Page 1

Liebherr Port Cranes

FCC and TCC

Page 2

FCC 350 with timber grab

2

Page 3

Table of Contents

Product Range 4

Design Overview 6

Modularity 7

Applications 8

FCC – Confi guration and

Installation 12

TCC - Confi guration and

Installation

Operational Comfort 16

Liebherr Service 17

14

3

Page 4

Product Range

Many years of experience in the construction of maritime cranes is one of Liebherr’s core competences. Constant technical

progress ensures innovative and fl exible solutions orientated towards customer requirements.

The Liebherr FCC/TCC series is designed for the fl exible

handling of dry bulk, general cargoes and containers in both

sea and domestic ports. Low initial outlay as well as minimum

running and maintenance costs round off the operational profi le of the FCC/TCC series.

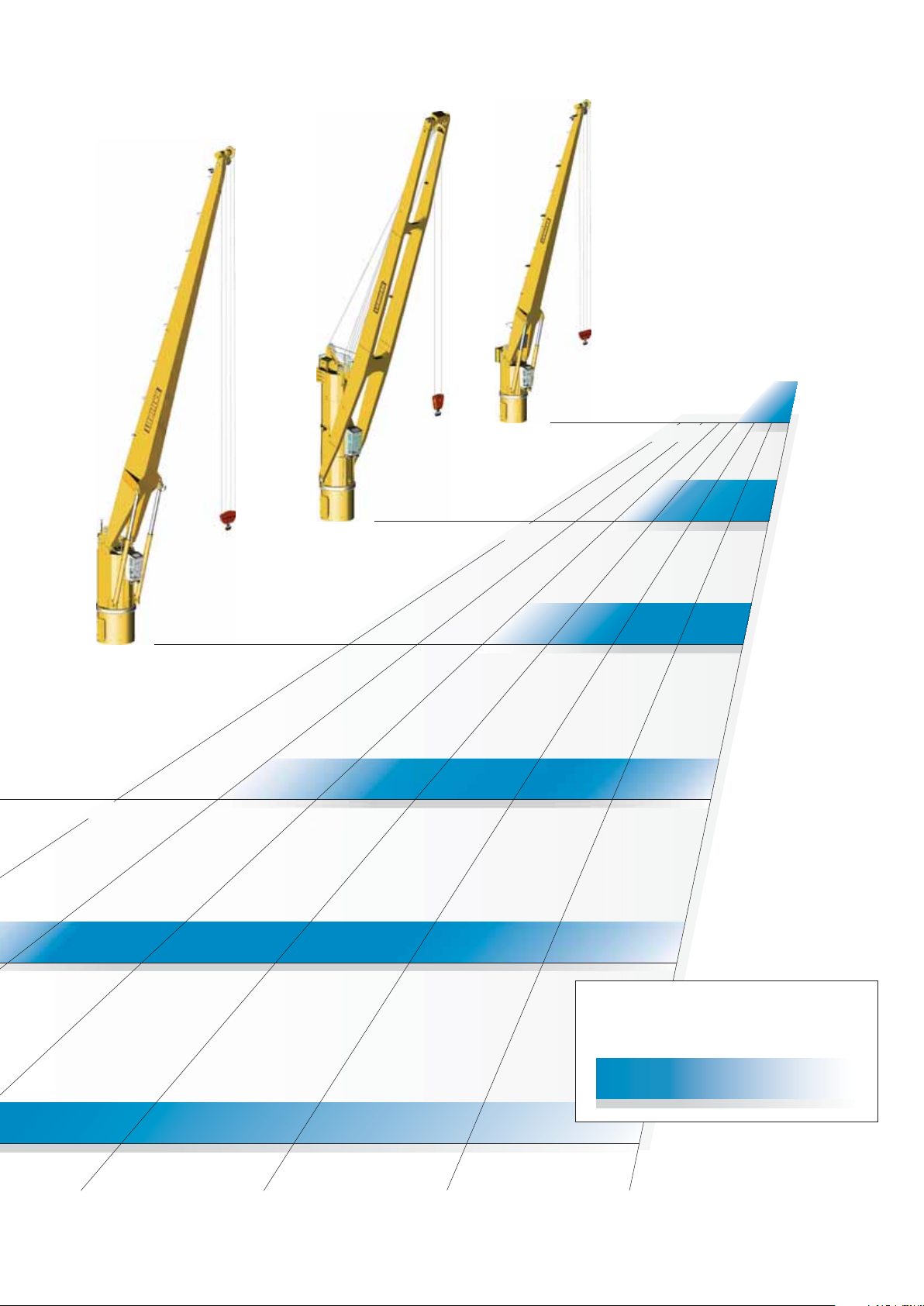

350 series

Radius 36 m

Max. capacity 45 t

Continuous heavy duty grab and

multi-purpose operation

300 series

Radius 30 m

Max. capacity 30 t

Continuous heavy duty grab operation

Capesize

Post Panamax

280 R series

Radius 33 m

Max. capacity 120 t

Multi-purpose and he

Panama

4

Page 5

280 series

Radius 35 m

Max. capacity 45 t

Multi-purpose operation

230 series

Radius 29.5 m

Max. capacity 45 t

Multi-purpose operation

230 R series

Radius 32 m

Max. capacity 45 t

Multi-purpose operation

Application:

