Page 1

Excavators Electric

Material Handlers

ER 934 C - ER 954 C

ER 934 C Operating Weight: 38,050 – 39,450 kg

ER 944 C Operating Weight: 52,050 – 53,750 kg

ER 954 C Operating Weight: 63,900 – 76,200 kg

Page 2

ER 934 C

ER 944 C

Operating Weight: 38,050 – 39,450 kg

Engine Capacity: 160 kW / 218 PS

ER 954 C

Operating Weight: 63,900 – 76,200 kg

Engine Capacity: 250 kW / 340 PS

Operating Weight: 52,050 – 53,750 kg

Engine Capacity: 200 kW / 272 PS

ER 934 C ER 944 C ER 954 C Material Handlers

2

Page 3

Performance

These new electric Material Handlers have been designed

to meet the specific needs of industrial handling. A wide

range of equipment and uppercarriages optimized for

long working radius provide the ideal answer to all the

demands which arise in the industry.

The performance of the kinematic chain formed from components from our in-house production, combined with the

power of the electric motor, maximize the performance

of the machine when it comes to lifting power, precision,

and speed of operation. The equipment’s performance is

enhanced by the mobility provided by the crawler undercarriage.

Comfort

Helping the operator to concentrate on his work and get

the best out of his machine is achieved by providing a

comfortable driving position, good visibility, and a highly

ergonomic layout of the controls. The new electric Material Handlers offer the same level of comfort as on the

mobile excavators (arrangement of the controls, driver’s

seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks

to the low noise emissions and absence of vibration. For

Liebherr, comfort also means ease of daily maintenance

of the machine in terms of access to the service and inspection points, so as to minimize down time.

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the

new ER 934 C, ER 944 C and ER 954 C with the aim of

providing top performance whatever the challenge might

be. The structure of the machine, using components from

our own manufacture for the electric drive, has been

completely rethought, and so moves away from simply

being an adaptation of a diesel-engine machine. Being

intended for key functions in the organization of industrial

sites, Liebherr electric Material Handlers provide a very

high level of reliability. The service life of the hydraulic

components has also been increased, thanks to

the smoother movement of the electric drive. The

concept of the single actuator (one single elec-

tric motor for all the hydraulic functions) allows

all the low-voltage functions to be concentrated

in a single box.

Economy

Investing in the acquisition of an electric Material Handler

is a great long-term advantage. Constant increases in the

costs of conventional energy sources are pushing up operating charges, and reducing profi t margins considerably. Environmental criteria, in particular CO2 emissions,

are also playing a constantly greater part in the choice of

power systems and working methods. With the electric

drive, Liebherr offers an economical alternative to conventional diesel-engine machines, and a solution with

real respect for the environment. Also, the excavator is

permanently available, with no need to refill. There are no

constraints (e.g. DPF or AdBlue).

ER 934 C ER 944 C ER 954 C Material Handlers

3

Page 4

ER 934 C ER 944 C ER 954 C Material Handlers

4

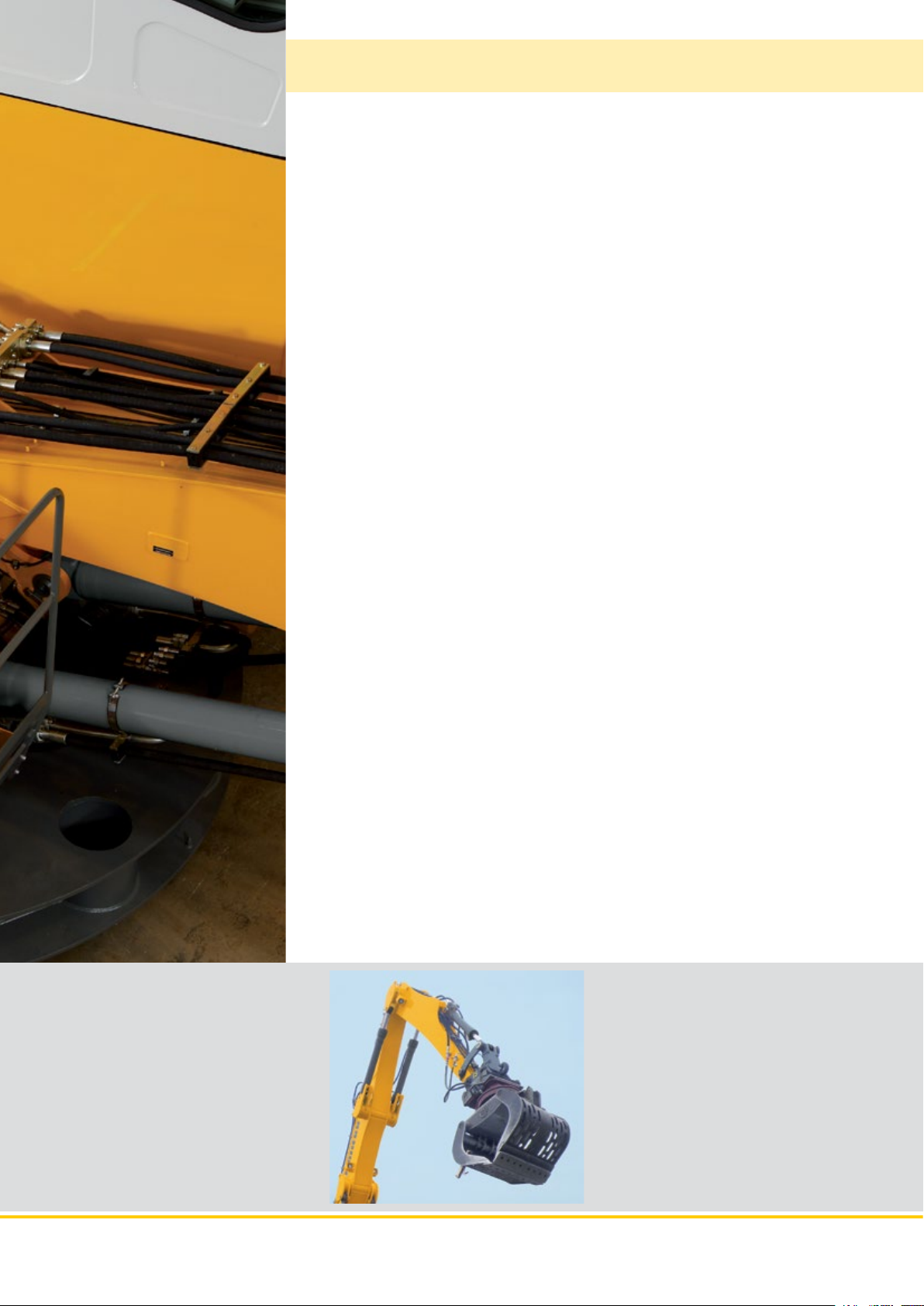

Side or rear cable opening for freely

positioning the cable on the ground

•Powersupplythroughmulticorewiring

cable entrance (funnel-shaped) especially

designed for travelling machines

•Forlongerdistancesacablereelcan

be proposed as an option

•Heavydutyconnectingboxttedonthemiddle

piece of the undercarriage with switching system

Page 5

Performance

These new electric Material Handlers have been designed to meet the specifi c

needs of industrial handling. A wide range of equipment and uppercarriages optimized for long working radius provide the ideal answer to all the demands which

arise in the industry. The performance of the kinematic chain formed from components from our in-house production, combined with the power of the electric

motor, maximize the performance of the machine when it comes to lifting power,

precision, and speed of operation. The equipment’s performance is enhanced by

the mobility provided by the crawler undercarriage.

Exceptional lift capacity

Excellent Working

Radius

Fast work cycles

Precision

Thanks to optimized kinematics and uppercarriage,

the machines offer extended reach and balance

with a better absorption of mechanical forces.

Designed for the most demanding applications, the

machines offer extended reach and lift capacity in

wide working radius.

The ER 934 C, ER 944 C and ER 954 C electric

excavators are fitted with the Liebherr Torque Control system. The hydraulic guidance system on the

excavator operates as a closed circuit, and does

not affect the speed of movement of the equipment during the working cycle. The high torque and

high oil delivery from the guide pump maximize the

excavator swing speed.

A two-pump hydraulic system allows for operating

speeds to be reached which are unequalled anywhere. Regeneration on the circuits for the equipment allows for optimization of the hydraulic power

available and minimizing response time to the operator’s commands.

The hydraulic control allows for exceptional precision - even at extended reach - contributing to the

confidence of the operator and achieving high performance as a result.

Distributor

•Fineresponseofhydrauliccontrol

for maximum working precision

•Immediateresponsetooperator‘s

commands

•Three-pumphydraulicsystem,oneof

which is a closed circuit dedicated to

uppercarriage swing

High strenght structure

•Highstrengthsteelsheetatpoints

subject to severe stress.

•Stablemountingofequipment

elements

•Exceptionalstrength,evenunder

intense loading

ER 934 C ER 944 C ER 954 C Material Handlers

5

Page 6

ER 934 C ER 944 C ER 954 C Material Handlers

6

Reliability - Safety

•AutomaticPowercutoffif

the cabinet doors are opened

•Automaticpowercutoffin

the event of any anomalies

(electric motor or its bearings

overheating)

•Activesafetyon

the transformers in

the electric cabinet

•Possibletolockwithpadlock

Page 7

Reliability

Backed by more than 30 years experience in the construction of electric excavators, Liebherr designed the new ER 934 C, ER 944 C and ER 954 C with the aim of

providing top performance whatever the challenge might be. The structure of the

machine, using components from our own manufacture for the electric drive, has

been completely rethought, and so moves away from simply being an adaptation

of a diesel-engine machine. Being intended for key functions in the organization

of industrial sites, Liebherr electric Material Handlers provide a very high level of

reliability. The service life of the hydraulic components has also been increased,

thanks to the smoother movement of the electric drive. The concept of the single

actuator (one single electric motor for all the hydraulic functions) allows all the

low-voltage functions to be concentrated in a single box.

