Page 1

LightOn/Off

Zone UpUpDown

41

On/Off SuperFrost Alarm

Down

64

0

Installation

Instructions

For wine cooler with

NoFrost freezer compartment and

Side-By-Side Units

with IceMaker

Instructions

de montage

Armoire de mise en température des

vins avec congélateur NoFrost et les

appareils côte à côte

2-6

4-8

6-12

4

Instrucciones

avec IceMaker

2-6

4-8

6-12

3

2-6

4-8

6-12

2

2-6

4-8

6-12

1

de instalación

Armario de acondicionamiento de

vinos con congelador NoFrost y

unidades lado a lado

con IceMaker

WFI1051 / EWTN/ 2956

7082 408-00

Page 2

I

MPORTANT

PLEASE READ AND FOLLOW

THESE INSTRUCTIONS

These instructions contain Warning and Caution

statements. This information is important for safe

and efficient installation.

Always read and follow all Warning and Caution

statements!

WARNING

!

States a hazard that may cause serious

injury or death if precautions are not followed.

CAUTION

!

Signals a situation where minor injury of

product damage may occur if you do not

follow instructions.

IMPORTANT

This highlights information that is especially

relevant to a problem-free installation.

Make sure incoming voltage is the same as the unit

rating.

To reduce the risk of fire, electric shock, or personal injury, installation work and electrical wiring must

be done by a qualified electrician in accordance

with all applicable codes and standards, including

fire-rated construction.

A delight in freshness

ii

WFI1051 / EWTN 2956

Page 3

TO THE INSTALLER

It is very important that the guidelines and

instructions are followed in the manual to ensure

proper installation and operation of the unit. The

Installation Guidelines section contains important

information for making sure the installation is correct. Read and understand all the information in

Installation Guidelines, and in this manual before

the unit is installed.

I

MPORTANT

WFI1051 / EWTN 2956

A delight in freshness

1

Page 4

T

ABLE

OF

Contents Page

Installation Guidelines ................................................................................. 3

Area Requirements ............................................................................... 3

Electrical Requirement .......................................................................... 3

Customer’s Responsibility .................................................................... 3

Blocking For Safety ............................................................................... 3

Unit Venting ........................................................................................... 3

Planning Information ................................................................................... 4

Cabinet Opening Dimensions ............................................................... 4

Assembling Decorative Panels ................................................................... 7

Integrating Cabinetry ................................................................................... 8

Framed Panels ...................................................................................... 8

Overlay Panels ...................................................................................... 9

Reversing Door Hinges ............................................................................. 14

Door Opening Angle ........................................................................... 17

Installation ................................................................................................. 18

Blocking For Safety ................................................................................... 22

IceMaker .................................................................................................... 23

Water Connection ............................................................................... 23

Connection to the Water Supply ......................................................... 24

Side-By-Side Installation ........................................................................... 25

C

ONTENTS

A delight in freshness

2

WFI1051 / EWTN 2956

Page 5

I

NSTALLATION

G

UIDELINES

Area Requirements

Verify the following:

• Floors can support refrigerator’s weight plus

approximately 1200 pounds (544 kg) of food

weight.

• Finished kitchen floor height has to be level.

Appliance must be shimmed to the floor level if

the floor heights are not equal to make sure air

vents are not obstructed.

• Remove anything attached to rear or side walls

that can obstruct refrigerator opening.

• Cutout dimensions are accurate.

• Electrical outlet is in correct location.

Do not install this unit next to any other refrigerator

or freezer except another Liebherr model. Liebherr

models are designed to allow side-by-side installation. They are equipped with a heating system

to eliminate condensation when units are installed

side by side. Installing this unit next to any other

refrigerator or freezer can cause condensation or

cause damage to the Liebherr unit.

WARNING

!

ELECTROCUTION HAZARD

Electrical Grounding Required. This appliance is equipped with a three-prong

(grounding) polarized plug for your protection against possible shock hazards.

DO NOT remove the round grounding

•

prong from the plug.

DO NOT use a two-prong grounding

•

adapter.

DO NOT use an extension cord to

•

connect power to the unit.

Customer’s Responsibility

A 115 Volt, 60 Hz, 15 Amp (20 Amp for side-byside installation) fused electrical supply is required.

We recommend using a dedicated circuit for this

appliance to prevent electrical overload. Follow the

National Electrical Code and local codes and ordinances when installing the receptacle.

Blocking For Safety

The anti-tip brackets must be installed to prevent

the unit from tipping after it is installed. Refer to

Blocking For Safety.

Electrical Requirement

If codes require a separate grounding circuit to be

used, have a qualified electrician install the circuit.

WARNING

!

Do not ground to a gas pipe. Check with

a qualified electrician if you are not sure

the appliance is properly grounded. Do not

have a fuse in the neutral or grounding

circuit.

WARNING

!

ELECTRICAL SHOCK HAZARD

• Electrically ground refrigerator.

• Do not use an extension cord.

• Failure to follow these instructions

could result in fire or electrical shock.

Unit Venting

DO NOT restrict the air flow. Air flow must be provided for the unit to operate. The factory air vents

provide 31 square inches (200 cm²) of air flow per

unit. If you are replacing the factory air vents with

an overlay, the air flow must be the same or greater

than the factory air vents.