AdditionalOptimal

5

Page 6

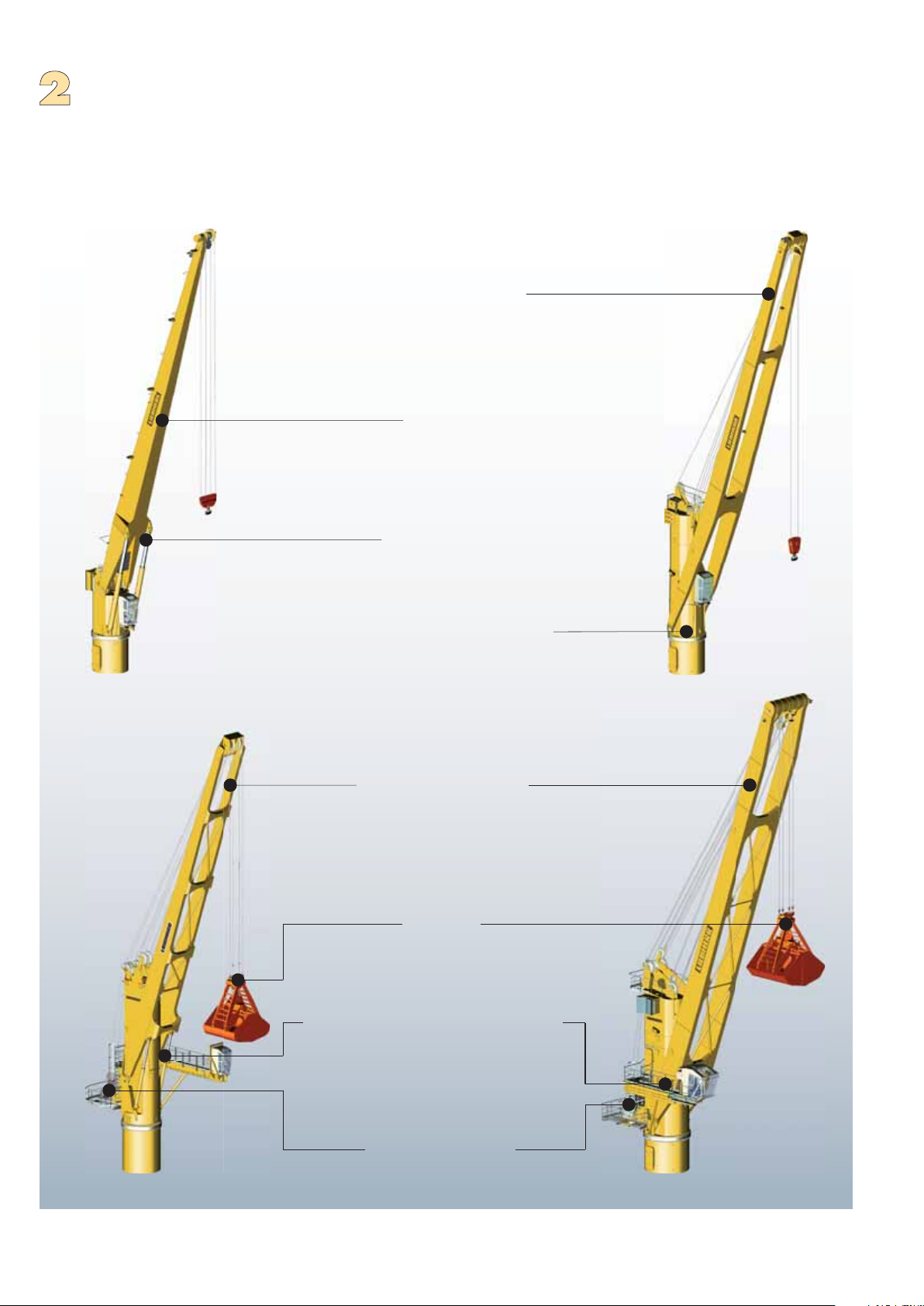

Design Overview

Liebherr port cranes have been developed using the latest scientifi c and technical knowledge and excel through

the following design features:

230/280 series

230 R/280 R series

Double chord box girder jib

(high stability)

Box type jib

Luffing cylinder

(maintenance free)

Internal hoisting and luffing winches

(optimum protection)

300 series

Double chord box girder jib

(high stability)

Luffing cylinder

(maintenance free)

Single layer holding and

closing winch

350 series

4-rope grab

Internal

luffing winches

6

Page 7

Modularity

The Liebherr port crane concept is distinguished by its unique modularity. Three different crane types and two different substructures

are available. Under consideration of the infrastructure and individual needs of the port the optimum combination can be determined.

FCC – Fixed Cargo Crane

The FCCs are fi tted on fi xed pedestals. Due to their slender design

they are especially suitable for operation on narrow quaysides.

Thanks to jib lengths of up to 36 m vessels and barges can be

effi ciently loaded and unloaded from a fi xed position.

TCC – Travelling Cargo Crane

TCCs are fi tted on rail-mounted travelling gantries. A system of

parallel tracks under the gantry enables travel along the length

of the quayside. This means relocation of the vessels and barges

is not necessary during loading and unloading of cargoes, thus

improving effi ciency.

7

Page 8

Applications

Whether container, general cargo or dry bulk handling Liebherr port cranes can meet a wide variety of cargo demands

ranging from universal to special applications.

Container and General Cargo Handling

No matter what type of vessel thanks to the various jib lengths

