la porte à niveau.

u

Fig. 25

u

Détacher le cache

remettre en place de l'autre côté.

u

Encliqueter l’unité supérieure de l’amortisseur de

fermeture avec l’articulation du côté charnière (A) et la

guider pour la repositionner (B).

w

Les trous de vissage gauche et droit doivent se superposer avec exactitude.

u

Visser à fond l’unité de l’amortisseur de fermeture(2 vis

Torx 15)

* selon le modèle et l‘équipement 43

Fig. 25 (7)

Fig. 25 (9)

.

du panneau

Fig. 25 (1)

et le

Dévisser la vis du milieu de la charnière inférieure

Fig. 21 (20)

u

Aligner éventuellement la porte par rapport aux deux

trous oblongs de la charnière inférieure

qu'elle affleure avec l'habillage de l'appareil.

.

Fig. 21 (20)

pour

Page 44

Prise d'eau

AVERTISSEMENT

Risque de blessures lorsque la porte culbute !

Si les éléments du support d’appui et de charnière ne

sont pas serrées avec le bon couple de serrage, la porte

de culbuter.

u

Visser les supports d'appui/pivots avec un couple de

serrage de 3 lb-ft (4 Nm).

u

Vérifier la bonne fixation de chaque vis, si nécessaire

resserrer les vis.

8 Prise d'eau*

AVERTISSEMENT

Risque de décharge électrique !

u

Débranchez l'appareil de la prise avant de le raccorder

à la conduite d'eau.

u

Coupez l'alimentation en eau avant de raccorder les

conduites d'arrivée d'eau du distributeur de glaçons.

u

Le raccord au réseau d'eau potable doit être uniquement effectué par un plombier qualifié.

Fig. 27

u

Retirer le capuchon

Fig. 27 (2)

u

S'assurer que le joint

coude

u

Raccorder le coude

et bien serrer à l'aide d'une clé plate par exemple.

ATTENTION

Danger d'endommagement du filetage !

u

Ne pas trop serrer la pièce coudée.

.

Fig. 27 (4)

.

Fig. 27 (4)

Fig. 27 (1)

Fig. 27 (3)

à l'électrovanne

de l'électrovanne

est inséré dans le

Fig. 27 (2)

AVERTISSEMENT

Danger d'intoxication !

u

La qualité de l'eau doit être conforme à celle prescrite

par le décret relatif à l'eau potable du pays dans lequel

l'appareil est utilisé.

u

L'IceMaker sert uniquement à produire des glaçons en

quantité normale pour un usage domestique et doit

fonctionner avec de l'eau appropriée à la consommation.

Pression d'eau :

psi MPa (bar)

21,76 à 87,02 0,15 à 0,6 (1,5 à 6)

Si un filtre à eau est utilisé, les données de la pression

d'eau du chapitre Installer le filtre à eau (voir 13) sont

valables.

- L'arrivée d'eau à l'appareil doit se faire via une conduite

d'eau froide résistant à la pression de service et

conforme aux normes en matière d'hygiène.

- Tous les appareils et dispositifs utilisés pour l'arrivée

de l'eau doivent satisfaire aux prescriptions en vigueur

dans le pays respectif.

- L'électrovanne se trouve sur la paroi arrière de l'appareil en bas. Elle possède un filetage de raccordement

métrique R3/4.

u

Raccorder la ligne domestique

ex.) au coude

Avant l'installation dans la niche du meuble :

u

Vérifier l'étanchéité de l'ensemble du système d'eau.

Avant la première mise en service :

u

Faire purger la canalisation d'eau par un spécialiste

compétent.

ATTENTION

Dysfonctionnement de l'arrivée d'eau !

Si l'arrivée d'eau est coupée pendant le fonctionnement,

mais que l'IceMaker continue de fonctionner, le tuyau

d'arrivée d'eau risque de geler.

u

Éteindre l'IceMaker quand l'arrivée d'eau est interrompue (quand vous partez en vacances p. ex.).

Fig. 27 (4)

.

Fig. 27 (5)

(cuivre par

9 Sécurité anti-basculement

Les vis de fixation de la sécurité anti-basculement ne sont

pas fournies avec l'appareil. Utiliser des vis appropriées

au matériel sur lequel la sécurité va être fixée (bois,

béton, ...).