WFI1051 / EWTN 2956

A delight in freshness

3

Page 6

P

LANNING

I

NFORMATION

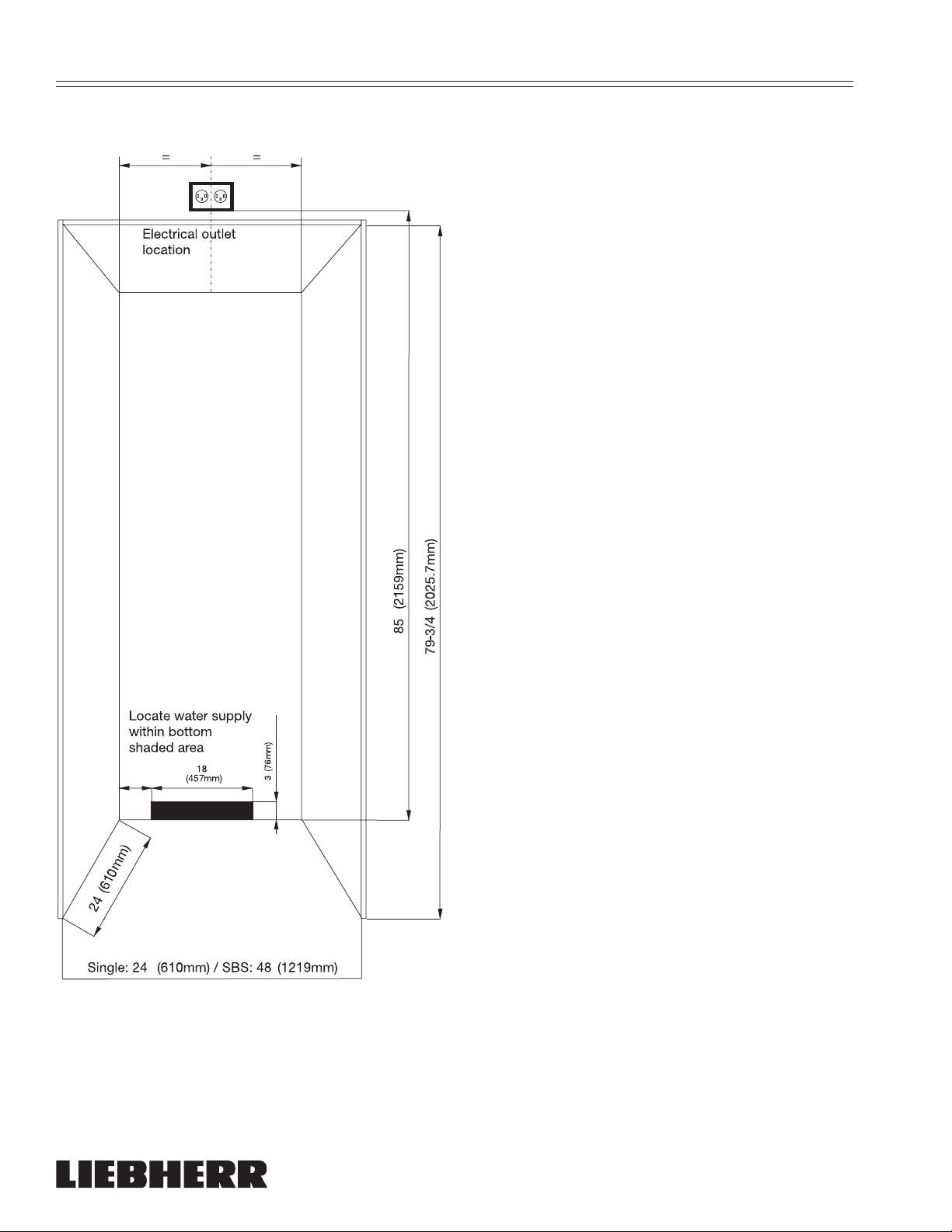

Cabinet Opening Dimensions - Figure 1

Allow units to open a minimum of 90° to prevent

problems removing drawers. With the door opening 90°, you may have to move drawers slightly to

clear the door interior.

Refer to the minimum door clearances in the PreInstallation Specifications chart.

• Allow for a minimum 3-3/4" (95 mm) filler, for

corner installations, so the door can open to 90°.

If you’re using raised panels, consider using a

wider filler.

IMPORTANT

Refer to the full scale illustrations at the end of

this section for specifics on door openings and

filler size alternatives.

"

3"

(76mm)

"

"

"

"

Figure 1

"

"