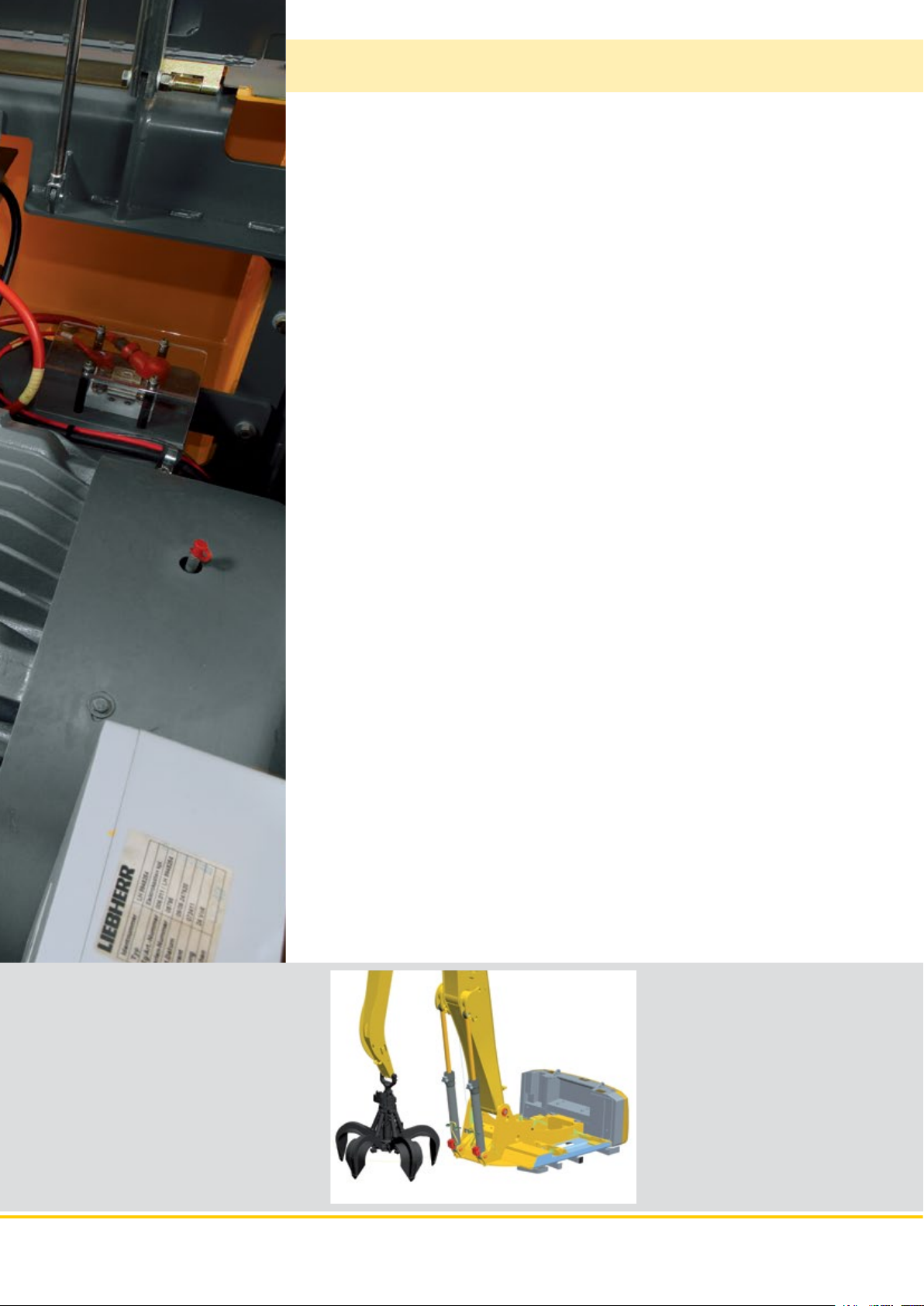

Electrical

system

Protected

electric cabinet

Electric motor

Totally integrated into the structure of the uppercarriages

and accommodated in a metal container, the electric cabinet

provides a three-fold level of protection to the components

of the electrical system:

- Mechanical (insulation from vibrations and from the possible impact of falling objects)

- Heat (maintains a constant temperature thanks to the heating resistors which prevent corrosion from condensation)

- Electrical earthing of the structure and disconnection from

current is controlled from the cab by way of a motorised

circuit-breaker.

The electric cabinet, such as the collecting pipe, provides

IP55 class protection. A filtered ventilation system which

avoids any dust penetration and, with permanent ventilation, ensures the thermal balance of all the components.

Liebherr electric excavators are equipped with motors especially designed for really tough applications. The dimensions

of the motor allow for the full power to be drawn from the

kinematic chain, and so maximises the performance of the

machine especially in the combined movements. The motor

can resist a momentary overload of up to +25 % of its rated

capacities. Protected against penetration by water and dust,

its properties correspond to protection class IP55.

The temperature of the roller bearings and other bearing

elements is constantly monitored, and, in the event of overheating, the operator is warned of malfunction on the console at the driving position.

Cooling system

•Generousdimensions

for high cooling capacity

•Verticalarrangementforincreased

efficiency and minimal incursion of

foreign bodies

•Poweredbyathermostatically

regulated hydraulic motor

•Hingedtoallowforcomplete

cleaning

•Reversibleactuationofthefan

(without time limit) as option

Undercarriage

•TheundercarriagesarethoseoftheEW

or S-EW diesel machines for industrial

applications, flat or ribbed tiles

•Theundercarriagesaredesignedand

built especially for electric excavators:

- side cable opening

- armoured junction box

- electrical collecting pipe

ER 934 C ER 944 C ER 954 C Material Handlers

7

Page 8

ER 934 C ER 944 C ER 954 C Material Handlers

8

Cab with control panel

•Thecommandarrangementfor

putting the electrical system under

voltage is progressive (3 functions)

and the emergency stop button allows for the general cutting of the

electric cabinet supply

•Availableasanoptionisacutoff

system deriving from one source

point, which can be activated from

the driving position via an additional rotating joint

Page 9

Comfort

Helping the operator to concentrate on his work and get the best out of his machine is achieved by providing a comfortable driving position, good visibility, and

a highly ergonomic layout of the controls. The new electric Material Handlers

offer the same level of comfort as on the mobile excavators (arrangement of the

controls, driver’s seat, climate control, large window areas, etc.). The electric motor system adds a further layer of comfort thanks to the low noise emissions and

absence of vibration. For Liebherr, comfort also means ease of daily maintenance

of the machine in terms of access to the service and inspection points, so as to

minimize down time.

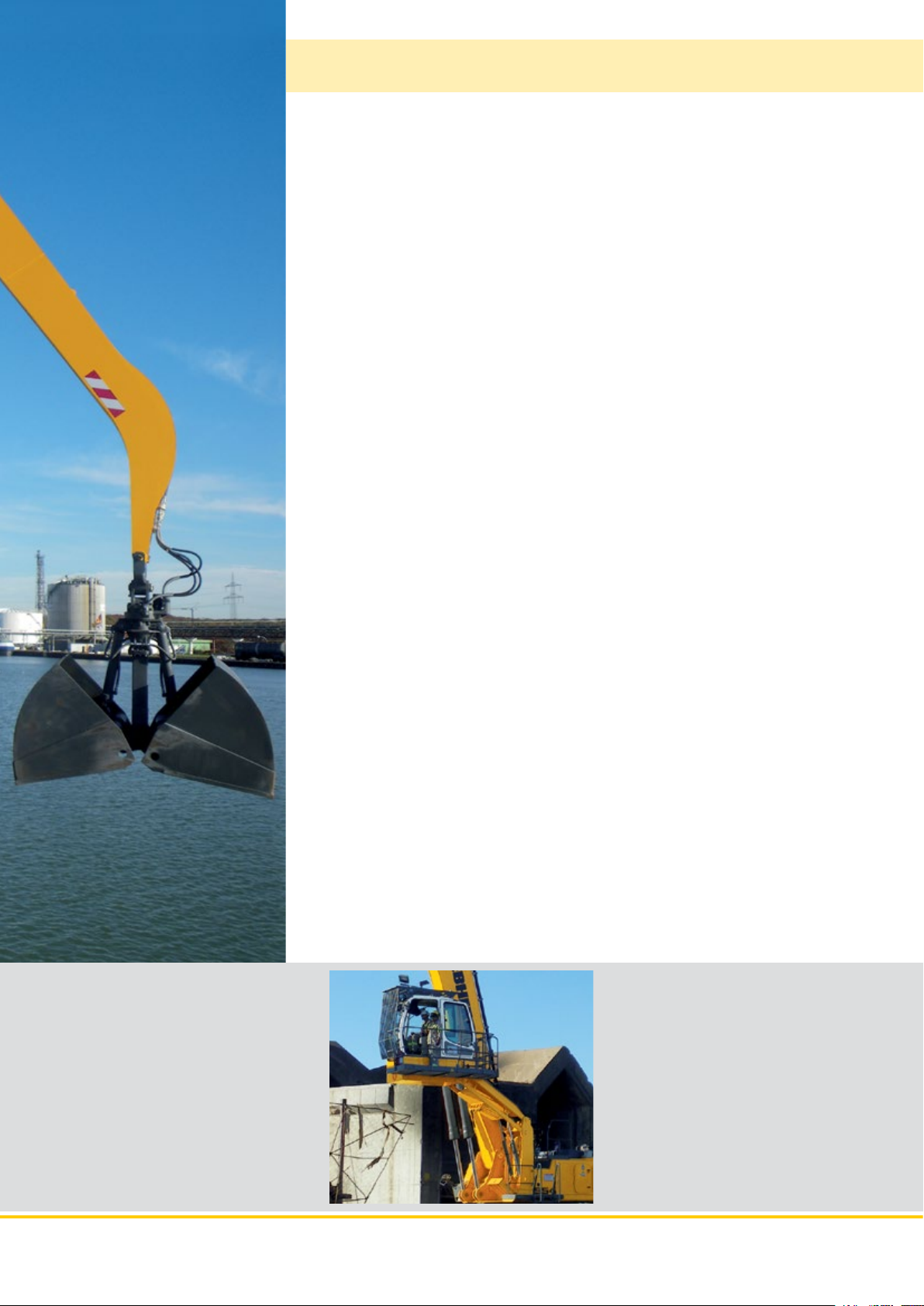

Driving position

Low noise emissions

Carbon gas emission

Mounted as standard on a fixed platform of

1,200 mm ( 2,000 mm or hydraulic platform on request), the new cab on the electric excavators

meetsallsafetystandardsinforce(24 Vsupplyin

the operator’s compartment), comfort, panoramic

visibility, and ergonomic arrangement of the controls for perfect control of the machine.

Liebherr electric excavators are really quiet in operation. Their measured acoustic level is from 4 to

5 dB lower than an equivalent diesel-engine version.

The level of noise intensity from a Liebherr electric

excavator represents less than a third of the noise

generated by a diesel-engine unit.

Zero grams of CO

emitted per tonne of product

2

handled!

Climate control entirely automatic

•Automaticclimatecontrolensuresa

level of comfort similar to a private car

•Twosensorsforprecisetemperature

regulation

•Ventilationapscanbeadjusted

at the touch of a button

•Rapiddemistinganddefrosting

of the windscreen thanks to the

«reheat“ function

Parallelogram hydraulic lift

•Improvedvisibilityoftheoperator

over his workspace

ER 934 C ER 944 C ER 954 C Material Handlers

9

Page 10

ER 934 C ER 944 C ER 954 C Material Handlers

10

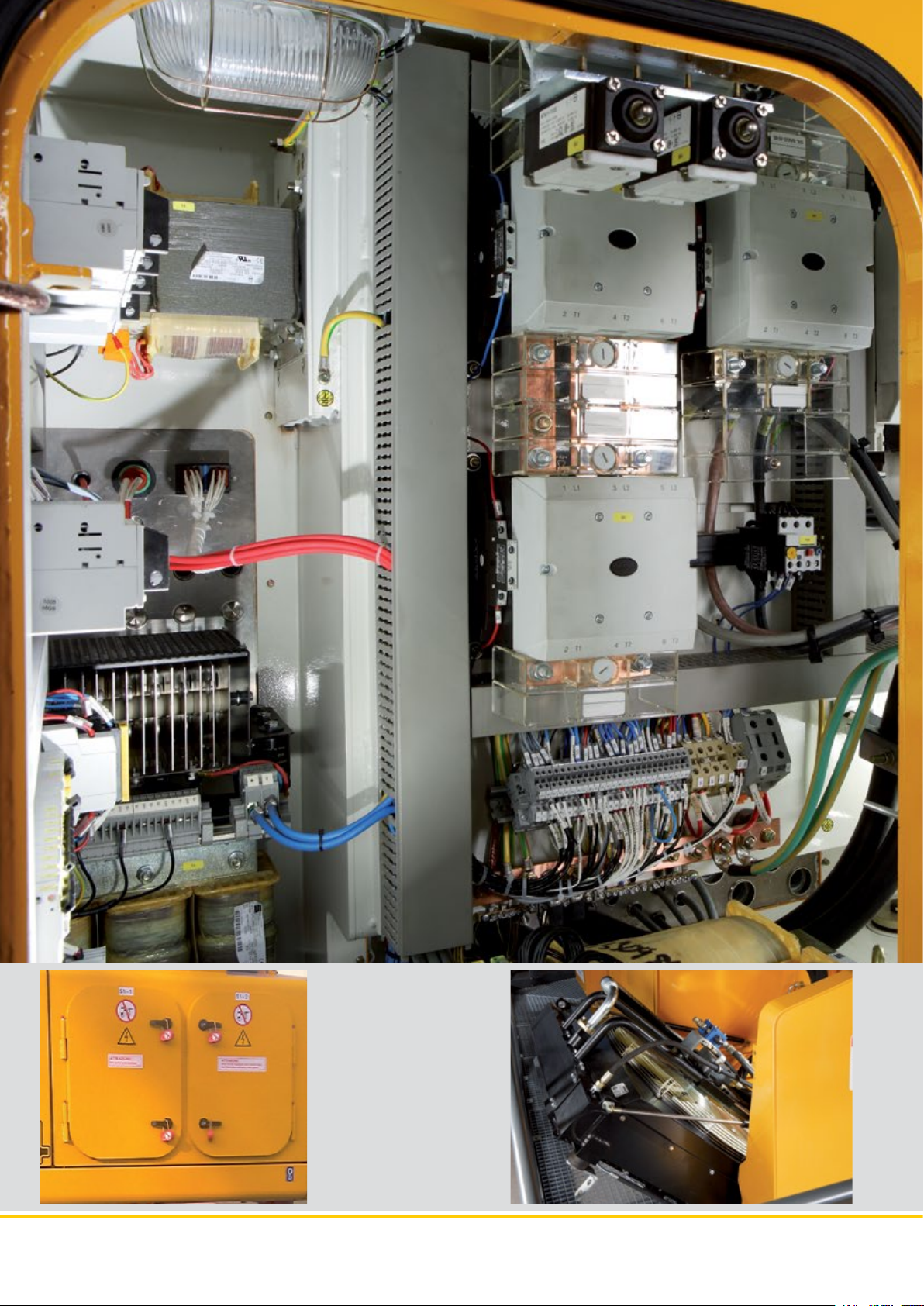

Wide range of solutions

•Modulararrangement

for rapid changeover

•Liebherrquick-couplingsystem,

mechanical and hydraulic, for

efficient equipment changeover

•Quick-couplingarrangementfor

hydraulic lines (Multi-Coupler)