Liebherr port cranes invariably fulfi l your needs. With up to 25

cycles per hour vessels and barges can be quickly and effi ciently

loaded or unloaded.

For container and general cargo handling the cranes can

be equipped with a rotator. Manual, semi or fully automatic

spreaders are available for all regular container sizes.

FCC 230 FCC 230 R

8

Page 9

TCC 230

9

Page 10

TCC 350

10

Page 11

Dry Bulk Handling

Various types of grab, ranging from motor grab up to fourrope grab, can be easily fi tted and operated. Liebherr’s

leading position in dry bulk handling is emphasized by its high

performance crane series 300 and 350 offering the following

benefi ts:

s¬ classifi ed for 360 days 24 hours continuous operation

s¬ up to 45 cycles per hour

s¬ operation of all 3 motions simultaneously at full load/full speed

s¬ continuously variable speed control from zero to max. speed

s¬ independent closed hydraulic circuits for each crane motion

TCC 300FCC 280 R

11

Page 12

FCC – Confi guration and Installation

Practical Application

Liebherr port cranes are tailor-made to meet individual customer requirements and are especially suitable for operation on narrow

quaysides thanks to their compact design and the following features:

s¬ economical and robust pedestal design

s¬ point reinforcement of the quayside keeps the foundation costs at a minimum

s¬ relatively low forces and moments affect the crane’s pedestal making dense

positioning of the cranes on the quayside possible

s¬ electric components are protected from the environment

FCC series

B1 = ship width

B2 = quay

B3 = ship width

R = max. working radius

B1

R

B2

B3

R

12

Page 13

Pedestal

The upper pedestal of the crane is welded to the lower pedestal,

enabling straightforward and uncomplicated installation of the

cranes.