A delight in freshness

4

WFI1051 / EWTN 2956

Page 7

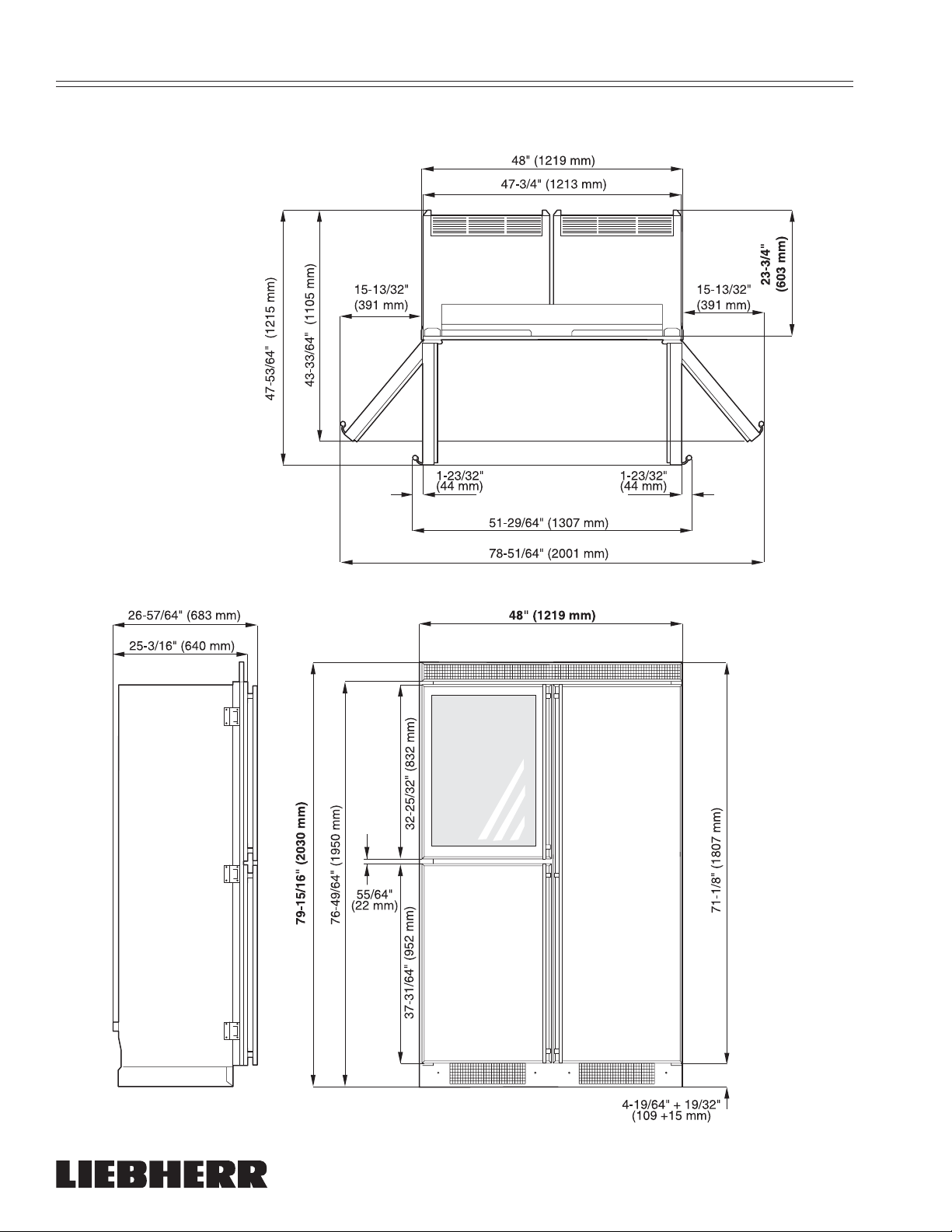

WFI 1051 - Figure 2

P

LANNING

I

NFORMATION

WFI1051 / EWTN 2956

Figure 2

A delight in freshness

5

Page 8

P

LANNING

Side-By-Side WFI 1051 - RBI 1400 - Figure 3

I

NFORMATION

A delight in freshness

6

WFI1051 / EWTN 2956

Page 9

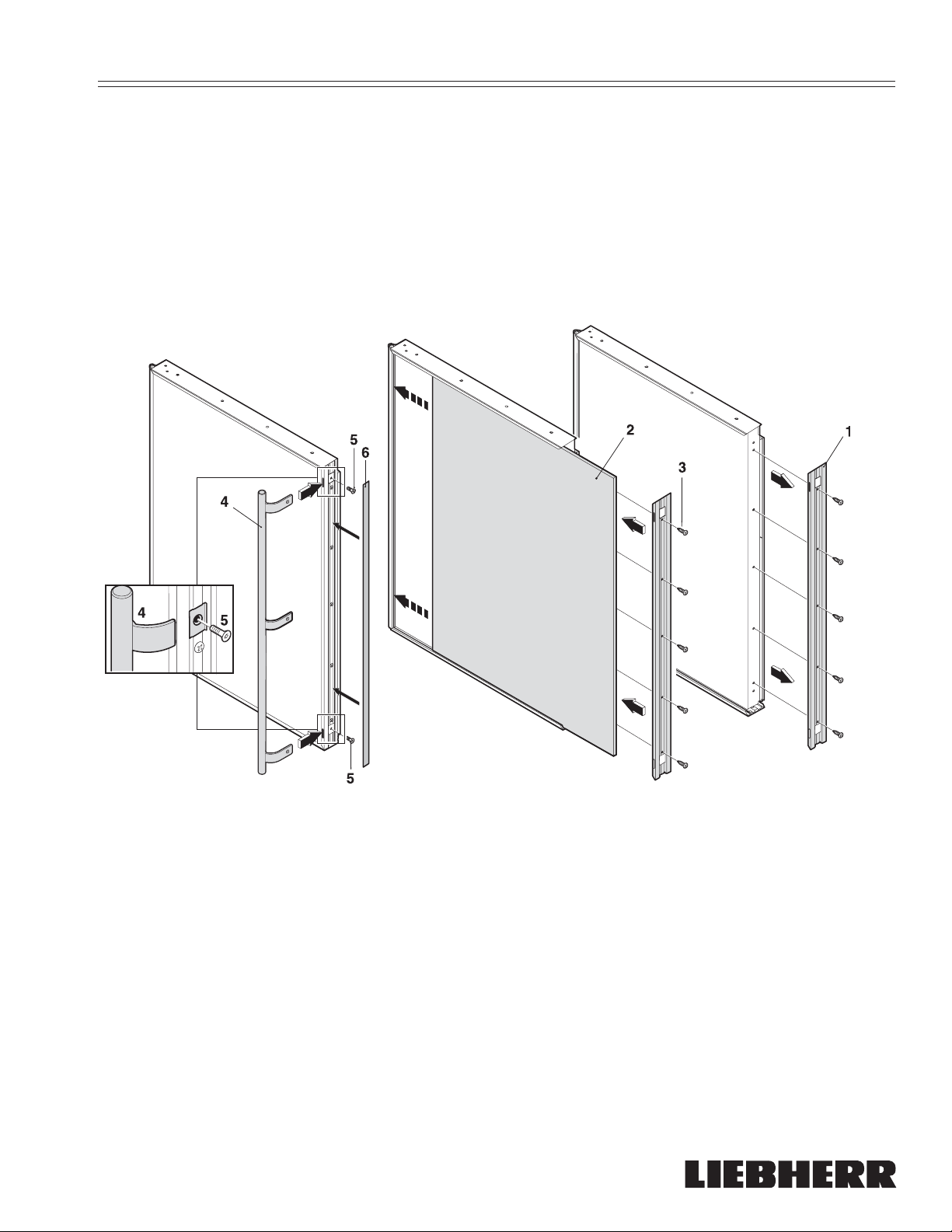

A

SSEMBLING

Figure 4

Proceed as shown in the illustration:

(1) Door change frames

(2) Decorative panel

(3) Screws for door change frames

(4) Handle, depending on model

(5) M4 x 10 screws for handle

(6) Filler strip

D

ECORATIVE

P

ANELS

WFI1051 / EWTN 2956

Figure 4

A delight in freshness

7

Page 10

I

NTEGRATING

C

ABINETRY

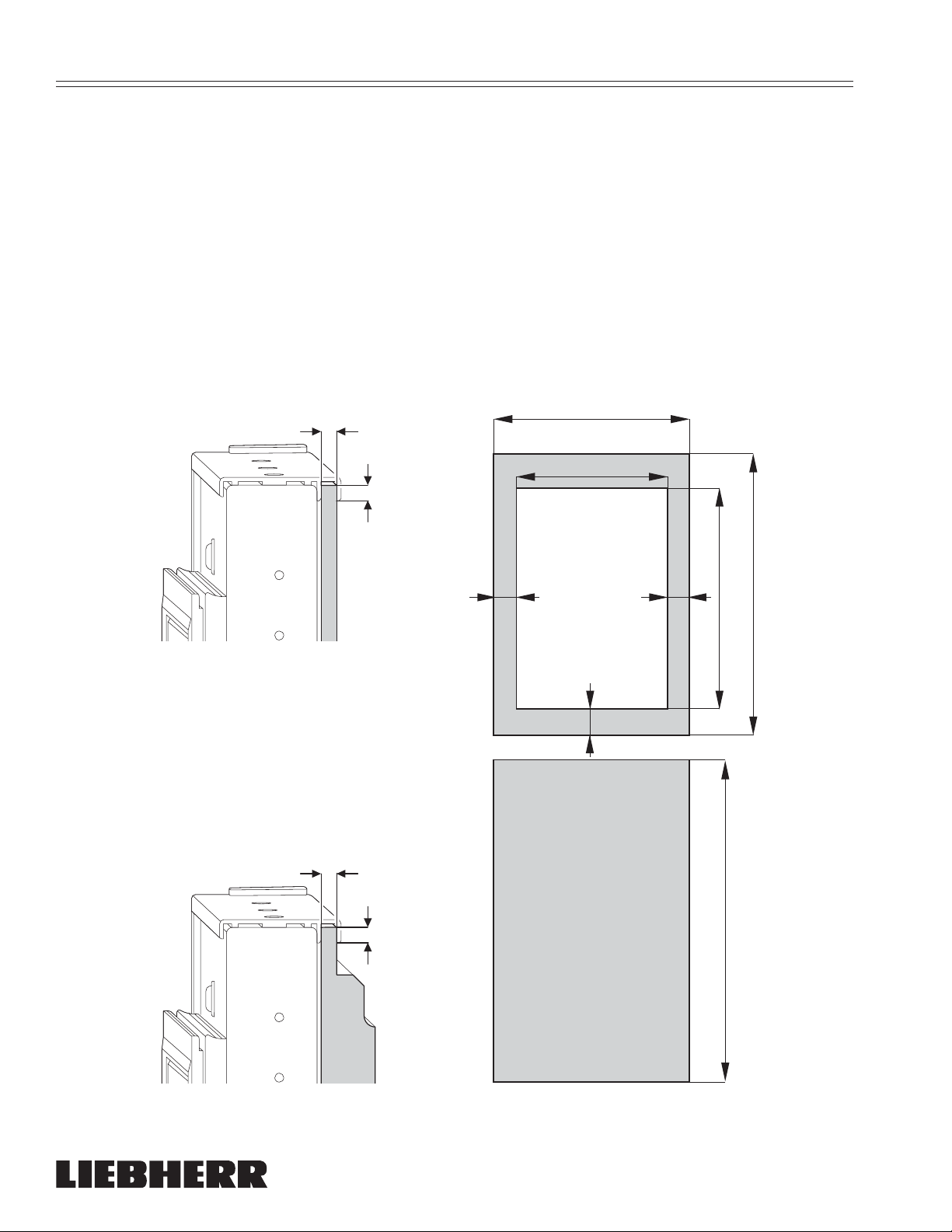

Framed Panels - Figure 5

If the thickness of the custom panels is less than

1/4" (6.4 mm), they must be backed up with a sheet

of shim material to build the total thickness to 1/4"

(6.4 mm). If the panel is thicker than 1/4" (6.4 mm),

an edge must be routed around the panel to

ensure a proper fit.

1/4"

(6.4 mm)

1/4" (6.4 mm)

IMPORTANT

If you are replacing the factory air vents with

an overlay, DO NOT restrict the air flow. The air

flow must be the same or greater than the factory air vents of 31 square inches (200 cm²).

The door handles must be installed before the

screw covers are installed. If you fail to install

the handles before the screw covers, you can

damage the covers. The screw covers are

taped to the unit doors during shipping. Use

care when removing covers.

The door panel weight must not exceed

25 lb (11,3 kg).

22-9/16" (573 mm)

max. 17-1/2" (445 mm)

Window cutout

= =

1/4"

(6.4 mm)

1/4" (6.4 mm)

3-1/16"

(78 mm)

32-37/64" (828 mm)

max. 25-1/2" (648 mm)

37-9/32" (947 mm)