•Completerangeofgrapples

•Rangeofdifferentwoodgrapples

and grab buckets from Liebherr

Page 11

Economy

Investing in the acquisition of an electric Material Handler is a great long-term

advantage. Constant increases in the costs of conventional energy sources are

pushing up operating charges, and reducing profit margins considerably. Environmental criteria, in particular CO2 emissions, are also playing a constantly

greater part in the choice of power systems and working methods. With the electric drive, Liebherr offers an economical alternative to conventional diesel-engine

machines, and a solution with real respect for the environment. Also, the excavator is permanently available, with no need to refill. There are no constraints (e.g.

DPF or AdBlue).

Flexibility and versatility

Energy costs cut

Increased service life

Maximum availability

Liebherr electric Material Handlers are multi-tasking

machines. With a wide range of tools, which can be

combined with Liebherr quick-coupling systems,

they can create a degree of flexibility and versatility

which has no comparison anywhere.

The energy yield from an electric motor is greater

than that of a diesel-engine. Delivering the same kW

output in hydraulic power costs three to five times

less with an electric excavator than with a diesel-engine unit. Liebherr excavators deliver the full power

from their kinematic chain and at a lot less cost.

The smooth actuation of the electric drive and the

reliability of Liebherr hydraulic components mean

that the maintenance costs of the excavator can be

reduced considerably.

The absence of vibrations and variations in output

from a motor, which operates on a torque principle

and at constant output, means that the stress on

the kinematic chain can be reduced and the optional pre-heating of the hydraulic system allows for the

hydraulic oil to be kept at an optimum temperature

right from the start.

The costs associated with maintenance operations

are reduced to a minimum, and that also cuts downtimes. The electric motor does not require any maintenance beyond lubrication of the bearings every

3,000 hours. No filters (air, oil) to be changed and no

draining of engine oil throughout the entire service

life of the machine.

Kinematic chain made by Liebherr

•Constantprovisionofpower

for the kinematic chain

•Reducedwearofhydraulic

components

•Optimumexploitationofthehydraulic

power potential of the system

Backhoe stick with sorting grapple

•Numerouscombinationsareassociated with Liebherr’s wide range of tools

(straight and angled mono boom,

sticks and industrial sticks, etc.)

ER 934 C ER 944 C ER 954 C Material Handlers

11

Page 12

VarioLiftPlus

Variable Boom Mounting Positions for Optimized Lift Capacities

with the same working range with a different working range

Hole A

Hole B

Hole 3

Hole 2

Version 2A

2A

2A

3B

3B

3A

Kinematic variant 2A:

Increased lift capacities above ground level

Kinematic variant 3B:

Increased lift capacities below ground level

and when working at large outreach

with a different working range

Kinematic variant 3A:

Altered range curve with additional reach

depth, e.g. for unloading from ships

Hole D

Hole C

Hole 3

Hole 2

Version 3D

3D

3D

Kinematic variant 3D:

Increased lift capacities below ground level

and when working at large outreach

3C

Kinematic variant 3C:

Altered range curve with additional reach

depth, e.g. for unloading from ships

12 ER 934 C ER 944 C ER 954 C Material Handlers

Page 13

Technical Data

Electric Motor

������������������������������

Engine

934 944 954

Power rating

(as per CEI 34-1)

Rated voltage

Number of poles

Design type

Standard degree of protection

Insulation

Cooling

Heat protection for windings

Heat protection for bearings

Anti-condensation heating system resistors

������������������

���������������������

������������������

�����������������������

��������������������������

�����������������������������

induction motor dedicated definition Liebherr

160

kW (217 HP)

400 V – 50 Hz *

4

horizontal axle B35

axle height 315 mm

��

IP55

class F

IC06

200

kW (272 HP)

250

kW (340 HP)

Electric System

The 400 V electrical cabinet provides a degree of protection to IP55.

This houses the following components:

– Main contactor – remote control inside the cab

– Star/delta starter for motor

– Outlets for supplying auxiliary elements: heating, climate control

– Overheat protection devices

– Integrated heating and ventilation

– Filtered booster

– Transformers – rectifier for 24 V control circuit

– Motor protection

– Auxiliary batteries: 2 x 135 Ah/12 V: secured functions: lighting for excavator/

attachment position (option)

– Connecting inside closed panel

– Equipment: slip ring collector

power connector

embedded cable reel

Swing Drive

����������������������������

Drive by

Transmission

Swing ring

934 944 954

Swing speed

Swing torque

Holding brake

Option

����������������������

�������������������������

����������������������

����������������������

���������������������

������������������������������

hydraulic swash plate motor with integrated

brake valves

Liebherr compact planetary reduction gear

Liebherr, sealed single race ball bearing swing

ring, internal teeth

0 – 9.4 RPM 0 – 7.9 RPM 0 – 5.6 RPM

stepless stepless stepless

81.07 kNm 119 kNm 167.23 kNm

oil-bath disk brake (negative action)

pedal controlled positioning brake

Operator’s Cab

���������������������������������

Cab

Operator’s seat

Controls

Monitoring

Climate control

Noise emission

2000/14/EC 934 944 954

L

WA

�������������������

����������������������������

�������������������������

�������������������

(surround noise)

single shell concept with shaped profiles, resil-

iently mounted, sound insulated, tinted windows.

Front window can be folded away under roof,

door with sliding window

shock absorbing suspension, adjustable to

operator’s weight, 6-way adjustable seat

integrated into adjustable seat consoles

menu driven digital display of current operating

conditions. Automatic monitoring, display, warn-

ing (audible and visual signal) and saving of

machine malfunction data, such as overheating

of windings, motor bearings, or low hydraulic

oil level

standard climate control system, combined

cooler/heater, additional dust filter in the outside/

fresh air circuit

�������

101 dB(A) 103 dB(A) 105 dB(A)

ER 954 C ER 944 C ER 934 C

Hydraulic System

934 944 954

Hydraulic pump

for the attachment

Max. flow

Max. pressure

Pumpenansteuerung

Hydraulic pump

for the swing drive

Max. flow

Max. pressure

Hydraulic tank

Hydraulic system

���������������������������

Filtration

�����������������������������

Cooling

Tool Control

�����������������������

����������

���������������������

���������������

������������

����������

���������������������

���������������

��������������������

�����������������

two Liebherr swash plate pumps with variable

output

2 x 253 l/min. 2 x 305 l/min. 2 x 341 l/min.

350 bar

electro-hydraulic, with electronic regulation by

power limit, minimum pump flow at max. pres-

sure, distribution of oil to different receptor

components proportional to demand

reversible swash plate pump, in closed circuit

170 l/min. 205 l/min. 205 l/min.

370 bar

340 l 460 l 440 l

550 l 710 l 790 l

934: filter in the return circuit, with integrated fine

filter elements (5 μm)

944/954: 2 filters in the return circuit, with inte-

grated fine filter elements (5 μm)

radiator equipped with hydrostatic drive fan for

cooling the hydraulic oil and climate control

condenser

10 flow rates and pressures adjustable as option

for optional accessories

Hydraulic Controls

Power distribution

Flow summation

Closed-loop circuit

Control

Attachment and swing

Travel

Additional functions

����������������

������������

���������

�����

�������������������������

��������������

with the aid of hydraulic distributors with

integrated safety valves

to boom stick and stick

for uppercarriage swing drive mechanism

proportional by handling element in cross

operation

proportional by pedals or by lever

proportional by pedals or by toggle switch

Undercarriage

Versions

934: EW

944: S-EW

954: S-EW

Drive

Transmission

934 944 954

Travel speed

Drawbar pull max.

Track components

Track rollers/Carrier rollers

Tracks

Track pads

Digging locks

Brake valves

����������������������

�������������������

��������������������������������

�������������������

����������������������

����������������������

����������������

���������������

������������������������������

������������������������

���������������������

����������������������

�����

special material handling, extra wide gauge

special material handling, extra wide gauge,

reinforced track components

removable side frames, extra wide gauge

Liebherr swash plate motors with integrated

brake valves on both sides

Liebherr planetary reduction gears

2.8 km/h 2.8 km/h 2.6 km/h

323 kN 429 kN 478 kN

maintenance- maintenance- maintenance-

free free free

B 60 D 7 G D 7 G

9/2 10/2 13/3

sealed and greased

triple grouser

wet multi-discs (spring applied, pressure

released)

integrated into travel motor

Attachment

��������������������������������

Type

Hydraulic cylinders

�������������������������������

Pivots

Lubrication

VarioLift

������������������������

�������������������������

Plus

���������������

high-strength steel for extreme stresses. Bearings

designed for optimum distribution of stresses

Liebherr cylinders with end-of-travel shock

absorbing, fitted with guide and sealing joints

sealed, low maintenance

centralised semi-automatic Liebherr lubrication

system

variable boom mounting positions for optimized

lift capacities

* Other voltages and frequencies possible on request.

ER 934 C ER 944 C ER 954 C Material Handlers 13

Page 14

The Right Attachment

for Every Application

ER 934 C

Sorting grapple

Wood grapple

Stick 5.0 0 m

Stick 6.0 0 m

Industrial stick 6.00 m

Industrial-type straight mono boom 7.60 m

Rigid cab elevation

Industrial-t ype straight mono boom 8.60 m

Hydraulic cab elevation

Hydraulic cab elevation

+ intermediate piece

Multiple Tine

Grapple

Clamshell bucket

Industrial stick 7.50 m

Industrial-type angled mono boom 7.60 m

Industrial-type angled mono boom 8.60 m

Undercarriage

For further information please contact your Liebherr dealer.