Power Supply

An external electric cable provides power for the electrohydraulic cranes. This cable is embedded in the quayside and is

lead through the inside of the lower pedestal to the terminal box

on the slipring.

Upper pedestal

scope of supply - Liebherr

Slip ring collector

electrical connection interface

Welded connection

scope of supply - customer

Electric cable

scope of supply - customer

Foundation - quay

scope of supply - customer

Lower pedestal

scope of supply - customer or Liebherr

13

Page 14

TCC – Confi guration and Installation

Gantry Design

Based on many years of experience in gantry construction, Liebherr designs and manufactures tailor-made gantries to meet the

requirements of individual port infrastructures.

s¬ the width of the gantry is determined by the rail span

s¬ the working height of the gantry and the TCC port crane is optimized to suit the types of vessels to be handled

s¬ the clearance height of the gantry depends on the transport requirements on the quayside. For example, TCCs in intermodal

ports can be designed to enable the free movement of trucks and rail-mounted vehicles under the gantry in order to allow for

improved cargo clearance

s¬ the number of bogies is dependent on the type of crane and the maximum permissible wheel load on the quayside

s¬ counterweights are necessary where rail spans are narrow in order to reduce overturning moment and ensure safe operation and

stability

TCC series

H1 = clearance height

H2 = eye level

W = track gauge

14

H2

H1

W

Page 15

Installation

s¬ gantry drives are electrically powered

s¬ prevailing forces and moments are evenly distributed to all

wheels on the gantry and so absorbed by the quay foundation

s¬ crane can be either central or side-mounted depending on

cargo handling requirements

s¬ safe and direct access to the driver’s cab via stairway and

ladders

s¬ gantries are optionally fi tted with a mechanical locking device

in order to prevent gantry travel during gales/storms

Power Supply

An external electric cable provides power for the electro-hydraulic

travelling cargo cranes. This cable is embedded in the quayside

and leads to the TCC through a cable guide which should be

positioned in the middle of the quayside in order to optimize the

size of the cable drum.

Positioning of the pedestal

to one side upon request

Cable drum

Cable guide

Access

Electric drive motor

Cross girder

Side girder

Pedestal (variable height)

Bogie (variable number)

Electric supply in cable duct

Rail span (variable)

Cable drum and cable guide

15

Page 16

Operational Comfort

Optional Driver’s Cabin

Particular attention has been paid to the ergonomic layout of

the cabin as well as the optical and acoustic requirements of

the driver:

s¬ COMFORTABLE¬ADJUSTABLE¬DRIVERS¬SEAT¬

s¬ FULL¬ VISION¬ WITH¬ FRONT¬ OVERHEAD¬ m¬OOR¬ AND¬ SIDE¬ WINDOWS¬ OF

tinted safety glass

s¬ TWO¬SELFCENTRING¬ERGONOMICALLY¬POSITIONED¬JOYSTICKS¬ALLOW¬ALL

motions to be operated simultaneously

s¬ AIRCONDITIONING¬

s¬ SWING¬EQUALIZERS¬TO¬REDUCE¬VIBRATION¬TO¬A¬MINIMUM

Litronic Crane Control

Liebherr’s own crane control system Litronic facilitates smooth

and high speed operation as well as preventive maintenance

and includes:

s¬ LOAD¬INDICATION¬AND¬LIMITATION¬

s¬ LOAD¬RECORDING

s¬ MACHINE¬DATA¬RECORDING¬INCLUDING¬ALARMS¬AND¬FAILURES¬

s¬ DETERMINATION¬OF¬SERVICE¬¬INSPECTION¬INTERVALS

s¬ MODEM¬ACCESS¬FOR¬REMOTE¬FAULTl¬NDING¬

s¬ SOFTWARE¬AVAILABLE¬IN¬SEVERAL¬LANGUAGES

Maximum visibility range Extended cabin

16

Page 17

Liebherr Service

Over 10,000 marine and port cranes are attended by Liebherr-Werk Nenzing GmbH through a world-wide network of service centres

with the aim of providing maximum effi ciency through maximum machine availability.

Competence on Site

Speed and reliability are inherent attributes of Liebherr’s service.

Short response times mean reduced downtime and contribute

to the quick restoration of crane productivity.

A close service network throughout the world guarantees

support within 24 hours, if necessary. Qualifi ed specialists are

on stand-by to provide maximum availability, round the clock if

required.

Optimal Spare Parts Logistics – quick,

reliable, at all times

Every working hour is vital for the effi ciency of a port crane. The

Liebherr original spare parts service is available for customers

round the clock, even at weekends and on public holidays.

Liebherr’s standardised overnight distribution service secures

quick and universal delivery of original parts.

Dependable Partnership

Comprehensive know-how ensures fi rst-class and effective

execution of all service and maintenance work, which contributes

to availability and productivity. Liebherr combines expertise with

customer’s practical experience in order to constantly optimize

equipment and service.

s¬ PREVENTIVE¬MAINTENANCE¬AND¬SAFETY¬CHECKS

s¬ INDIVIDUAL¬CUSTOMER¬SERVICE¬AND¬MAINTENANCE¬AGREEMENTS

s¬ COMPREHENSIVE¬ TRAINING¬ FOR¬ CRANE¬ DRIVERS¬ SERVICE¬ AND

maintenance personnel

s¬ WORLDWIDE¬HOUR¬CUSTOMER¬HOTLINE

s¬ IMPLEMENTATION¬OF¬TECHNICAL¬MODIl¬CATIONS¬AND¬UPGRADES

s¬ REMOTE¬DIAGNOSES¬FOR¬FAULTl¬NDING¬AND¬RECTIl¬CATION

Organisation with high-speed guarantee

17

Page 18

The Liebherr Group –

Partner for the Future

Today, Liebherr is among the leading manufacturers in the fi elds of hoisting technology and materials handling equipment. The name

Liebherr stands for products and services. It has become a synonym for ideas and innovations.

Liebherr – A Family Enterprise

In family-operated companies, ownership merges with active

entrepreneurship. This results in characteristic principles.

Liebherr is both a family business and a corporation. This does

not have to be a contradiction, as the continuous success and

steady growth prove.

To create top products, the development capacities and production facilities must measure up to the highest standards. This

requires substantial investments. From stable locations, Liebherr

is following a solidly fi nanced expansion course. The profi ts

made are almost entirely retained within the Group. This provides

ample scope for extensive investments. The economic power of

the Liebherr Group is best shown by its unusually high equity

ratio of more than 50%. This sound economic basis makes

Liebherr highly independent in its strategic decisions, and it

provides an important basis for future investment and innovation

strategies. Offering high-quality products and services which are

aimed towards customers’ needs remains the benchmark.

18

Page 19

Mastering Key Technologies Decentralized and International,

In view of the high quality that Liebherr demands of its products, mastering key technologies internally and keeping core

competencies in-house has always been of great importance

to the company. Therefore, Liebherr develops and produces

crucial components, such as the entire propulsion and control

technology, themselves. Further examples are hydraulic

components, slip ring elements, and diesel engines. Here, Group

suppliers are measured against the best and most effi cient

external provider.

Based on Tradition

Operating effi ciently in manageable, self-dependent units and

aiming strategically at emerging markets have always formed

part of the basic business principles. Thus, Liebherr regularly

invests substantially in further marketing and service companies

as well as in new production sites. Entering and expanding

into new markets means being locally available to assure the

customer receives full and lasting manufacturer support.