Figure 5

A delight in freshness

8

WFI1051 / EWTN 2956

Page 11

I

NTEGRATING

C

ABINETRY

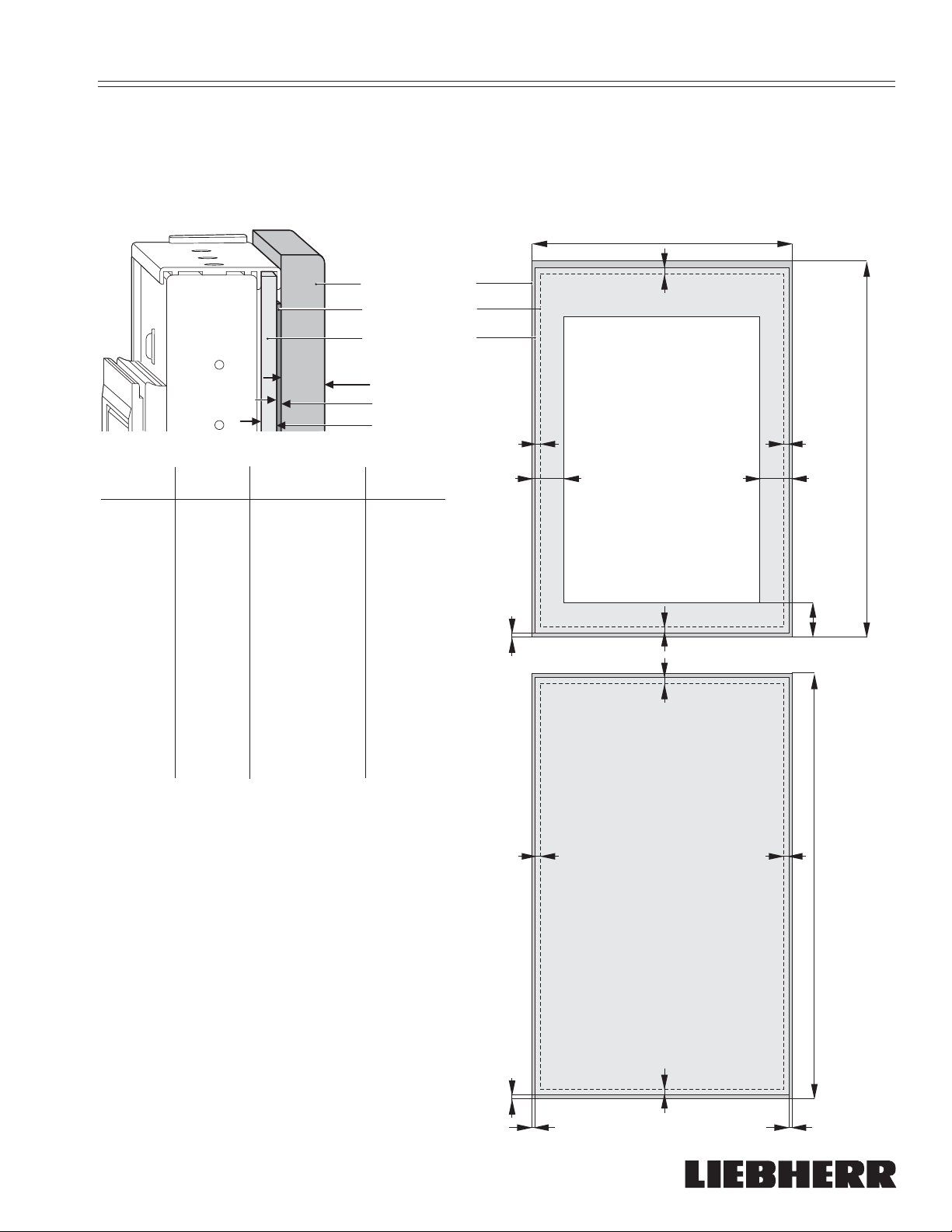

Overlay Panels - single install - Figure 6

The overlay design line allows decorative panels to

cover the door trim for a more seamless appearance that blends with the design of the room. To

achieve this look, the most common way is to work

1 Overlay Panel

2 Spacer Panel

3 Backer Panel

Approx. 3/4"

(19.1mm)

3/32" (2.5mm)

1/4" (6.4mm)

W

H - Winecooler H - Freezer

1 Overlay

Panel

23-5/16"

(592 mm)

33-5/8"

(854 mm)

38"

(965 mm)

with three panels, the decorative overlay panel, a

3/32" (2.5 mm) spacer panel and a 1/4" (6.4 mm)

backer panel.

Depending on your cabinet manufacturer, this could

be one panel routed for different dimensions or,

more likely, three different panels.

W

=

Window cutout

= =

==

H

Winecooler

2 Spacer

Panel

3 Backer

Panel

Window

cutout

21-3/4"

(553 mm)

22-3/4"

(576 mm)

max17-1/2"

(445 mm)

31-1/2"

(800 mm)

32-37/64"

(828 mm)

max 25-1/2"

(648 mm)

36-1/4"

(921 mm)

37-9/32"

(947 mm)

IMPORTANT

If you are replacing the factory air vents with an

overlay, DO NOT restrict the air flow. The air flow

must be the same or greater than the factory air

vents of 31 square inches (200 cm²).

The door handles must be installed on the

overlay panels before the screw covers are

installed. If you fail to install the handles on

the overlay panels before the screw covers ,

you can damage the covers. The screw covers

are taped to the unit doors during shipping.

Use care when removing covers.

3/8"

(9mm)

=

=

==

3-1/16"

(78mm)

H

Freezer

The door panel weight must not exceed

25 lb (11,3 kg).

Figure 6

WFI1051 / EWTN 2956

3/8"

(9mm)

A delight in freshness

9

=

==

Page 12

I

NTEGRATING

C

ABINETRY

Overlay Panels - side by side install

The overlay design line allows decorative panels to

cover the door trim for a more seamless appearance that blends with the design of the room. To

achieve this look, the most common way is to work

1 Overlay Panel

2 Spacer Panel

3 Backer Panel

Approx. 3/4"

(19.1mm)

3/32" (2.5mm)

1/4" (6.4mm)

W

H - Winecooler H - Freezer

1 Overlay

Panel

23-5/16"

(592 mm)

33-5/8"

(854 mm)

38"

(965 mm)

with three panels, the decorative overlay panel, a

3/32" (2.5 mm) spacer panel and a 1/4" (6.4 mm)

backer panel.

Depending on your cabinet manufacturer, this could

be one panel routed for different dimensions or,

more likely, three different panels.

W

=

==

Window cutout

= =

H

Winecooler

2 Spacer

Panel

3 Backer

Panel

Window

cutout

21-3/4"

(553 mm)

22-3/4"

(578 mm)

max17-1/2"

(445 mm)

31-1/2"

(800 mm)

32-37/64"

(828 mm)

max 25-1/2"

(648 mm)

36-1/4"

(921 mm)

37-9/32"

(947 mm)

IMPORTANT

If you are replacing the factory air vents with an

overlay, DO NOT restrict the air flow. The air flow

must be the same or greater than the factory air

vents of 31 square inches (200 cm²).

The door handles must be installed on the

overlay panels before the screw covers are

installed. If you fail to install the handles on

the overlay panels before the screw covers ,

you can damage the covers. The screw covers

are taped to the unit doors during shipping.

Use care when removing covers.

3/8"

(9mm)

Handle Side

=

=

==

3-1/16"

(78mm)

H

Freezer

Hinge Side

The door panel weight must not exceed

25 lb (11,3 kg).

3/8"

(9mm)

A delight in freshness

10

=

3/16"

(4.7mm)

WFI1051 / EWTN 2956

Page 13

I

NTEGRATING

C

ABINETRY

Figure 7

C

The factory setting for the door to swing open is

130°. Use this illustration to ensure other cabinets or counters do not interfere with the door

opening.

Frameless cabinets: The casing trim overlaps

the cabinets at the side and top. Cabinets may

require filler strips to prevent interference with

the cabinet door swing. The door opening must

allow for filler strips.

1"

(25.4 mm)

1-1/4"

(31.8 mm)

(12.7 mm)

(19.1 mm)

(25.4 mm)

(6.4 mm)

3/4"

1"

1/4"

1/2"

3"

(76.2 mm)

2-3/4"

(69.9 mm)

2-1/2"

(63.5 mm)

(57.2 mm)

2"

(50.8 mm )

1-3/4"

(44.5 mm)

1-1/2"

(38.1 mm)

2-1/4"

3/4"

(19.1 mm)

(12.7 mm)

(1219.2 mm)

A

1/2"

1/4"

(6.4 mm)

24" (609.6 mm)

48"

1"

(25.4 mm)

3/4"

(19.1 mm)

1/2"

(12.7 mm)

1/4"

(6.4 mm)

3/32"

(2.4 mm)

D

LBR026

Figure 7

WFI1051 / EWTN 2956

A delight in freshness

11

Page 14

I

NTEGRATING

Figure 8

The optional setting for the door to swing open is

90°. Use this illustration to ensure other cabinets or

counters do not interfere with the door opening.