14 ER 934 C ER 944 C ER 954 C Material Handlers

Page 15

Dimensions

W

L

U

Z

V

X

mm

A 3,225

C 3,480

D 3,240

E 3,240

H 2,615

K 1,200

L 3,848

P 1,056

Q 400

S 3,400

U 4,720

N 500 600 750

B 3,998 4,000 4,150

G 4,195 4,195 4,195

G1 4,610 4,610 4,610

Z 5,600

E = Tail radius

E

D

H

K

N

A

P

Q

S

B

G

G1

Industrial-Type Straight Mono Boom 8.60 m

and Industrial Stick m 6.00 7.50

V mm 6,700 5,600

W mm 2,800 4,200

X mm 12,200 12,050

Industrial-Type Straight Mono Boom 8.60 m

and Stick m 5.00 6.00

V mm 6,200 5,500

W mm 2,550 3,050

X mm 11,200 11,150

ER 934 C

C

E

D

W

L

U

Z

V

X

H

K

N

A

C

P

Q

S

B

G

G1

ER 934 C ER 944 C ER 954 C Material Handlers 15

Page 16

Industrial Attachment

with Industrial-Type Straight Mono Boom 8.60 m

ft

m

60

18

16

50

ER 934 C

14

40

12

10

30

8

20

6

4

10

2

0

0

-2

-10

-20

-30

-4

-6

-8

1618

14

60

50

1

2

3

4

0 m24681012

0 ft10203040

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 6.00 m

2 with industrial stick 7.50 m

3 with industrial stick 6.00 m and grapple model GM 65

4 with industrial stick 7.50 m and grapple model GM 65

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 7.5 t, industrial-type straight mono boom

8.60 m, industrial stick 6.00 m and grapple model GM 65 with

5 semi-closed tines 0.60 m

Undercarriage EW

Pad width mm 600 750

Weight kg 38,050 38,550

Ground pressure kg/cm

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 7.5 t, industrial-type straight mono boom

8.60 m, industrial stick 7.50 m and grapple model GM 65 with

5 semi-closed tines 0.60 m

Undercarriage EW

Pad width mm 600 750

Weight kg 38,100 38,600

Ground pressure kg/cm

3

(1,415 kg).

3

(1,415 kg).

2

0.83 0.67

2

0.83 0.67

16 ER 934 C ER 944 C ER 954 C Material Handlers

Page 17

Lift Capacities

with Industrial-Type Straight Mono Boom 8.60 m

Industrial Stick 6.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m

Under m carriage m

16.5 EW

15.0 EW

13.5 EW

12.0 EW

10.5 EW

9.0 EW

7.5 EW

6.0 EW

4.5 EW

3.0 EW

1.5 EW

0 EW

– 1.5 EW

– 3.0 EW

– 4.5 EW

9.9* 9.9* 7.7* 7.7* 6.0

9.6* 9.6* 8.1* 8.1* 6.2* 6.2* 8.5

9.3* 9.3* 8.0* 8.0* 5.5* 5.5* 10.2

9.2* 9.2* 8.1* 8.1* 6.3 6.8 5.2* 5.2* 11.5

9.3* 9.3* 8.1* 8.1* 6.3 6.8 5.0 5.4 4.6 4.9* 12.5

11.3* 11.3* 9.5* 9.5* 8.0 8.2* 6.2 6.8 5.0 5.4 4.1 4.5 13.2

12.3* 12.3* 11.9* 11.9* 9.8* 9.8* 7.8 8.4* 6.1 6.6 4.9 5.3 4.0 4.3 3.8 4.2 13.7

24.9* 24.9* 16.7* 16.7* 12.6* 12.6* 9.9 10.2* 7.5 8.1 5.9 6.4 4.8 5.2 3.9 4.3 3.6 4.0 14.1

17.9* 17.9* 12.9 13.2* 9.3 10.2 7.1 7.8 5.7 6.2 4.6 5.1 3.9 4.2 3.5 3.9 14.3

5.8* 5.8* 12.0 13.2* 8.8 9.7 6.8 7.5 5.5 6.0 4.5 4.9 3.8 4.1 3.5 3.8 14.3

4.9* 4.9* 11.4 12.5* 8.4 9.2 6.5 7.2 5.3 5.8 4.4 4.8 3.7 4.1 3.5 3.7* 14.1

5.6* 5.6* 11.1* 11.1* 8.1 9.0 6.4 7.0 5.2 5.7 4.3 4.8 3.6* 3.6* 3.5* 3.5* 13.5

9.0* 9.0* 7.7* 7.7* 6.3 6.4* 5.1 5.2* 4.1* 4.1* 11.9

ER 934 C

Industrial Stick 7.50 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m

Under m carriage m

16.5 EW

15.0 EW

13.5 EW

12.0 EW

10.5 EW

9.0 EW

7.5 EW

6.0 EW

4.5 EW

3.0 EW

1.5 EW

0 EW

– 1.5 EW

– 3.0 EW

– 4.5 EW

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

6.8* 6.8* 6.5* 6.5* 6.2

7.0* 7.0* 5.1* 5.1* 9.0

7.8* 7.8* 6.8* 6.8* 5.1* 5.1* 4.5* 4.5* 10.8

7.5* 7.5* 6.6* 6.6* 4.6* 4.6* 4.1* 4.1* 12.2

7.5* 7.5* 6.6 6.7* 5.2 5.6 3.9* 3.9* 13.3

7.5* 7.5* 6.6 6.7* 5.2 5.6 4.2 4.5 3.7 3.8* 14.2

8.7* 8.7* 7.6* 7.6* 6.5 6.8* 5.1 5.6 4.1 4.5 3.4 3.7* 14.8

9.1* 9.1* 7.9* 7.9* 6.3 6.8 5.0 5.5 4.1 4.5 3.3 3.7 3.2 3.5 15.3

10.7* 10.7* 9.5* 9.5* 7.8 8.1* 6.1 6.6 4.9 5.3 4.0 4.4 3.3 3.6 3.1 3.4 15.6

19.2* 19.2* 16.4* 16.4* 12.4* 12.4* 9.8 10.0* 7.4 8.1 5.8 6.4 4.7 5.1 3.9 4.3 3.2 3.6 3.0 3.3 15.7

2.7* 2.7* 17.6* 17.6* 12.7 13.0* 9.1 10.0 7.0 7.7 5.6 6.1 4.5 5.0 3.8 4.1 3.2 3.5 2.9 3.2 15.8

2.2* 2.2* 7.2* 7.2* 11.8 13.0* 8.6 9.5 6.6 7.3 5.3 5.8 4.4 4.8 3.7 4.0 3.1 3.4 2.9 3.2* 15.6

2.9* 2.9* 6.1* 6.1* 11.2 12.3* 8.1 9.0 6.3 7.0 5.1 5.6 4.2 4.7 3.6 4.0 3.1 3.3* 2.9* 2.9* 15.3

6.4* 6.4* 10.8 10.9* 7.9 8.7 6.1 6.8 5.0 5.5 4.2 4.6 3.5 3.8* 3.2* 3.2* 14.2

8.9* 8.9* 7.5* 7.5* 6.1 6.2* 4.9 5.1* 4.0* 4.0* 3.7* 3.7* 12.3

ER 934 C ER 944 C ER 954 C Material Handlers 17

Page 18

Industrial Attachment

with Industrial-Type Straight Mono Boom 8.60 m

ft

m

60

18

55

16

ER 934 C

50

14

45

40

12

35

10

30

8

25

20

6

15

4

10

2

5

0

0

-5

-2

-10

-4

-15

-20

-6

60 5152535455 5

14

1618

50

1

2

0 m24681012

0 f t10203 040

Attachment Envelope

Kinematic variant 2A

1 with stick 5.00 m

2 with stick 6.00 m

3 with stick 5.00 m and sorting grapple SG 30

4 with stick 6.00 m and sorting grapple SG 30

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 7.5 t, industrial-type straight mono boom

8.60 m, stick 5.00 m and sorting grapple SG 30 with tines 0.80 m

(1,730 kg).

Undercarriage EW

Pad width mm 600 750

Weight kg 38,750 39,250

Ground pressure kg/cm

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 7.5 t, industrial-type straight mono boom

8.60 m, stick 6.00 m and sorting grapple SG 30 with tines 0.80 m

(1,730 kg).

Undercarriage EW

Pad width mm 600 750

Weight kg 38,950 39,450

Ground pressure kg/cm

2

0.84 0.68

2

0.84 0.68

3

3

18 ER 934 C ER 944 C ER 954 C Material Handlers

Page 19

Lift Capacities

with Industrial-Type Straight Mono Boom 8.60 m

Stick 5.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m

Under m carriage m

16.5 EW

15.0 EW

13.5 EW

12.0 EW

10.5 EW

9.0 EW

7.5 EW

6.0 EW

4.5 EW

3.0 EW

1.5 EW

0 EW

– 1.5 EW

– 3.0 EW

– 4.5 EW

13.4* 13.4* 12.3* 12.3* 3.5

12.3* 12.3* 10.5* 10.5* 8.1* 8.1* 7.0

11.2* 11.2* 9.5* 9.5* 7.1* 7.1* 6.9* 6.9* 9.0

11.1* 11.1* 9.3* 9.3* 7.6 8.1* 5.7 6.2 10.5

11.2* 11.2* 9.4* 9.4* 7.6 8.1* 5.8 6.3 4.8 5.2 11.5

13.1* 13.1* 11.6* 11.6* 9.6* 9.6* 7.4 8.1 5.7 6.2 4.5 4.9 4.2 4.6 12.3

12.3* 12.3* 15.9* 15.9* 12.2* 12.2* 9.7 9.9* 7.2 7.9 5.6 6.1 4.4 4.9 3.9 4.3 12.9

17.2* 17.2* 12.7* 12.7* 9.2 10.1 6.9 7.6 5.4 5.9 4.3 4.8 3.6 4.0 13.2

3.3* 3.3* 12.0 12.9* 8.6 9.5 6.6 7.3 5.2 5.7 4.2 4.7 3.5 3.9 13.4

1.6* 1.6* 11.3 12.5* 8.2 9.1 6.3 7.0 5.0 5.6 4.1 4.6 3.5 3.8* 13.4

2.5* 2.5* 9.8* 9.8* 7.9 8.8 6.1 6.8 4.9 5.4 4.1 4.5 3.3* 3.3* 13.3

9.2* 9.2* 7.7 7.9* 6.0 6.5* 4.8 5.2* 3.9* 3.9* 3.6* 3.6* 12.2

ER 934 C

Stick 6.00 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m

Under m carriage m

16.5 EW

15.0 EW

13.5 EW

12.0 EW

10.5 EW

9.0 EW

7.5 EW

6.0 EW

4.5 EW

3.0 EW

1.5 EW

0 EW

– 1.5 EW

– 3.0 EW

– 4.5 EW

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

10.4* 10.4* 8.2* 8.2* 7.6* 7.6* 6.3

9.8* 9.8* 8.4* 8.4* 6.0* 6.0* 8.7

8.9* 8.9* 7.8 7.8* 5.3* 5.3* 10.4

8.8* 8.8* 7.7* 7.7* 5.9 6.5 4.7 4.9* 11.7

8.9* 8.9* 7.7* 7.7* 5.9 6.5 4.6 5.0 4.1 4.5 12.6

10.8* 10.8* 9.1* 9.1* 7.6 7.8* 5.8 6.4 4.6 5.0 3.6 4.0 13.4

10.5* 10.5* 11.5* 11.5* 9.4* 9.4* 7.4 7.9* 5.7 6.2 4.5 4.9 3.6 3.9 3.4 3.7 13.9

15.7* 15.7* 16.2* 16.2* 12.2* 12.2* 9.5 9.7* 7.1 7.7 5.5 6.0 4.4 4.8 3.5 3.9 3.2 3.5 14.2

17.1* 17.1* 12.5 12.7* 8.9 9.8 6.7 7.4 5.3 5.8 4.2 4.7 3.4 3.8 3.1 3.4 14.4

4.1* 4.1* 11.5 12.7* 8.3 9.2 6.4 7.0 5.0 5.6 4.1 4.5 3.4 3.7 3.0 3.4 14.4

3.6* 3.6* 10.9 11.9* 7.9 8.8 6.1 6.7 4.9 5.4 4.0 4.4 3.3 3.7 3.0* 3.0* 14.3

4.5* 4.5* 10.5* 10.5* 7.6 8.5 5.9 6.5 4.7 5.2 3.9 4.3 3.1* 3.1* 3.0* 3.0* 13.5

8.4* 8.4* 7.1* 7.1* 5.8 5.9* 4.7 4.7* 3.6* 3.6* 11.9

ER 934 C ER 944 C ER 954 C Material Handlers 19

Page 20

The Right Attachment

for Every Application

Industrial-type straight mono boom 8.50 m

ER 944 C

Sorting

grapple

Industrial stick 5.80 m

Stick 6.00 m

Industrial-t ype straight mono boom 9.50 m

Rigid cab elevation

Wood

grapple

Mutiple tine

grapple

Clamshell

bucket

Industrial stick 7.30 m

Industrial stick 8.80 m

Industrial-type angled mono boom 7.50 m

Hydraulic cab elevation

Hydraulic cab elevation

+ intermediate piece

For further information please contact your Liebherr dealer.

