Page 1

Technical Description

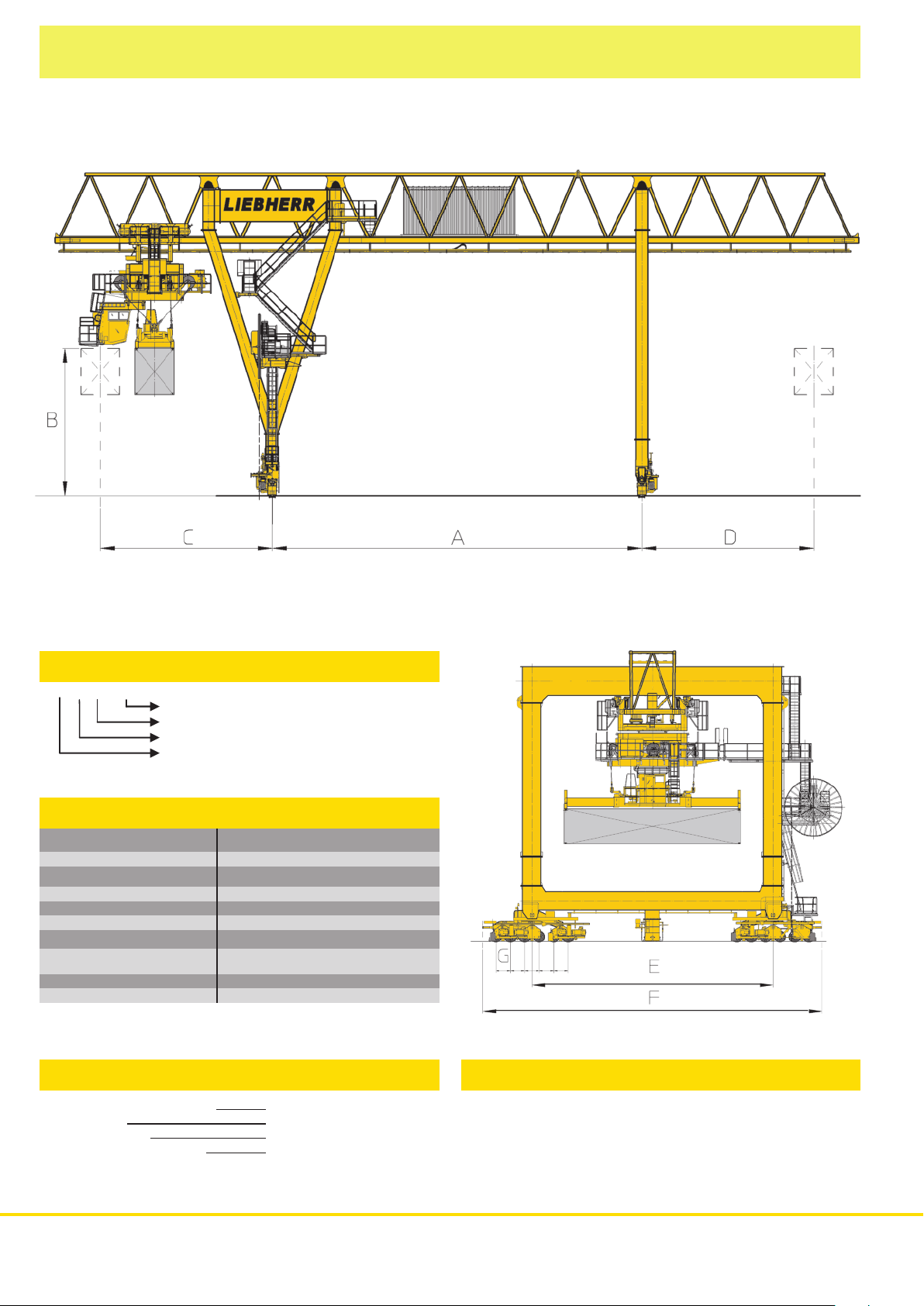

Liebherr Rail Mounted Gantry Crane (RMG)

Page 2

Dimensions

2 Rail Mounted Gantry Crane

Typical RMG Model Range*

RMG Model Designation (example)

Typical Design Parameters

S190L(MT)/(RT)

Rotating Machinery Trolley (Optional)

Machinery Trolley

Lattice Structure for Main Beam

Hoist Motor Size

Classification according F.E.M.