Frameless cabinets: The casing trim overlaps the

cabinets at the side and top. Cabinets may require

filler strips to prevent interference with the cabinet

door swing. The door opening must allow for filler

strips.

C

ABINETRY

A delight in freshness

12

WFI1051 / EWTN 2956

Page 15

I

NTEGRATING

C

ABINETRY

(25.4 mm)

1-1/4"

(31.8 mm)

1-1/2"

(38.1 mm)

(12.7 mm)

3/4"

(19.1 mm)

1"

1/4"

(6.4 mm)

1/2"

3"

(76.2 mm)

2-3/4"

(69.9 mm)

2-1/2"

(63.5 mm)

2-1/4"

(57.2 mm)

(2.4 mm)

2"

(50.8 mm )

3/32”

C

1-3/4"

(44.5 mm)

1-1/2"

(38.1 mm)

(25.4 mm)

1-1/4"

(31.8 mm)

1"

(19.1 mm)

3/4"

1/2"

(12.7 mm)

(6.4 mm)

24”

(609.6 mm)

48”

(1219.2 mm)

A

1/4"

WFI1051 / EWTN 2956

1/4"

(6.4 mm)

1/2"

(12.7 mm)

3/4"

(19.1 mm)

1"

(25.4 mm)

Figure 8

A delight in freshness

13

D

LBR025

Page 16

7

R

EVERSING

The door hinges can be changed from one side to

the other if required.

1. Figure 10: Top: Unscrew the hinge pin (2) and

remove the screw (5) with the eccentric.

2. Swivel out the door at the top, ensuring that

you do not lose the stop (7) and bushing (8); lift

off the door and place it on the floor.

3. Center: Pull out the hinge pin (9) with its washer.

4. Swivel out the lower door, lift it out and place it

on the floor. Take care not to lose the stop (7)

and washers (8).

5. Unscrew all the door fittings (14, 15, 16, 17).

6. Figure 11: Unscrew all the door change frames

and exchange them with one another (6 with 8,

4 with 7 and handle - remove cover 1). Secure

them in position using the same screws.

7. Ensure that the door change frames are correctly positioned and mitered.

WARNING

!

D

OOR

H

INGES

8

8

LBR02

Figure 10

Make sure the corners of the door change

frames are positioned correctly. Sharp

edges will be exposed if they are not

mitered or positioned correctly.

Figure 11

A delight in freshness

14

WFI1051 / EWTN 2956

Page 17

R

EVERSING

D

OOR

H

INGES

8. Figure 12: Unscrew the lower hinge (13).

- Remove the stop and bushings (7, 8).

- Transfer hinge pin (2) to the opposite side.

- Turn the stop (7) 180° and position bushings (8) as shown in the detailed drawing.

- Screw on hinge (13) on the new hinge side.

9. On the lower door: Reinstall the door fittings

(14, 15). Pay special attention to the part (14)

with the stop.

10. Unscrew the center hinge (10) and cover (11),

pull them off to the side and after turning

them 180°, slide them on again on the opposite

side and secure them.

11. Place the lower door on the hinge pin (2) at the

bottom.

- Swivel in the door.

- Pay special attention to the bushing (12) in the

center hinge (10).

- Insert hinge pin (9) and add the washer.

WFI1051 / EWTN 2956

LBR029

Figure 12

A delight in freshness

15

Page 18

R

180

°

EVERSING

D

OOR

H

INGES

12. Figure 13: Lift up cover (3) on handle side,

push outward; lift up cover (1) on hinge side

and pull off.

13. Unscrew mounting plate (21): first mounting

screw (20), then inner retaining screw (25).

- Unscrew hinge (4): first remove the mount-

ing screw (20), then retaining screws (25). Fit

hinge (4) to opposite side: for easy assembly, fit hinge from above and first tighten

with the upper retaining screw (25) M5, then

screw (25) and finally mounting screw M4 (20).

- Turn mounting plate (21) 180° and screw tight

again on the new handle side: first retaining

screw (25), then mounting screw (20).

20

25

4

180°

25

21

20

14. Remove the eccentric (5) with the retaining

screw in the hinge (4).

15. On the upper door: Reinstall the door fittings

(16, 17). Pay special attention to the fitting (17)

with the stop.

16. Place the upper door on the center hinge, fit the

bushing (8), stop (7) and washer on the door,

swivel in the door at the top and insert and

secure the hinge pin (2) from above through the

hinge and stop.

17. Re-insert the eccentric (5) with the retaining

screw as shown in the detailed drawing.

Check for proper alignment of all doors. Adjust

them if necessary using the slots on the hinge.

21

4

12

14

15

17

16

15

Figure 13

A delight in freshness

16

WFI1051 / EWTN 2956

Page 19

R

EVERSING

Door Opening Angle - Figures 14, 15

The appliance is delivered with a door opening

angle of 130°.

If the angle is to be decreased to 90°, proceed as

follows:

• Insert attached screw (6) in the upper hinge as

shown in Figure 14.

• Insert attached screw (6) in the lower hinge as

shown in Figure 15.

D

OOR

H

INGES

Figure 14

Figure 15

WFI1051 / EWTN 2956

A delight in freshness

17

Page 20

I

NSTALLATION

Only install the winecooler/freezer in a stable kitchen cabinet that has been properly aligned.

- Mount and fix the handles, depending on your

model and choice.

Unpacking

Unpack the installation kit and check with the provided parts list if all parts are included.

The part numbers given in the parts list are identical

to the numbers in the respective fi gures.

For installation you will need the following tools:

Included:

- Star Key Torx® 15

- Star Key Torx® 20

- Star Key Torx® 25

- Socket Wrench 8 mm

- Open-end Wrench 10 mm

Not in package:

- Phillips (star) screwdriver

- Level

- Ruler

Figure 16: Installation with Ventilation Grille Set:

1. Screw the installation frame at the top (1) onto

the appliance with screws (2).

2. Place the ventilation grille (3) on this, align it in

the center and secure at the front from underneath.

3. Slide brackets (4) onto the side installation

frames (5) from above and below.

4. Using the frame (5), screw the brackets onto

the side wall*.

5. Slide the side installation frames (5) upwards

until they are in contact with the underside of

the ventilation grille.

6. Secure the side frames with the adhesive section (7) to prevent them from sliding down.

Remove the protective film and affix the adhesive sections over the upper brackets on the

handle and hinge sides.