20 ER 934 C ER 944 C ER 954 C Material Handlers

Industrial-type angled mono boom 9.50 m

Undercarriage

Page 21

Dimensions

W

V

X

mm

A 3,070

C 3,630

D 3,605

E 3,605

H 3,050

K 1,320

L 4,400

P 1,170

Q 475

S 3,800

U 5,360

N 500 600 750

B 4,412 4,412 4,550

G 4,620 4,620 4,620

G1 5,025 5,025 5,025

Z 6,300

E = Tail radius

E

D

H

K

L

U

Z

N

A

Q

S

B

G

G1

Industrial-Type Straight Mono Boom 9.50 m

and Industrial Stick m 7.30 8.80

V mm 6,700 5,650

W mm 3,350 4,650

X mm 13,600 13,400

Industrial-Type Angled Mono Boom 9.50 m

and Industrial Stick m 7.30

V mm 6,400

W mm 3,600

X mm 13,500

C

P

ER 944 C

E

D

W

L

U

Z

V

X

These dimensions are stated with cab carrier. This assembly is only valid for transportation.

A

C

H

K

Q

N

S

B

G

G1

P

ER 934 C ER 944 C ER 954 C Material Handlers 21

Page 22

Industrial Attachment

with Industrial-Type Straight Mono Boom 9.50 m

mft

20

65

19

60

18

17

55

16

50

15

14

45

13

40

12

11

35

10

ER 944 C

30

9

8

25

7

20

6

5

15

4

10

3

2

5

1

0

0

-1

-5

-2

-3

-10

-4

-15

-20

-25

-30

-5

-6

-7

-8

-9

-10

1

3

2

4

01

234567891011121314151617 181920

0mft5101520253045 4055 5065 60 35

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 7.30 m

2 with industrial stick 7.30 m and grapple model GM 70C

3 with industrial stick 8.80 m

4 with industrial stick 8.80 m and grapple model GM 70C

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 11.0 t, industrial-type straight mono boom

9.50 m, industrial stick 7.30 m and grapple model GM 70C with

5 semi-closed tines 0.80 m

Undercarriage S-EW

Pad width mm 600 750

Weight kg 52,050 53,400

Ground pressure kg/cm

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 11.0 t, industrial-type straight mono boom

9.50 m, industrial stick 8.80 m and grapple model GM 70C with

5 semi-closed tines 0.80 m

Undercarriage S-EW

Pad width mm 600 750

Weight kg 52,400 53,750

Ground pressure kg/cm

3

(1,705 kg).

3

(1,705 kg).

2

0.99 0.81

2

0.99 0.81

22 ER 934 C ER 944 C ER 954 C Material Handlers

Page 23

Lift Capacities

with Industrial-Type Straight Mono Boom 9.50 m

Industrial Stick 7.30 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m

carriage

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

m

12.5* 12.5* 12.5* 12.5* 4.5

12.3* 12.3* 10.3* 10.3* 9.1* 9.1* 8.1

11.8* 11.8* 10.3* 10.3* 7.9* 7.9* 10.3

11.5* 11.5* 10.1* 10.1* 9.0* 9.0* 7.2* 7.2* 11.9

11.4* 11.4* 10.0* 10.0* 8.9* 8.9* 7.8 7.9* 6.5 6.8* 13.2

11.5* 11.5* 10.0* 10.0* 8.9* 8.9* 7.9 7.9* 6.3 7.0 5.7 6.4 14.1

11.7* 11.7* 10.1* 10.1* 8.9* 8.9* 7.8 7.9* 6.3 7.0 5.1 5.8 14.9

14.2* 14.2* 12.0* 12.0* 10.3* 10.3* 9.0* 9.0* 7.6 8.0* 6.2 6.9 5.0 5.7 4.7 5.3 15.5

13.9* 13.9* 15.3* 15.3* 12.5* 12.5* 10.6* 10.6* 9.1* 9.1* 7.4 8.0* 6.0 6.8 5.0 5.6 4.4 5.0 15.9

24.1* 24.1* 21.5* 21.5* 16.2* 16.2* 13.0* 13.0* 10.8* 10.8* 8.9 9.2* 7.1 8.0* 5.9 6.6 4.9 5.5 4.2 4.8 16.2

22.8* 22.8* 16.8* 16.8* 13.3* 13.3* 10.7 10.9* 8.5 9.2* 6.9 7.7 5.7 6.4 4.8 5.4 4.1 4.6* 16.3

7.3* 7.3* 16.7* 16.7* 13.1 13.2* 10.1 10.8* 8.1 9.1* 6.6 7.5 5.5 6.2 4.7 5.3 4.1 4.2* 16.3

2.0* 2.0* 6.2* 6.2* 15.9* 15.9* 12.4 12.7* 9.6 10.4* 7.7 8.7* 6.4 7.2 5.4 6.1 4.6 4.9* 3.7* 3.7* 16.1

6.9* 6.9* 13.7* 13.7* 11.6* 11.6* 9.2 9.7* 7.5 8.1* 6.2 6.7* 5.2 5.5* 4.2* 4.2* 3.3* 3.3* 15.8

11.8* 11.8* 10.1* 10.1* 8.5* 8.5* 7.1* 7.1* 5.8* 5.8* 4.6* 4.6* 3.6* 3.6* 14.5

8.0* 8.0* 6.8* 6.8* 5.7* 5.7* 4.6* 4.6* 12.0

ER 944 C

Industrial Stick 8.80 m (Variant 2A)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m

carriage

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

m

11.2* 11.2* 11.1* 11.1* 4.6

9.2* 9.2* 7.8* 7.8* 8.4

9.1* 9.1* 7.1* 7.1* 6.6* 6.6* 10.8

9.5* 9.5* 8.5* 8.5* 7.0* 7.0* 6.0* 6.0* 12.5

9.3* 9.3* 8.4* 8.4* 7.6* 7.6* 6.4* 6.4* 5.6* 5.6* 13.9

9.2* 9.2* 8.3* 8.3* 7.5* 7.5* 6.6 6.8* 5.3 5.3* 14.9

9.3* 9.3* 8.3* 8.3* 7.5* 7.5* 6.6 6.8* 5.3 6.0 4.7 5.2* 15.8

9.4* 9.4* 8.4* 8.4* 7.5* 7.5* 6.6 6.8* 5.3 6.0 4.3 4.9 4.3 4.9 16.5

9.6* 9.6* 8.5* 8.5* 7.6* 7.6* 6.4 6.8* 5.2 5.9 4.3 4.9 4.0 4.5 17.0

11.6* 11.6* 9.9* 9.9* 8.7* 8.7* 7.7* 7.7* 6.3 6.8* 5.1 5.8 4.2 4.8 3.8 4.3 17.4

12.9* 12.9* 12.2* 12.2* 10.3* 10.3* 8.9* 8.9* 7.4 7.7* 6.0 6.8 5.0 5.6 4.2 4.7 3.6 4.1 17.7

18.5* 18.5* 21.2* 21.2* 15.9* 15.9* 12.7* 12.7* 10.5* 10.5* 8.8 9.0* 7.1 7.8* 5.8 6.6 4.8 5.5 4.1 4.6 3.5 4.0* 17.8

3.7* 3.7* 22.4* 22.4* 16.5* 16.5* 13.0* 13.0* 10.5 10.7* 8.3 9.0* 6.7 7.6 5.6 6.3 4.7 5.3 4.0 4.5 3.5 3.7* 17.8

2.9* 2.9* 9.1* 9.1* 16.4* 16.4* 12.9 12.9* 9.9 10.5* 7.9 8.8* 6.4 7.3 5.4 6.1 4.5 5.2 3.9 4.4* 3.3* 3.3* 17.6

3.7* 3.7* 7.7* 7.7* 15.5* 15.5* 12.1 12.3* 9.3 10.1* 7.5 8.4* 6.2 7.0 5.2 5.9 4.4 4.9* 3.8* 3.8* 2.9* 2.9* 17.3

4.9* 4.9* 8.0* 8.0* 13.9* 13.9* 11.3* 11.3* 8.9 9.3* 7.2 7.8* 6.0 6.5* 5.0 5.4* 4.3* 4.3* 2.9* 2.9* 2.9* 2.9* 16.5

8.9* 8.9* 11.7* 11.7* 9.8* 9.8* 8.1* 8.1* 6.8* 6.8* 5.6* 5.6* 4.5* 4.5* 3.3* 3.3* 3.2* 3.2* 15.1

7.7* 7.7* 6.5* 6.5* 5.4* 5.4* 4.4* 4.4* 4.2* 4.2* 12.2

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

ER 934 C ER 944 C ER 954 C Material Handlers 23

Page 24

Industrial Attachment

with Industrial-Type Angled Mono Boom 9.50 m

mft

17

55

16

50

15

14

45

13

40

12

11

35

10

30

9

8

25

ER 944 C

-10

-15

-20

-25

-30

-35

7

20

6

5

15

4

10

3

2

5

1

0

0

-1

-5

-2

-3

-4

-5

-6

-7

-8

-9

-10

-11

1

3

2

4

1011121314151617 18

23456789

01

0mft5101520253045 4 05560 50 35

Attachment Envelope

Kinematic variants 3C/3D

1 with industrial stick 7.30 m (3D)

2 with industrial stick 7.30 m and grapple model GM 70C (3D)

3 with industrial stick 7.30 m (3C)

4 with industrial stick 7.30 m and grapple model GM 70C (3C)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

1.20 m, counterweight 11.0 t, industrial-type angled mono boom

9.50 m, industrial stick 7.30 m and grapple model GM 70C with

5 semi-closed tines 0.80 m

Undercarriage S-EW

Pad width mm 600 750

Weight kg 52,250 53,600

Ground pressure kg/cm

3

(1,705 kg).

2

0.99 0.81

24 ER 934 C ER 944 C ER 954 C Material Handlers

Page 25

Lift Capacities

with Industrial-Type Angled Mono Boom 9.50 m

Industrial Stick 7.30 m (Variant 3C)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m

carriage

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

m

5.9* 5.9* 11.5

5.6* 5.6* 5.7* 5.7* 12.8

5.6* 5.6* 5.5* 5.5* 5.5* 5.5* 13.7

5.9* 5.9* 5.7* 5.7* 5.5* 5.5* 5.5* 5.5* 14.5

6.2* 6.2* 5.9* 5.9* 5.7* 5.7* 5.1 5.5* 5.1 5.5* 15.1

7.3* 7.3* 6.6* 6.6* 6.2* 6.2* 5.8* 5.8* 5.0 5.6* 4.7 5.3 15.5

11.1* 11.1* 9.2* 9.2* 8.0* 8.0* 7.2* 7.2* 6.5* 6.5* 5.9 6.1* 4.9 5.6 4.5 5.1 15.8

4.3* 4.3* 18.5* 18.5* 13.2* 13.2* 10.5* 10.5* 8.8* 8.8* 7.7* 7.7* 6.9 6.9* 5.7 6.4* 4.8 5.4 4.3 4.9 15.9

3.1* 3.1* 9.8* 9.8* 15.1* 15.1* 11.7* 11.7* 9.6* 9.6* 8.1 8.3* 6.6 7.3* 5.5 6.3 4.6 5.3 4.2 4.8 15.9

4.2* 4.2* 8.3* 8.3* 16.4* 16.4* 12.3 12.6* 9.6 10.3* 7.7 8.7* 6.4 7.2 5.3 6.1 4.5 5.2 4.2 4.8 15.7