U7-Q2-A7 (Singlelift)

In service wind

72km/h (20m/s)

Out of service wind

151.2km/h (42m/s)

Ambient Temperature Range

- 45°C to +45°C

A Gantry Span 22.0m - 70.0m

B Lifting Height From 9.20m for 1 over 2

Up to 21.0m for 1 over 6

C Cantilever 0 - 20.0m

D Cantilever 0 - 20.0m

E Travel Wheel Gauge 16.50m - 18.20m

F Buffer to Buffer 23.20m - 25.50m

G Wheel Spacing

1.0m - 2.0m (Dependant on Required

Wheel Loads)

Wheels per Corner 6 - Wide Leg

4 - Narrow Leg

* other features and dimensions also available

Advantages of RMG for Yard Stack-

- Suitable for both Port and Rail Terminals

- Suitable for Various Yard Space Conditions

- Increased Yard Capacity with Wider and Higher Stack Possibilities

- Reduction in Emissions and Noise

- Minimal Maintenance

- Electric Supply - More Energy Efficient (Lower Running Costs)

Page 3

Liebherr Anti - Sway System

Eight Rope Reeving

Advantages by Design

Minimal Spreader Positioning Times

NO - Sway: Hoist, Trolley & Travel Directions

Anti - Skew

No Additional Ropes or Devices Necessary

No HeadBlock - Reduced Rope Load

Lower Energy Consumption

All Electric Spreader - Less Maintenance

Increased Productivity of between 30 - 40% when compared to alternative designs.

Motors & Speed Control System

Motors / Suppliers

All Drives are Sized for Maximum Torque and Power

Requirements Guaranteeing Extended Lifetime.

All Major Components Sourced From Reputable European

Manufacturers

Speed Control System

The Control System used has been specifically developed

for container cranes by Liebherr, which has resulted in a

flexible, robust construction with exceptional reliability.

equipment is designed to maximise crane availability and

to minimise the necessity for highly skilled electronic

personnel.

-

Simultaneous operation of all main motors is possible. This means that the crane driver can Hoist, Trolley

and Crane Travel at the same time.

Rail Mounted Gan try Crane 3

Page 4

Liebherr Container Cranes Ltd.

Fossa, Killarney, Ireland

Tel.: +353 64 6670200, Fax: +353 64 6631602

www.liebherr.com, E-Mail: sales.lcc@liebherr.com

R

MG

0

7/2

0

13 Subjec

t

t

o

c

h

a

ng

e w

i

thout

no

tic

e

Liebherr Reeving System: Sway Prevention, NOT Sway Correction

Regeneration During Lowering of Load and Drive Deceleration

Results in Overall Reduction in Power Consumption

Stable, Rigid, High Quality Steel Structure Design

Accurate and Faster Stacking

Ideal for Automation

Separate Drives for Hoist, Trolley, Travel and Slewing (If Installed)

Allowing Superior Fine Positioning

Simultaneous Motion

No Need for Side Shift on Spreader

Liebherr Drive Systems

Worldwide Liebherr Service Network

Extensive Training (In - House & On - Site Following Commissioning)

Purpose Built State-of-the-Art Design & Production Facilities Located in Ireland Since 1958

Highly Skilled & Experienced Employees (Expertise In House - For After Sales Service)

Responsibility with Liebherr (Eliminating Interface and Compatibility Problems)

(i.e. Structural, Mechanical and Electrical Design, Production, Commissioning and Service)

tfiL elgniS 40.6t - 50t

Twin Lift (optional)

50t - 65t

Hoisting with No Load 52m/min - 80m/min

Hoisting with Rated Load

23m/min - 40m/min

Trolley Travel (with & without load)

Up to 180m/min

Gantry Travel (without load)

Up to 240m/min

Slewing ±190°(Optional)

1.2 r.p.m.

* Higher Speeds Also Available on Request.

- Rotating Machinery Trolley

- Interface with TOS (Terminal Operating System)

- Trim and Skew Spreader Positioning

- Energy Chain / Festoon System

- Non Contact Anti-Collision System

- Automation of RMG and Container Tracking

- Container Positioning System

- Remote Operation Optional

- Fault Data Between Crane & Office by RF Link/Fibre Optic with

Optional Link to Liebherr Factory.

Lifting Capacity

Working Speeds*

Supplier Liebherr

Operating System

Windows

Logic Control System

CoDeSys

Description:

- Status of Switchgear and External Electrical Components

- Storage Capacity of Faults (Up to 20,000)

- User-Friendly Interface with Easy To-Use Colourful Screens

- Independence of Crane Logic System, Therefore NOT Interfering

with Crane Control in Event of Self-Failure.

- Includes Trending & Tables for Production Data and Drive Data

Summary of Main System Features:

- General Control Overview

- Crane ON Status

- Individual Drive ON Screens (One for Each Drive)

- Detailed Drive Data (Motor Current, Voltage, Speed)

- Wind Speed & History

- Spreader Status

- Fault Stack

- Load Statistics

- Maintenance

Diagnostic & Management System

Options

Liebherr Rail Mounted Gantry Crane

Loading...

Loading...