* Depending on model and options

A delight in freshness

18

LBR034

Figure 16

WFI1051 / EWTN 2956

Page 21

I

6

NSTALLATION

- Figure 17: Connect the appliance to the

main power supply.

- If the appliance is equipped with an

IceMaker, establish the connection for

the water supply. See “IceMaker, Water

Connection”.

1

1 2

1. Carefully slide the appliance into the cabinet

until the ventilation grille touches the surrounding kitchen cabinet.

2. Align the appliance until it is parallel with the

surrounding kitchen cabinet. Use the openend wrench 10 mm (3) to adjust the feet at the

front. Turn clockwise for up and counterclockwise for down. For the rear use the adjusting

2

3

2

2

3

8 spanner

3

Figure 17

3. Figure 18: Align the appliance at the side with the

4. Fit the ventilation grille at the bottom [(3) if the

10 spanner

bolt (2). Turn clockwise for down and counterclockwise for up.

Maximum adjustment: 19/64" (15 mm).

cabinet side panel and attach it with screws (1).

- Cover the screws with cover caps (2).

door is hinged on the left, (4) if it is on the right]:

Secure the ventilation grille so that it touches

the floor and then adjust it using the slots.

WFI1051 / EWTN 2956

LBR03

Figure 18

A delight in freshness

19

Page 22

I

NSTALLATION

The following ventilation cross-section

and distances must be observed:

- There must be a ventilation space of

at least 31 square inches (200 cm²)

per appliance in the cabinet plinth

and under the cabinet top panel.

- The depth of the ventilation duct at

the rear of the cabinet must be at

least 1-1/2" (38 mm).

Alternatively:

1. For built-in appliances without ven-

tilation grilles and only with an installation frame, ventilation must take place

through the ventilation duct at the rear

of the cabinet.

Built-in appliances with an installation

frame:

• Figure 19:

- Screw the complete installation

frame (2) to the appliance.

1 1/2”

(38mm)

At least 31 square inches (200cm2)

”

/4

)

3

m

0

m

2

7

2

5

(

1

2

1

2. Built-in appliances with a wooden

ventilation grille:

Figure 20: Cut out the wooden trim

for use as a ventilation grille using the

enclosed template.

- The required ventilation cross-section must be at least 31 square

inches (200 cm²) when a single

appliance is installed, which corresponds to template “small” (If you

install two appliances side-by-side,

the cross-section must be at least

62 square inches, (400 cm²), which

corresponds to template “doublesize;” for more information see “Sideby-Side Installation”).

• Remove the attachment bracket (2)

from the installation frame and screw it

to the appliance (1) from underneath.

Place the wooden ventilation grille (5)

on the appliance, align it in the center

and secure it from the rear using the

attachment bracket (2).

Figure 19

2

1

(609,6 mm)

3-11/16"

(93,7 mm)

5

24"

1/2"

(13 mm)

A delight in freshness

20

Figure 20

WFI1051 / EWTN 2956

Page 23

N

OTES

WFI1051 / EWTN 2956

A delight in freshness

21

Page 24

B

LOCKING

F

OR

S

AFETY

Figure 21: Secure the appliance in place so it does

not tip forward when the fully stocked door is

opened.

2. Measure the distance from the floor to the

upper edge of the unit.

3. Locate and mark two wall studs (1) against the

wall where the refrigerator will be located. The

space between the unit top and the bottom of

the brackets must not be more than

1/4" (6.4 mm).

4. Make sure the screws (2) extend a minimum of

1" (25.4 mm) into each of the wall studs.

5. Make sure the anti-tip brackets (3) extend

at least 3" (76.2 mm) over the unit and are

securely in place.

IMPORTANT

The anti-tip brackets can be installed in either

direction or closer together. Always position

the anti-tip brackets as wide apart as possible, but make sure they are anchored to two

studs.

6. Using the adjustable roller base, raise the unit

until it makes contact with the brackets. Make

sure the front levelers are firmly on the floor to

prevent appliance from tipping forward.

IMPORTANT

If your unit is positioned in between the

wall studs, a board can be secured to the

wall. Make sure the board is secured to the

studs with screws that will penetrate into the

studs a minimum of 1" (25.4 mm). The board

should be a minimum of 1" x 6" (25.4 mm x

152.4 mm) and long enough to secure both

ends to the wall studs.

3

1

min 3"

Figure 21

A delight in freshness

22

WFI1051 / EWTN 2956

Page 25

Water Connection - Figure 22

Please read the first three points of the safety

instructions and warnings before connecting the

appliance to the main water supply.

• The water pressure must be between 21.8-

87.0 psi (1.5-6 bar).

• Use a 1/4" OD copper line to connect the water

supply to the solenoid valve. This is not sup-

plied with the appliance (Figure 22).

• A shut-off valve, such as the saddle valve illustration here, must be installed between the hose

line and the main water supply so the water supply can be stopped if necessary.

I

CE

M

AKER

Do not install the shut-off valve behind the

appliance.

Figure 22

• If you have hard water, we recommend you install

a water softener. Also, a filter must be installed if

the water contains solids such as sand.

• All equipment and devices used to supply the

water to the appliance must comply with the current regulations for your geographical area.

WFI1051 / EWTN 2956

A delight in freshness

23

Page 26

I

CE

M

AKER

Connection to the Water Supply

1. Install the shut-off valve, water filter and automatic shut-off device as required.

Note

The solenoid valve is located at the rear of

your unit.

2. Place a 1/4" OD copper tubing between the

shut-off valve and solenoid valve. Make sure

there is approximately 30" (70 cm) of excess

tubing behind the unit for easy connection.

IMPORTANT

The solenoid valve has a Metric R3/4 male

connection.

A R3/4(metric) to a 1/4" OD adapter and

cable clip are supplied with the icemaker.

Figure 24: Remove the cover cap (4) from

the solenoid valve (1). Install the connection

bracket (2) with sealing ring (6) on the solenoid

valve (1). Attach the copper tube to the connection bracket (2). Secure the copper tube (3) to

the appliance using the cable clip (5).

3. Open the shut-off valve for the water supply

and check the entire water system for leaks.

Before the appliance is used for the first time a

licensed plumber should bleed air from the system.

4. Insert the electrical plug for the combined appliance into the electrical outlet (Figure 23).

5. Move the appliance into final position in the

room.