5.6* 5.6* 8.7* 8.7* 15.0* 15.0* 11.8 13.3* 9.2 10.5 7.4 8.5 6.1 7.0 5.2 5.9 4.4 5.1 4.3 4.9 15.3

7.0* 7.0* 9.6* 9.6* 14.6* 14.6* 11.5 13.3 8.9 10.2 7.2 8.3 6.0 6.9 5.1 5.8 4.5 5.1 14.9

10.6* 10.6* 15.1* 15.1* 11.4 13.2 8.8 10.1 7.1 8.2 5.9 6.8 5.1 5.8 4.8 5.5 14.2

16.0 16.1* 11.4 13.2* 8.8 10.1 7.1 8.2 6.0 6.8 5.2 6.0 13.3

8.9 10.2* 7.6 8.7 10.2

ER 944 C

Industrial Stick 7.30 m (Variant 3D)

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m

Under m

carriage

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

m

7.6* 7.6* 7.3* 7.3* 9.8

7.2* 7.2* 6.9* 6.9* 6.7* 6.7* 11.5

6.7* 6.7* 6.5* 6.5* 6.4* 6.4* 12.8

7.1* 7.1* 6.7* 6.7* 6.4* 6.4* 6.2* 6.2* 6.2* 6.2* 13.7

7.4* 7.4* 6.9* 6.9* 6.5* 6.5* 6.2* 6.2* 5.5 6.0* 14.5

8.7* 8.7* 7.8* 7.8* 7.2* 7.2* 6.7* 6.7* 6.3* 6.3* 5.1 5.8 5.0 5.7 15.1

11.1* 11.1* 9.5* 9.5* 8.4* 8.4* 7.6* 7.6* 6.9* 6.9* 6.1 6.4* 5.0 5.7 4.7 5.3 15.5

25.8* 25.8* 17.0* 17.0* 12.9* 12.9* 10.6* 10.6* 9.1* 9.1* 8.0* 8.0* 7.2* 7.2* 5.9 6.6* 4.9 5.6 4.5 5.1 15.8

4.3* 4.3* 20.5* 20.5* 14.8* 14.8* 11.7* 11.7* 9.8* 9.8* 8.5* 8.5* 6.9 7.5* 5.7 6.5 4.8 5.4 4.3 4.9 15.9

3.1* 3.1* 9.8* 9.8* 16.3* 16.3* 12.6* 12.6* 10.1 10.4* 8.1 8.9* 6.6 7.5 5.5 6.3 4.6 5.3 4.2 4.8 15.9

4.2* 4.2* 8.3* 8.3* 17.0 17.2* 12.3 13.3* 9.6 10.9* 7.7 8.8 6.3 7.2 5.3 6.1 4.5 5.2 4.2 4.8 15.7

5.6* 5.6* 8.7* 8.7* 15.0* 15.0* 11.8 13.6 9.2 10.5 7.4 8.5 6.1 7.0 5.2 5.9 4.4 5.1 4.3 4.9 15.3

9.6* 9.6* 14.6* 14.6* 11.5 13.3 8.9 10.2 7.2 8.3 6.0 6.9 5.1 5.8 4.5 5.1 14.9

15.1* 15.1* 11.4 13.2 8.8 10.1 7.1 8.2 5.9 6.8 5.1 5.8 4.8 5.5 14.1

7.5 8.6 10.1

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

ER 934 C ER 944 C ER 954 C Material Handlers 25

Page 26

The Right Attachment

for Every Application

Industrial-type straight mono boom 8.50 m

ER 954 C

Mutiple tine

Sorting

grapple

Wood

grapple

grapple

Stick 7.00 m

Industrial stick 7.80 m

Industrial stick 9.00 m

Rigid cab elevation

Industrial-t ype straight mono boom 10.50 m

Hydraulic cab elevation

Industrial-type straight mono boom 11.50 m

Hydraulic cab elevation

+ intermediate piece

Clamshell

bucket

For further information please contact your Liebherr dealer.

Industrial stick 10.00 m

Industrial-t ype angled mono boom 10.50 m

Industrial-type angled mono boom 11.50 m

Undercarriage

26 ER 934 C ER 944 C ER 954 C Material Handlers

Page 27

Dimensions

W

V

X

mm

A 3,300

C 4,055

D 3,825

E 3,825

H 3,470

K 1,730

L 6,000

P 1,280

Q 420

S 5,000

U 7,000

N 750

B 5,830

G 5,860

G1 6,235

Z 7,310

E = Tail radius

E

D

H

K

L

U

Z

N

A

Q

S

B

G

G1

Industrial-Type Straight Mono Boom 10.50 m

and Industrial Stick m 7.80 9.00

V mm 7,750 6,750

W mm 3,550 3,850

X mm 14,900 14,900

Industrial-Type Angled Mono Boom 10.50 m

and Industrial Stick m 7.80 9.00

V mm 7,760 7,000

W mm 4,200 4,200

X mm 14,900 14,900

C

P

ER 954 C

E

D

W

L

U

Z

V

X

These dimensions are stated with cab carrier. This assembly is only valid for transportation.

A

H

K

Q

N

S

B

G

G1

C

P

ER 934 C ER 944 C ER 954 C Material Handlers 27

Page 28

Industrial Attachment

with Industrial-Type Straight Mono Boom 10.50 m

mf t

22

70

20

60

18

16

50

14

40

12

Attachment Envelope

Kinematic variant 2A

1 with industrial stick 7.80 m

2 with industrial stick 9.00 m

3 with industrial stick 7.80 m and grapple model GM 72C

4 with industrial stick 9.00 m and grapple model GM 72C

10

30

8

20

6

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

2.00 m, counterweight 14.5 t, industrial-type straight mono boom

4

10

ER 954 C

2

0

0

10.50 m, industrial stick 7.80 m and grapple model GM 72C with

5 semi-closed tines 1.20 m

3

(2,920 kg).

Undercarriage S-EW

Pad width mm 750

-10

-20

-30

-10

-2

-4

-6

-8

1

2

3

4

0 m2468101214161820

0 ft1020304050608 0

Weight kg 75,400

Ground pressure kg/cm

2

0.84

Operating weight includes basic machine with rigid cab elevation

2.00 m, counterweight 14.5 t, industrial-type straight mono boom

10.50 m, industrial stick 9.00 m and grapple model GM 72C with

5 semi-closed tines 1.20 m

3

(2,920 kg).

Undercarriage S-EW

Pad width mm 750

Weight kg 75,800

Ground pressure kg/cm

2

0.84

28 ER 934 C ER 944 C ER 954 C Material Handlers

Page 29

Lift Capacities

with Industrial-Type Straight Mono Boom 10.50 m

Industrial Stick 7.80 m (Variant 2A)

Under m carriage m

S-EW

21.0

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

14.3* 14.3* 14.0* 14.0* 5.0

14.4* 14.4* 11.8* 11.8* 11.0* 11.0* 8.7

15.5* 15.5* 14.1* 14.1* 12.0* 12.0* 9.7* 9.7* 11.0

15.2* 15.2* 13.8* 13.8* 11.6* 11.6* 8.9* 8.9* 12.7

15.5* 15.5* 13.8* 13.8* 12.4* 12.4* 10.9* 10.9* 8.5* 8.5* 14.1

15.6* 15.6* 13.8* 13.8* 12.3* 12.3* 11.1* 11.1* 9.4* 9.4* 8.2* 8.2* 15.1

17.1* 17.1* 15.8* 15.8* 13.9* 13.9* 12.4* 12.4* 11.1* 11.1* 9.9* 9.9* 8.0* 8.0* 16.0

18.2* 18.2* 16.1* 16.1* 14.1* 14.1* 12.5* 12.5* 11.1* 11.1* 9.9* 9.9* 8.7* 8.7* 7.9* 7.9* 16.7

18.5* 18.5* 19.5* 19.5* 16.5* 16.5* 14.3* 14.3* 12.6* 12.6* 11.1* 11.1* 9.9* 9.9* 8.6* 8.6* 7.9* 7.9* 17.2

13.4* 13.4* 21.3* 21.3* 25.2* 25.2* 20.2* 20.2* 16.9* 16.9* 14.5* 14.5* 12.6* 12.6* 11.1* 11.1* 9.8* 9.8* 8.5* 8.5* 7.4* 7.4* 17.6

36.1* 36.1* 26.5* 26.5* 20.9* 20.9* 17.3* 17.3* 14.6* 14.6* 12.6* 12.6* 11.0* 11.0* 9.6* 9.6* 8.3* 8.3* 6.9* 6.9* 17.8

4.7* 4.7* 26.9* 26.9* 21.1* 21.1* 17.3* 17.3* 14.6* 14.6* 12.5* 12.5* 10.8* 10.8* 9.4* 9.4* 8.0* 8.0* 6.3* 6.3* 17.9

3.1* 3.1* 11.4* 11.4* 20.7* 20.7* 17.0* 17.0* 14.3* 14.3* 12.2* 12.2* 10.5* 10.5* 9.0* 9.0* 7.5* 7.5* 5.8* 5.8* 17.9

3.7* 3.7* 9.2* 9.2* 19.5* 19.5* 16.2* 16.2* 13.6* 13.6* 11.6* 11.6* 9.9* 9.9* 8.3* 8.3* 6.7* 6.7* 5.1* 5.1* 17.7

5.0* 5.0* 9.2* 9.2* 17.5* 17.5* 14.8* 14.8* 12.6* 12.6* 10.7* 10.7* 9.0* 9.0* 7.4* 7.4* 5.7* 5.7* 4.6* 4.6* 17.4

10.1* 10.1* 14.9* 14.9* 12.9* 12.9* 11.0* 11.0* 9.4* 9.4* 7.8* 7.8* 6.2* 6.2* 5.1* 5.1* 16.3

10.4* 10.4* 9.0* 9.0* 7.6* 7.6* 6.3* 6.3* 14.2

ER 954 C

Industrial Stick 9.00 m (Variant 2A)

Under m carriage m

S-EW

21.0

S-EW

19.5

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

13.8* 13.8*

12.6* 12.6* 10.2* 10.2* 10.1* 10.1* 8.3

12.4* 12.4* 10.5* 10.5* 8.7* 8.7* 10.9

13.2* 13.2* 12.0* 12.0* 10.3* 10.3* 7.9* 7.9* 12.8

12.9* 12.9* 11.7* 11.7* 9.8* 9.8* 7.4* 7.4* 14.3

13.1* 13.1* 11.8* 11.8* 10.7* 10.7* 9.0* 9.0* 7.0* 7.0* 15.5

13.1* 13.1* 11.8* 11.8* 10.7* 10.7* 9.7* 9.7* 7.4* 7.4* 6.8* 6.8* 16.5

14.6* 14.6* 13.3* 13.3* 11.9* 11.9* 10.7* 10.7* 9.7* 9.7* 8.7* 8.7* 6.7* 6.7* 17.3

15.3* 15.3* 13.5* 13.5* 12.0* 12.0* 10.8* 10.8* 9.7* 9.7* 8.7* 8.7* 6.7* 6.7* 6.6* 6.6* 17.9

15.4* 15.4* 15.7* 15.7* 13.7* 13.7* 12.2* 12.2* 10.8* 10.8* 9.7* 9.7* 8.6* 8.6* 7.5* 7.5* 6.6* 6.6* 18.4

15.5* 15.5* 18.3* 18.3* 16.2* 16.2* 14.0* 14.0* 12.3* 12.3* 10.9* 10.9* 9.7* 9.7* 8.5* 8.5* 7.4* 7.4* 6.6* 6.6* 18.7

12.7* 12.7* 21.1* 21.1* 24.8* 24.8* 20.1* 20.1* 16.7* 16.7* 14.3* 14.3* 12.4* 12.4* 10.9* 10.9* 9.6* 9.6* 8.4* 8.4* 7.2* 7.2* 6.2* 6.2* 19.0

22.6* 22.6* 26.3* 26.3* 20.7* 20.7* 17.0* 17.0* 14.4* 14.4* 12.4* 12.4* 10.8* 10.8* 9.4* 9.4* 8.2* 8.2* 6.9* 6.9* 5.7* 5.7* 19.1