While maintaining the proven decentralized organizational form,

a divisional company structure, whose international expansion is

being carried forward, was implemented globally.

19

Page 20

Maritime Equipment Worldwide

Sunderland

Killarney

Rostock

Nenzing

Manufacturing Head Offices

Sales and Service Stations

Representative Offices

Members of Liebherr-MCCtec GmbH (Maritime Division):

Liebherr-Werk Nenzing GmbH

P.O. Box 10,

6710 Nenzing/Austria

Tel.: +43 50809 41 0

Fax. +43 50809 41 500

E-Mail: info.lwn@liebherr.com

Liebherr Container Cranes Ltd.

Killarney, Co. Kerry

Republic of Ireland

Tel.: +353 64 70 200

Fax. +353 64 31 602

E-Mail: sales.lcc@liebherr.com

Liebherr-MCCtec Rostock GmbH

Liebherrstrasse 1

18147 Rostock

Germany

Tel.: +49 381 60 06 0

Fax. +49 381 60 06 100

E-Mail: info.mcr@liebherr.com

Liebherr Sunderland Works Ltd.

Ayres Quay, Deptford Terrace

Sunderland

Tyne and Wear, SR4 6DD

Great Britain

Tel.: +44 191 51 43 001

Fax. +44 191 51 44 191

E-Mail: info.lsw@liebherr.com

Sales and Service Stations:

Liebherr Nenzing Crane Co.

11801 NW 100th Road, Suite 17

Miami, FL 33178

USA

Tel.: +1 305 889 0176

Fax. +1 305 889 0655

Liebherr Great Britain Ltd.

Stratton Business Park

Normandy Lane

Biggleswade, SG18 8QB

Great Britain

Tel.: +44 1767 602 160

Fax. +44 1767 602 161

Liebherr Brasil Port Equipment

Latin America

Rua do Rócio, 288 - Cjs 81 e 82

Vila Olímpia

04552-000 Sao Paulo - SP

Brazil

Tel.: +55 11 3845 4181

Fax. +55 11 3845 7268

Liebherr-Werk Nenzing GmbH

P.O. Box 10, A-6710 Nenzing/Austria

Tel.: +43 50809 41-280

Fax: +43 50809 41-448

ship.port.crane@liebherr.com

www.liebherr.com

Liebherr Nenzing Service GmbH

Am Neuländer Baggerteich 1

21079 Hamburg

Germany

Tel.: +49 40 767 022 00

Fax. +49 40 767 587 86

Liebherr Singapore Pte. Ltd.

8 Pandan Avenue

Singapore 609384

Singapore

Tel.: +65 6265 2305

Fax. +65 6261 6485

Liebherr Ibérica S.A.

Carretera A-2, km 41

c/Aluminio, parcela 6-8

Poligono Industrial Miralcampo

19200 Azuqueca de Henares,

Guadalajara

Spain

Tel.: +34 949 348 730

Fax. +34 949 262 853

Liebherr-Maritime Benelux B.V.

Beeldschmerweg 2

3821 AH Amersfoort

Netherlands

Tel.: +31 33 4500 830

Fax. +31 33 4500 899

Liebherr Russland

1-aja Borodinskaja str. 5

Office 302

121059 Mosc ow

Russian Federation

Tel.: +7 495 502 1734

Fax. +7 495 933 7223

Liebherr EMtec Italia S.p.A.

Via dell’Industria, 8-12

24040 Lallio (BG)

Italy

Tel.: +39 035 69691 40

Fax. +39 035 69691 49

Liebherr India Private Limited

D-16/3 MICD, Ground Floor

TCC Industrial Area, Turbhe

Navi Mumbai - 400 703

India

Tel.: +91 22 6795 7500

Fax. +91 22 6795 7505

www.liebherr.com

FCC-TCC – 10567009 – 06/2011 Subject to change without notice.

Loading...

Loading...