Figure 23

A delight in freshness

24

WFI1051 / EWTN 2956

Page 27

S

IDE

4

-B

Y

-S

1

IDE

I

NSTALLATION

WFI1051 / EWTN 2956

1

6

2

3

5

5

Figure 24

A delight in freshness

25

Page 28

S

IDE

-B

Y

-S

IDE

I

NSTALLATION

Unpacking

Unpack the side by side installation kit and check

with the provided parts list if all parts are included.

The part numbers given in the parts list are identical

to the numbers in the respective fi gures.

For installation you will need the following tools:

Included:

- Star Key Torx® 15

- Star Key Torx® 20

- Star Key Torx® 25

- Socket Wrench 8 mm

- Open-end Wrench 10 mm

Not in package:

- Phillips (star) screwdriver

- Level

- Ruler

Figure 25: To install the WFI 1051 appliances sideby-side, proceed as follows:

- Always place the WF/WFI 1051 with the hinges

on the left-hand side (looking from the front).

Installation with SBS Ventilation Grille Set:

1. Affix the spacer (1) on the side wall of the appli-

ance – remove the protective film.

2. Push the appliances together,

- align them parallel to each other.

3. Use a level on the top to align them to the

same height:

4. Use the open-end wrench 10 mm (3) to adjust

the feet at the front of the roller base. Turn

clockwise for up and counterclockwise for down.

For the rear, turn the adjusting bolt (2) clockwise down and counterclockwise up.

Figure 25

A delight in freshness

26

4

WFI1051 / EWTN 2956

Page 29

S

IDE

-B

Y

-S

IDE

I

NSTALLATION

5. Figure 26: Secure the installation frame (3)

at the top to the appliances with screws (2).

- Align the appliance at the front bottom.

- Use the predrilled holes to align the

installation frame (2).

- First mount the installation (3) frame with

4 screws (2) to one appliance, then align

the other appliance with the predrilled

holes to the installation frame (3) and

secure it with the screws (2).

6. Figure 26: Position the attachment brack-

ets (6) at the rear of the appliances at the

top and bottom. Slide the upper attachment

bracket upwards as far as possible. Secure it

at the side using the screws provided (5). Do

not overtighten!

5

2

3

6

A delight in freshness

6

Figure 26

8-1/4"

ca. (210)

6

5

5

6

WFI1051 / EWTN 2956

27

Page 30

S

IDE

7. Figure 27: Push the long carriage bolt

M5x260 (7) through the leveling wheels as shown.

Fit in a washer (8). Screw on the wing nut (9) and

tighten it manually. Do not overtighten.

8. Turn the adjustable roller base up. Otherwise

you will damage the floor when you push in the

appliances.

9. Secure the ventilation grille (10) to the appliance with screws (11). Push in the sealing

strip (4) as shown.

-B

Y

-S

IDE

I

NSTALLATION

10

9

11

9 8 7

4

7

4

10 spanner

Figure 27

A delight in freshness

28

7

8 spanner

2

3

WFI1051 / EWTN 2956

8

Page 31

S

IDE

-B

Y

-S

IDE

I

NSTALLATION

10. Figures 28, 29: Slide the side installation

frames (15) upward until they are in contact with the underside of the ventilation

grille, Figure 28.

11. Secure the side frames with the adhesive section (17) to prevent them from

sliding down. Remove the protective film

and place the adhesive sections over the

upper brackets.

12. Install anti-tip brackets for each appliance.

Refer to “Blocking For Safety.”

10

15

17

17

11

15

11

17

min 3"

Figure 29

A delight in freshness

Figure 28

WFI1051 / EWTN 2956

29

Page 32

S

IDE

13. Figure 30, 31: Connect the appliances:

- to the main power supply and

- to the water supply if the appliance is equipped

with an IceMaker. See “IceMaker, Water

Connection,” Figure 30.

14. Carefully slide the connected appliances into the

recess until the ventilation grille touches the top,

Figure 31.

-B

Y

-S

IDE

I

NSTALLATION

15. Align the appliances by using only the outer leveling wheels at the front (3) and rear (2).

13

Figure 30

14

10 spanner

Figure 31

A delight in freshness

30

15

2

8 spanner

3

LBR042

WFI1051 / EWTN 2956

Page 33

S

IDE

16. Figure 32: Attach the aligned combination

to the surrounding kitchen cabinet. Secure it

through the side frames using the screws (20)

provided.

- Cover the screws with cover caps (21).

17. Now adjust the center adjustable roller

bases (22) so that they make slight contact

with the floor.

18. Install the lower ventilation grille (23): Secure

the ventilation grille so that it touches the floor

and adjust it using the slots. Do not overtighten!

-B

Y

-S

IDE

I

NSTALLATION

20

22

16

17

18

10 spanner

24

2

21

8 spanner

3

WFI1051 / EWTN 2956

24

24

23

24

Figure 32

A delight in freshness

31

LBR043

Page 34

S

IDE

-B

Y

-S

IDE

I

NSTALLATION

1. For built-in appliances without ventilation

grilles and only with installation frame (2), ven-

tilation must take place through the ventilation

duct at the rear of the cabinet. Ensure that the

ventilation cross-section is at least 31 square

inches (200 cm²) per appliance.

At least 62 square inches (400 cm²) for side-byside installation of two appliances. Built-in appliances with an installation frame:

- Figure 33: Screw the installation frame (2) to

the appliance through the attachment brackets.

1 1/2”

(38mm)

At least 31 square inches (200cm2)

”

/4

)

3

m

0

2

m

7

2

”

5

(

/4

)

3

0

m

2

m

7

2

5

(

per unit

1

2

Figure 33

A delight in freshness

32

WFI1051 / EWTN 2956

Page 35

S

IDE

-B

Y

-S

IDE

I

NSTALLATION

Built-in appliances with a wooden ventilation

grille:

2. Figure 34: Cut out the wooden trim for use as

a ventilation grille using the attached template.

- The required ventilation cross-section must

be at least 62 square inches (400 cm²) for

side-by-side installation of two appliances,

which corresponds to the attached template

“double-size.”

- Remove the attachment brackets from the

installation frame (2) and screw them to the

appliance from underneath.

- Place the wooden ventilation grille (5) on the

appliance, align it in the center and secure it

from the rear using the attachment brackets.

2

WFI1051 / EWTN 2956

3-11/16"

(93,7 mm)

Figure 34

A delight in freshness

33

48"

(1219,2 mm)

5

1/2"

(13 mm)

Loading...

Loading...