0.6* 0.6* 5.7* 5.7* 22.4* 22.4* 20.7* 20.7* 17.0* 17.0* 14.3* 14.3* 12.2* 12.2* 10.6* 10.6* 9.2* 9.2* 7.8* 7.8* 6.5* 6.5* 5.3* 5.3* 19.0

1.5* 1.5* 4.7* 4.7* 11.9* 11.9* 20.1* 20.1* 16.5* 16.5* 13.9* 13.9* 11.8* 11.8* 10.2* 10.2* 8.7* 8.7* 7.3* 7.3* 5.8* 5.8* 4.7* 4.7* 18.9

2.8* 2.8* 5.2* 5.2* 10.1* 10.1* 18.8* 18.8* 15.6* 15.6* 13.1* 13.1* 11.2* 11.2* 9.5* 9.5* 8.0* 8.0* 6.6* 6.6* 4.9* 4.9* 4.1* 4.1* 18.6

6.2* 6.2* 10.2* 10.2* 16.7* 16.7* 14.1* 14.1* 12.0* 12.0* 10.1* 10.1* 8.6* 8.6* 7.1* 7.1* 5.6* 5.6* 4.2* 4.2* 17.9

10.8* 10.8* 14.0* 14.0* 12.1* 12.1* 10.3* 10.3* 8.7* 8.7* 7.3* 7.3* 5.8* 5.8* 4.8* 4.8* 16.4

8.2* 8.2* 6.9* 6.9* 6.5* 6.5* 13.7

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

ER 934 C ER 944 C ER 954 C Material Handlers 29

Page 30

Industrial Attachment

with Industrial-Type Angled Mono Boom 10.50 m

mf t

20

60

18

16

50

14

40

12

10

30

8

20

6

4

10

2

ER 954 C

0

0

-2

-10

-4

-6

-20

-30

-40

-8

-10

-12

1

2

3

4

0 m2468101214161820

Attachment Envelope

Kinematic variants 3C/3D

1 with industrial stick 7.80 m (3D)

2 with industrial stick 7.80 m and grapple model GM 72C (3D)

3 with industrial stick 7.80 m (3C)

4 with industrial stick 7.80 m and grapple model GM 72C (3C)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

2.00 m, counterweight 14.5 t, industrial-type angled mono boom

10.50 m, industrial stick 7.80 m and grapple model GM 72C with

5 semi-closed tines 1.20 m

Undercarriage S-EW

Pad width mm 750

Weight kg 75,800

Ground pressure kg/cm

3

(2,920 kg).

2

0.84

-10

-20

-30

-40

0 ft102030405 060

mf t

20

60

18

16

50

14

40

12

10

30

8

20

6

4

10

2

0

0

-2

Attachment Envelope

Kinematic variants 3C/3D

1 with industrial stick 9.00 m (3D)

2 with industrial stick 9.00 m and grapple model GM 72C (3D)

3 with industrial stick 9.00 m (3C)

4 with industrial stick 9.00 m and grapple model GM 72C (3C)

Operating Weight

and Ground Pressure

Operating weight includes basic machine with rigid cab elevation

2.00 m, counterweight 14.5 t, industrial-type angled mono boom

10.50 m, industrial stick 9.00 m and grapple model GM 72C with

5 semi-closed tines 1.20 m

Undercarriage S-EW

3

(2,920 kg).

Pad width mm 750

-10

-12

-4

-6

-8

1

2

3

4

0 m2468101214161820

Weight kg 76,200

Ground pressure kg/cm

2

0.85

30 ER 934 C ER 944 C ER 954 C Material Handlers

0 ft102030405 06070

Page 31

Lift Capacities

with Industrial-Type Angled Mono Boom 10.50 m

Industrial Stick 7.80 m (Variant 3C)

Under m carriage m

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

S-EW

– 9.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

8.3* 8.3* 8.3* 8.3* 12.2

8.1* 8.1* 8.0* 8.0* 8.0* 8.0* 13.6

8.1* 8.1* 7.9* 7.9* 7.9* 7.9* 14.7

8.2* 8.2* 8.0* 8.0* 7.8* 7.8* 7.8* 7.8* 15.6

8.6* 8.6* 8.2* 8.2* 7.9* 7.9* 7.8* 7.8* 16.2

9.7* 9.7* 9.0* 9.0* 8.5* 8.5* 8.1* 8.1* 7.8* 7.8* 7.8* 7.8* 16.8

11.7* 11.7* 10.5* 10.5* 9.6* 9.6* 8.9* 8.9* 8.4* 8.4* 8.0* 8.0* 7.9* 7.9* 17.1

3.4* 3.4* 27.0* 27.0* 19.3* 19.3* 15.4* 15.4* 13.0* 13.0* 11.3* 11.3* 10.2* 10.2* 9.3* 9.3* 8.7* 8.7* 8.2* 8.2* 7.8 8.0* 17.4

7.5* 7.5* 22.6* 22.6* 17.4* 17.4* 14.3* 14.3* 12.2* 12.2* 10.8* 10.8* 9.8* 9.8* 9.0* 9.0* 8.4 8.4* 7.6 8.1* 17.4

1.4* 1.4* 5.5* 5.5* 13.5* 13.5* 19.1* 19.1* 15.5* 15.5* 13.1* 13.1* 11.5* 11.5* 10.3* 10.3* 9.4* 9.4* 8.2 8.7* 7.6 8.3* 17.4

3.2* 3.2* 5.9* 5.9* 11.1* 11.1* 20.4* 20.4* 16.4* 16.4* 13.8* 13.8* 12.0* 12.0* 10.7* 10.7* 9.3 9.6* 8.1 8.8* 7.6 8.5* 17.2

4.8* 4.8* 6.8* 6.8* 10.8* 10.8* 18.8* 18.8* 17.1* 17.1* 14.4* 14.4* 12.4* 12.4* 10.6 11.0* 9.1 9.9* 8.0 8.9* 7.7 8.7* 16.9

7.9* 7.9* 11.3* 11.3* 17.7* 17.7* 17.5* 17.5* 14.7* 14.7* 12.3 12.7* 10.4 11.2* 9.0 9.9* 8.0 9.0* 16.5

9.0* 9.0* 12.0* 12.0* 17.9* 17.9* 17.6* 17.6* 14.6 14.8* 12.1 12.8* 10.3 11.2* 9.0 9.8* 8.5 9.2* 15.8

13.0* 13.0* 18.8* 18.8* 17.2* 17.2* 14.6* 14.6* 12.1 12.5* 10.4 10.8* 9.2 9.5* 15.1

16.4* 16.4* 13.9* 13.9* 11.8* 11.8* 10.7* 10.7* 13.8

ER 954 C

Industrial Stick 9.00 m (Variant 3C)

Under m carriage m

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

S-EW

– 9.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

7.4* 7.4*

7.2* 7.2* 7.0* 7.0* 13.8

7.0* 7.0* 7.0* 7.0* 6.8* 6.8* 15.0

7.0* 7.0* 7.0* 7.0* 6.6* 6.6* 16.0

7.1* 7.1* 7.0* 7.0* 6.9* 6.9* 6.6* 6.6* 16.8

7.4* 7.4* 7.1* 7.1* 7.0* 7.0* 6.6* 6.6* 17.4

8.1* 8.1* 7.7* 7.7* 7.4* 7.4* 7.1* 7.1* 6.7* 6.7* 6.7* 6.7* 17.9

9.4* 9.4* 8.6* 8.6* 8.1* 8.1* 7.7* 7.7* 7.3* 7.3* 7.1* 7.1* 6.8* 6.8* 18.3

13.4* 13.4* 11.5* 11.5* 10.2* 10.2* 9.3* 9.3* 8.6* 8.6* 8.0* 8.0* 7.6* 7.6* 7.2* 7.2* 7.0* 7.0* 18.5

4.4* 4.4* 21.8* 21.8* 19.7* 19.7* 15.4* 15.4* 12.9* 12.9* 11.2* 11.2* 10.0* 10.0* 9.1* 9.1* 8.4* 8.4* 7.8* 7.8* 7.3 7.4* 6.9 7.2* 18.6

2.9* 2.9* 8.3* 8.3* 22.6* 22.6* 17.3* 17.3* 14.2* 14.2* 12.1* 12.1* 10.6* 10.6* 9.6* 9.6* 8.7* 8.7* 8.1* 8.1* 7.1 7.6* 6.8 7.4* 18.5

3.6* 3.6* 6.9* 6.9* 13.8* 13.8* 18.9* 18.9* 15.3* 15.3* 12.9* 12.9* 11.3* 11.3* 10.0* 10.0* 9.1* 9.1* 8.0 8.4* 7.0 7.7* 6.8 7.6* 18.4

4.6* 4.6* 7.0* 7.0* 11.7* 11.7* 20.1* 20.1* 16.2* 16.2* 13.6* 13.6* 11.8* 11.8* 10.4* 10.4* 9.1 9.4* 7.9 8.5* 6.9 7.8* 18.1

5.6* 5.6* 7.6* 7.6* 11.3* 11.3* 18.8* 18.8* 16.8* 16.8* 14.1* 14.1* 12.2 12.2* 10.3 10.7* 8.9 9.6* 7.7 8.6* 7.1 8.1* 17.6

6.6* 6.6* 8.4* 8.4* 11.6* 11.6* 17.8* 17.8* 17.2* 17.2* 14.4* 14.4* 11.9 12.4* 10.1 10.9* 8.8 9.6* 7.7 8.6* 7.5 8.3* 17.1

9.2* 9.2* 12.2* 12.2* 17.9* 17.9* 17.1* 17.1* 14.3 14.4* 11.9 12.4* 10.1 10.8* 8.7 9.5* 8.0 8.6* 16.3

13.0* 13.0* 18.7* 18.7* 16.7* 16.7* 14.1* 14.1* 11.9 12.1* 10.1 10.5* 8.9 9.0* 8.7 8.8* 15.4

15.7* 15.7* 13.3* 13.3* 11.5* 11.5* 13.3

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

ER 934 C ER 944 C ER 954 C Material Handlers 31

Page 32

Lift Capacities

with Industrial-Type Angled Mono Boom 10.50 m

Industrial Stick 7.80 m (Variant 3D)

Under m carriage m

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

ER 954 C

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

S-EW

– 9.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

10.1* 10.1* 7.9

9.9* 9.9* 9.0* 9.0* 10.4

9.9* 9.9* 9.5* 9.5* 8.5* 8.5* 12.2

9.7* 9.7* 9.3* 9.3* 9.0* 9.0* 8.1* 8.1* 13.6

9.8* 9.8* 9.3* 9.3* 8.9* 8.9* 7.9* 7.9* 14.7

10.0* 10.0* 9.4* 9.4* 9.0* 9.0* 8.6* 8.6* 7.9* 7.9* 15.6

11.4* 11.4* 10.5* 10.5* 9.7* 9.7* 9.1* 9.1* 8.7* 8.7* 7.9* 7.9* 16.2

13.8* 13.8* 12.2* 12.2* 11.1* 11.1* 10.1* 10.1* 9.4* 9.4* 8.9* 8.9* 8.4* 8.4* 8.0* 8.0* 16.8

24.2* 24.2* 18.7* 18.7* 15.4* 15.4* 13.3* 13.3* 11.8* 11.8* 10.6* 10.6* 9.8* 9.8* 9.1* 9.1* 8.5* 8.5* 8.1 8.1* 17.1

3.4* 3.4* 30.2* 30.2* 21.7* 21.7* 17.2* 17.2* 14.4* 14.4* 12.5* 12.5* 11.2* 11.2* 10.1* 10.1* 9.3* 9.3* 8.6 8.7* 7.8 8.3* 17.4

7.5* 7.5* 24.5* 24.5* 18.9* 18.9* 15.5* 15.5* 13.3* 13.3* 11.7* 11.7* 10.5* 10.5* 9.6* 9.6* 8.4 8.8* 7.6 8.4* 17.4

1.4* 1.4* 5.5* 5.5* 13.5* 13.5* 20.3* 20.3* 16.5* 16.5* 14.0* 14.0* 12.2* 12.2* 10.8* 10.8* 9.5 9.8* 8.2 8.9* 7.6 8.5* 17.4

5.9* 5.9* 11.1* 11.1* 21.3* 21.3* 17.2* 17.2* 14.5* 14.5* 12.6* 12.6* 10.8 11.1* 9.3 10.0* 8.1 9.0* 7.6 8.6* 17.2

6.8* 6.8* 10.8* 10.8* 18.8* 18.8* 17.7* 17.7* 14.9* 14.9* 12.5 12.8* 10.6 11.3* 9.1 10.0* 8.0 8.9* 7.7 8.7* 16.9

11.3* 11.3* 17.7* 17.7* 17.7* 17.7* 14.8 14.9* 12.3 12.9* 10.4 11.2* 9.0 9.9* 8.0 8.8* 16.5

12.0* 12.0* 17.9* 17.9* 17.4* 17.4* 14.6 14.7* 12.1 12.6* 10.3 11.0* 9.0 9.5* 8.5 8.9* 15.8

14.1* 14.1* 12.1* 12.1* 11.5* 11.5* 13.7

Industrial Stick 9.00 m (Variant 3D)

Under m carriage m

S-EW

18.0

S-EW

16.5

S-EW

15.0

S-EW

13.5

S-EW

12.0

S-EW

10.5

S-EW

9.0

S-EW

7.5

S-EW

6.0

S-EW

4.5

S-EW

3.0

S-EW

1.5

S-EW

0

S-EW

– 1.5

S-EW

– 3.0

S-EW

– 4.5

S-EW

– 6.0

S-EW

– 7.5

S-EW

– 9.0

3.0 m 4.5 m 6.0 m 7.5 m 9.0 m 10.5 m 12.0 m 13.5 m 15.0 m 16.5 m 18.0 m

8.5* 8.5* 8.1* 8.1* 10.2

9.1* 9.1* 8.5* 8.5* 7.4* 7.4* 12.2

8.5* 8.5* 8.2* 8.2* 7.0* 7.0* 13.8

8.4* 8.4* 8.1* 8.1* 7.4* 7.4* 6.8* 6.8* 15.0

8.4* 8.4* 8.1* 8.1* 7.8* 7.8* 6.6* 6.6* 16.0

9.0* 9.0* 8.6* 8.6* 8.2* 8.2* 7.9* 7.9* 7.6* 7.6* 6.6* 6.6* 16.8

9.4* 9.4* 8.9* 8.9* 8.4* 8.4* 8.0* 8.0* 7.7* 7.7* 6.6* 6.6* 17.4

10.9* 10.9* 10.0* 10.0* 9.3* 9.3* 8.7* 8.7* 8.2* 8.2* 7.8* 7.8* 6.7* 6.7* 6.7* 6.7* 17.9

13.6* 13.6* 12.0* 12.0* 10.7* 10.7* 9.8* 9.8* 9.0* 9.0* 8.4* 8.4* 7.9* 7.9* 7.5* 7.5* 6.8* 6.8* 18.3

38.1* 38.1* 25.0* 25.0* 18.9* 18.9* 15.4* 15.4* 13.1* 13.1* 11.5* 11.5* 10.4* 10.4* 9.4* 9.4* 8.7* 8.7* 8.1* 8.1* 7.4 7.7* 7.0* 7.0* 18.5

4.4* 4.4* 21.8* 21.8* 21.9* 21.9* 17.2* 17.2* 14.3* 14.3* 12.4* 12.4* 10.9* 10.9* 9.9* 9.9* 9.0* 9.0* 8.3* 8.3* 7.3 7.8* 6.9 7.2* 18.6

2.9* 2.9* 8.3* 8.3* 23.0* 23.0* 18.9* 18.9* 15.4* 15.4* 13.1* 13.1* 11.5* 11.5* 10.2* 10.2* 9.3* 9.3* 8.2 8.5* 7.1 7.9* 6.8 7.5* 18.5

3.6* 3.6* 6.9* 6.9* 13.8* 13.8* 20.1* 20.1* 16.3* 16.3* 13.8* 13.8* 12.0* 12.0* 10.6* 10.6* 9.3 9.5* 8.0 8.7* 7.0 7.9* 6.8 7.8* 18.4

4.6* 4.6* 7.0* 7.0* 11.7* 11.7* 20.9* 20.9* 17.0* 17.0* 14.3* 14.3* 12.3* 12.3* 10.6 10.8* 9.0 9.7* 7.9 8.7* 6.9 7.9* 18.1

7.6* 7.6* 11.3* 11.3* 18.8* 18.8* 17.3* 17.3* 14.5* 14.5* 12.2 12.5* 10.3 11.0* 8.9 9.7* 7.7 8.7* 7.1 8.0* 17.6

8.4* 8.4* 11.6* 11.6* 17.8* 17.8* 17.3* 17.3* 14.4 14.5* 12.0 12.5* 10.1 10.9* 8.8 9.6* 7.7 8.4* 7.5 8.1* 17.1

12.2* 12.2* 17.9* 17.9* 16.8* 16.8* 14.2* 14.2* 11.9 12.2* 10.1 10.6* 8.8 9.2* 8.3 8.7* 16.1

Height Can be slewed through 360° In longitudinal position of undercarriage Max. reach * Limited by hydr. capacity

The lift capacities are stated in metric tonnes (t) on the lifting gear’s stick tip, and can be lifted 360° on firm, level supporting surface. Capacities

are valid for 600 mm wide triple grouser pads. Indicated loads are based on ISO 10567 standard and do not exceed 75 % of tipping or 87 % of

hydraulic capacity (indicated via *). Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible

load of the load hook.

According to European Standard, EN 474-5: In the European Union excavators have to be equipped with an overload warning device, a load

diagram and automatic safety check valves on hoist cylinders and stick cylinder(s), when they are used for lifting operations which require the use

of lifting accessories.

32 ER 934 C ER 944 C ER 954 C Material Handlers

Page 33

Choice of Cab Elevation

and Cab Protection

D

C

B

D2

D1

C2

B2

C1

B1

D2

D1

C2

B2

C1 E

B1

C1

Rigid Cab Elevation

934 944 954 934 944 954

mm mm mm mm mm mm

Height 1,200 1,200 1,200 2,000 2,000 2,000

B 3,865 3,995 4,405 4,665 4,795 5,205

C 4,365 4,490 4,900 5,165 5,290 5,700

D 780 765 1,105 780 765 1,105

Additional weight with fixed cab elevation 2,000 mm in relation to cab

elevation 1,200 mm:

934: 400 kg 944: 200 kg 954: 400 kg

Hydraulic Cab Elevation

934 944 954

mm mm mm

B1 2,660 2,790 3,200

B2 5,160 5,290 5,700

C1 3,160 3,290 3,700

C2 5,660 5,790 6,200

D1 1,485 1,450 1,800

D2 1,730 1,700 2,050

E 3,080 3,200 3,640

Additional weight in relation to cab elevation 1,200 mm:

934: 500 kg 944: 600 kg 954: 500 kg

Hydraulic Cab Elevation

(Parallelogram)

+ Intermediate Piece 0.5 m

944 954

mm mm

B1 3,300 3,705

B2 6,885 7,275

C1 3,798 4,200

C2 7,383 7,770

D1 2,490 2,890

D2 2,630 3,040

E 3,785 4,160

Additional weight in relation to cab elevation 1,200 mm:

944: 1,700 kg 954: 1,600 kg

ER 954 C ER 944 C ER 934 C

FOPS Guard

ER 934 C ER 944 C ER 954 C Material Handlers 33

Front Guard

Page 34

Variety of Tools

Shells for loose material with

Shells for Loose Material

cutting edge (without teeth)

Clamshell Model GM 20B

Cutting width of shells mm 1,000 1,200 1,600

ER 934 CER 944 CER 954 C

Capacity m

Weight kg 1,355 1,415 1,550

Clamshell Model GM 22C

Cutting width of shells mm 1,500 1,500 2,000

Capacity m

Weight kg 2,500 2,600 3,050

Clamshell Model GMZ 50

Cutting width of shells mm 1,400

Capacity m

Weight kg 2,670

Multiple Tine Grapples open tines semi-closed tines closed tines

Grapple Model GM 64 Capacity m

(4 tines) Weight kg 845 1,130 1,055 1,330 1,060 1,520

Grapple Model GM 65 Capacity m

(5 tines) Weight kg 1,150 1,230 1,285 1,415 1,325 1,520

Grapple Model GM 69 Capacity m

(4 tines) Weight kg 1,345 1,395 1,535 1,640 1,900 2,060

Grapple Model GM 70C Capacity m

(5 tines) Weight kg 1,485 1,590 1,705 1,860 1,950 1,995

Grapple Model GM 72C Capacity m

(4 tines) Weight kg 2,090 2,140 2,160 2,410 2,470 2,510 2,700 2,760 2,810

Grapple Model GM 72C Capacity m

(5 tines) Weight kg 2,520 2,570 2,590 2,920 2,990 3,040 3,020 3,100 3,160

Grapple Model GMM 80 Capacity m

(4 tines) Weight kg 1,950 1,990 2,050 2,130 2,195 2,250 – – –

Grapple Model GMM 80 Capacity m

(5 tines) Weight kg 2,190 2,240 2,310 2,400 2,480 2,550 2,550 2,600 2,720

3

1.30 1.50 2.00

3

1.85 2.20 3.00

3

3.50

3

0.40 0.60 0.40 0.60 0.40 0.60

3

0.40 0.60 0.40 0.60 0.40 0.60

3

0.80 1.10 0.80 1.10 0.80 1.10

3

0.80 1.10 0.80 1.10 0.80 1.10

3

1.20 1.40 1.60 1.20 1.40 1.60 1.20 1.40 1.60

3

1.20 1.40 1.60 1.20 1.40 1.60 1.20 1.40 1.60

3

1.10 1.40 1.70 1.10 1.40 1.70 – – –

3

1.10 1.40 1.70 1.10 1.40 1.70 1.10 1.40 1.70

Crane Hook with Suspension

Max. load t 12.5 32

Weight kg 96 180

Electro Magnets with Suspension

Magnet information on request

34 ER 934 C ER 944 C ER 954 C Material Handlers

Page 35

Equipment

Uppercarriage

Complete tool set •

Engine hood with pneumatic damping and mechanical stop •

Handrails, non-slip surfaces •

Junction box with active protection •

Lockable tool box •

Maintenance-free swing brake lock, integrated in the transmission •

Sound insulation •

Extension of security system for access to the machine +

Frequency of 60 Hz +

Pedal controlled positioning swing brake +

Special painting +

Voltage other than 400 V +

Wide walkways and handrails +

Hydraulics

Electronic regulation by power limit •

Filter with integrated fine filter area (5 µm) •

Measuring points for hydraulic circuit pressure •

Minimum flow at high pressure •

Operating mode selector with continuous regulation •

Pressure accumulator for controlled lowering of attachments

withthe engine turned off •

Shut-off valve between hydraulic tank and pumps •

Filling with bio-degradable oil +

Filter for secondary circuit +

Liebherr Tool Control +

Supplementary hydraulic circuits +

Operator’s Cab

Automatic climate control with defrosting function •

Cab front roof •

Cigar lighter and ashtray •

Closed storage space •

Coat hook •

Emergency exit through rear window •

Floor mat •

Interior lighting •

Interior rear-view mirror •

Multi-function display •

Operating hours display, visible from the outside •

Panoramic tinted windows •

Pocket storage space •

Radio pre-equipment •

Right-hand window without central mounting •

Roof window and windshield in laminated glass •

Seat adjusted independently or in association with the console

(6 adjustment positions) •

Seat belt •

Sliding window in door •

Sun blind •

Windshield wipers and windshield wash •

Additional spotlights on cab roof (front/rear) +

Armored windshield (not movable) +